Effects of Electric Current on the Mechanical Properties of Cu/Nb Multilayer Composites by Accumulative Roll Bonding

Abstract

:1. Introduction

2. Materials and Methods

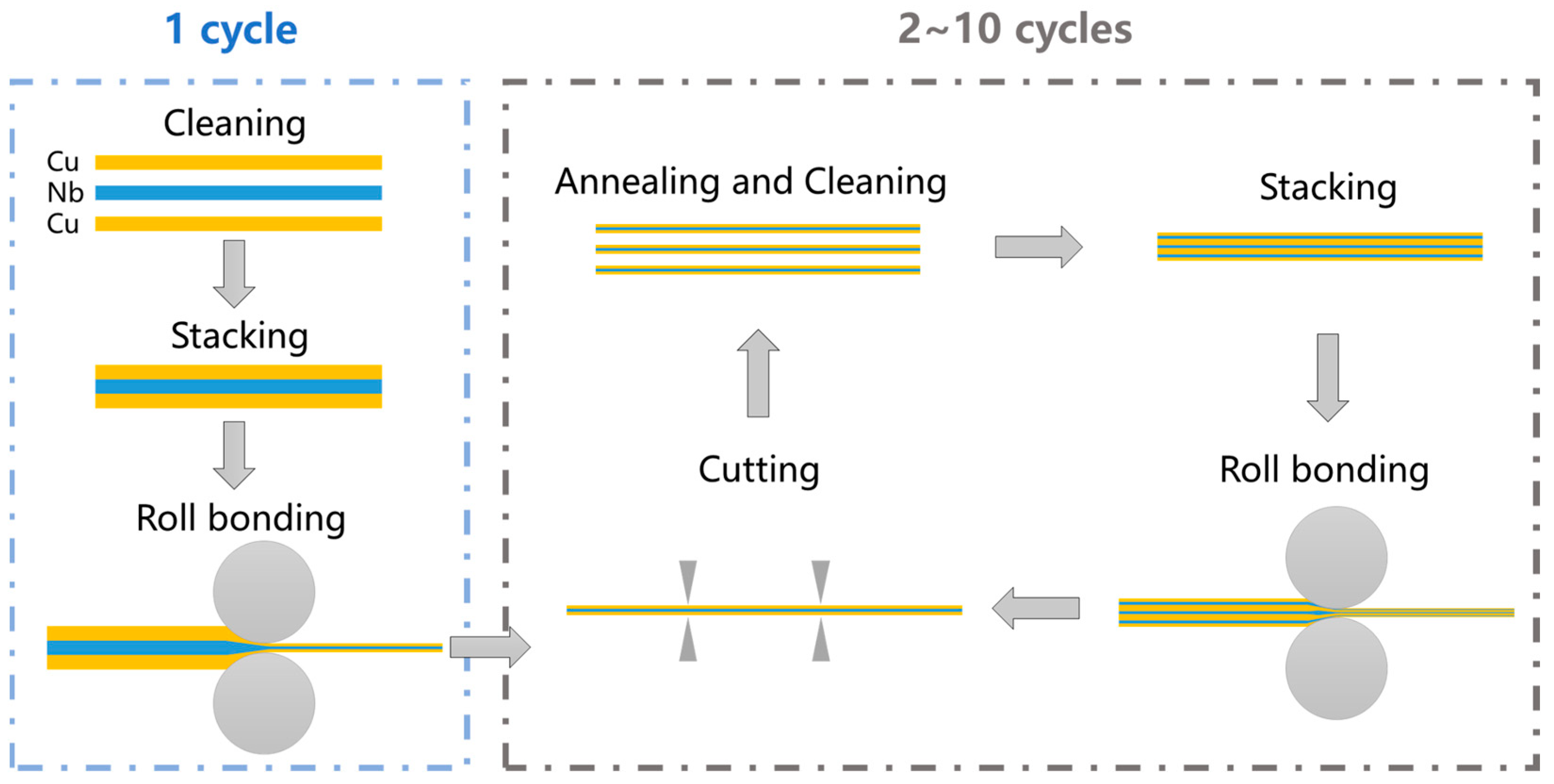

2.1. Sample Preparation

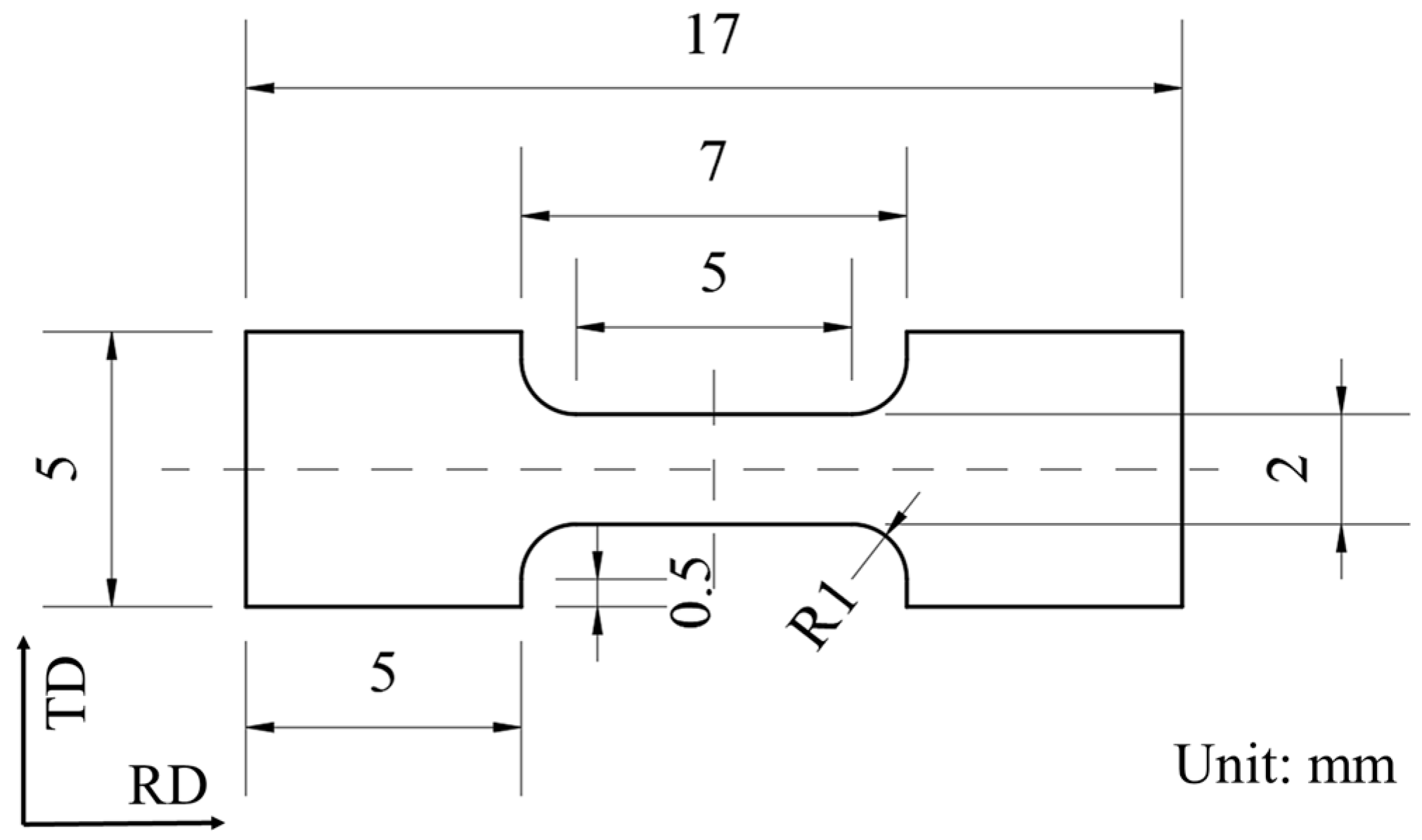

2.2. Experimental Procedures

3. Results and Discussion

3.1. Microstructure

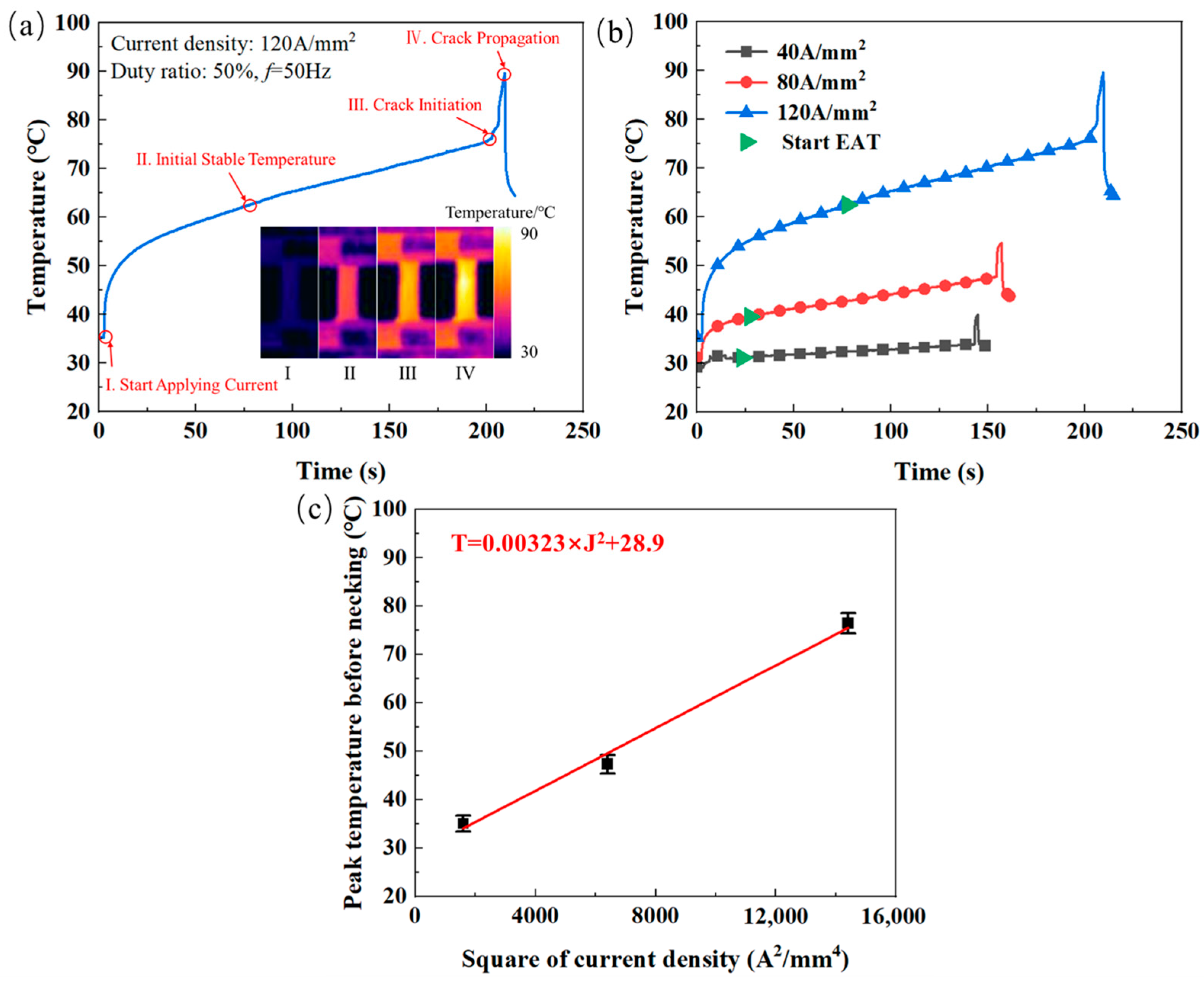

3.2. Temperature Variation

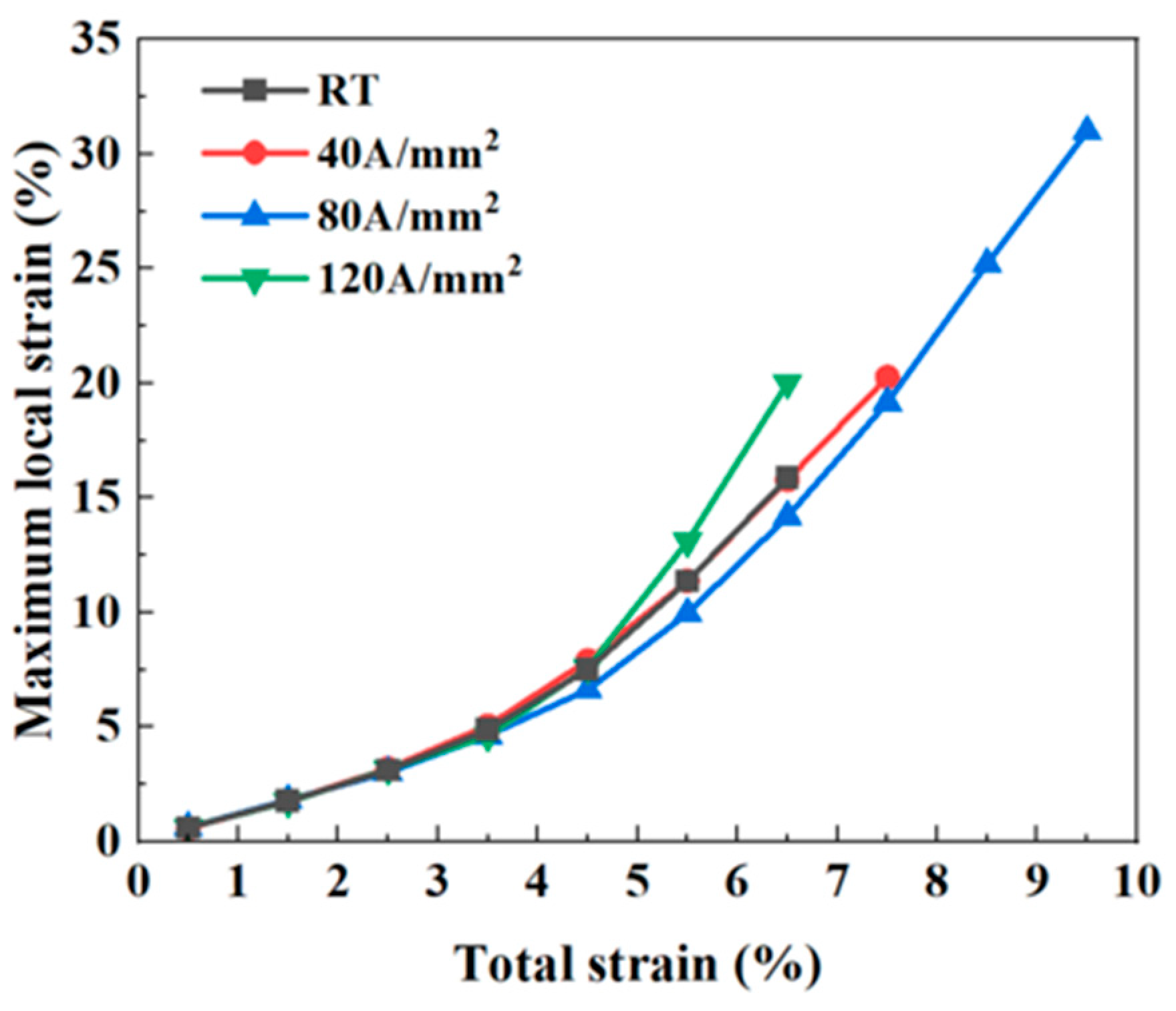

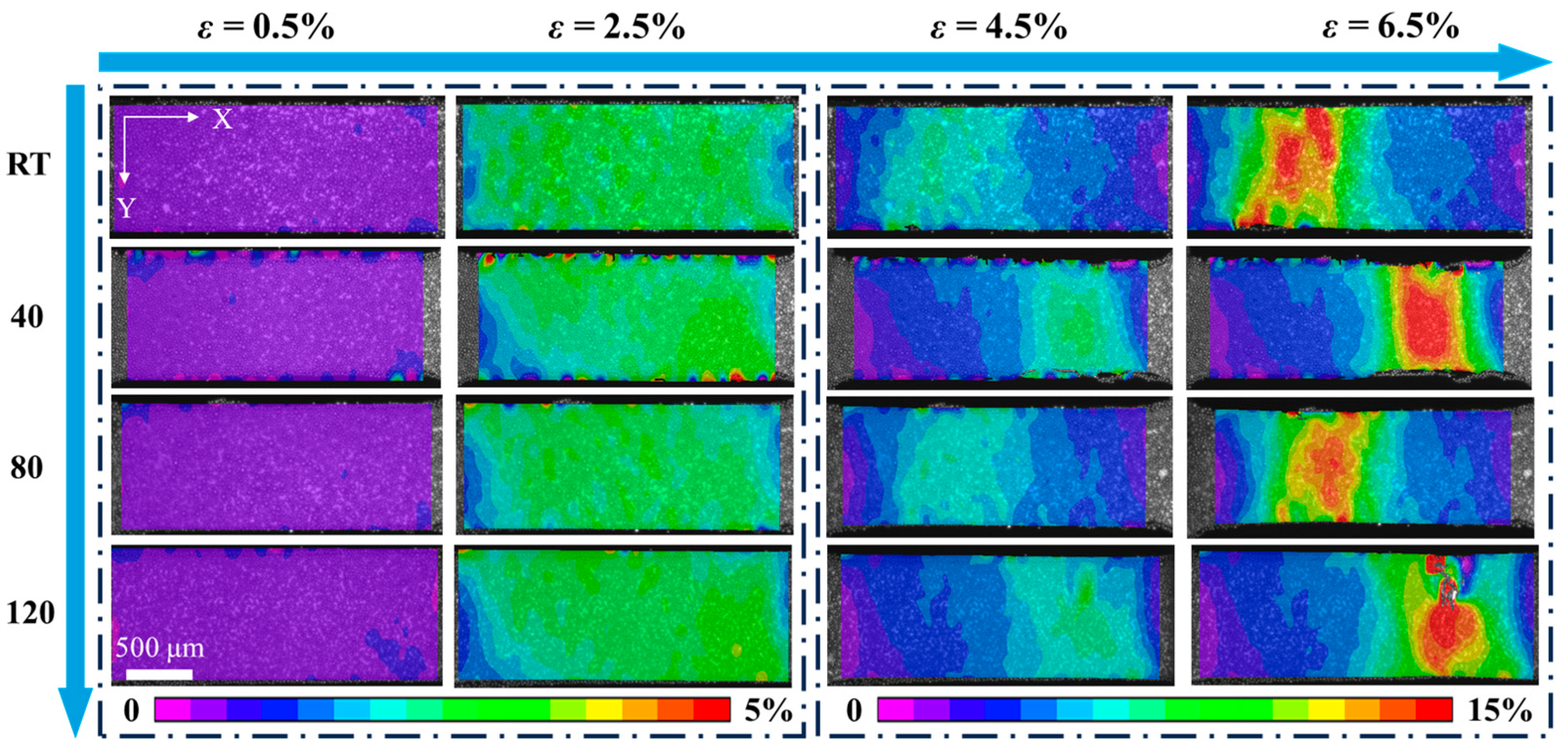

3.3. Local Strain Evolution

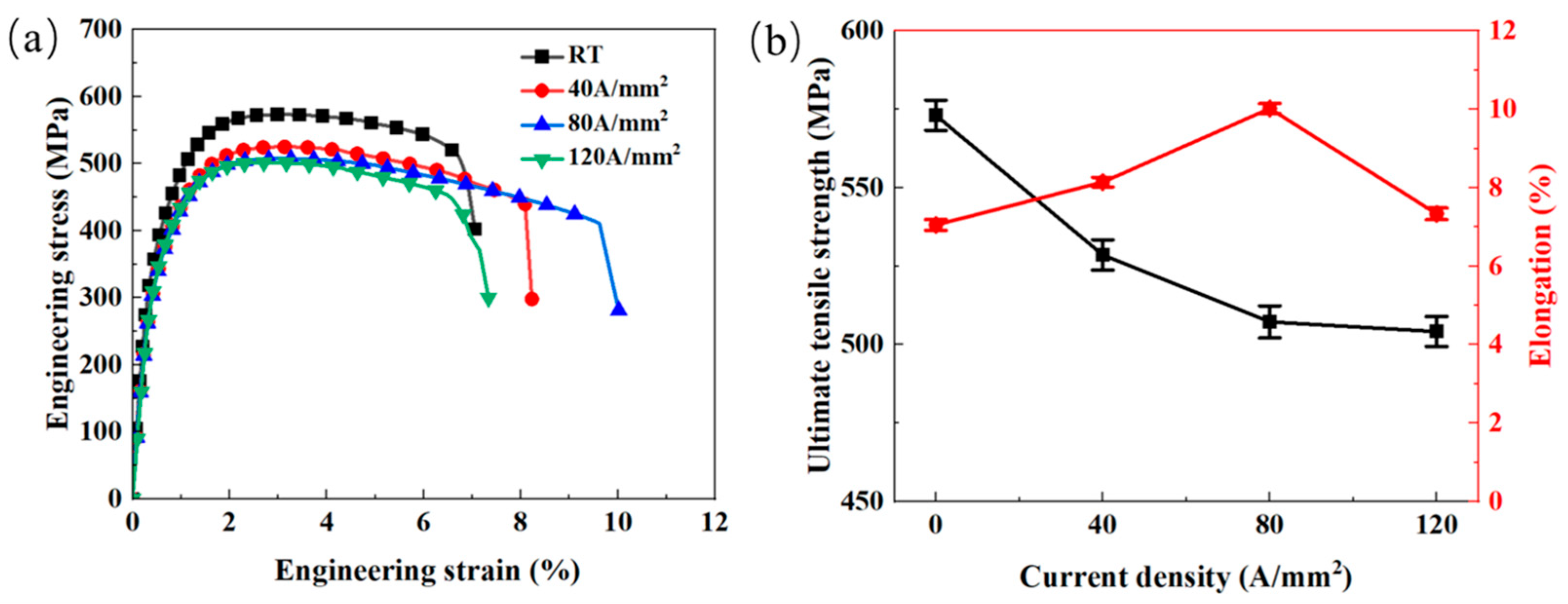

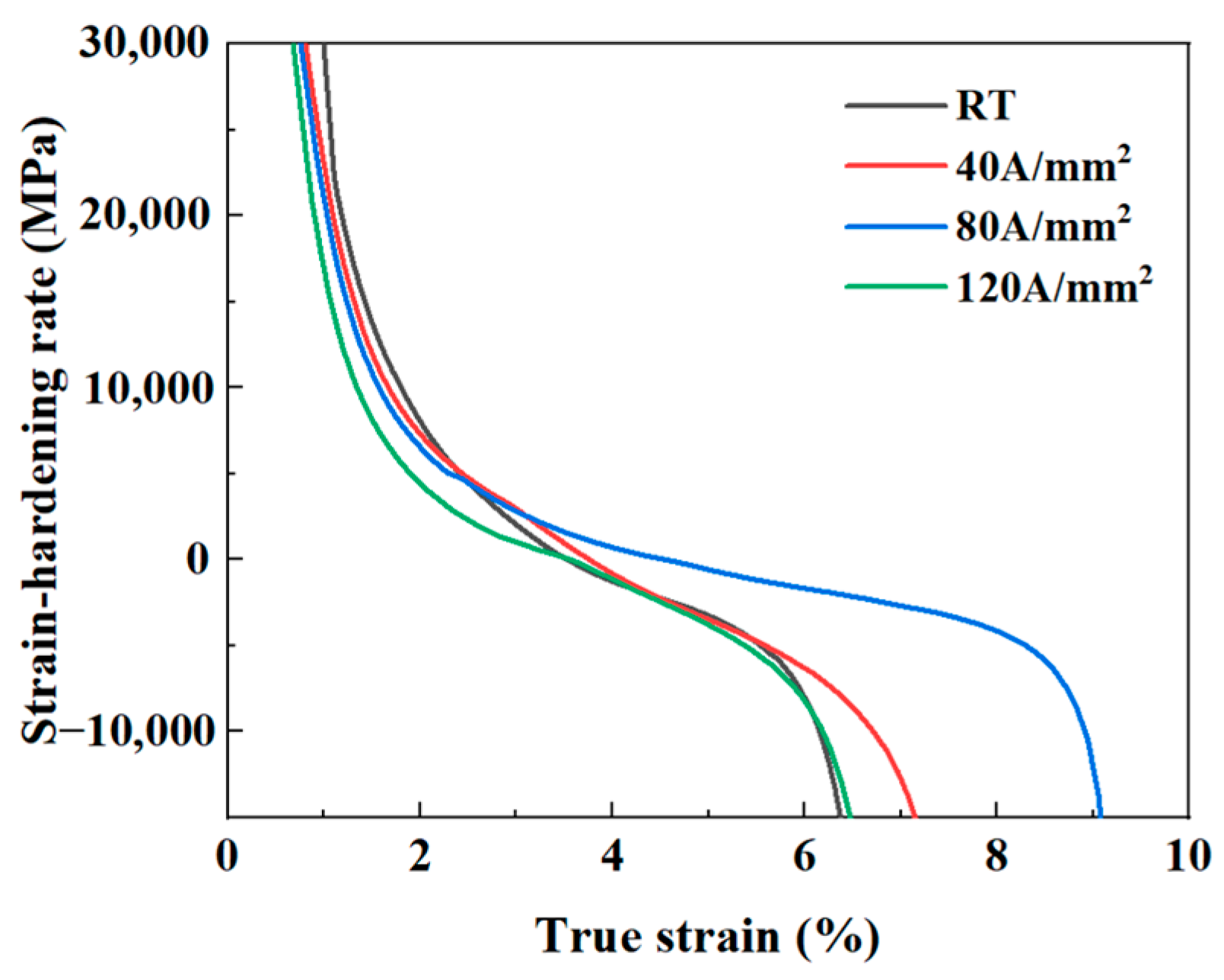

3.4. Mechanical Properties

3.5. Fracture Morphologies

4. Conclusions

- (1)

