Numerical Simulation and Process Optimization of Sn-0.3Ag-0.7Cu Alloy Casting

Abstract

1. Introduction

2. Materials and Methods

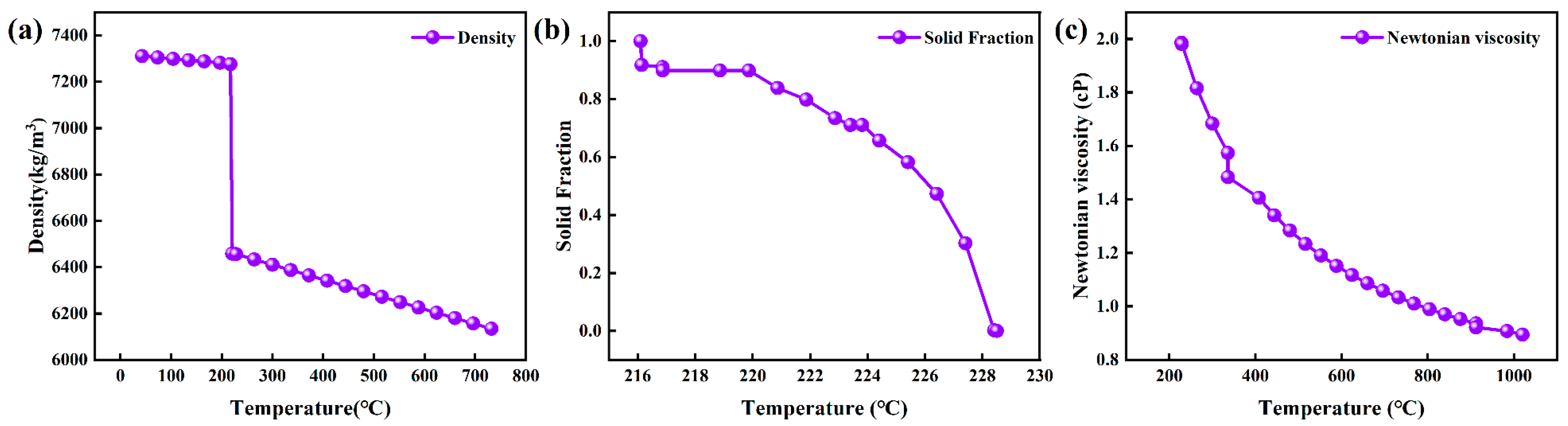

2.1. Numerical Simulation

2.1.1. Physical Process and Governing Equations

2.1.2. Heat Transfer Theory of the Solidification Process

2.1.3. Mathematical Model of Macroscopic Temperature Field

2.1.4. Porosity and Shrinkage Criteria

2.1.5. Simulation Setup

2.2. Experiments

3. Results and Discussion

3.1. Temperature and Solid Fraction Evolution During Solidification

