Effects of Nickel and Iron Content on the Microstructures and Mechanical Properties of Cemented Carbide with Coarse and Fine-Grained Heterostructures

Highlights

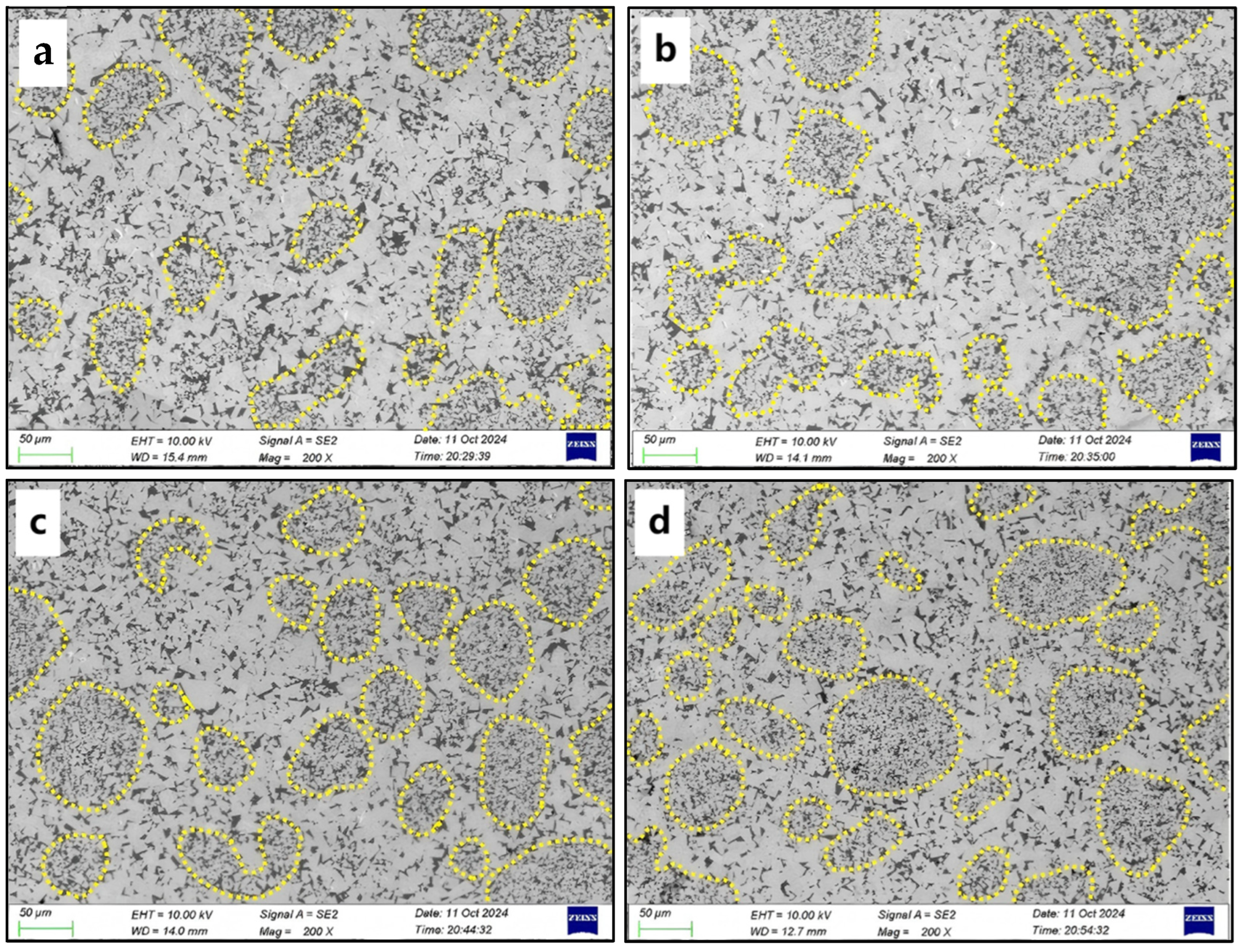

- Heterogeneous structure: Fine WC-Co grains uniformly embedded in coarse WC-NiFe regions form a network-like mixed-grain structure.

