3.1. General Characteristics of the Cotton—NBT Dosimeters

Dosimeters based on woven fabrics modified with radiation-sensitive compounds, including tetrazolium salts and leuco-dyes, are an original idea from the DosLab research group, which has been described in the scientific literature for over fifteen years. Dosimetric systems manufactured by the screen printing and padding—squeezing—drying method using NBT were characterized in terms of their response to UV and ionizing radiation doses. Some of the developed solutions were also applied to measure the UV and ionizing radiation 2D dose distributions using the polyGeVero

®-CT software package (v.1.2, GeVero Co., Lodz, Poland). The mechanism of the transformation of the NBT molecule into formazan is also known and has been described under different conditions in other publications [

9,

10,

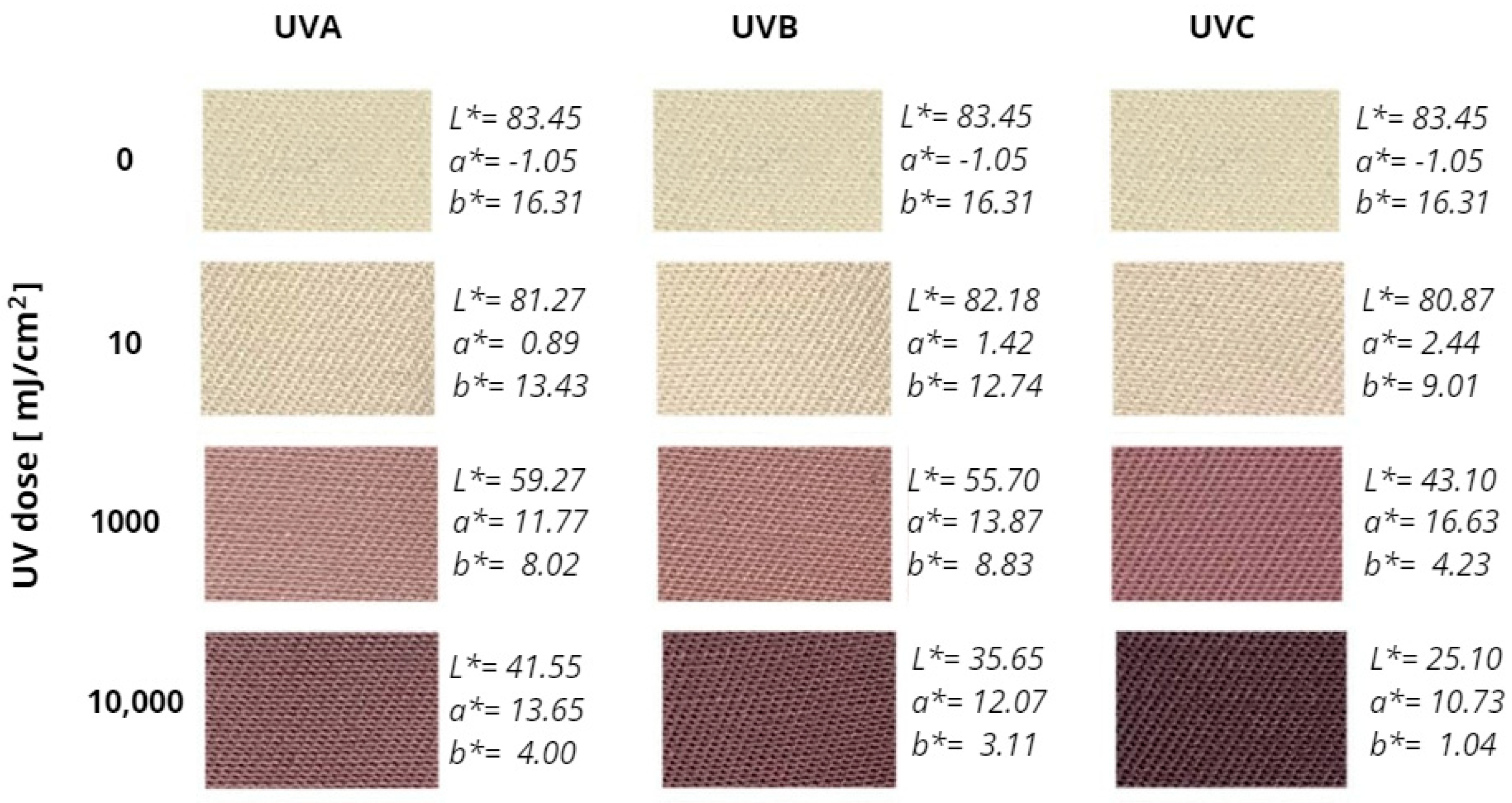

14]. Regardless of the type of radiation and the dosimeter manufacturing method, NBT-modified fabrics change color from light yellow to purple-brown. The intensity and rate of the color change depend on (i) the type of radiation, (ii) the range of radiation doses, (iii) the concentration of NBT used for modification, and (iv) the type of textile substrate, including the weave structure. In general, the higher the concentration of NBT, the more pronounced the response of the samples to radiation is. In the case of UVA (315–400 nm), UVB (280–360 nm), and UVC (100–280 nm) radiation, a similar nature of color change was observed in the cotton—NBT dosimeters after irradiation, but in the case of UVC, the intensity of color changes was the most pronounced. Comparing the CIE

L*,

a*, and

b* values for individual doses, it was found that the UVC-irradiated samples achieved a higher degree of color conversion. Photographs of the selected cotton—NBT dosimeters and changes in the CIE

L*,

a*, and

b* color coordinates values after irradiation with UVA, UVB, and UVC radiation in the range of 0–10,000 mJ/cm

2 are presented in

Figure 1.

