Effect of the Addition of Al-5Ti-0.25C and Annealing on the Mechanical Properties of Open-Cell Al Foams

Abstract

1. Introduction

2. Materials and Methods

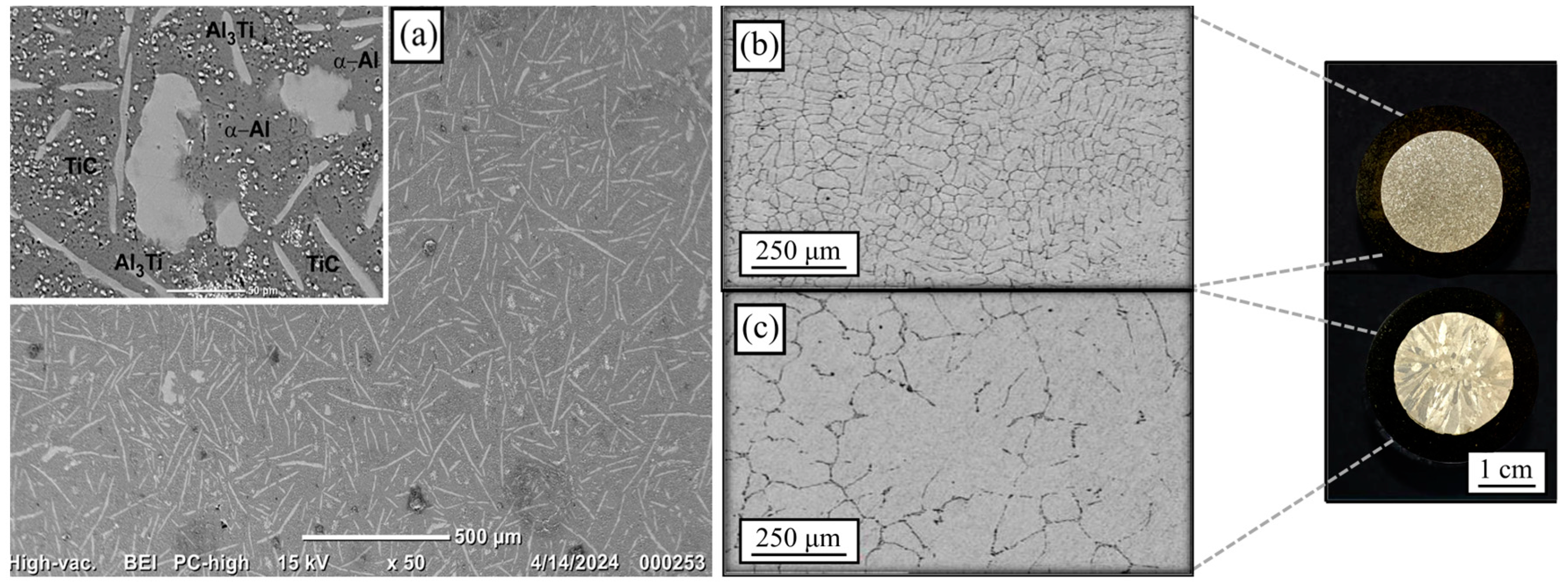

2.1. Fabrication of Refining Agent Al-5Ti-0.25C

2.2. Fabrication of Refined Open-Cell Al Foams

2.3. Microstructural and Mechanical Characterization

3. Results and Discussion

4. Conclusions