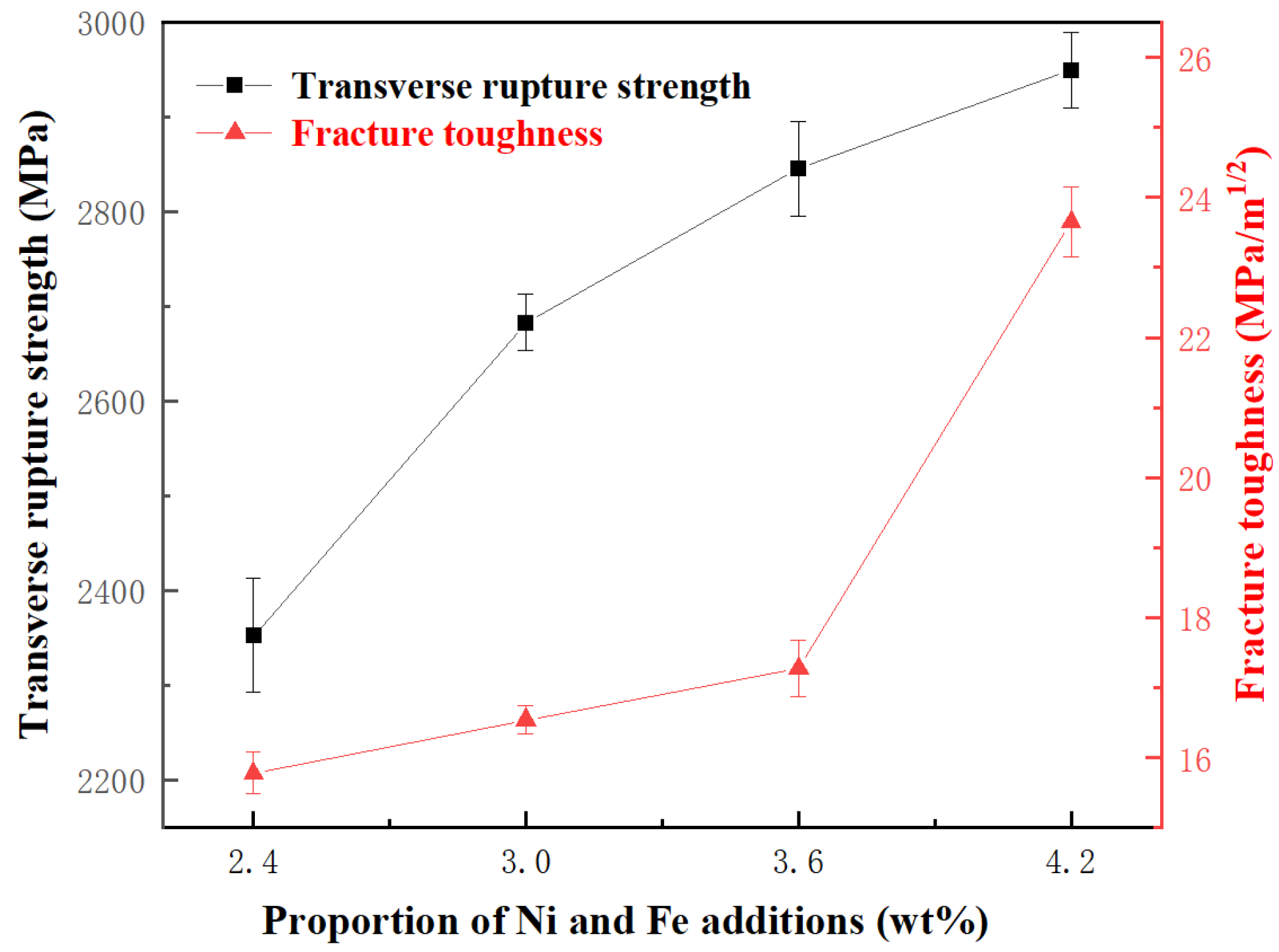

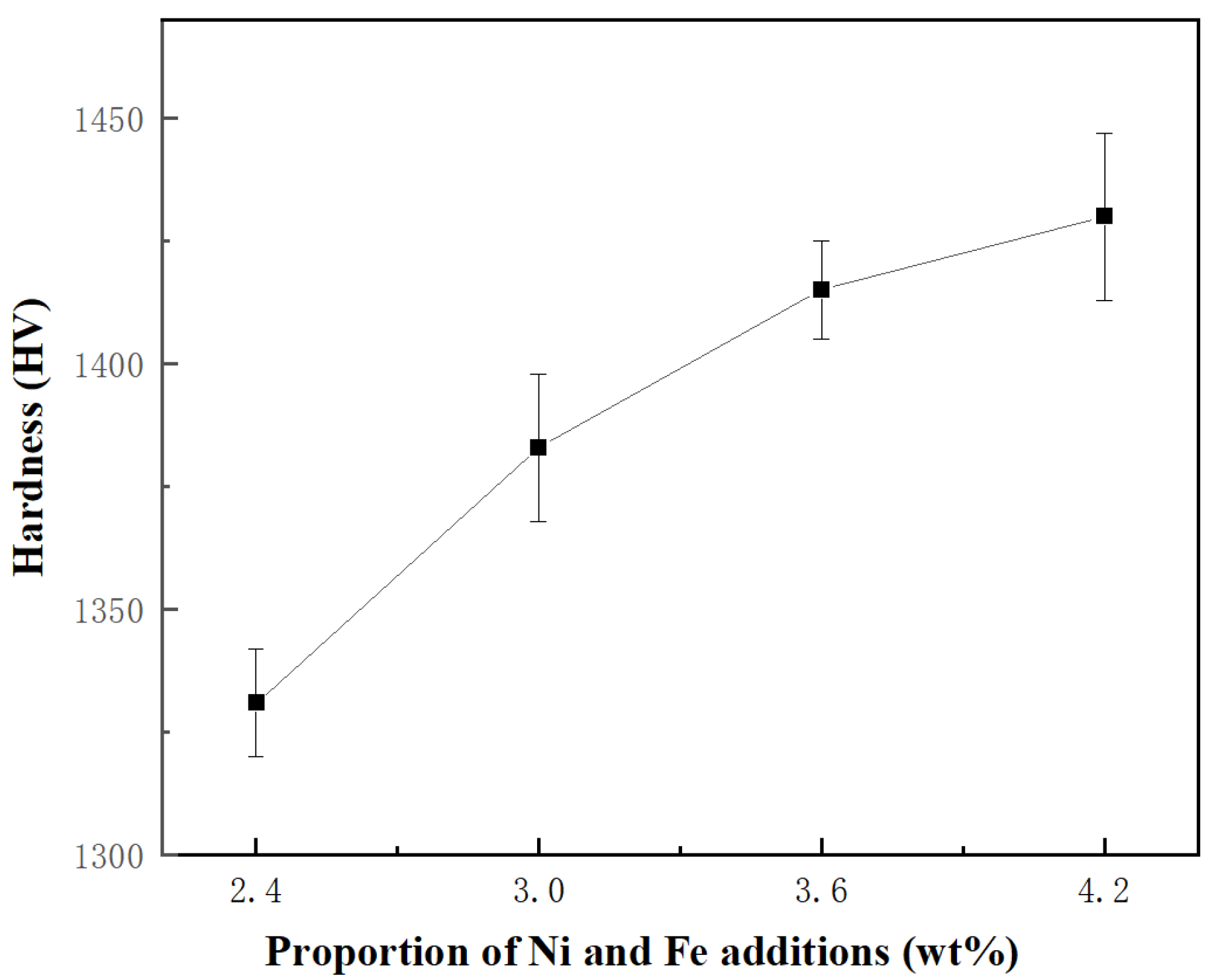

- Ni and Fe content impact: Optimal strength–toughness balance (2949 MPa transverse rupture strength, 23.65 kg·mm−3/2 fracture toughness) at 4.2 wt.% Ni and Fe.

