Study on Microstructure and Mechanical Properties of Core–Shell-Structured Ti@TixN Reinforced Al Composite Prepared by Pressure Infiltration

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

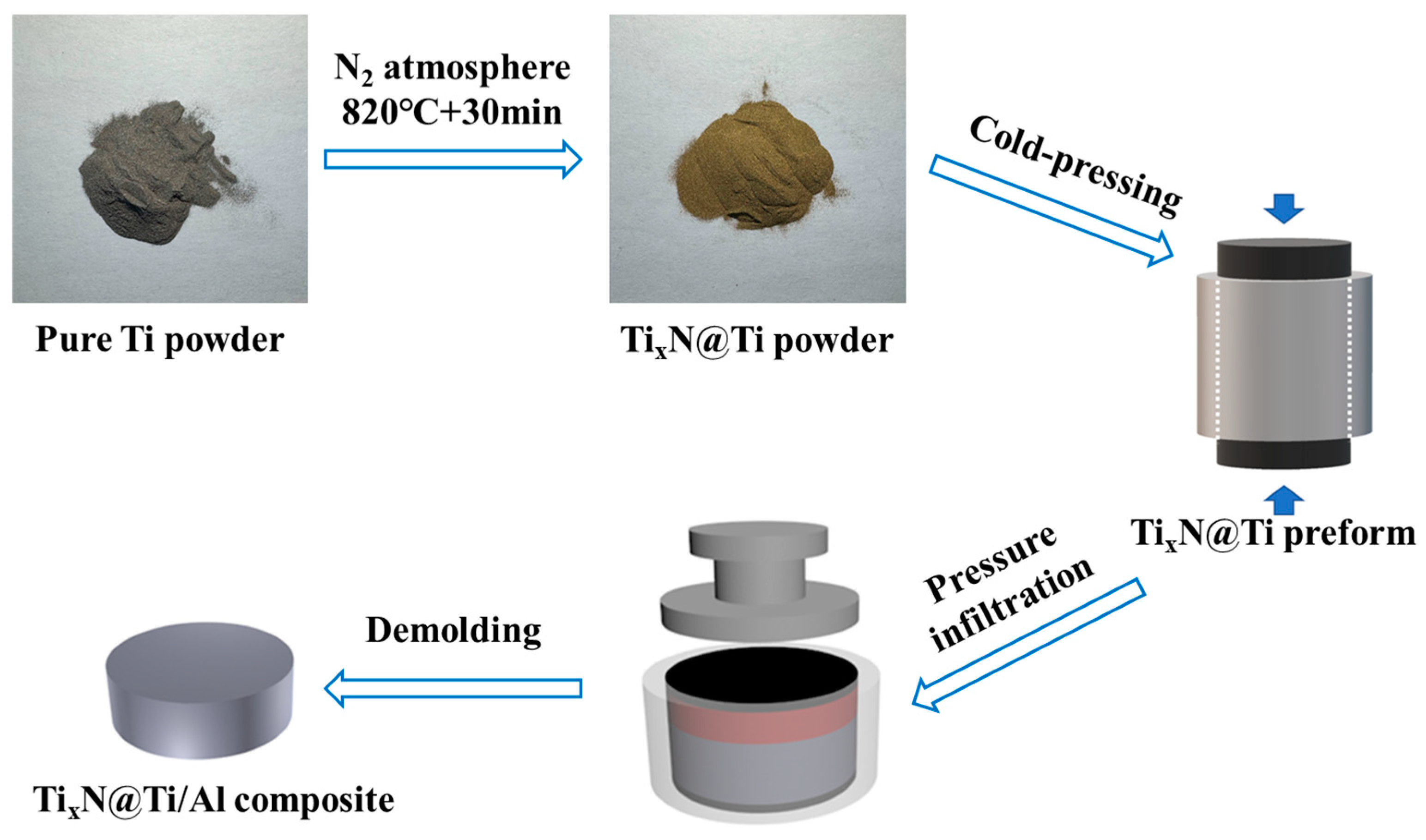

2.2. Fabrication Process

2.3. Characterization

3. Results and Discussion

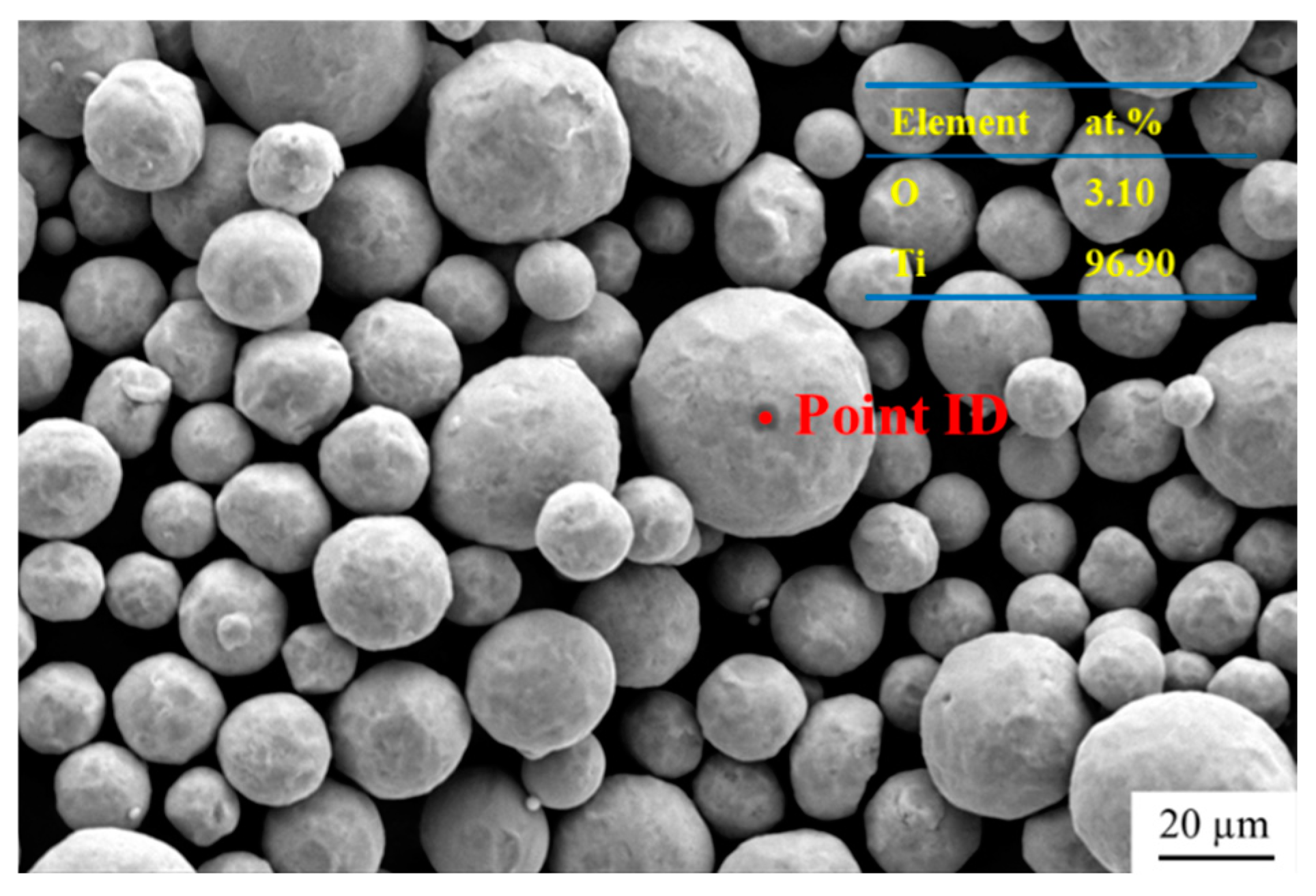

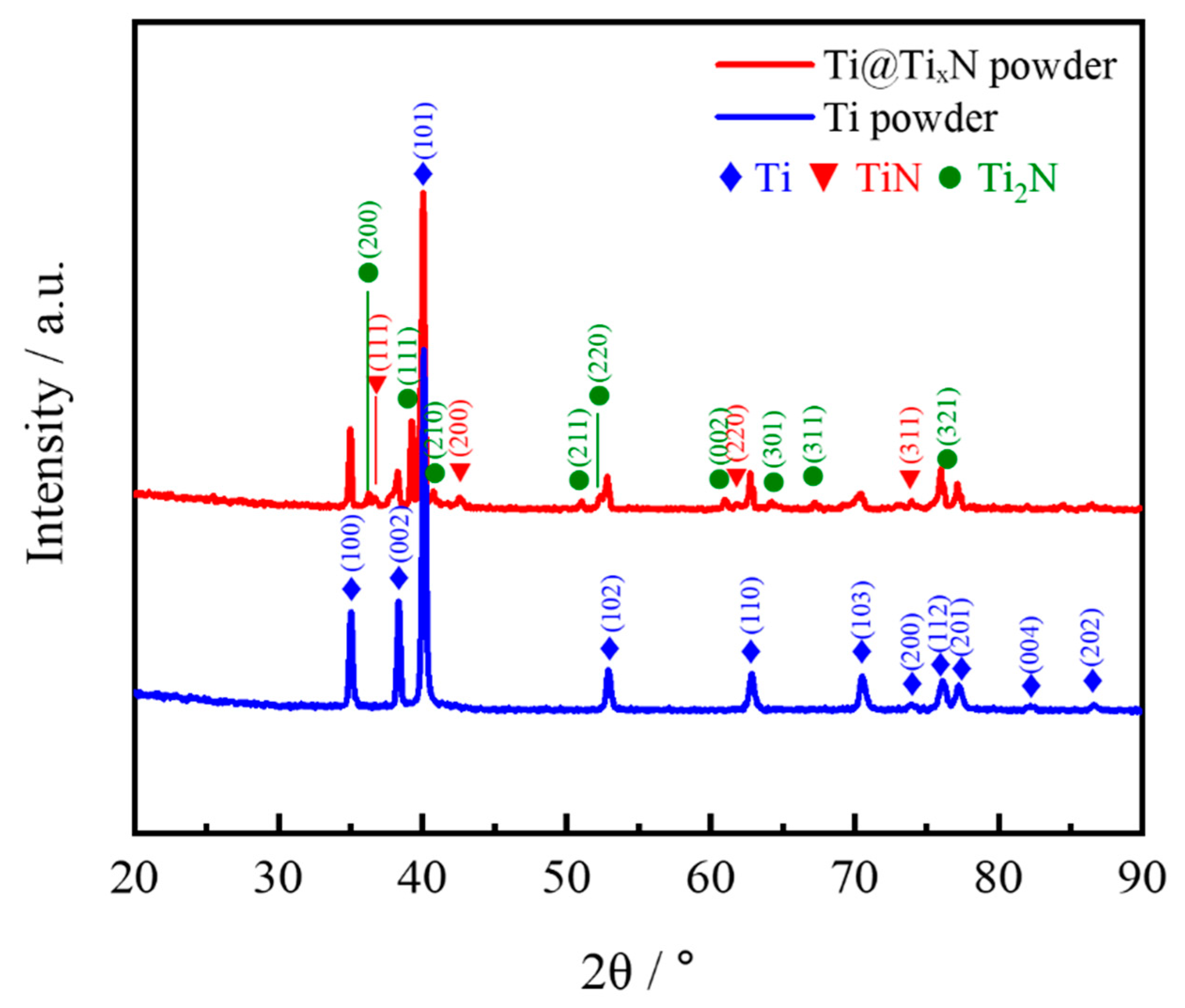

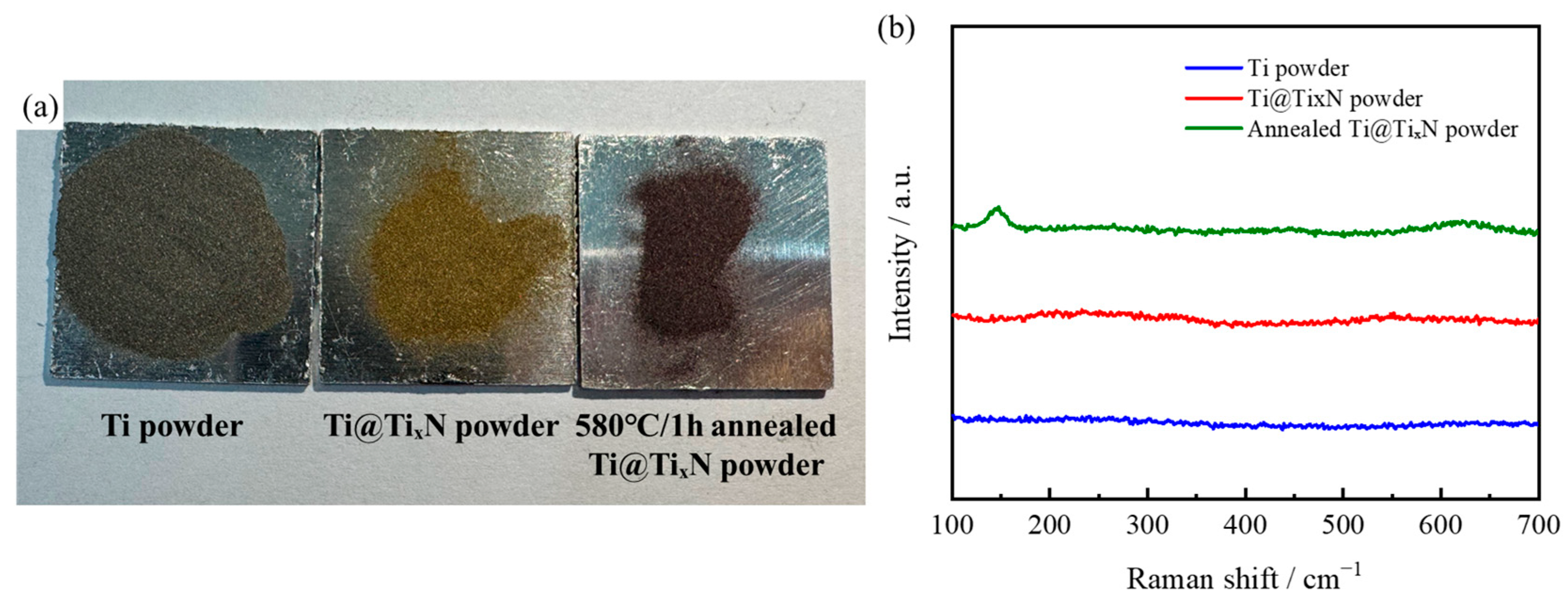

3.1. Morphology and Phase Composition of Powders

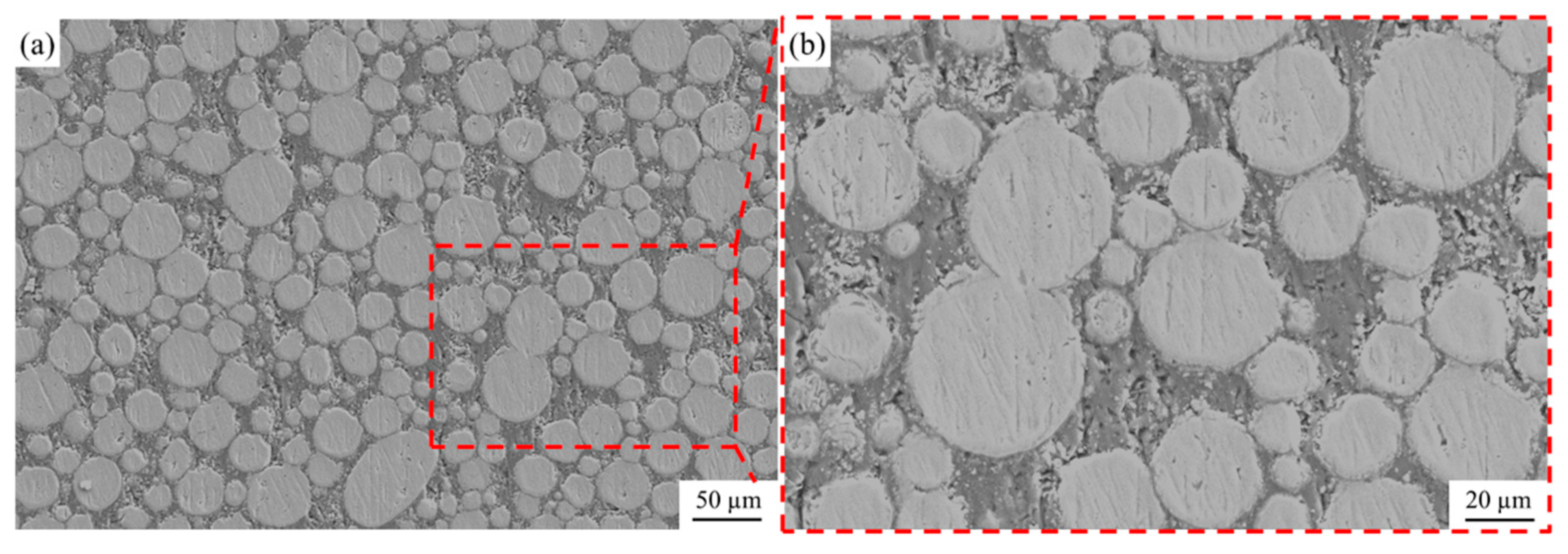

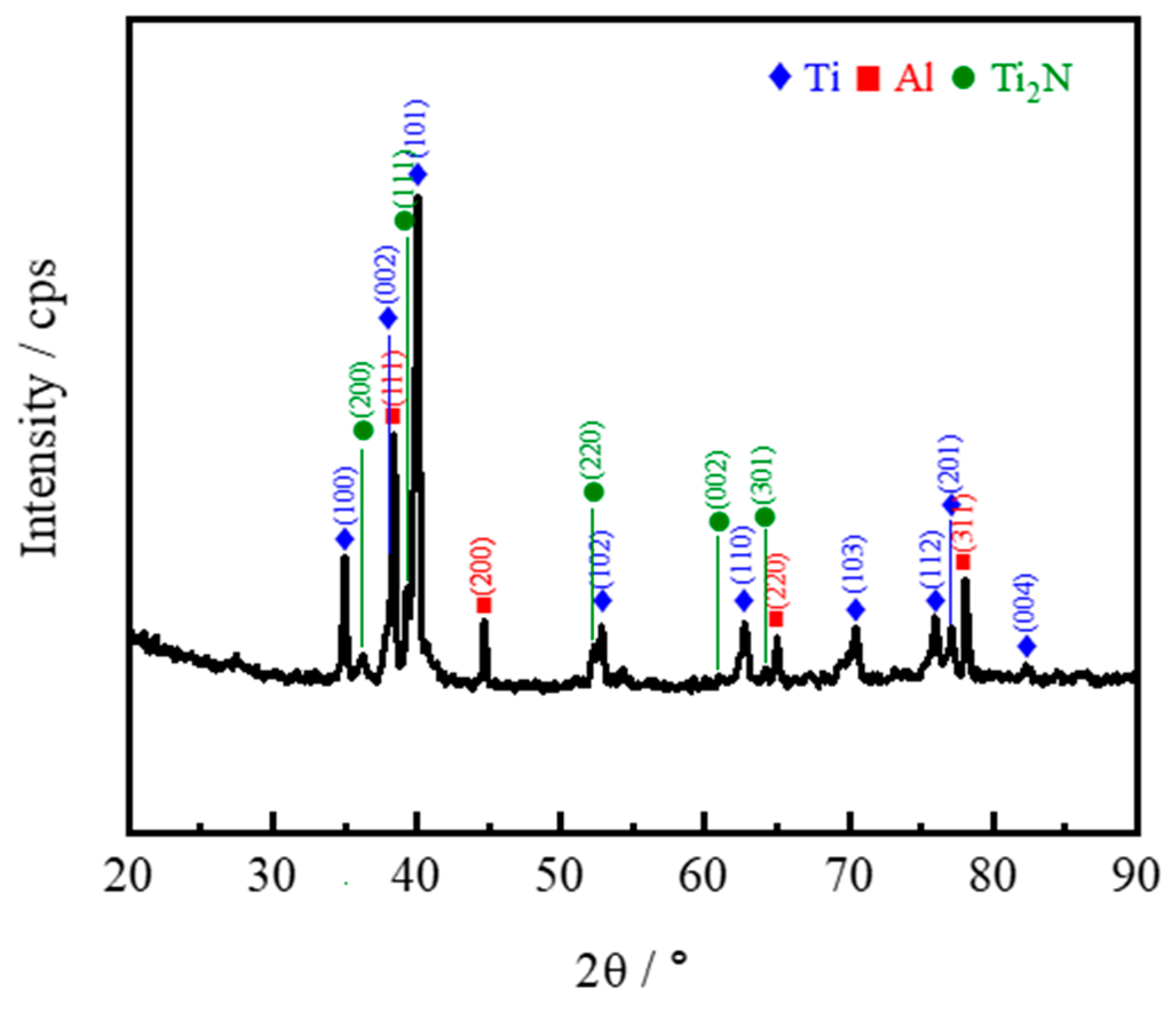

3.2. Morphology and Phase Composition of Composite

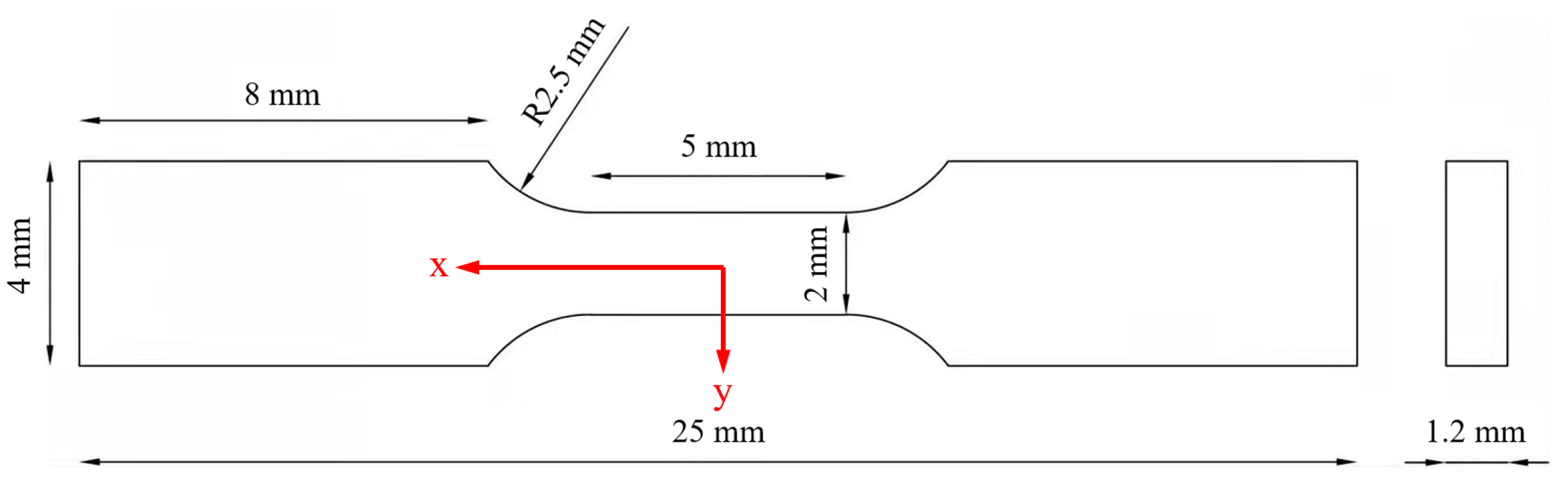