Directly after the preparation of the cotton—NBT dosimeter, all samples were light yellow with a visible fabric weave structure. In the case of textile dosimeters, the structure of the textile material plays an important role in the process of reading information about the dose and the 2D distribution of the radiation dose. The modified textile material must maintain its size and shape during dosimeter preparation, irradiation, and measurements. Therefore, knitted and nonwoven fabrics, which are more stretchable, were not used to construct textile dosimeters. In previous work, the influence of fabric structure on 2D measurements of radiation dose was also investigated using a flatbed scanner. It was shown that fabrics with simple, plain weaves are more suitable for the construction of dosimeters due to better surface uniformity and less visibility of the weave after sample irradiation. Moreover, if the padding—squeezing—drying method is used for textile dosimeter manufacturing, it is suitable to use cotton fabric due to the even absorption of the solution with the radiation-sensitive compound by hydrophilic cellulose fibers. It should be emphasized that access to white cotton fabrics, with a plain weave and without additional refining agents, is very limited. Typically, these types of fabrics are additionally finished with optical brighteners, which adversely affect the uniformity of color changes in the dosimeter after irradiation and cause errors during light reflectance measurements and the determination of the CIE L*, a*, and b* color coordinates. In addition, our limited access to fabric manufacturers did not allow for the production of a model fabric with the specified technological parameters. Therefore, in the presented research, a white cotton fabric with a twill weave was used, and only UVC radiation was used for sample irradiation.

3.2. Repeatability of Reflectance Measurements vs. Storage Conditions

To investigate the repeatability of light reflectance measurements and the reproducibility of samples, 15 cotton-NBT samples were prepared according to the procedure described in

Section 2.1 and irradiated with a dose of 10,000 mJ/cm

2 UVC. High-dose UVC irradiation induced maximum conversion of the radiation-sensitive compound and a color change that can be obtained for a given NBT concentration. Thus, during the reflectance measurements, it was not necessary to use additional shields to avoid accidentally exposing the samples to radiation, e.g., from artificial light sources from lamps illuminating the measurement room. For all cotton—NBT samples, the light reflectance in the wavelength range of 400–700 nm was measured with a Spectraflash 300 reflectance spectrophotometer under standard D65 illumination (angle of 10°; resolution of 10 nm; measurement error of 0.1%). To limit the influence of the weave structure on the color changes of the samples during reflectance measurements, an average of five measurement samples was used. An equation characterizing the repeatability of the obtained measurements at 550 nm was also determined, Reflectance (λ = 550 nm) [%] = 5.8702 [%]−0.0046 [%] × Sample number [−], R

2 = 0.8647, and the results are presented in

Figure 2. For example, the standard deviation (SD) was 0.0401, 0.0295, 0.0266, 0.0337, and 0.0742 at wavelengths of 450, 500, 550, 600, and 650 nm, respectively.

Thus, it was concluded that textile dosimeters made from a single fabric batch have satisfactory reproducibility. Therefore, the average measurements from five samples of cotton—NBT at 550 nm were used in the studies on sample storage conditions. In the next step, directly after preparation, the cotton—NBT samples were divided into four series, which were stored in different conditions: (i) at room temperature (23–25 °C, humidity 40–60%, without access to light); (ii) in a fridge (3–5 °C, humidity 70–90%, without access to light); (iii) in a freezer (−17 to −20 °C, humidity 80–90%, without access to light); and (iv) at room temperature (23–25 °C, humidity 40–60%), with access to light from lamps illuminating the laboratory room. Temperature changes in the laboratory room, fridge, and freezer may result from (i) closing and opening the fridge and freezer, (ii) temperature fluctuations in the laboratory room during the day, and (iii) seasonal changes in the laboratory room during the experiment over a six-month period from summer to winter. It is important that the first light reflectance measurement in all series was performed after 24 h of the samples being in the given temperature and humidity conditions. For the storage of the dosimeters in the fridge and freezer, the cotton—NBT samples were taken out two hours before UVC irradiation to reach ambient temperature and eliminate water vapor condensation on the sample surface. Measurements of cold or frozen samples may cause unwanted water vapor condensation on the fabric surface and contribute to increased measurement uncertainty. Furthermore, according to the ISO 105-J01:1997 [

15] standard, the color of textiles should be assessed for dry fabric at ambient temperature, without additional conditioning and ironing. No additional moisture measurements were performed for the cotton—NBT samples. To analyze the measurement repeatability of dosimeters stored under different conditions (the similarity and differences between the samples with respect to their color), light reflectance measurements were performed for non-irradiated and irradiated samples with a dose of 100 and 10,000 mJ/cm

2 UVC after 24 h from their preparation. Five samples were selected from each series, and after averaging the measurement points, the results are presented in

