3.1. Microstructure

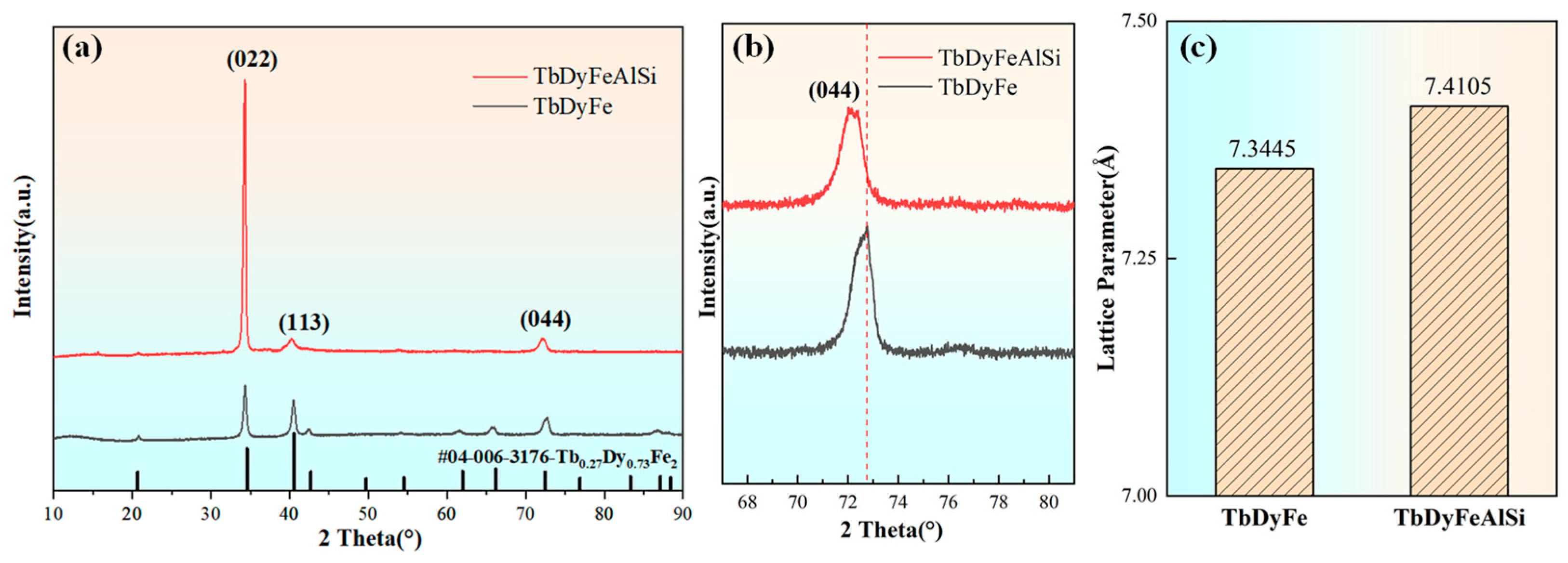

Figure 1 shows the XRD patterns of the TDF and TDF-AlSi alloys. The alloy maintains the MgCu

2-type cubic Laves phase structure after the addition of Al and Si (

Figure 1a). Compared to PDF standard cards (#04-006-3176), the directionally solidified samples exhibit significant <110> axial preferred orientation, as evidenced by the highest intensity of the diffraction peak for the (022) plane. In the magnified spectrum in

Figure 1b, the (044) peak shifts toward lower angles after alloying, indicating that the lattice parameter changes after Al and Si co-addition. The calculation reveals that the lattice parameter increases from 7.3445 Å for TDF to 7.4105 Å for TDF-AlSi, as shown in

Figure 1c, indicating a lattice expansion of approximately 0.9% after alloying. Additionally, the enhanced relative intensity of (022) peak after alloying of Al and Si elements suggests that the composite addition promoted the development of <110> preferred orientation. This enhanced <110> texture may be attributed to modifications in surface formation energy induced by Al-Si co-addition. An analogous phenomenon has been reported in magnetostrictive Fe-Ga alloys, where first-principles calculations demonstrated that B doping altered the surface formation energy and consequently shifted the preferred growth direction from <110> to <100> [

31].

