Refined Multi-Scale Mechanical Modeling of C/C-SiC Ceramic Matrix Composites

Abstract

1. Introduction

2. Material and Characterization

2.1. Material System

2.2. CMC’s Microstructures Characterization

2.3. Methodology

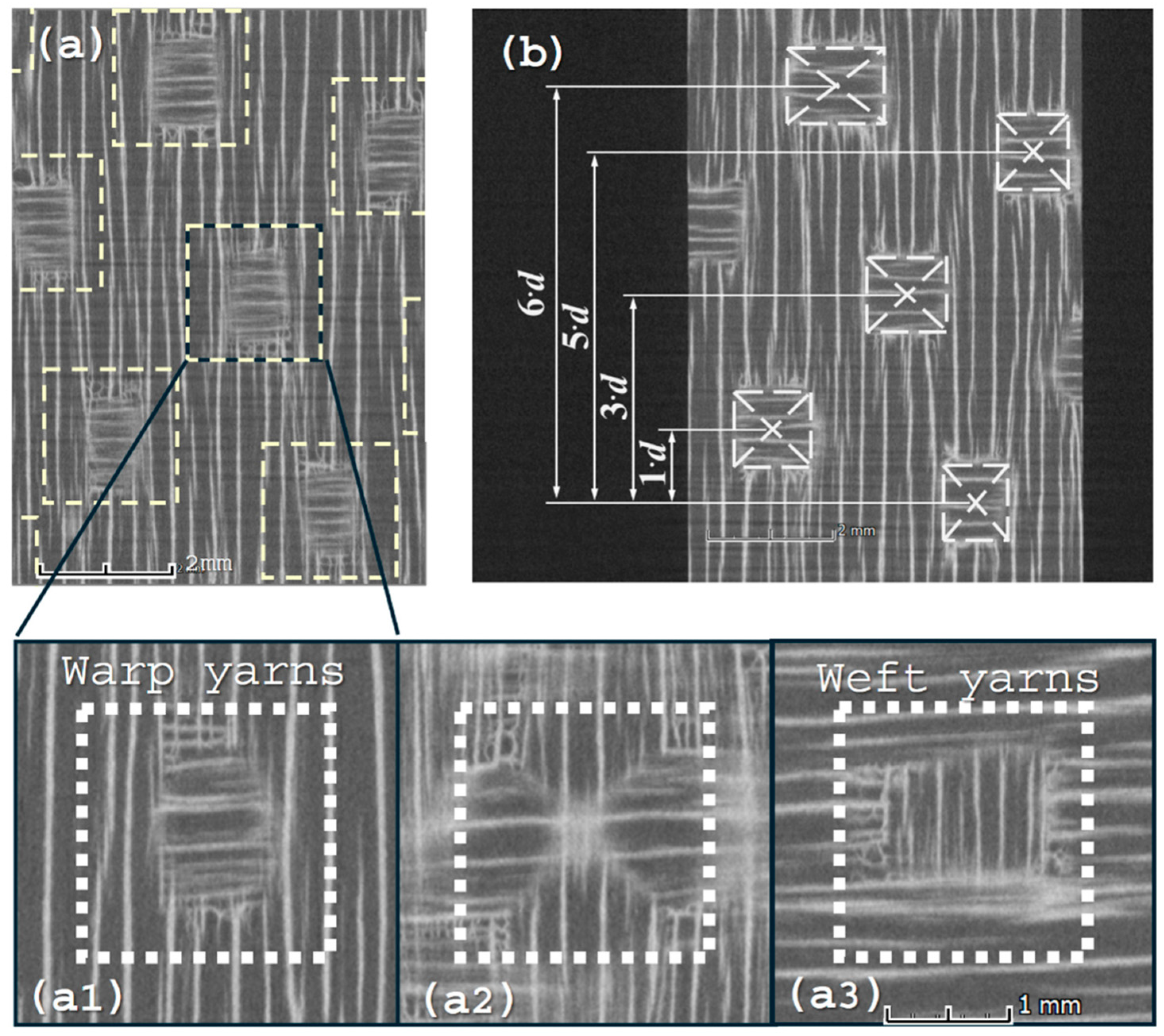

2.3.1. 8HS Inter-Layer Meso-Scale RVE

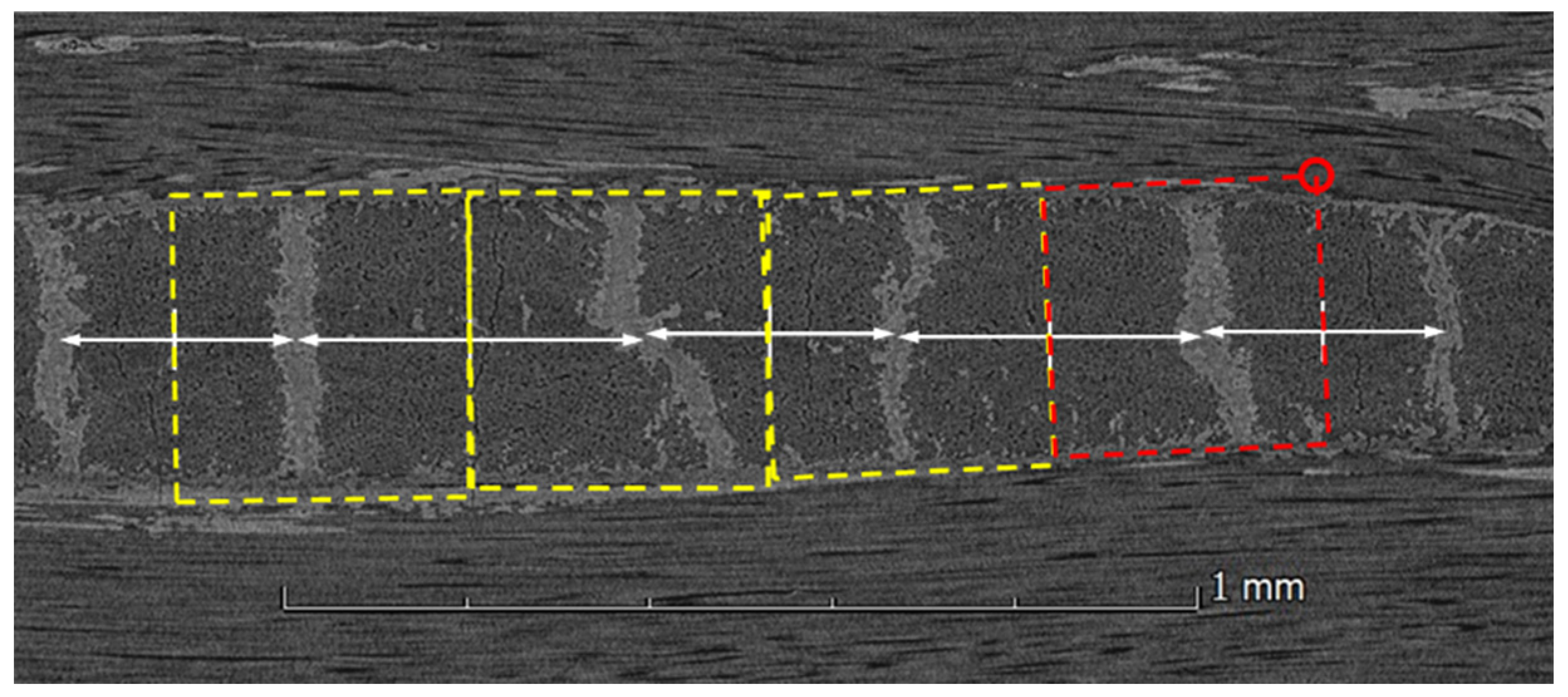

2.3.2. Intra-Layer Meso-Scale RVE

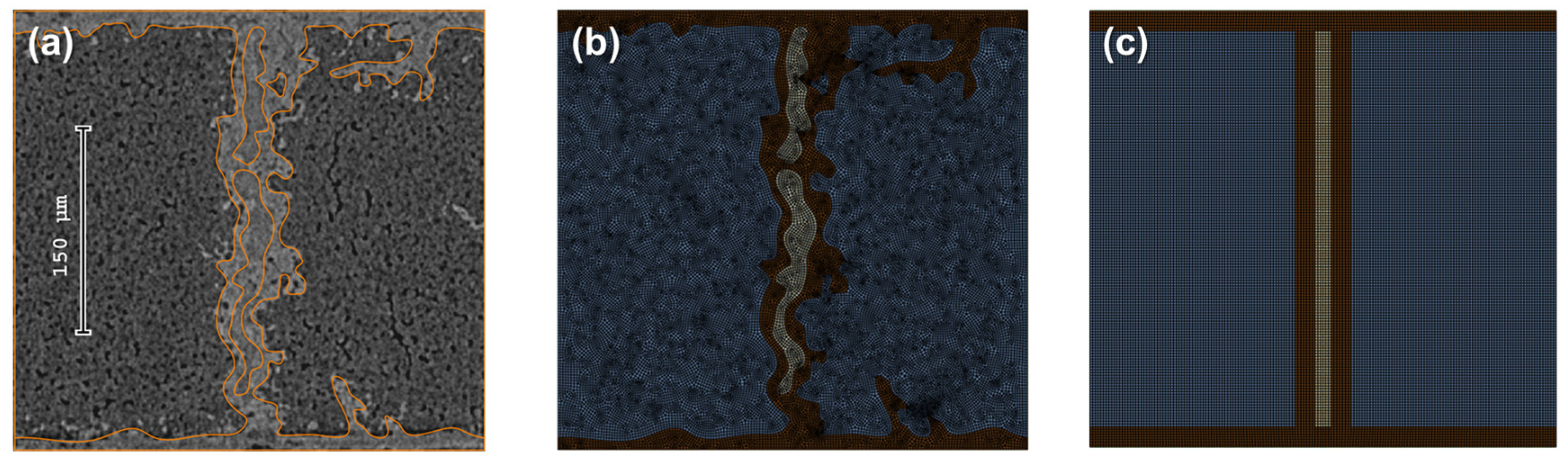

2.3.3. C/C Micro-Scale RVE

2.3.4. Simplified RVEs

3. Dedicated CMC Extension of the Nested PHFGMC

4. Results and Discussion

4.1. Micro-Scale RVE for the C/C Phase

4.2. Intra-Layer RVE

4.3. Meso-Scale RVE of 8-HS Inter-Layer

5. Conclusions

- A CT- and SEM-informed hierarchical RVE construction was developed, spanning the fiber/matrix micro-scale, the intra-yarn meso-scale, and the full 8-harness satin ply scale, thereby resolving microstructural features across more than three orders of magnitude in length scale.

- A physically representative geometric description of the woven architecture was achieved using a trapezoidal yarn cross-section approximation, eliminating artificial residual volumes (often interpreted as resin pockets in other composite systems) and enforcing continuous surface contact between interlacing yarns.

