Elastic Energy Storage in Al–Al4C3 Composites: Effects of Dislocation Character and Interfacial Graphite Formation

Abstract

1. Introduction

2. Materials and Methods

3. Results

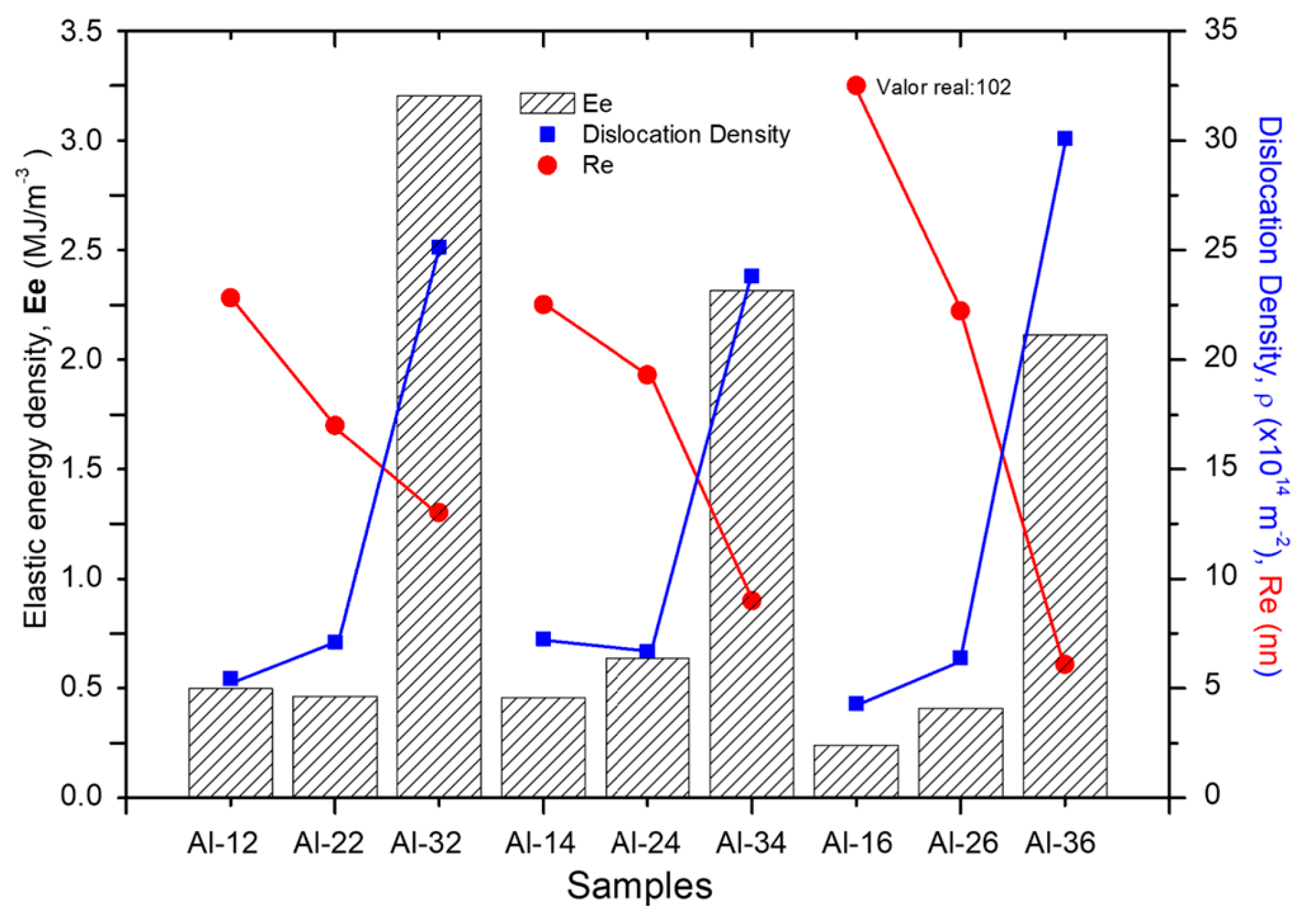

3.1. Elastic Energy Density Analysis

3.2. Strain Energy Density Analysis

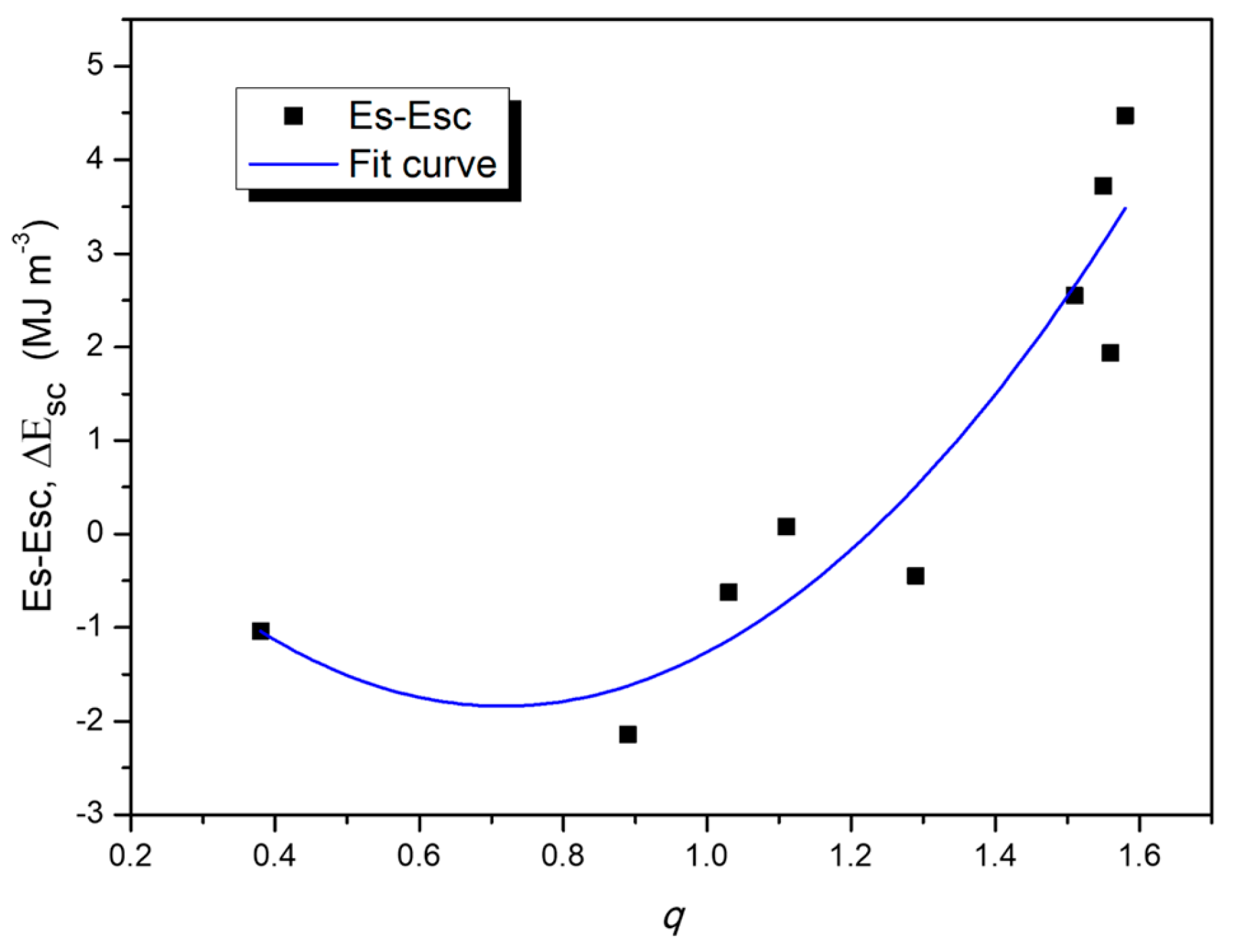

3.3. Mathematical Model for Estimating Es

4. Results Discussion

5. Conclusions

- Compression tests were conducted to determine the stored strain energy density (Es) in the Al/Al4C3 composites, and these results were compared with the initial elastic energy density (Ee) calculated from microstructural parameters obtained by X-ray diffraction (XRD).

- A mathematical model based on dislocation character was developed, allowing us to establish that the difference observed between Es and the proportional increase in Ee associated with elastic deformation of the Al matrix depends on the distribution of energy stored in microstructural defects generated during the fabrication processes.