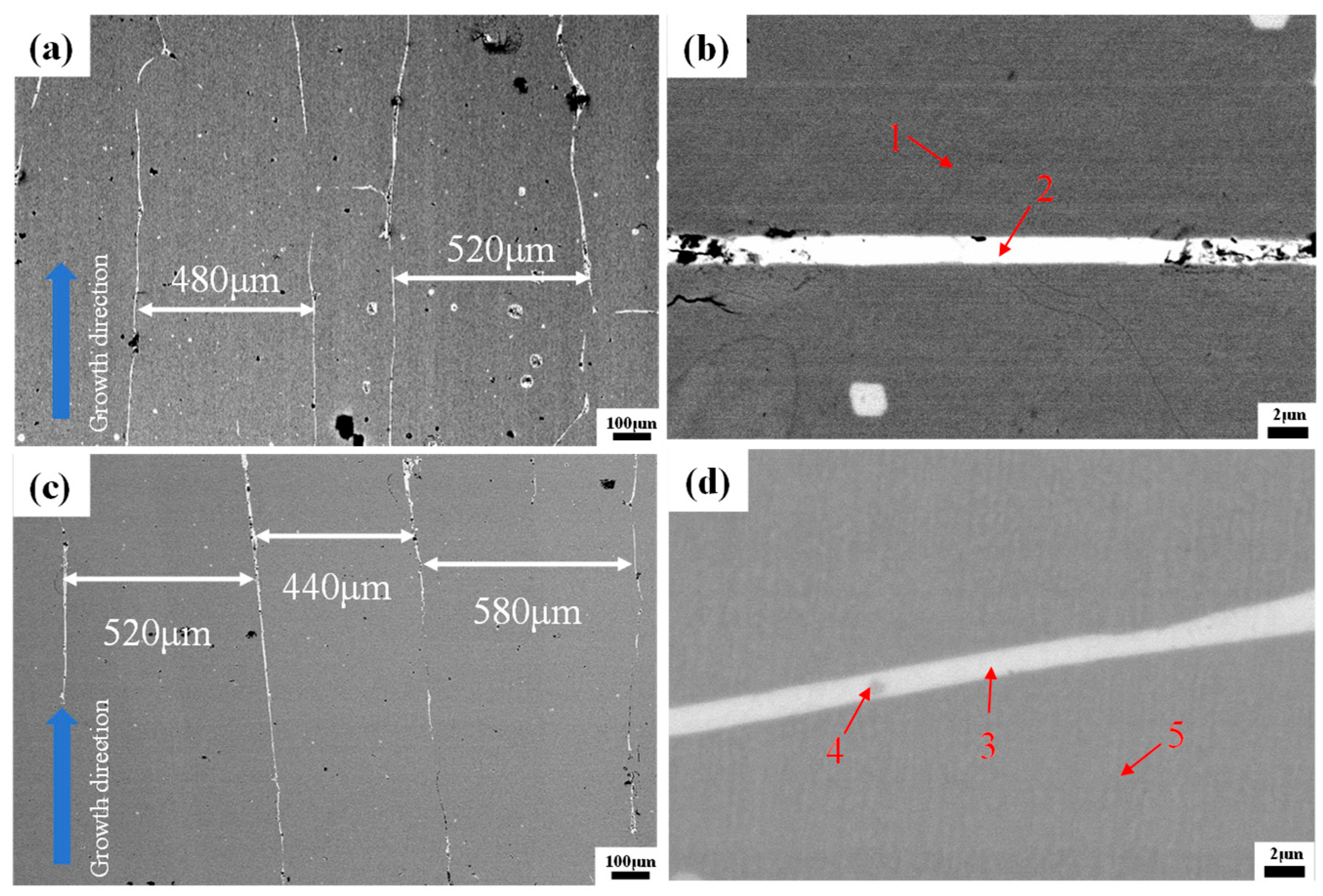

BSE imaging of directionally solidified TDF and TDF-AlSi alloys reveals a dual-phase microstructure, as shown in

Figure 2. The predominant phase appears as dark-gray contrast corresponding to the Re(Tb,Dy)-Fe matrix, while bright-white regions indicate RE-rich secondary phases localized at grain boundaries (

Figure 2a,c). Consistent with the directional solidification process, the matrix develops an elongated columnar morphology extending several hundred micrometers along the growth direction. The RE-rich phase forms continuous intergranular networks with typical widths in the micrometer range.

The compositional variations across different microstructural regions, as marked in

Figure 2b,d, were quantified using energy-dispersive X-ray spectroscopy (EDS), with results summarized in

Table 1. For the TDF alloy, the grain boundary phase exhibits enrichment in Tb and Dy, whereas Fe content within the matrix region corresponds well with the designed stoichiometry. Upon Al-Si co-addition, a notable redistribution of alloying elements is observed: Al dissolves preferentially into the matrix phase with relatively uniform distribution, while Si demonstrates a pronounced tendency to accumulate at grain boundaries where it combines with Tb and Dy to form RE(Tb,Dy)-Si intermetallic compounds. Only trace amounts of Si remain detectable within the matrix interior.

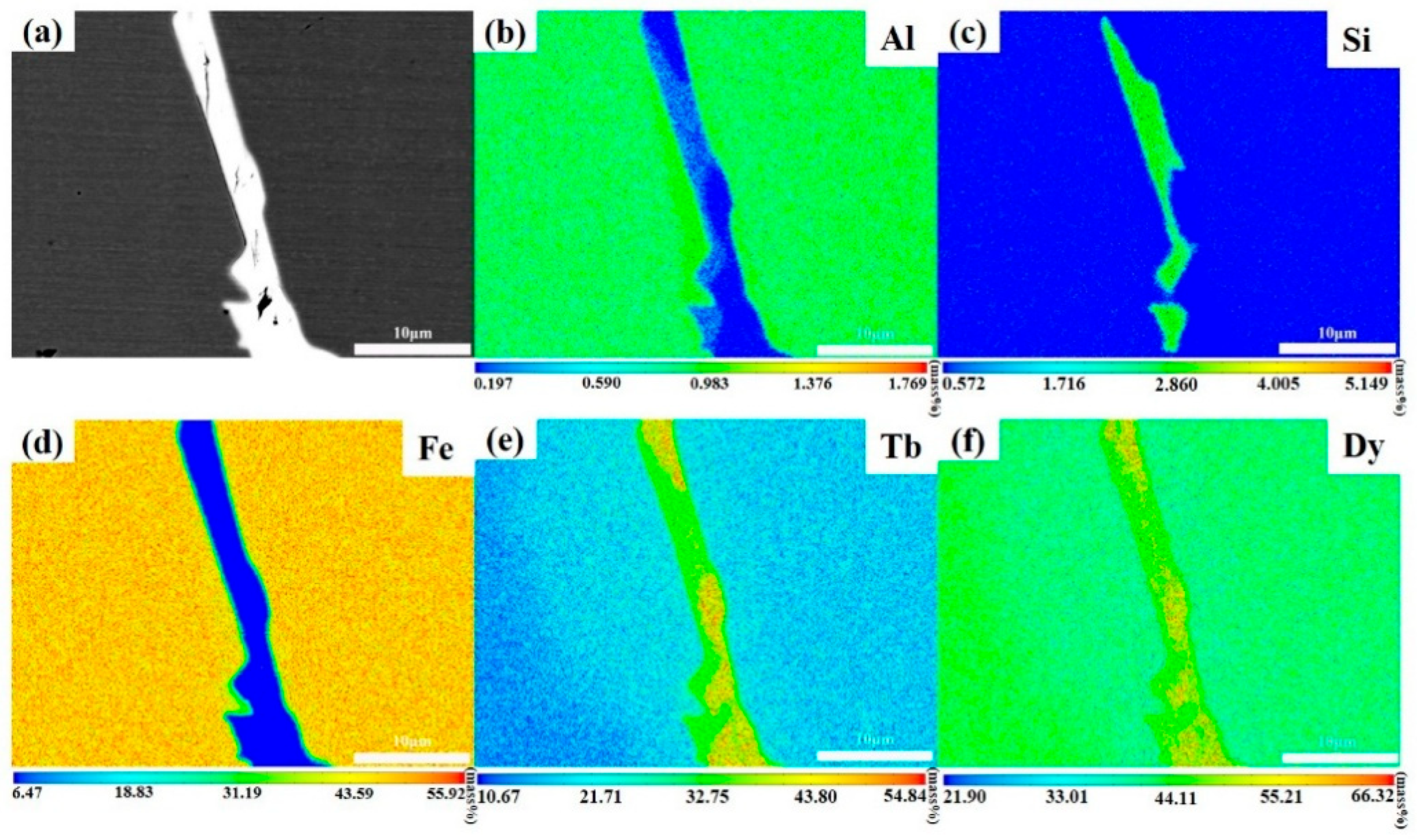

To further analyze the elemental distribution characteristics in the alloys, the detailed elemental distribution analysis of the TDF-AlSi alloys was performed using an electron probe microanalyzer (EPMA).