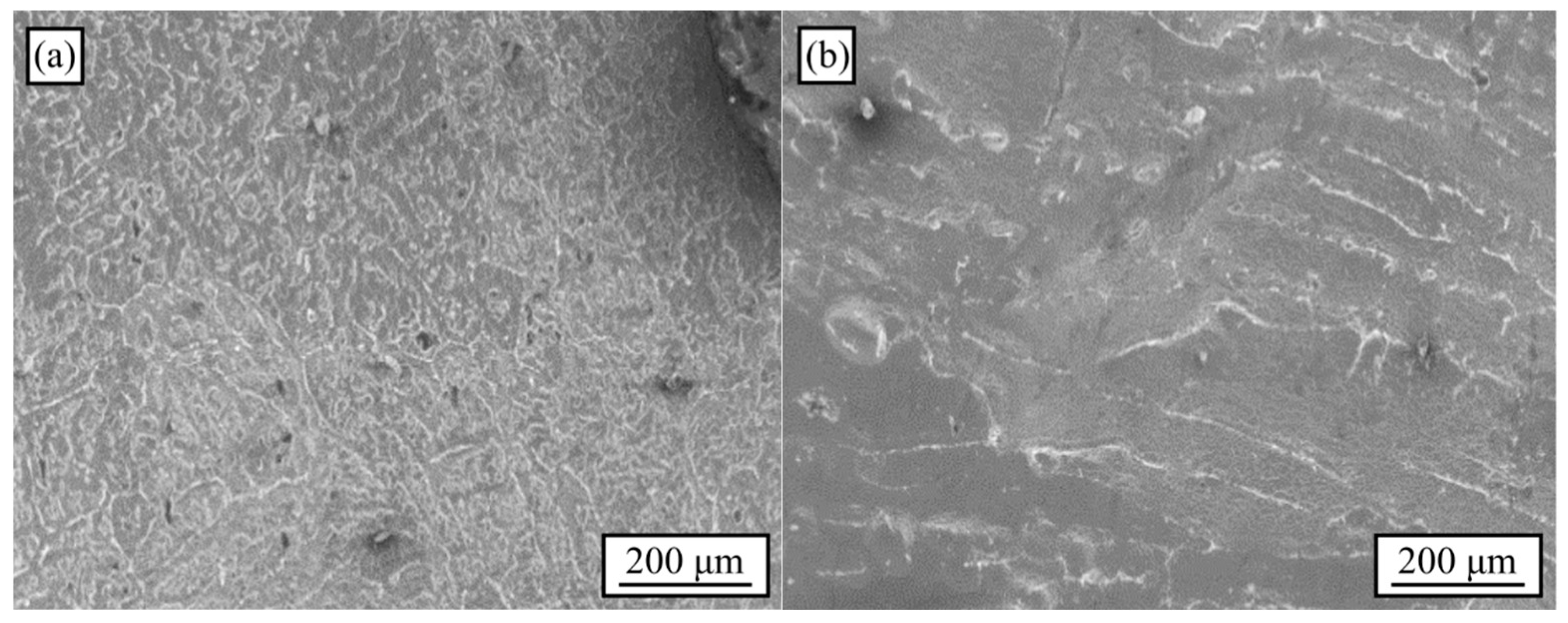

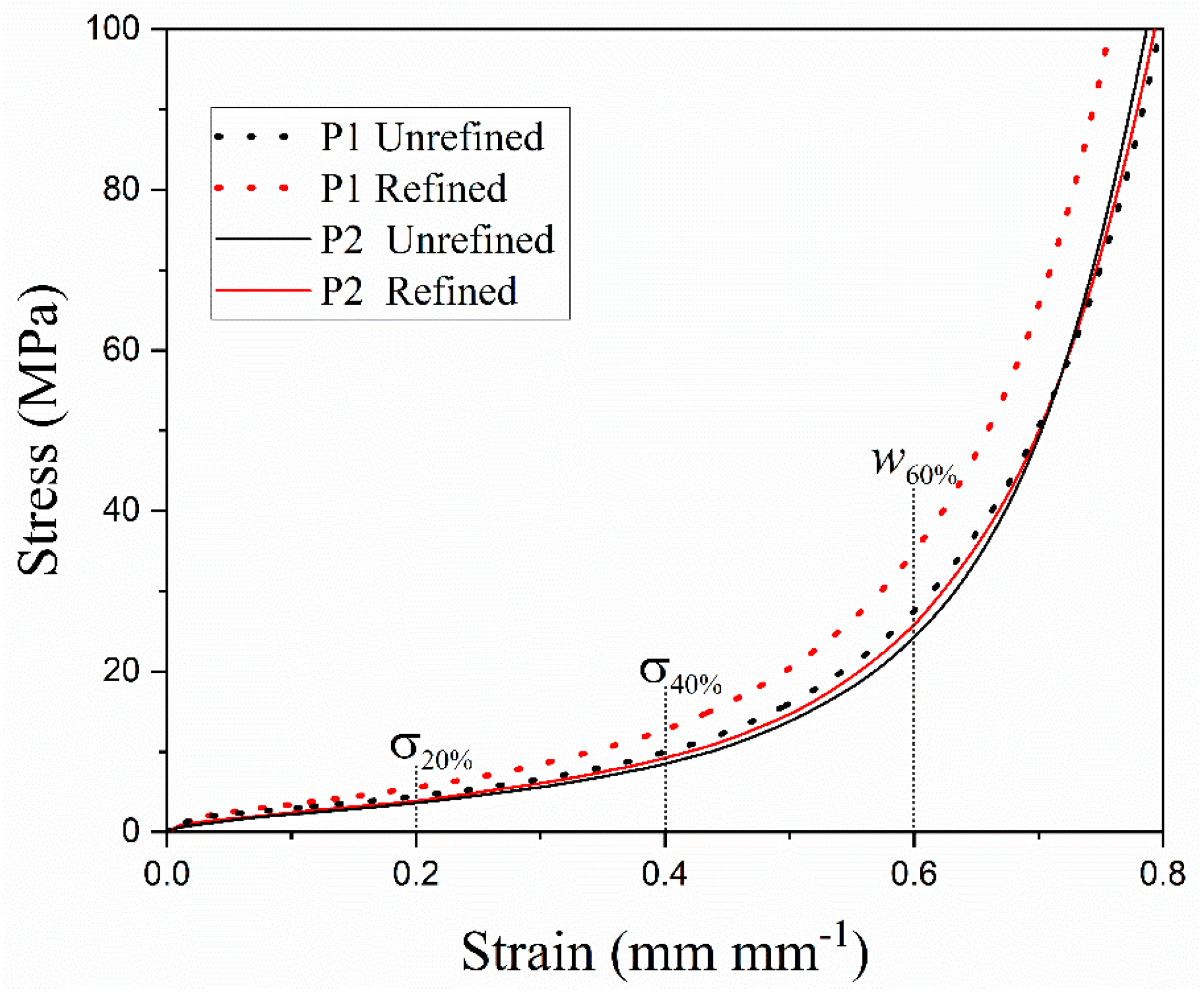

- Aluminum (Al) was effectively refined through the addition of the Al-5Ti-0.25C master alloy, which enabled the formation of Al3Ti and TiC intermetallics. These intermetallics served as nucleation points during the solidification process of the Al matrix. Both refined and unrefined open-cell Al foams were produced with two distinct pore sizes.

