Fabrication of Mechanically Robust Hydrophobic Surfaces Using Femtosecond Laser Shock Peening

Abstract

:1. Introduction

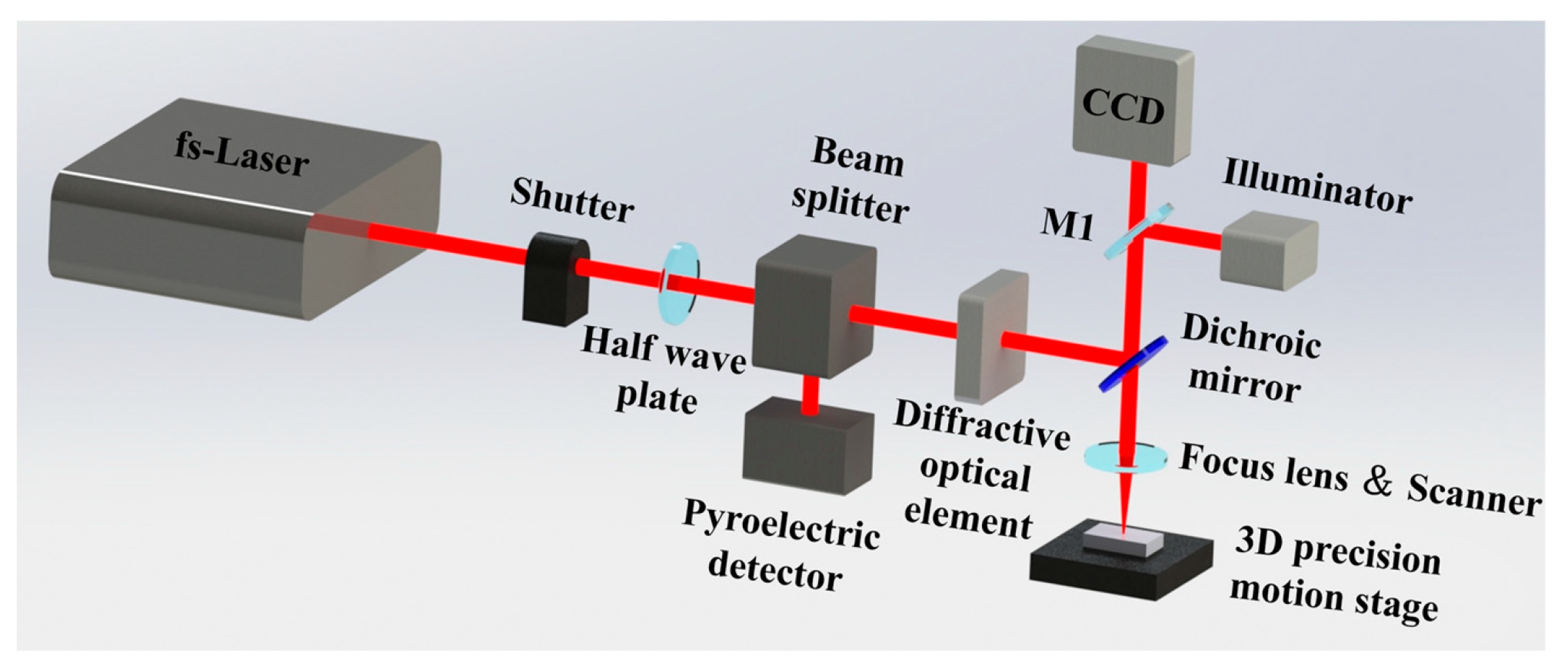

2. Experimental Procedure

2.1. Materials and fs-LSP Processing

2.2. Microstructure Characterization and Mechanical Property Testing

3. Results

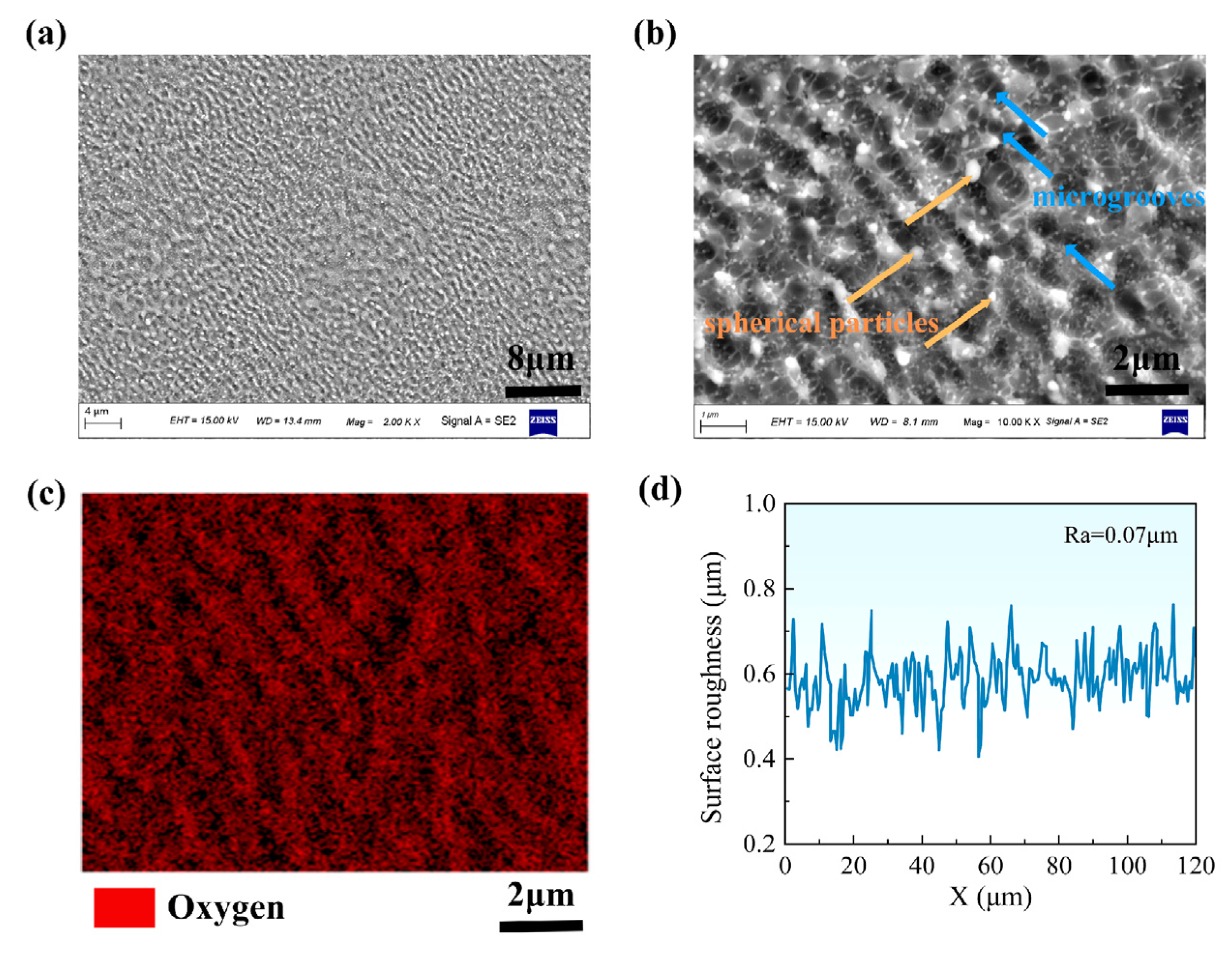