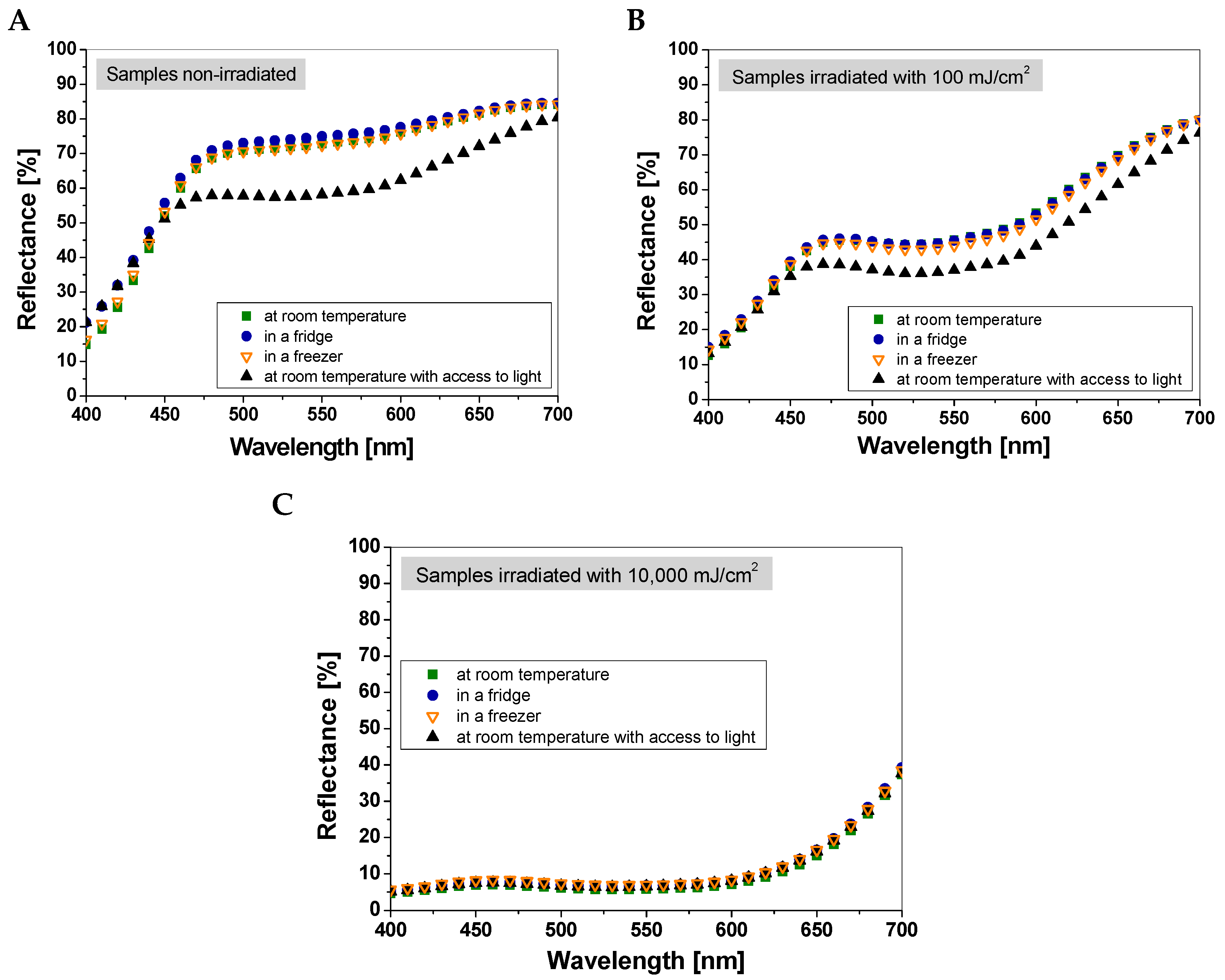

Figure 3.

In the case of non-irradiated and 100 mJ cm

2-irradiated samples (

Figure 3A,B), a similarity in the spectral curves can be seen. In both cases, the largest change in light reflectance was visible for the sample stored at room temperature with access to light. For non-irradiated cotton—NBT dosimeters, the differences in light reflectance at 550 nm between the samples stored at room temperature, in a fridge, in a freezer, and at room temperature with access to light were 2.78%, 0.68%, and 22.34%, respectively. For samples irradiated with 100 mJ/cm

2, the difference between the reflectance for samples (in the same storage conditions) was 0.48%, 3.63%, and 18.45%, respectively. For cotton—NBT samples irradiated with a dose of 10,000 mJ/cm

2 UVC, the change in light reflectance depending on storage conditions is not so pronounced (

Figure 3C). Comparing the light reflectance at 550 nm values, the differences between the sample stored at room temperature and those stored in the fridge, freezer, and room temperature with access to light were 0.17%, 0.67%, and 0.53%, respectively.

3.3. Long-Term Stability and Dose Response of Cotton—NBT Dosimeters

The stability over time of the cotton—NBT dosimeters was determined over a period of 180 days from their preparation. Based on previous work [

8,

9] and experience with cotton—NBT dosimeters, the results were analyzed for reflectance at 550 nm and are presented in