Figure 3 shows the EPMA results of the grain boundary regions. The BSE image of grain boundary phase is presented in

Figure 3a, and

Figure 3b–f display the elemental distribution images of Al, Si, Fe, Tb, and Dy, respectively. The elemental distribution analysis reveals the distinct distribution patterns for each element. The element of Al is primarily distributed in the matrix phase region with relatively uniform distribution, while Si exhibits significant enrichment in the grain boundary phase regions, showing the discontinuous distribution characteristics along the grain boundaries. Furthermore, Fe, Tb, and Dy, as the primary alloying elements, are relatively uniformly distributed throughout the matrix phase. These results were consistent with the previous EDS analyses. The distinct distribution behaviors of Al and Si can be attributed to differences in their thermodynamic interactions with the Tb-Dy-Fe matrix. For Al, the atomic radius (0.143 nm) is close to that of Fe (0.124 nm), with a size difference of approximately 15%, which favors the formation of substitutional solid solution. Previous studies on RE(Fe,Al)

2 Laves phases have demonstrated that Al can substitute Fe atoms while maintaining the C15-type cubic structure [

30]. Therefore, Al preferentially dissolves into the (Tb,Dy)Fe

2 matrix phase and exhibits uniform distribution. In contrast, Si exhibits strong chemical affinity with rare earth elements due to the highly negative formation enthalpy of RE-Si compounds [

32]. Consequently, during solidification, Si preferentially segregates to the RE-rich grain boundary regions and reacts with Tb and Dy to form silicide phases.

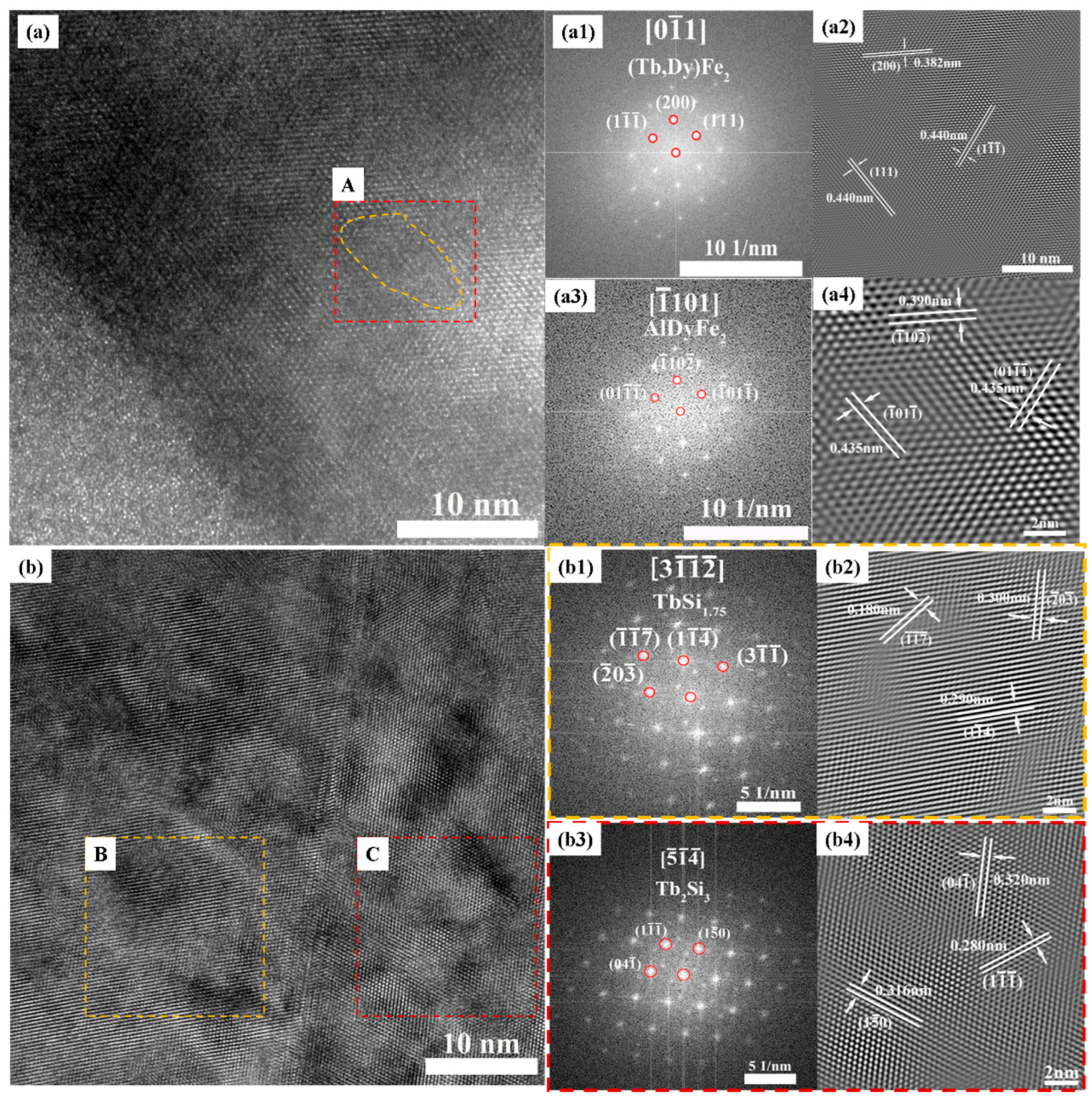

The distribution and phase formation of Al and Si elements following composite addition in the <110>-oriented polycrystalline TDF-AlSi alloys was investigated using the focused ion beam (FIB) technique to extract specimens for high-resolution transmission electron microscopy (HRTEM) analysis, as shown in

Figure 4. TEM images of the matrix phase and grain boundary phase of the TDF-AlSi alloys are shown in

Figure 4a and

Figure 4b, respectively.