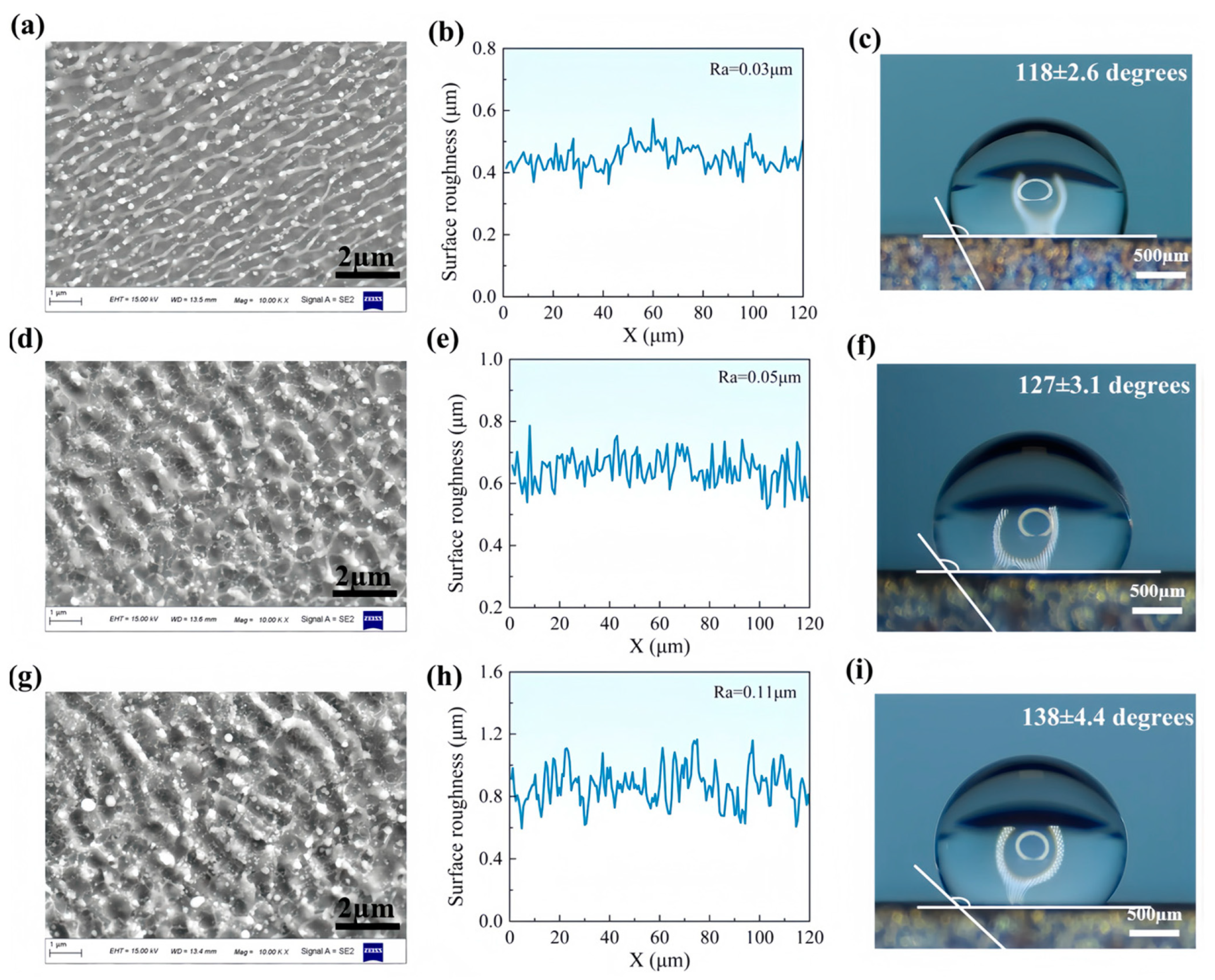

3.1. Surface Morphology and Roughness

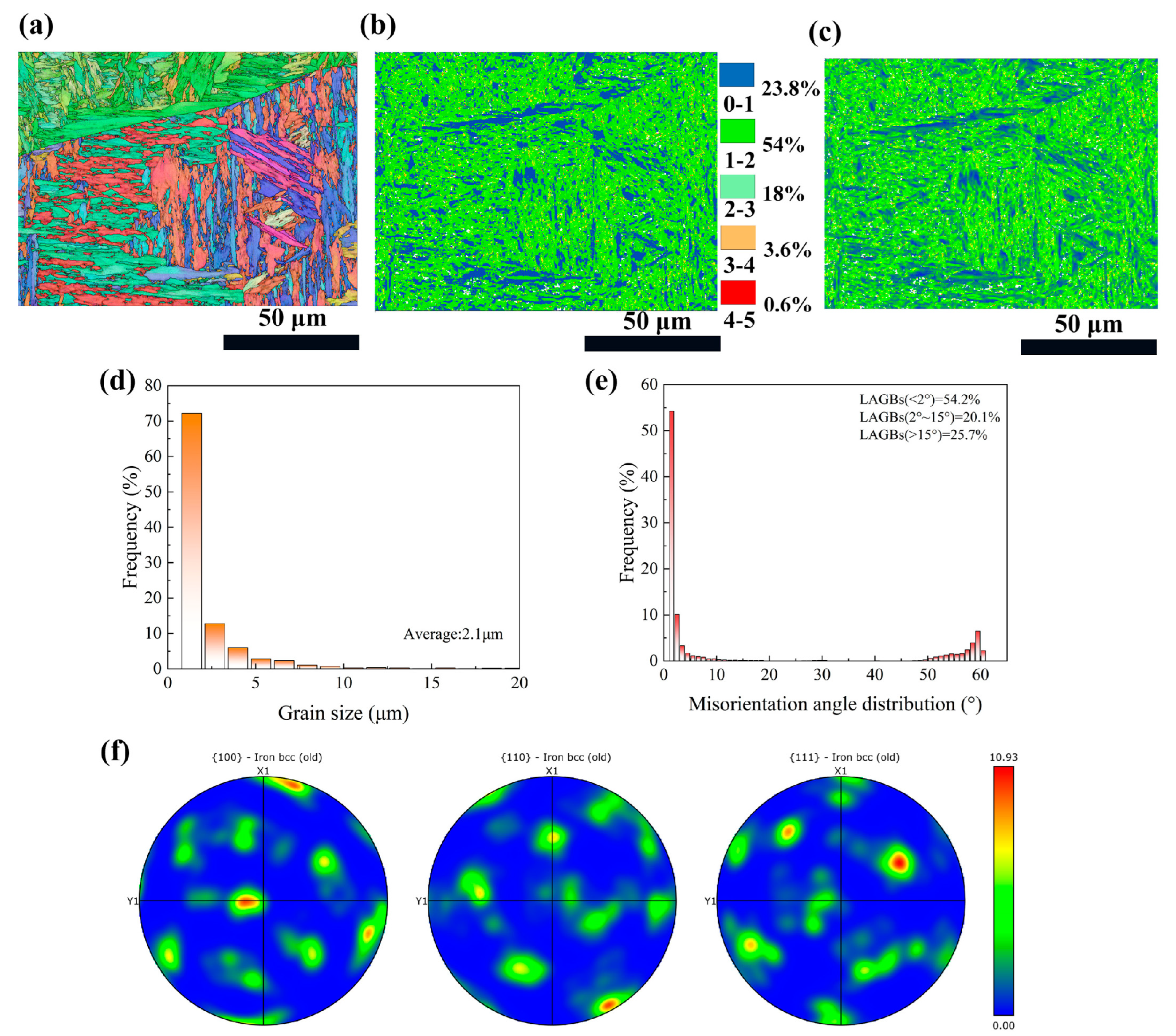

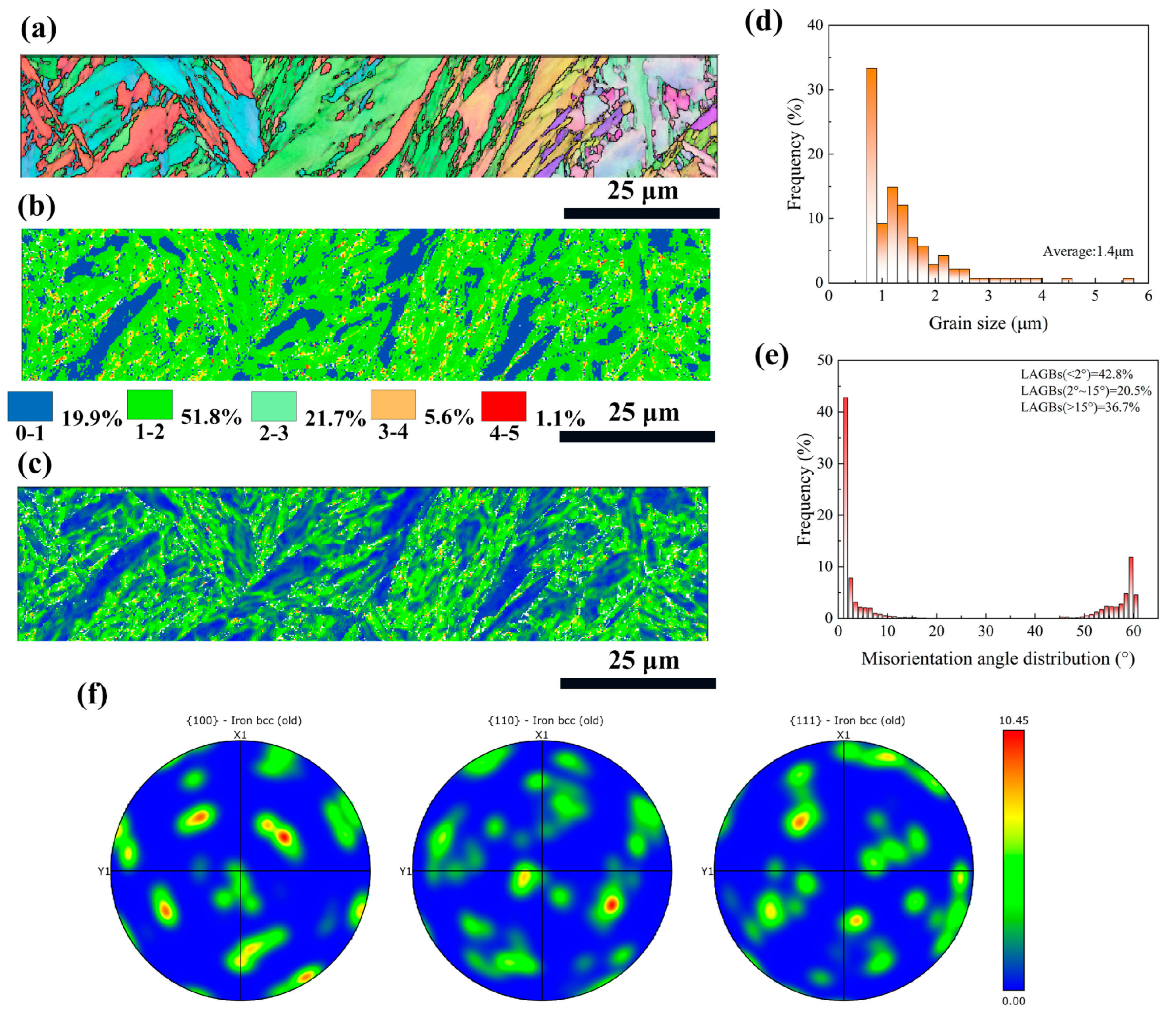

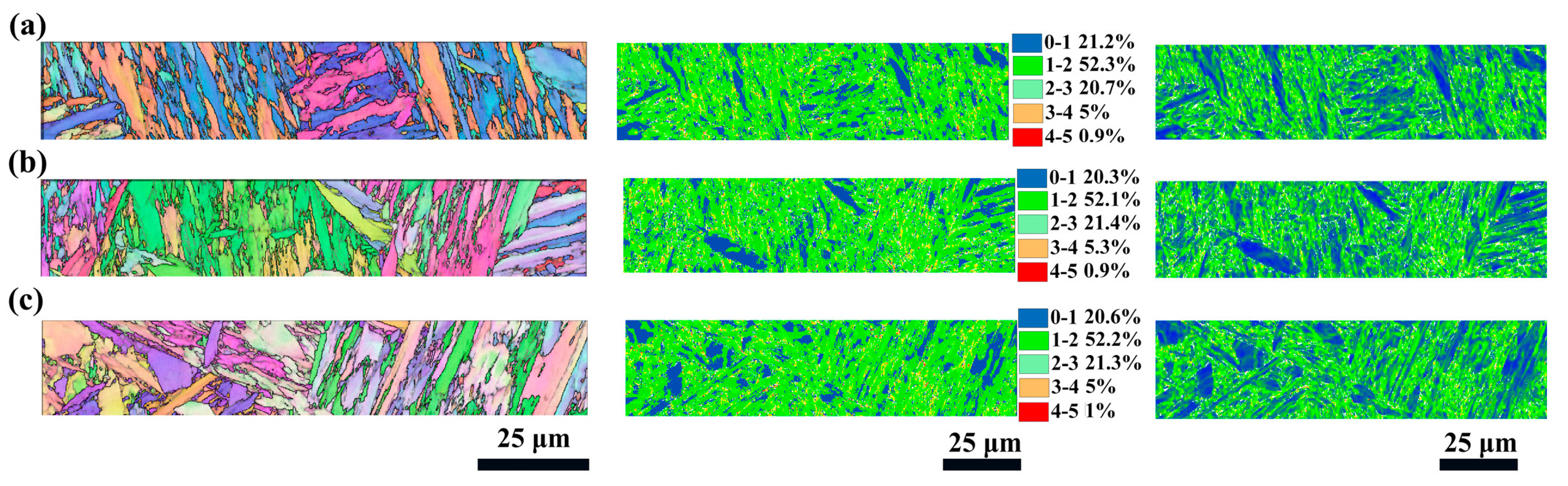

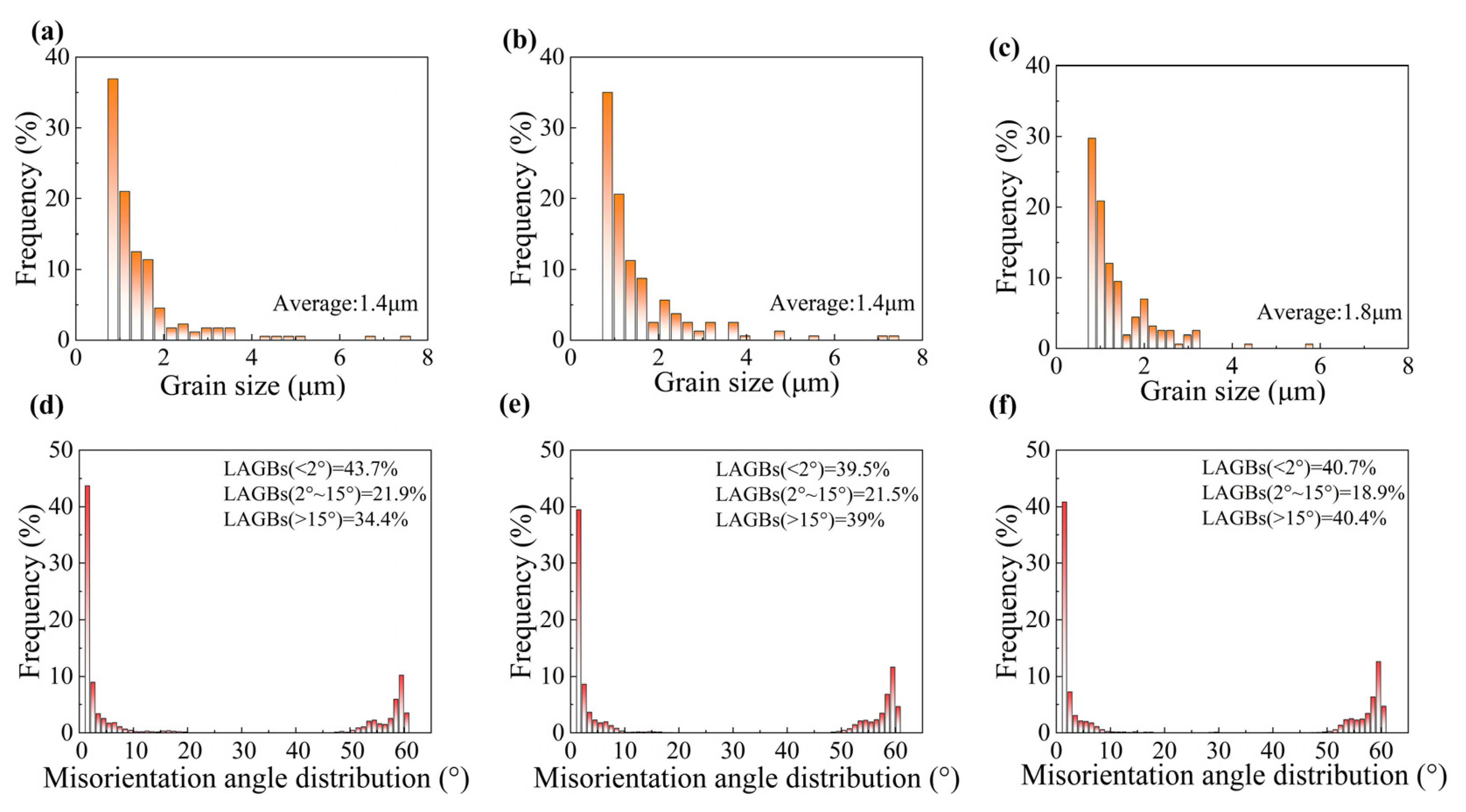

3.2. Cross-Section Microstructure

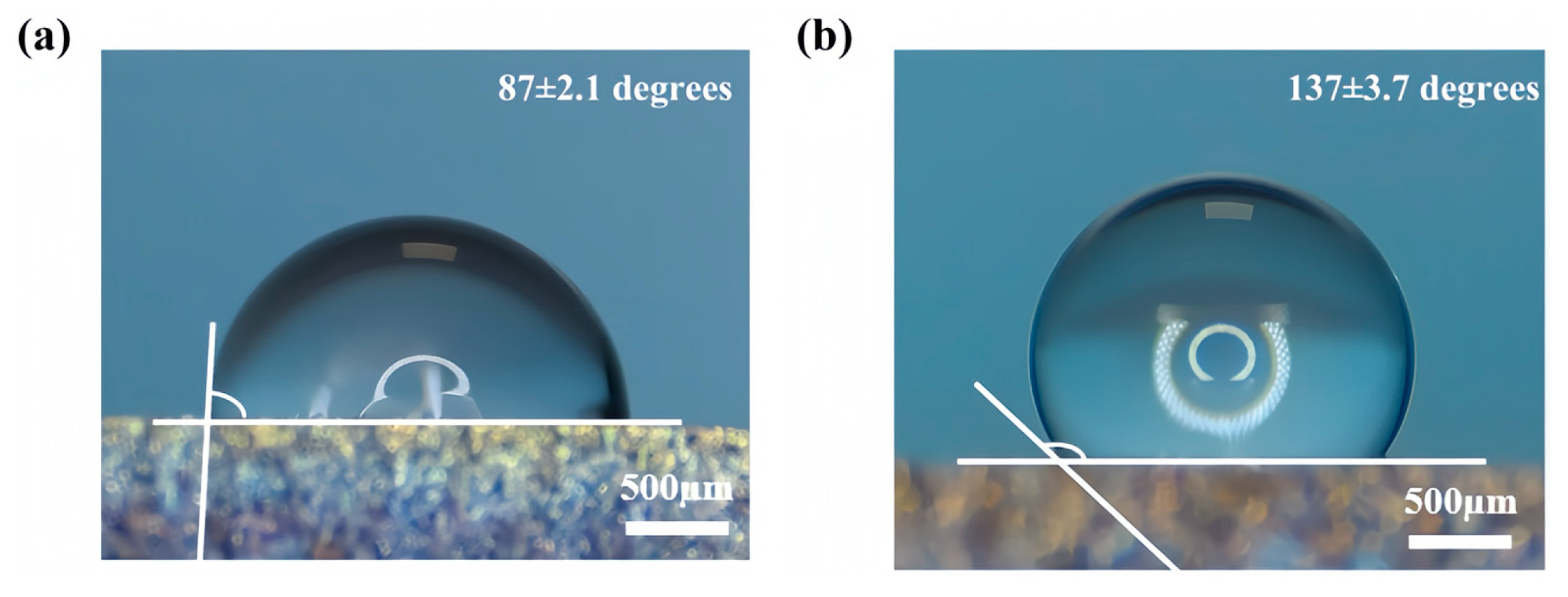

3.3. Wetting Properties