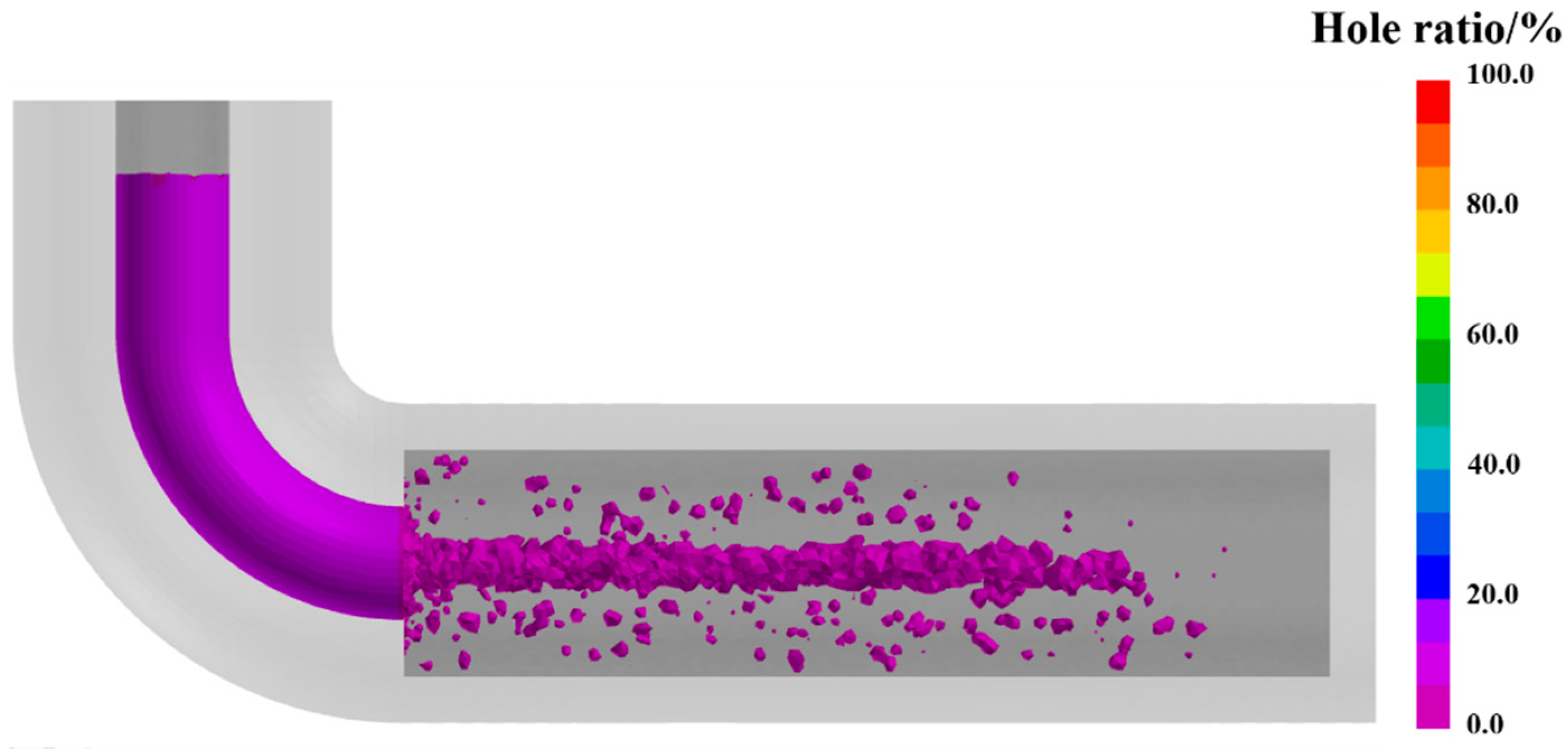

3.2. Porosity Prediction and Analysis

3.3. Effect of Pouring Temperature on Porosity

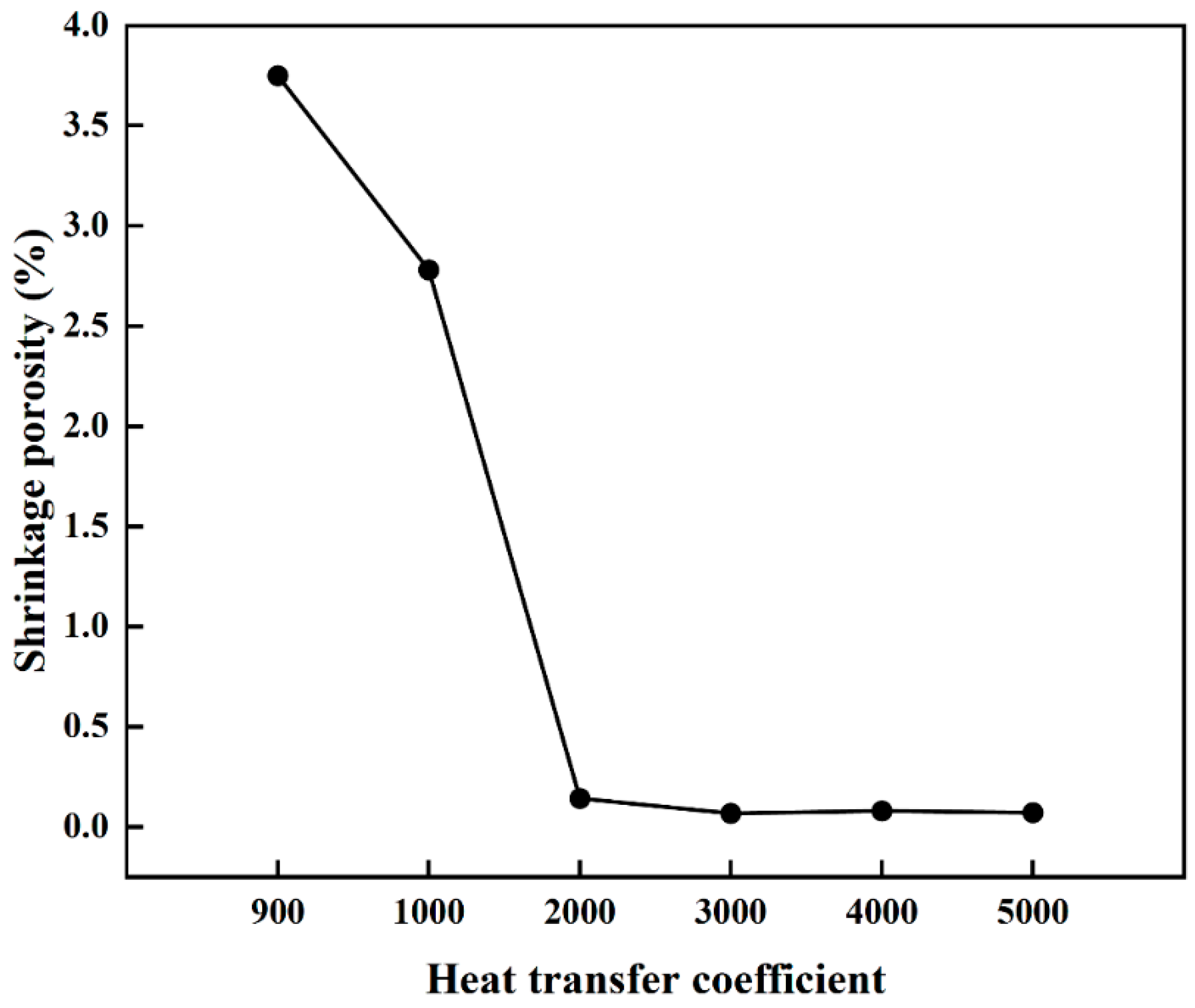

3.4. Effect of the Heat Transfer Coefficient on Porosity

3.5. Experimental Validation of Process Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, A.; Lu, Y.; Duan, Y.; Li, M.; Zheng, S.; Peng, M. Tuning the Growth of Intermetallic Compounds at Sn-0.7Cu Solder/Cu Substrate Interface by Adding Small Amounts of Indium. J. Mater. Sci. Technol. 2024, 182, 246–259. [Google Scholar] [CrossRef]

- Anousheh, A.; Soleimani, M. Advances in Microstructural Evolution and Reliability-Driven Mechanical and Corrosion Properties of Lead-Free SAC Solder Alloys. Mater. Des. 2025, 258, 114510. [Google Scholar] [CrossRef]

- El-Daly, A.A.; Eid, N.A.M.; Ibrahiem, A.A. Synergic Effect of Te, Ni and MWCNT on Creep Behavior and Microstructural Evolution of Sn-1.0Ag-0.7Cu Low-Ag Solder. J. Alloys Compd. 2022, 902, 163808. [Google Scholar] [CrossRef]