- Effect mechanism: Increased Ni and Fe content reduces binder melting point, boosts diffusion, and inhibits W/C re-precipitation.

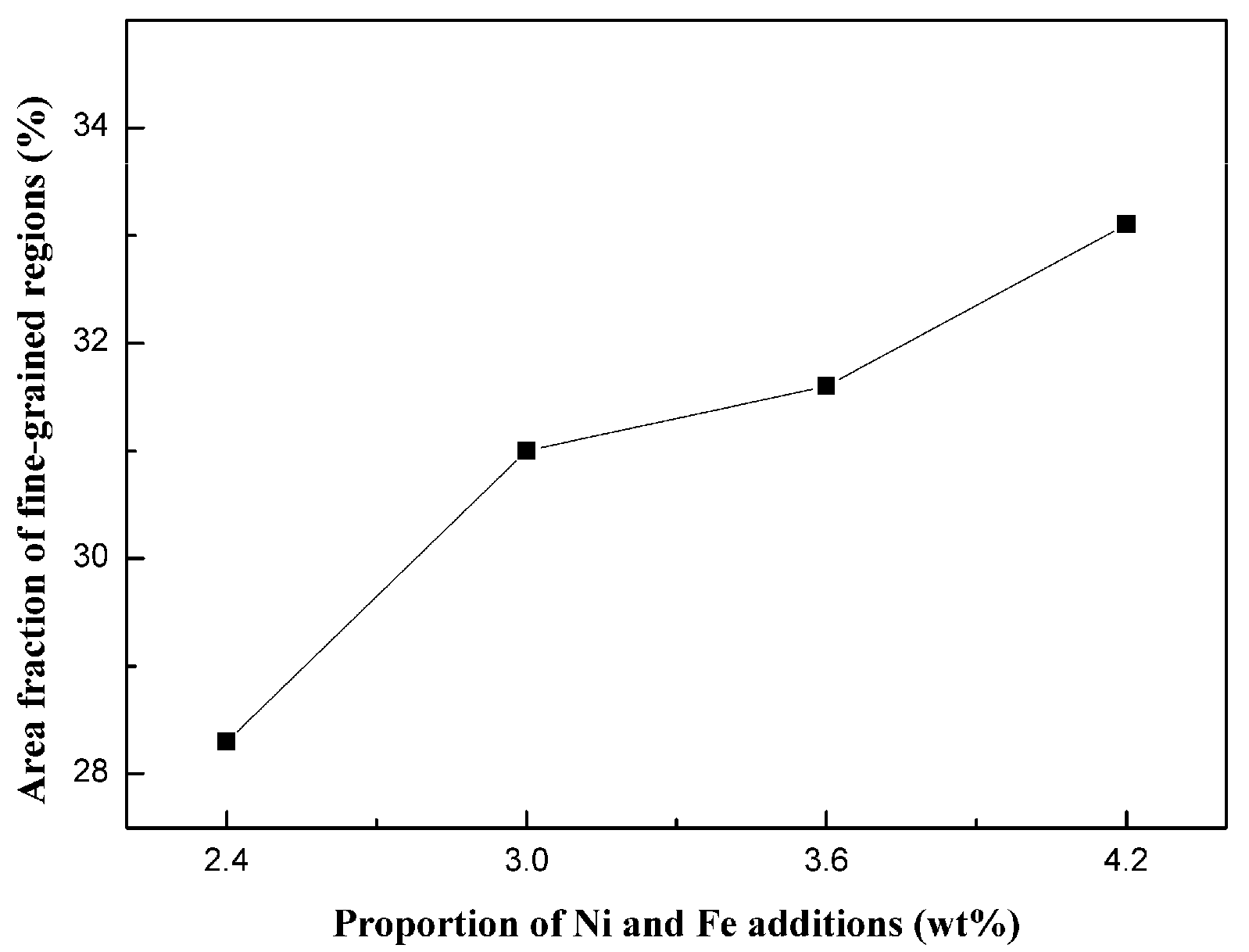

- Element diffusion: Liquid-phase sintering enhances Ni/Fe/Co diffusion, increasing the fine-grained region volume.