- Accurate prediction of effective elastic properties was obtained, with the homogenized stiffness values showing good agreement with the linear regime of tensile and shear experimental data for LSI C/C–SiC composites.

- Refined microstructural RVEs were shown to be essential for local stress-field resolution, as simplified C/C and intra-yarn geometries led to noticeable deviations in transverse stress distributions, highlighting the limitations of idealized representations when local damage-driving fields are of interest.

- A parameter-driven modeling strategy was introduced, providing flexibility to adapt the RVE geometry to different manufacturing conditions, segmentation morphologies, and weave configurations without altering the underlying micromechanical formulation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krenkel, W.; Schanz, P. Fiber ceramic structures based on liquid impregnation technique. Acta Astronaut. 1992, 28, 159–169. [Google Scholar] [CrossRef]

- Krenkel, W.; Berndt, F. C/C–SiC composites for space applications and advanced friction systems. Mater. Sci. Eng. A 2005, 412, 177–181. [Google Scholar] [CrossRef]

- Heidenreich, B.; Hofmann, S.; Keck, M.; Jemmali, R.; Friefiβ, M.; Koch, D. C/C-SiC materials based on melt Infiltration-manufacturing methods and experiences from serial production. In High Temperature Ceramic Matrix Composites 8; Zhang, L., Jiang, D., Eds.; Wiley-VCH: Weinheim, Germany, 2014; pp. 295–310. [Google Scholar]

- Clauß, B. Fibers for ceramic matrix composites. In Ceramic Matrix Composites; Krenkel, W., Ed.; Wiley-VCH: Weinheim, Germany, 2008; pp. 1–20. [Google Scholar]

- Shi, Y.; Jain, N.; Koch, D. Investigation and modeling of tensile failure properties of wound ceramic matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 114, 316–326. [Google Scholar] [CrossRef]

- Shi, Y.; Li, S.; Sitnikova, E.; Cepli, D.; Koch, D. Experimental evaluation and theoretical prediction of elastic properties and failure of C/C-SiC composite. Int. J. Appl. Ceram. Technol. 2022, 19, 7–21. [Google Scholar] [CrossRef]

