Phase Change Materials in Residential Buildings: Challenges, Opportunities, and Performance

Abstract

1. Introduction

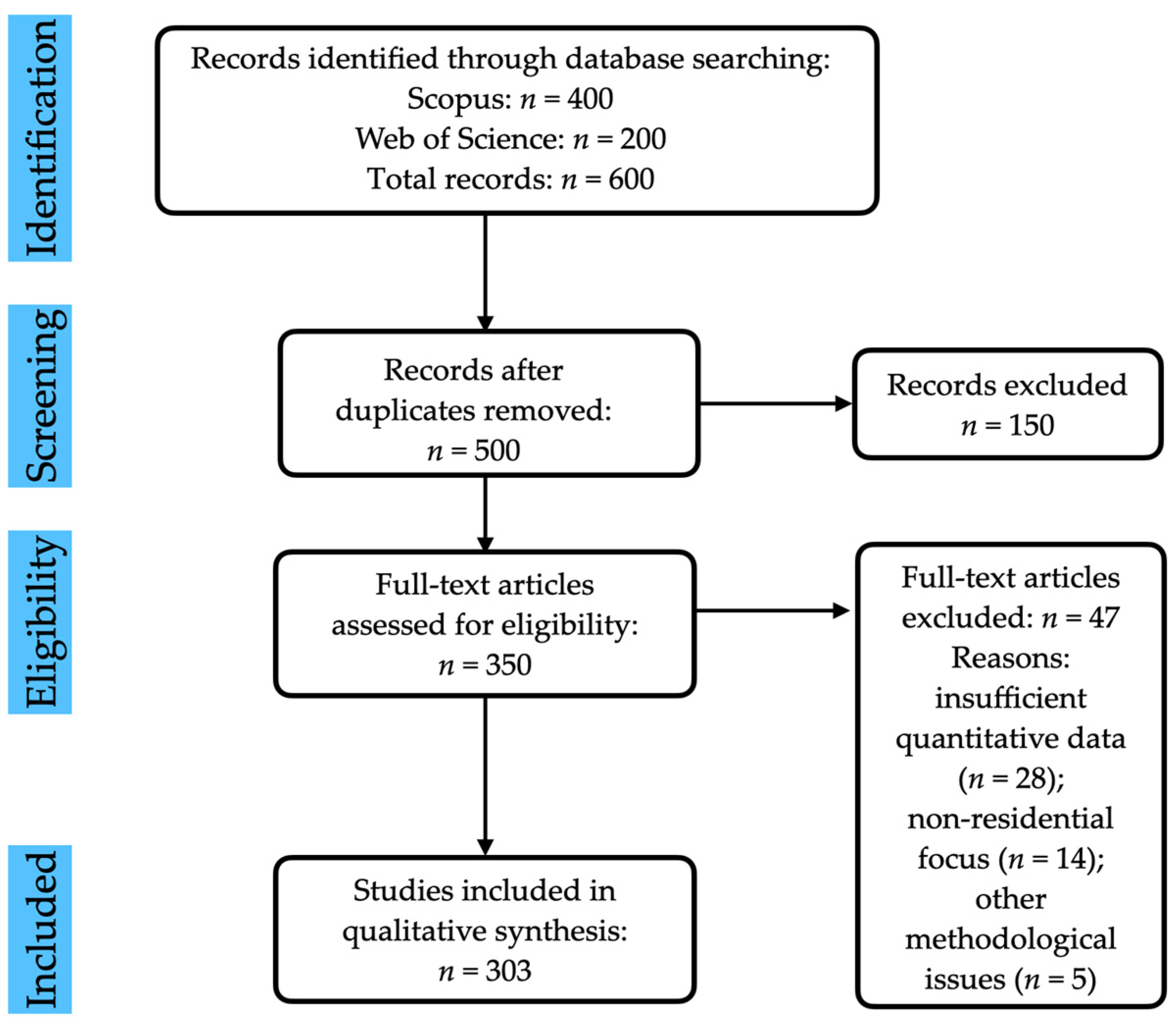

2. Methodology

2.1. Data Sources and Search Strategy

- Scopus: (“phase change material” OR “PCM”) AND (“residential building” OR “housing” OR “domestic building”) AND (“thermal performance” OR “energy efficiency” OR “thermal storage” OR “heat transfer” OR “encapsulation”).

- Web of Science: (“phase change material” OR PCM) AND (“residential building” OR housing OR “domestic building”) AND (“thermal performance” OR “energy efficiency” OR “thermal conductivity” OR “latent heat”).

2.2. Inclusion/Exclusion Criteria

- PCM integration into residential buildings in walls, ceilings, floors, and windows, among other elements.

- Thermal performance metrics exposing heat flux, thermal conductivity, latent heat, and indoor thermal comfort.

- Quantitative/qualitative data comparing PCM-integrated systems with traditional building materials.

- Publication in peer-reviewed journals or conference proceedings.

- The papers were excluded if they met the following criteria:

- They focused exclusively on industrial, commercial, or non-building applications of PCMs.

- They did not provide quantitative/qualitative data on PCM performance.

- They were not peer-reviewed, technical reports, or non-academic publications.

2.3. Study Selection Process

2.4. Data Extraction and Analysis

- PCM properties (e.g., phase transition temperature, latent heat, thermal conductivity).

- Types of building elements with PCM integration (walls, ceilings, floors, windows, among others).

- Thermal performance outcomes, including energy savings, temperature regulation, and indoor comfort improvement.

- Technical challenges, such as phase separation, low thermal conductivity, leakage, and overall investment cost.

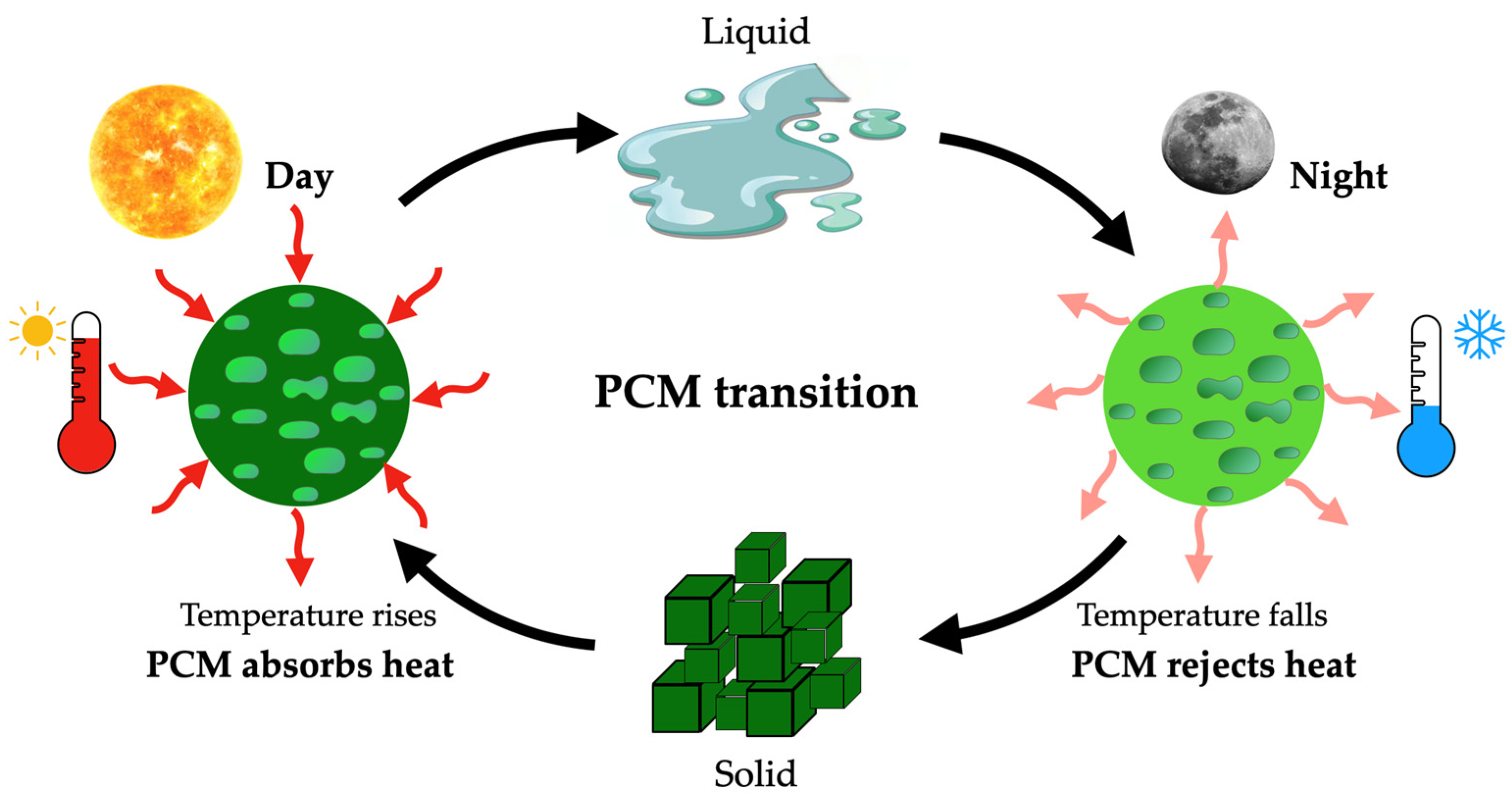

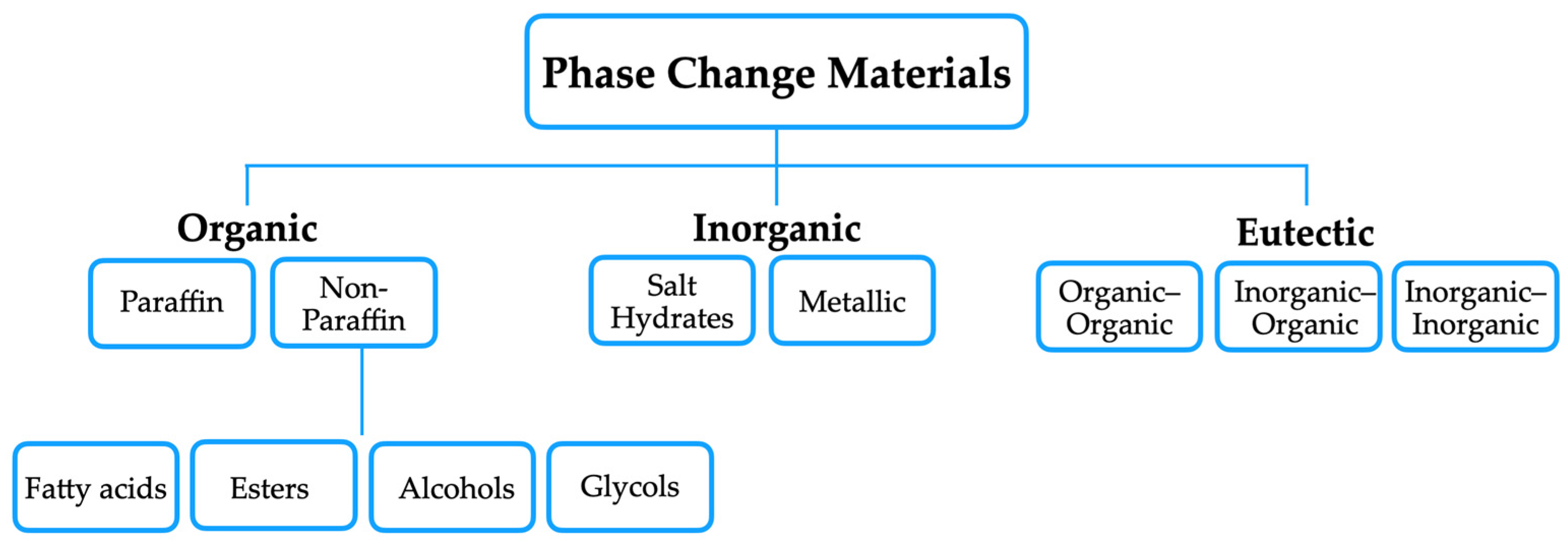

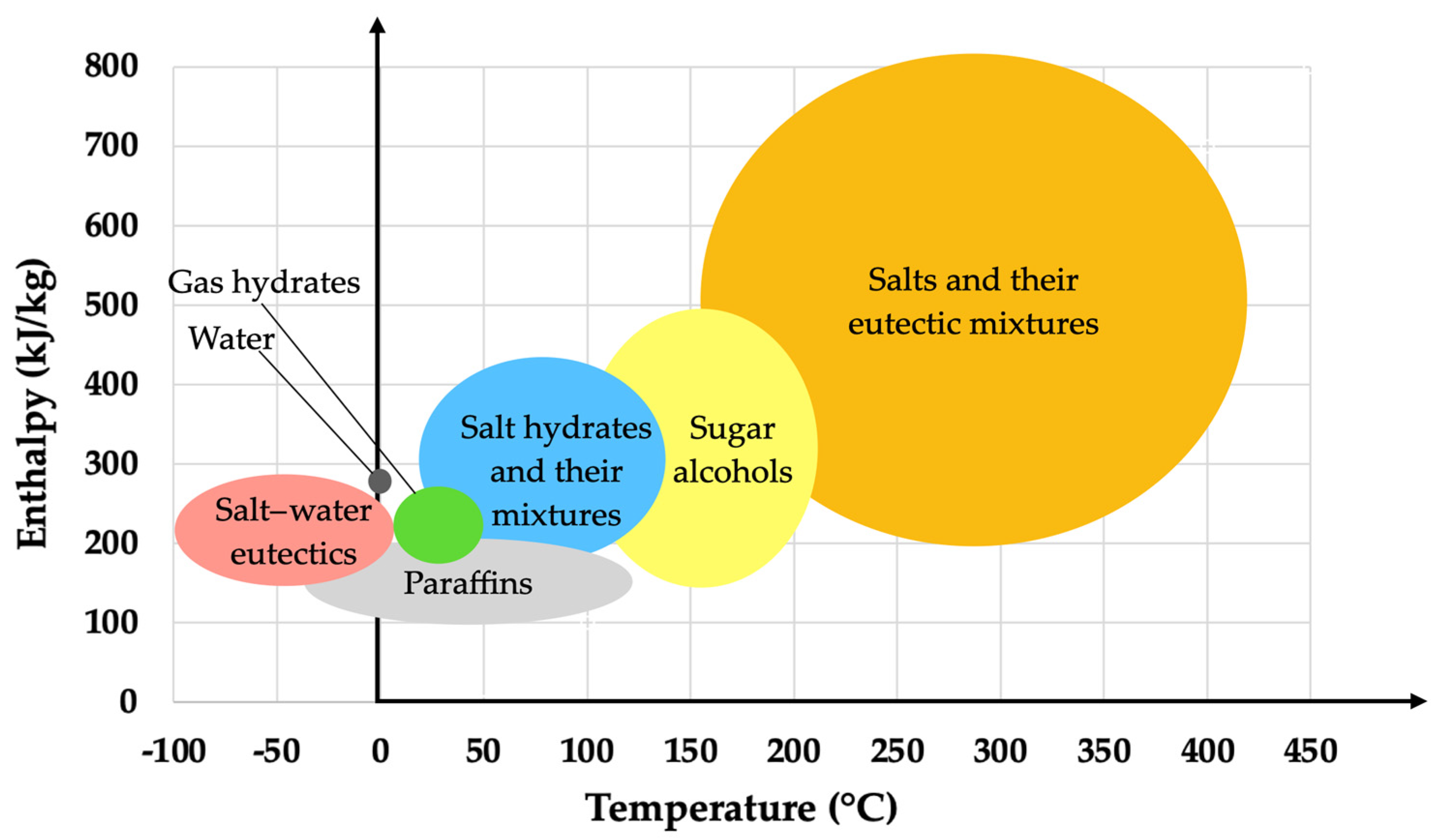

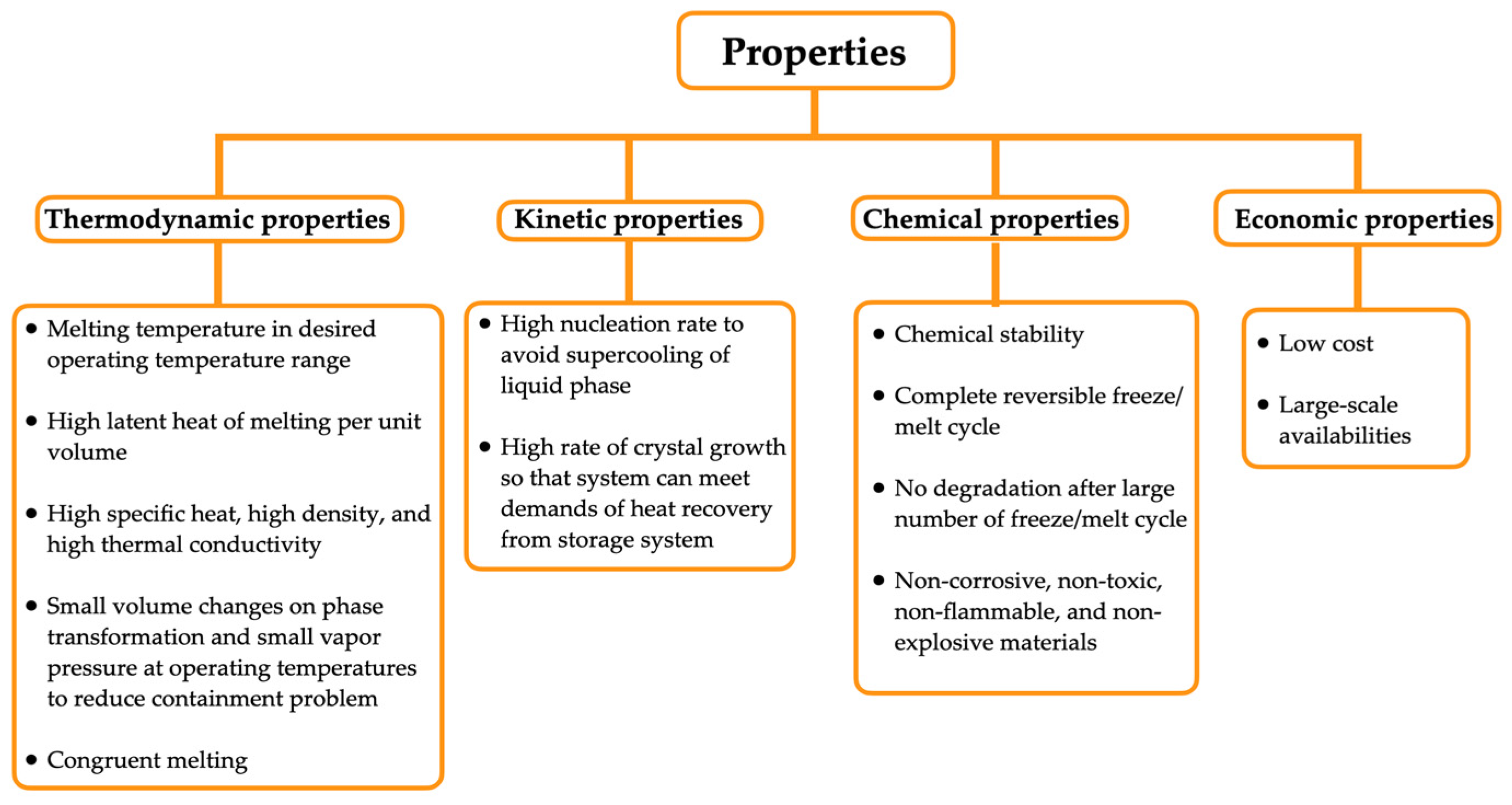

3. Properties and Types of PCMs

4. PCM Incorporation Methods

- (a)

- Direct incorporation.