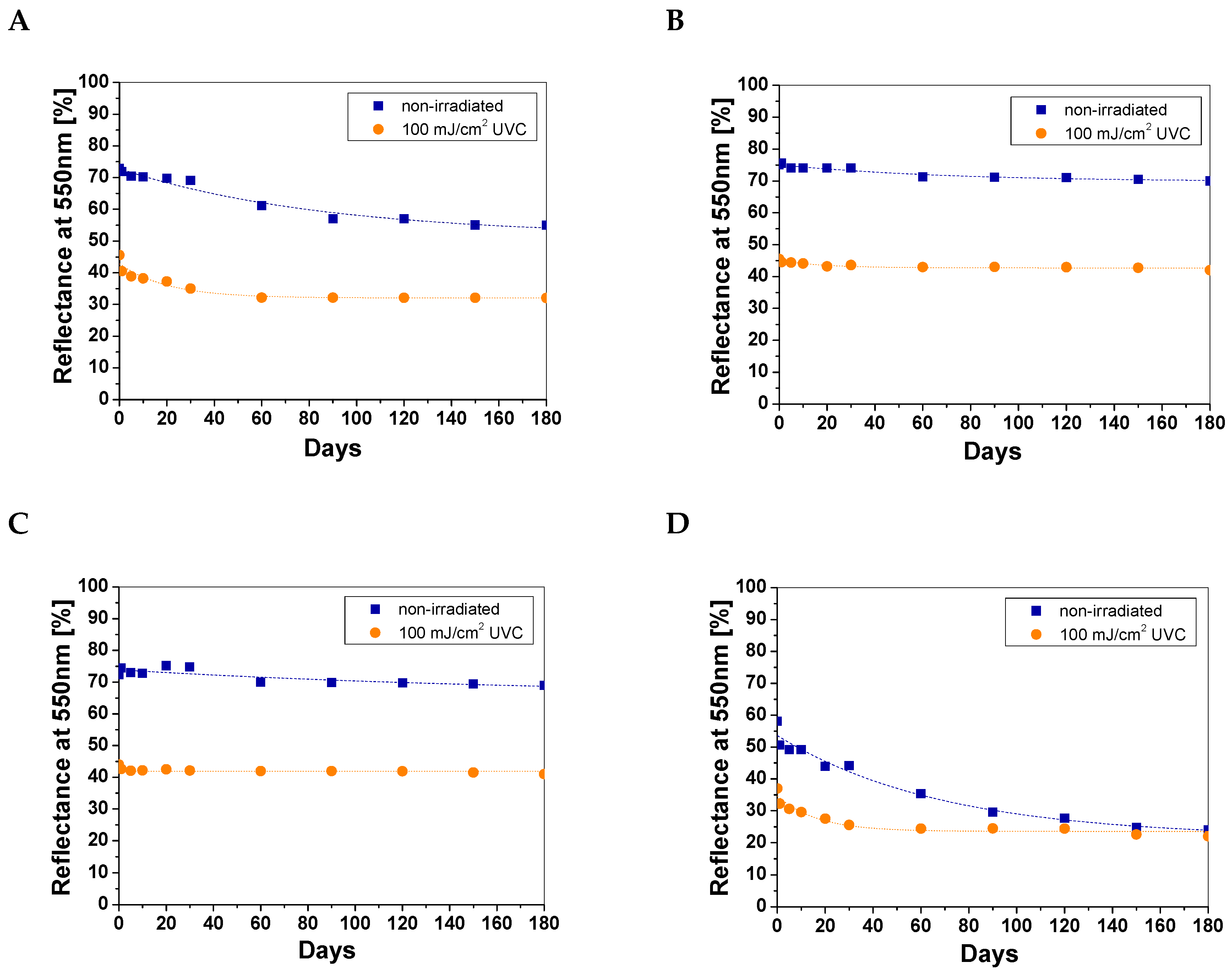

Figure 4. As in the case of sample repeatability measurements, each point on the graph is the average value of five measurement points. Comparing the obtained light reflectance results, the highest stability over time was observed for the cotton—NBT samples stored in the fridge and freezer (

Figure 4B,C). In the case of samples stored at room temperature, the non-irradiated samples change color much faster. After 180 days, the shade difference was 23.93% and 54.19% for the samples stored at room temperature under an aluminum foil cover and at room temperature with access to light, respectively (

Figure 4A,D).

Moreover, the color change under these conditions for the 100 mJ/cm

2 UVC-irradiated cotton—NBT samples was also more intensive. During the initial period of storage of the samples at room temperature, the light remission value decreased by 8.03% and 23.01% for the samples stored at room temperature under an aluminum foil cover and at room temperature with access to light, respectively. The characteristics of the changes occurring during sample storage are presented in

Table 1. The percentage change in color intensity was calculated by comparing the reflectance values for a given sample with a blank sample within 180 days of dosimeter preparation. Thus, it was concluded that non-irradiated cotton—NBT samples should be stored in a freezer or fridge because, under these storage conditions, the change in color intensity was the smallest. However, in the case of the UVC-irradiated samples, storage at room temperature with a cover of aluminum foil turned out to be better. It should be emphasized that, in practice, dosimeters of the single-use type are very rarely stored over long periods of time. They cannot be stored in direct contact with non-irradiated samples to limit possible post-radiation reactions between dosimeters and their influence on dose measurement and uncertainty. If there are no special procedures for their deactivation or disposal, they are simply thrown away. However, in the case discussed above, the greatest influence on the color changes of the cotton—NBT dosimeters was probably the change in the humidity of the samples. Thus, in the next stage of the study, the influence of storage time and conditions on the response of the cotton—NBT dosimeter to the UVC dose was analyzed. For this purpose, 12 samples were irradiated with a dose of 100 mJ/cm

2 at different time intervals to demonstrate the repeatability of the dose response and thus the repeatability of production and to determine the optimal shelf life (

Figure 5).