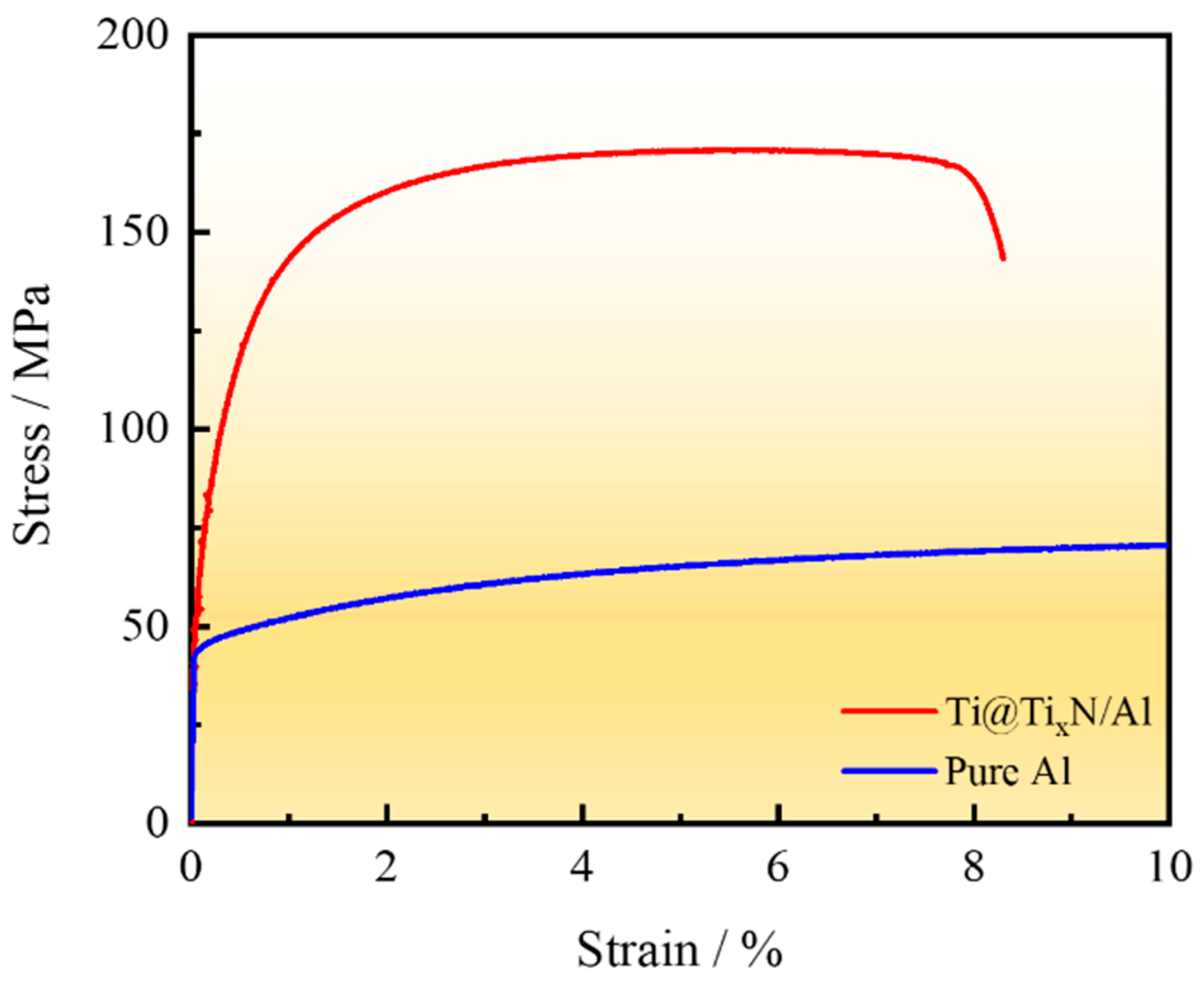

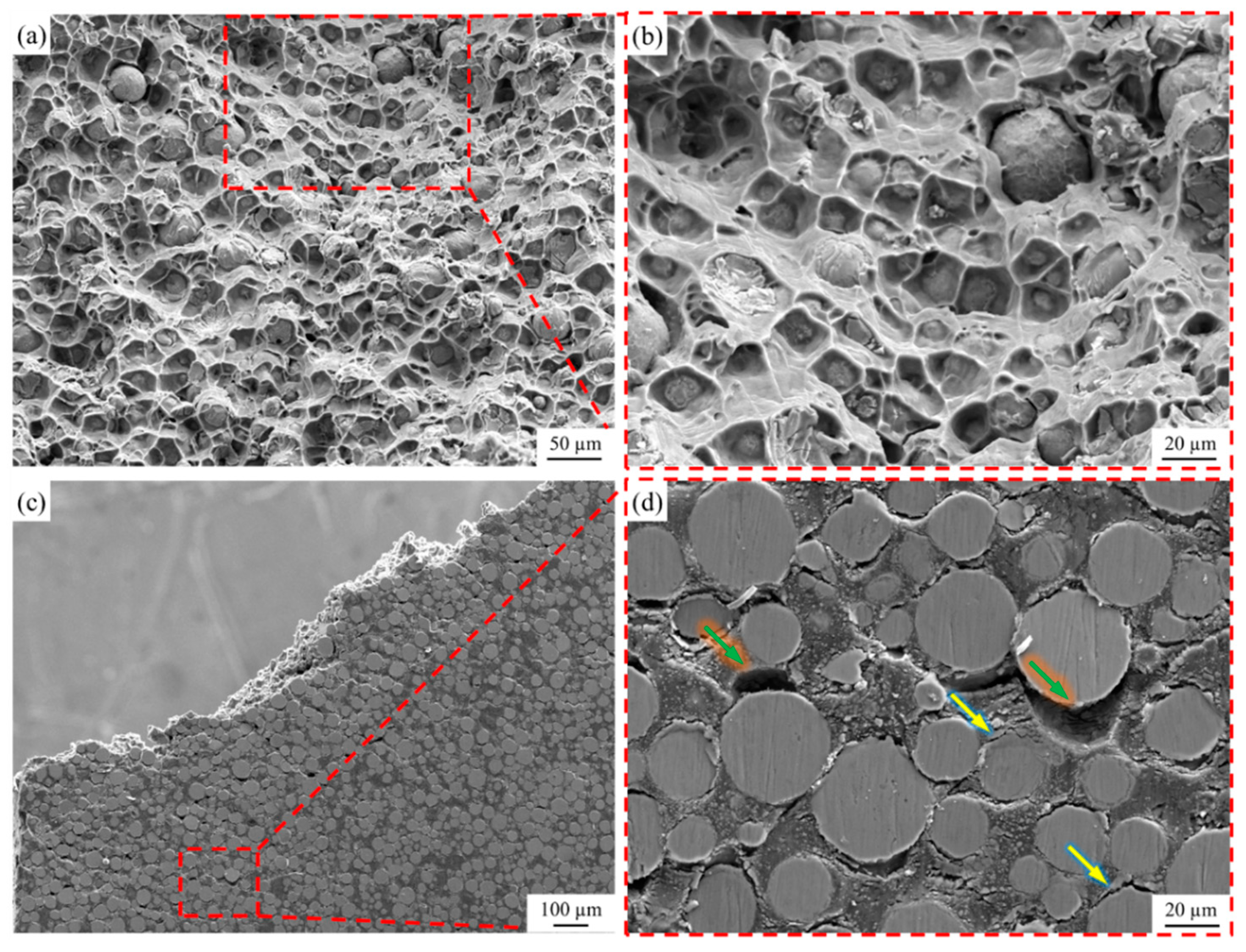

3.3. Mechanical Properties and Fracture Analysis

4. Conclusions

- 1.

- The TixN shell formed by the reaction between N2 gas and Ti powder consists of TiN and Ti2N, with TiN in the outer layer and Ti2N in the inner layer.

- 2.

- The TixN shell prevented the reaction between Ti and Al, and no intermediate phases of Ti and Al were observed in the composite.

- 3.

- The tensile strength, yield strength, and elongation of the Ti@TixN/Al composite are 173 ± 7.7 MPa, 115 ± 8.1 MPa, and 7.5 ± 0.55%, respectively, with a hardness of 71.6 ± 8.4 HB. Compared to the pure Al matrix, these properties are significantly improved, and the Ti@TixN reinforcement played a certain load-bearing role.