- Performance enhancement: Solid solution strengthening and high interfacial binding energy at WC/CoNiFe interfaces to resist crack propagation.

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Preparation

2.2. Microstructure Characterization

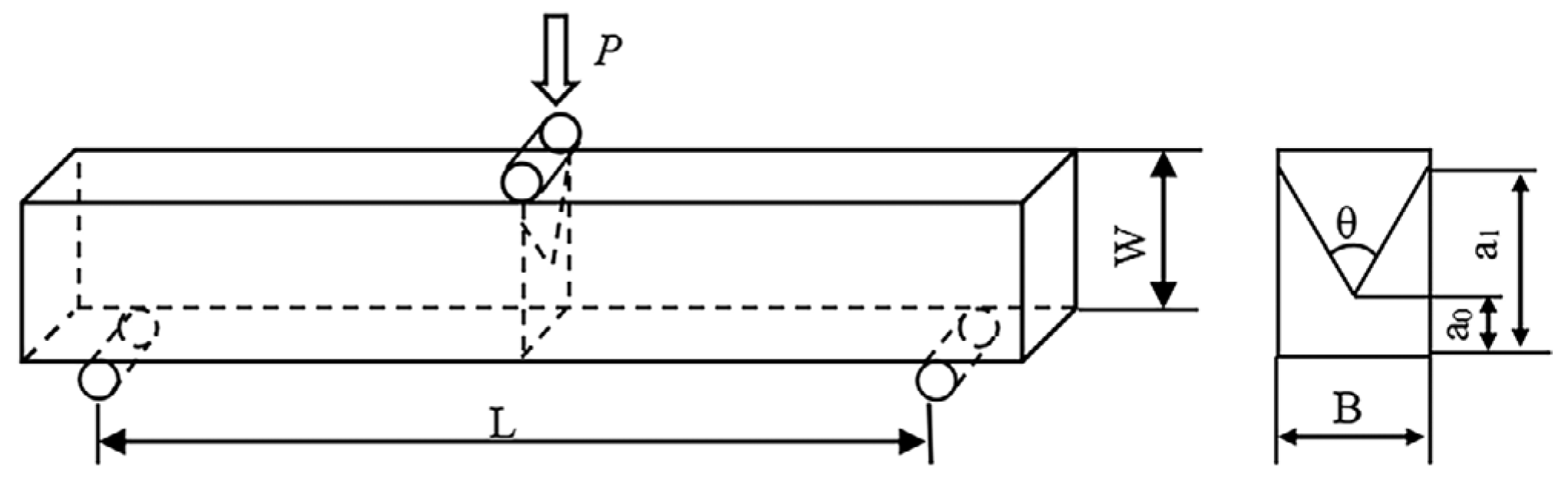

2.3. Mechanical Properties Testing