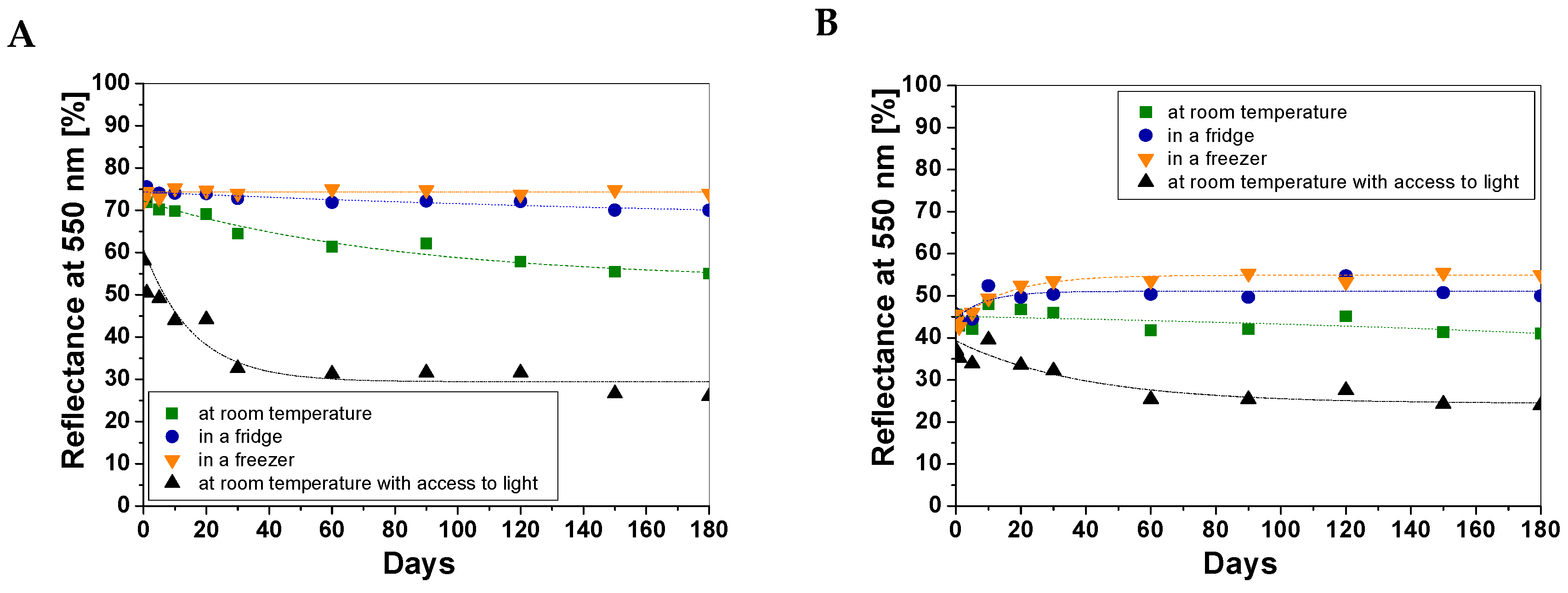

For non-irradiated cotton—NBT samples, the obtained results confirmed that storage in a freezer and fridge is the most optimal due to the high stability of the color intensity for 180 days (

Figure 5A). After irradiation of the same samples with a dose of 100 mJ/cm

2, a slight decrease in the color intensity of the samples (higher reflectance values) was observed for up to 20 days (

Figure 5B). This effect was also visible for samples stored at room temperature. Only for samples stored at room temperature with access to light it was visible that their color intensity increased over 20 days of storage (decrease in reflectance values). For example, the change in light reflectance values over 20 days from the preparation of the non-irradiated cotton—NBT dosimeter was 5.21%, 2.43%, 39.36%, and 3.88% for samples stored at room temperature, in a fridge, in a freezer, and at room temperature with access to light, respectively. Of course, cotton—NBT dosimeters can be used immediately after preparation. Depending on the type of application and the nature of changes in dosimeters during storage, it seems that the optimal solution would be to start using cotton—NBT dosimeters for dose measurements at least 20 days after their preparation. For example, the difference in color of the samples over 20–180 days did not exceed 2.72% and 4.81% for samples stored in a fridge and freezer, respectively. However, the scatter of points may also result from the fact that the measurements of textile products are difficult due to their texture, and therefore, not only the weave but also the accidental creasing of the sample resulting from touching it may affect the light reflectance measurement.