- 4.

- The fracture mode of the Ti@TixN/Al composite is primarily interfacial debonding, while the plasticity of pure Al maintained the overall plasticity of the composite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, L.M.; Zhang, J.F.; Liu, Z.Y.; Liu, X.L.; Xiao, B.L.; Ma, Z.Y. Mechanical behavior analysis on SiC/Al composites via in-situ neutron diffraction combined with finite element methods. Mater. Sci. Eng. A 2024, 912, 147003. [Google Scholar] [CrossRef]

- Ma, G.; Zhu, S.; Wang, D.; Xue, P.; Xiao, B.; Ma, Z. Effect of heat treatment on the microstructure, mechanical properties and fracture behaviors of ultra-high-strength SiC/Al–Zn–Mg–Cu composites. Int. J. Min. Met. Mater. 2024, 31, 2233–2243. [Google Scholar] [CrossRef]

- Luan, B.F.; Qiu, R.S.; Li, C.H.; Yang, X.F.; Li, Z.Q.; Zhang, D.; Liu, Q. Hot deformation and processing maps of Al2O3/Al composites fabricated by flake powder metallurgy. Trans. Nonferrous Met. Soc. China 2015, 25, 1056–1063. [Google Scholar] [CrossRef]

- Zaiemyekeh, Z.; Liaghat, G.H.; Ahmadi, H.; Khan, M.K.; Razmkhah, O. Effect of strain rate on deformation behavior of aluminum matrix composites with Al2O3 nanoparticles. Mater. Sci. Eng. A 2019, 753, 276–284. [Google Scholar] [CrossRef]

