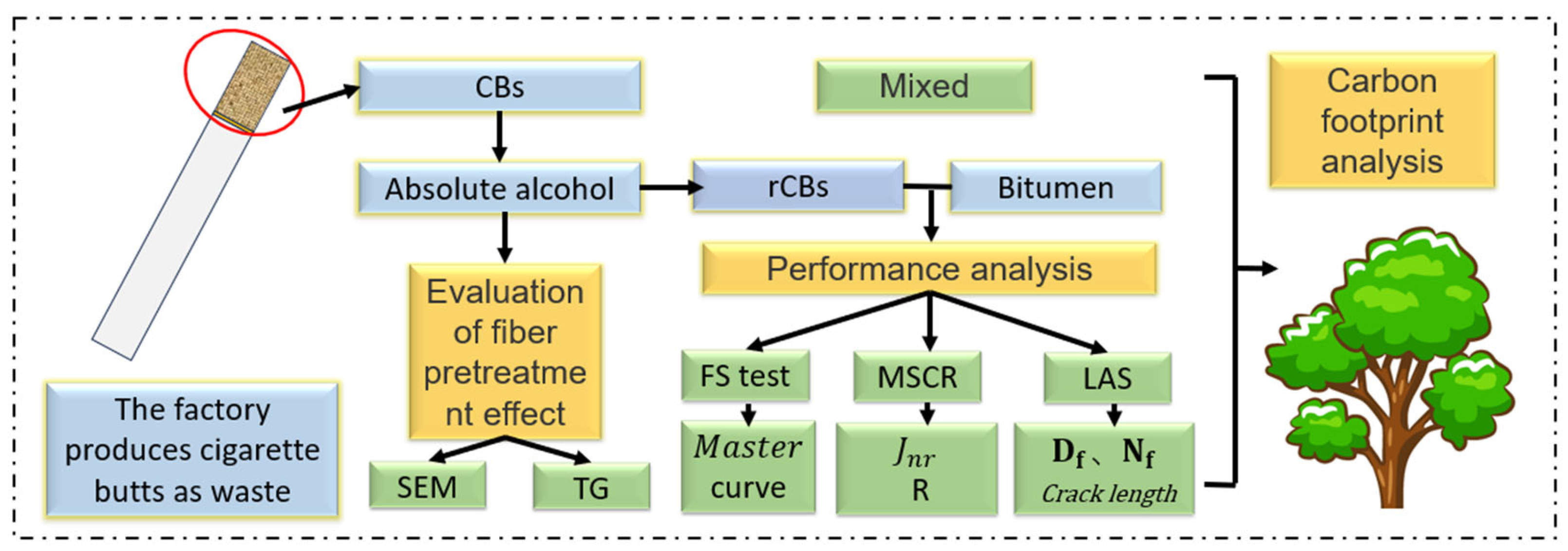

Effect of Waste Cigarette Butt Fibers on the Properties and CO2 Footprint of Bitumen