Figure 4(a1,a3) show the fast Fourier transform (FFT) patterns of the overall matrix phase region and yellow dashed Region A, respectively, with their corresponding inverse fast Fourier transform (IFFT) patterns shown in

Figure 4(a2,a4). The analysis of PDF-standard-calibrated interplanar spacing measurements reveals that the FFT pattern of the entire matrix phase region in

Figure 4(a1) exhibits high consistency with the DyFe

2 phase along the [

] zone axis. The interplanar spacing measurements in

Figure 4(a2) show

nm,

nm and

nm. Compared with the standard lattice parameters of the DyFe

2 phase (d

111 = 0.424 nm, d

200 = 0.367 nm), the (111) and (200) interplanar spacings increase by approximately 3.8% and 4.1%, respectively. This proportional increase in interplanar spacing indicated that Al predominantly exists in solid solution form within the matrix (Tb,Dy)Fe

2 phase through partially substituting Fe atoms. Furthermore, an Al-enriched cluster of approximately 10 nm was observed in the matrix phase region (region A in

Figure 4a, marked by yellow dashed lines). The combined FFT and EDS (shown in

Table 2) analyses identify this cluster as the AlDyFe

2 phase along the

zone axis, with interplanar spacings

= 0.390 nm,

= 0.435 nm and

= 0.435 nm, as shown in

Figure 4(a4), which is consistent with the standard values (

= 0.394 nm,

= 0.435 nm and

= 0.435 nm). Therefore, HRTEM analysis confirms that the element of Al exhibits dual existence forms in the matrix phase region: predominantly as substitutional solid solution atoms replacing Fe positions, and partially as nanoscale Al(Tb,Dy)Fe

2 precipitate clusters.

The bright-field image in

Figure 4b shows distinct phase separation in the grain boundary phase region, forming a complex microstructure with multi-phase coexistence. It can be seen from the FFT images (

Figure 4(b1,b3)) that the two regions marked B and C (shown in

Figure 4b) correspond to the different phase composition regions within grain boundary phase. TEM analysis of the grain boundary region reveals the complex distribution characteristics of Si elements. Furthermore, the FFT analysis of the region B indicates that it corresponds to TbSi

1.75 phase along the [

] zone axis, with the measured interplanar spacings

= 0.180 nm,

= 0.290 nm and

0.300 nm, as shown in

Figure 4(b2). They are consistent with the standard values (

= 0.181 nm,

= 0.288 nm and

= 0.299 nm). Similarly, the FFT analysis of region C shows the correspondence with Tb

2Si

3 phase along the

zone axis, with interplanar spacings

= 0.280 nm,

= 0.320 nm and

= 0.316 nm, as shown in

Figure 4(b4), which are consistent with the standard values (

= 0.281 nm,

= 0.322 nm and

= 0.316 nm). In summary, the analysis results demonstrate that the element of Si is predominantly enriched in grain boundary phase regions, coexisting as two distinct silicide phases of TbSi

1.75 and Tb

2Si

3. These phases exhibit the intimate interfacial relationships within the grain boundary regions.

To provide a quantitative estimation of the microstructural features described above, the volume fractions of different phases were analyzed. Based on BSE image analysis (

Figure 2) and EDS compositional data (

Table 1), the volume fractions of different phases were estimated. The RE-rich grain boundary phase (containing silicides) occupies approximately 8–12% of the total volume, as determined by area fraction analysis of BSE images. Within this grain boundary region, the TbSi

1.75 and Tb

2Si

3 silicide phases account for approximately 40–50% of the grain boundary volume based on Si concentration mapping. For the Al(Tb,Dy)Fe

2 nanoclusters in the matrix phase, TEM observation (

Figure 4a) reveals a sparse distribution with an average cluster size of ~10 nm and an estimated volume fraction of approximately 0.1–0.5%, corresponding to a number density of approximately 10

21–10

22 m

−3. While the nanoclusters represent a minor volume fraction, their nanoscale dimensions create substantial interface area (~10

5–10

6 m

2/m

3) that contributes significantly to electron scattering. The predominant resistivity enhancement originates from the solid solution Al atoms uniformly distributed throughout the matrix phase (~6 at. % based on EDS Point 5 in

Table 1), which cause widespread lattice distortion and electron scattering throughout the bulk material.

3.2. Mechanical Properties, Resistivity, and Magnetic Properties

The 2 × 2 × 40 mm rectangular specimens were prepared from the TDF and TDF-AlSi alloy samples for electrical resistivity measurements. The electrical resistivity was measured at room temperature using an AT515 resistance tester. The electrical resistivity (ρ) was calculated according to Equation (1):

where

ρ is the electrical resistivity in Ω·m;

R is the resistance in Ω;

L is the conductor length in m; and

S is the cross-sectional area of the conductor in m

2.