- Xue, W.; Chao, Z.; Han, H.; Zhao, Q.; Han, B.; Du, S.; Kang, P.; Mei, Y.; Jiang, L. Research on low flow stress and quantitative DRX analysis in B4C/Al composites with interfacial amorphous B2O3 layer. Compos. Part B-Eng. 2024, 272, 111226. [Google Scholar] [CrossRef]

- Lii, D.; Huang, J.; Chang, S. The mechanical properties of AlN/Al composites manufactured by squeeze casting. J. Eur. Ceram. Soc. 2002, 22, 253–261. [Google Scholar] [CrossRef]

- Gong, D.; Zhu, M.; You, Z.; Han, H.; Chao, Z.; Jiang, L. In-situ TEM study on the effect of stacking faults on micro-plasticity and proportional limit in SiC/Al composites. Compos. Part B-Eng. 2022, 244, 110180. [Google Scholar] [CrossRef]

- Xie, M.S.; Suryanarayana, C.; Zhao, Y.L.; Zhang, W.W.; Yang, C.; Zhang, G.Q.; Fu, Y.N.; Wang, Z. Abnormal hot deformation behavior in a metallic-glass-reinforced Al-7075 composite. Mater. Sci. Eng. A 2020, 785, 139212. [Google Scholar] [CrossRef]

- Wang, Y.B.; Jiang, H.J.; Liu, C.Y.; Huang, H.F.; Qin, F.C. Influence of Al particle layer on damping behavior of Alp/7075Al composites fabricated by hot rolling. J. Alloys Compd. 2021, 882, 160763. [Google Scholar] [CrossRef]

- Xu, K.; Russell, A.M.; Chumbley, L.S.; Laabs, F.C.; Gantovnik, V.B.; Tian, Y. Characterization of strength and microstructure in deformation processed Al-Mg composites. J. Mater. Sci. 1999, 34, 5955–5959. [Google Scholar] [CrossRef]