- These microstructural defects are directly related to the dislocation character, as reflected by the q parameter obtained from CMWP analysis. Samples with a dislocation density dominated by screw segments exhibited a more efficient energy redistribution during processing, attributed to the dissociation of dislocations into partials and the formation of stacking faults, resulting in an increase in the energy absorption efficiency (EAE).

- In contrast, samples containing predominantly edge dislocations showed a higher proportion of dislocation dipoles, which generate highly localized strain fields and consequently reduce the EAE.

- The increased presence of screw dislocations is associated with the formation of graphite at the Al4C3 nanorod interfaces, a phase that develops as a consequence of prolonged sintering times.

- The generation of dislocations at both the graphite/Al4C3 interface and the Al4C3/Al matrix interface originates mainly from the thermal mismatch among the graphite phase, Al4C3, and the aluminum matrix during cooling.

- HRTEM analyses revealed the presence of graphite regions in the vicinity of Al4C3 nanorods, which, together with thermal mismatch during cooling, promote the activation of dislocation mechanisms dominated by screw segments, their extension into partial dislocations, and the formation of stacking faults. These processes facilitate a more efficient redistribution of stored energy and are reflected in an improvement in the composite toughness.

- For samples with 1 wt.% and 3 wt.% reinforcement, a sintering time of 6 h promoted an increase in EAE, an effect associated with enhanced graphite formation during prolonged sintering. In contrast, for samples with 2 wt.% reinforcement, the maximum EAE was achieved at a sintering time of 4 h, suggesting the existence of an optimal graphite formation condition under these processing parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Simões, S. Design and Development of Metal Matrix Composites. Metals 2025, 15, 848. [Google Scholar] [CrossRef]

- Rey, P.; González-Doncel, G. Advances in Lightweight Metal Matrix Composites. Metals 2025, 15, 160. [Google Scholar] [CrossRef]

- Lattanzi, L.; Jarfors, A.E.W. Advances in Metal Matrix Composites: Structure, Properties and Applications. Crystals 2025, 15, 1016. [Google Scholar] [CrossRef]

- Pan, S.; Wang, T.; Jin, K.; Cai, X. Understanding and designing metal matrix nanocomposites with high electrical conductivity: A review. J. Mater. Sci. 2022, 57, 6487–6523. [Google Scholar] [CrossRef]

- Li, Z.; Li, Q.; You, J.; Li, F.; Yu, G.; Zhang, W.; Liang, Z. Preparation of Aluminum Matrix Composites Reinforced with Hybrid MAX–MXene Particles. J. Compos. Sci. 2025, 9, 552. [Google Scholar] [CrossRef]

- Miclosina, C.-O.; Belu-Nica, R.; Ciubotariu, C.R.; Marginean, G. Processing and Evaluation of an Aluminum Matrix Composite Material. J. Compos. Sci. 2025, 9, 335. [Google Scholar] [CrossRef]

- Rativa-Parada, W.; Nilufar, S. Influence of Heat Treatment on Microstructure and Mechanical Properties of Aluminum Matrix Composites Reinforced with Carbon Nanoparticles. Nanomaterials 2024, 14, 1342. [Google Scholar] [CrossRef]

- Sarmah, P.; Gupta, K. Recent Advancements in Fabrication of Metal Matrix Composites: A Systematic Review. Materials 2024, 17, 4635. [Google Scholar] [CrossRef]

- da Silva, L.J.; Pacheco, J.T.; Moura, E.I.F.; de Araújo, D.B.; Reis, R.P.; D’Oliveira, A.S.C.M. Metal Matrix Composite Coatings Deposited by Laser Cladding: On the Effectiveness of WC Reinforcement for Wear Resistance and Its Synergy with the Matrix Material (Ni Versus Co Alloys). Coatings 2025, 15, 468. [Google Scholar] [CrossRef]

- Prosviryakov, A.S.; Bazlov, A.I.; Churyumov, A.Y.; Mikhaylovskaya, A.V. A Study on the Influence of Zr on the Strengthening of the Al-10% Al2O3 Composite Obtained by Mechanical Alloying. Metals 2023, 13, 2008. [Google Scholar] [CrossRef]

- Wąsik, A.; Leszczyńska-Madej, B.; Madej, M. Sustainability in the Manufacturing of Eco-Friendly Aluminum Matrix Composite Materials. Sustainability 2024, 16, 903. [Google Scholar] [CrossRef]