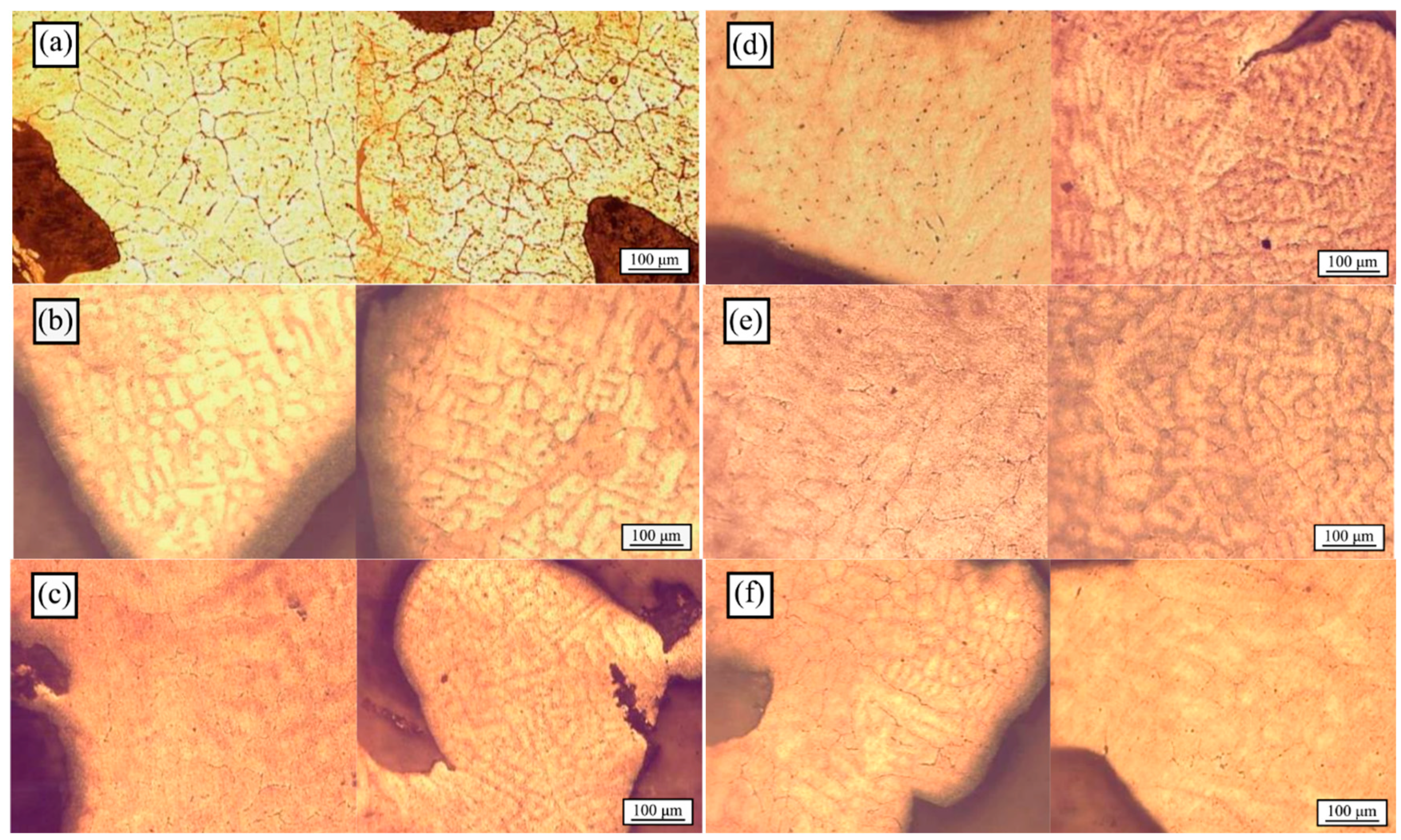

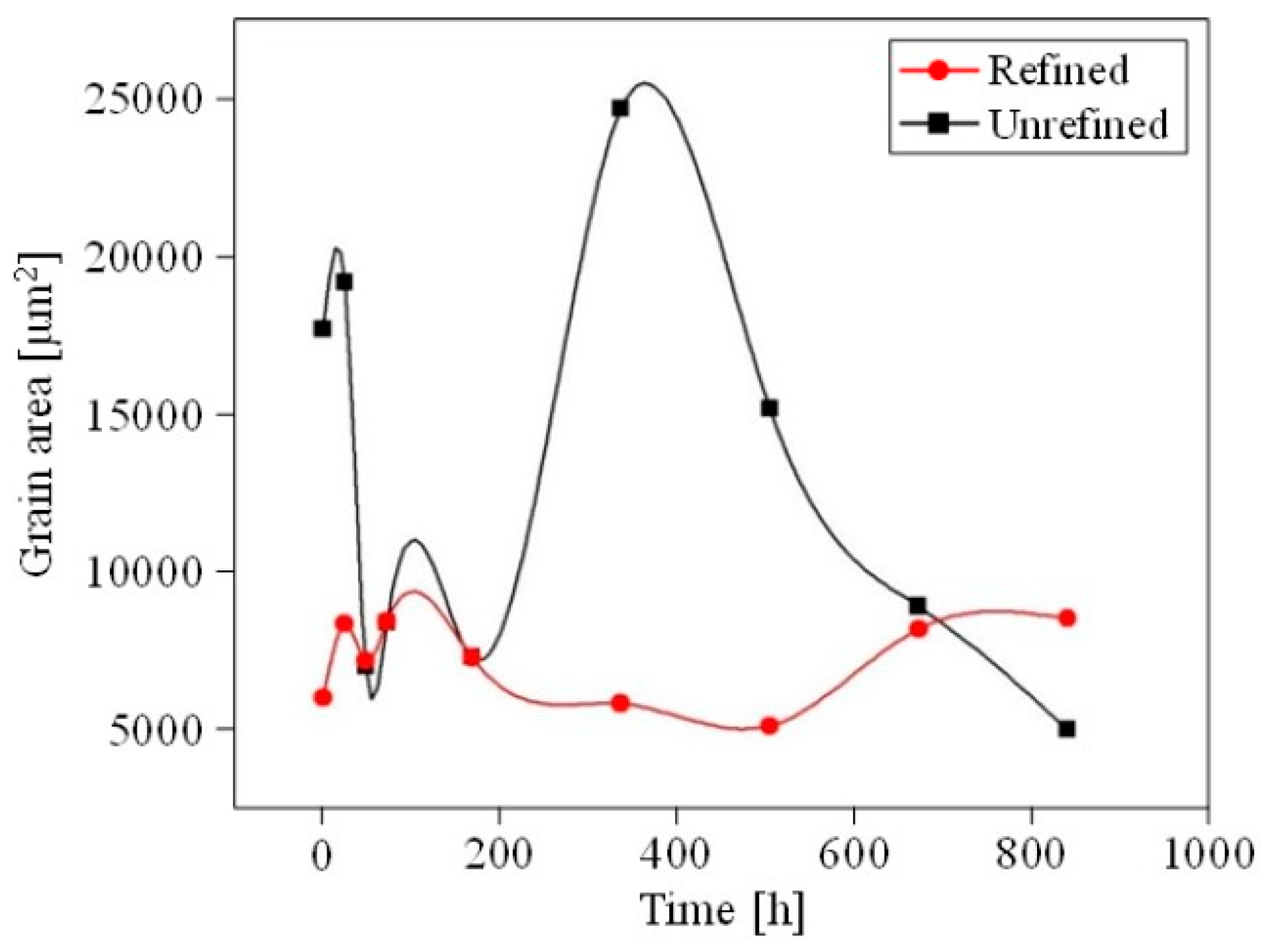

- The refined samples exhibited a finer as-cast microstructure compared to their unrefined counterparts. The recrystallization behavior of the analyzed foams was assessed through annealing at different times.