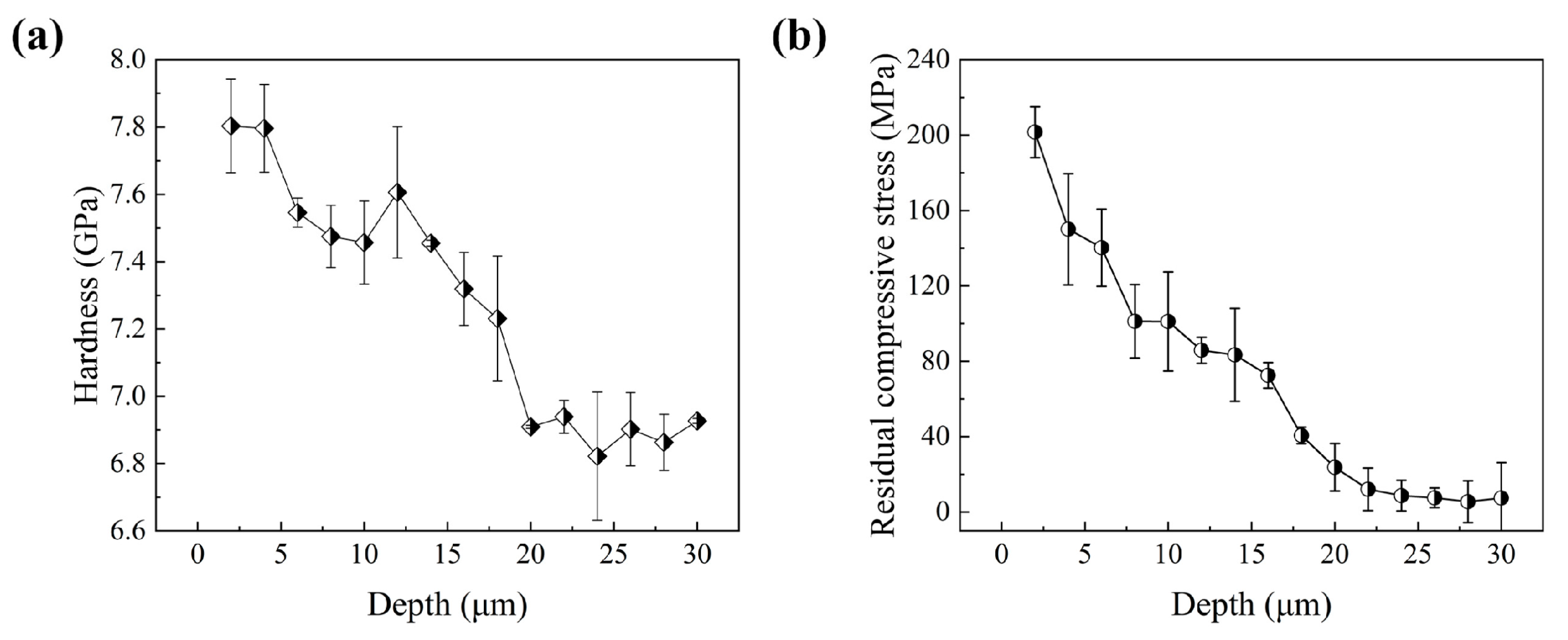

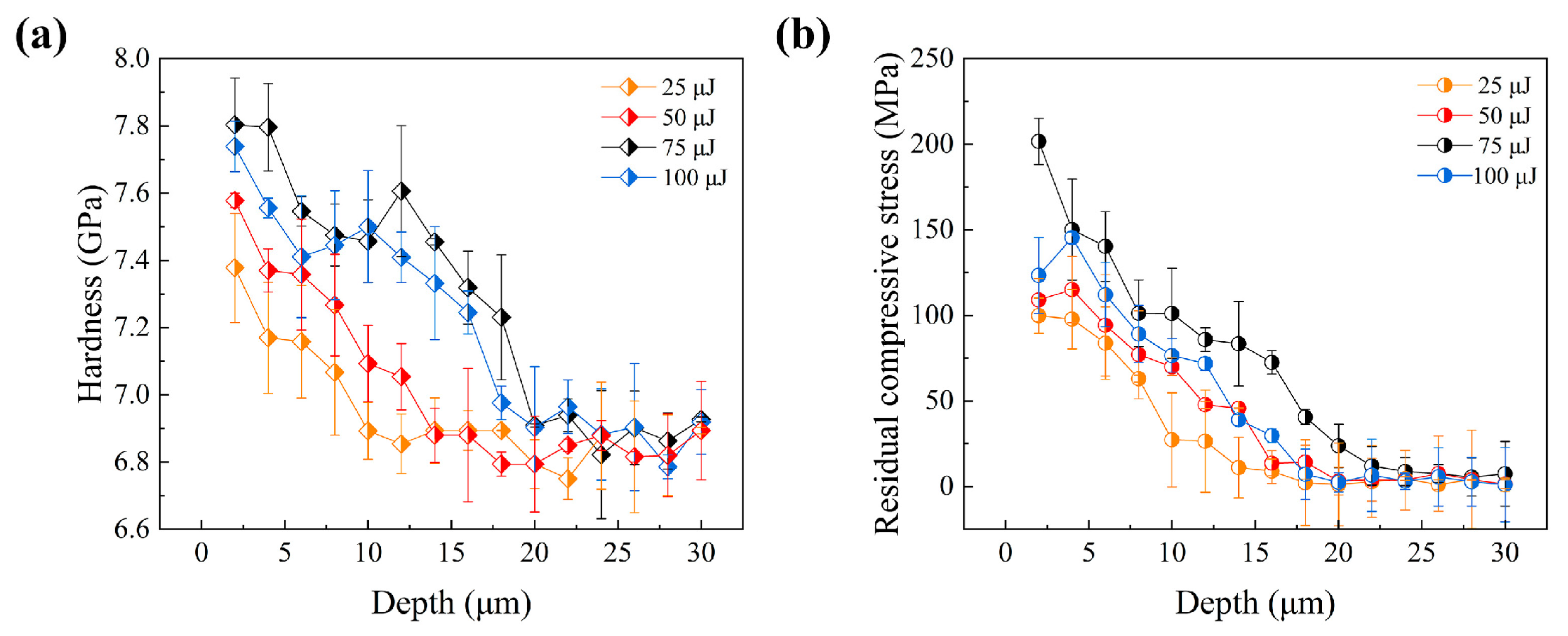

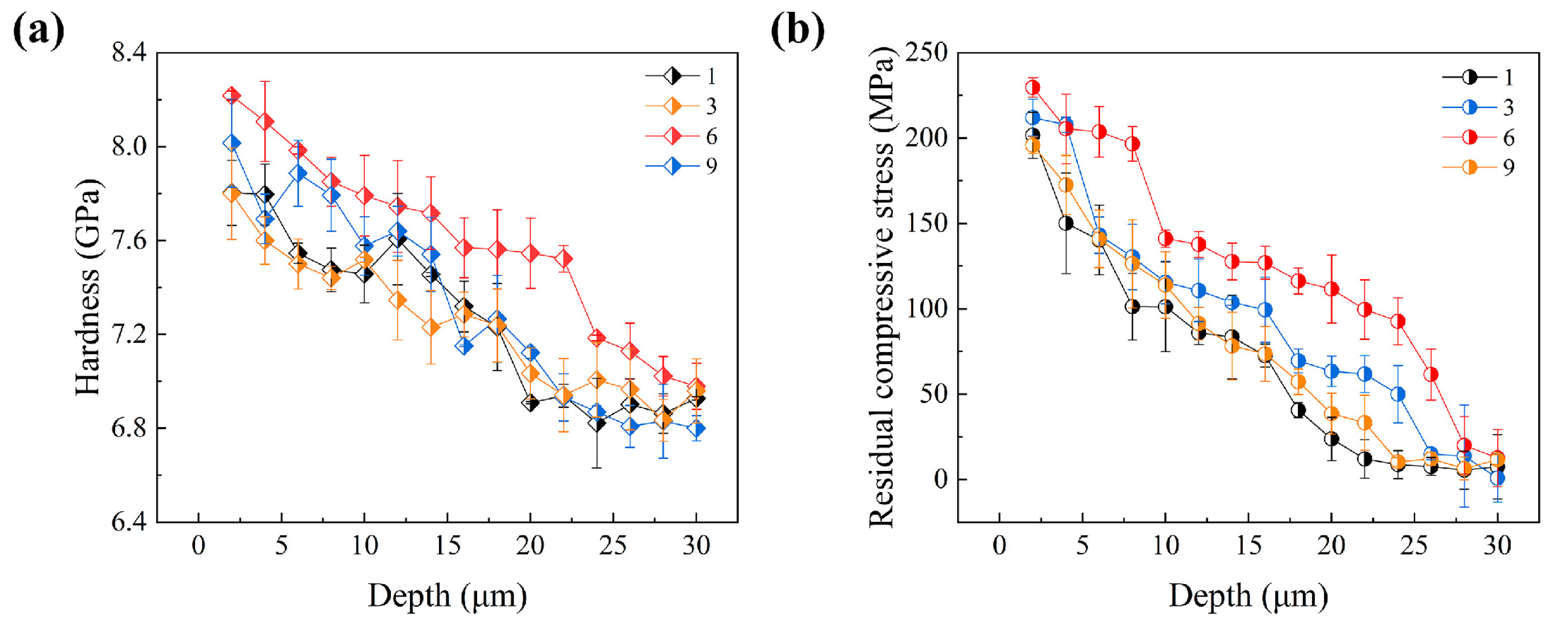

3.4. Mechanical Properties

4. Discussion

4.1. Effect of Pulse Energy on fs-LSP Results

4.2. Effect of the Number of Impacts on fs-LSP Results

5. Conclusions

- (1)

- The fs-LSP method achieved a comprehensive improvement in both the hydrophobicity and mechanical properties of the CH1900 steel surface. The refinement of surface grains, increase in dislocation density, and other microstructural transformations are the reasons for the enhancement of mechanical properties, while the hydrophobicity originates from the LIPSS. When the pulse energy is 75 μJ and the number of impacts is 6, the surface hardness reaches maximum (8.2 GPa), and the contact angle reaches 140 degrees.

- (2)

- With the increase in pulse energy, the LIPSS size increases, the alignment direction changes, and surface roughness increases, collectively creating favorable conditions for the improvement in material wettability. At the same time, the microhardness and residual stress increase significantly, reaching the maximum when the pulse energy is 75 μJ. However, high energy will cause surface damage and material melting, which will weaken the strengthening effect, which indicates that the optimization of pulse energy plays a key role in achieving the best strengthening effect of fs-LSP.