- Hayhurst, D.; Leckie, F.; Evans, A.G. Component design-based model for deformation and rupture of tough fibre-reinforced ceramic matrix composites. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1991, 434, 369–381. [Google Scholar] [CrossRef]

- Talreja, R. Continuum modelling of damage in ceramic matrix composites. Mech. Mater. 1991, 12, 165–180. [Google Scholar] [CrossRef]

- Lamon, J. A micromechanics-based approach to the mechanical behavior of brittle-matrix composites. Compos. Sci. Technol. 2001, 61, 2259–2272. [Google Scholar] [CrossRef]

- Weigel, N.; Kröplin, B.; Dinkler, D. Micromechanical modeling of damage and failure mechanisms in C/C–SiC. Comput. Mater. Sci. 1999, 16, 120–132. [Google Scholar] [CrossRef]

- Tang, C.; Blacklock, M.; Hayhurst, D. Stress—Strain response and thermal conductivity degradation of ceramic matrix composite fiber tows in 0–90° unidirectional and woven composites. J. Compos. Mater. 2011, 45, 1461–1482. [Google Scholar] [CrossRef]

- Blacklock, M.; Hayhurst, D. Initial elastic properties of unidirectional ceramic matrix composite fiber tows. J. Appl. Mech. 2012, 79, 051020. [Google Scholar] [CrossRef]

- Chen, M.; Blacklock, M.; Zhang, D.; Gong, J. Effects of stochastic tow waviness on stiffness and strength of plain-weave ceramic matrix composites. Adv. Mech. Eng. 2017, 9, 1687814017727973. [Google Scholar] [CrossRef]

- Pineda, E.J.; Fassin, M.; Reese, S.; Simon, J.-W. Method of cells-based multi-scale modeling of elastic properties of filament wound C/C-SiC including free Si and matrix porosity. J. Mater. Sci. Technol. 2019, 35, 2906–2918. [Google Scholar] [CrossRef]

- Aboudi, J. Generalized effective stiffness theory for the modeling of fiber-reinforced composites. Int. J. Solids Struct. 1981, 17, 1005–1018. [Google Scholar] [CrossRef]

- Skinner, T.; Rai, A.; Chattopadhyay, A. Multi-scale ceramic matrix composite thermomechanical damage model with fracture mechanics and internal state variables. Compos. Struct. 2020, 236, 111847. [Google Scholar] [CrossRef]

- Khafagy, K.H.; Chattopadhyay, A. High-fidelity micromechanical modeling of the effects of defects on damage and creep behavior in single tow ceramic matrix composite. J. Compos. Mater. 2023, 57, 377–392. [Google Scholar] [CrossRef]

- Aboudi, J.; Arnold, S.M.; Bednarcyk, B.A. Practical Micromechanics of Composite Materials, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2021. [Google Scholar]

- Hughes, T.J.R. The Finite Element Method: Linear Static and Dynamic Finite Element Analysis; Dover Publication: Mineola, NY, USA, 2000. [Google Scholar]

- Zhang, D.; Hayhurst, D. Stress–strain and fracture behaviour of 0°/90° and plain weave ceramic matrix composites from tow multi-axial properties. Int. J. Solids Struct. 2010, 47, 2958–2969. [Google Scholar] [CrossRef]

- Zhang, D.; Hayhurst, D. Prediction of stress–strain and fracture behaviour of an 8-Harness satin weave ceramic matrix composite. Int. J. Solids Struct. 2014, 51, 3762–3775. [Google Scholar] [CrossRef]

- Haj-Ali, R.; Aboudi, J. Nonlinear micromechanical formulation of the high fidelity generalized method of cells. Int. J. Solids Struct. 2009, 46, 2577–2592. [Google Scholar] [CrossRef]

- Haj-Ali, R.; Aboudi, J. Formulation of the high-fidelity generalized method of cells with arbitrary cell geometry for refined micromechanics and damage in composites. Int. J. Solids Struct. 2010, 47, 3447–3461. [Google Scholar] [CrossRef]

- Tang, C.; Hayhurst, D. Predictions of thermo-mechanical behavior of a Nicalon-CAS 0–90° ceramic matrix composite from constituent materials properties. J. Compos. Mater. 2011, 45, 1337–1350. [Google Scholar] [CrossRef]

- Zhang, C.; Binienda, W.K.; Goldberg, R.K.; Kohlman, L.W. Meso-scale failure modeling of single layer triaxial braided composite using finite element method. Compos. Part A Appl. Sci. Manuf. 2014, 58, 36–46. [Google Scholar] [CrossRef]

- Yang, Z.; Yan, H. Multi-scale modeling and failure analysis of an 8-harness satin woven composite. Compos. Struct. 2020, 242, 112186. [Google Scholar] [CrossRef]

- Whitcomb, J.D. Three-Dimensional Stress Analysis of Plain Weave Composites; NASA Technical Memorandum NASA-TM-101672; NASA: Washington, DC, USA, 1989.