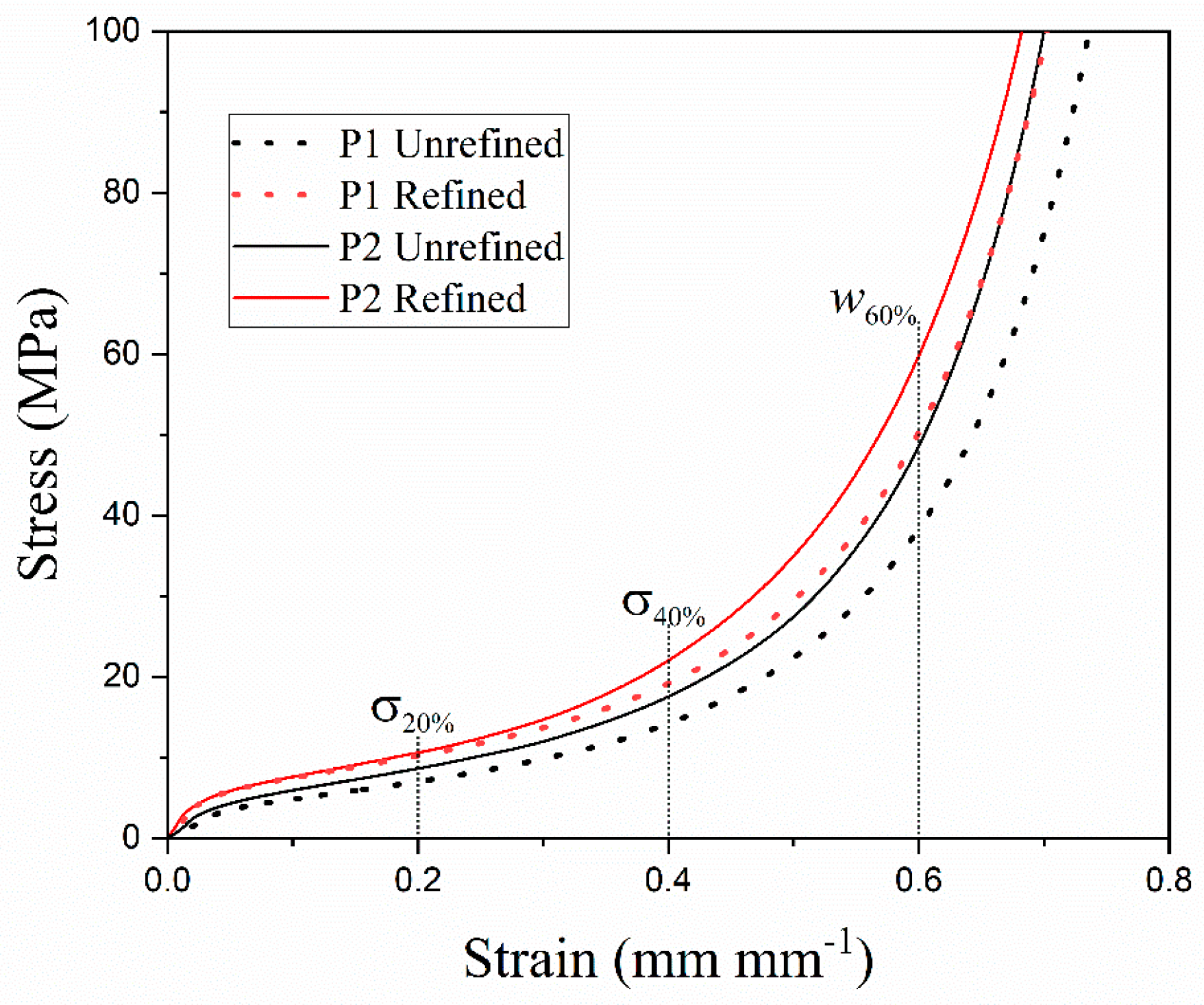

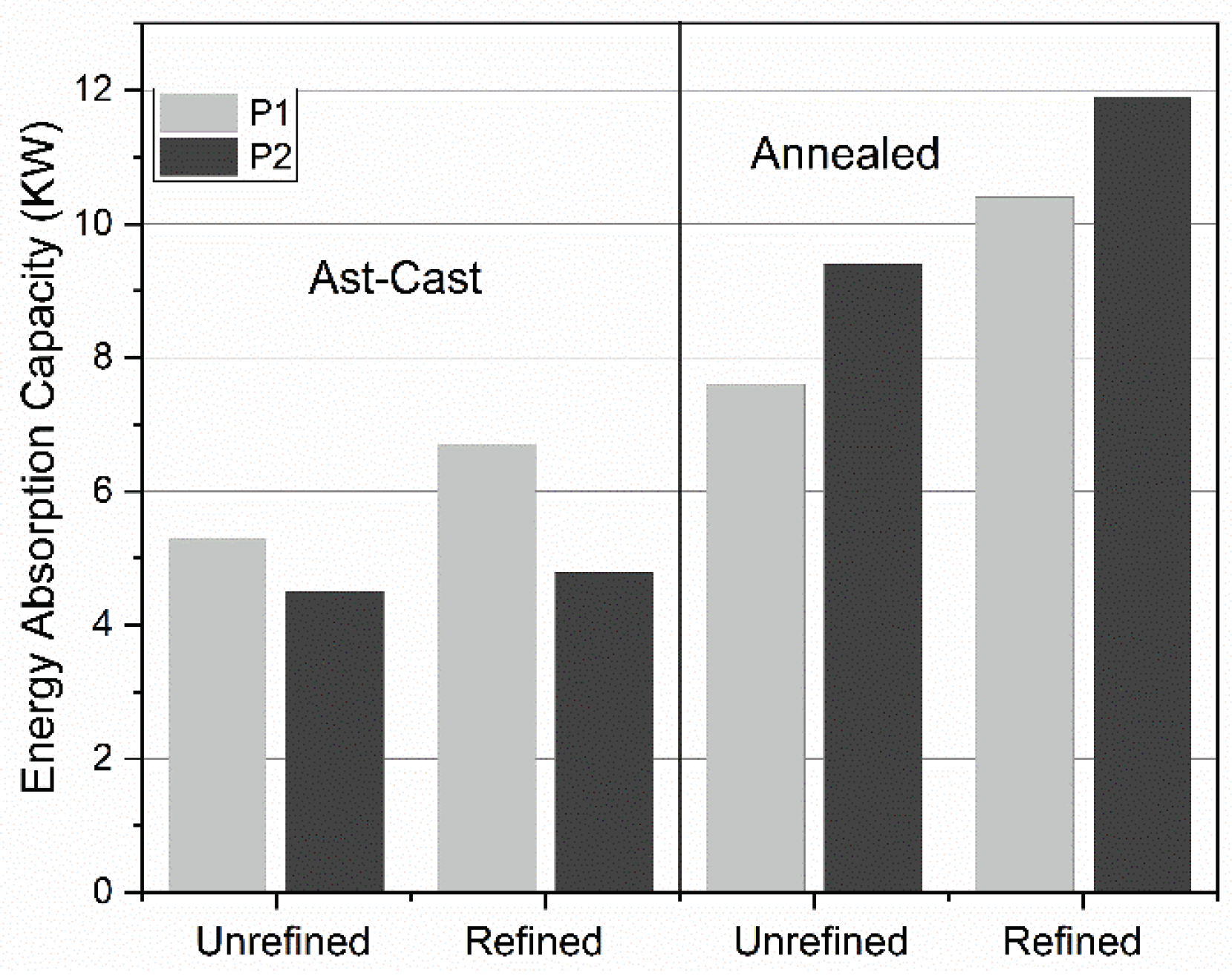

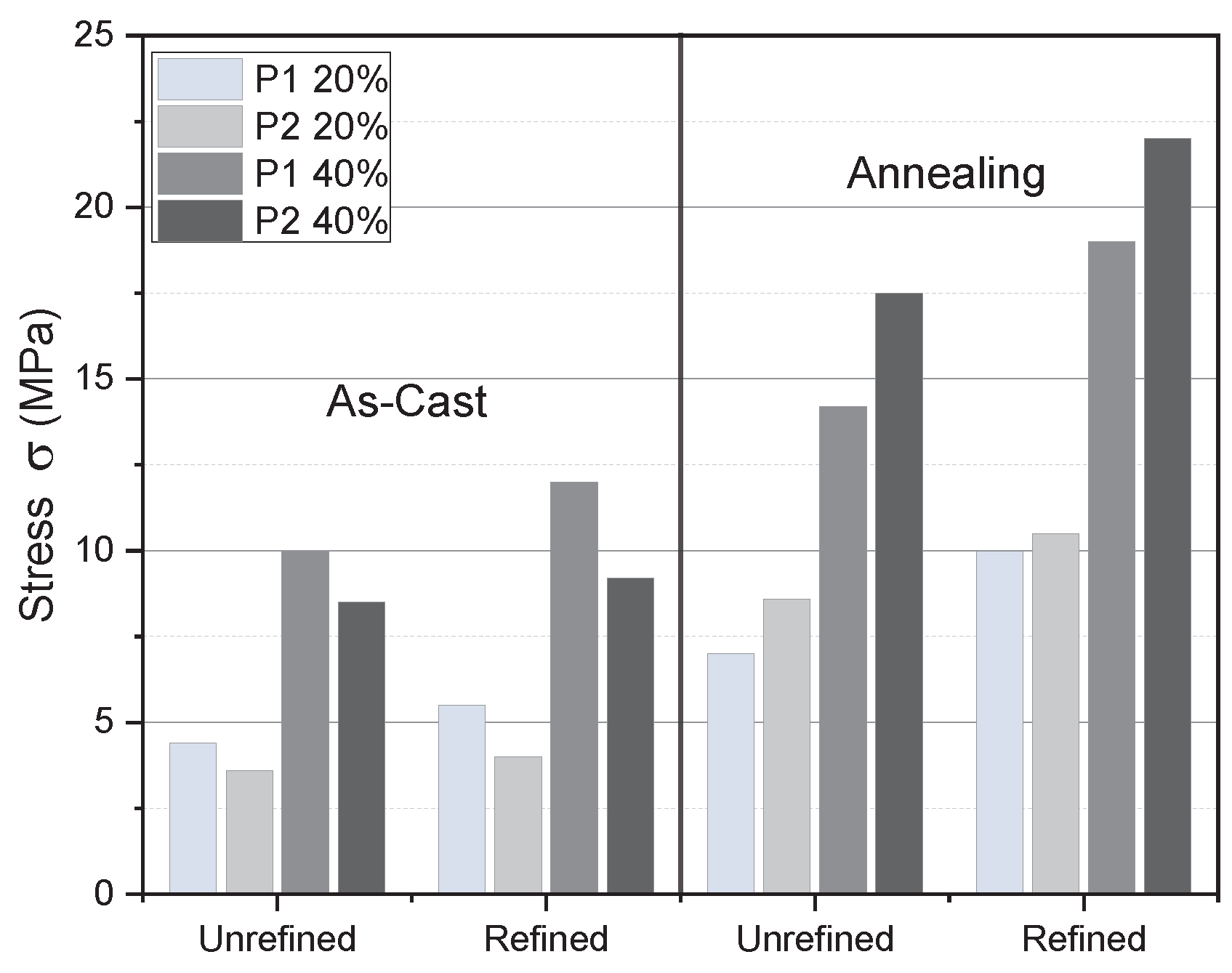

- The optimal conditions were identified as 480 °C for 504 h, improving the microstructural homogeneity. The refined foams showed a 15% increase in mechanical strength and a 30% increase in energy absorption capacity, respectively, compared to unrefined foams.

- This enhancement was attributed to the grain refinement effects resulting from the presence of the TiC intermetallic and Al3Ti phases. Notably, the addition of Al-5Ti-0.25C to the foams, along with subsequent annealing, exhibited a 35% improvement in mechanical properties.

- The findings presented in this work support the development of mechanically enhanced open-cell aluminum foams suitable for applications in shock absorption and damping.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- García-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 9, 85–112. [Google Scholar] [CrossRef]