- Larraza, A.; Burke, S.; Sotoudehbagha, P.; Razavi, M. Fabrication and Processing of Magnesium-Based Metal Matrix Nanocomposites for Bioabsorbable Implants. Metals 2024, 14, 1318. [Google Scholar] [CrossRef]

- Almotairy, S.M.; Alharthi, N.H.; Abdo, H.S. Regulating Mechanical Properties of Al/SiC by Utilizing Different Ball Milling Speeds. Crystals 2020, 10, 332. [Google Scholar] [CrossRef]

- Sun, L.; Gibson, R.F.; Gordaninejad, F.; Suhr, J. Energy absorption capability of nanocomposites: A review. Compos. Sci. Technol. 2009, 69, 2392–2409. [Google Scholar] [CrossRef]

- Tan, Z.H.; Pang, B.J.; Qin, D.T.; Shi, J.Y.; Gai, B.Z. The compressive properties of 2024Al matrix composites reinforced with high content SiC particles at various strain rates. Mater. Sci. Eng. A 2008, 489, 302–309. [Google Scholar] [CrossRef]

- Seo, H.Y.; Jiang, L.R.; Kang, C.G.; Jin, C.K. Effect of Compression Process of MWCNT-Reinforced Al6061 Powder on Densification Characteristics and Its Mechanical Properties. Metals 2017, 7, 437. [Google Scholar] [CrossRef]

- Bai, Y.; Zhou, J.; Zhao, C.; Yun, K.; Qi, L. Enhanced strength and toughness of carbon fiber reinforced aluminum matrix composite prepared via novel indirect extrusion method. J. Alloys Compd. 2024, 1005, 176013. [Google Scholar] [CrossRef]

- Edosa, O.O.; Tekweme, F.K.; Olubambi, P.A.; Gupta, K. Microstructural Analysis, Compressive Strength, and Wear Properties of Spark-Plasma-Sintered Al–Mg–PPA Composites. Quantum Beam Sci. 2024, 8, 32. [Google Scholar] [CrossRef]

- Clouet, E. Elastic energy of a straight dislocation and contribution from core tractions. Philos. Mag. 2009, 89, 1565–1584. [Google Scholar] [CrossRef]

- Akhlaghi, M.; Meka, S.R.; Jägle, E.A.; Kurz, S.J.B.; Bischoff, E.; Mittemeijer, E.J. Formation Mechanisms of Alloying Element Nitrides in Recrystallized and Deformed Ferritic Fe–Cr–Al Alloy. Metall. Mater. Trans. A 2016, 47, 4578–4593. [Google Scholar] [CrossRef]

- Bailey, J.E.; Hirsch, P.B. The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Philos. Mag. 1960, 5, 485–497. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D.J. Introduction to Dislocations, 5th ed.; Chapter 9, Plastic Deformation, Recovery and Recrystallization, Section 9.1; Butterworth-Heinemann: Oxford, UK, 2011; Available online: https://www.academia.edu/33899552/Introduction_to_Dislocations (accessed on 22 August 2025).

- Ribárik, G.; Jóni, B.; Ungár, T. The Convolutional Multiple Whole Profile (CMWP) fitting method, a global optimiza-tion procedure for microstructure determination. Crystals 2020, 10, 623. [Google Scholar] [CrossRef]

- Sendrowicz, A.; Myhre, A.O.; Yasnikov, I.S.; Vinogradov, A. Stored and dissipated energy of plastic deformation revisited from the viewpoint of dislocation kinetics modelling approach. Acta Materialia 2022, 237, 118190. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Sheng, H.W.; Lu, K. Microstructure evolution and thermal properties in nanocrystalline Fe during me-chanical attrition. Acta Materialia 2001, 49, 365–375. [Google Scholar] [CrossRef]

- Frey, M.R.; Williams, S.L.; Srubar, W.V., III; Torres-Machi, C. Characterization and Evaluation of Agar as a Bio-Based Asphalt Binder Alternative. Infrastructures 2025, 10, 223. [Google Scholar] [CrossRef]

- Zhang, Z.; Ódor, É.; Farkas, D.; Jóni, B.; Ribárik, G.; Tichy, G.; Nandam, S.-H.; Ivanisenko, J.; Preuss, M.; Ungár, T. Dislocations in Grain Boundary Regions: The Origin of Heterogeneous Microstrains in Nanocrystalline Materials. Metall. Mater. Trans. A 2020, 51, 513–527. [Google Scholar] [CrossRef]