Abstract

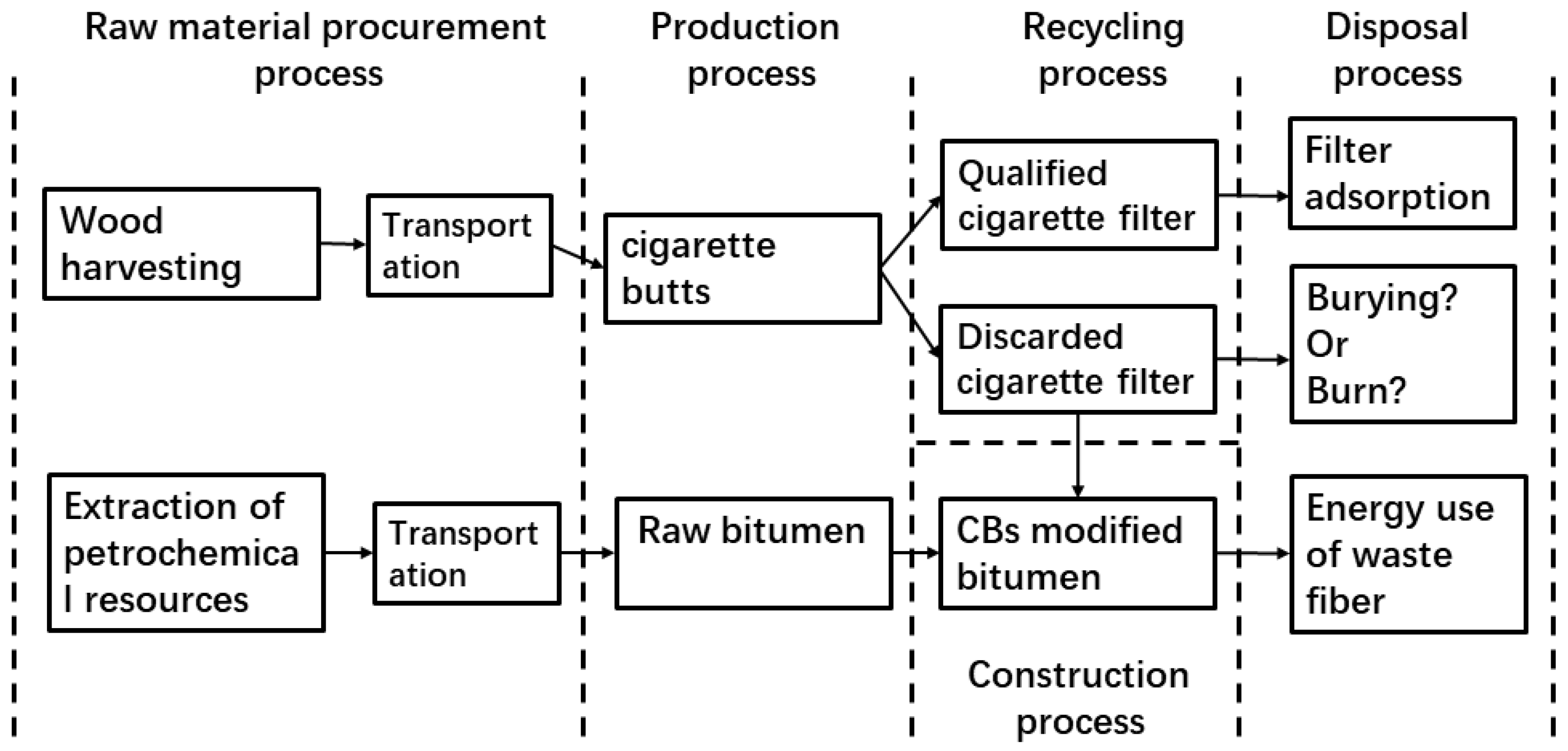

1. Introduction

2. Materials and Methods

2.1. Raw Materials

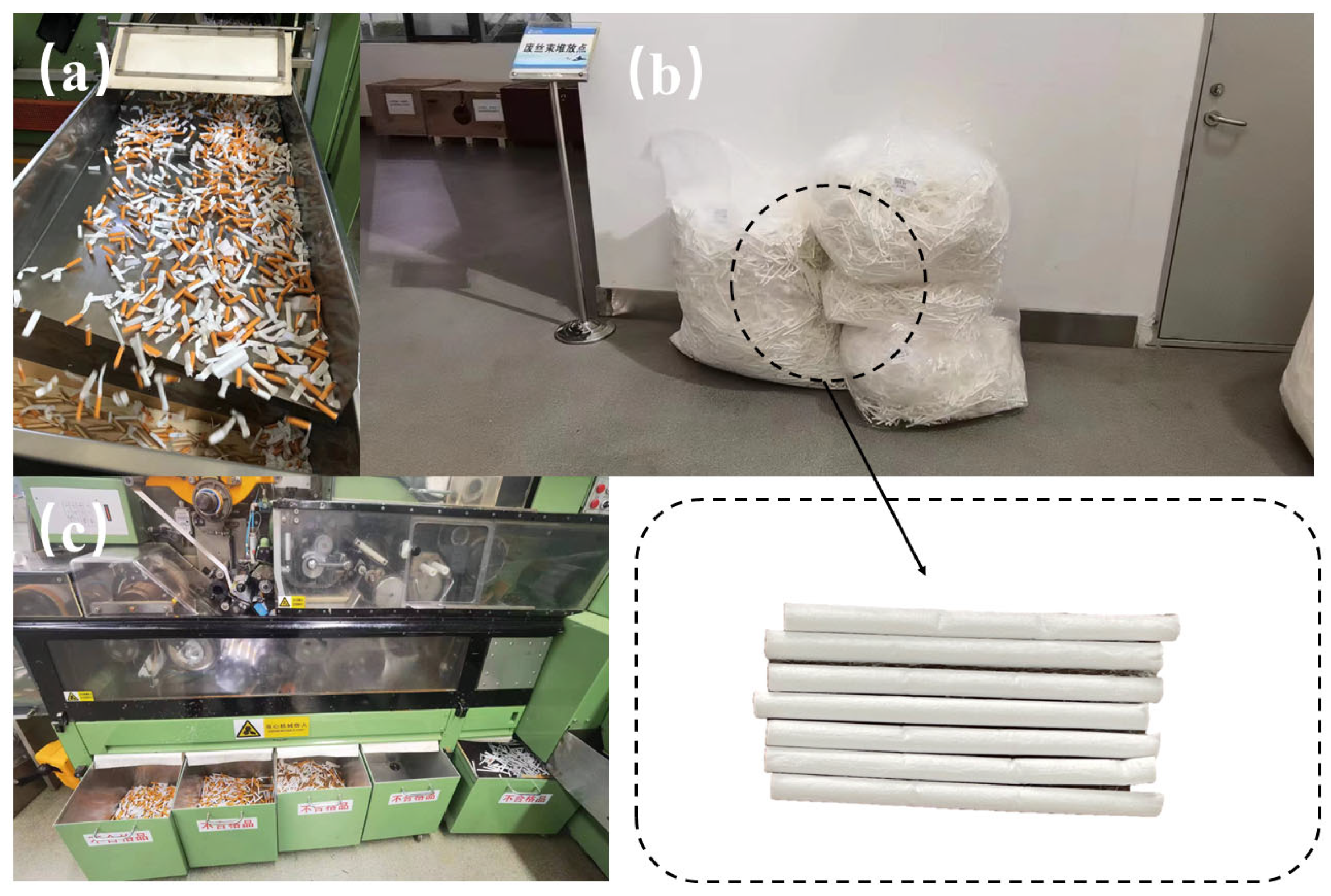

2.2. CBs

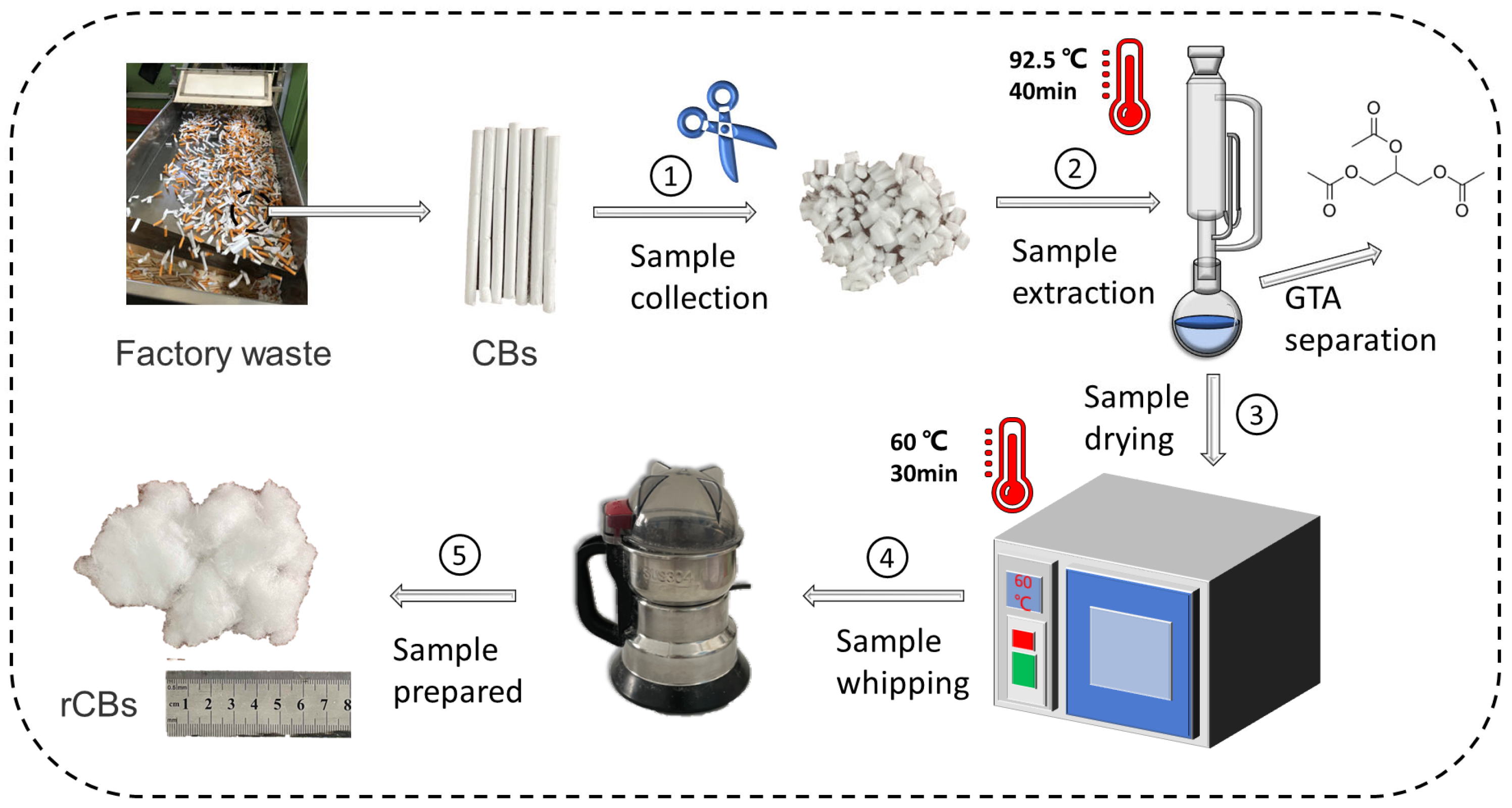

2.3. Fiber Preparation and Treatment

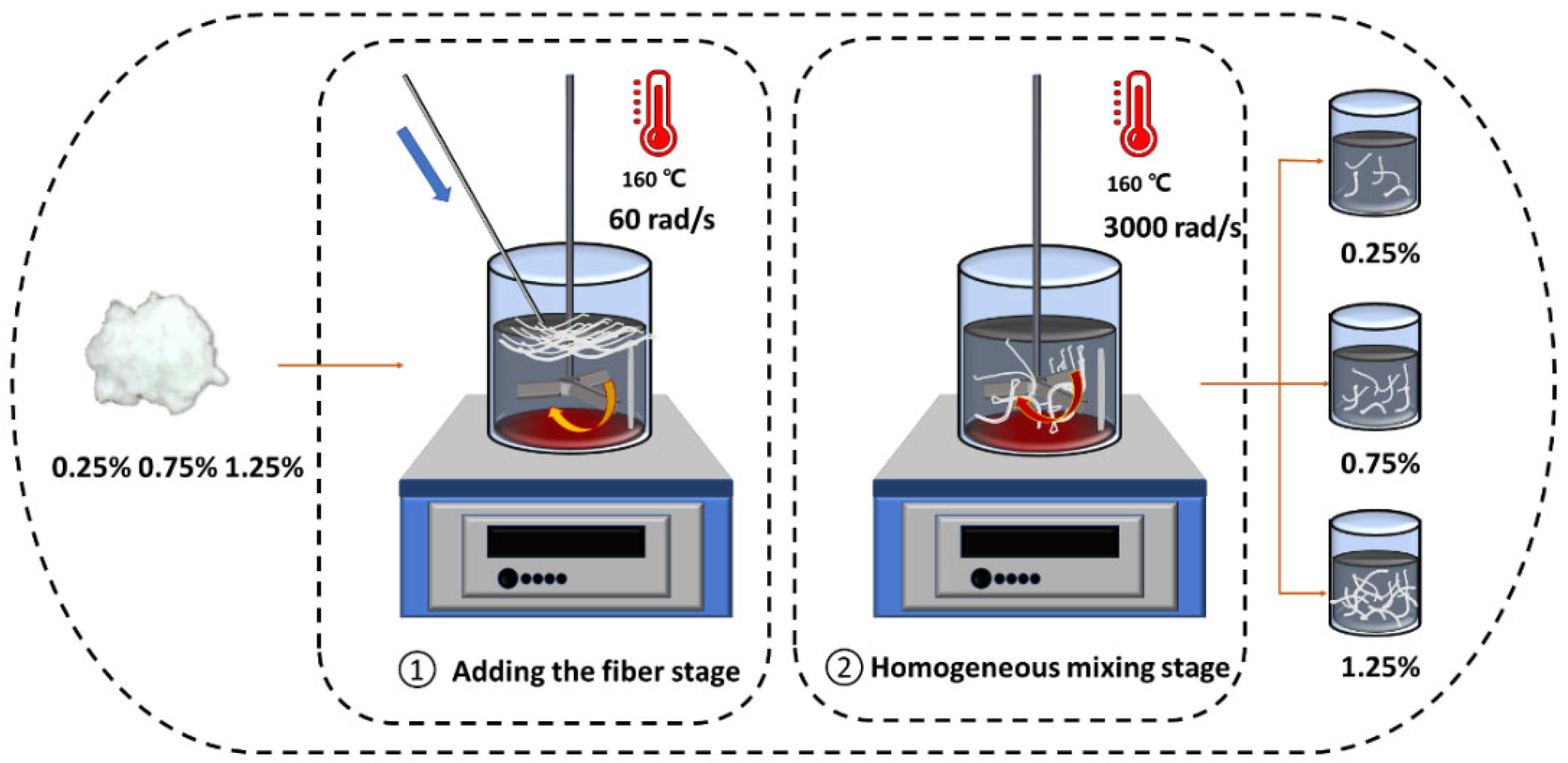

2.4. Fiber Binders’ Preparation

- (1)

- First, 450 g of the bitumen matrix was heated in a vacuum oven at 90 °C and held for 2 h to remove moisture. The treated fibers were then added to the bitumen matrix at different percentages (0.25%, 0.75%, and 1.25% by wt. of bitumen).

- (2)

- Using a glass rod, we pushed the loose fibers into the bitumen mastic in small quantities and in even batches.

- (3)

- Then, we used the mixing heads at a low speed of 60 rad/s to divide the fibers in the bitumen mastic. After high-speed mixing at 165 °C, a uniform sample was made after 1 h.

- (4)

- According to the distribution mixing method, the preparation of the acetate fiber–bitumen mixture with an acetate fiber dosing of 0.25%, 0.75%, and 1.25% was completed. This process is shown in Figure 4.