3. Results and Discussion

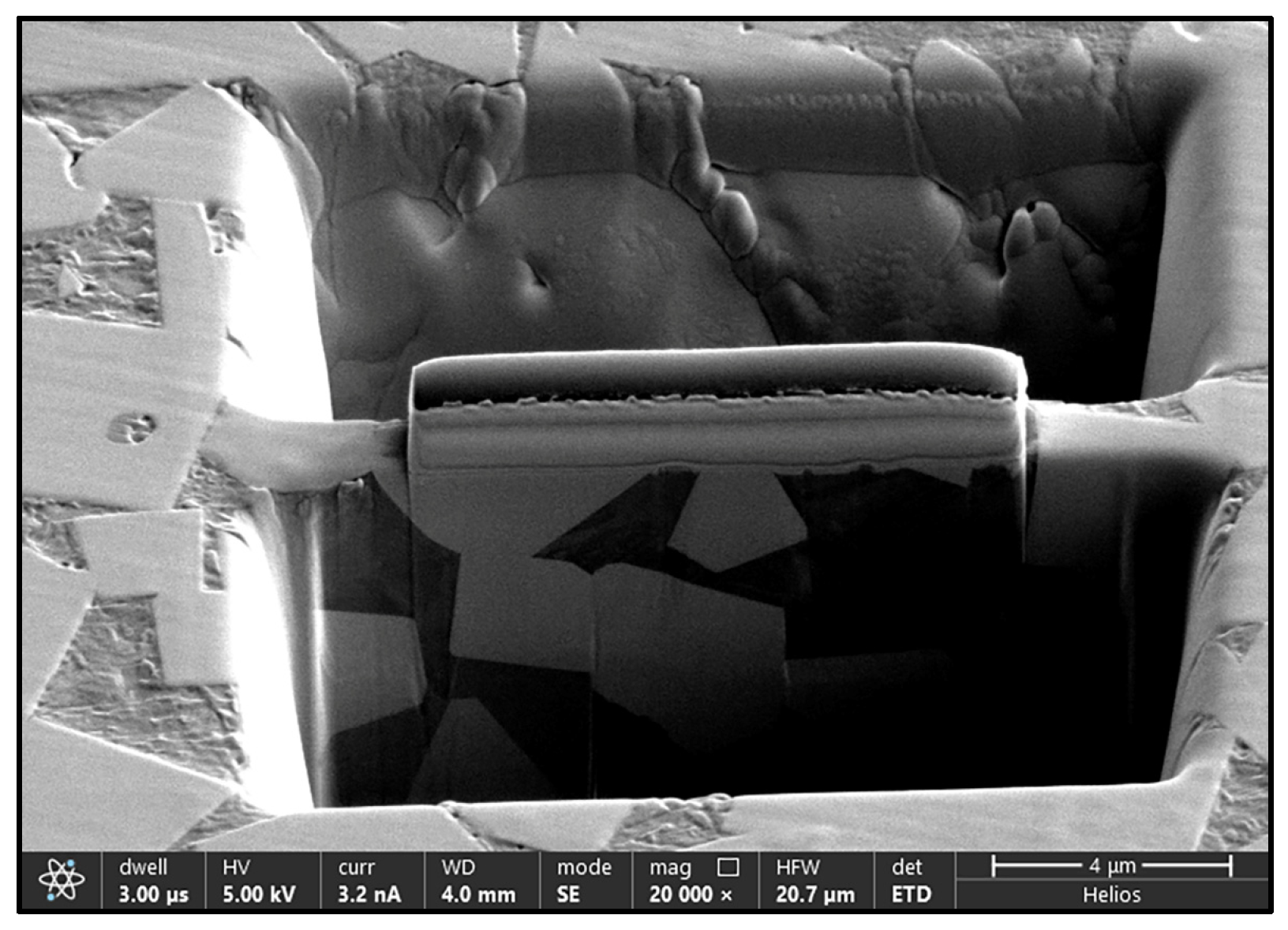

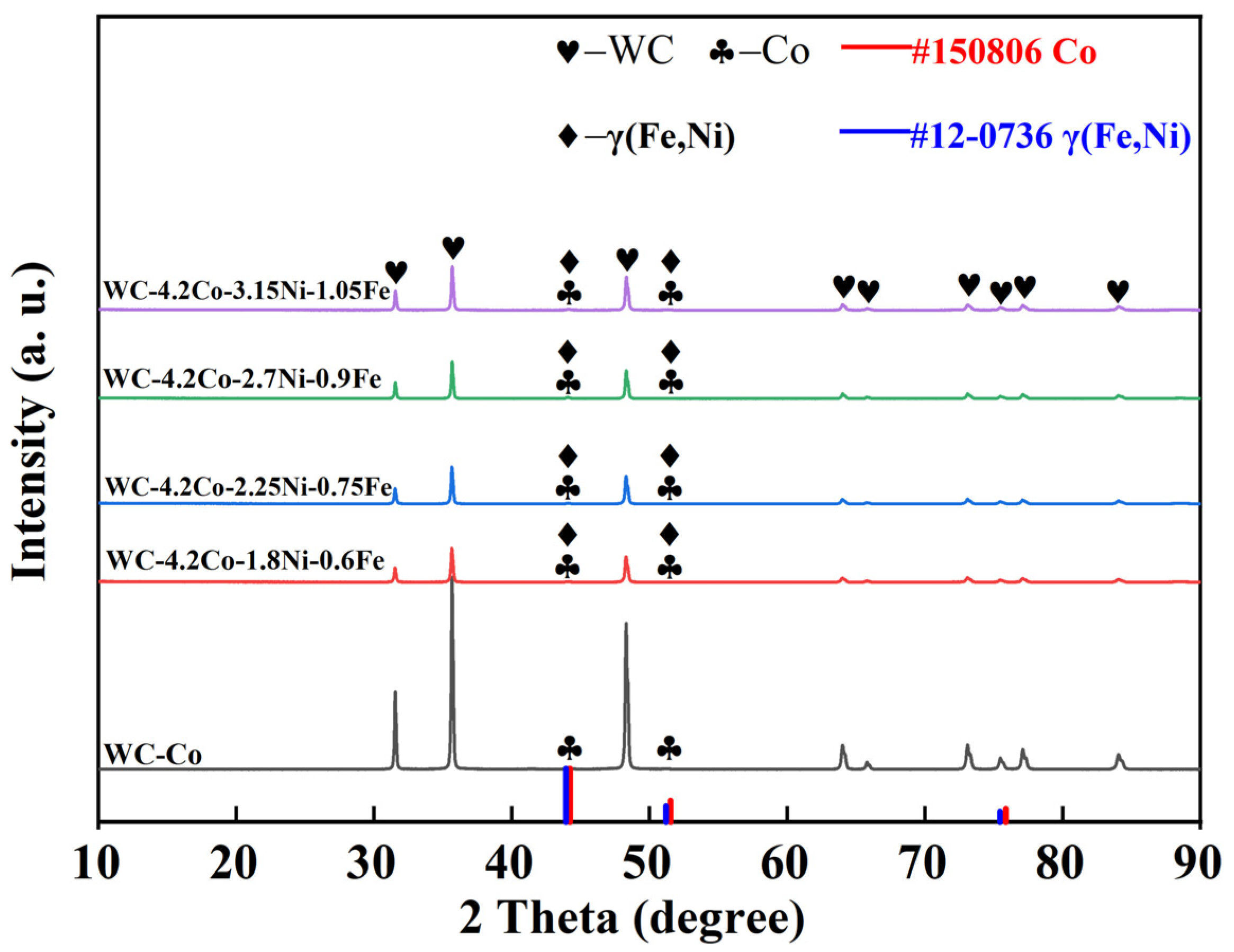

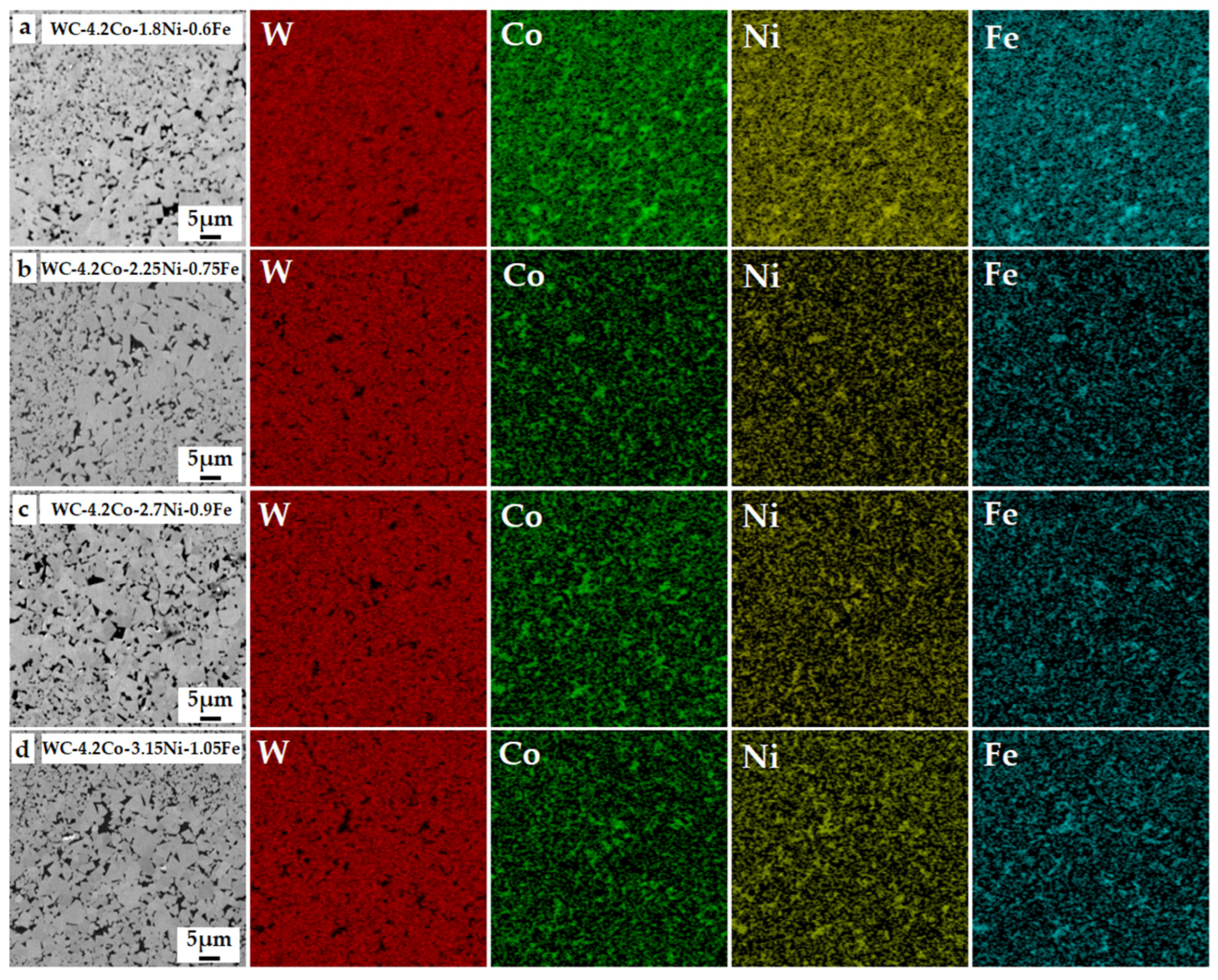

3.1. Effects of Ni and Fe Content on the Microstructures

3.2. Effects of Ni and Fe Content on Mechanical Behavior

4. Conclusions

- (1)

- The cemented carbides with a heterogeneous structure consist of a fine-grained region (corresponding to WC-Co granules) and a coarse-grained region (corresponding to WC-NiFe powders). Fine-grained granules are uniformly embedded in the coarse-grained region, forming a typical network mixed-grain structure.

- (2)