- Singh, S.; Bhatnagar, N. A survey of fabrication and application of metallic foams (1925–2017). J. Porous Mater. 2018, 25, 537–554. [Google Scholar] [CrossRef]

- Wan, T.; Liu, Y.; Zhou, C.; Chen, X.; Li, Y. Fabrication, properties, and applications of open-cell aluminum foams: A review. J. Mater. Sci. Technol. 2021, 62, 11–24. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.G.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N.G. Metal Foams: A Design Guide; Butter-worth-Heinemann Publications: Waltham, MA, USA, 2000. [Google Scholar]

- Lara-Rodriguez, G.; Figueroa, I.; Suarez, M.; Novelo-Peralta, O.; Alfonso, I.; Goodall, R. A replication-casting device for manufacturing open-cell Mg foams. J. Mech. Work. Technol. 2017, 243, 16–22. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Duarte, I.; Ferreira, J.M.F. Composite and Nanocomposite Metal Foams. Materials 2016, 9, 79. [Google Scholar] [CrossRef]

- Azamar, M.F.; Hernández, B.J.; Figueroa, I.A.; Gonzalez, G.; Novelo-Peralta, O.; Ramos, C.D. Effect of the Cu addition on the mechanical properties and microstructure of open-cell Al foams. J. Mater. Res. 2021, 36, 3194–3202. [Google Scholar] [CrossRef]