- Muhammed, H.J.; Prabhu, K.N. Effect of Ni Nanoparticles Reinforcement on Wettability, Microstructure and Mechanical Properties of SAC387 Lead-Free Solder Alloy. Microelectron. Reliab. 2025, 174, 115895. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, J.; Ji, H.; Huang, X.; Xiao, W. Creep of Sn-0.3Ag-0.7Cu Solder in Electronic Packaging: Experiment and Simulation. J. Mater. Res. Technol. 2025, 34, 585–603. [Google Scholar] [CrossRef]

- Tamizi, M.; Movahedi, M.; Kokabi, A.H.; Miyashita, Y. Cobalt-Graphene NanoSheets Enhanced Sn–0.3Ag–0.7Cu Composite Solder: Study on Microstructure, Crystal Orientation Relations and Mechanical Properties. Mater. Sci. Eng. A 2024, 894, 146199. [Google Scholar] [CrossRef]

- Luo, A.A.; Sachdev, A.K.; Apelian, D. Alloy Development and Process Innovations for Light Metals Casting. J. Mater. Process. Technol. 2022, 306, 117606. [Google Scholar] [CrossRef]

- Jia, Y.; Zou, Q.; Chen, X.; Le, Q.; Xin, Y.; Liu, Q. Study on Heat Transfer Behavior and Process Optimization in Differential Phase Electromagnetic DC Casting of Extra-Large AZ31B Alloy Flat Ingot: Numerical Simulation and Experimental Verification. J. Mater. Res. Technol. 2023, 24, 1108–1131. [Google Scholar] [CrossRef]

- Li, F.; Yang, Z.; Guo, J.; Li, Z.; Ma, Z.; Bai, L. Simulation and Optimization of the Casting Process for a New Commercial Al-4Cu-0.3Mg-0.25Mn-0.05Ag Alloy Cylinder Head. J. Mater. Res. Technol. 2025, 38, 1355–1366. [Google Scholar] [CrossRef]

- Kwon, Y.-D.; Lee, Z.-H. The Effect of Grain Refining and Oxide Inclusion on the Fluidity of Al–4.5Cu–0.6Mn and A356 Alloys. Mater. Sci. Eng. A 2003, 360, 372–376. [Google Scholar] [CrossRef]

- Chen, K.; He, X.; Liu, Z.; Li, G.; Zhang, P.; Liu, H. Porosity Forming Mechanism and Numerical Simulation of Casting Process Optimization of Nickel-Based Heat-Resistant Alloy Electrode Ingot with Large Height to Diameter Ratio. J. Mater. Res. Technol. 2024, 29, 2363–2375. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, D.-R.; Bao, H.; Pu, Z.; Feng, Y.; Guo, E. Process Optimization of Gravity Sand Casting Process for Thin-Walled Castings of Al–7Si-0.5 Mg Alloy Using a Coupled Simulation-Experiment Method. J. Mater. Res. Technol. 2025, 38, 432–450. [Google Scholar] [CrossRef]

- Liu, X.; Song, J.-W.; Wang, X.; Li, Z.-G.; Zhang, S.-Y.; Jia, W.-T.; Wang, C.; Wang, H.-Y. Prediction on the Solidification Behavior of AA6005 Aluminum Alloys Produced by Inclined Twin-Roll Casting: A Finite Element Analysis. J. Mater. Res. Technol. 2024, 29, 2405–2413. [Google Scholar] [CrossRef]

- Zhang, Z.; Pan, Y.; Dong, A.; Chen, Z.; Sui, D. Numerical Simulation-Driven Optimization of the Counter-Gravity Adjusted-Pressure Casting Process for Large Thin-Wall Ni-Based Superalloy Combustion Chamber Casings. J. Mater. Res. Technol. 2025, 37, 1029–1040. [Google Scholar] [CrossRef]

- Ridgeway, C.D.; Gu, C.; Ripplinger, K.; Detwiler, D.; Ji, M.; Soghrati, S.; Luo, A.A. Prediction of Location Specific Mechanical Properties of Aluminum Casting Using a New CA-FEA (Cellular Automaton-Finite Element Analysis) Approach. Mater. Des. 2020, 194, 108929. [Google Scholar] [CrossRef]