- (b)

- Immersion.

- (c)

- Encapsulation (macroencapsulation, microencapsulation, nanoencapsulation).

- (d)

- Shape-stabilized PCM.

- (e)

- Form-stabilized PCM.

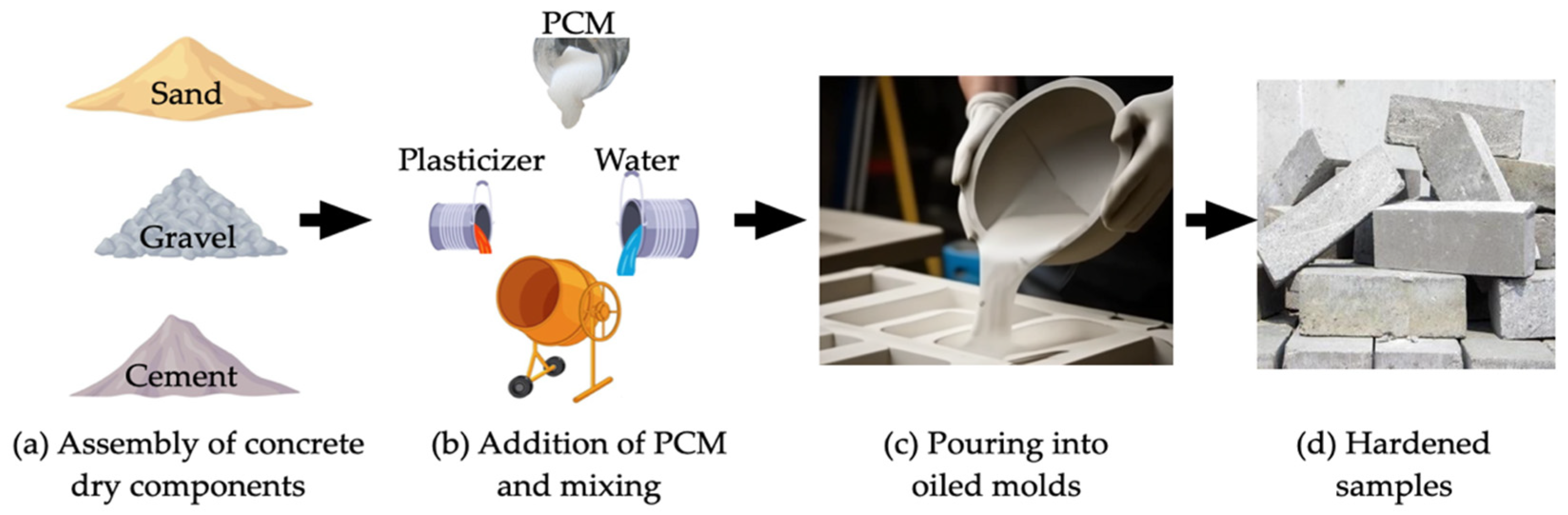

4.1. Direct Incorporation

4.2. Immersion

4.3. Encapsulation

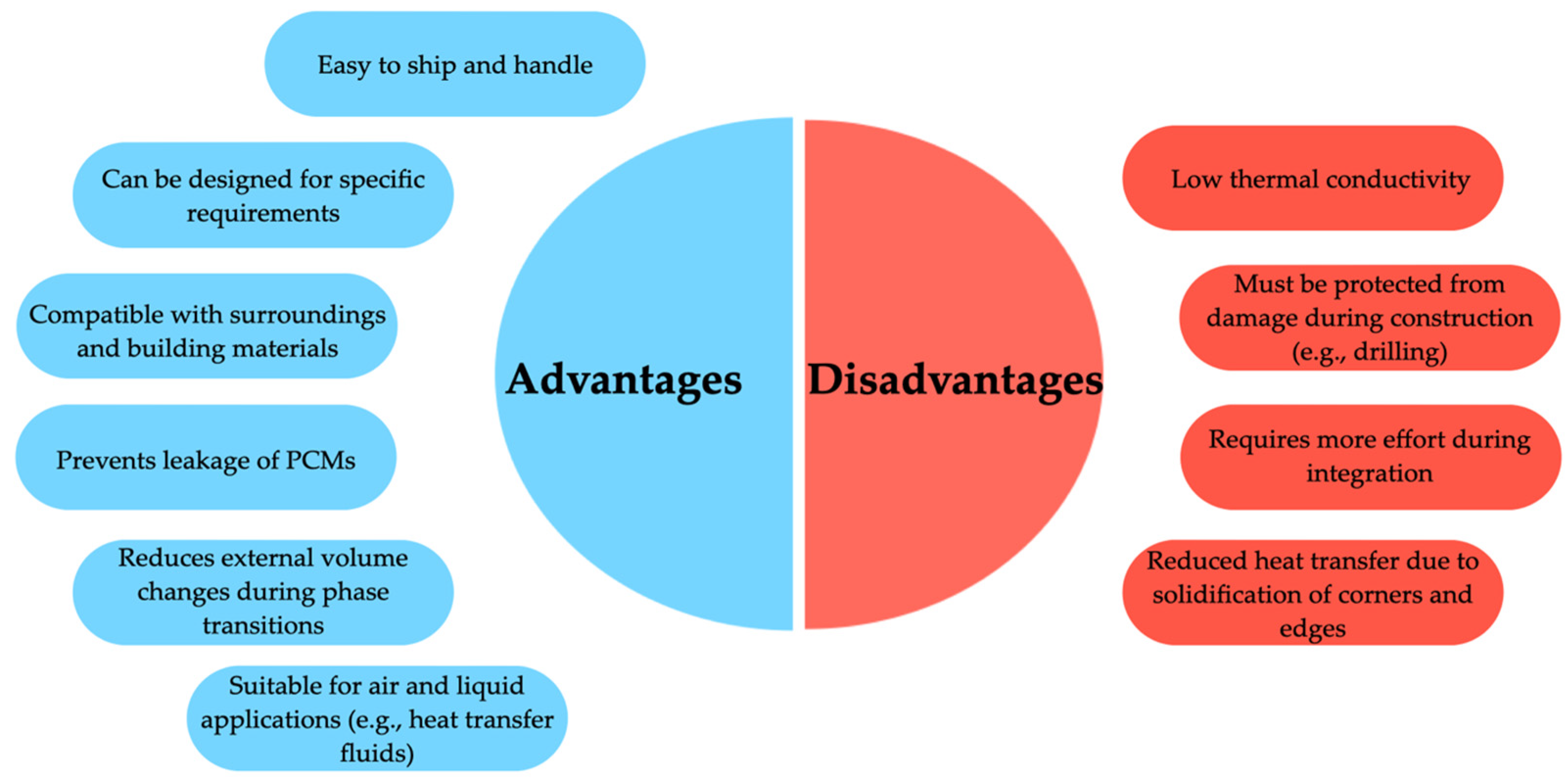

4.3.1. Macroencapsulation

4.3.2. Microencapsulation

- Suspension polymerization, where particle coalescence, break-up, secondary nucleation, and monomer diffusion collectively influence the morphology and surface characteristic of the microcapsules [66];

- Dispersion polymerization, which requires careful control of factors such as the initiator, monomer, stabilizer concentration, and reaction time to achieve desired particle properties.

- Physicochemical approaches, such as simple and complex coacervation, sol–gel encapsulation, and supercritical CO2-assisted techniques;

- Physicomechanical methods, including spray-drying, electrostatic encapsulation, and one-step processes.

4.3.3. Nanoencapsulation

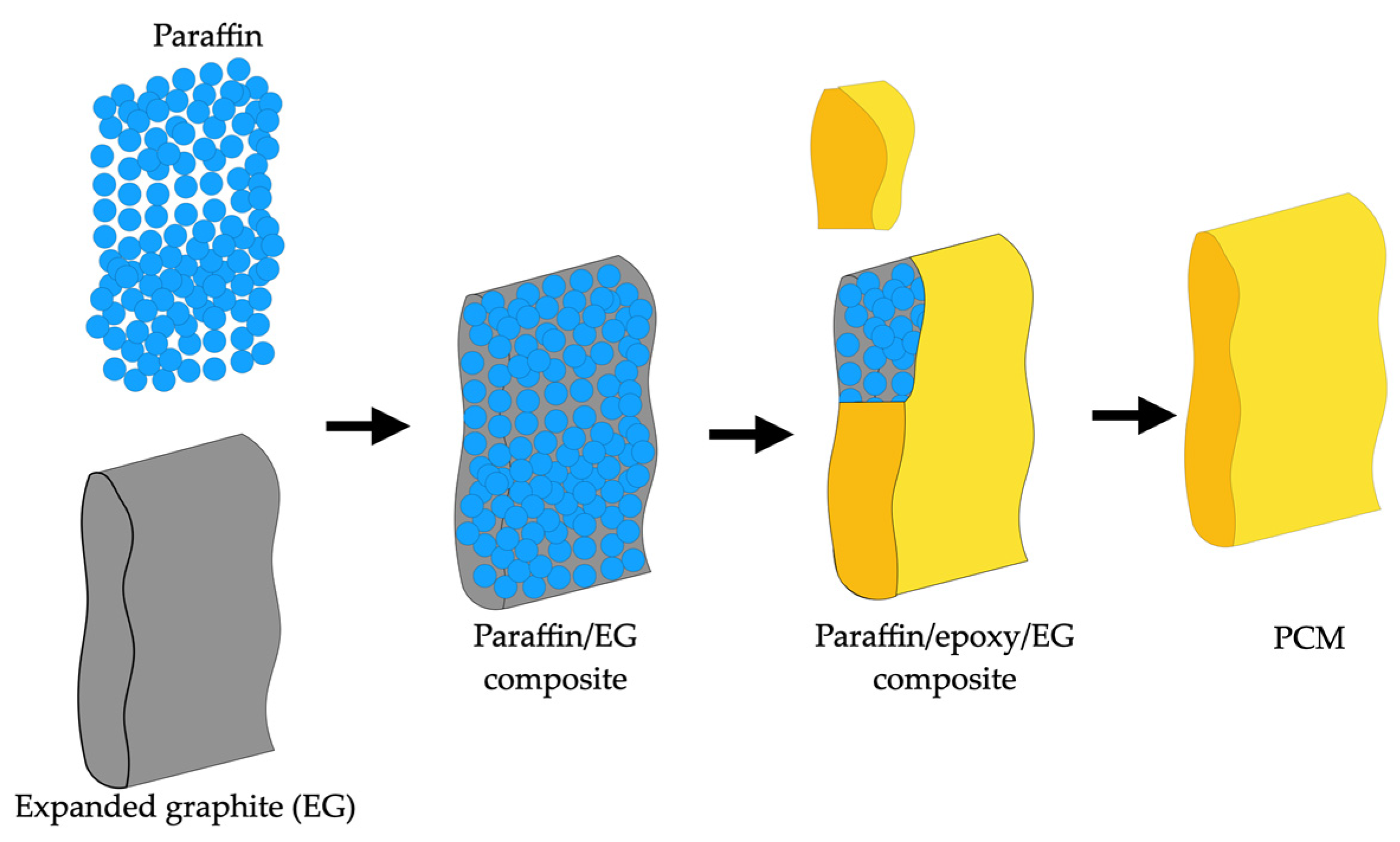

4.4. Shape-Stabilized PCM

- Elevated specific temperature.

- Satisfactory thermal conductivity capacity.

- Resistance to shape changes during phase transition.

- Stability in performance after extended periods of heat cycling.

- No need for packaging.

- Capability to be employed as internal linings in buildings.

- A PCM ratio reaching up to 80%.

- The prevention of leakage even when the material is exposed to temperatures above the PCM’s melting point.