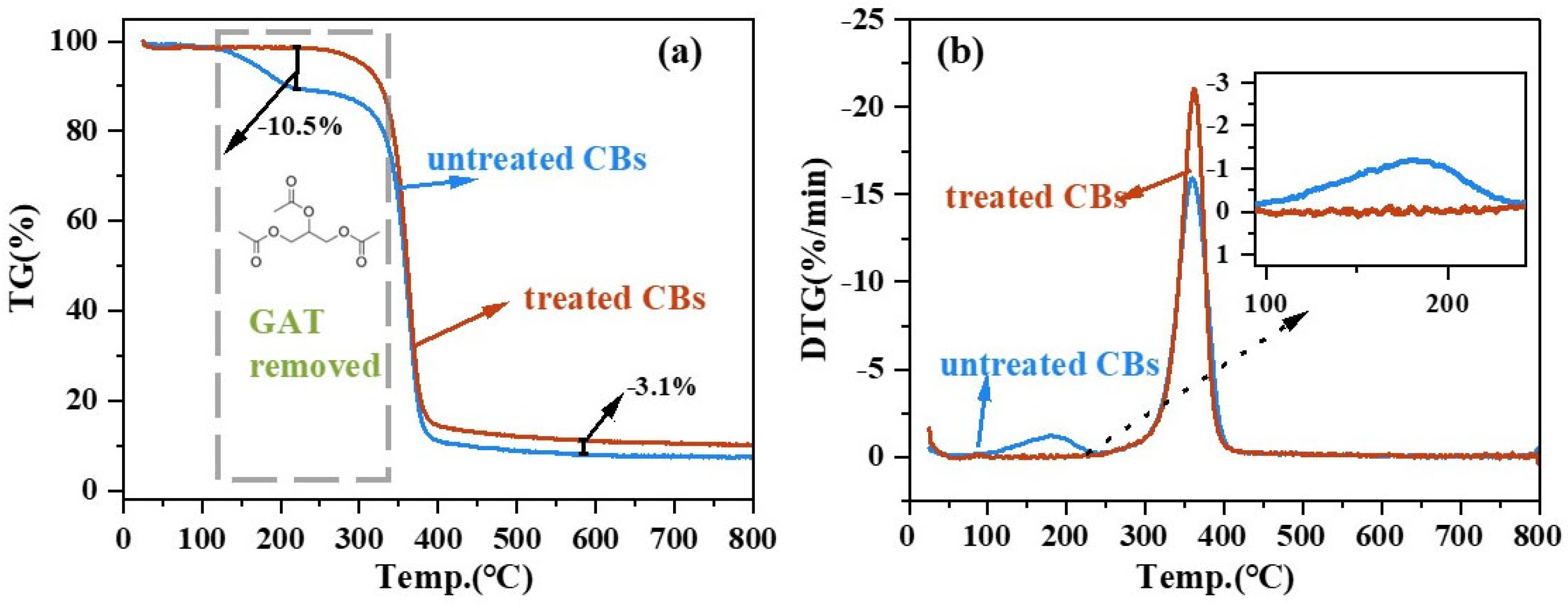

2.5. Evaluating the Effect of Fiber Pretreatment

2.6. Frequency Sweep Test

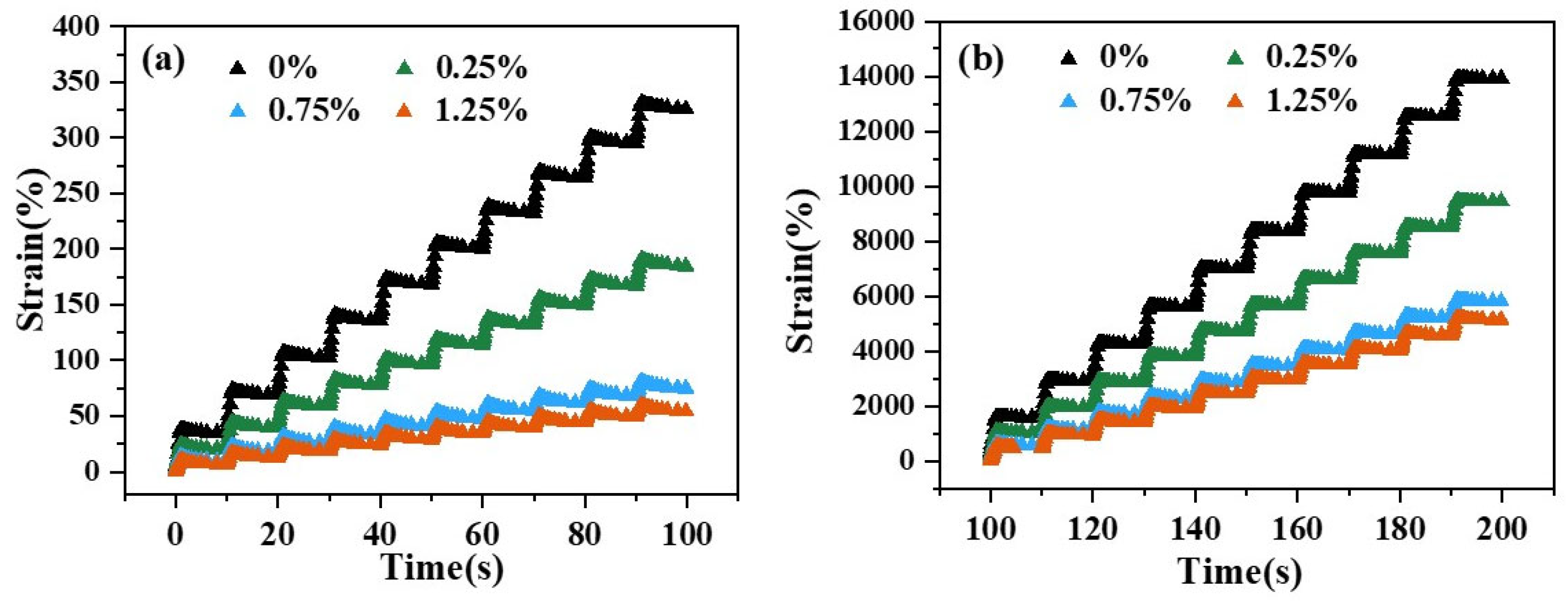

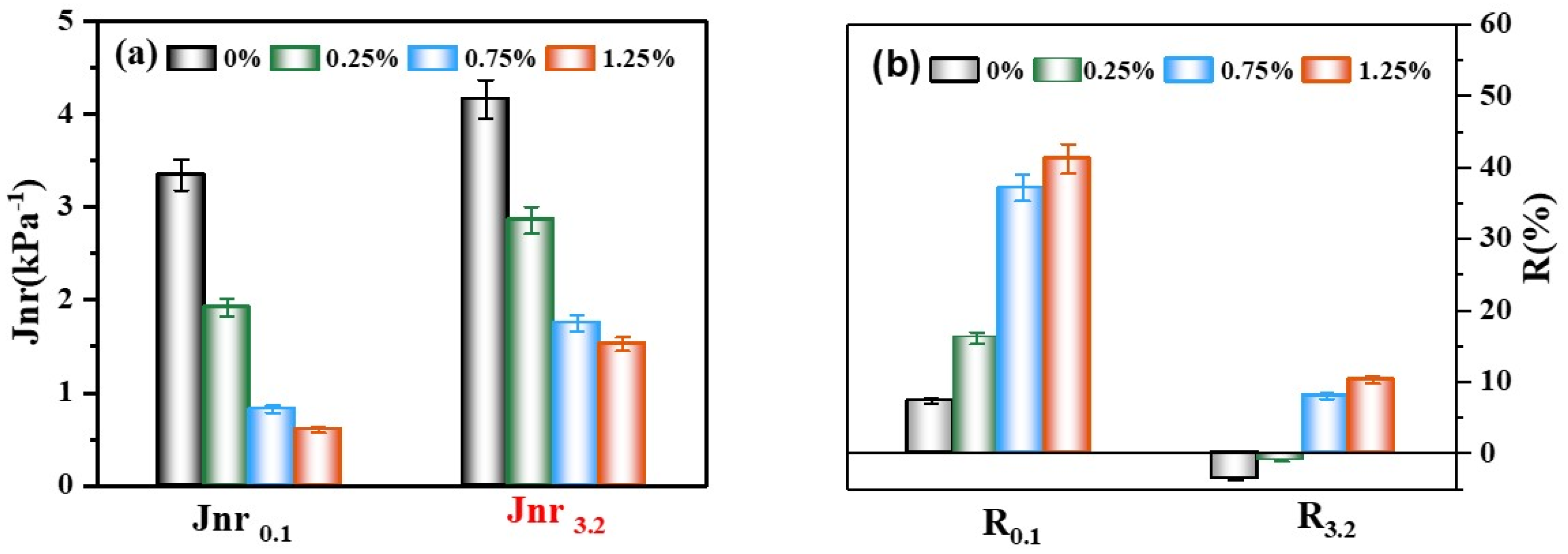

2.7. Multiple Stress Creep Recovery Test

2.8. Damage Tolerance—Linear Amplitude Sweep

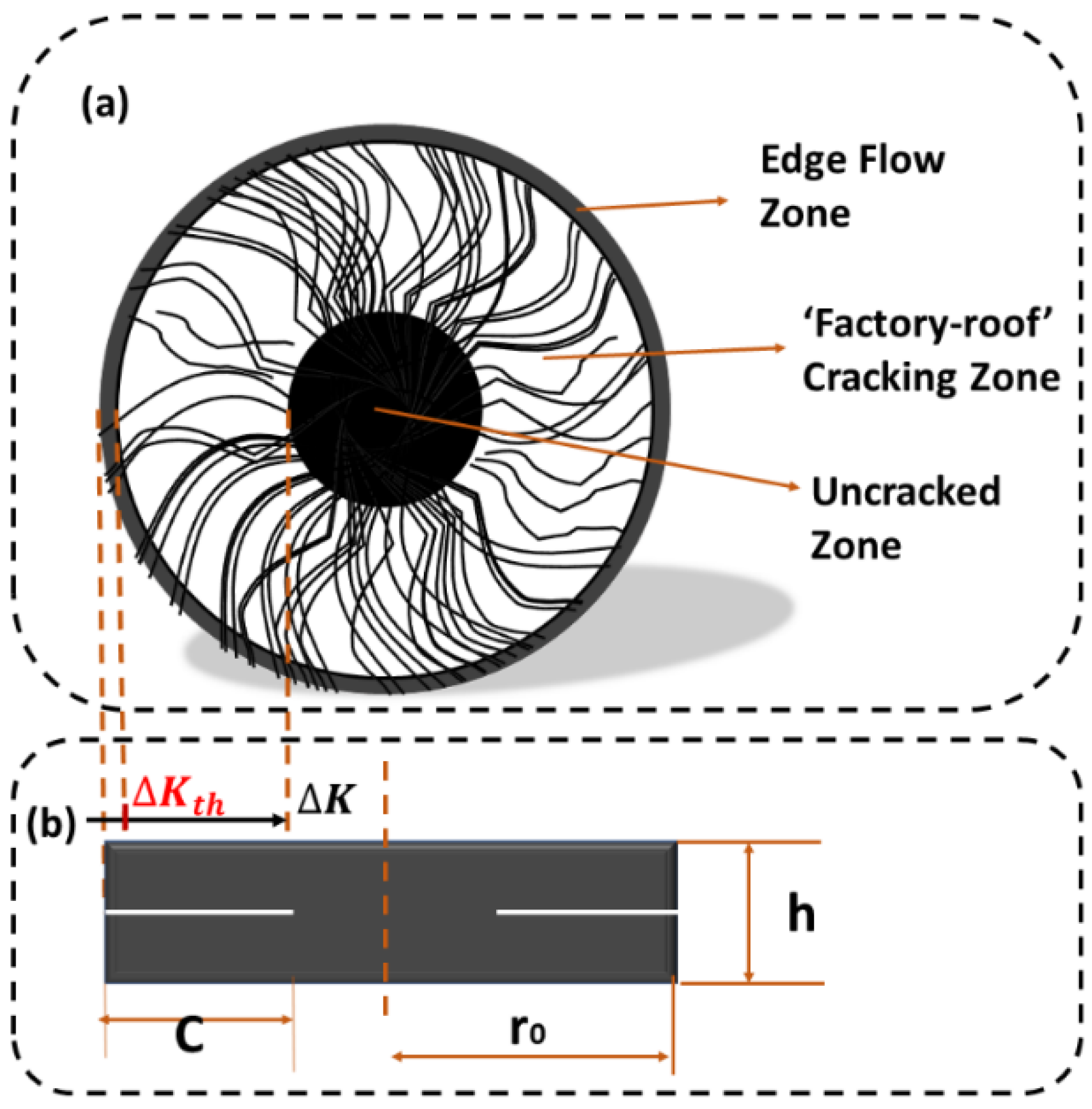

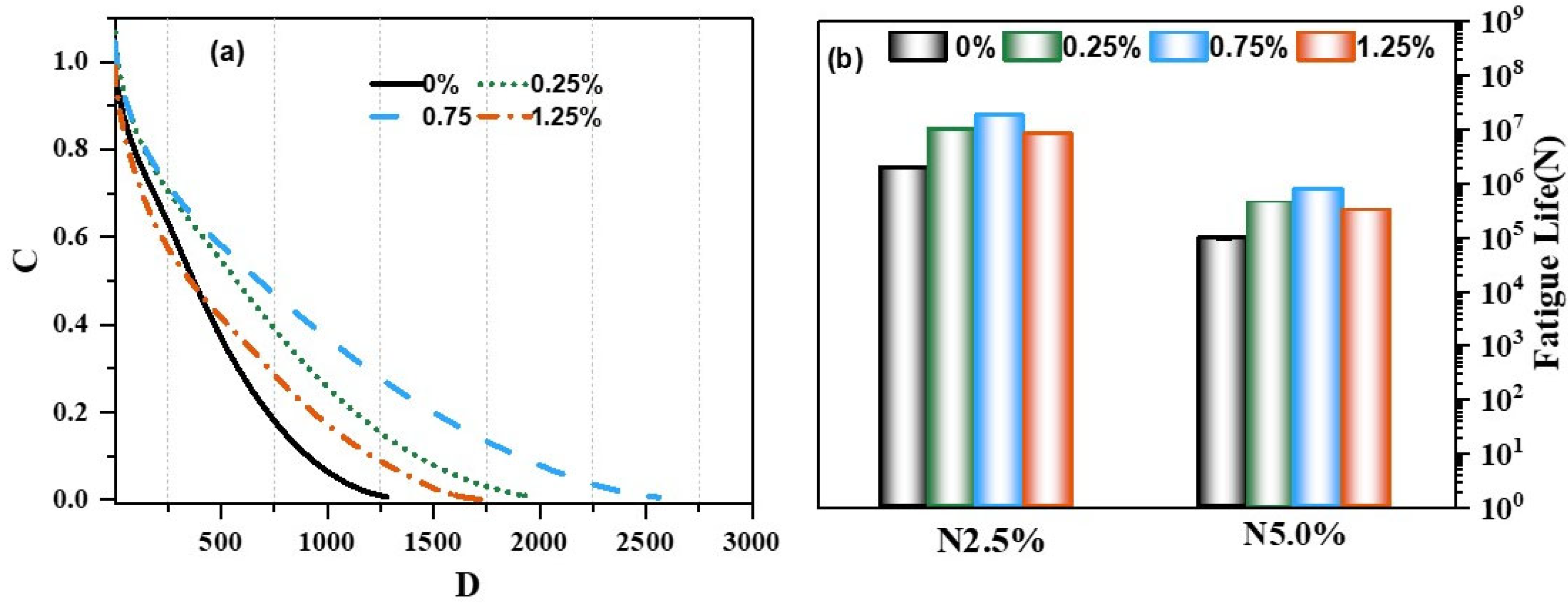

2.9. Crack Sprouting and Expansion

- (1)

- Edge flow zone: The stage where the stress intensity is less than the extended critical stress intensity . Cracks sprout early in fatigue and occur in the edge region. Edge flow arises from the instability of complex edge regions [39].

- (2)

- “Factory roof” crack zone: The stage where the stress intensity is greater than the extended critical stress intensity . Under cyclic shear, the crack expands steadily toward the center, forming a rough region on the specimen surface similar to a factory roof [37].

- (3)

- Crack-free zone: The region where cracks do not occur in the center of the specimen.