- (3)

- Excessive impact times lead to the destruction of the LIPSS and the increase in the average grain size, which is due to the accumulation of thermal effects leading to melting, oxidation, and stress relaxation, which limits the further optimization of the microstructure. It indicates that the number of impacts needs to be optimized to achieve the best strengthening effect. In the current study, the optimal surface strengthening effect can be achieved with 6 impact times.

- (4)

- The proposed fs-LSP technology provides a strategy for the fabrication of hydrophobic surfaces with excellent mechanical properties. Additionally, fs-LSP technology is expected to further optimize the multifunctional performance of materials and promote its application in high-end fields such as aerospace.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Yu, S.; Li, W.; Song, Y.; Gong, P.; Zhang, M.; Li, H.; Sun, D.; Yang, X.; Wang, X. Superhydrophobic and photocatalytic synergistic Self-Cleaning ZnS coating. Appl. Surf. Sci. 2022, 595, 153565. [Google Scholar] [CrossRef]

- Nystrom, D.; Lindqvist, J.; Ostmark, E.; Antoni, P.; Carlmark, A.; Hult, A.; Malmstrom, E. Superhydrophobic and self-cleaning bio-fiber surfaces via ATRP and subsequent postfunctionalization. ACS Appl. Mater. Interfaces 2009, 1, 816–823. [Google Scholar] [CrossRef] [PubMed]

- Zhou, R.; Lin, S.; Shen, F.; Khew, S.Y.; Hong, M. A universal copper mesh with on-demand wettability fabricated by pulsed laser ablation for oil/water separation. Surf. Coat. Technol. 2018, 348, 73–80. [Google Scholar] [CrossRef]

- Wang, H.; He, M.; Liu, H.; Guan, Y. One-step fabrication of robust superhydrophobic steel surfaces with mechanical durability, thermal stability, and anti-icing function. ACS Appl. Mater. Interfaces 2019, 11, 25586–25594. [Google Scholar] [CrossRef]

- Qing, Y.; Yang, C.; Yu, N.; Shang, Y.; Sun, Y.; Wang, L.; Liu, C. Superhydrophobic TiO2/polyvinylidene fluoride composite surface with reversible wettability switching and corrosion resistance. Chem. Eng. J. 2016, 290, 37–44. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Xia, M.; Hu, Y. Laser shock peening enables 3D gradient metal structures: A case study on manufacturing self-armored hydrophobic surfaces. Int. J. Mach. Tools Manuf. 2023, 185, 103993. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, L.; Li, W.; Liu, H. Rapid reversible superhydrophobicity-to-superhydrophilicity transition on alternating current etched brass. ACS Appl. Mater. Interfaces 2013, 5, 4808–4814. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, M.; Zhang, T.; Yu, Y.; Yang, Z.; Wang, Y.; Wang, C.; Lv, Z.; Xu, W. Efficient prediction of long-term wettability evolution in laser-textured surfaces using short-term data and cyclic deep learning. Opt. Laser Technol. 2025, 184, 112558. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, G.; Zhou, R.; Huang, W.; Hong, M. Rich CuO Nanowires Fabrication via Laser Post-Treatment of Laser-Textured Copper Substrate. Inorganics 2022, 10, 236. [Google Scholar] [CrossRef]

- Wang, D.; Sun, Q.; Hokkanen, M.J.; Zhang, C.; Lin, F.-Y.; Liu, Q.; Zhu, S.-P.; Zhou, T.; Chang, Q.; He, B.; et al. Design of robust superhydrophobic surfaces. Nature 2020, 582, 55–59. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Hu, Y. 3D hot laser shock peening without coating based on Leidenfrost effect enables self-armored hydrophobic surface with enhanced fatigue properties. Int. J. Fatigue 2023, 177, 107932. [Google Scholar] [CrossRef]

- Trdan, U.; Sano, T.; Klobčar, D.; Sano, Y.; Grum, J.; Šturm, R. Improvement of corrosion resistance of AA2024-T3 using femtosecond laser peening without protective and confining medium. Corros. Sci. 2018, 143, 46–55. [Google Scholar] [CrossRef]

- Dai, F.; Geng, J.; Ren, X.; Lu, J.; Huang, S. Dynamic response of surface micro-features subjected to a laser shock wave planishing technique. J. Alloys Compd. 2018, 742, 54–65. [Google Scholar] [CrossRef]

- Jia, M.; Wang, Y.; Yue, J.; Cao, C.; Li, K.; Yu, Y.; Li, Y.; Lu, Z. Recent progress in laser shock peening: Mechanism, laser systems and development prospects. Surf. Interfaces 2024, 44, 103757. [Google Scholar] [CrossRef]

- Deng, W.; Wang, C.; Lu, H.; Meng, X.; Wang, Z.; Lv, J.; Luo, K.; Lu, J. Progressive developments, challenges and future trends in laser shock peening of metallic materials and alloys: A comprehensive review. Int. J. Mach. Tools Manuf. 2023, 191, 104061. [Google Scholar] [CrossRef]

- Gong, Z.; Zhang, Z.; Jia, M.; Li, M.; Liu, F. Study on the residual stress field of laser shock strengthening with square spot of 2A12 aluminum alloy. J. Hebei Univ. Technol. 2024, 53, 59–67. [Google Scholar]

- Zhang, X.; Xia, M.; Zhang, C.; Hu, Y. Multistage laser shock improves surface structural properties of aluminum alloy. Int. J. Mech. Sci. 2023, 245, 108101. [Google Scholar] [CrossRef]

- Bovid, S.; Kattoura, M.; Clauer, A.; Vivek, A.; Daehn, G.; Niezgoda, S. Pressure amplification and modelization in laser shock peening of Ti-6Al-4V and AA7085 with adhesive-backed opaque overlays. J. Mater. Process. Technol. 2022, 299, 117381. [Google Scholar] [CrossRef]

- Wang, M.; Chen, X.; Dai, F.; Siddiquee, A.N.; Konovalov, S. Effects of different laser shock processes on the surface morphology and roughness of TC4 titanium alloy. J. Mater. Process. Technol. 2024, 325, 118301. [Google Scholar] [CrossRef]