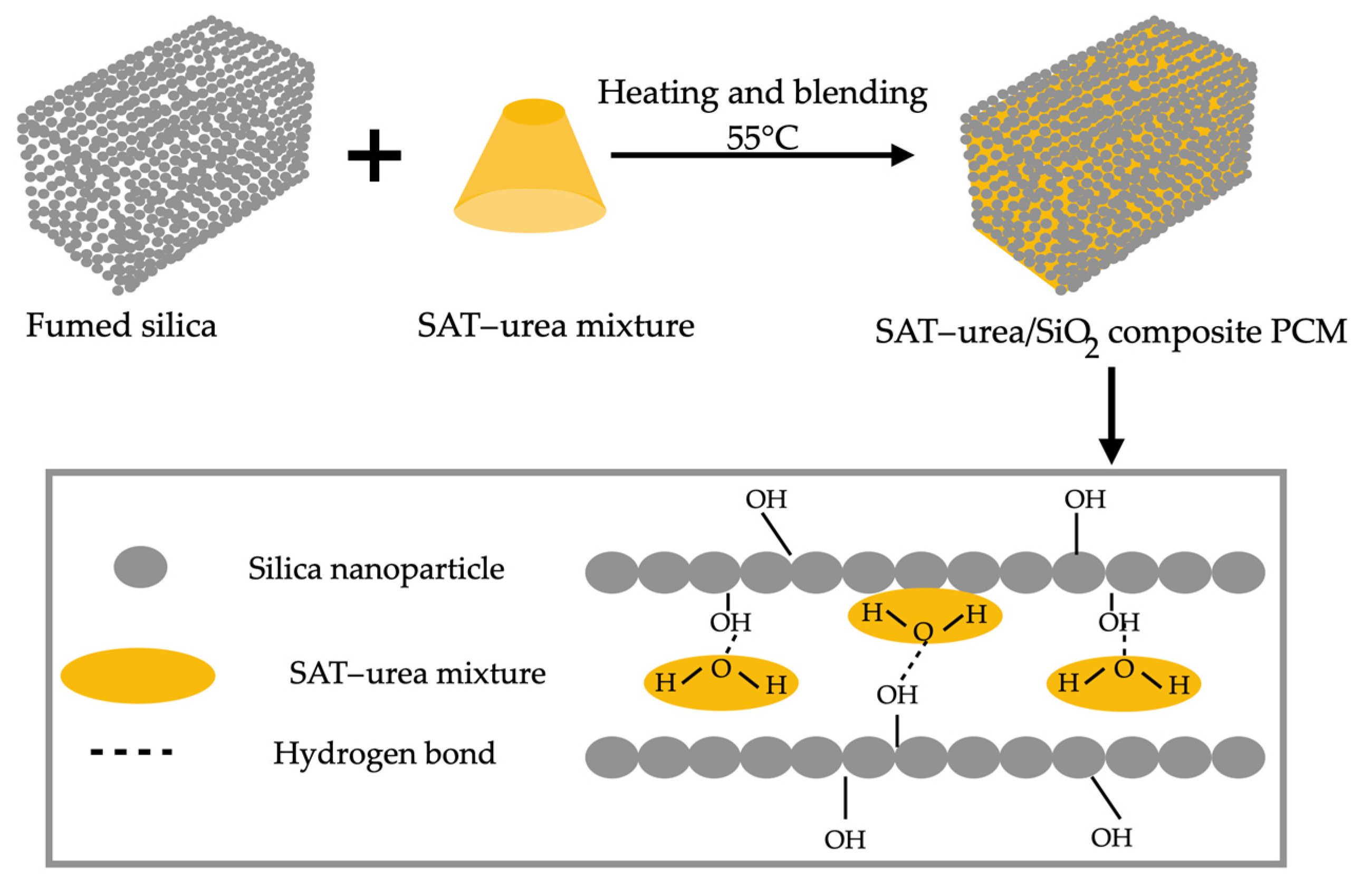

4.5. Form-Stabilized PCM

4.6. Encapsulation Performance Parameters

5. Nano-Enhanced PCM Composites

6. Economic Analysis of PCMs

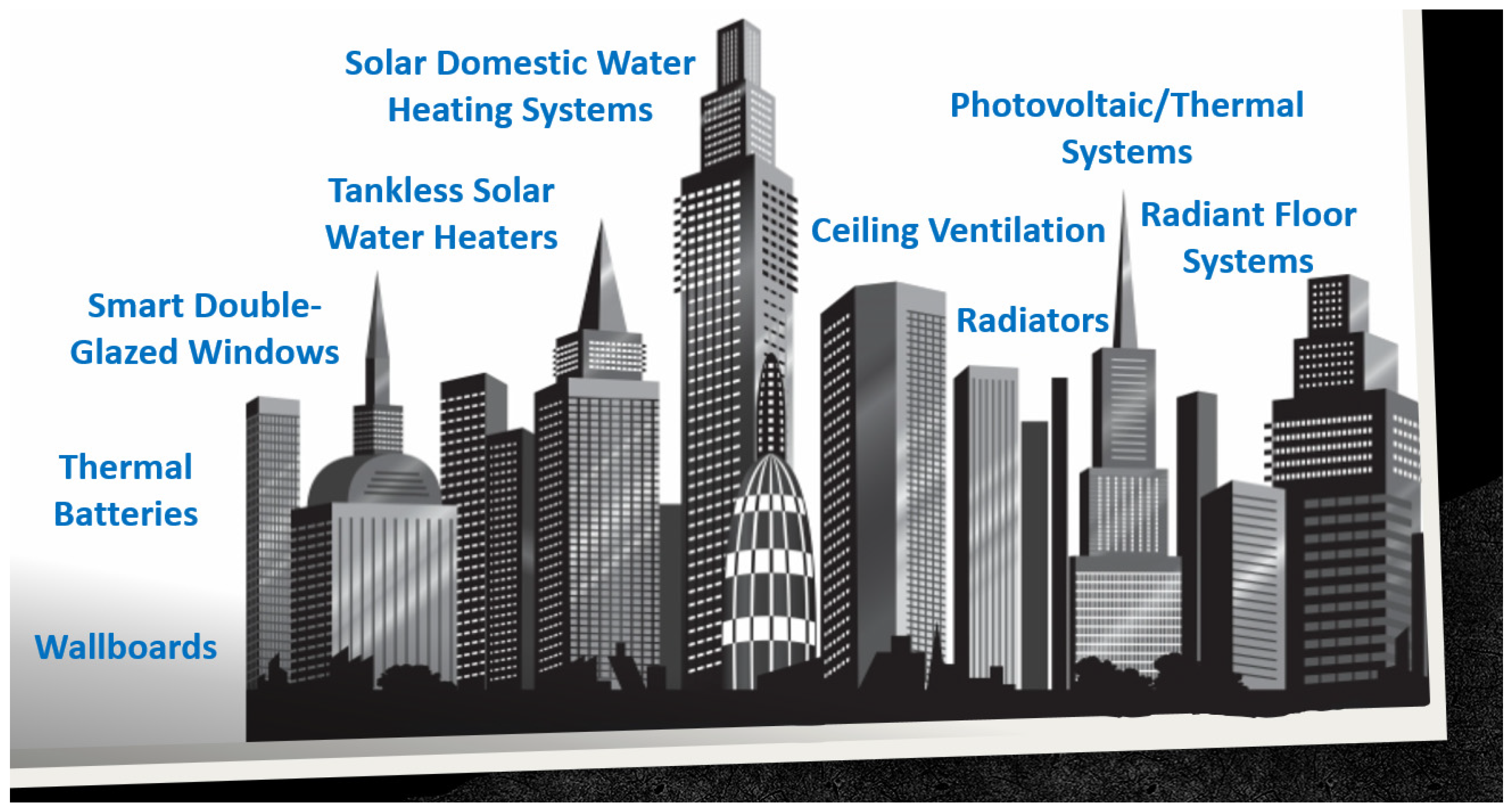

7. Applications for PCMs in Construction Materials

7.1. Background and Advances in PCM-Integrated Concrete

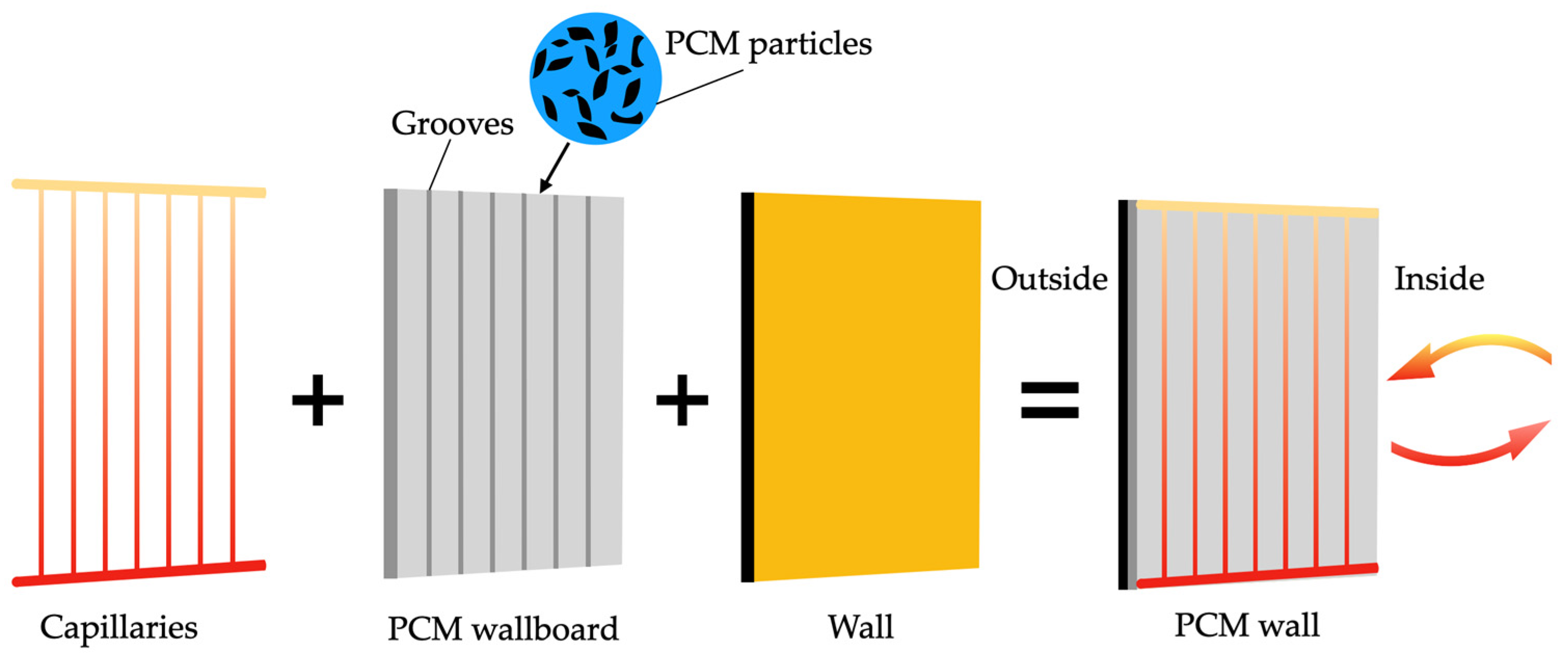

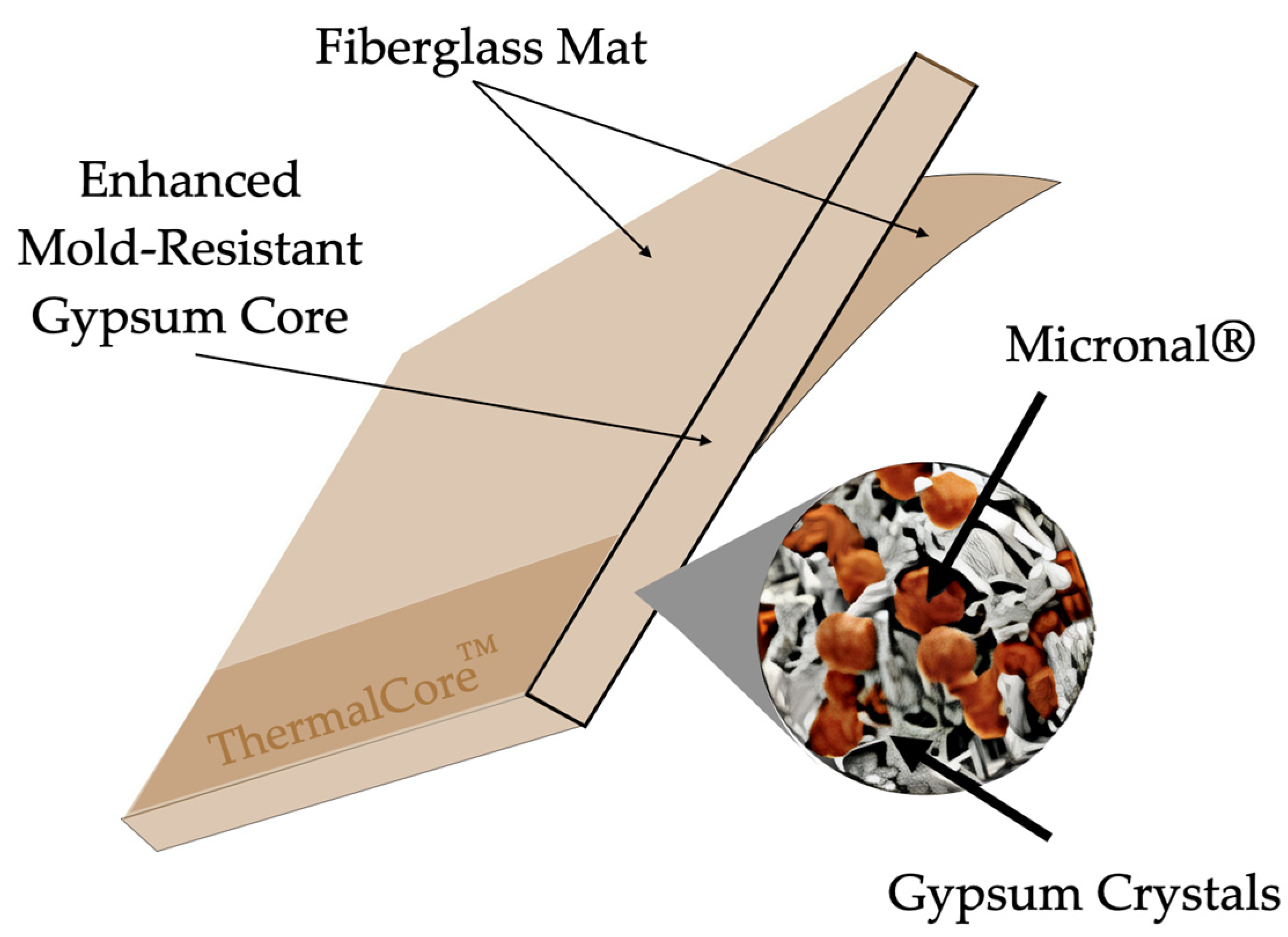

7.2. PCM in Wallboards

7.3. PCM in Bricks

8. Performance Parameters for PCMs in Buildings

8.1. Melting Temperature of PCMs

8.2. Thickness of PCMs

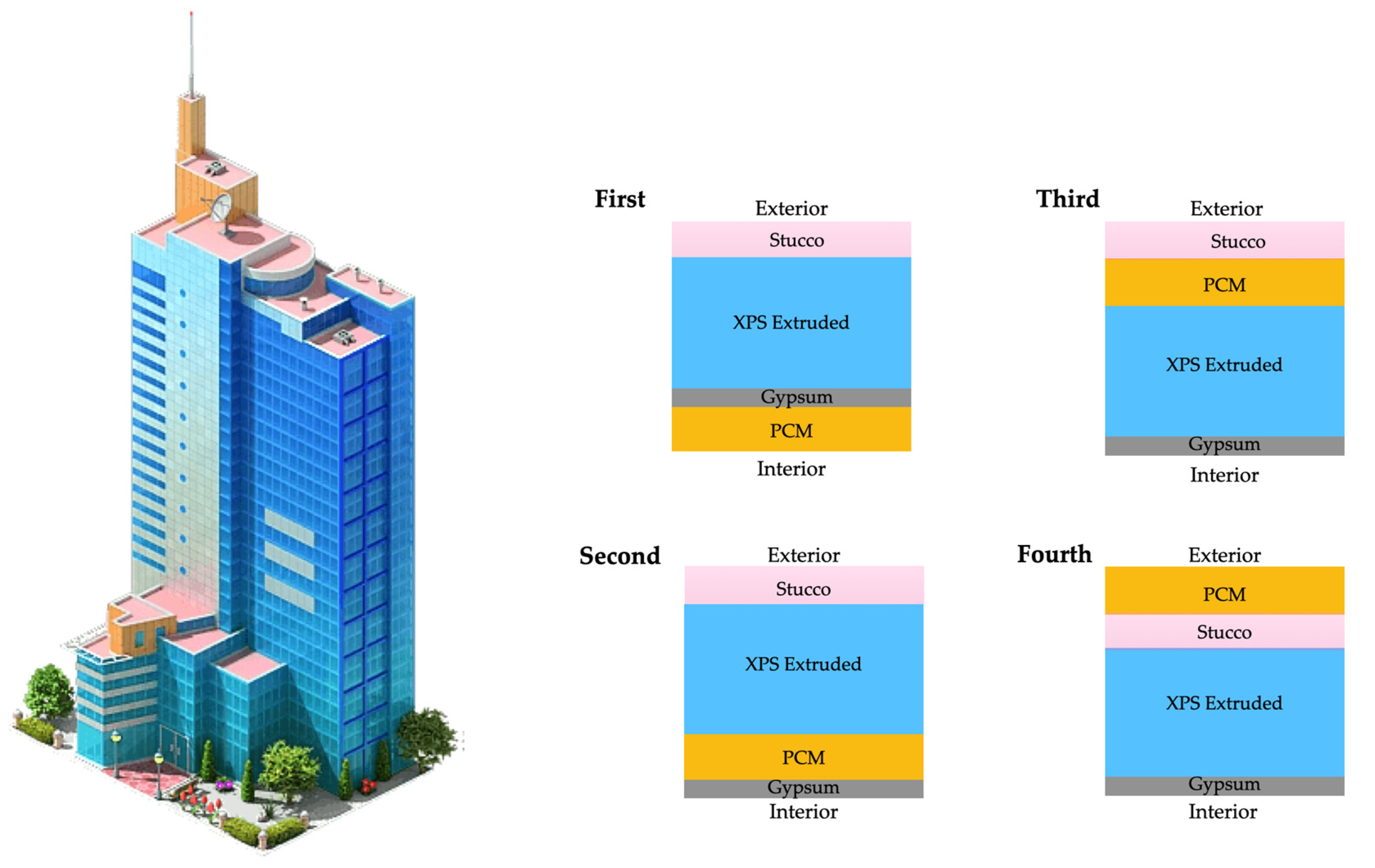

8.3. Positioning of PCMs

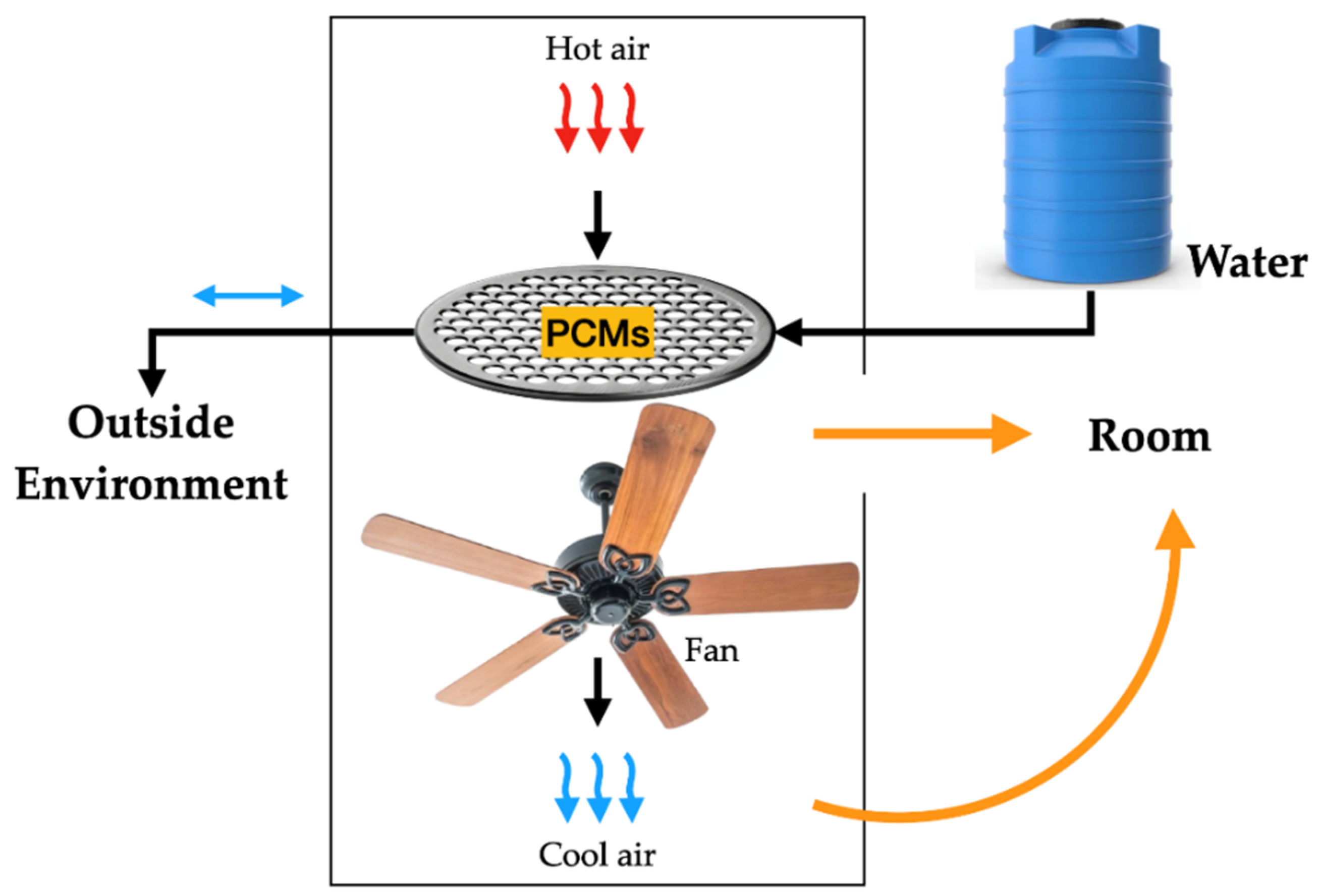

8.4. Heat Transfer Fluid

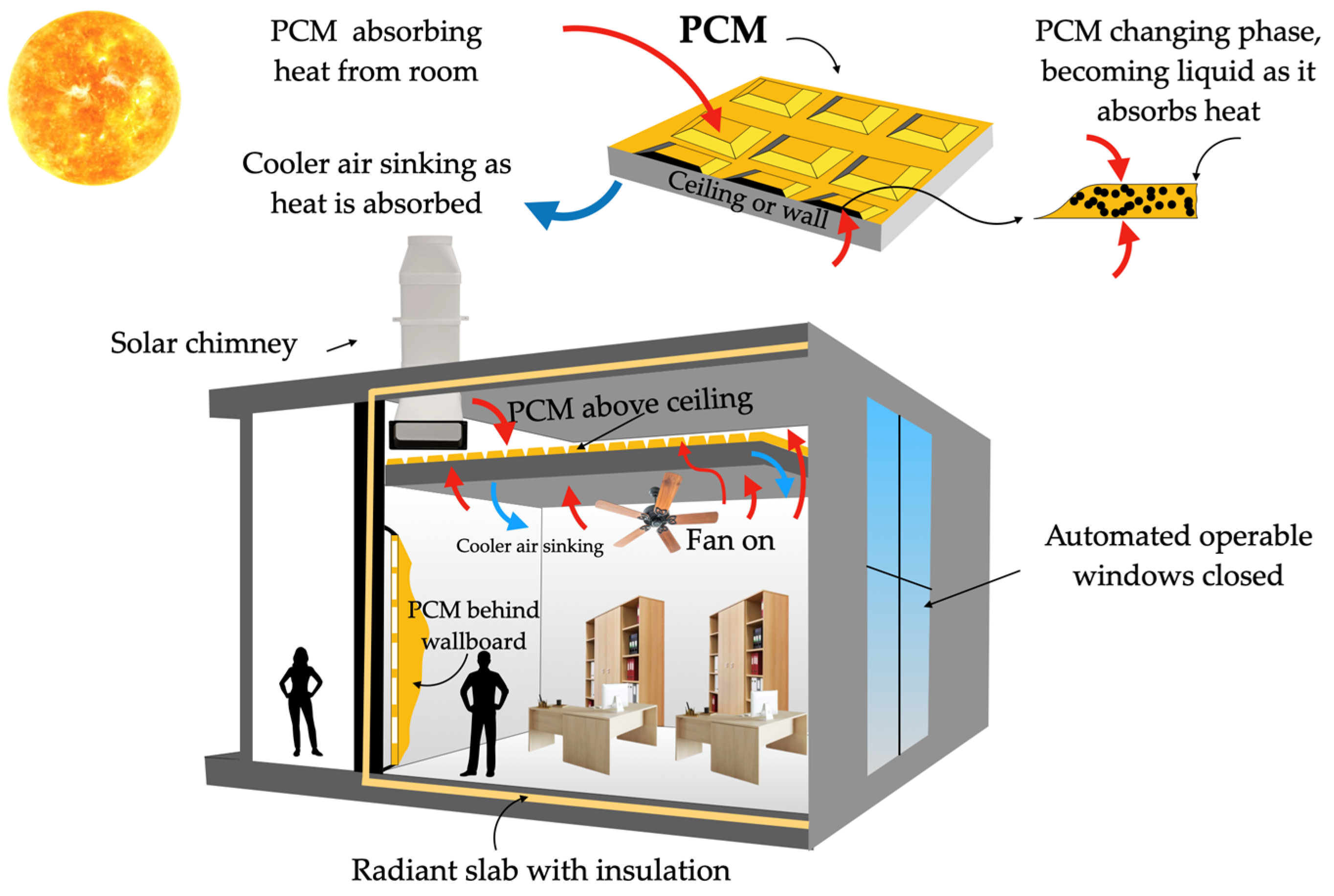

9. Applications for PCMs in Building Thermal Management

10. Energy Performance and Efficiency in Residential Buildings

11. Advances in PCM Integration in Buildings for Enhancing Thermal Comfort

11.1. Roofs

11.2. Ceilings

11.3. Walls

- Radiant Wall Integration:

- Multi-Layer Wall Systems:

- Numerical Simulations:

- PCM Placement and Performance:

- State-Space Model for PCM Walls:

- Shape-Stabilized PCM in Plaster:

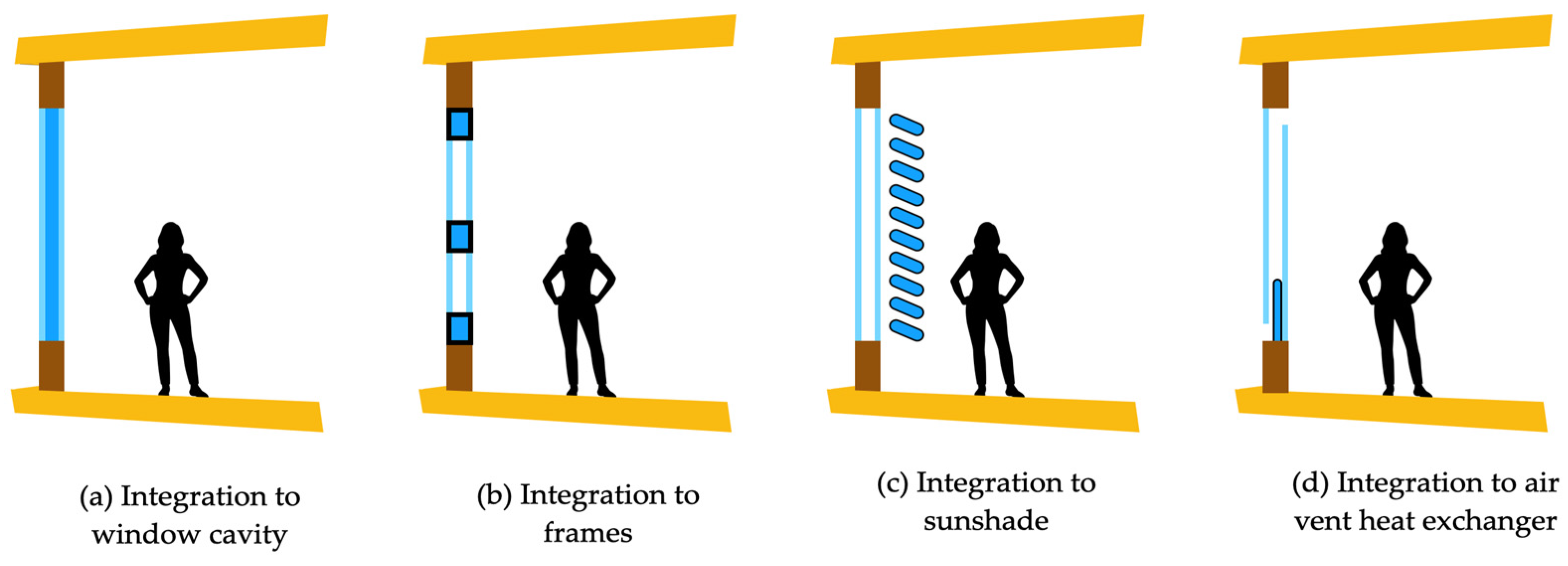

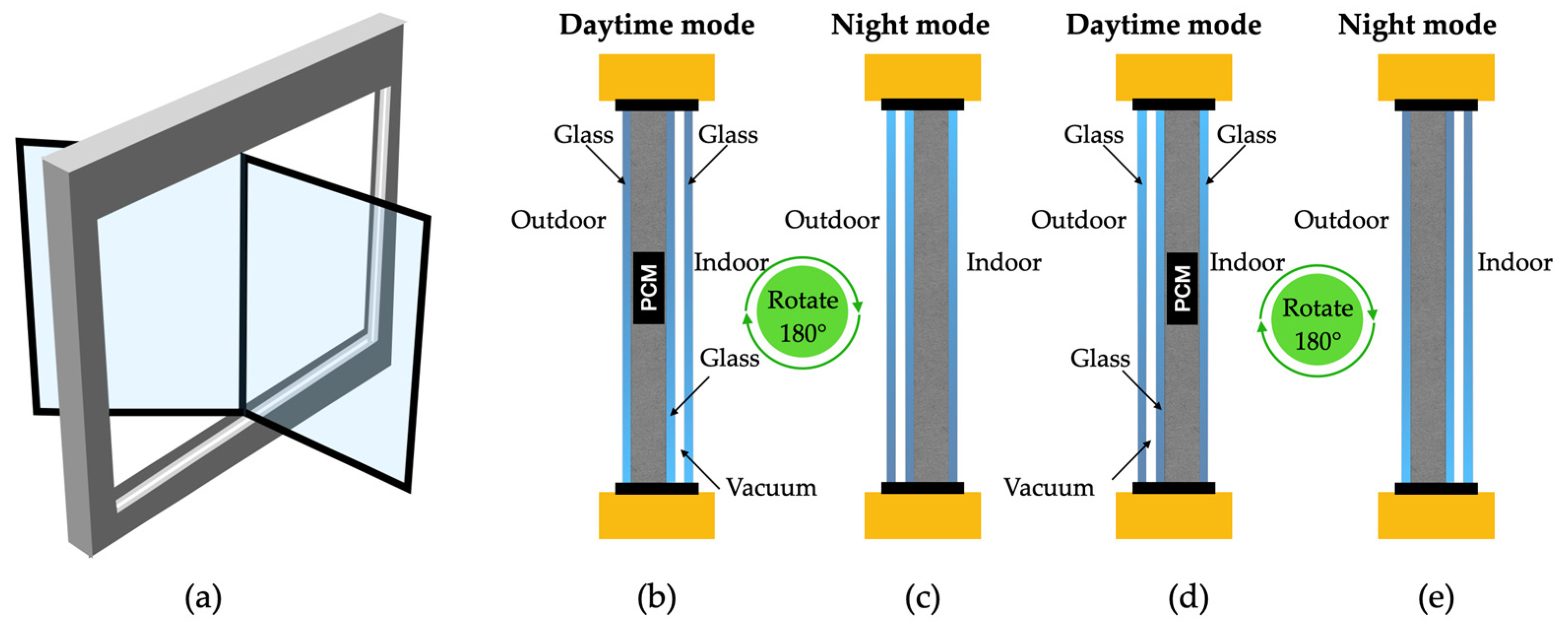

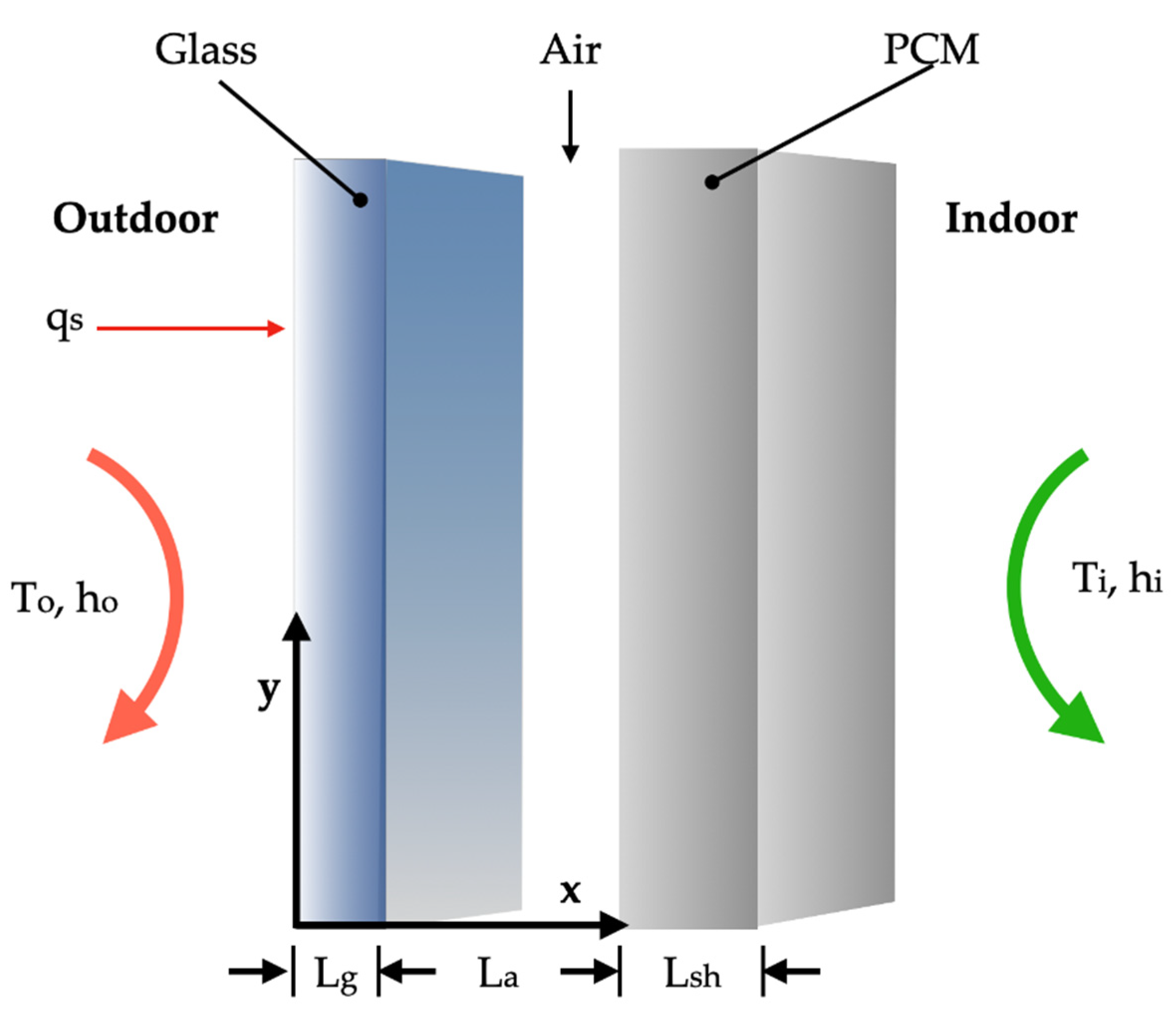

11.4. Windows and Shutters

11.5. Floors

12. Dynamic Energy Modeling of PCM-Enhanced Passive Buildings

12.1. Software

12.1.1. Energy Plus

12.1.2. TRNSYS

12.1.3. ESP-r

12.1.4. Ansys Fluent

12.2. Mathematical Modeling of PCMs in Building Energy Simulation Tools

12.3. Machine Learning

12.4. Gaps Between Simulations and Experiments

- Material Properties: Simulations usually rely on generalized PCM properties, which may not account for practical real-world fluctuations such as aging, impurities, and fabrication inconsistencies.

- Boundary Conditions: Experimental setups may have complex boundary conditions that are difficult to replicate accurately in simulations.

- Thermal Hysteresis: Many simulations tools struggle to model the thermal hysteresis of PCMs, which affects their phase change behavior.

- Dynamic Interactions: Real-world interactions between PCMs and other building materials, such as thermal bridging or moisture transfer, are usually simplified too much in simulations.

- Occupant Behavior: Simulations rarely account for variability in human behavior including door and window opening or thermostat adjustments, which considerably impact energy consumption.

- Climatic Data: Simulations should use historical or average climatic information, which might not reflect microclimatic variations or future weather patterns.

- Enhanced Material Databases: Develop comprehensive databases with detailed PCM properties, including variations caused by aging and environmental factors.

- Advanced Modeling Techniques: Incorporate models to simulate thermal hysteresis and dynamic interactions more accurately.

- Integration of Real-Time Data: Use real-time monitoring data from experimental setups to validate and refine simulation models.

- Combined Simulations: Combine thermal, moisture, and structural simulations to capture the holistic behavior of PCM-integrated systems.