- The peak temperature of Cu/Nb multilayer composites increases with the increase in current density, and the relationship between the maximum temperature before necking and the current density satisfies Joule’s heat law. Additionally, the strain concentration at a high current density is caused by the temperature increase and uneven temperature distribution.

- (2)

- A pulsed current reduces the UTS of Cu/Nb multilayer composites, and this effect tends to saturate at high current densities. Compared with the EL at RT, the EL is significantly improved when the current density is 40 A/mm2 and 80 A/mm2, but without significant change at 120 A/mm2, which is attributed to electric current reduces the strain concentration and enhance the ductility at low current density.

- (3)

- Fracture morphologies show that the current increases the size and depth of the dimples. Furthermore, during the EAT process, the fracture mode of the Cu/Nb multilayer composite is a ductile fracture, and the application of current does not change the fracture mode of the Cu/Nb multilayer composite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, Y.; Wu, X. Heterostructured Materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Sathiyamoorthi, P.; Kim, H.S. High-Entropy Alloys with Heterogeneous Microstructure: Processing and Mechanical Properties. Prog. Mater. Sci. 2022, 123, 100709. [Google Scholar] [CrossRef]

- Romero-Resendiz, L. Paradoxes of Heterostructured Materials. J. Mater. Res. 2025, 1–21. [Google