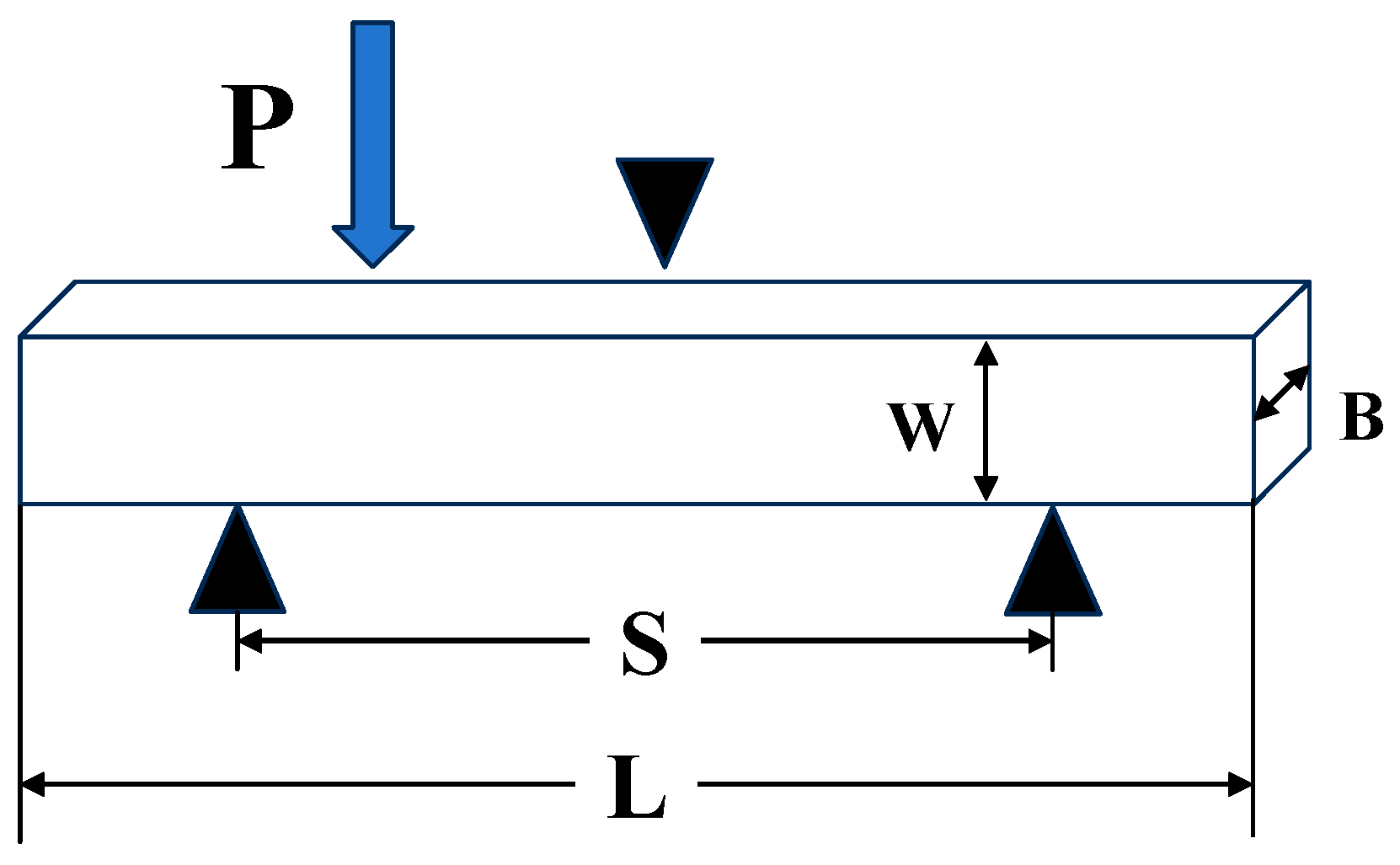

The bending strengths of TDF and TDF-AlSi alloys were determined using three-point bending tests on an MTS-810 machine at 0.1 mm/min. Specimens measuring 20 × 5 × 2.5 mm were prepared using wire electrical discharge machining with a span length of 16.8 mm. The bending strength was calculated using Equation (2):

where

W is the specimen thickness;

B is the specimen width;

P is the applied load; and

S is the distance between the two support points. The schematic diagram of three-point bending test specimen is shown in

Figure 5.

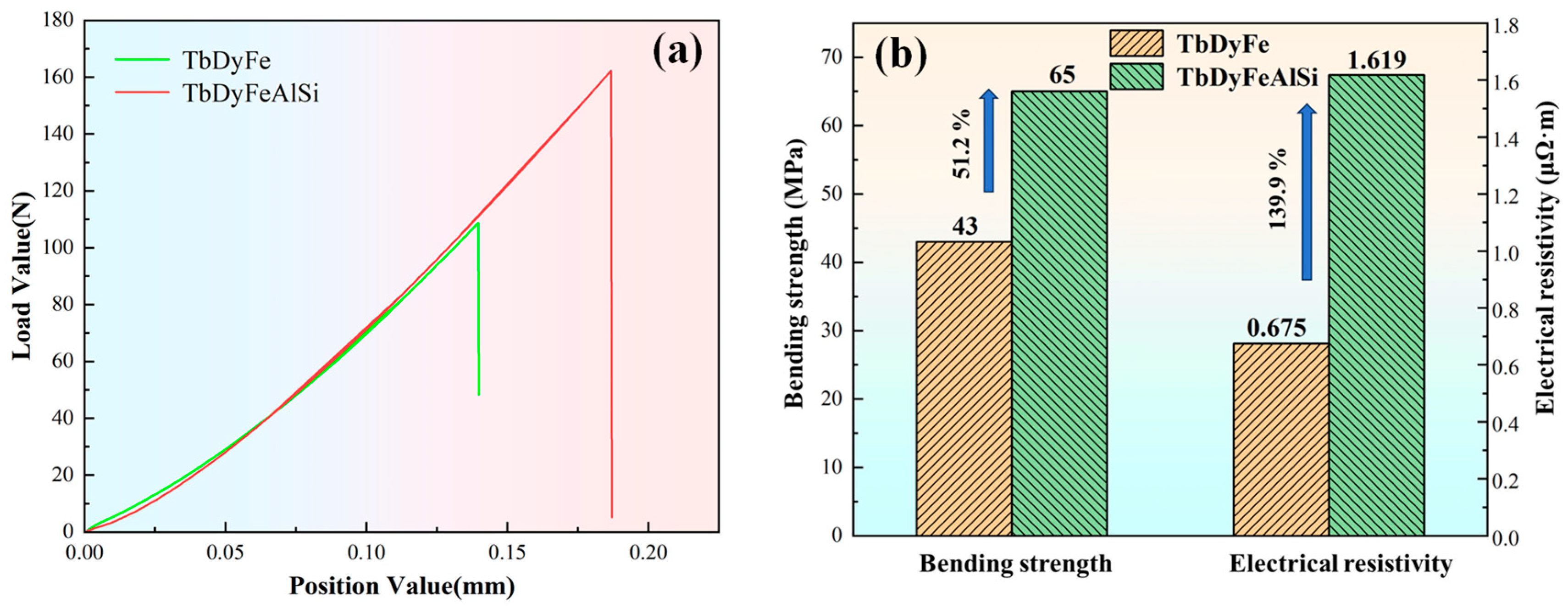

Figure 6 demonstrates the significantly enhanced bending strength and electrical resistivity in Al/Si co-added TDF-AlSi alloy relative to the unmodified TDF alloy. The bending strength increases by 51.2% from 43 MPa to 65 MPa, while electrical resistivity rises by 139.9% from 0.675 μΩ m to 1.619 μΩ m. The composite addition of Al and Si elements significantly enhances the bending strength of the TDF alloys. The reasons for the improvement of mechanical properties of TDF-AlSi alloys by adding Al can be summarized through two mechanisms: solid solution strengthening and precipitation strengthening. On the one hand, in the matrix phase, Al partially substituted Fe atom positions to form solid solutions, resulting in the lattice distortion and the enhanced resistance to dislocation movement. On the other hand, the hexagonal Al(Tb,Dy)Fe

2 phase clusters contribute to the additional precipitation strengthening. In addition, the reason why Si element improves the mechanical properties of the Al-Si co-added Tb-Dy-Fe alloys can be summarized as follows: the element of Si is precipitated as Tb

2Si

3 and TbSi

1.75 phases within grain boundary phase regions, contributing to precipitation strengthening and optimizing the grain boundary structure, thereby improving crack propagation resistance. In summary, these microstructural modifications worked synergistically to significantly enhance the alloys’ bending strength.