- Liao, Q.; Ge, P.; Lu, G.; Song, Y.; Ye, W.; Gao, J.; Luo, X. Simulation Study on the Investment Casting Process of a Low-Cost Titanium Alloy Gearbox Based on ProCAST. Adv. Mater. Sci. Eng. 2022, 2022, 4484762. [Google Scholar] [CrossRef]

- Lian, Y.; Gan, Z.; Yu, C.; Kats, D.; Liu, W.K.; Wagner, G.J. A Cellular Automaton Finite Volume Method for Microstructure Evolution during Additive Manufacturing. Mater. Des. 2019, 169, 107672. [Google Scholar] [CrossRef]

- Li, G.; Ma, G.; Zhong, X.; Liu, M. Heterogeneous Constitutive Modeling and Finite Element Simulation of Cutting for Cladding Layers Based on Microstructural Prediction. Mater. Today Commun. 2025, 49, 113817. [Google Scholar] [CrossRef]

- Ruan, X.; Karabulut, B.; MacDonald, S.; Dobrić, J.; Rossi, B. Effect of Boundary Conditions on Residual Stress in Cold Metal Transfer-Based Wire Arc Additively Manufactured Steel Components. Mater. Des. 2025, 249, 113548. [Google Scholar] [CrossRef]

- Johnson, G.A.; Sikan, F.; Quintana, M.J.; Collins, P.C. Combining Gleeble Thermomechanical Simulations and Finite Element Analysis to Replicate the Material State of Additively Manufactured Duplex Stainless Steels. J. Mater. Res. Technol. 2025, 36, 5178–5192. [Google Scholar] [CrossRef]

- Palumbo, G.; Piglionico, V.; Sorgente, D.; Piccininni, A.; Guglielmi, P.; Tricarico, L. Correlating Shrinkage Microporosity with the Mechanical Properties of Sand-Cast Superduplex Stainless Steel Using a Numerical/Experimental Approach. Mater. Des. 2016, 93, 168–179. [Google Scholar] [CrossRef]

- Ghodrati, N.; Ménard, P.; Morin, J.-B.; Jahazi, M. Influence of Hot Top Geometry on Columnar-to-Equiaxed Transition in a 12 MT Steel Ingot. J. Mater. Res. Technol. 2024, 31, 3489–3508. [Google Scholar] [CrossRef]

- Hallam, C.P.; Griffiths, W.D. A Model of the Interfacial Heat-Transfer Coefficient for the Aluminum Gravity Die-Casting Process. Metall. Mater. Trans. B 2004, 35, 721–733. [Google Scholar] [CrossRef]

- Dong, G.; Li, S.; Ma, S.; Zhang, D.; Bi, J.; Wang, J.; Starostenkov, M.D.; Xu, Z. Process Optimization of A356 Aluminum Alloy Wheel Hub Fabricated by Low-Pressure Die Casting with Simulation and Experimental Coupling Methods. J. Mater. Res. Technol. 2023, 24, 3118–3132. [Google Scholar] [CrossRef]

- Seydani, M.Z.; Krimi, A.; Khelladi, S.; Bedel, M.; El Mansori, M. 3D Numerical Simulation and Experimental Validation of Resin-Bonded Sand Gravity Casting: Filling, Cooling, and Solidification with SPH and ProCAST Approaches. Therm. Sci. Eng. Prog. 2024, 47, 102329. [Google Scholar] [CrossRef]

- Li, L.; Zhang, R.; Yuan, Q.; Huang, S.; Jiang, H. An Integrated Approach to Study the Hot Tearing Behavior by Coupling the Microscale Phase Field Model and Macroscale Casting Simulations. J. Mater. Process. Technol. 2022, 310, 117782. [Google Scholar] [CrossRef]