3.4. Radiation 2D Dose Distribution vs. Storage Conditions of the Cotton—NBT Dosimeter

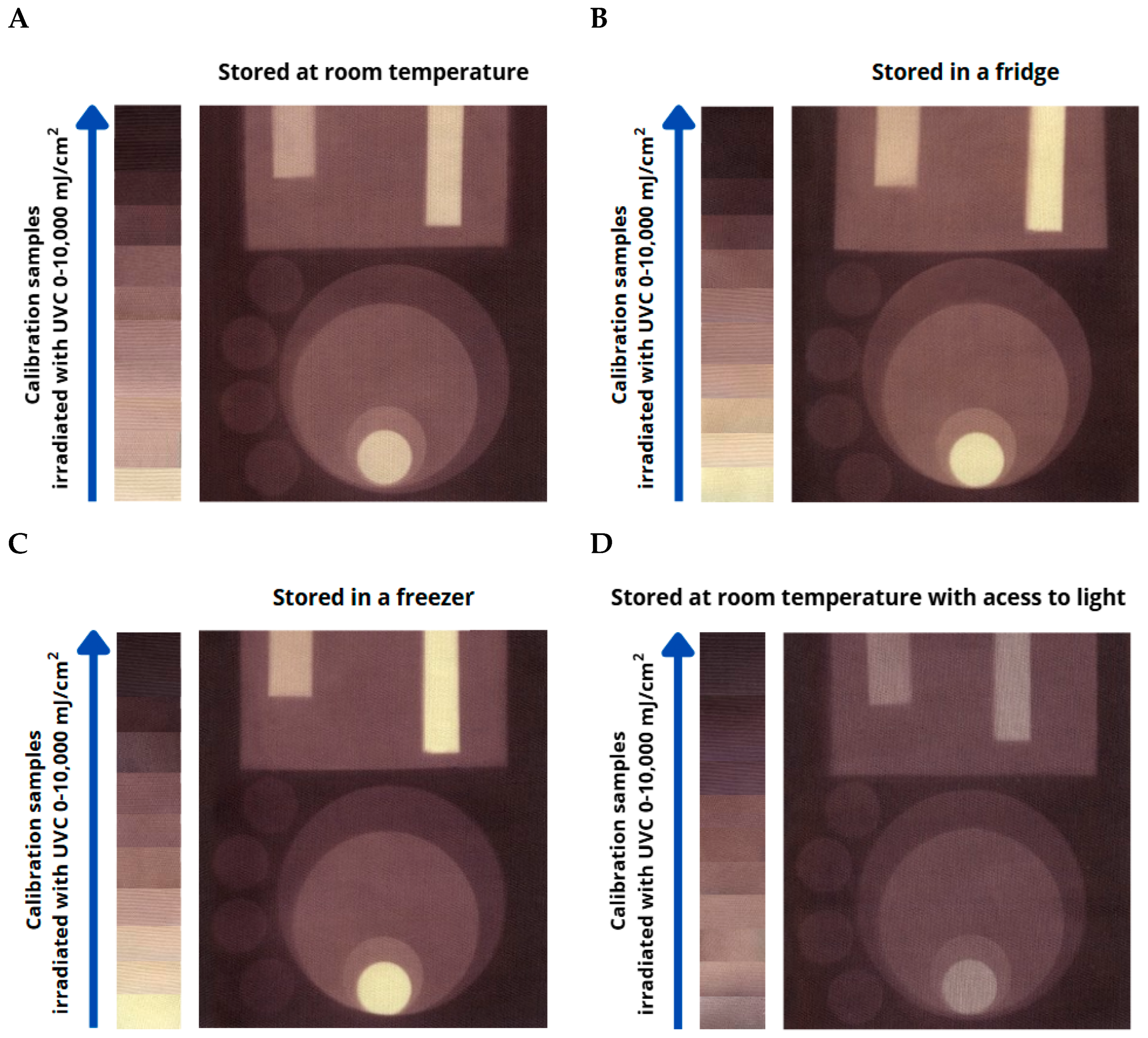

The cotton-NBT dosimeter samples, stored under different conditions described in previous sections, were also non-homogeneously irradiated to confirm that we could register a 2D UV dose distribution eight months after their preparation. To perform non-homogeneous UVC irradiation, brass metal elements were placed on the surface of the samples. It was important that during irradiation, these objects adhered well to the fabric surface, did not reflect UV radiation, and did not create additional artifacts on the textile substrate. Cotton—NBT dosimeters with calibration samples were irradiated with UVC doses in the dose range of 0–10,000 mJ/cm

2. The scheme of non-homogeneous UVC irradiation is presented in

Figure 6. After irradiation, all samples were scanned with a flatbed scanner, and the obtained images of the cotton—NBT samples after scanning are presented in

Figure 7. Regardless of the storage conditions, all cotton—NBT samples showed a visible fabric weave structure after scanning. Previous research has shown that the quality of images obtained after scanning textile dosimeters is influenced by (i) the type of textile substrate, including its weave, used for the dosimeter preparation; (ii) the scanning resolution and scanner control software settings; and (iii) the averaging of data after scanning [

9,

10,

16]. In addition, the samples after irradiation looked very similar to each other. Of course, the difference in shade was due to the storage conditions of the cotton—NBT samples over eight months, but after irradiation, the samples changed color from yellow to purple-brown, which indicates the possibility of using such dosimeters for longer periods of time. However, the samples stored at room temperature (

Figure 7A,B) were slightly darker than those stored in the fridge and freezer (

Figure 7B,C).