Scholar] [CrossRef]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured Materials: Superior Properties from Hetero-Zone Interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Ding, Z.; Ding, C.; Yang, Z.; Zhang, H.; Wang, F.; Li, H.; Xu, J.; Shan, D.; Guo, B. Ultra-High Strength in FCC+BCC High-Entropy Alloy via Different Gradual Morphology. Materials 2024, 17, 4535. [Google Scholar] [CrossRef] [PubMed]

- Ebrahimi, M.; Luo, B.; Wang, Q.; Attarilar, S. High-Performance Nanoscale Metallic Multilayer Composites: Techniques, Mechanical Properties and Applications. Materials 2024, 17, 2124. [Google Scholar] [CrossRef]

- Wadsworth, J.; Lesuer, D.R. Ancient and Modern Laminated Composites—From the Great Pyramid of Gizeh to Y2K. Mater. Charact. 2000, 45, 289–313. [Google Scholar] [CrossRef]

- Jayadevan, K.P.; Tseng, T.Y. Review Composite and Multilayer Ferroelectric Thin Films: Processing, Properties and Applications. J. Mater. Sci. Mater. Electron. 2002, 13, 439–459. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Luo, B.; Wang, Q.; Attarilar, S. Enhanced Multifaceted Properties of Nanoscale Metallic Multilayer Composites. Materials 2024, 17, 4004. [Google Scholar] [CrossRef]

- Xu, J.; Shen, Y.; Wang, C.; Dai, J.; Tai, Y.; Ye, Y.; Shen, R.; Wang, H.; Zachariah, M.R. Controlling the Energetic Characteristics of Micro Energy Storage Device by in Situ Deposition Al/MoO3 Nanolaminates with Varying Internal Structure. Chem. Eng. J. 2019, 373, 345–354. [Google Scholar] [CrossRef]