- Xie, Y.; Yin, Y.J.; Wang, D.X.; Li, J.Y.; Ji, X.Y.; Li, W.; Shen, X.; Fu, W.; Zhou, J.X. High ductility of Be-Al alloy fabricated by investment casting. J. Mater. Res. Technol. 2024, 29, 789–802. [Google Scholar] [CrossRef]

- Nardone, V.C.; Garosshen, T.J. Evaluation of the tensile and fatigue behaviour of ingot metallurgy beryllium/aluminium alloys. J. Mater. Sci. 1997, 32, 3975–3985. [Google Scholar] [CrossRef]

- Tian, L.; Russell, A.; Riedemann, T.; Mueller, S.; Anderson, I. A deformation-processed Al-matrix/Ca-nanofilamentary composite with low density, high strength, and high conductivity. Mater. Sci. Eng. A 2017, 690, 348–354. [Google Scholar] [CrossRef]

- Wriedt, H.A.; Murray, J.L. The N-Ti (Nitrogen-Titanium) system. Bull. Alloy Phase Diagr. 1987, 8, 378–388. [Google Scholar] [CrossRef]

- Hwang, Y.-H.; Lin, C.-I. Preparation of Titanium Nitride from Direct Nitridation of Titanium. J. Chem. Eng. Jpn. 1998, 31, 214–219. [Google Scholar] [CrossRef]

- Eslamloo-Grami, M.; Munir, Z.A. Effect of Porosity on the Combustion Synthesis of Titanium Nitride. J. Am. Ceram. Soc. 1990, 73, 1235–1239. [Google Scholar] [CrossRef]

- Zhang, F.; Kaczmarek, W.A.; Lu, L.; Lai, M.O. Formation of titanium nitrides via wet reaction ball milling. J. Alloys Compd. 2000, 307, 249–253. [Google Scholar] [CrossRef]

- Shimada, S.; Hasegawa, M. Preparation of Titanium Nitride Films from Amide Precursors Synthesized by Electrolysis. J. Am. Ceram. Soc. 2003, 86, 177–179. [Google Scholar] [CrossRef]

- Trenczek-Zajac, A.; Kowalski, K.; Zakrzewska, K.; Radecka, M. Nitrogen-doped titanium dioxide—Characterization of structural and optical properties. Mater. Res. Bull. 2009, 44, 1547–1552. [Google Scholar] [CrossRef]

- Chen, H.; Lu, F. Oxidation behavior of titanium nitride films. J. Vac. Sci. Technol. A 2005, 23, 1006–1009. [Google Scholar] [CrossRef]

- Hou, X.-M.; Hu, X.-J.; Chou, K.-C. Kinetics of Thermal Oxidation of Titanium Nitride Powder at Different Oxidizing Atmospheres. J. Am. Ceram. Soc. 2011, 94, 570–575. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y.; Liu, X. Enhancing interface bonding strength of Ti/Al laminated composites via periodic surface nano-crystallization pretreatment. Mater. Sci. Eng. A 2024, 901, 146560. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, C.; Liu, Z.; Meng, Z.; Yan, J.; Chen, L.; Zhao, G. Novel interface characteristics and strengthening mechanisms in extruded fiber(Ti)-reinforced Al-based composites. J. Mater. Process. Technol. 2024, 325, 118304. [Google Scholar] [CrossRef]

- Huang, T.; Song, Z.; Chen, F.; Guo, J.; Pei, Y.; Xing, B.; Xiang, N.; Song, K. Influence of the Anisotropy on the Microstructure and Mechanical Properties of Ti/Al Laminated Composites. Materials 2020, 13, 3556. [Google Scholar] [CrossRef]

- Park, K.; Kim, D.; Kim, K.; Cho, S.; Kwon, H. Behavior of Intermetallic Compounds of Al-Ti Composite Manufactured by Spark Plasma Sintering. Materials 2019, 12, 331. [Google Scholar] [CrossRef]

- Tian, Y.; Shen, J.; Hu, S.; Gou, J.; Cui, Y. Effects of cold metal transfer mode on the reaction layer of wire and arc additive-manufactured Ti-6Al-4V/Al-6.25Cu dissimilar alloys. J. Mater. Sci. Technol. 2021, 74, 35–45. [Google Scholar] [CrossRef]

- Wang, P.; Chen, Z.; Hu, C.; Li, B.; Lin, J.; Liu, Q. Effects of annealing on the interface microstructures and mechanical properties of hot roll bonded Ti6Al4V/AA6061 clad sheets. J. Mater. Res. Technol. 2020, 9, 11813–11825. [Google Scholar] [CrossRef]

- Yu, M.; Zhao, H.; Jiang, Z.; Guo, F.; Zhou, L.; Song, X. Microstructure and mechanical properties of friction stir lap AA6061-Ti6Al4V welds. J. Mater. Process. Technol. 2019, 270, 274–284. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, C.; Meng, Z.; Liu, Z.; Chen, L.; Zhao, G. Enhancing strength and ductility of extruded Ti-alloy-reinforced Al-Mg-Si composites: Roles of interface nanostructures and chemical bonding. Int. J. Plast. 2024, 178, 104009. [Google Scholar] [CrossRef]

- Xiu, Z.Y.; Chen, G.Q.; Wang, M.; Hussain, M. Effect of TiN coating on microstructure of Tif/Al composite. Micron 2013, 45, 92–96. [Google Scholar] [CrossRef]

- Cheng, Y.; Wu, Z.; He, X.; Zhou, Y.; Xu, C.; Niu, Z.; Jiang, F.; Xu, C.; Wang, Z. In-situ study of tensile behavior of Ti/Al laminated metal composites fabricated via ultrasonic additive manufacturing. Compos. Commun. 2024, 51, 102095. [Google Scholar] [CrossRef]