- User-Centric Design: Include stochastic models to simulate occupant behavior and its impact on the building thermal performance.

- Future-Proofing: Integrate predictive climate models to evaluate the long-term performance of PCM-based designs under changing weather conditions.

13. Results and Discussion

13.1. Thermal Performance and Energy Savings

13.2. Challenges and Limitations for PCM Usage

- Low Thermal Conductivity: Organic PCMs, such as paraffin, have low thermal conductivity, limiting the rate of heat transfer and reducing overall system efficiency. Strategies such as incorporating metallic foams and nanoparticles (e.g., CuO, Al2O3) have shown potential to enhance conductivity.

- Phase Separation: Inorganic PCMs, including salt hydrates, are prone to phase separation, leading to reduced thermal stability over time. Encapsulation techniques, such as microencapsulation and composite materials, have been explored to address this issue.

- Compatibility with Construction Materials: PCM leakage during phase transition can compromise the structural integrity of construction materials. Advanced encapsulation and composite materials have been proposed as solutions.

- Thermal Hysteresis: PCMs can exhibit different melting and freezing points, leading to inefficiency in heat storage and release.

- Durability: Prolonged use with repeated phase transitions may lead to degradation, reducing their effectiveness over time.

- Compatibility with Existing Materials: Incorporating PCMs into building structures (e.g., walls, ceilings) demands careful design and compatibility with existing materials.

- Limited Usability: Certain applications might limit their usability in specific climates or building types due to temperature range constraints.

- Standardization: The lack of universal standards or guidelines for PCMs’ selection and implementation in real-world scenarios complicates their adoption.

- Cost: The production costs of advanced encapsulated PCMs and composite solutions remain high, limiting market penetration.

- Life Cycle Costs: Maintenance and replacement costs are significant due to PCM aging or performance degradation over time. Cost effectiveness can vary, depending on factors like local energy tariffs and climate conditions.

- Return on Investment: Energy savings provided by the PCMs may take prolonged periods to offset the initial investment costs, particularly in the regions with moderate climates where passive heating/cooling benefits are limited.

- Material Sourcing: Natural PCMs (e.g., paraffin wax or salt hydrates) can have environmental impacts during extraction and processing like resource depletion.

- Manufacturing Energy Use: The production of synthetic PCMs, especially for advanced applications, often involves energy-intensive processes contributing to greenhouse gas emissions.

- Waste Management: The disposal of aged or damaged PCMs raises concerns, particularly with synthetic types, which may not biodegrade or could release harmful substances.

- Net Benefits: On the positive side, PCMs significantly reduce operational energy consumption in buildings and decrease reliance on fossil fuels and overall carbon emissions during their usage phase. When implemented sustainably, they can have a net positive environmental impact.