- Ma, Y.J.; Cai, Y.P.; Wang, G.J.; Cui, M.J.; Sun, C.; Cao, Z.H.; Meng, X.K. Enhanced Thermal Stability by Heterogeneous Interface and Columnar Grain in Nanoscale Cu/Ru Multilayers. Mater. Sci. Eng. A 2019, 742, 751–759. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Zhang, X.; Liu, G.; Zhang, G.J.; Sun, J. Dominant Factor Controlling the Fracture Mode in Nanostructured Cu/Cr Multilayer Films. Mater. Sci. Eng. A 2011, 528, 2982–2987. [Google Scholar] [CrossRef]

- Yu, H.L.; Lu, C.; Tieu, A.K.; Li, H.J.; Godbole, A.; Zhang, S.H. Special Rolling Techniques for Improvement of Mechanical Properties of Ultrafine-Grained Metal Sheets: A Review. Adv. Eng. Mater. 2016, 18, 754–769. [Google Scholar] [CrossRef]

- Feng, B.; Yang, H.; Li, X.; Feng, X.; Chen, T.; Li, G. Development of Accumulative Roll Bonding for Metallic Composite Material Preparation and Mechanical/Functional Applications. J. Iron Steel Res. Int. 2024, 31, 2611–2621. [Google Scholar] [CrossRef]

- Scharnweber, J.; Chekhonin, P.; Oertel, C.-G.; Romberg, J.; Freudenberger, J.; Jaschinski, J.; Skrotzki, W. Microstructure, Texture, and Mechanical Properties of Laminar Metal Composites Produced by Accumulative Roll Bonding. Adv. Eng. Mater. 2019, 21, 1800210. [Google Scholar] [CrossRef]

- Jiang, S.; Jia, N.; Zhou, X.H.; Zhang, H.; He, T.; Zhao, X. Microstructure and Mechanical Properties of Multilayered Cu/Ti Composites Fabricated by Accumulative Roll Bonding. Mater. Trans. 2017, 58, 259–265. [Google Scholar] [CrossRef]

- Hosseini, M.; Pardis, N.; Danesh Manesh, H.; Abbasi, M.; Kim, D.-I. Structural Characteristics of Cu/Ti Bimetal Composite Produced by Accumulative Roll-Bonding (ARB). Mater. Des. 2017, 113, 128–136. [Google Scholar] [CrossRef]

- Eizadjou, M.; Kazemitalachi, A.; Daneshmanesh, H.; Shakurshahabi, H.; Janghorban, K. Investigation of Structure and Mechanical Properties of Multi-Layered Al/Cu Composite Produced by Accumulative Roll Bonding (ARB) Process. Compos. Sci. Technol. 2008, 68, 2003–2009. [Google Scholar] [CrossRef]

- Li, X.-B.; Yang, Y.; Xu, Y.-S.; Zu, G.-Y. Deformation Behavior and Crack Propagation on Interface of Al/Cu Laminated Composites in Uniaxial Tensile Test. Rare Met. 2020, 39, 296–303. [Google Scholar] [CrossRef]

- Tayyebi, M.; Eghbali, B. Study on the Microstructure and Mechanical Properties of Multilayer Cu/Ni Composite Processed by Accumulative Roll Bonding. Mater. Sci. Eng. A 2013, 559, 759–764. [Google Scholar] [CrossRef]

- Shabani, A.; Toroghinejad, M.R. Investigation of the Microstructure and the Mechanical Properties of Cu-NiC Composite Produced by Accumulative Roll Bonding and Coating Processes. J. Mater. Eng. Perform. 2015, 24, 4746–4754. [Google Scholar] [CrossRef]

- Luo, J.-G.; Acoff, V.L. Using Cold Roll Bonding and Annealing to Process Ti/Al Multi-Layered Composites from Elemental Foils. Mater. Sci. Eng. A 2004, 379, 164–172. [Google Scholar] [CrossRef]

- Xing, B.; Huang, T.; Song, K.; Xu, L.; Yan, S.; Xiang, N.; Chen, F. Effect of Electric Current on Mechanical Properties and Microstructure of Ti/Al Laminated Composite during Electrically Assisted Tension. Vacuum 2023, 210, 111805. [Google Scholar] [CrossRef]

- Nie, J.F.; Liu, M.X.; Wang, F.; Zhao, Y.H.; Li, Y.S.; Cao, Y.; Zhu, Y.T. Fabrication of Al/Mg/Al Composites via Accumulative Roll Bonding and Their Mechanical Properties. Materials 2016, 9, 951. [Google Scholar] [CrossRef]

- Chang, H.; Zheng, M.Y.; Xu, C.; Fan, G.D.; Brokmeier, H.G.; Wu, K. Microstructure and Mechanical Properties of the Mg/Al Multilayer Fabricated by Accumulative Roll Bonding (ARB) at Ambient Temperature. Mater. Sci. Eng. A 2012, 543, 249–256. [Google Scholar] [CrossRef]

- Shahabi, H.S.; Manesh, H.D. Micro-Structural Evaluation of Cu/Nb Nano-Layered Composites Produced by Repeated Press and Rolling Process. J. Alloys Compd. 2009, 482, 526–534. [Google Scholar] [CrossRef]

- Kuglstatter, M.; Nitschky, M.; Hartmann, A.; Kümmel, F.; Fecher, J.; Felfer, P.; Höppel, H.W.; Göken, M. Adapting Conductivity and Mechanical Properties through Layer Thickness Variation in Copper Niobium Laminated Metallic Composites. Adv. Eng. Mater. 2024, 26, 2400266. [Google Scholar] [CrossRef]

- Ding, C.G.; Xu, J.; Shan, D.B.; Guo, B.; Langdon, T.G. Sustainable Fabrication of Cu/Nb Composites with Continuous Laminated Structure to Achieve Ultrahigh Strength and Excellent Electrical Conductivity. Compos. Part B 2021, 211, 108662. [Google Scholar] [CrossRef]

- An, Q.; Yang, W.; Liu, B.; Zheng, S. Interface Effects on the Properties of Cu–Nb Nanolayered Composites. J. Mater. Res. 2020, 35, 2684–2700. [Google Scholar] [CrossRef]