According to Matthiessen’s rule (

ρ =

ρ0 +

ρph +

ρm), the total resistivity consists of residual resistivity (

ρ0), phonon scattering contribution (

ρph), and magnetic scattering contribution (

ρm) [

27]. The Al-Si co-addition enhances resistivity through: (1) Increased ρ

0 due to lattice distortion caused by Al solid solution (lattice parameter change from 7.3445 Å to 7.4105 Å, ~0.9% expansion) and the formation of nanoscale interfaces around Al(Tb,Dy)Fe

2 clusters; (2) Enhanced

ρph resulting from the expanded lattice which modifies the phonon spectrum and increases electron-phonon scattering probability; (3) Increased

ρm from magnetic scattering at nanocluster-matrix interfaces. The formation of poorly conductive silicide phases (TbSi

1.75, Tb

2Si

3) at grain boundaries further impedes intergranular electron transport. Similar mechanisms have been reported in Mn-doped Tb-Dy-Fe alloys [

26].

To semi-quantitatively evaluate the relative contributions to resistivity enhancement, the total resistivity increase (Δ

ρ = 0.944 μΩ·m) can be decomposed into matrix-dominated (Δ

ρmatrix) and grain-boundary-dominated (Δ

ρGB) contributions. Considering that Al is uniformly distributed throughout the matrix phase at ~6 at. % (

Table 1), while Si-containing silicides occupy only 8–12% of the total volume at grain boundaries, the matrix-phase scattering is expected to dominate. Based on the volume fraction analysis and the continuous nature of the matrix phase versus the discrete distribution of grain-boundary precipitates, we estimate that Δ

ρmatrix accounts for approximately 70–90% of the total resistivity increase, with the remaining 10–30% attributed to grain-boundary silicides (Δ

ρGB). This analysis indicates that the matrix-phase modification through Al solid solution is the dominant factor in resistivity enhancement, while the grain-boundary silicides provide a supplementary contribution by impeding intergranular electron transport. This is consistent with the microstructural observation that Al is uniformly distributed throughout the matrix phase, whereas Si is localized at grain boundaries.

Based on the elemental distribution characteristics discussed in

Section 3.1, the resistivity enhancement mechanisms can be understood as follows. In the matrix phase, the Al solid solution (~6 at. %) and dispersed Al(Tb,Dy)Fe

2 nanoclusters collectively enhance electron scattering through lattice distortion and interface effects. At the grain boundaries, the Si-rich silicide phases (TbSi

1.75 and Tb

2Si

3) act as resistive barriers that impede intergranular electron transport. The synergistic contribution from both matrix-level and grain-boundary-level modifications accounts for the substantial resistivity enhancement.

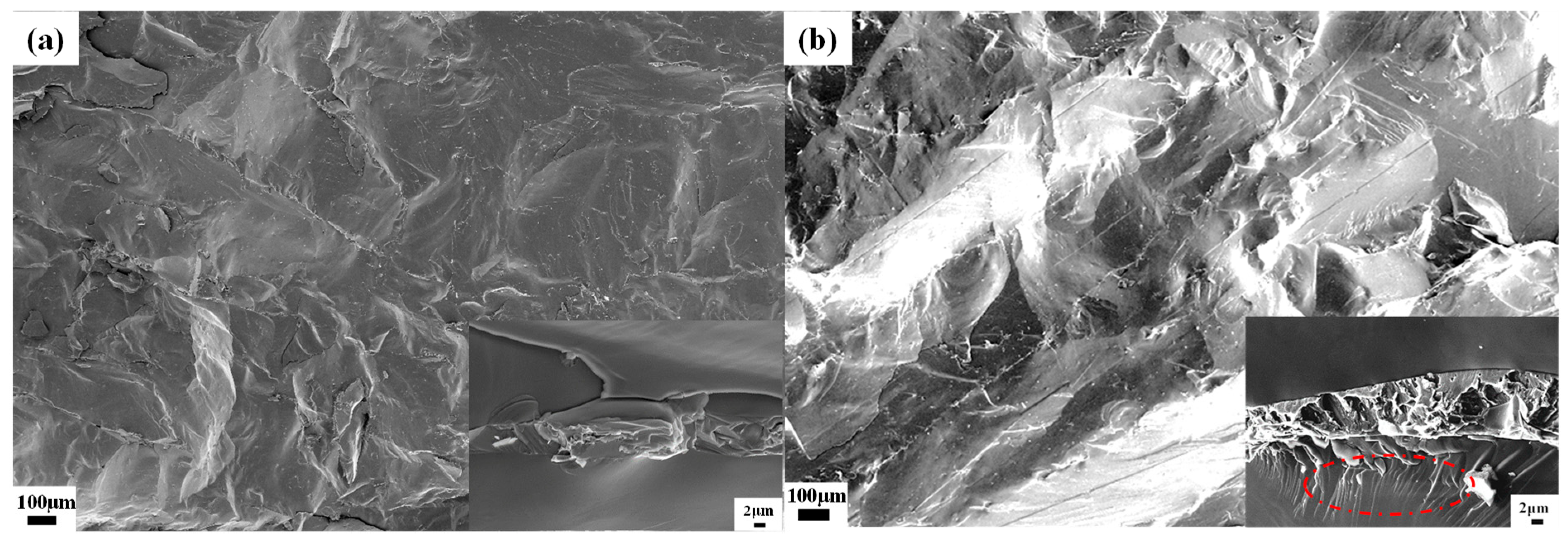

Comparative analysis of fracture morphologies is shown in

Figure 7. From

Figure 7a, it can be seen that the fracture surface of TDF alloy appears flat and smooth, exhibiting typical brittle fracture characteristics. The fracture surface exhibits a flat morphology with clear crack propagation paths, primarily characterized by intergranular fracture. In the directional solidified TDF alloy, grains align in parallel layers along the growth direction. This alignment causes cracks to propagate through grains with the same orientation over long distances, facilitating cleavage fracture. This fracture pattern suggests that the alloys experience quick brittle failure when subjected to external forces, showing minimal energy absorption and poor plastic deformation.