- Martínez-García, J.; Leoni, M.; Scardi, P. A General Approach for Determining the Diffraction Contrast Factor of Straight-Line Dislocations. Acta Cryst. A 2009, 65, 109–119. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The Contrast Factors of Dislocations in Cubic Crystals: The Disloca-tion Model of Strain Anisotropy in Practice. J. Appl. Cryst. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Wilkens, M. Theoretical Aspects of Kinematical X-ray Diffraction Profiles from Crystals Containing Dislocation Ensembles. Phys. Status Solidi A 1970, 2, 359–370. [Google Scholar] [CrossRef]

- ASTM Standard E9-092009; Standard Test Methods of Compression Testing of Metallica Materials at Room Temperature. ASTM International: West Conshohocken, PA, USA, 1 November 2009.

- Santos Beltrán, A.; Gallegos Orozco, V.; Santos Beltrán, M.; Medrano Prieto, H.; Estrada Guel, I.; Gallegos Orozco, C.; Martínez Sánchez, R. Time-Dependent Evolution of Al–Al4C3 Composite Microstructure and Hardness during the Sintering Process. Materials 2024, 17, 4818. [Google Scholar] [CrossRef]

- Pawlyta, M. Transmission electron microscope studies on carbon nanostructured materials. Arch. Mater. Sci. Eng. 2013, 63, 58–67. [Google Scholar]

- Anderson, P.M.; Hirth, J.P.; Lothe, J. Theory of Dislocations, 3rd ed.; Cambridge University Press: Cambridge, UK, 2017; 718p. [Google Scholar]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2009; 856p. [Google Scholar] [CrossRef]

- Courtney, T.H. Mechanical Behavior of Materials, 2nd ed.; Waveland Press: Long Grove, IL, USA, 2000; 733p. [Google Scholar]

- Srinivasan, S.G.; Liao, X.Z.; Baskes, M.I.; McCabe, R.J.; Zhao, Y.H.; Zhu, Y.T. Compact and Dissociated Disloca-tions in Aluminum: Implications for Deformation. Phys. Rev. Lett. 2005, 94, 155502. [Google Scholar] [CrossRef] [PubMed]

- Gilman, J.J. Influence of Dislocation Dipoles on Physical Properties. Discuss. Faraday Soc. 1964, 38, 123–130. [Google Scholar] [CrossRef]

- Christian, J.W.; Vítek, V. Dislocations and stacking faults. Rep. Prog. Phys. 1970, 33, 307. [Google Scholar] [CrossRef]

- Yildirim, C.; Poulsen, H.F.; Winther, G.; Detlefs, C.; Huang, P.H.; Dresselhaus-Marais, L.E. Extensive 3D Mapping of Dislocation Structures in Bulk Aluminum. Sci. Rep. 2023, 13, 3834. [Google Scholar] [CrossRef]

- Hennig, G.R. Screw Dislocations in Graphite. Science 1965, 147, 733–734. [Google Scholar] [CrossRef] [PubMed]

- Mardix, S.; Kalman, Z.H.; Steinberger, I.T. Periodic Slip Process in Zinc Sulfide Crystals. J. Appl. Phys. 1968, 39, 734–739. [Google Scholar]

- Reiche, M.; Kittler, M. Electronic and Optical Properties of Dislocations in Silicon. Crystals 2016, 6, 74. [Google Scholar] [CrossRef]

- Sara, I.; Ahmad Zekri, A.; Youssef, K.M. The role of twinning and stacking fault-induced plasticity on the mechanical properties of aluminum-lithium-graphene nanocomposites. Nanocomposites 2024, 10, 91–107. [Google Scholar] [CrossRef]

| Nomenclature | Al (wt. %) | R, Mixture Powder (wt. %) | Sintering Time (h) |

|---|---|---|---|

| Al-30 | 99 | 3 | 0 |

| Al-32 | 99 | 3 | 2 |

| Al-34 | 99 | 3 | 4 |

| Al-36 | 99 | 3 | 6 |

| Composition | Dislocations ρ (1014 m−2) | <x> area (nm) | q | Dislocation Character | A | M | Re (nm) | Elastic Energy Density, Ee (MJ m−3) |