- Barannyk, L.L.; Crepeau, J.C.; Paulus, P.; Sakhnov, A.Y.; Williams, S.D.V. The Phase Change Problem in Materials with Internal Heat Generation in a Cylinder. Int. Commun. Heat Mass Transf. 2024, 159, 108150. [Google Scholar] [CrossRef]

- Bousquet-Melou, P.; Goyeau, B.; Quintard, M.; Fichot, F.; Gobin, D. Average Momentum Equation for Interdendritic Flow in a Solidifying Columnar Mushy Zone. Int. J. Heat Mass Transf. 2002, 45, 3651–3665. [Google Scholar] [CrossRef]

- Köse, S.; Çolak, M.; Şüküroğlu, E.E. Investigation of the Effects of Filling Speed, Casting Temperature and Metallurgical Quality on Fluidity of Lamellar Graphite Cast Iron at Different Section Thicknesses. Int. J. Met. 2025, 19, 282–292. [Google Scholar] [CrossRef]

- Sha, P.F.; Zhu, Z.W.; Fu, H.M.; Li, H.; Wang, A.M.; Zhang, H.W.; Zhang, H.F.; Hu, Z.Q. Effects of Casting Temperature on the Microstructure and Mechanical Properties of the TiZr-Based Bulk Metallic Glass Matrix Composite. Mater. Sci. Eng. A 2014, 589, 182–188. [Google Scholar] [CrossRef]

- Kurtulus, K.; Bolatturk, A.; Coskun, A.; Gürel, B. An Experimental Investigation of the Cooling and Heating Performance of a Gravity Die Casting Mold with Conformal Cooling Channels. Appl. Therm. Eng. 2021, 194, 117105. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, G.; Zhang, L.; Guo, Y.; Tong, X.; Li, L.; Xiong, X. Effect of Pouring and Mold Temperatures on Fluidity and Hot Tearing Behavior of Cast Al−Li−Cu−Mg−Sc−Zr−Ti Alloy. Trans. Nonferrous Met. Soc. China 2025, 35, 669–683. [Google Scholar] [CrossRef]

- Wang, R.; Zuo, Y.; Zhu, Q.; Liu, X.; Wang, J. Effect of Temperature Field on the Porosity and Mechanical Properties of 2024 Aluminum Alloy Prepared by Direct Chill Casting with Melt Shearing. J. Mater. Process. Technol. 2022, 307, 117687. [Google Scholar] [CrossRef]

| Cu | Ag | Pb | Ni | Others (Bi, Zn, Al) | Sn |

|---|---|---|---|---|---|

| 0.7 | 0.3 | 0.05 | 0.05 | <0.01 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Zhou, H.; Wang, Y.; He, J.; Jin, C.; Ayiqujin; Lei, D.; Fang, H.; Xiong, K. Numerical Simulation and Process Optimization of Sn-0.3Ag-0.7Cu Alloy Casting. Materials 2026, 19, 198. https://doi.org/10.3390/ma19010198

Zhou H, Wang Y, He J, Jin C, Ayiqujin, Lei D, Fang H, Xiong K. Numerical Simulation and Process Optimization of Sn-0.3Ag-0.7Cu Alloy Casting. Materials. 2026; 19(1):198. https://doi.org/10.3390/ma19010198

Chicago/Turabian StyleZhou, Hao, Yingwu Wang, Jianghua He, Chengchen Jin, Ayiqujin, Desheng Lei, Hui Fang, and Kai Xiong. 2026. "Numerical Simulation and Process Optimization of Sn-0.3Ag-0.7Cu Alloy Casting" Materials 19, no. 1: 198. https://doi.org/10.3390/ma19010198

APA StyleZhou, H., Wang, Y., He, J., Jin, C., Ayiqujin, Lei, D., Fang, H., & Xiong, K. (2026). Numerical Simulation and Process Optimization of Sn-0.3Ag-0.7Cu Alloy Casting. Materials, 19(1), 198. https://doi.org/10.3390/ma19010198