In contrast, although the TDF-AlSi alloy still exhibits brittle fracture behavior (

Figure 7b), the fracture morphology displays notably more complex and rough characteristics compared to the unmodified alloy, indicating enhanced energy absorption during the fracture process. The high-magnification image (2 μm scale, lower right corner) reveals distinct microstructural features in different regions. In the grain boundary regions, numerous fine fibrous tensile traces and complex network-like microstructures are observed, including tearing ridges, step-like structures, and undulating features, which are characteristic of quasi-cleavage fracture with improved ductile response. These interlaced fibrous patterns suggest that crack propagation encountered significant resistance, requiring multiple deflections and bifurcations to bypass the strengthening phases. In the matrix region near the grain boundaries, a significant number of shear bands emerge (indicated by the red ellipse in

Figure 7b), suggesting that the Al solid solution has modified the deformation behavior of the matrix, enabling localized plastic flow prior to final fracture. The above fracture characteristics correlate well with the observed 51.2% increase in bending strength (from 43 MPa to 65 MPa), which can be attributed to synergistic strengthening mechanisms. The addition of aluminum provides two strengthening effects: solid solution strengthening by distorting the lattice and precipitation strengthening through dispersed nanoscale Al(Tb,Dy)Fe

2 precipitates in the matrix phase. Moreover, the formation of TbSi

1.75 and Tb

2Si

3 phases at grain boundary regions not only enhanced boundary cohesion but also established an effective barrier network for crack propagation, compelling cracks to follow more tortuous paths. To clarify the relative contributions of matrix strengthening versus grain-boundary reinforcement, the following mechanistic analysis was performed. For matrix strengthening, the solid solution strengthening contribution from Al arises from atomic size misfit (~15% between Al and Fe) and modulus differences, which impede dislocation motion. With ~6 at. % Al uniformly distributed in the matrix, this mechanism is expected to contribute significantly to the overall strength increase. The Al(Tb,Dy)Fe

2 nanoclusters (~10 nm, ~0.1–0.5 vol.%) provide additional precipitation strengthening by acting as obstacles to dislocation motion. For grain-boundary reinforcement, the silicide phases at grain boundaries (~8–12 vol.% grain boundary phase, ~40–50% of which contains silicides) primarily contribute to crack deflection and propagation resistance rather than initial yield strength. The fracture morphology (

Figure 7b) provides direct evidence for these mechanisms: the shear bands in the matrix region indicate enhanced plasticity from Al solid solution, while the fibrous patterns at grain boundaries confirm effective crack deflection by silicides. Based on this analysis, we estimate that matrix strengthening (solid solution + precipitation) contributes approximately 60–70% of the total strength increase (~13–15 MPa), while grain-boundary reinforcement contributes approximately 30–40% (~7–9 MPa) primarily through improved crack propagation resistance and energy absorption during fracture. The complex fibrous patterns seen in the high-magnification images of

Figure 7b directly reflect the coordinated deformation between the strengthening phases and the matrix phase. This demonstrates that the Al-Si co-addition effectively enhanced the mechanical properties of Tb-Dy-Fe alloys.

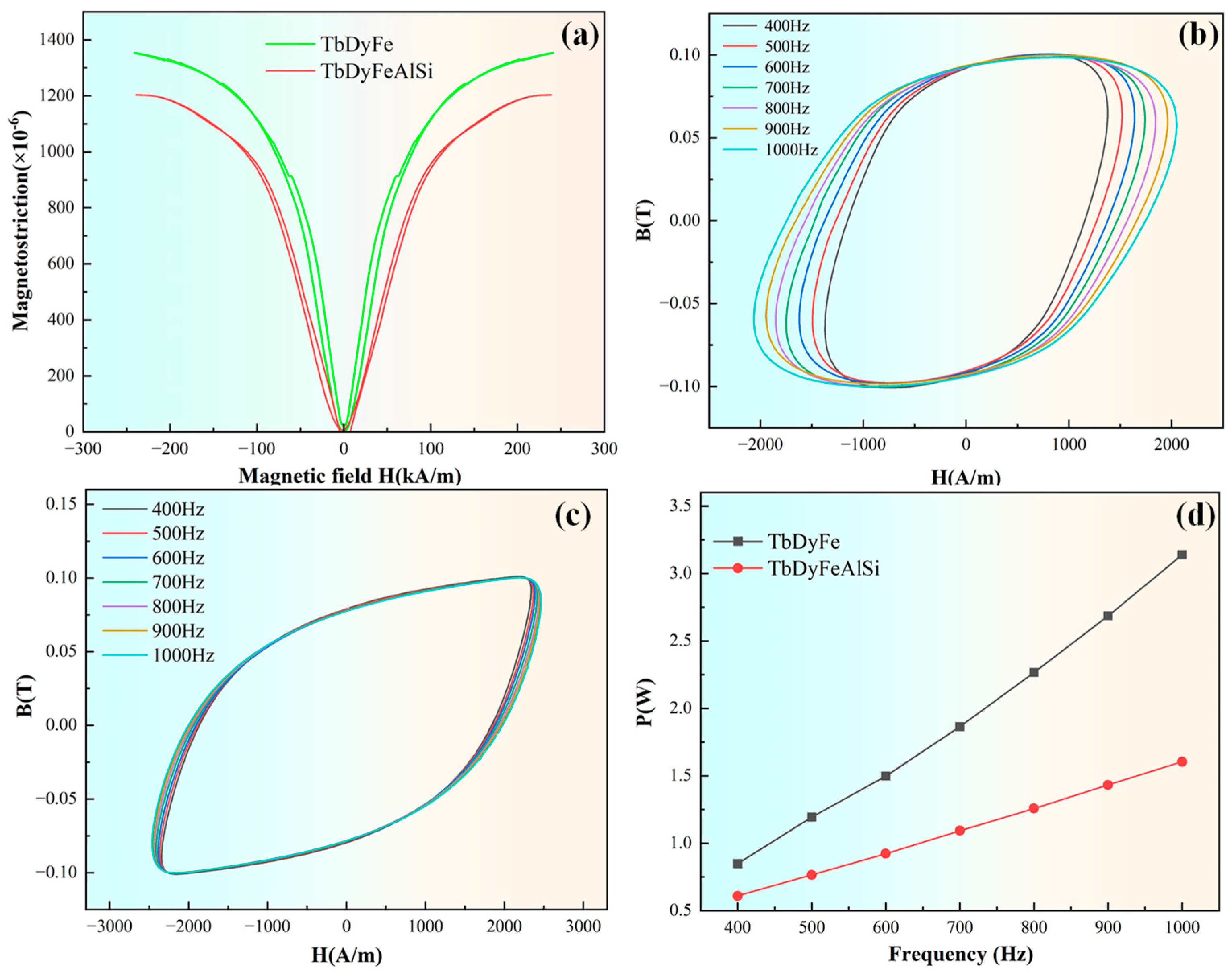

The magnetostrictive behavior of directionally solidified polycrystalline specimens of TDF and TDF-AlSi was evaluated under 10 MPa axial pre-compression, with the measurement results presented in