- Sun, Y.; Burgueño, R.; Vanderklok, A.J.; Tekalur, S.A.; Wang, W.; Lee, I. Compressive behavior of aluminum/copper hybrid foams under high strain rate loading. Mater. Sci. Eng. A 2014, 592, 111–120. [Google Scholar] [CrossRef]

- Antenucci, A.; Guarino, S.; Tagliaferri, V.; Ucciardello, N. Improvement of the mechanical and thermal characteristics of open cell aluminum foams by the electrodeposition of Cu. Mater. Des. 2014, 59, 124–129. [Google Scholar] [CrossRef]

- Zhou, J.; Gao, Z.; Cuitino, A.; Soboyejo, W. Effects of heat treatment on the compressive deformation behavior of open cell aluminum foams. Mater. Sci. Eng. A 2004, 386, 118–128. [Google Scholar] [CrossRef]

- Conde, Y.; Mortensen, A. Age-hardening Response of Replicated Microcellular Al-4.5%Cu. Adv. Eng. Mater. 2008, 10, 849–852. [Google Scholar] [CrossRef]

- Guan, R.-G.; Tie, D. A Review on Grain Refinement of Aluminum Alloys: Progresses, Challenges and Prospects. Acta Met. Sin. 2017, 30, 409–432. [Google Scholar] [CrossRef]