13.3. Optimal Placement and Configuration

13.4. Comparative Analysis of PCM-Based Solutions

14. Recommendations for Further Studies

- Developing high-conductivity composite PCMs through nanoparticle integration.

- Enhancing encapsulation methods to prevent phase separation and leakage.

- Designing cost-effective manufacturing processes to facilitate large-scale adoption.

- Investigating the long-term stability of PCMs under cyclic thermal loads.

- Numerical simulation has been proven to be a powerful tool for investigating the thermal properties of nano-enhanced PCMs. These methods allow for the accurate description of thermal properties at the molecular scale, providing insight into energy transport mechanisms and helping to understand the enhanced thermal conductivity resulting from the dispersion of nanomaterials into the base PCM.

- Among the most detailed approaches is molecular dynamics simulation, which computes the motion of individual molecules. This technique has been widely applied to understand the microscopic behavior of materials. For example, Babaei et al. [301] employed molecular dynamics simulations to explore the thermal conductivity enhancement of paraffin when combined with carbon-based nanofillers.

- Further studies should focus on improving the accuracy of these simulations, using real-time measurements of heat flux and temperature distribution in PCM-integrated building systems. Moreover, long-term experimental investigations are essential to better understand the aging behavior and reliability of PCMs over extended periods. To make PCMs more accessible for large-scale implementation, cost-effective and scalable manufacturing processes must also be prioritized.

- Currently, the most suitable climates for the use of PCMs are those presenting considerable temperature changes within a day, but with little temperature variations across the year. Further research to develop PCMs with less supercooling could help to expand their potential areas of application.

- While phase change materials are most investigated for applications in outward-facing building parts like walls and roofs, recent research has also discussed their possible application in floors, storage heaters, and blinds. Further studies on the matter should contemplate full lifetime cycle assessments to infer the effectiveness of PCMs in green buildings.

- The risk of leakage is one of the main challenges linked with PCM, which can be overcome via encapsulation. The incorporation of nanomaterials in these encapsulating polymers has also been demonstrated to increase thermal conductivity. The usage of nanoparticles playing the role of nucleating agents can also aid in reducing supercooling, enabling their application in regions with lower daily temperature gradients.

- The elevated flammability of PCMs when applied in residential buildings is also one of the most relevant concerns and challenges. Further research on the incorporation of fire retardants in the PCMs composites should, at least, partially overcome the flammability limitation. Fire retardants like melamine-based compounds should be further examined in practical situations.

- More and more efficient composites should be studied at the laboratory scale and in real practical applications in buildings. For example, the inclusion of PCMs and nanocomposites has even been found to improve the compressive strength of cement. It should be stated that further research would be able to mitigate the challenges associated with the exploration of PCM composites.

- It is suggested to perform more experimental works on the incorporation of fatty acids and corresponding composites such as eutectic PCM into cement by the vacuum method to decrease the indoor temperature during the melting and solidification periods. Also, the inclusion of PCMs in roofs can reduce their temperature and heat gain.

- The usage of PCMs in passive cooling systems in warm-temperature climates has been more studied than that in other climates, and considerable cooling energy savings have been shown. Nonetheless, it is recommended to perform more experimental and numerical works on heating-dominant climates to optimize the melting temperatures of PCMs to attain higher total annual savings.

- To further optimize the design and implementation of PCM curtain windows, approaches to depress/suppress natural convection in air gaps should be studied. Also, a cascaded PCM layer with distinct melting points in the vertical direction may be used. One shortcoming of PCM curtains is that the transparency of windows will be lost when adding an opaque layer, and this will require extra lighting.

15. Conclusions

- PCMs can be categorized into organic, inorganic, and eutectic materials. The organic class can also be divided into paraffin and non-paraffin materials, and the inorganic category can be separated into salt hydrates, metallic PCMs, and eutectic PCM s. Encapsulated PCMs must be encapsulated by macroencapsulation, microencapsulation, or nanoencapsulation.

- The selection of the most adequate base PCMs and nanomaterials is essential to develop effective nano-enhanced PCM s. For building applications, PCMs used should have a melting temperature in the desired range of the practical operation of the buildings. The first approximation proposed by the authors Peippo et al. [303] could be useful for determining the ideal melting temperature of PCMs to be used in building envelopes. PCMs to be considered for building applications should have a high latent heat of fusion, elevated specific heat capacity, high thermal conductivity, and minimum sub-cooling and should be chemically stable, non-toxic, non-flammable, and non-corrosive.

- The use of PCMs in building components can strongly benefit the energy efficiency of a building, primarily by temperature modulation in both hot and cold climates, leading to lowered energy consumption, as well as a shift in electrical load.

- There are many possible applications of PCMs in residential buildings like those in bricks, concrete, walls, wallboards, gypsum, and plaster and many other applications. To choose the adequate PCM, thermophysical and chemical properties and economic parameters should be considered, among other factors.

- Researchers have explored the integration of PCMs in various building elements, including vertical walls, partitions, floors, ceilings, and attic floors, as well as components of green and cool roofs. Among these applications, PCM-enhanced wallboards have gained significant attention due to their ease of incorporation on interior walls and ceiling surfaces, cost effectiveness, and proven ability to moderate indoor temperatures and reduce cooling energy demand. Additionally, recent studies have investigated the use of PCMs to improve the performance and durability of cool roofing systems, highlighting their potential for broader implementation in passive thermal regulation strategies.

- Further numerical investigations are essential to explore the benefits of coupling PCM-based passive systems with natural night ventilation, aiming to enhance their overall thermal performance. This review of the available literature showed that there is no detailed work on such synergistic systems using more sophisticated numerical methods.

- To overcome the actual challenges closely linked with the incorporation of PCMs in building materials like thermal conductivity, cooling time, flammability, and phase segregation, the addition of certain materials to PCMs can form composite materials with enhanced characteristics; for example, the inclusion of copper oxide can prevent low thermal conductivity.

- The changing of temperature during the day should be regulated by PCMs; in the cooling period, PCMs should be solidified during the night when the ambient temperature is lower to afford cooling during the day when the ambient temperature is higher. Accordingly, PCMs should melt during periods of elevated ambient temperature to afford the required heating capability in the heating period. Consequently, the melting point of PCMs must be carefully selected, relating to the average temperature during the year, to become solidified and melted every day. A too-high or too-low melting point results in phase stability that eliminates energy storage. Thus, the optimization of the location is vital to attain the most suitable interaction with the surrounding conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Butler, D. Architecture: Architects of a low-energy future. Nature 2008, 452, 520–523. [Google Scholar] [CrossRef] [PubMed]

- Rashid, F.L.; Dulaimi, A.; Hatem, W.A.; Al-Obaidi, M.A.; Ameen, A.; Eleiwi, M.A.; Jawad, S.A.; Bernardo, L.F.A.; Hu, J.W. Recent Advances and Developments in Phase Change Materials in High-Temperature Building Envelopes: A Review of Solutions and Challenges. Buildings 2024, 14, 1582. [Google Scholar] [CrossRef]

- Jha, S.K.; Sankar, A.; Zhou, Y.; Ghosh, A. Incorporation of Phase Change Materials in Buildings. Constr. Mater. 2024, 4, 676–703. [Google Scholar] [CrossRef]

- Sloka, P.Y.; Kaushik, S.A.S. Phase Changing Material (PCM) Based Envelope Materials for Energy Efficient Buildings. IOP Conf. Ser. Earth Environ. Sci. 2024, 1326, 12067. [Google Scholar] [CrossRef]

- Aidi, M.; Harnane, Y.; Bouzid, S.; Bordja, L. Numerical Study on the Effect of Incorporating Phase Change Materials in a Wall. Int. J. Automot. Mech. Eng. 2024, 21, 11287–11301. [Google Scholar] [CrossRef]

- Mandal, S. Advancements in Phase Change Material s: Stabilization Techniques and Applications. Prabha Mater. Sci. Lett. 2024, 3, 254–267. [Google Scholar] [CrossRef]

- Mohammed, H.I. Enhancing Heat Storage Capacity: Nanoparticle and Shape Optimization for PCM Systems. Energy Storage 2024, 6, e70078. [Google Scholar] [CrossRef]

- Jones, A.; Darabi, J. Enhancing Thermal Performance in a PCM Heatsink Assembly by Incorporating Fins and Copper Oxide Nanoparticles. In Proceedings of the ASME 2024 Heat Transfer Summer Conference collocated with the ASME 2024 Fluids Engineering Division Summer Meeting and the ASME 2024 18th International Conference on Energy Sustainability, Anaheim, CA, USA, 15–17 July 2024. [Google Scholar] [CrossRef]

- Islam, A.; Pandey, A.P.; Sharma, K.; Bhutto, Y.A. Enhancing thermo-physical properties of hybrid nanoparticle-infused RT-54HC organic PCMs using graphene nanoplatelets and multiwall carbon nanotubes. arXiv 2024. [Google Scholar] [CrossRef]

- Bouzyan, L.; Toublanc, C.; Ousegui, A. Numerical Investigation on the Charging Process of Phase Change Materials (PCM) in Thermal Energy Storage Systems. In Proceedings of the 4th International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), Fez, Morocco, 16–17 May 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Gallero, F.; González, J.; Siles, G.G.; Maestre, I.R.; Blázquez, J.L.F.; Pérez-Lombard, L. Performance of a Simplified Computational Fluid Dynamics Model for a Phase Change Material—Water Finned Heat Exchanger Under Different Orientations. Energy Storage 2024, 6, e70021. [Google Scholar] [CrossRef]

- Min, L.; Liu, Y.; Wang, C.; Du, Y.; Fang, H. A novel stereotyped phase change material with a low leakage rate for new energy storage building applications. Constr. Build. Mater. 2024, 433, 136757. [Google Scholar] [CrossRef]

- Schossig, P.; Henning, H.-M.; Gschwander, S.; Haussmann, T. Micro-encapsulated phase-change materials integrated into construction materials. Sol. Energy Mater. Sol. Cells 2005, 89, 297–306. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007, 39, 113–119. [Google Scholar] [CrossRef]

- Zhang, Y.; Tao, W.; Wang, K.; Li, D. Analysis of thermal properties of gypsum materials incorporated with microencapsulated phase change materials based on silica. Renew. Energy 2020, 149, 400–408. [Google Scholar] [CrossRef]

- Hepple, R.; Zhao, Y.; Yang, R.; Zhang, Q.; Yang, S. Investigating the Effects of PCM-Integrated Walls on Thermal Performance for UK Residential Buildings of Different Typologies. Buildings 2024, 14, 3382. [Google Scholar] [CrossRef]

- Sarı, A. Composites of polyethylene glycol (PEG600) with gypsum and natural clay as new kinds of building PCMs for low temperature-thermal energy storage. Energy Build. 2014, 69, 184–192. [Google Scholar] [CrossRef]

- Sarı, A.; Hekimoğlu, G.; Tyagi, V.V.; Sharma, R.K. Evaluation of pumice for development of low-cost and energy-efficient composite phase change materials and lab-scale thermoregulation performances of its cementitious plasters. Energy 2020, 207, 118242. [Google Scholar] [CrossRef]

- Sarı, A.; Bicer, A.; Al-Sulaiman, F.A.; Karaipekli, A.; Tyagi, V.V. Diatomite/CNTs/PEG composite PCMs with shape-stabilized and improved thermal conductivity: Preparation and thermal energy storage properties. Energy Build. 2018, 164, 166–175. [Google Scholar] [CrossRef]

- Hekimoğlu, G.; Sarı, A.; Gencel, O.; Tyagi, V.V. Thermal conductivity enhancement of silica fume based composite thermal energy storage material using different carbon nanomaterials. Energy Build. 2022, 257, 111789. [Google Scholar] [CrossRef]

- Gencel, O.; Ustaoglu, A.; Sarı, A.; Hekimoğlu, G.; Sutcu, M.; Tozluoglu, A.; Tutus, A.; Cicekler, M.; Tyagi, V.V. Developing Wallpaper/Dodecyl alcohol composite phase change materials as new kind of wall covering elements for building interior thermoregulation. Therm. Sci. Eng. Prog. 2023, 46, 102183. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Roca, J.; Nogueés, M.; Mehling, H.; Hiebler, S. Long term immersion corrosion tests on metal-PCM pairs used for latent heat storage in the 24 to 29 °C temperature range. Mater. Corros.-Werkst. Korros. 2005, 56, 33–39. [Google Scholar] [CrossRef]

- Gonçalves, M.; Figueiredo, A.; Vela, G.; Rebelo, F.; Almeida, R.M.S.F.; Oliveira, M.S.A.; Vicente, R. Effect of Macrocapsule Geometry on PCM Performance for Thermal Regulation in Buildings. Energies 2025, 18, 303. [Google Scholar] [CrossRef]

- Laasri, I.A.; Es-Sakali, N.; Charai, M.; Mghazli, M.O.; Outzourhit, A. Recent Progress, Limitations, and Future Directions of Macro-Encapsulated Phase Change Materials for Building Applications. Renew. Sustain. Energy Rev. 2024, 199, 114481. [Google Scholar] [CrossRef]

- Dellagi, A.; Ayed, R.; Bouadila, S.; Guizani, A. Computational and experimental analysis of PCM-infused brick for sustainable heat regulation. J. Build. Phys. 2024, 48, 222–243. [Google Scholar] [CrossRef]

- Mahdaoui, M.; Hamdaoui, S.; Msaad, A.A.; Kousksou, T.; El Rhafiki, T.; Jamil, A.; Ahachad, M. Building bricks with phase change material (PCM): Thermal performances. Constr. Build. Mater. 2021, 269, 121315. [Google Scholar] [CrossRef]

- Vicente, R.; Silva, T. Brick masonry walls with PCM macrocapsules: An experimental approach. Appl. Therm. Eng. 2014, 67, 24–34. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Soares, N.; Ferreira, V. Experimental testing and numerical modelling of masonry wall solution with PCM incorporation: A passive construction solution. Energy Build. 2012, 49, 235–245. [Google Scholar] [CrossRef]

- Yasin, M.; Scheidemantel, E.; Klinker, F.; Weinläder, H.; Weismann, S. Generation of a simulation model for chilled PCM ceilings in TRNSYS and validation with real scale building data. J. Build. Eng. 2019, 22, 372–382. [Google Scholar] [CrossRef]

- Zhu, Y.; Qin, Y.; Wei, C.; Liang, S.; Luo, X.; Wang, J.; Zhang, L. Nanoencapsulated phase change materials with polymer-SiO2 hybrid shell materials: Compositions, morphologies, and properties. Energy Convers. Manag. 2018, 164, 83–92. [Google Scholar] [CrossRef]

- Valizadeh, S.; Ehsani, M.; Angji, M.T. Development and thermal performance of wood-HPDE- PCM nanocapsule floor for passive cooling in building. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2114–2127. [Google Scholar] [CrossRef]

- Maleki, B.; Khadang, A.; Maddah, H.; Alizadeh, M.; Kazemian, A.; Ali, H.M. Development and thermal performance of nanoencapsulated PCM/ plaster wallboard for thermal energy storage in buildings. J. Build. Eng. 2020, 32, 101727. [Google Scholar] [CrossRef]

- Aidi, M.; Harnane, Y.; Poós, T.; Bordja, L. Investigation of the Effect of Nanoparticles in Phase Change Materials on Heat Transfer in Building Wall. Period. Polytech. Mech. Eng. 2025, 69, 10–22. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Alktranee, M.; Szabó, M.; Arıcı, M. Building envelope-enhanced phase change material and night ventilation: Effect of window orientation and window-to-wall ratio on indoor temperature. Renew. Energy 2023, 218, 119263. [Google Scholar] [CrossRef]

- Gobinath, S.; Senthilkumar, G.; Beemkumar, N. Comparative study of room temperature control in buildings with and without the use of PCM in walls. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 1765–1771. [Google Scholar] [CrossRef]

- Murathan, E.K.; Manioğlu, G. A simulation-based evaluation of using PCMs in buildings for energy efficiency under different climate conditions. J. Energy Storage 2024, 75, 109738. [Google Scholar] [CrossRef]

- Sun, X.; Jovanovic, J.; Zhang, Y.; Fan, S.; Chu, Y.; Mo, Y.; Liao, S. Use of encapsulated phase change materials in lightweight building walls for annual thermal regulation. Energy 2019, 180, 858–872. [Google Scholar] [CrossRef]

- Musa, B.; Nasir, S.; Idris, M.B.; Muhammad, Y.A.; Muhammad, N.; Nuhu, M. An appraisal of phase change materials: Characteristics, categorization, benefits, drawbacks and utilizations. A review. Dutse J. Pure Appl. Sci. 2024, 10, 12–24. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM thermal storage in buildings: A state of art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Panda, D.; Sahu, A.K.; Gangawane, K.M. Eutectic phase change composites with MXene nanoparticles for enhanced photothermal absorption and conversion capacity. Sol. Energy Mater. Sol. Cells 2024, 272, 112911. [Google Scholar] [CrossRef]

- Zalba, B.; Marín, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis, and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM: An Up to Date Introduction into Basics and Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Ravotti, R.; Oliver Fellmann, O.; Lardon, N.; Fischer, L.J.; Stamatiou, A.; Worlitschek, J. Synthesis and Investigation of Thermal Properties of Highly Pure Carboxylic Fatty Esters to Be Used as PCM. Appl. Sci. 2018, 8, 1069. [Google Scholar] [CrossRef]

- Huang, W.-Y.; Liu, Y.-C.; Lin, S.K.; Chen, W.-H. Computational Thermodynamics-Assisted Design of Nitrate-Based Phase Change Materials for Waste Heat Recovery. Int. J. Energy Res. 2022, 46, 14452–14461. [Google Scholar] [CrossRef]

- Mishra, L.; Sinha, A.; Gupta, R. Thermo-economic Study of Phase Change Materials (PCMs) for Thermal Energy Storage. In Proceedings of the Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering; Biswal, B., Sarkar, B., Mahanta, P., Eds.; Springer: Singapore, 2020; pp. 1217–1226. [Google Scholar] [CrossRef]