3. Results and Discussion

3.1. Fiber Thermal Stability Analysis

3.2. Evaluation of Fiber Pretreatment

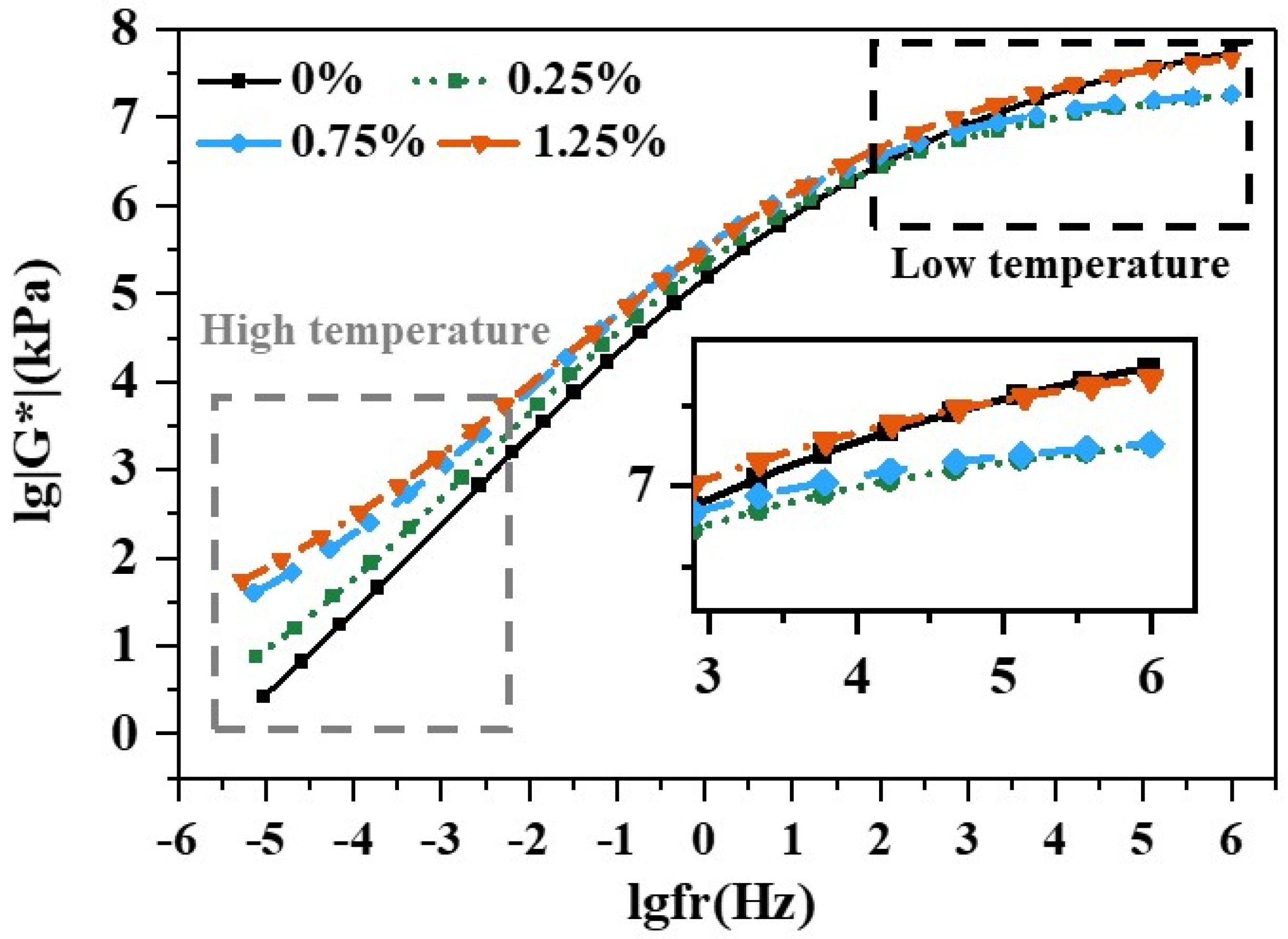

3.3. Complex Shear Modulus Master Curve

3.4. High-Temperature Performance

3.5. Fatigue Performance

3.6. Crack Growth Characteristics

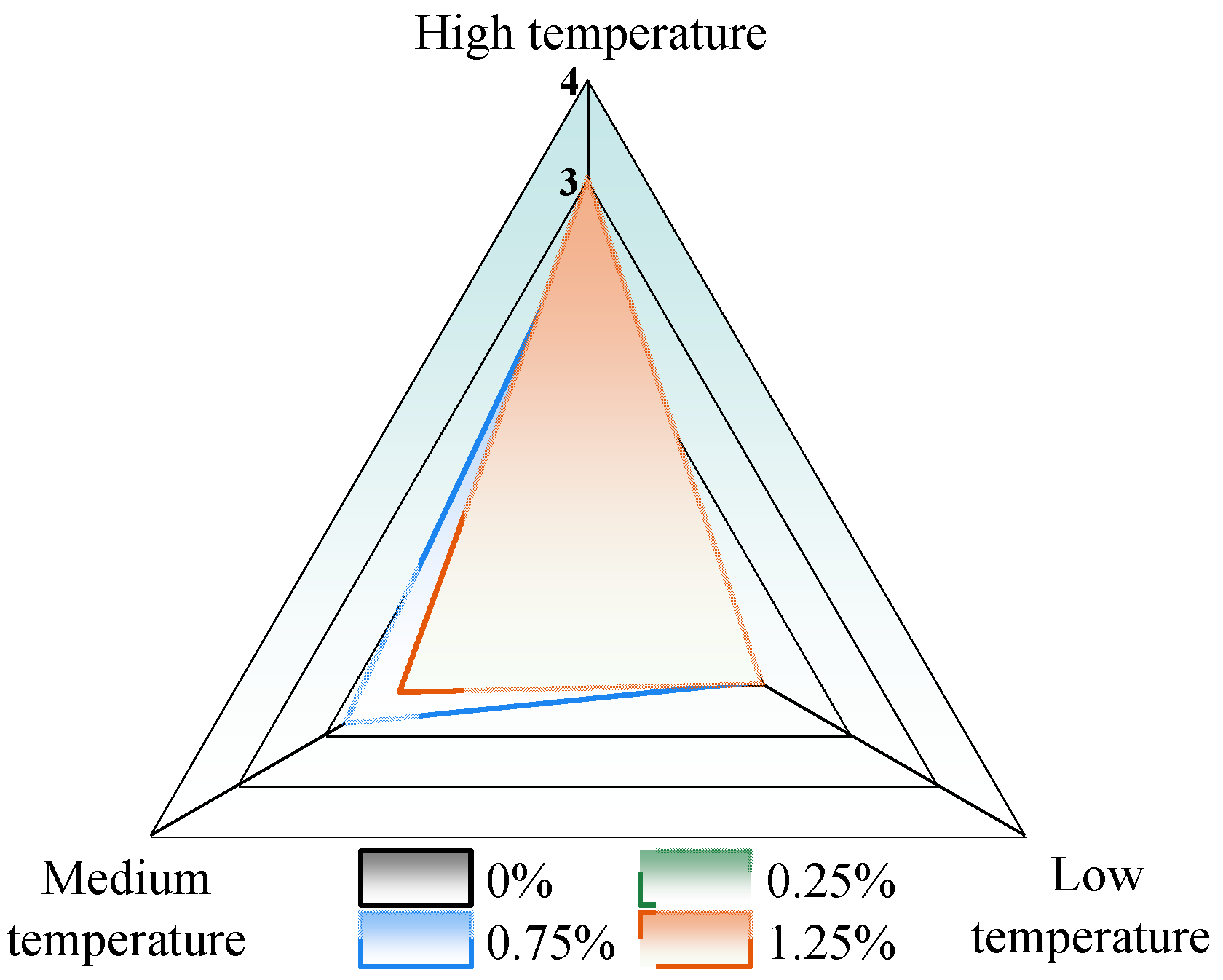

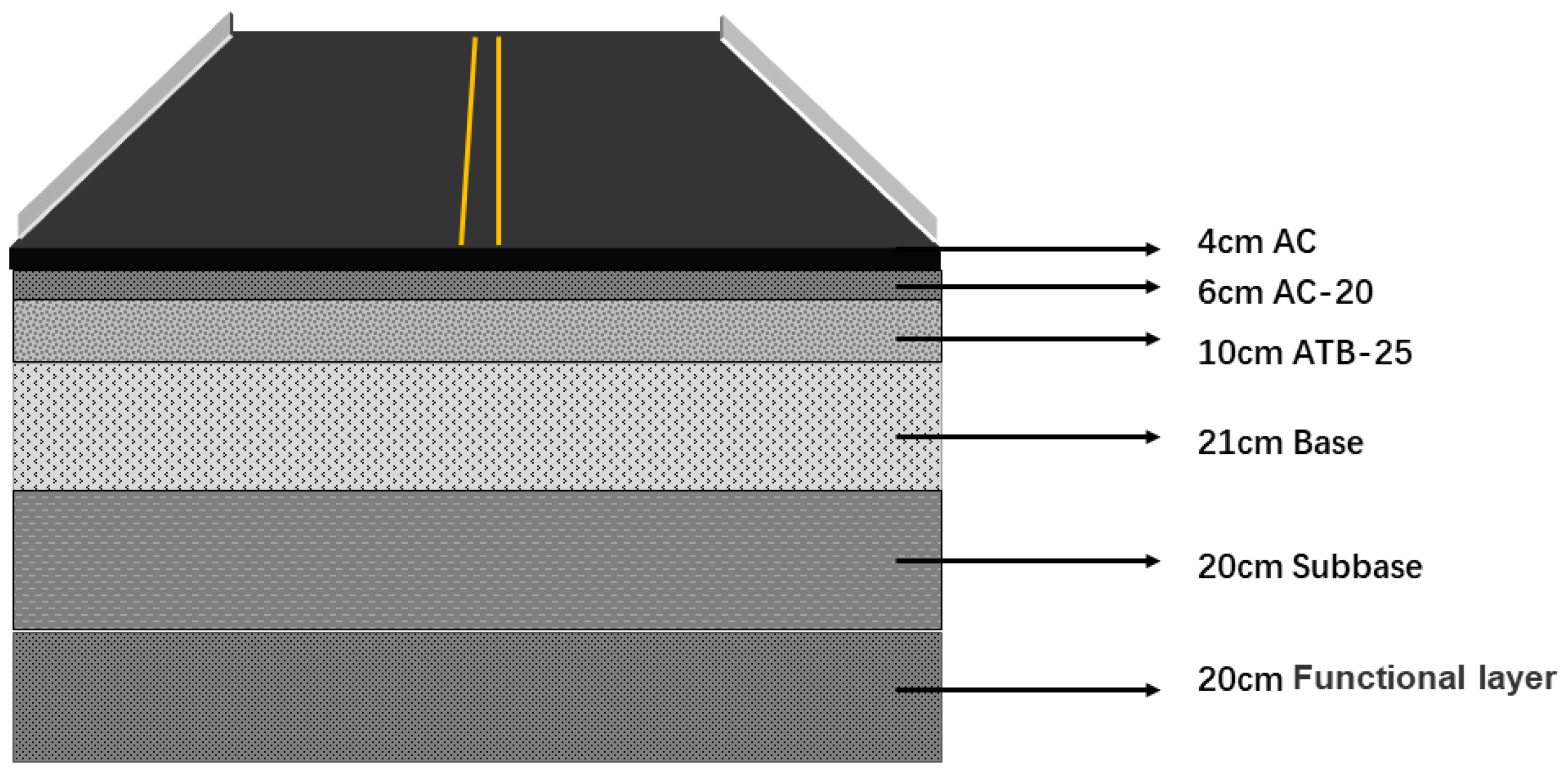

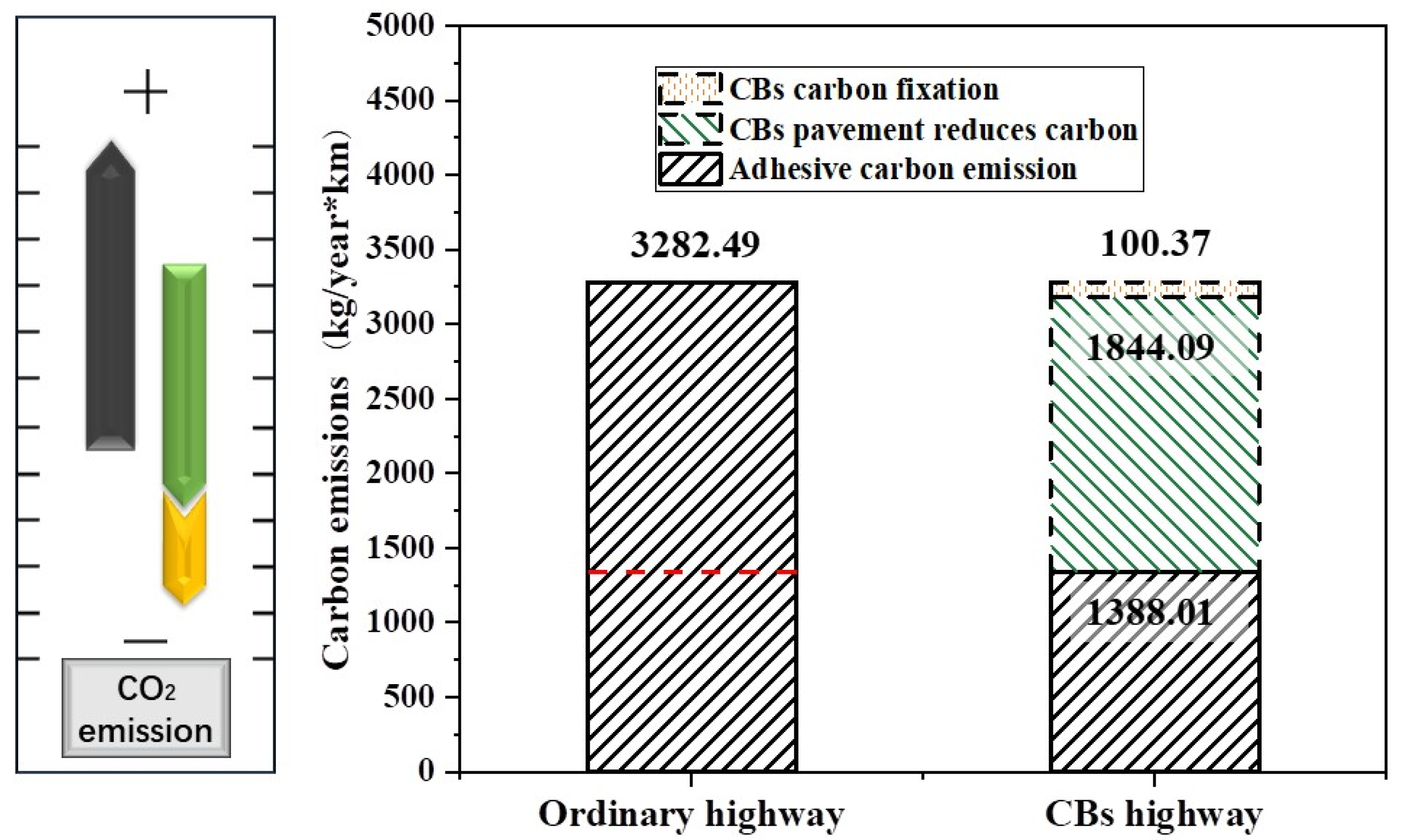

3.7. Ecological Benefit Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- WHO. Report on the Global Tobacco Epidemic; WHO: Geneva, Switzerland, 2021. [Google Scholar]

- Reitsma, M.B.; Fullman, N.; Ng, M.; Salama, J.S.; Abajobir, A.; Abate, K.H.; Abbafati, C.; Abera, S.F.; Abraham, B.; Abyu, G.Y.; et al. Smoking prevalence and attributable disease burden in 195 countries and territories, 1990–2015: A systematic analysis from the Global Burden of Disease Study 2015. Lancet 2017, 389, 1885–1906. [Google Scholar] [CrossRef] [PubMed]

- Mercedes, C.; Emilio, S.M.J. Toward a sustainable circular economy for cigarette butts, the most common waste worldwide on the coast. Sci. Total Environ. 2022, 16, 961–968. [Google Scholar] [CrossRef]

- Green, D.S.; Tongue, A.D.; Boots, B. The ecological impacts of discarded cigarette butts. Trends Ecol. Evol. 2021, 37, 183–192. [Google Scholar] [CrossRef] [PubMed]

- Gill, H.; Rogers, K.; Rehman, B.; Moynihan, J. Cigarette butts may have low toxicity to soil-dwelling invertebrates: Evidence from a land snail. Sci. Total Environ. 2018, 628, 556–561. [Google Scholar] [CrossRef]

- De Fenzo, A.; Giordano, M.; Sansone, L. A Clean Process for Obtaining High-Quality Cellulose Acetate from Cigarette Butts. Materials 2020, 13, 4710. [Google Scholar] [CrossRef]

- Kagawa, S.; Suzuki, K. Preparation of Activated Carbons from Cigarette Butts. Kagaku Kogaku Ronbunshu 2005, 31, 80–83. [Google Scholar] [CrossRef]

- Lima, H.H.C.; Maniezzo, R.S.; Kupfer, V.L.; Guilherme, M.R.; Moises, M.P.; Arroyo, P.A.; Rinaldi, A.W. Hydrochars based on cigarette butts as a recycled material for the adsorption of pollutants. J. Environ. Chem. Eng. 2018, 6, 7054–7061. [Google Scholar] [CrossRef]

- Li, S.; Shi, C.L.; Wang, Y.-Z.; Sun, X.D.; Qi, D.-W.; Wu, D.; Wang, Y.; Zhu, J. New efficient selective adsorbent of tobacco specific nitrosamines derived from discarded cigarette filters. Microporous Mesoporous Mater. 2019, 284, 393–402. [Google Scholar] [CrossRef]