- Li, Y.; Ren, Z.; Jia, X.; Yang, W.; Nassreddin, N.; Dong, Y.; Ye, C.; Fortunato, A.; Zhao, X. The effects of the confining medium and protective layer during femtosecond laser shock peening. Manuf. Lett. 2021, 27, 26–30. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Z.; Gao, S.; Zhu, L.; Yu, W.; Zheng, H. Investigation on femtosecond laser shock peening of commercially pure copper without ablative layer and confinement layer in air. Opt. Laser Technol. 2022, 153, 108207. [Google Scholar] [CrossRef]

- Kumthekar, A.; Laitinen, V.; Ullakko, K. Characterization of hydrophobic metasurfaces fabricated on Ni-Mn-Ga-based alloys using femtosecond pulsed laser ablation. Mater. Des. 2024, 244, 113128. [Google Scholar] [CrossRef]

- Suresh, S.; Giannakopoulos, A. A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 1998, 46, 5755–5767. [Google Scholar] [CrossRef]

- Bonse, J. Quo Vadis LIPSS?—Recent and Future Trends on Laser-Induced Periodic Surface Structures. Nanomaterials 2020, 10, 1950. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J.; Höhm, S.; Rosenfeld, A. Femtosecond laser-induced periodic surface structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

- Li, X.; Liu, P.; Wang, L.; Yang, F.; Zhou, L. Wear resistance of AISI 5140 steel with Micro-laser shock peening. Mater. Lett. 2023, 346, 134328. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Chi, J.; Han, G.; Sun, R.; Che, Z.; Zhang, H.; Guo, W. Microstructural evolution, mechanical behaviors and strengthening mechanism of 300 M steel subjected to multi-pass laser shock peening. Opt. Laser Technol. 2022, 148, 107726. [Google Scholar] [CrossRef]

- Sun, R.; Che, Z.; Cao, Z.; Zou, S.; Wu, J.; Guo, W.; Zhu, Y. Fatigue behavior of Ti-17 titanium alloy subjected to different laser shock peened regions and its microstructural response. Surf. Coat. Technol. 2020, 383, 125284. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z.; Zhao, Z.; Liu, Y.; Wang, C.; Xu, W. Multimodal Deep-Learning Framework for Accurate Prediction of Wettability Evolution of Laser-Textured Surfaces. ACS Appl. Mater. Interfaces 2023, 15, 10261–10272. [Google Scholar] [CrossRef]

- Khan, S.A.; Boltaev, G.S.; Iqbal, M.; Kim, V.; Ganeev, R.A.; Alnaser, A.S. Ultrafast fiber laser-induced fabrication of superhydrophobic and self-cleaning metal surfaces. Appl. Surf. Sci. 2021, 542, 148560. [Google Scholar] [CrossRef]

- Barthlott, W.; Schimmel, T.; Wiersch, S.; Koch, K.; Brede, M.; Barczewski, M.; Walheim, S.; Weis, A.; Kaltenmaier, A.; Leder, A.; et al. The Salvinia Paradox: Superhydrophobic Surfaces with Hydrophilic Pins for Air Retention Under Water. Adv. Mater. 2010, 22, 2325–2328. [Google Scholar] [CrossRef] [PubMed]

- Majumdar, J.D.; Gurevich, E.L.; Kumari, R.; Ostendorf, A. Investigation on femto-second laser irradiation assisted shock peening of medium carbon (0.4% C) steel. Appl. Surf. Sci. 2016, 364, 133–140. [Google Scholar] [CrossRef]

- Hua, Y.; Guo, B.; Jiang, L.; Chen, R.; Zhang, T.; Chen, M. Strengthened and hydrophobic surface of titanium alloy by femtosecond laser shock peening without a protective or sacrificial layer. Opt. Laser Technol. 2023, 167, 109787. [Google Scholar] [CrossRef]

- Lian, Y.; Hua, Y.; Sun, J.; Wang, Q.; Chen, Z.; Wang, F.; Zhang, K.; Lin, G.; Yang, Z.; Zhang, Q.; et al. Martensitic transformation in temporally shaped femtosecond laser shock peening 304 steel. Appl. Surf. Sci. 2021, 567, 150855. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, T.; He, P.; Zhou, L.; Pan, X.; Liang, X.; Jia, W.; An, Z.; Liu, P.; Zhang, H. Effect of pulsed femtosecond laser shock peening surface modification on anti-wear failure properties of AISI 9310 gear steel. Eng. Fail. Anal. 2024, 159, 108146. [Google Scholar] [CrossRef]

- López, J.M.; Munoz-Martin, D.; Moreno-Labella, J.J.; Panizo-Laiz, M.; Gomez-Rosas, G.; Molpeceres, C.; Morales, M. Picosecond laser shock micro-forming of stainless steel: Influence of high-repetition pulses on thermal effects. Materials 2022, 15, 4226. [Google Scholar] [CrossRef] [PubMed]

- Shu, S.; Shen, Y.; Cheng, Z.; Xiong, W.; He, Z.; Song, S.; Liu, W. Laser shock peening regulating residual stress for fatigue life extension of 30CrMnSiNi2A high-strength steel. Opt. Laser Technol. 2024, 169, 110094. [Google Scholar] [CrossRef]

- Hoppius, J.S.; Kukreja, L.M.; Knyazeva, M.; Pöhl, F.; Walther, F.; Ostendorf, A.; Gurevich, E.L. On femtosecond laser shock peening of stainless steel AISI 316. Appl. Surf. Sci. 2018, 435, 1120–1124. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Jia, M.; Gu, Y.; Wang, P.; Zhang, Z.; Wang, Y. Fabrication of Mechanically Robust Hydrophobic Surfaces Using Femtosecond Laser Shock Peening. Materials 2025, 18, 2154. https://doi.org/10.3390/ma18092154

Xu C, Jia M, Gu Y, Wang P, Zhang Z, Wang Y. Fabrication of Mechanically Robust Hydrophobic Surfaces Using Femtosecond Laser Shock Peening. Materials. 2025; 18(9):2154. https://doi.org/10.3390/ma18092154

Chicago/Turabian StyleXu, Chao, Mengyu Jia, Yucheng Gu, Peishuo Wang, Zhen Zhang, and Yulei Wang. 2025. "Fabrication of Mechanically Robust Hydrophobic Surfaces Using Femtosecond Laser Shock Peening" Materials 18, no. 9: 2154. https://doi.org/10.3390/ma18092154

APA StyleXu, C., Jia, M., Gu, Y., Wang, P., Zhang, Z., & Wang, Y. (2025). Fabrication of Mechanically Robust Hydrophobic Surfaces Using Femtosecond Laser Shock Peening. Materials, 18(9), 2154. https://doi.org/10.3390/ma18092154