- Bednarcyk, B.A.; Pindera, M.-J. Micromechanical Modeling of Woven Metal Matrix Composites; NASA Contractor Report NASA-CR-204153; NASA: Washington, DC, USA, 1997.

- Searles, K.; Odegard, G.; Kumosa, M. Micro-and mesomechanics of 8-harness satin woven fabric composites: I—Evaluation of elastic behavior. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1627–1655. [Google Scholar] [CrossRef]

- Hivet, G.; Boisse, P. Consistent 3D geometrical model of fabric elementary cell. Application to a meshing preprocessor for 3D finite element analysis. Finite Elem. Anal. Des. 2005, 42, 25–49. [Google Scholar] [CrossRef]

- Onal, L.; Adanur, S. Modeling of elastic, thermal, and strength/failure analysis of two-dimensional woven composites—A review. Appl. Mech. Rev. 2007, 60, 37–49. [Google Scholar] [CrossRef]

- Choudhry, R.S.; Khan, K.A.; Khan, S.Z.; Khan, M.A.; Hassan, A. Micromechanical modeling of 8-harness satin weave glass fiber-reinforced composites. J. Compos. Mater. 2017, 51, 705–720. [Google Scholar] [CrossRef]

- Zhang, P.; Pai, S.; Turicek, J.S.; Snyder, A.D.; Patrick, J.F.; Soghrati, S. An integrated microstructure reconstruction and meshing framework for finite element modeling of woven fiber-composites. Comput. Methods Appl. Mech. Eng. 2024, 422, 116797. [Google Scholar] [CrossRef]

- Huang, W.; Causse, P.; Brailovski, V.; Hu, H.; Trochu, F. Reconstruction of mesostructural material twin models of engineering textiles based on Micro-CT Aided Geometric Modeling. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105481. [Google Scholar] [CrossRef]

- Choi, K.-H.; Hwang, Y.-T.; Kim, H.-J.; Kim, H.-S. Progressive failure analysis of woven composites considering structural characteristics based on micro-mechanics. Compos. Struct. 2019, 224, 110990. [Google Scholar] [CrossRef]

- ASTM C373-14; Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products, Ceramic Tiles, and Glass Tiles. ASTM: West Conshohocken, PA, USA, 2014.

- Fang, D.; Liu, T. On the effect of fiber shape and packing array on elastic properties of fiber-polymer-matrix composites. Int. J. Polym. Mater. 1996, 34, 75–90. [Google Scholar] [CrossRef]

- D’Mello, R.J.; Waas, A.M. Influence of unit cell size and fiber packing on the transverse tensile response of fiber reinforced composites. Materials 2019, 12, 2565. [Google Scholar] [CrossRef]

- Kim, D.-W.; Lim, J.H.; Kim, S.-W.; Kim, Y. Micro-computed tomography-aided modeling for misaligned and noncircular fibers of unidirectional composites and validation under a transverse tensile loading. Compos. Sci. Technol. 2021, 212, 108879. [Google Scholar] [CrossRef]

- Higuchi, R.; Yokozeki, T.; Nishida, K.; Kawamura, C.; Sugiyama, T.; Miyanaga, T. High-fidelity computational micromechanics of composite materials using image-based periodic representative volume element. Compos. Struct. 2024, 328, 117726. [Google Scholar] [CrossRef]

- Arhatari, B.D.; Zonneveldt, M.; Thornton, J.; Abbey, B. Local structural damage evaluation of a C/C–SiC ceramic matrix composite. Microsc. Microanal. 2017, 23, 518–526. [Google Scholar] [CrossRef] [PubMed]

- Hönig, S.; Koch, D.; Weber, S.; Etzold, S.; Tonnesen, T.; Telle, R.; Traon, N. Evaluation of dynamic modulus measurement for C/C-SiC composites at different temperatures. Int. J. Appl. Ceram. Technol. 2019, 16, 1723–1733. [Google Scholar] [CrossRef]