- Goli, E.; Eghbali, B.; Sahu, S. Texture Evolution and Mechanical Properties of Copper/Niobium Laminated Composite Processed through Accumulative Roll Bonding and Intermediate Annealing. Metall. Microstruct. Anal. 2024, 13, 657–666. [Google Scholar] [CrossRef]

- Su, R.; Neffati, D.; Li, Q.; Xue, S.; Fan, C.; Cho, J.; Zhang, Y.; Li, J.; Wang, H.; Kulkarni, Y.; et al. Ultra-High Strength and Plasticity Mediated by Partial Dislocations and Defect Networks: Part II: Layer Thickness Effect. Acta Mater. 2021, 204, 116494. [Google Scholar] [CrossRef]

- Wang, J.; Misra, A. An Overview of Interface-Dominated Deformation Mechanisms in Metallic Multilayers. Curr. Opin. Solid State Mater. Sci. 2011, 15, 20–28. [Google Scholar] [CrossRef]

- Izadpanah, S.; Cao, X.; An, D.; Li, X.; Chen, J. One Step Forward to Electrically Assisted Forming Mechanisms and Computer Simulation: A Review. Adv. Eng. Mater. 2023, 25, 2200425. [Google Scholar] [CrossRef]

- Xu, Z.T.; Jiang, T.H.; Huang, J.H.; Peng, L.F.; Lai, X.M.; Fu, M.W. Electroplasticity in Electrically-Assisted Forming: Process Phenomena, Performances and Modelling. Int. J. Mach. Tools Manuf. 2022, 175, 103871. [Google Scholar] [CrossRef]

- Li, H.; Peng, L.F.; Meng, B.; Xu, Z.T.; Wang, L.L.; Ngaile, G.; Fu, M.W. Energy Field Assisted Metal Forming: Current Status, Challenges and Prospects. Int. J. Mach. Tools Manuf. 2023, 192, 104075. [Google Scholar] [CrossRef]

- Huang, T.; Yang, F.; Xing, B.-H.; Song, K.-X.; Xiang, N.; Zhang, Y.-M.; Chen, X.-W.; Guo, J.-Q. Effects of Electrical Pulse on Metal Deformation Behaviors. Mater. Res. Express 2024, 11, 32003. [Google Scholar] [CrossRef]

- Salandro, W.A.; Bunget, C.; Mears, L. Thermo-Mechanical Investigations of the Electroplastic Effect. In Proceedings of the ASME 2011 International Manufacturing Science and Engineering Conference, Corvallis, OR, USA, 13–17 June 2011; Volume 1, pp. 573–582. [Google Scholar]

- Zhao, S. Defect Reconfiguration in a Ti–Al Alloy via Electroplasticity. Nat. Mater. 2021, 20, 573–582. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-J.; Lee, K.; Oh, K.H.; Choi, I.-S.; Yu, H.-H.; Hong, S.-T.; Han, H.N. Electric Current-Induced Annealing during Uniaxial Tension of Aluminum Alloy. Scr. Mater. 2014, 75, 58–61. [Google Scholar] [CrossRef]

- Yan, S.; Yang, L.; Hu, L.; Liu, Z.; Meng, M.; Peng, H.; Yu, S.; Xue, K. Unconventional Mechanical Responses and Mechanisms of Ti-6Al-4V Sheet Subjected to Electrically-Assisted Cyclic Loading-Unloading: Thermal and Athermal Effects. Mater. Sci. Eng. A 2024, 918, 147394. [Google Scholar] [CrossRef]

- Li, X.F.; Ji, B.Y.; Zhou, Q.; Chen, J.; Gao, P. Influence of Grain Size on Electrically Assisted Tensile Behavior of Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2016, 25, 4514–4520. [Google Scholar] [CrossRef]

- Bao, J.X.; Ding, C.G.; Xu, J.; Yang, Z.Q.; Shan, D.B.; Guo, B. Characterization of Stress Drop and Strain Localization for Titanium Alloy Subjected to Electrically-Assisted Tension. J. Mater. Res. Technol. 2024, 28, 4600–4614. [Google Scholar] [CrossRef]

- Wang, X.W.; Xu, J.; Jiang, Z.L.; Zhu, W.-L.; Shan, D.B.; Guo, B.; Cao, J. Size Effects on Flow Stress Behavior during Electrically-Assisted Micro-Tension in a Magnesium Alloy AZ31. Mater. Sci. Eng. A 2016, 659, 215–224. [Google Scholar] [CrossRef]

- Wang, X.W.; Xu, J.; Shan, D.B.; Guo, B.; Cao, J. Modeling of Thermal and Mechanical Behavior of a Magnesium Alloy AZ31 during Electrically-Assisted Micro-Tension. Int. J. Plast. 2016, 85, 230–257. [Google Scholar] [CrossRef]

- Wang, X.W.; Xu, J.; Shan, D.B.; Guo, B.; Cao, J. Effects of Specimen and Grain Size on Electrically-Induced Softening Behavior in Uniaxial Micro-Tension of AZ31 Magnesium Alloy: Experiment and Modeling. Mater. Des. 2017, 127, 134–143. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Bao, J.X.; Ding, C.G.; Son, S.; Ning, Z.L.; Xu, J.; Shan, D.B.; Guo, B.; Kim, H.S. Electroplasticity in the Al0.6CoCrFeNiMn High Entropy Alloy Subjected to Electrically-Assisted Uniaxial Tension. J. Mater. Sci. Technol. 2023, 148, 209–221. [Google Scholar] [CrossRef]

- Kim, M.-J.; Lee, M.-G.; Hariharan, K.; Hong, S.-T.; Choi, I.-S.; Kim, D.; Oh, K.H.; Han, H.N. Electric Current–Assisted Deformation Behavior of Al-Mg-Si Alloy under Uniaxial Tension. Int. J. Plast. 2017, 94, 148–170. [Google Scholar] [CrossRef]

- Ding, C.G.; Xu, J.; Li, X.W.; Shan, D.B.; Guo, B.; Langdon, T.G. Microstructural Evolution and Mechanical Behavior of Cu/Nb Multilayer Composites Processed by Accumulative Roll Bonding. Adv. Eng. Mater. 2020, 22, 1900702. [Google Scholar] [CrossRef]