- Li, L.; Jia, C.; Zhu, X. Utilization of cigarette butt waste as functional carbon precursor for supercapacitors and adsorbents. J. Clean. Prod. 2020, 256, 120326. [Google Scholar] [CrossRef]

- Sun, H.; La, P.; Yang, R.; Zhu, Z.; Liang, W.; Yang, B.; Li, A.; Deng, W. Innovative nanoporous carbons with ultrahigh uptakes for capture and reversible storage of CO2 and volatile iodine. J. Hazard. Mater. 2017, 321, 210–217. [Google Scholar] [CrossRef]

- Yu, C.; Hou, H.; Liu, X.; Han, L.; Yao, Y.; Dai, Z.; Li, D. The Recovery of the Waste Cigarette Butts for N-Doped Carbon Anode in Lithium Ion Battery. Front. Mater. 2018, 5, 63. [Google Scholar] [CrossRef]

- Wang, H.; Gao, M.; Guo, Y.; Yang, Y. A natural extract of tobacco rob as scale and corrosion inhibitor in artificial seawater. Desalination 2016, 398, 198–207. [Google Scholar] [CrossRef]

- Micevska, T.; Warne, M.S.J.; Pablo, F.; Patra, R. Variation in, and causes of, toxicity of cigarette butts to a cladoceran and mi-crotox. Arch. Environ. Contam. Toxicol. 2006, 50, 205–212. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y. Asphalt pavement rutting disease and the mechanism of action of anti-rutting agent. Transp. World 2018, 479, 87–88. [Google Scholar]

- Chen, J.-S. Mechanism and behavior of bitumen strength reinforcement using fibers. J. Mater. Sci. 2005, 40, 87–95. [Google Scholar] [CrossRef]

- Peltonen, P.V. Characterization and testing of fiber-modified bitumen composites. J. Mater. Sci. 1991, 26, 5618–5622. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, X.; Lv, J.; Zhu, Z.; Zou, X. Numerical analysis of the rheological behaviors of basalt fiber reinforced asphalt mortar using ABAQUS. Constr. Build. Mater. 2017, 157, 392–401. [Google Scholar]

- Tang, Q.; Xiao, P.; Lou, K.; Wu, Y. Interfacial characteristics of fiber asphalt mastic and aggregates: Impact on mixture crack resistance performance. Constr. Build. Mater. 2024, 414, 134866. [Google Scholar]

- Bonica, C.; Toraldo, E.; Andena, L.; Marano, C.; Mariani, E. The effects of fibers on the performance of bituminous mastics for road pavements. Compos. Part B Eng. 2016, 95, 76–81. [Google Scholar]

- Mohajerani, A.; Kadir, A.A. A practical proposal for solving the world’s cigarette butt problem: Recycling in fired clay bricks. Waste Manag. 2016, 52, 228–244. [Google Scholar] [CrossRef]