|---|---|---|---|---|---|---|---|---|

| Al-12 | 4.75 † | 172.5 † | 1.56 † | Screw | 0.079 | 0.343 † | 20.02 † | 0.311 |

| Al-14 | 2.9 † | 154.0 † | 1.11 † | Mixture | 0.099 | 0.443 † | 20.33 † | 0.502 |

| A1-16 | 1.8 † | 184.3 † | 1.58 † | Screw | 0.079 | 1.37 † | 102.38 † | 0.240 |

| Al-22 | 4.6 † | 139.2 † | 1.55 † | Screw | 0.079 | 0.312 † | 14.50 † | 0.464 |

| AL24 | 4.16 † | 199.3 † | 1.03 † | Mixture | 0.099 | 0.34 † | 16.81 † | 0.428 |

| AL26 | 3.87 † | 271.8 † | 1.29 † | Screw | 0.079 | 0.38 † | 19.72 † | 0.408 |

| Al-32 | 22.63 | 62.3 | 0.89 | Mixture | 0.099 | 0.5 | 10.52 | 2.147 |

| Al-34 | 21.30 | 43.3 | 0.38 | Edge | 0.118 | 0.29 | 6.49 | 3.077 |

| Al-36 | 27.60 | 62.9 | 1.51 | Screw | 0.079 | 0.188 | 3.58 | 2.115 |

| Composition | Proportional Stress σp (Mpa) | SD | Proportional Strain, εp | Strain Energy Density, Es (MJ m−3) | SD |

|---|---|---|---|---|---|

| Al-12 | 131.45 | 24 | 1.116 | 3.70 | 0.7 |

| Al-14 | 117.82 | 1 | 1.56 | 1.44 | 0.1 |

| A1-16 | 177.14 | 29 | 1.58 | 5.32 | 0.7 |

| Al-22 | 97.99 | 9 | 1.55 | 1.27 | 0.1 |

| AL24 | 180.33 | 18 | 1.03 | 5.37 | 0.5 |

| AL26 | 73.06 | 5 | 1.29 | 1.00 | 0.1 |

| Al-32 | 214.83 | 80 | 0.89 | 7.39 | 0.1 |

| Al-34 | 297.77 | 55 | 0.38 | 8.72 | 2 |

| Al-36 | 326.35 | 14 | 1.51 | 10.04 | 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Santos Beltrán, A.; Gallegos Orozco, V.; Medrano Prieto, H.M.; Estrada Guel, I.; Reyes, C.G.G.; Santos Beltrán, M.; Santos Gallegos, D.V.; Gallegos Orozco, C.; Martínez Sánchez, R. Elastic Energy Storage in Al–Al4C3 Composites: Effects of Dislocation Character and Interfacial Graphite Formation. Materials 2026, 19, 181. https://doi.org/10.3390/ma19010181

Santos Beltrán A, Gallegos Orozco V, Medrano Prieto HM, Estrada Guel I, Reyes CGG, Santos Beltrán M, Santos Gallegos DV, Gallegos Orozco C, Martínez Sánchez R. Elastic Energy Storage in Al–Al4C3 Composites: Effects of Dislocation Character and Interfacial Graphite Formation. Materials. 2026; 19(1):181. https://doi.org/10.3390/ma19010181

Chicago/Turabian StyleSantos Beltrán, Audel, Verónica Gallegos Orozco, Hansel Manuel Medrano Prieto, Ivanovich Estrada Guel, Carlos Gamaliel Garay Reyes, Miriam Santos Beltrán, Diana Verónica Santos Gallegos, Carmen Gallegos Orozco, and Roberto Martínez Sánchez. 2026. "Elastic Energy Storage in Al–Al4C3 Composites: Effects of Dislocation Character and Interfacial Graphite Formation" Materials 19, no. 1: 181. https://doi.org/10.3390/ma19010181

APA StyleSantos Beltrán, A., Gallegos Orozco, V., Medrano Prieto, H. M., Estrada Guel, I., Reyes, C. G. G., Santos Beltrán, M., Santos Gallegos, D. V., Gallegos Orozco, C., & Martínez Sánchez, R. (2026). Elastic Energy Storage in Al–Al4C3 Composites: Effects of Dislocation Character and Interfacial Graphite Formation. Materials, 19(1), 181. https://doi.org/10.3390/ma19010181