Figure 8a. At an applied field of 200 kA/m, the unmodified and Al-Si co-added alloys exhibited magnetostrictive strains of 1353 ppm and 1212 ppm, respectively. Despite a 10.4% reduction in strain output for the modified composition, the TDF-AlSi alloy still demonstrates substantial magnetostrictive capability, indicating that appropriate Al and Si incorporation preserves favorable magnetomechanical response. Comparable findings have been documented in prior investigations on single-element additions. Prajapati K et al. examined Fe-site substitution by Al in Tb

0.3Dy

0.7(Fe

1−xAl

x)

1.95 (0 ≤ x ≤ 0.1) compositions and reported peak strain values approaching 1200 ppm when subjected to 120 kA/m field strength and 12 MPa compressive loading [

21,

28,

29]. Similarly, Xu, L.H. et al. explored Si incorporation in Tb

0.3Dy

0.7(Fe

1−xSi

x)

1.95 (x = 0, 0.025, 0.1) systems and observed that the x = 0.025 specimen achieved a maximum strain of 794 ppm under 4 kOe magnetic excitation in the stress-free condition [

18].

The observed 10.4% decrease in magnetostriction can be attributed primarily to Al addition, with Si playing a secondary role. As established in

Section 3.1, Al predominantly dissolves into the matrix phase while Si segregates to grain boundaries, resulting in fundamentally different influences on magnetostrictive behavior. For Al (primary factor), the incorporation of non-magnetic Al atoms into the (Tb,Dy)Fe

2 matrix affects magnetostriction through four mechanisms: (1) reduced magnetic moment density due to replacement of magnetic Fe atoms, which weakens the overall magnetoelastic response; (2) altered local electronic structure that reduces the spin-orbit coupling strength—the fundamental microscopic origin of magnetostriction [

21,

27,

28]; (3) modified magnetoelastic coupling coefficients, leading to reduced λ

111 and λ

100 values [

27,

28]; and (4) domain wall pinning by Al(Tb,Dy)Fe

2 nanoclusters (~10 nm,

Figure 4), which increases the energy barrier for domain wall motion and reduces low-field magnetostrictive response [

30]. For Si (secondary factor), since Si preferentially segregates to grain boundaries forming TbSi

1.75 and Tb

2Si

3 silicides, its direct impact on the matrix-dominated magnetostrictive response is minimal [

18,

30]. Potential indirect effects through modified grain boundary stress states, magnetic decoupling between grains, or local demagnetizing fields are expected to be secondary, given that the grain boundary phase occupies only ~8–12% of the total volume. This interpretation is supported by the observation that our magnetostriction reduction is comparable to values reported for similar Al substitution levels without Si addition [

21].

The enhanced <110> preferred orientation observed after Al-Si co-addition (

Figure 1b) may theoretically benefit magnetostrictive response by increasing the proportion of favorably oriented grains. However, the observed 10.4% decrease indicates that any beneficial texture effect is overwhelmed by the detrimental influence of Al substitution on intrinsic magnetoelastic coupling. Quantitative separation of texture and compositional effects would require future comparative studies with controlled texture development.

In summary, the distinct distribution behaviors of Al and Si—matrix dissolution versus grain boundary segregation—enable simultaneous optimization of multiple properties: significant improvements in mechanical strength (51.2%) and electrical resistivity (139.9%) are achieved with only a minor reduction in magnetostriction (10.4%), demonstrating effective synergistic performance enhancement.

Additionally, the enhanced <110> texture (

Figure 1b) may contribute to the mechanical property improvement through anisotropic deformation behavior. The aligned columnar grain structure along the solidification direction could facilitate more uniform stress distribution, potentially contributing to the improved bending strength. However, quantitative separation of texture effects from compositional effects remains a direction for future investigation. fracture morphology.

The directionally solidified <110>-oriented polycrystalline TDF and TDF-AlSi specimens were examined by recording their dynamic hysteresis loops over a frequency span of 400–1000 Hz utilizing a NIM-3000S soft magnetic measurement system, with the outcomes illustrated in

Figure 8b–d. The enclosed region within each hysteresis loop quantifies the energy consumption during one complete magnetization-demagnetization cycle. By integrating the measured loop area, the total core loss at a given operating frequency can be obtained.

Figure 8b,c display the dynamic hysteresis responses of both alloys across the 400–1000 Hz frequency range. The AC magnetization data reveal that the TDF-AlSi alloy exhibits diminished core loss following Al and Si co-incorporation. The frequency-dependent loss characteristics derived from loop integration are depicted in

Figure 8d, with corresponding numerical data tabulated in

Table 3. These results demonstrate that the aggregate loss of the modified alloy decreases substantially after Al and Si co-addition. As evidenced in

Table 3, the loss reduction exhibits a positive correlation with operating frequency, escalating from 28.2% at 400 Hz to 49.0% at 1000 Hz. This trend is primarily ascribed to the elevated electrical resistivity of the modified alloy. The observed frequency-dependent behavior aligns well with the theoretical quadratic relationship between eddy current loss and excitation frequency.

It should be noted that our analysis of AC magnetic loss reduction is based primarily on the eddy current loss mechanism, which exhibits the characteristic quadratic frequency dependence (P

eddy ∝ f

2/

ρ) as observed in

Figure 8d. This interpretation implicitly assumes that changes in intrinsic magnetic damping (viscous domain wall motion) and quasi-static hysteresis loss are secondary to the eddy current contribution. This assumption is reasonable for the following reasons: (1) The total loss scales approximately with f

2 as expected for eddy-current-dominated behavior; (2) The 139.9% increase in resistivity directly corresponds to the observed loss reduction trend; (3) The Al-Si co-addition does not significantly alter the coercivity or hysteresis loop shape at low frequencies (

Figure 8b,c), suggesting minimal change in quasi-static hysteresis loss.