- Cao, M.; Deng, K.; Nie, K.; Wang, C.; Wang, L.; Liang, W. Microstructure, mechanical properties and formability of Ti/Al/Ti laminated composites fabricated by hot-pressing. J. Manuf. Process. 2020, 58, 322–334. [Google Scholar] [CrossRef]

- Huang, M.; Xu, C.; Fan, G.; Maawad, E.; Gan, W.; Geng, L.; Lin, F.; Tang, G.; Wu, H.; Du, Y.; et al. Role of layered structure in ductility improvement of layered Ti-Al metal composite. Acta Mater. 2018, 153, 235–249. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhang, W. Analysis on the mechanism of titanium plate pretreated by ultrasonic shot peening in improving interfacial shear strength of Ti/Al laminated composite. Mater. Sci. Eng. A 2024, 917, 147393. [Google Scholar] [CrossRef]

- Li, X.; Sun, H.; Fang, W.; Ding, Y. Structure and morphology of Ti-Al composite powders treated by mechanical alloying. Trans. Nonferrous Met. Soc. China 2011, 21, s338–s341. [Google Scholar] [CrossRef]

- Fang, W.; Li, X.; Sun, H.; Ding, Y. Characterization of Ti-50%Al composite powder synthesized by high energy ball milling. Trans. Nonferrous Met. Soc. China 2011, 21, s333–s337. [Google Scholar] [CrossRef]

- Zhou, C.; Zhou, Y.; Zhang, Q.; Meng, Q.; Zhang, L.; Kobayashi, E.; Wu, G. Near-zero thermal expansion of ZrW2O8/Al–Si composites with three dimensional interpenetrating network structure. Compos. Part B-Eng. 2021, 211, 108678. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, Y.; Sun, K.; Zhang, Q.; Zhou, C.; Shao, P.; Xiu, Z.; Wu, G. Enhanced ductility of Ti3AlC2 particles reinforced pure aluminum composites by interface control. Mater. Sci. Eng. A 2022, 832, 142393. [Google Scholar] [CrossRef]

- Xue, W.; Jiang, L.; Kang, P.; Yang, W.; Zhao, Q.; Xu, Z.; Zhang, N.; Liu, H.; Wu, G. Design and fabrication of a nanoamorphous interface layer in B4C/Al composites to improve hot deformability and corrosion resistance. ACS Appl. Nano Mater. 2020, 3, 5752–5761. [Google Scholar] [CrossRef]

- Liu, H.; Kang, P.; Yang, W.; Zhang, N.; Sun, Y.; Wu, G. Ablation behavior of Al20Si/graphite composite nozzle-throats in a solid rocket motor environment. Ceram. Int. 2020, 46, 13317–13323. [Google Scholar] [CrossRef]

- Xiu, Z.; Ju, B.; Zhan, J.; Chen, W.; Yin, A.; Zhu, X.; Wang, P.; Wu, P.; Yang, W. Study on the Preparation of Network Ti-N/Ti Composites by Nitridation of Ti Powders. Materials 2023, 16, 5259. [Google Scholar] [CrossRef] [PubMed]

- Ramanavicius, S.; Jagminas, A. Synthesis, Characterisation, and Applications of TiO and Other Black Titania Nanostructures Species (Review). Crystals 2024, 14, 647. [Google Scholar] [CrossRef]

- Yadav, S.K.; Ramprasad, R.; Misra, A.; Liu, X.Y. First-principles study of shear behavior of Al, TiN, and coherent Al/TiN interfaces. J. Appl. Phys. 2012, 111, 083505. [Google Scholar] [CrossRef]

- Hou, C.; Zhang, S.; Ma, Z.; Lu, B.; Wang, Z. Effects of SiC Fibers and Laminated Structure on Mechanical Properties of Ti–Al Laminated Composites. Materials 2021, 14, 1323. [Google Scholar] [CrossRef]

- Yu, C.; He, Z.; Lv, Q.; Yu, J.; Xiao, H. Preparation of Ti/Al composite plates by differential temperature rolling with induction heating. Int. J. Adv. Manuf. Technol. 2021, 117, 383–394. [Google Scholar] [CrossRef]

| Material | Brinell Hardness/HB | Tensile Strength/MPa | Yield Strength/MPa | Elongation/% |

|---|---|---|---|---|

| Pure Al | 20.1 ± 0.2 | 74 | 44 | 38.7% |

| Ti@TixN/Al composite | 71.6 ± 8.4 | 173 ± 7.7 | 115 ± 8.1 | 7.5 ± 0.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, Y.; Sun, Z.; Zhu, P.; Hu, J.; Hao, L.; Liu, Y.; Ju, B.; Chen, G.; Yang, W. Study on Microstructure and Mechanical Properties of Core–Shell-Structured Ti@TixN Reinforced Al Composite Prepared by Pressure Infiltration. Materials 2025, 18, 1200. https://doi.org/10.3390/ma18061200

Xia Y, Sun Z, Zhu P, Hu J, Hao L, Liu Y, Ju B, Chen G, Yang W. Study on Microstructure and Mechanical Properties of Core–Shell-Structured Ti@TixN Reinforced Al Composite Prepared by Pressure Infiltration. Materials. 2025; 18(6):1200. https://doi.org/10.3390/ma18061200

Chicago/Turabian StyleXia, Yixiao, Zhiyu Sun, Ping Zhu, Juanrui Hu, Leilei Hao, Yun Liu, Boyu Ju, Guoqin Chen, and Wenshu Yang. 2025. "Study on Microstructure and Mechanical Properties of Core–Shell-Structured Ti@TixN Reinforced Al Composite Prepared by Pressure Infiltration" Materials 18, no. 6: 1200. https://doi.org/10.3390/ma18061200

APA StyleXia, Y., Sun, Z., Zhu, P., Hu, J., Hao, L., Liu, Y., Ju, B., Chen, G., & Yang, W. (2025). Study on Microstructure and Mechanical Properties of Core–Shell-Structured Ti@TixN Reinforced Al Composite Prepared by Pressure Infiltration. Materials, 18(6), 1200. https://doi.org/10.3390/ma18061200