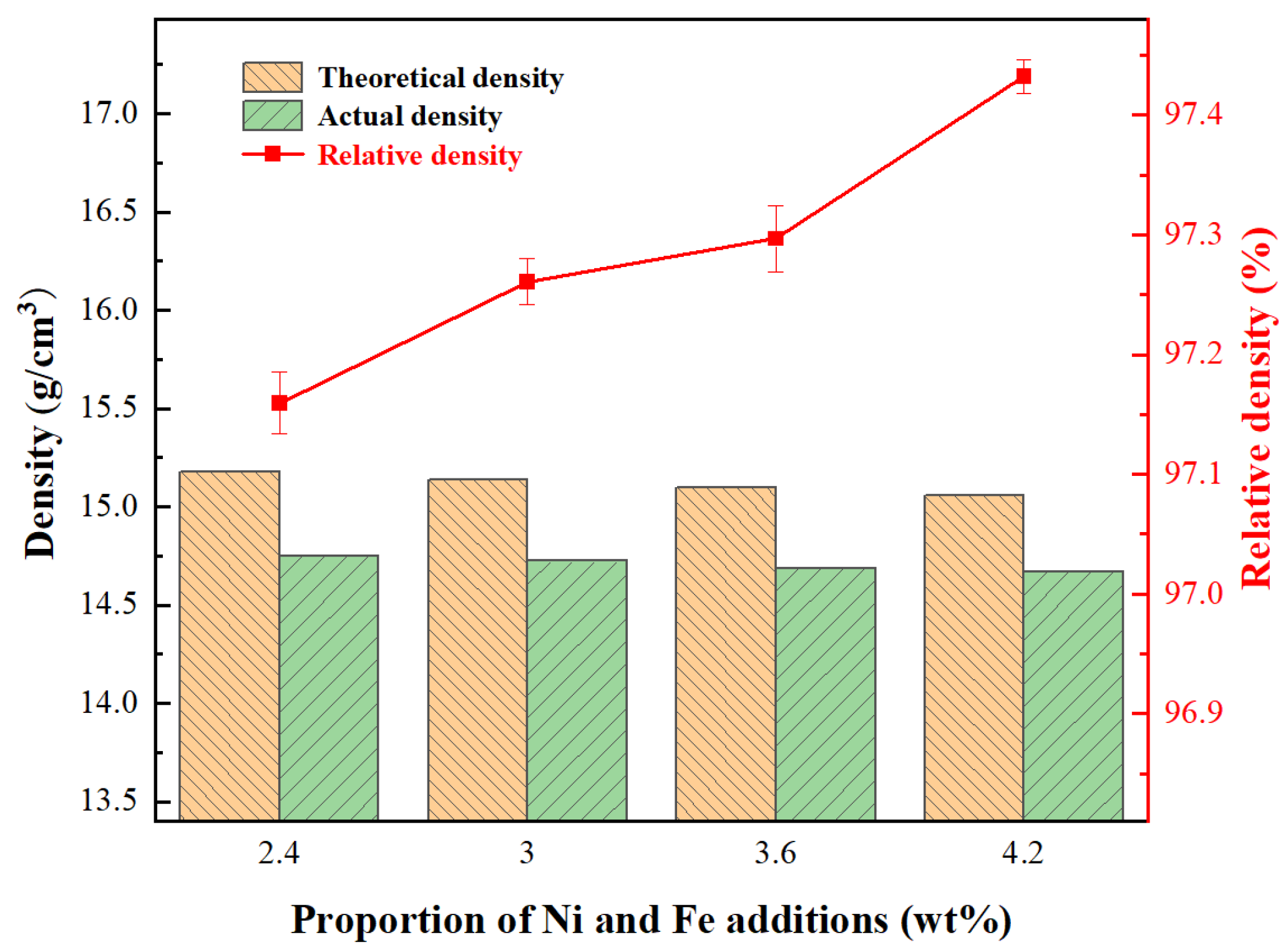

- As the Ni and Fe content increase from 2.4 to 4.2 wt.%, the actual density of cemented carbides decreases, while the average relative density increases from 97.15% to 97.43%. The addition of Ni and Fe elements contributes to reducing the melting point and prompting the diffusion coefficient of cemented carbides, which can be attributed to liquid phase sintering.

- (3)

- As the proportion of Ni and Fe content increased, the average transverse rupture strength increased from 2352 to 2949 MPa, the average fracture toughness increased from 15.78 to 23.65 MPa·m−1/2, and the average hardness increased from 1332 to 1430 HV. The enhanced volume fraction and dimensional stability of CoNiFe binder phases promote the interfacial decohesion at WC/WC and WC/binder boundaries, suppressing transgranular fracture while facilitating intergranular crack propagation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, D.; Yue, W.; Kang, J.; Wang, C. Effects of different substrates on the formability and densification behaviors of cemented carbide processed by laser powder bed fusion. Materials 2021, 14, 5027. [Google Scholar] [CrossRef]

- Li, C.; Li, T.; Zhang, X.; He, T.; Su, L.; Wen, D.; Shao, S.; Cai, X.; Cao, Q. Investigating the influence of laser-etched straight and wavy textures on grinding efficiency and tool quality of WC-Co carbide cutting tools. Materials 2025, 18, 528. [Google Scholar] [CrossRef]

- Min, F.; Wang, S.; Yu, S.; Yang, H.; Yao, Z.; Ni, J.; Zhang, J. Enhanced coarse-grained WC-Co(Ce) cemented carbide prepared through Co-precipitation. Materials 2023, 16, 5506. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, Z.; Qin, Y.; Bao, Z.; Luo, L. Ultrafine/nano WC-Co cemented carbide: Overview of preparation and key technologies. J. Mater. Res. Technol. 2023, 27, 5822–5839. [Google Scholar] [CrossRef]

- Straumal, B.B.; Shchur, L.N.; Kagramanyan, D.G.; Konstantinova, E.P.; Druzhinin, A.V.; Nekrasov, A.N. Topology of WC/Co interfaces in cemented carbides. Materials 2023, 16, 5560. [Google Scholar] [CrossRef] [PubMed]

- Wachowicz, J.; Dembiczak, T.; Fik, J.; Bałaga, Z.; Kruzel, R.; Náprstková, N.; Kuśmierczak, S. Spark plasma sintering of fine-grained WC-Co composites. Materials 2023, 16, 7526. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Lu, H.; Chen, J.; Liu, X.; Song, X. Toughening cemented carbides by phase transformation of zirconia. Mater. Des. 2021, 202, 109559. [Google Scholar] [CrossRef]

- Tao, S.; He, W.; Liang, S.; Huang, J.; Ouyang, S. Microstructures, properties, and wear mechanism of binderless WC-ZrO2 cemented carbide. Ceram. Int. 2024, 50, 54586–54595. [Google Scholar] [CrossRef]