- Mohajerani, A.; Tanriverdi, Y.; Nguyen, B.T.; Wong, K.K.; Dissanayake, H.N.; Johnson, L.; Whitfield, D.; Thomson, G.; Alqattan, E.; Rezaei, A. Physico-mechanical properties of asphalt concrete incorporated with encapsulated cigarette butts. Constr. Build. Mater. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Tareq, R.M. Thermal conductivity and environmental aspects of cigarette butt modified asphalt. Case Stud. Constr. Mater. 2021, 15, e00569. [Google Scholar] [CrossRef]

- Rahman, M.T.; Mohajerani, A. Possible Recycling of Cigarette Butts as Fiber Modifier in Bitumen for Asphalt Concrete. Materials 2020, 13, 734. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.T.; Mohajerani, A.; Giustozzi, F. Possible use of cigarette butt fiber modified bitumen in stone mastic asphalt. Constr. Build. Mater. 2020, 263, 120134. [Google Scholar] [CrossRef]

- Hu, X.; Chen, X.; Yu, J.; Cheng, G.; Yuan, Y.; Zhang, L. Physical Properties and Rheological Characteristics of Cigarette Butt-Modified Asphalt Binders. Coatings 2025, 15, 170. [Google Scholar] [CrossRef]

- Li, J.; Shen, J.; Xiao, W.; Yao, Z. Exploration and application of cellulose diacetate filter rod recycling process for cigarette. Synth. Fibers 2017, 2017, 15–16. [Google Scholar]

- Lei, C.; Yang, H.; Zhang, Q. Synthesis of nitrogen-rich and thermostable energetic materials based on hetarenecarboxylic acids. Dalton Trans. 2021, 50, 14462–14468. [Google Scholar] [CrossRef]

- Dehghan, Z. Evaluating the fatigue properties of hot mix asphalt reinforced by recycled PET fibers using 4-point bending test. Constr. Build. Mater. 2017, 139, 384–393. [Google Scholar] [CrossRef]

- Suyatma, N.E.; Tighzert, L.; Copinet, A.; Coma, V. Effects of hydrophilic plasticizers on mechanical, thermal, and surface properties of chitosan films. J. Agric. Food Chem. 2005, 53, 3950–3957. [Google Scholar] [CrossRef]

- Wang, B.-K.; Zhou, L.-J.; Li, P.-Y.; Su, S.-P. Recovery and TG-FTIR coupling characterization of cellulose acetate for cigarette pipes. Fine Chem. Intermed. 2022, 2022, 72–76. [Google Scholar]

- Pipintakos, G.; Hasheminejad, N.; Lommaert, C.; Bocharova, A.; Blom, J. Application of Atomic Force (AFM), Environmental Scanning Electron (ESEM) and Confocal Laser Scanning Microscopy (CLSM) in bitumen: A review of the ageing effect. Micron 2021, 147, 103083. [Google Scholar] [CrossRef] [PubMed]

- ASTM D7175-15; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). ASTM: Philadelphia, PA, USA, 2015.

- AASHTO T350; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2018; p. 8.

- AASHTO TP 101-15; Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep. American Association of State and Highway Transportation Officials (AASHTO): Washington, DC, USA, 2015; p. 9.

- Li, N.; He, Z.; Xin, Y.; Wei, T. Investigation of the aging behavior of cellulose fiber in reclaimed asphalt pavement. Constr. Build. Mater. 2020, 271, 121559. [Google Scholar] [CrossRef]

- Gao, Y.; Li, L. Modelling crack initiation in bituminous binders under a rotational shear fatigue load. Int. J. Fatigue 2020, 139, 105738. [Google Scholar] [CrossRef]

- Cui, X.; Huang, D.; Liu, L.; Lan, R.; Lyu, H.; Zhao, Y.; Cao, W.; Chang, C. Progress of Mechanics Research on Asphalt Pavement Disease. J. Shandong Univ. (Eng. Ed.) 2016, 46, 68–87. [Google Scholar]

- Hintz, C. Understanding mechanisms leading to asphalt binder fatigue in the dynamic shear rheometer. Road Mater. Pavement Des. 2013, 14, 231–251. [Google Scholar] [CrossRef]

- Chen, J. Adsorption Properties of Activated Carbon on Glycerol Triacetate and Its Application in Tobacco; Huaqiao University: Quanzhou, China, 2013. [Google Scholar]

- Zhao, Y.; Jia, X.; Liang, N.; Chen, S. Fatigue performance analysis of polyvinyl alcohol fiber asphalt mortar based on dispersion technology. Sci. Technol. Eng. 2021, 21, 13886–13892. [Google Scholar]

- Xie, T.; Zhao, K. Reinforcement Effect of Different Fibers on Asphalt Mastic. Materials 2022, 15, 8304. [Google Scholar] [CrossRef]

- Geçkil, T. Physical, Chemical, Microstructural and Rheological Properties of Reactive Terpolymer-Modified Bitumen. Materials 2019, 12, 921. [Google Scholar] [CrossRef]

- Mohammed, M.; Parry, T. Influence of fibers on rheological properties and toughness of bituminous binder. Constr. Build. Mater. 2018, 163, 901–911. [Google Scholar] [CrossRef]

- Bai, L.; Zhang, Y. Analysis of Coupling Effect and Heavy Load of High-Temperature Stability of Asphalt Mixture. Adv. Mater. Sci. Eng. 2022, 2022, 5722752. [Google Scholar] [CrossRef]

- Xing, X.; Chen, S.; Li, Y.; Pei, J.; Zhang, J.; Wen, Y.; Li, R.; Cui, S. Effect of different fibers on the properties of asphalt mastics. Constr. Build. Mater. 2020, 262, 120005. [Google Scholar] [CrossRef]

- Tacettin, G.; Beyza, İ.C. Physical, rheological and microstructural properties of waste LDPE and TEOA modified bitumen. J. Chin. Inst. Eng. 2022, 45, 477–487. [Google Scholar] [CrossRef]

- BSI. Newly Revised PAS 2050 Poised to Boost International Efforts to Carbon Footprint Products; BSI: Milton Keynes, UK, 2011. [Google Scholar]

| Experimental Projects | Unit | Test Result | Technology Requirements |

|---|---|---|---|

| Needle Penetration (25 °C, 5 s, 100 g) | 0.1 mm | 65.4 | 60~80 |

| Softening Point | °C | 46.6 | ≥46 |

| Ductility (15 °C) | cm | >150 | ≥100 |

| TFOT Needle Penetration Ratio (25 °C) | % | 76.9 | ≥61% |

| Residual Ductility (15 °C) | cm | 132.9 | ≥15 |

| Materials | Consumption/t | Carbon Emission Factor/(kg/t) |

|---|---|---|

| Bitumen | 260.62 | 189.12 |

| CB fiber | 1.954 | -- |

| Mineral powder | 298.61 | 7.36 |

| Cement | 540.35 | 870.50 |

| Aggregates | 603.38 | 2.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Cheng, C.; Yan, Y.; Wu, Q.; Du, R. Effect of Waste Cigarette Butt Fibers on the Properties and CO2 Footprint of Bitumen. Materials 2025, 18, 2059. https://doi.org/10.3390/ma18092059

Yang K, Cheng C, Yan Y, Wu Q, Du R. Effect of Waste Cigarette Butt Fibers on the Properties and CO2 Footprint of Bitumen. Materials. 2025; 18(9):2059. https://doi.org/10.3390/ma18092059

Chicago/Turabian StyleYang, Kai, Cheng Cheng, Yong Yan, Qinglin Wu, and Ru Du. 2025. "Effect of Waste Cigarette Butt Fibers on the Properties and CO2 Footprint of Bitumen" Materials 18, no. 9: 2059. https://doi.org/10.3390/ma18092059

APA StyleYang, K., Cheng, C., Yan, Y., Wu, Q., & Du, R. (2025). Effect of Waste Cigarette Butt Fibers on the Properties and CO2 Footprint of Bitumen. Materials, 18(9), 2059. https://doi.org/10.3390/ma18092059