- Voelker, C.; Kornadt, O.; Ostry, M. Temperature reduction due to the application of phase change materials. Energy Build. 2008, 40, 937–944. [Google Scholar] [CrossRef]

- Suresh, C.; Hotta, T.K.; Saha, S.K. Phase change material incorporation techniques in building envelopes for enhancing the building thermal Comfort-A review. Energy Build. 2022, 268, 112225. [Google Scholar] [CrossRef]

- da Cunha, J.P.; Eames, P. Thermal energy storage for low and medium temperature applications using phase change materials—A review. Appl. Energy 2016, 177, 227–238. [Google Scholar] [CrossRef]

- Feldman, D.; Banu, D.; Hawes, D.; Ghanbari, E. Obtaining an energy storing building material by direct incorporation of an organic phase change material in gypsum wallboard. Sol. Energy Mater. 1991, 22, 231–242. [Google Scholar] [CrossRef]

- Cunha, S.; Leite, P.; Aguiar, J. Characterization of innovative mortars with direct incorporation of phase change materials. J. Energy Storage 2020, 30, 101439. [Google Scholar] [CrossRef]

- Cellat, K.; Tezcan, F.; Beyhan, B.; Kardaş, G.; Paksoy, H. A comparative study on corrosion behavior of rebar in concrete with fatty acid additive as phase change material. Constr. Build. Mater. 2017, 143, 490–500. [Google Scholar] [CrossRef]

- Yu, Z.; Shao, R.; Li, J.; Wu, C. An in-depth review of phase change materials in concrete for enhancing building energy-efficient temperature control systems. J. Energy Storage 2024, 104, 114533. [Google Scholar] [CrossRef]

- Chandel, S.S.; Agarwal, T. Review of current state of research on energy storage, toxicity, health hazards and commercialization of phase changing materials. Renew. Sustain. Energy Rev. 2017, 67, 581–596. [Google Scholar] [CrossRef]

- Milián, Y.E.; Gutiérrez, A.; Grágeda, M.; Ushak, S. A review on encapsulation techniques for inorganic phase change materials and the influence on their thermophysical properties. Renew. Sustain. Energy Rev. 2017, 73, 983–999. [Google Scholar] [CrossRef]

- Ghasemi, K.; Tasnim, S.; Mahmud, S. PCM, nano/microencapsulation and slurries: A review of fundamentals, categories, fabrication, numerical models and applications. Sustain. Energy Technol. Assess. 2022, 52, 102084. [Google Scholar] [CrossRef]

- Palacios, A.; Navarro-Rivero, M.E.; Zou, B.; Jiang, Z.; Harrison, M.T.; Ding, Y. A perspective on Phase Change Material encapsulation: Guidance for encapsulation design methodology from low to high-temperature thermal energy storage applications. J. Energy Storage 2023, 72, 108597. [Google Scholar] [CrossRef]

- El Majd, A.; Sair, S.; Ousaleh, H.A.; Berardi, U.; Moulakhnif, K.; Belouaggadia, N.; Younsi, Z.; El Bouari, A. Advancing PCM research in building efficiency: A comprehensive investigation into PCM selection and critical integration strategies. J. Build. Eng. 2024, 96, 110485. [Google Scholar] [CrossRef]

- Wang, S.; Lei, K.; Wang, Z.; Wang, H.; Zou, D. Metal-based phase change material (PCM) microcapsules/nanocapsules: Fabrication, thermophysical characterization and application. Chem. Eng. J. 2022, 438, 135559. [Google Scholar] [CrossRef]

- Castell, A.; Martorell, I.; Medrano, M.; Pérez, G.; Cabeza, L.F. Experimental study of using PCM in brick constructive solutions for passive cooling. Energy Build. 2010, 42, 534–540. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Potential of macroencapsulated PCM for thermal energy storage in buildings: A comprehensive review. Constr. Build. Mater. 2019, 225, 723–744. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Experimental evaluation of the optimal position of a macroencapsulated phase change material incorporated composite roof under hot climate conditions. Sustain. Energy Technol. Assess. 2021, 45, 101121. [Google Scholar] [CrossRef]

- Konuklu, Y.; Ostry, M.; Paksoy, H.O.; Charvat, P. Review on using microencapsulated phase change materials (PCMs) in building applications. Energy Build. 2015, 106, 134–155. [Google Scholar] [CrossRef]

- Peng, G.; Dou, G.; Hu, Y.; Sun, Y.; Chen, Z. Phase Change Material (PCM) Microcapsules for Thermal Energy Storage. Adv. Polym. Technol. 2020, 2020, 9490873. [Google Scholar] [CrossRef]

- Giro-Paloma, J.; Martínez, M.; Cabeza, L.F.; Fernández, A.I. Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): A review. Renew. Sustain. Energy Rev. 2016, 53, 1059–1075. [Google Scholar] [CrossRef]

- Beyhan, B.; Cellat, K.; Konuklu, Y.; Gungor, C.; Karahan, O.; Dundar, C.; Paksoy, H. Robust microencapsulated phase change materials in concrete mixes for sustainable buildings. Int. J. Energy Res. 2017, 41, 113–126. [Google Scholar] [CrossRef]

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Bui, T.Q.; Carmona, M.; Rodriguez, J.F.; Kjøniksen, A.-L. Thermal analysis of geopolymer concrete walls containing microencapsulated phase change materials for building applications. Sol. Energy 2019, 178, 295–307. [Google Scholar] [CrossRef]

- Balapour, M.; Mutua, A.W.; Farnam, Y. Evaluating the thermal efficiency of microencapsulated phase change materials for thermal energy storage in cementitious composites. Cem. Concr. Compos. 2021, 116, 103891. [Google Scholar] [CrossRef]

- Alehosseini, E.; Jafari, S.M. Nanoencapsulation of phase change materials (PCMs) and their applications in various fields for energy storage and management. Adv. Colloid Interface Sci. 2020, 283, 102226. [Google Scholar] [CrossRef]

- Liu, K.; Yuan, Z.F.; Zhao, H.X.; Shi, C.H.; Zhao, F. Properties and applications of shape-stabilized phase change energy storage materials based on porous material support—A review. Mater. Today Sustain. 2023, 21, 100336. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ramadan, E.; Elsadek, N.E.; Emam, S.E.; Shimizu, T.; Ando, H.; Ishima, Y.; Elgarhy, O.H.; Sarhan, H.A.; Hussein, A.K.; et al. Polyethylene glycol (PEG): The nature, immunogenicity, and role in the hypersensitivity of PEGylated products. J. Control. Release 2022, 351, 215–230. [Google Scholar] [CrossRef]

- Jeong, S.-G.; Lee, J.-H.; Seo, J.; Kim, S. Thermal performance evaluation of Bio-based shape stabilized PCM with boron nitride for energy saving. Int. J. Heat Mass Transf. 2014, 71, 245–250. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, W.; Fu, S.; Zhang, H. Study of a novel ceramsite-based shape-stabilized composite phase change material (PCM) for energy conservation in buildings. Constr. Build. Mater. 2020, 246, 118479. [Google Scholar] [CrossRef]

- Li, Y.; Dong, M.; Song, W.; Liang, X.; Chen, Y.; Liu, Y. Preparation and Characterization of Paraffin/Mesoporous Silica Shape-Stabilized Phase Change Materials for Building Thermal Insulation. Materials 2021, 14, 1775. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Situ, W.; Li, X.; Zhang, G.; Huang, Z.; Yuan, W.; Yang, C.; Yang, C. Novel Shape Stabilized Phase Change Material Based on Epoxy Matrix with Ultrahigh Cycle Life for Thermal Energy Storage. Appl. Therm. Eng. 2017, 123, 1006–1012. [Google Scholar] [CrossRef]

- McCord, M.R.Y.; Baniasadi, H. Advancements in form-stabilized phase change materials: Stabilization mechanisms, multifunctionalities, and applications—A comprehensive review. Mater. Today Energy 2024, 41, 101532. [Google Scholar] [CrossRef]

- Kenisarin, M.M.; Kenisarina, K.M. Form-stable phase change materials for thermal energy storage. Renew. Sustain. Energy Rev. 2012, 16, 1999–2040. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M.M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 2004, 45, 263–275. [Google Scholar] [CrossRef]

- Lamastra, F.R.; Bragaglia, M.; Paleari, L.; Nanni, F.; Fabborcino, F.; Scarselli, M. Form-Stable Phase-Change Materials Using Chemical Vapor Deposition-Derived Porous Supports: Carbon Nanotube/Diatomite Hybrid Powder and Carbon Nanotube Sponges. Materials 2024, 17, 5721. [Google Scholar] [CrossRef]

- Prabhu, B.; Nižetić, S.; Arıcı, M.; Nallamuthu, R. A Comprehensive Assessment on Bio-Mass Derived Form-Stabilized Composite Phase Change Materials for Solar Thermal Energy Storage Systems. J. Energy Storage 2024, 86, 111278. [Google Scholar] [CrossRef]

- Salunkhe, P.B.; Shembekar, P.S. A review on effect of phase change material encapsulation on the thermal performance of a system. Renew. Sustain. Energy Rev. 2012, 16, 5603–5616. [Google Scholar] [CrossRef]

- Jacob, R.; Bruno, F. Review on shell materials used in the encapsulation of phase change materials for high temperature thermal energy storage. Renew. Sustain. Energy Rev. 2015, 48, 79–87. [Google Scholar] [CrossRef]

- Zhao, W.; Zheng, Y.; Sabol, J.C.; Tuzla, K.; Neti, S.; Oztekin, A.; Chen, J.C. High temperature calorimetry and use of magnesium chloride for thermal energy storage. Renew. Energy 2013, 50, 988–993. [Google Scholar] [CrossRef]

- Qiu, X.; Song, G.; Chu, X.; Li, X.; Tang, G. Preparation, thermal properties and thermal reliabilities of microencapsulated n-octadecane with acrylic-based polymer shells for thermal energy storage. Thermochim. Acta 2013, 551, 136–144. [Google Scholar] [CrossRef]

- He, F.; Wang, X.; Wu, D. New approach for sol–gel synthesis of microencapsulated n-octadecane phase change material with silica wall using sodium silicate precursor. Energy 2014, 67, 223–233. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, D. Innovative design of microencapsulated phase change materials for thermal energy storage and versatile applications: A review. Sustain. Energy Fuels 2019, 3, 1091–1149. [Google Scholar] [CrossRef]

- Shi, J.; Wu, X.; Sun, R.; Ban, B.; Li, J.; Chen, J. Synthesis and performance evaluation of paraffin microcapsules with calcium carbonate shell modulated by different anionic surfactants for thermal energy storage. Colloids Surf. A Physicochem. Eng. Asp. 2019, 571, 36–43. [Google Scholar] [CrossRef]

- Li, C.; Yu, H.; Song, Y.; Liang, H.; Yan, X. Preparation and characterization of PMMA/TiO2 hybrid shell microencapsulated PCMs for thermal energy storage. Energy 2019, 167, 1031–1039. [Google Scholar] [CrossRef]

- Belessiotis, G.V.; Papadokostaki, K.G.; Favvas, E.P.; Efthimiadou, E.K.; Karellas, S. Preparation and investigation of distinct and shape stable paraffin/SiO2 composite PCM nanospheres. Energy Convers. Manag. 2018, 168, 382–394. [Google Scholar] [CrossRef]

- Li, J.; Lu, W.; Luo, Z.; Zeng, Y. Synthesis and thermal properties of novel sodium nitrate microcapsules for high-temperature thermal energy storage. Sol. Energy Mater. Sol. Cells 2017, 159, 440–446. [Google Scholar] [CrossRef]

- Fang, M.; Cao, L.; Cao, Y.; Hou, F. Enhanced thermal energy storage in molten salt-based date-occupied composites with SiO2 nanoparticles. Appl. Therm. Eng. 2025, 270, 126209. [Google Scholar] [CrossRef]

- Nomura, T.; Zhu, C.; Sheng, N.; Saito, G.; Akiyama, T. Microencapsulation of Metal-based Phase Change Material for High-temperature Thermal Energy Storage. Sci. Rep. 2015, 5, 9117. [Google Scholar] [CrossRef]

- Al-Shannaq, R.; Kurdi, J.; Al-Muhtaseb, S.; Dickinson, M.; Farid, M. Supercooling elimination of phase change materials (PCMs) microcapsules. Energy 2015, 87, 654–662. [Google Scholar] [CrossRef]

- Zhu, K.; Qi, H.; Wang, S.; Zhou, J.; Zhao, Y.; Su, J.; Yuan, X. Preparation and Characterization of Melamine-Formaldehyde Resin Micro- and Nanocapsules Filled with n-Dodecane. J. Macromol. Sci. Part B 2012, 51, 1976–1990. [Google Scholar] [CrossRef]

- Huang, Y.; Stonehouse, A.; Abeykoon, C. Encapsulation methods for phase change materials—A critical review. Int. J. Heat Mass Transf. 2023, 200, 123458. [Google Scholar] [CrossRef]

- Yamagishi, Y.; Sugeno, T.; Ishige, T.; Takeuchi, H.; Pyatenko, A.T. An Evaluation of Microencapsulated PCM for Use in Cold Energy Transportation Medium. In Proceedings of the 1st Intersociety Energy Conversion Engineering Conference (IECEC 96), Washington, DC, USA, 11–16 August 1996; Volume 3, pp. 2077–2083. [Google Scholar] [CrossRef]

- Sukhorukov, G.; Fery, A.; Möhwald, A. Intelligent micro- and nanocapsules. Prog. Polym. Sci. 2005, 30, 885–897. [Google Scholar] [CrossRef]

- Ghoghaei, M.S.; Mahmoudian, A.; Mohammadi, O.; Shafii, M.B.; Mosleh, H.J.; Zandieh, M.; Ahmadi, M.H. A review on the applications of micro-/nano-encapsulated phase change material slurry in heat transfer and thermal storage systems. J. Therm. Anal. Calorim. 2021, 145, 245–268. [Google Scholar] [CrossRef]

- Nahak, P.K.; Athawale, V.; Jegatheesan, M.; Rath, P.; Bhattacharya, A. Effect of variable capsule size distribution for unstructured packed bed encapsulated phase change material system. Int. J. Heat Mass Transf. 2022, 197, 123354. [Google Scholar] [CrossRef]

- Baruah, J.S.; Athawale, V.; Rath, P.; Bhattacharya, A. Melting and energy storage characteristics of macro-encapsulated PCM-metal foam system. Int. J. Heat Mass Transf. 2022, 182, 121993. [Google Scholar] [CrossRef]

- Liu, C.; Rao, Z.; Zhao, J.; Huo, Y.; Li, Y. Review on nanoencapsulated phase change materials: Preparation, characterization and heat transfer enhancement. Nano Energy 2015, 13, 814–826. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, W.; Jiang, Z.; He, F.; Zhang, K.; Fan, J.; Wu, J. Graphene oxide-modified microencapsulated phase change materials with high encapsulation capacity and enhanced leakage-prevention performance. Appl. Energy 2017, 197, 354–363. [Google Scholar] [CrossRef]

- Valizadeh, S.; Ehsani, M.; Angaji, M.T. Preparation, characterization and thermal properties of PCM nanocapsules with polystyrene/nano graphene oxide shell for energy storage. Heat Mass Transf. 2020, 56, 575–586. [Google Scholar] [CrossRef]

- Kumar, K.R.; Balasubramanian, K.R.; Kumar, G.P.; Kumar, C.B.; Cheepu, M.M. Experimental Investigation of Nano-encapsulated Molten Salt for Medium-Temperature Thermal Storage Systems and Modeling of Neural Networks. Int. J. Thermophys. 2022, 43, 145. [Google Scholar] [CrossRef]

- Said, Z.; Pandey, A.K.; Tiwari, A.K.; Kalidasan, B.; Jamil, F.; Thakur, A.K.; Tyagi, V.V.; Sarı, A.; Ali, H.M. Nano-enhanced phase change materials: Fundamentals and applications. Prog. Energy Combust. Sci. 2024, 104, 101162. [Google Scholar] [CrossRef]

- Coetzee, D.; Venkataraman, M.; Militky, J.; Petru, M. Influence of Nanoparticles on Thermal and Electrical Conductivity of Composites. Polymers 2020, 12, 742. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.-W.; Fang, X.; Wang, X.; Zeng, Y.; Xiao, Y.-Q.; Yu, Z.-T.; Xu, X.; Hu, Y.-C.; Cen, K.-F. Effects of various carbon nanofillers on the thermal conductivity and energy storage properties of paraffin-based nanocomposite phase change materials. Appl. Energy 2013, 110, 163–172. [Google Scholar] [CrossRef]

- Shi, J.-N.; Ger, M.-D.; Liu, Y.-M.; Fan, Y.-C.; Wen, N.-T.; Lin, C.-K.; Pu, N.-W. Improving the thermal conductivity and shape-stabilization of phase change materials using nanographite additives. Carbon 2013, 51, 365–372. [Google Scholar] [CrossRef]

- Li, M. A nano-graphite/paraffin phase change material with high thermal conductivity. Appl. Energy 2013, 106, 25–30. [Google Scholar] [CrossRef]

- Warzoha, R.J.; Weigand, R.M.; Fleischer, A.S. Temperature-dependent thermal properties of a paraffin phase change material embedded with herringbone style graphite nanofibers. Appl. Energy 2015, 137, 716–725. [Google Scholar] [CrossRef]

- Colla, L.; Fedele, L.; Mancin, S.; Danza, L.; Manca, O. Nano-PCMs for enhanced energy storage and passive cooling applications. Appl. Therm. Eng. 2017, 110, 584–589. [Google Scholar] [CrossRef]

- Renteria, J.D.; Nika, D.L.; Balandin, A.A. Graphene Thermal Properties: Applications in Thermal Management and Energy Storage. Appl. Sci. 2014, 4, 525–547. [Google Scholar] [CrossRef]

- Selvam, C.; Lal, D.M.; Harish, S. Thermal conductivity and specific heat capacity of water–ethylene glycol mixture-based nanofluids with graphene nanoplatelets. J. Therm. Anal. Calorim. 2017, 129, 947–955. [Google Scholar] [CrossRef]