- Easton, M.A.; Qian, M.A.; St John, D.H. Grain Refinement in Alloys: Novel Approaches. Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Guo, H.-M.; Zhang, A.-S.; Yang, X.-J.; Yan, M.-M. Grain refinement of Al–5%Cu aluminum alloy under mechanical vibration using meltable vibrating probe. Trans. Nonferrous Met. Soc. China 2014, 24, 2489–2496. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, H.; Jia, G.; Ke, G.; Zhang, J.; Yuan, G. Effect of grain size on the mechanical properties of Mg foams. J. Mater. Sci. Technol. 2020, 58, 46–54. [Google Scholar] [CrossRef]

- Lehmhus, D.; Hünert, D.; Mosler, U.; Martin, U.; Weise, J. Effects of Eutectic Modification and Grain Refinement on Microstructure and Properties of PM AlSi7 Metallic Foams. Metals 2019, 9, 1241. [Google Scholar] [CrossRef]

- Wang, E.; Gao, T.; Nie, J.; Liu, X. Grain refinement limit and mechanical properties of 6063 alloy inoculated by Al–Ti–C (B) master alloys. J. Alloys Compd. 2014, 594, 7–11. [Google Scholar] [CrossRef]

- Osorio-Hernández, J.; Suarez, M.; Goodall, R.; Lara-Rodriguez, G.; Alfonso, I.; Figueroa, I. Manufacturing of open-cell Mg foams by replication process and mechanical properties. Mater. Des. 2014, 64, 136–141. [Google Scholar] [CrossRef]

- Trinidad, J.; Marco, I.; Arruebarrena, G.; Wendt, J.; Letzig, D.; de Argandoña, E.S.; Goodall, R. Processing of Magnesium Porous Structures by Infiltration Casting for Biomedical Applications. Adv. Eng. Mater. 2014, 16, 241–247. [Google Scholar] [CrossRef]

- Azamar, M.F.; Figueroa, I.A.; Gonzalez, G.; Alfonso, I. Drop of Pressure Behavior of Open-Cell Aluminum Foams at High Pressure Flow. J. Appl. Res. Technol. 2021, 19, 603–621. [Google Scholar] [CrossRef]

- Wei, N.; Han, X.; Zhang, X.; Cao, Y.; Guo, C.; Lu, Z.; Jiang, F. Characterization and properties of intermetallic Al3Ti alloy synthesized by reactive foil sintering in vacuum. J. Mater. Res. 2016, 31, 2706–2713. [Google Scholar] [CrossRef]

- Birol, Y. Grain refining efficiency of Al–Ti–C alloys. J. Alloy. Compd. 2006, 422, 128–131. [Google Scholar] [CrossRef]

- Salanne, M.; Marrocchelli, D.; Merlet, C.; Ohtori, N.; Madden, A.P. Thermal conductivity of ionic systems from equilibrium molecular dynamics. J. Phys. Condens. Matter. 2011, 23, 102101. [Google Scholar] [CrossRef] [PubMed]

- Mahmudi, R. Grain boundary strengthening in a fine grained aluminium alloy. Scr. Met. Mater. 1995, 32, 781–786. [Google Scholar] [CrossRef]

- Soni, B.; Biswas, S. Development of Al Foams by a Low-cost Salt Replication Method for Industrial Applications. Mater. Today Proc. 2015, 2, 1886–1891. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Novelo-Peralta, O.; Azamar, M.F.; Méndez Durán, J.E.; Ávila, Y.L.; Salas Reyes, A.E.; Bazáez, R.; Figueroa, I.A.; Lara Rodríguez, G.Á. Effect of the Addition of Al-5Ti-0.25C and Annealing on the Mechanical Properties of Open-Cell Al Foams. Materials 2025, 18, 2147. https://doi.org/10.3390/ma18092147

Novelo-Peralta O, Azamar MF, Méndez Durán JE, Ávila YL, Salas Reyes AE, Bazáez R, Figueroa IA, Lara Rodríguez GÁ. Effect of the Addition of Al-5Ti-0.25C and Annealing on the Mechanical Properties of Open-Cell Al Foams. Materials. 2025; 18(9):2147. https://doi.org/10.3390/ma18092147

Chicago/Turabian StyleNovelo-Peralta, Omar, Manuel Farid Azamar, Julio Esteban Méndez Durán, Yessica Lizbeth Ávila, Antonio Enrique Salas Reyes, Ramiro Bazáez, Ignacio Alejandro Figueroa, and Gabriel Ángel Lara Rodríguez. 2025. "Effect of the Addition of Al-5Ti-0.25C and Annealing on the Mechanical Properties of Open-Cell Al Foams" Materials 18, no. 9: 2147. https://doi.org/10.3390/ma18092147

APA StyleNovelo-Peralta, O., Azamar, M. F., Méndez Durán, J. E., Ávila, Y. L., Salas Reyes, A. E., Bazáez, R., Figueroa, I. A., & Lara Rodríguez, G. Á. (2025). Effect of the Addition of Al-5Ti-0.25C and Annealing on the Mechanical Properties of Open-Cell Al Foams. Materials, 18(9), 2147. https://doi.org/10.3390/ma18092147