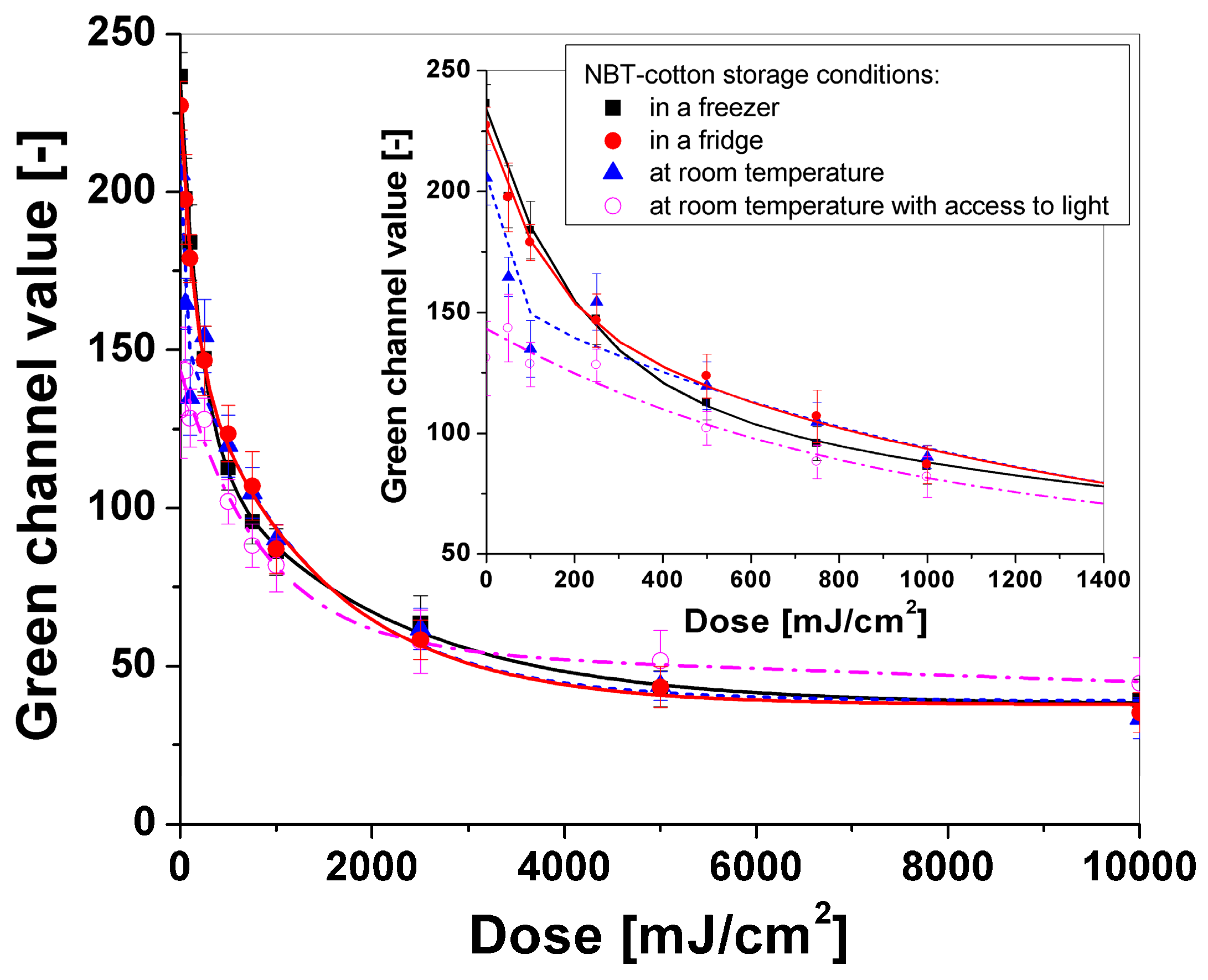

After irradiation, the samples were scanned using a flatbed scanner at a 75 dpi resolution without additional color correction and image sharpening. The use of low-resolution scanning allows for a reduction in noise from the weave of the textile substrate, which affects the quality of images after applying the filtering described in

Section 2.5. The images of the cotton–NBT calibration samples after scanning were then processed using the polyGeVero

®-CT software package to decompose them into color channels in the RGB color model. All RGB channels contributed significantly to the color change in the irradiated cotton—NBT samples, similarly to previous research [

9,

10]. However, the greatest change in color intensity was visible for the green channel, which was selected for further analysis. Using the tools of the polyGeVero

® software package, all images were filtered. The following settings were used: average filter; kernel size: 3; kernel unit: mm; kernel mode: 2D; iterations: 2. The selected settings allowed for smoothing the images of the scanned cotton—NBT samples without distorting their dimensions and shapes. This procedure allowed for the preparation of a calibration relation between the green channel values and the UVC-absorbed dose, which is presented in

Figure 8. Each measurement point is the average value of the entire calibration sample image, with an area of 7000–10,000 points and the standard deviation bars marked. After analyzing the dose response of the cotton—NBT dosimeters, it can be concluded that regardless of the storage conditions, the dynamic dose response reaches up to approximately 2500 mJ/cm

2. Above a dose of 3000 mJ/cm

2, a slight change in the dose response of the dosimeters to the UVC was observed. It was also seen that the dose sensitivity decreased with increasing purple-brown color conversion, becoming apparent in the dose range above 100 mJ/cm

2. The decrease in the green channel value as a function of the absorbed dose can be described by the following calibration equation: Green channel = A1 × exp(-Dose/t1) + A2 × exp(-Dose/t2) + y0.

Table 2 presents the characteristics of dosimeters stored in the freezer, in the fridge, at room temperature, and at room temperature with access to light.