- Ding, C.G.; Xu, J.; Shan, D.B.; Guo, B.; Langdon, T.G. Influence of Bimetal Interface Confinement on the Hall-Petch Slope of Multiscale Cu/Nb Multilayer Composites. Heliyon 2023, 9, e16231. [Google Scholar] [CrossRef]

- Ding, C.G.; Xu, J.; Shan, D.B.; Guo, B.; Langdon, T.G. The Thermal Instability Mechanism and Annealed Deformation Behavior of Cu/Nb Nanolaminate Composites. J. Mater. Sci. Technol. 2023, 157, 163–173. [Google Scholar] [CrossRef]

- Li, H.S.; Liu, X.Y.; Wang, J.Y.; Xu, Z.H.; Ding, C.G.; Xu, J.; Guo, B.; Shan, D.B. Effect of the Individual Layer Thickness and Relative Blanking Clearance on Micro-Blanking for Cu/Nb Multilayer Composite Sheets. MATEC Web Conf. 2024, 401, 4008. [Google Scholar] [CrossRef]

- Li, H.; Ding, C.; Ding, Z.; Zhang, H.; Wang, F.; Chen, Y.; Bao, J.; Xu, J.; Guo, B.; Shan, D. Mechanical Properties and Fracture Behavior of Laminated Heterostructured Composites under Different Current Densities. Rare Met. Mater. Eng. 2024, 53, 2713–2717. [Google Scholar]

- Zhang, X.; Li, H.; Zhan, M. Mechanism for the Macro and Micro Behaviors of the Ni-Based Superalloy during Electrically-Assisted Tension: Local Joule Heating Effect. J. Alloys Compd. 2018, 742, 480–489. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, J.; Guo, B.; Shan, D. Effect of Pulsed Current-Assisted Tension on the Mechanical Behavior and Local Strain of Nickel-Based Superalloy Sheet. Materials 2023, 16, 1589. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.-R.; Wang, L.; Lei, Z.-K.; Han, X.-F.; Shi, J.-N. Study on Bending Damage and Failure of Basalt Fiber Reinforced Concrete under Freeze-Thaw Cycles. Constr. Build. Mater. 2018, 163, 460–470. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Yan, S.; Zhang, N. Experimental Study and Analysis on the Electrically-Assisted Tensile Behaviors of Inconel 718 Alloy. Procedia Eng. 2017, 207, 365–370. [Google Scholar] [CrossRef]

- Molinari, A.; Ravichandran, G. Constitutive Modeling of High-Strain-Rate Deformation in Metals Based on the Evolution of an Effective Microstructural Length. Mech. Mater. 2005, 37, 737–752. [Google Scholar] [CrossRef]

- Li, H.S.; Ding, C.G.; Zhang, H.; Wang, J.Y.; Chen, Y.X.; Yang, Z.Q.; Xu, J.; Guo, B.; Shan, D.B.; Langdon, T.G. Flow Stress Softening and Deformation Mechanism under Competition of Current Density and Strain Rate in Basket Structured High-Entropy Alloy. Rare Met. 2025, 44, 2705–2719. [Google Scholar] [CrossRef]

- Wang, F.; Ding, C.; Yang, Z.; Zhang, H.; Ding, Z.; Li, H.; Xu, J.; Shan, D.; Guo, B. Microstructure Evolution and Mechanical Properties of AlCoCrFeNi2.1 Eutectic High-Entropy Alloys Processed by High-Pressure Torsion. Materials 2024, 17, 2954. [Google Scholar] [CrossRef]

- He, J.; Zeng, Z.; Li, H.B.; Wang, S. The Microstructure and Mechanical Properties of Copper in Electrically Assisted Tension. Mater. Des. 2020, 196, 109171. [Google Scholar] [CrossRef]

- Chen, W.J.; Xu, J.; Ding, C.G.; Shan, D.B.; Guo, B.; Langdon, T.G. Fracture Mechanism of Electrically-Assisted Micro-Tension in Nanostructured Titanium Using Synchrotron Radiation X-Ray Tomography. Scr. Mater. 2023, 222, 114997. [Google Scholar] [CrossRef]

- Wang, X.; Sánchez Egea, A.J.; Xu, J.; Meng, X.; Wang, Z.; Shan, D.; Guo, B.; Cao, J. Current-Induced Ductility Enhancement of a Magnesium Alloy AZ31 in Uniaxial Micro-Tension below 373 K. Materials 2018, 12, 111. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.Z.; Meng, B.; Du, M.; Wan, M. Electroplastic Effect and Microstructural Mechanism in Electrically Assisted Deformation of Nickel-Based Superalloys. Mater. Sci. Eng. A 2022, 840, 142975. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, C.; Ding, C.; Wang, F.; Li, H.; Zhu, Q.; Shan, D. Effects of Electric Current on the Mechanical Properties of Cu/Nb Multilayer Composites by Accumulative Roll Bonding. Materials 2025, 18, 2109. https://doi.org/10.3390/ma18092109

Ni C, Ding C, Wang F, Li H, Zhu Q, Shan D. Effects of Electric Current on the Mechanical Properties of Cu/Nb Multilayer Composites by Accumulative Roll Bonding. Materials. 2025; 18(9):2109. https://doi.org/10.3390/ma18092109

Chicago/Turabian StyleNi, Chenghang, Chaogang Ding, Fanghui Wang, Hushan Li, Qiang Zhu, and Debin Shan. 2025. "Effects of Electric Current on the Mechanical Properties of Cu/Nb Multilayer Composites by Accumulative Roll Bonding" Materials 18, no. 9: 2109. https://doi.org/10.3390/ma18092109

APA StyleNi, C., Ding, C., Wang, F., Li, H., Zhu, Q., & Shan, D. (2025). Effects of Electric Current on the Mechanical Properties of Cu/Nb Multilayer Composites by Accumulative Roll Bonding. Materials, 18(9), 2109. https://doi.org/10.3390/ma18092109