- Pop, E.; Varshney, V.; Roy, A.K. Thermal properties of graphene: Fundamentals and applications. MRS Bull. 2012, 37, 1273–1281. [Google Scholar] [CrossRef]

- Abdelrazik, A.; Saidur, R.; Al-Sulaiman, F.; Al-Ahmed, A.; Ben-Mansour, R. Multiwalled CNT and graphene nanoplatelets based nano-enhanced PCMs: Evaluation for the thermal performance and its implications on the performance of hybrid PV/thermal systems. Mater. Today Commun. 2022, 31, 103618. [Google Scholar] [CrossRef]

- Yan, K.; Qiu, L.; Feng, Y. Erythritol/expanded graphite form-stable phase change materials with excellent thermophysical properties. J. Energy Storage 2023, 68, 107667. [Google Scholar] [CrossRef]

- Yan, K.; Feng, Y.; Qiu, L. Thermal and photo/electro-thermal conversion characteristics of high energy storage density expanded graphite/polyethylene glycol shaped composite phase change materials. Sol. Energy 2024, 272, 112477. [Google Scholar] [CrossRef]

- Ouikhalfan, M.; Sarı, A.; Hekimoğlu, G.; Gencel, O.; Tyagi, V.V. Thermal energy storage properties, thermal conductivity, chemical/and thermal reliability of three different organic phase change materials doped with hexagonal boron nitride. Surf. Interfaces 2022, 32, 102176. [Google Scholar] [CrossRef]

- Advincula, P.A.; de Leon, A.C.; Rodier, B.J.; Kwon, J.; Advincula, R.C.; Pentzer, E.B. Accommodating volume change and imparting thermal conductivity by encapsulation of phase change materials in carbon nanoparticles. J. Mater. Chem. A 2018, 6, 2461–2467. [Google Scholar] [CrossRef]

- Luo, W.; Hu, X.; Che, Y.; Zu, S.; Li, Q.; Jiang, X.; Liu, D. Form-stable phase change materials enhanced photothermic conversion and thermal conductivity by Ag-expanded graphite. J. Energy Storage 2022, 52 Part C, 105060. [Google Scholar] [CrossRef]

- Hirschey, J.; Goswami, M.; Akamo, D.O.; Kumar, N.; Li, Y.; LaClair, T.J.; Gluesenkamp, K.R.; Graham, S. Effect of expanded graphite on the thermal conductivity of sodium sulfate decahydrate (Na2SO4·10H2O) phase change composites. J. Energy Storage 2022, 52 Part B, 104949. [Google Scholar] [CrossRef]

- Aktay, K.S.C.; Tamme, R.; Müller-Steinhagen, H. Thermal Conductivity of High-Temperature Multicomponent Materials with Phase Change. Int. J. Thermophys. 2008, 29, 678–692. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, C.; Lu, Y.; Kong, Q.; Wei, H.; Yang, Y.; Gao, Q.; Wu, Y.; Sciacovelli, A. Comprehensive performance of composite phase change materials based on eutectic chloride with SiO2 nanoparticles and expanded graphite for thermal energy storage system. Renew. Energy 2021, 172, 1120–1132. [Google Scholar] [CrossRef]

- Xiao, J.; Huang, J.; Zhu, P.; Wang, C.; Li, X. Preparation, characterization and thermal properties of binary nitrate salts/expanded graphite as composite phase change material. Thermochim. Acta 2014, 587, 52–58. [Google Scholar] [CrossRef]

- Ling, Z.; Chen, J.; Xu, T.; Fang, X.; Gao, X.; Zhang, Z. Thermal conductivity of an organic phase change material/expanded graphite composite across the phase change temperature range and a novel thermal conductivity model. Energy Convers. Manag. 2015, 102, 202–208. [Google Scholar] [CrossRef]

- Yang, X.H.; Lu, T.J.; Kim, T. Temperature effects on the effective thermal conductivity of phase change materials with two distinctive phases. Int. Commun. Heat Mass Transf. 2011, 38, 1344–1348. [Google Scholar] [CrossRef]

- Guo, H.; Jiao, W.; Jin, H.; Yuan, Z.; He, X. Microsphere Structure Composite Phase Change Material with Anti-Leakage, Self-Sensing, and Photothermal Conversion Properties for Thermal Energy Harvesting and Multi-Functional Sensor. Adv. Funct. Mater. 2023, 33, 2209345. [Google Scholar] [CrossRef]

- Konstantinidou, C.A.; Lang, W.; Papadopoulos, A.M.; Santamouris, M. Life cycle and life cycle cost implications of integrated phase change materials in office buildings. Int. J. Energy Res. 2019, 43, 150–166. [Google Scholar] [CrossRef]

- Saafi, K.; Daouas, N. Energy and cost efficiency of phase change materials integrated in building envelopes under Tunisia Mediterranean climate. Energy 2019, 187, 115987. [Google Scholar] [CrossRef]

- Mi, X.; Liu, R.; Cui, H.; Memon, S.A.; Xing, F.; Lo, Y. Energy and economic analysis of building integrated with PCM in different cities of China. Appl. Energy 2016, 175, 324–336. [Google Scholar] [CrossRef]

- Statistical Database for Annual Data. National Bureau of Statistics of China. 2016. Available online: https://www.stats.gov.cn/sj/ndsj/2016/indexeh.htm (accessed on 27 April 2025).

- Zhou, K.; Yang, S. Demand side management in China: The context of China’s power industry reform. Renew. Sustain. Energy Rev. 2015, 47, 954–965. [Google Scholar] [CrossRef]

- Hawes, D.W.; Feldman, D.; Banu, D. Latent heat storage in building materials. Energy Build. 1993, 20, 77–86. [Google Scholar] [CrossRef]

- Sarı, A.; Nas, M.; Yeşilata, B.; Ustaoğlu, A.; Erdoğmuş, E.; Torlaklı, H.; Hekimoğlu, G.; Gencel, O. A Novel Cement Mortar Comprising Natural Zeolite/Dodecyl Alcohol Shape Stable Composite Phase Change Material for Energy Effective Buildings. J. Energy Storage 2024, 87, 111266. [Google Scholar] [CrossRef]

- Ubertini, F.; Laamme, S.; D’Alessandro, A. Smart Cement Paste with Carbon Nano- Tubes. In Innovative Developments of Advanced Multifunctional Nanocomposites in Civil and Structural Engineering; Loh, K.J., Nagarajaiah, S., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 97–120. [Google Scholar]

- D’Alessandro, A.; Pisello, A.L.; Fabiani, C.; Fubertini, F.; Cabeza, L.F.; Cotana, F. Multifunctional Smart Concretes with Novel Phase Change Materials: Mechanical and Thermo-Energy Investigation. Appl. Energy 2018, 212, 1448–1461. [Google Scholar] [CrossRef]

- Song, H.; Kim, D.; Yoon, S.; Yum, W.S.; Jeon, D.; Oh, J.E. Development of Artificial Leak-Free Phase Change Material (PCM) Aggregates Using Emulsion Technique, Cementless Binder, and Cold-Bonded Pelletization. Constr. Build. Mater. 2023, 411, 134293. [Google Scholar] [CrossRef]

- Fatmanur, A.; Woo, B.-H.; Jang, C.; Kim, H.G. Enhancing Cementitious Composites with PCM-Impregnated Cork Granules for Sustainable and Energy-Efficient Building Elements. Constr. Build. Mater. 2024, 416, 135071. [Google Scholar] [CrossRef]

- Niall, D.; West, R. Development of Concrete Façade Sandwich Panels Incorporating Phase Change Materials. Energies 2024, 17, 2924. [Google Scholar] [CrossRef]

- Ziga-Carbarín, J.; Gómez-Zamorano, L.Y.; Cruz-López, A.; Pushpan, S.; Vázquez-Rodríguez, S.; Balonis, M. Mechanical Properties and Durability of Composite Cement Pastes Containing Phase-Change Materials and Nanosilica. Materials 2024, 17, 3271. [Google Scholar] [CrossRef] [PubMed]

- Osibodu, S.J.; Adeyinka, A.M.; Mbelu, O.V. Phase Change Material Integration in Concrete for Thermal Energy Storage: Techniques and Applications in Sustainable Building. Sustain. Energy Res. 2024, 11, 45. [Google Scholar] [CrossRef]

- Belete, M.B.; Murimi, E.; Muiruri, P.I.; Munyalo, J. A Comprehensive Experimental Characterization of Cement Mortar Containing Sodium Sulfate Dehydrate/Calcium Chloride Hexahydrate/Graphite Shape-Stable PCM for Enhanced Thermal Regulation in Buildings. Results Eng. 2024, 22, 102028. [Google Scholar] [CrossRef]

- Liu, X.; Yang, Y.; Sheng, Z.; Wu, W.; Wang, Y.; Dumoulin, J. Study on Thermal Storage Effectiveness of a Novel PCM Concrete Applied in Buildings Located at Four Cities. Renew. Energy 2023, 218, 119262. [Google Scholar] [CrossRef]

- Al Jebaei, H.; Aryal, A.; Jeon, I.K.; Azzam, A.; Kim, Y.-R.; Baltazar, J.-C. Evaluating the potential of optimized PCM-wallboards for reducing energy consumption and CO2 emission in buildings. Energy Build. 2024, 315, 114320. [Google Scholar] [CrossRef]

- Shilei, L.; Neng, Z.; Guohui, F. Impact of phase change wall room on indoor thermal environment in winter. Energy Build. 2006, 38, 18–24. [Google Scholar] [CrossRef]

- Kuznik, F.; Virgone, J.; Roux, J.-J. Energetic efficiency of room wall containing PCM wallboard: A full-scale experimental investigation. Energy Build. 2008, 40, 148–156. [Google Scholar] [CrossRef]

- Zhu, N.; Li, X.; Hu, P.; Lei, F.; Wei, S.; Wang, W. An exploration on the performance of using phase change humidity control material wallboards in office buildings. Energy 2022, 239, 122433. [Google Scholar] [CrossRef]

- Li, C.; Wen, X.; Cai, W.; Wu, J.; Shao, J.; Yang, Y.; Yu, H.; Liu, D.; Wang, M. Energy performance of buildings with composite phase-change material wallboards in different climatic zones of China. Energy Build. 2022, 273, 112398. [Google Scholar] [CrossRef]

- Fahrezi, D.; Irawan, D.; Iwan, M.; Julianto, E.; Fahrurrozi, F.; Govari, M.K. Experimental Study of Conduction Heat Transfer Using Paraffin Phase Change Material on Bricks. Int. J. Ind. Innov. Mech. Eng. 2024, 2, 60–72. [Google Scholar] [CrossRef]

- Necib, H. Enhancing Building Thermal Inertia: Impact of Surface-to-Volume Ratio on Multi-Layered PCM-Integrated Brick Walls. Ann. West Univ. Timisoara-Phys. 2024, 66, 172–190. [Google Scholar] [CrossRef]

- Tunçbilek, E.; Arıcı, M.; Krajčík, M.; Nižetić, S.; Karabay, H. Thermal performance based optimization of an office wall containing PCM under intermittent cooling operation. Appl. Therm. Eng. 2020, 179, 115750. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhuang, S.; Wang, Q.; He, J. Experimental Research on the Thermal Performance of Composite PCM Hollow Block Walls and Validation of Phase Transition Heat Transfer Models. Adv. Mater. Sci. Eng. 2016, 2016, 6359414. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, W.W.; Zhang, Y.; He, J.P. Experiments of thermal response of phase change energy storage material on block walls. J. Nanjing Tech. Univ. 2016, 38, 119–124. [Google Scholar]

- Abbas, H.M.; Jalil, J.M.; Ahmed, S.T. Experimental and numerical investigation of PCM capsules as insulation materials inserted into a hollow brick wall. Energy Build. 2021, 246, 111127. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Fernández, C.; Cabeza, L.F. Simulation-based optimization of PCM melting temperature to improve the energy performance in buildings. Appl. Energy 2017, 202, 420–434. [Google Scholar] [CrossRef]

- Jelle, B.P.; Kalnæs, S.E. Chapter 3—Phase Change Materials for Application in Energy-Efficient Buildings. In Cost-Effective Energy Efficient Building Retrofitting; Pacheco-Torgal, F., Granqvist, C.-G., Jelle, B.P., Vanoli, G.P., Bianco, N., Kurnitski, J., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 57–118. [Google Scholar] [CrossRef]

- Farid, M.; Auckaili, A.; Gholamibozanjani, G. (Eds.) Thermal Energy Storage with Phase Change Materials, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Sarcinella, A.; Cunha, S.; Barroso de Aguiar, J.L.; Frigione, M. Thermo-Chemical Characterization of Organic Phase Change Materials (PCMs) Obtained from Lost Wax Casting Industry. Sustainability 2024, 16, 7057. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete. Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Baniassadi, A.; Sajadi, B.; Amidpour, M.; Noori, N. Economic optimization of PCM and insulation layer thickness in residential buildings. Sustain. Energy Technol. Assess. 2016, 14, 92–99. [Google Scholar] [CrossRef]

- Zhou, D.; Zhao, C.Y.; Tian, Y. Review on thermal energy storage with phase change materials (PCMs) building applications. Appl. Energy 2012, 92, 593–605. [Google Scholar] [CrossRef]

- Zhou, G.B.; Zhang, Y.P.; Lin, K.P.; Xiao, W. Thermal analysis of a direct-gain room with shape-stabilized PCM plates. Renew. Energy 2008, 33, 1228–1236. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Y.P.; Lin, K.P.; Di, H.F.; Yang, R. Modeling and simulation on the thermal performance of shape-stabilized phase change material floor used in passive solar buildings. Energy Build. 2005, 37, 1084–1091. [Google Scholar] [CrossRef]

- Athienitis, A.K.; Liu, C.; Hawes, D.; Banu, D.; Feldman, D. Investigation of the thermal performance of a passive solar test-room with wall latent heat storage. Build. Environ. 1997, 2, 3405–3410. [Google Scholar] [CrossRef]

- Pasupathy, A.; Velraj, R. Effect of double layer phase change material in building roof for year round thermal management. Energy Build. 2008, 40, 193–203. [Google Scholar] [CrossRef]

- Yu, J.; Yang, Q.; Ye, H.; Huang, J.; Liu, Y.; Tao, J. The Optimum Phase Transition Temperature for Building Roof with Outer Layer PCM in Different Climate Regions of China. Energy Procedia 2019, 158, 3045–3051. [Google Scholar] [CrossRef]

- Vukadinović, A.; Radosavljević, J.; Đorđević, A. Energy performance impact of using phase-change materials in thermal storage walls of detached residential buildings with a sunspace. Sol. Energy 2020, 206, 228–244. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. Numerical analysis for the optimal location of a thin PCM layer in frame walls. Appl. Therm. Eng. 2016, 103, 1057–1063. [Google Scholar] [CrossRef]

- Lagou, A.; Šadauskienė, A.K.J.; Fokaides, P.A. Numerical investigation of phase change materials (PCM) optimal melting properties and position in building elements under diverse conditions. Constr. Build. Mater. 2019, 225, 452–464. [Google Scholar] [CrossRef]

- Darvishi, F.; Markarian, E.; Ziasistani, N.; Ziasistani, N.; Javanshir, A. Energy Performance Assessment of PCM Buildings Considering Multiple Factors. In Proceedings of the 2019 International Conference on Power Generation Systems and Renewable Energy Technologies (PGSRET), Istanbul, Turkey, 26–27 August 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Piselli, C.; Prabhakar, M.; de Gracia, A.; Saffari, M.; Pisello, A.L.; Cabeza, L.F. Optimal control of natural ventilation as passive cooling strategy for improving the energy performance of building envelope with PCM integration. Renew. Energy 2020, 162, 171–181. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.-H. Phase change materials (PCMs) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Soudian, S.; Berardi, U. Assessing the effect of night ventilation on PCM performance in high-rise residential buildings. J. Build. Phys. 2019, 43, 229–249. [Google Scholar] [CrossRef]

- Barzin, R.; Chen, J.J.J.; Young, B.R.; Farid, M.M. Application of PCM energy storage in combination with night ventilation for space cooling. Appl. Energy 2015, 158, 412–421. [Google Scholar] [CrossRef]

- Berardi, U.; Soudian, S. Experimental investigation of latent heat thermal energy storage using PCMs with different melting temperatures for building retrofit. Energy Build. 2019, 185, 180–195. [Google Scholar] [CrossRef]

- Prakash, J.; Garg, H.P.; Datta, G. A solar water heater with a built-in latent heat storage. Energy Convers. Manag. 1985, 25, 51–56. [Google Scholar] [CrossRef]

- Kuravi, S.; Trahan, J.; Goswami, D.Y.; Rahman, M.M.; Stefanakos, E.K. Thermal energy storage technologies and systems for concentrating solar power plants. Prog. Energy Combust. Sci. 2013, 39, 285–319. [Google Scholar] [CrossRef]

- Arivazhagan, R.; Geetha, N.B.; Pandiyarajan, R. Experimental and numerical investigation of PCMS on ceilings for thermal management. J. Eng. Res. 2025, 13, 229–242. [Google Scholar] [CrossRef]

- Martín, M.; Villalba, A.; Fernández, A.I.; Barreneche, C. Energy & Buildings Development of New Nano-Enhanced Phase Change Materials (NEPCM) to Improve Energy Efficiency in Buildings: Lab-Scale Characterization. Energy Build. 2019, 192, 75–83. [Google Scholar] [CrossRef]

- George, M.; Pandey, A.K.; Rahim, N.A.; Tyagi, V.V.; Shahabuddin, S.; Saidur, R. A novel polyaniline (PANI)/paraffin wax nano composite phase change material: Superior transition heat storage capacity, thermal conductivity and thermal reliability. Sol. Energy 2020, 204, 448–458. [Google Scholar] [CrossRef]

- Habib, N.A.; Ali, A.J.; Chaichan, M.T.; Kareem, M. Carbon Nanotubes/Paraffin Wax Nanocomposite for Improving the Performance of a Solar Air Heating System. Therm. Sci. Eng. Prog. 2021, 23, 100877. [Google Scholar] [CrossRef]