- Flauder, S.; Bombarda, I.; D’Ambrosio, R.; Langhof, N.; Lazzeri, A.; Krenkel, W.; Schafföner, S. Size effect of carbon fiber-reinforced silicon carbide composites (C/C-SiC): Part 2-tensile testing with alignment device. J. Eur. Ceram. Soc. 2022, 42, 1227–1237. [Google Scholar] [CrossRef]

- Padan, R.; Davida, D.; Louzon, E.; Haj-Ali, R. A New Brazilian Disc Test Procedure for the Elastic Moduli of Orthotropic C/C-SiC Composites. Exp. Mech. 2024, 64, 325–339. [Google Scholar] [CrossRef]

| EL, GPa | ET, GPa | GL, GPa | GT, GPa | vL | vT | |

|---|---|---|---|---|---|---|

| Carbon fiber | 230.0 | 13.75 | 8.96 | 4.83 | 0.12 | 0.25 |

| Porous Carbon matrix | 60.68 | -- | -- | -- | 0.30 | -- |

| Refined RVE | Square-Packed Model | ||

|---|---|---|---|

| Value | %Δ (Refined RVE) | ||

| EL, GPa | 185.1 | 185.4 | 0% |

| ET, GPa | 19.9 | 21.5 | 8% |

| GL, GPa | 11.7 | 11.7 | 0% |

| GT, GPa | 7.1 | 6.5 | −8% |

| vL | 0.026 | 0.028 | 8% |

| vT | 0.29 | 0.25 | −16% |

| Aspect Ratio | Width/Height | Phase VF | % C/C | % SiC | % Si |

|---|---|---|---|---|---|

| Min. | 0.63 | Min. | 68% | 9% | 1% |

| Avg. | 1.07 | Avg. | 80% | 17% | 3% |

| Max. | 1.65 | Max. | 84% | 30% | 5% |

| EL, GPa | ET, GPa | GL, GPa | GT, GPa | vL | vT | |

|---|---|---|---|---|---|---|

| SiC | 0.001 | 15.0 | 5.77 | 5.77 | 0.0 | 0.3 |

| Free Silicon | 160 | -- | -- | -- | 0.22 | -- |

| EL | ELT | EST | GL-ST | GL-LT | GT | vL † | vT | |

|---|---|---|---|---|---|---|---|---|

| [GPa] | [GPa] | [GPa] | [GPa] | [GPa] | [GPa] | [-] | [-] | |

| Refined RVE | 154.1 | 20.01 | 20.77 | 11.23 | 10.87 | 7.10 | 0.03 | 0.28 |

| Idealized RVE | 153.2 | 20.88 | 23.09 | 11.36 | 10.57 | 6.51 | 0.03 | 0.23 |

| %Δ (Refined RVE) | −1% | 4% | 11% | 1% | −3% | −8% | 0% | −17% |

| W:H = 0.71 model | 166.9 | 20.74 | 22.42 | 12.45 | 11.36 | 7.31 | 0.03 | 0.26 |

| %Δ (Refined RVE) | 8% | 4% | 8% | 11% | 5% | 3% | 5% | −4% |

| W:H = 1.64 model | 139.9 | 19.18 | 19.36 | 10.40 | 10.32 | 6.97 | 0.03 | 0.29 |

| %Δ (Refined RVE) | −9% | −4% | −7% | −7% | −5% | −2% | −2% | 5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Padan, R.; Dahan-Sharhabani, C.; Regev, O.; Haj-Ali, R. Refined Multi-Scale Mechanical Modeling of C/C-SiC Ceramic Matrix Composites. Materials 2026, 19, 105. https://doi.org/10.3390/ma19010105

Padan R, Dahan-Sharhabani C, Regev O, Haj-Ali R. Refined Multi-Scale Mechanical Modeling of C/C-SiC Ceramic Matrix Composites. Materials. 2026; 19(1):105. https://doi.org/10.3390/ma19010105

Chicago/Turabian StylePadan, Royi, Chen Dahan-Sharhabani, Omri Regev, and Rami Haj-Ali. 2026. "Refined Multi-Scale Mechanical Modeling of C/C-SiC Ceramic Matrix Composites" Materials 19, no. 1: 105. https://doi.org/10.3390/ma19010105

APA StylePadan, R., Dahan-Sharhabani, C., Regev, O., & Haj-Ali, R. (2026). Refined Multi-Scale Mechanical Modeling of C/C-SiC Ceramic Matrix Composites. Materials, 19(1), 105. https://doi.org/10.3390/ma19010105