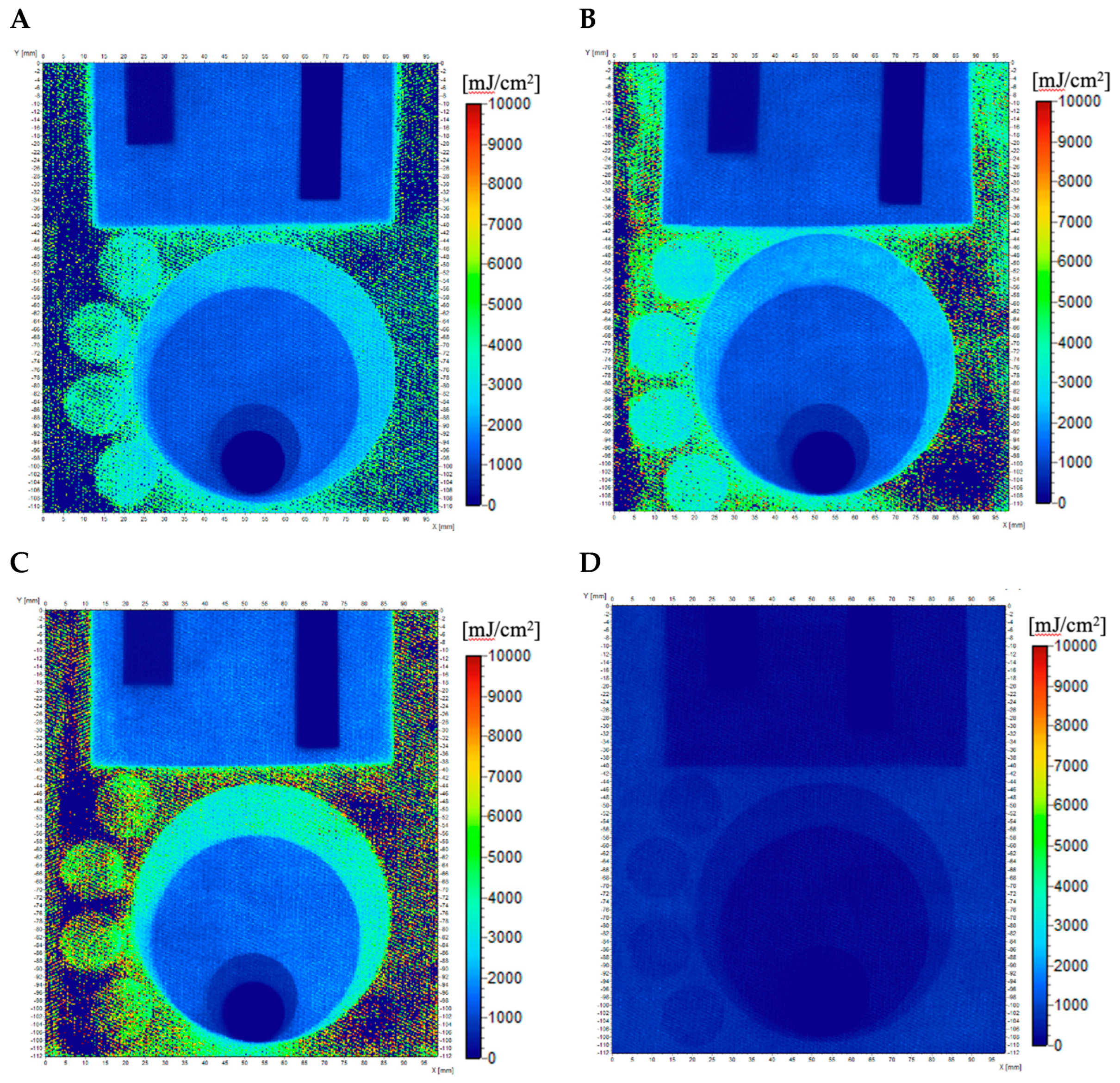

For non-homogeneously irradiated samples, the same procedure was followed. After scanning, the obtained images were processed with the polyGeVero

® software package, and the obtained images in the green RGB channel are presented in

Figure 9. The results confirm that the greatest change in color intensity was observed in samples stored in the freezer and fridge (

Figure 9B,C). In the case of the samples stored at room temperature, a decrease in color intensity was observed in the green channel, but it was still clearly visible.

After applying the calibration equations described previously, 2D UVC dose distribution maps were also generated and are presented in

Figure 10. Comparing the results obtained from the 2D distribution maps with the dose emitted by the UV source, after applying the calibration equation and assigning a color scale, the samples stored in the fridge and freezer registered a maximum dose of around 8000 mJ/cm

2 (

Figure 10B,C). In both cases, the sample surface shows marked red areas indicating the registration of higher doses, but they are random and not limited to the shape irradiated with 10,000 mJ/cm

2. It is assumed that this noise is related to the weave of the fabric, which appears darker in these areas. Therefore, after applying the calibration equation, the color scale suggests that these are areas irradiated with a higher UVC dose. For the sample stored at room temperature (

Figure 10A), the maximum registered dose is about 5000 mJ/cm

2, and for the sample stored with access to light (

Figure 10D), it is 1500 mJ/cm

2. For this last sample, the changes after applying the calibration equation are practically invisible in the obtained image. This is due to the sample’s lower sensitivity to the dose and its lower reflectance value before irradiation, which occurred after it was stored at room temperature for eight months without a foil cover and access to light.

In summary, the difference between the emitted and absorbed doses is visible and may be due to the following reasons: (i) the change in the sensitivity of the dosimetry system during the eight months of storage; (ii) partial scattering of UVC radiation on the elements covering the sample during non-homogeneous irradiation; (iii) the structure of the textile substrate used to prepare the dosimeter; (iv) the selection of parameters used during filtering and image processing after scanning; and (v) the calibration of the dosimetry system. However, the conducted studies prove that the cotton—NBT dosimeters are suitable for dose measurements and 2D dose distribution of UVC radiation with a non-homogeneous pattern eight months after dosimeter preparation.