- Sheng, N.; Rao, Z.; Zhu, C.; Habazaki, H. Honeycomb Carbon Fibers Strengthened Composite Phase Change Materials for Superior Thermal Energy Storage. Appl. Therm. Eng. 2020, 164, 114493. [Google Scholar] [CrossRef]

- Zhang, Q.; Sazon, T.A.S.; Fadnes, F.S.; Peng, X.; Ahmed, N.; Nikpey, H.; Mansouri, M.; Assadi, M. Design Optimization of the Cooling Systems with PCM-to-Air Heat Exchanger for the Energy Saving of the Residential Buildings. Energy Convers. Manag. X 2024, 23, 100630. [Google Scholar] [CrossRef]

- Kong, X.; Wang, L.; Li, H.; Yuan, G.; Yao, C. Experimental study on a novel hybrid system of active composite PCM wall and solar thermal system for clean heating supply in winter. Sol. Energy 2020, 195, 259–270. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Proposal of a unique index for selection of optimum phase change material for effective thermal performance of a building envelope. Sol. Energy 2021, 218, 129–141. [Google Scholar] [CrossRef]

- Luo, Z.; Liu, X.; Yang, Q.; Qu, Z.; Xu, H.; Xu, D. Numerical study on performance of porous brick roof using phase change material with night ventilation. Energy Build. 2023, 286, 112972. [Google Scholar] [CrossRef]

- Triano-Juárez, J.; Macias-Melo, E.V.; Hernández-Pérez, I.; Aguilar-Castro, K.M.; Xamán, J. Thermal behavior of a phase change material in a building roof with and without reflective coating in a warm humid zone. J. Build. Eng. 2020, 32, 101648. [Google Scholar] [CrossRef]

- Chang, S.J.; Wi, S.; Cho, H.M.; Jeong, S.-G.; Kim, S. Numerical analysis of phase change materials/wood–plastic composite roof module system for improving thermal performance. J. Ind. Eng. Chem. 2020, 82, 413–423. [Google Scholar] [CrossRef]

- Elawady, N.; Bekheit, M.; Sultan, A.A.; Radwan, A. Energy assessment of a roof-integrated phase change materials, long-term numerical analysis with experimental validation. Appl. Therm. Eng. 2022, 202, 117773. [Google Scholar] [CrossRef]

- Rangel, C.G.; Rivera-Solorio, C.I.; Gijón-Rivera, M.; Mousavi, S. The effect on thermal comfort and heat transfer in naturally ventilated roofs with PCM in a semi-arid climate: An experimental research. Energy Build. 2022, 274, 112453. [Google Scholar] [CrossRef]

- Sedaghat, A.; Salem, H.; Hussam, W.K.; Mahdizadeh, A.; Al-Khiami, M.I.; Malayer, M.A.; Soleimani, S.M.; Sabati, M.; Narayanan, R.; Rasul, M.; et al. Exploring energy-efficient building solutions in hot regions: A study on bio-phase change materials and cool roof coatings. J. Build. Eng. 2023, 76, 107258. [Google Scholar] [CrossRef]

- Basher, H.O.; Hasan, M.I.; Shdhan, A.O. Numerical Investigation of Phase Change Materials for Insulation of Residential Buildings in Hot Regions in Iraqi cities. Wasit J. Eng. Sci. 2018, 6, 1–20. [Google Scholar] [CrossRef]

- Abden, M.J.; Tao, Z.; Pan, Z.; George, L.; Wuhrer, R. Inclusion of methyl stearate/diatomite composite in gypsum board ceiling for building energy conservation. Appl. Energy 2020, 259, 114113. [Google Scholar] [CrossRef]

- Velasco-Carrasco, M.; Chen, Z.; Aguilar-Santana, J.L.; Riffat, S. Experimental Evaluation of Thermal Energy Storage (TES) with Phase Change Materials (PCMs) for Ceiling Tile Applications. Future Cities Environ. 2020, 6, 1–11. [Google Scholar] [CrossRef]

- Bogatu, D.-I.; Kazanci, O.B.; Olesen, B.W. An experimental study of the active cooling performance of a novel radiant ceiling panel containing phase change material (PCM). Energy Build. 2021, 243, 110981. [Google Scholar] [CrossRef]

- Skovajsa, J.; Drabek, P.; Sehnalek, S.; Zalesak, M. Design and experimental evaluation of phase change material based cooling ceiling system. Appl. Therm. Eng. 2022, 205, 118011. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. Thermal and Energy Performance Evaluation of a Full-Scale Test Cabin Equipped with PCM Embedded Radiant Chilled Ceiling. Build. Environ. 2023, 237, 110384. [Google Scholar] [CrossRef]

- ISO 7730; 2005—Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization: Geneva, Switzerland, 2005.

- Mustafa, J.; Alqaed, S.; Sharifpur, M. PCM embedded radiant chilled ceiling as a solution to shift the cooling peak load-focusing on solidification process acceleration. J. Build. Eng. 2022, 57, 104894. [Google Scholar] [CrossRef]

- Khattari, Y.; Arid, A.; El Ouali, A.; Kousksou, T.; Janajreh, I.; Ghoulam, E.M.B. CFD study on the validity of using PCM in a controlled cooling ceiling integrated in a ventilated room. Dev. Built Environ. 2022, 9, 100066. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y.; Zhao, Y.; Torres, J.F.; Wang, X. PCM-based ceiling panels for passive cooling in buildings: A CFD modelling. Energy Build. 2023, 285, 112898. [Google Scholar] [CrossRef]

- Stalin, M.; Krishnan, S.; Barath, P. Cooling of Room with Ceiling Fan Using Phase Change Materials. In Proceedings of the World Congress on Engineering, London, UK, 3–5 July 2013; Volume 3, pp. 1–4. [Google Scholar]

- Plytaria, M.T.; Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. Numerical simulation of a solar cooling system with and without phase change materials in radiant walls of a building. Energy Convers. Manag. 2019, 188, 40–53. [Google Scholar] [CrossRef]

- Kant, K.; Shukla, A.; Sharma, A. Numerical simulation of building wall incorporating phase change material for cooling load reduction. Energy Clim. Change 2020, 1, 100008. [Google Scholar] [CrossRef]

- Khan, R.J.; Bhuiyan, M.Z.H.; Ahmed, D.H. Investigation of heat transfer of a building wall in the presence of phase change material (PCM). Energy Built Environ. 2020, 1, 199–206. [Google Scholar] [CrossRef]

- Yu, N.; Chen, C.; Mahkamov, K.; Han, F.; Zhao, C.; Lin, J.; Jiang, L.; Li, Y. Selection of a phase change material and its thickness for application in walls of buildings for solar-assisted steam curing of precast concrete. Renew. Energy 2020, 150, 808–820. [Google Scholar] [CrossRef]

- Kishore, R.A.; Bianchi, M.V.A.; Booten, C.; Vidal, J.; Jackson, R. Optimizing PCM-integrated walls for potential energy savings in U.S. Buildings. Energy Build. 2020, 226, 110355. [Google Scholar] [CrossRef]

- Zaid, Z.B.; Tilioua, A.; Lamaamar, I.; Ansari, O.; Alaoui, M.A.H. Thermal performance of clay-straw wall incorporating phase change materials in Errachidia city (South Eastern Morocco): A simulation approach. Case Stud. Constr. Mater. 2021, 15, e00786. [Google Scholar] [CrossRef]

- Ouhsaine, L.; Ramenah, H.; El Ganaoui, M.; Mimet, A. Dynamic state-space model and performance analysis for solar active walls embedded phase change material, Sustainable Energy. Grids Netw. 2020, 24, 100401. [Google Scholar] [CrossRef]

- Hattan, H.A.; Madhkhan, M.; Marani, A. Thermal and mechanical properties of building external walls plastered with cement mortar incorporating shape-stabilized phase change materials (SSPCMs). Constr. Build. Mater. 2021, 270, 121385. [Google Scholar] [CrossRef]

- Yu, C.; Shen, D.; He, W.; Hu, Z.; Zhang, S.; Chu, W. Parametric analysis of the phase change material wall combining with micro-channel heat pipe and sky radiative cooling technology. Renew. Energy 2021, 178, 1057–1069. [Google Scholar] [CrossRef]

- Alharbey, R.A.; Daqrouq, K.O.; Alkhateeb, A. Energy exchange of Inserting Eco-friendly Bio Phase Change Material into the vertical walls to make the buildings energy-efficient. J. Build. Eng. 2022, 56, 104777. [Google Scholar] [CrossRef]

- Imafidon, O.J.; Ting, D.S.K. Energy consumption of a building with phase change material walls—The effect of phase change material properties. J. Energy Storage 2022, 52, 104777. [Google Scholar] [CrossRef]

- Nizovtsev, M.I.; Sterlyagov, A.N. Effect of phase change material (PCM) on thermal inertia of walls in lightweight buildings. J. Build. Eng. 2024, 82, 107912. [Google Scholar] [CrossRef]

- Sudha, D.; Gopal, S.R.; Sowmiya, J.K.; Kannadasan, B.; Narayan, P.; Ghosh, T. Study on the heat gain through a twin glass window (TGW) using an organic PCM. Mater. Today Proc. 2022, 69, 927–933. [Google Scholar] [CrossRef]

- Jiang, A.W.; Liu, B.; Zhang, X.; Zhang, T.; Li, D.; Ma, L. Energy performance of window with PCM frame. Sustain. Energy Technol. Assess. 2021, 45, 101109. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Development of a window shutter with phase change materials: Full scale outdoor experimental approach. Energy Build. 2015, 88, 110–121. [Google Scholar] [CrossRef]

- Bianco, L.; Komerska, A.; Cascone, Y.; Serra, V.; Zinzi, M.; Carnielo, E.; Ksionek, D. Thermal and optical characterization of dynamic shading systems with PCMs through laboratory experimental measurements. Energy Build. 2018, 163, 92–110. [Google Scholar] [CrossRef]

- King, M.F.L.; Rao, P.N.; Sivakumar, A.; Mamidi, V.K.; Richard, S.; Vijayakumar, M.; Arunprasath, K.; Kumar, P.M. Thermal performance of a double-glazed window integrated with a phase change material (PCM). Mater. Today Proc. 2022, 50, 1516–1521. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, Y.; Lin, P.; Zhu, X. Leakproof phase-change glass window: Characteristics and performance. Build. Environ. 2022, 218, 109088. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Z.; Wang, P.; Li, B. Performance evaluation of a novel rotatable dynamic window integrated with a phase change material and a vacuum layer. Energy Convers. Manag. 2022, 272, 116333. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, C.Y. Parametric Investigations of Using a PCM Curtain for Energy Efficient Buildings. Energy Build. 2015, 94, 33–42. [Google Scholar] [CrossRef]

- Lu, Y.; Aldawood, F.K.; Hu, W.; Ma, Y.; Kchaou, M.; Zhang, C.; Yang, X.; Yang, R.; Qi, Z.; Li, D. Optimization Strategy for Selecting the Combination Structure of Multilayer Phase Change Material (PCM) Glazing Windows under Different Climate Zones. Sustainability 2023, 15, 16267. [Google Scholar] [CrossRef]

- Wijesena, R.N.; Tissera, N.D.; Rathnayaka, V.W.S.G.; Rajapakse, H.D.; de Silva, R.M.; de Silva, K.M.N. Shape-stabilization of polyethylene glycol phase change materials with chitin nanofibers for applications in “smart” windows. Carbohydr. Polym. 2020, 237, 116132. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Wang, F.; Fang, Q.; Chen, S.; He, W.; Wang, N. Thermal-Responsive Smart windows with Passive Dimming and Thermal Energy Storage. ACS Omega 2024, 9, 27222–27231. [Google Scholar] [CrossRef] [PubMed]

- Fu, W.; Zou, T.; Liang, X.; Wang, S.; Gao, X.; Zhang, Z.; Fang, Y. Preparation and properties of phase change temperature-tuned composite phase change material based on sodium acetate trihydrate–urea/fumed silica for radiant floor heating system. Appl. Therm. Eng. 2019, 162, 114253. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, J.; Wang, J.; Xu, T.; Du, Y.; Fan, G.; Wu, H. Preparation and Application of Paraffin/Expanded Graphite-Based Phase Change Material Floor for Solar-Heat Pump Combined Radiant Heating Systems. ACS Sustain. Chem. Eng. 2023, 11, 2871–2884. [Google Scholar] [CrossRef]

- González, B.; Prieto, M.M. Radiant heating floors with PCM bands for thermal energy storage: A numerical analysis. Int. J. Therm. Sci. 2021, 162, 106803. [Google Scholar] [CrossRef]

- Ju, H.; Li, X.; Chang, C.; Zhou, W.; Wang, G.; Tong, C. Heating performance of PCM radiant floor coupled with horizontal ground source heat pump for single-family house in cold zones. Renew. Energy 2024, 235, 121306. [Google Scholar] [CrossRef]

- Park, J.; Kim, T. Analysis of the Thermal Storage Performance of a Radiant Floor Heating System with a PCM. Molecules 2019, 24, 1352. [Google Scholar] [CrossRef]

- Babaharra, O.; Choukairy, K.; Hamdaoui, S.; Khallaki, K.; Mounir, S.H. Thermal behavior evaluation of a radiant floor heating system incorporates a microencapsulated phase change material. Constr. Build. Mater. 2022, 330, 127293. [Google Scholar] [CrossRef]

- Lu, S.; Zhao, Y.; Fang, K.; Li, Y.; Sun, P. Establishment and experimental verification of TRNSYS model for PCM floor coupled with solar water heating system. Energy Build. 2017, 140, 245–260. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Y.; Ling, Z.; Fang, X.; Zhang, Z. Experimental Investigation on the thermal performance of double-layer PCM radiant floor system containing two types of inorganic composite PCMs. Energy Build. 2020, 211, 109806. [Google Scholar] [CrossRef]

- Murathan, E.K.; Manioğlu, G. Evaluation of phase change materials used in building components for conservation of energy in buildings in hot dry climatic regions. Renew. Energy. 2020, 162, 1919–1930. [Google Scholar] [CrossRef]

- Pan, Y.; Zhu, M.; Lv, Y.; Yang, Y.; Liang, Y.; Yin, R.; Yang, Y.; Jia, X.; Wang, X.; Zeng, F.; et al. Building energy simulation and its application for building performance optimization: A review of methods, tools, and case studies. Adv. Appl. Energy 2023, 10, 100135. [Google Scholar] [CrossRef]

- Mazzeo, D.; Matera, N.; Cornaro, C.; Oliveti, G.; Romagnoni, P.; De Santoli, L. EnergyPlus, IDA ICE and TRNSYS predictive simulation accuracy for building thermal behavior evaluation by using an experimental campaign in solar test boxes with and without a PCM module. Energy Build. 2020, 212, 109812. [Google Scholar] [CrossRef]

- Ibáñez, M.; Lázaro, A.; Zalba, B.; Cabeza, L.F. An approach to the simulation of PCMs in building applications using TRNSYS. Appl. Therm. Eng. 2005, 25, 1796–1807. [Google Scholar] [CrossRef]

- Padovan, R.; Manzan, M. Development of a stratified tank storage component for ESP-r with embedded phase change material modules. Proc. Inst. Mech. Eng. Part A J. Power Energy 2013, 227, 53–61. [Google Scholar] [CrossRef]

- Yamoul, N.; Dlimi, L.; ELHarrouni, K.; Mahjoub, C.E.L.; Chakir, B.A. Enhancing the Energy Efficiency of Building’s Envelope by the Application of PCM Materials. Civ. Eng. Archit. 2024, 12, 4108–4115. [Google Scholar] [CrossRef]

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M. Verification and validation of EnergyPlus phase change material model for opaque wall assemblies. Build. Environ. 2012, 54, 186–196. [Google Scholar] [CrossRef]

- Ellis, P.G.; Torcellini, P.A.; Crawley, D.B. Simulation of Energy Management Systems in EnergyPlus. In Proceedings of the Building Simulation 2007, Beijing, China, 3–6 September 2007; pp. 1346–1353. [Google Scholar]

- Nouidui, T.; Wetter, M.; Zuo, W. Functional mock-up unit for co-simulation import in EnergyPlus. J. Build. Perform. Simul. 2013, 7, 192–202. [Google Scholar] [CrossRef]

- Kim, W.; Jeon, S.W.; Kim, Y. Model-based multi-objective optimal control of a VRF (variable refrigerant flow) combined system with DOAS (dedicated outdoor air system) using genetic algorithm under heating conditions. Energy 2016, 107, 196–204. [Google Scholar] [CrossRef]

- Zhuang, C.-L.; Deng, A.-Z.; Chen, Y.; Li, S.-B.; Zhang, H.-Y.; Fan, G.-Z. Validation of Veracity on Simulating the Indoor Temperature in PCM Light Weight Building by EnergyPlus. In Life System Modeling and Intelligent Computing, Proceedings of the International Conference on Life System Modeling and Simulation, LSMS 2010, and International Conference on Intelligent Computing for Sustainable Energy and Environment, ICSEE 2010, Wuxi, China, 17–20 September 2010; Li, K., Fei, M., Jia, L., Irwin, G.W., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 6328. [Google Scholar] [CrossRef]

- Pandey, B.; Banerjee, R.; Sharma, A. Coupled EnergyPlus and CFD analysis of PCM for thermal management of buildings. Energy Build. 2021, 231, 110598. [Google Scholar] [CrossRef]

- Klein, S.A.; Beckman, W.A. TRNSYS 16: A transient system simulation program: Mathematical reference. TRNSYS 2007, 5, 389–396. [Google Scholar]

- Al-Saadi, S.N.; Zhai, Z. A new validated TRNSYS module for simulating latent heat storage walls. Energy Build. 2015, 109, 274–290. [Google Scholar] [CrossRef]

- Clarke, J.A.; Kelly, N.J.; Tang, D. A Review of ESP-r’s Flexible Solution Approach and its Application to Prospective Technical Domain Developments. Adv. Build. Energy Res. 2007, 1, 227–247. [Google Scholar] [CrossRef]

- Heim, D. Isothermal storage of solar energy in building construction. Renew. Energy 2010, 35, 788–796. [Google Scholar] [CrossRef]