- Sun, J.; Huang, Z.; Zhao, J. High-hard and high-tough WC-TiC-Co cemented carbide reinforced with graphene. Mater. Today Commun. 2021, 29, 102841. [Google Scholar] [CrossRef]

- Deng, X.C.; Zhang, G.H. Effects of sintering method and Al2O3 content on microstructure and mechanical properties of WC-10Co cemented carbide. Int. J. Refract. Met. Hard Mater. 2024, 124, 106812. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, Z.; Zan, X.; Luo, L.; Wu, Y. Change of interfacial structure between the matrix and second phase of Y-Zr-modified WC-8Co cemented carbide. Ceram. Int. 2024, 50, 8510–8519. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Huang, K.; Wang, L. Effects of Cr2 (C, N) addition on microstructure and comprehensive mechanical properties of ultrafine cemented carbide. Mater. Sci. Eng. A-Struct. 2023, 870, 144847. [Google Scholar] [CrossRef]

- Zou, Q.; Ren, H.; Li, Y.; Xiong, J.; Luo, Y. Fabrication and characterization of ultrafine WC-10CoCrNiCuFe cemented carbides. J. Mater. Sci. Technol. 2024, 190, 117–126. [Google Scholar] [CrossRef]

- Hui, J.; Qin, J.; Zhou, Y.; Sun, X.; Dong, W.; Zhu, S. Effect of Al content in CoCrFeNiAlx HEA on mechanical properties and high temperature oxidation resistance of WC-10% CoCrFeNiAlx hard alloy. Int. J. Refract. Met. Hard Mater. 2024, 122, 106712. [Google Scholar] [CrossRef]

- Liang, F.; Du, J.; Su, G.; Zhang, P.; Zhang, C. Investigating the effect of Al, Mo or Mn addition to CoCrFeNi entropy alloys on the interface binding properties of WC/HEA cemented carbides. Mater. Today Commun. 2023, 35, 105891. [Google Scholar] [CrossRef]

- Fan, C.; Sun, J.; Zhao, J.; Yun, X. High entropy alloy bonded cemented carbides: Composition, processing, microstructure, properties and applications. Ceram. Int. 2024, 50, 37460–37503. [Google Scholar] [CrossRef]

- Dong, X.X.; Gao, B.; Xiao, L.R.; Hu, J.J.; Xu, M.N.; Li, Z.Y.; Meng, J.Q.; Han, X.D.; Zhou, H.; Zhu, Y.T. Heterostructured metallic structural materials: Research methods, properties, and future perspectives. Adv. Funct. Mater. 2024, 34, 2410521. [Google Scholar] [CrossRef]

- Cai, K.; Sun, J.; Ning, S.; Li, X.; Zhao, J. Graphene reinforced medium entropy cemented carbide coupling medium-entropy ceramic and medium-entropy alloy. J. Alloys Compd. 2025, 1017, 179090. [Google Scholar] [CrossRef]

- Zhao, C.; Xu, S.; Pan, L.Y. Effect of WC particle size on the microstructure and mechanical properties of ni-co coarse grain cemented carbide. Int. J. Appl. Ceram. Technol. 2023, 20, 3701–3713. [Google Scholar] [CrossRef]

- Su, W.; Li, S.; Sun, L. Effect of multilayer graphene as a reinforcement on mechanical properties of WC-6Co cemented carbide. Ceram. Int. 2020, 46, 15392–15399. [Google Scholar] [CrossRef]

- Cahoon, J.R. A modified “Hole” theory for solute impurity diffusion in liquid metals. Metall. Mater. Trans. A 1997, 28, 583–593. [Google Scholar] [CrossRef]

- Qian, C.; Liu, Y.; Cheng, H.; Li, K.; Liu, B.; Zhang, X. Microstructure and mechanical behavior of functionally graded cemented carbides with CoNiFeCr multi-principal-element alloy binder. Int. J. Refract. Met. Hard Mater. 2023, 110, 106023. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Z.; Wang, B.; Yuan, J.; Huang, L.; Yin, Z. Microstructure and properties of WC-8Co cemented carbides prepared by multiple spark plasma sintering. Int. J. Appl. Ceram. Technol. 2021, 18, 2010–2019. [Google Scholar] [CrossRef]

- Herber, R.P.; Schubert, W.D.; Lux, B. Hardmetals with “rounded” WC grains. Int. J. Refract. Met. Hard Mater. 2006, 24, 360–364. [Google Scholar] [CrossRef]

- Kim, S.; Han, S.H.; Park, J.K.; Kim, H.E. Variation of WC grain shape with carbon content in the WC-Co alloys during liquid-phase sintering. Scr. Mater. 2003, 48, 635–639. [Google Scholar] [CrossRef]

- Qian, C.; Li, K.; Guo, X.Y.; Liu, B.; Long, Z.Y.; Liu, Y. Effect of WC grain size on mechanical properties and microstructures of cemented carbide with medium entropy alloy Co-Ni-Fe binder. J. Cent. South Univ. 2020, 27, 1146–1157. [Google Scholar] [CrossRef]

- Zhao, S.; Song, X.; Zhang, J.; Liu, X. Effects of scale combination and contact condition of raw powders on SPS sintered near-nanocrystalline WC-Co alloy. Mater. Sci. Eng. A-Struct. 2008, 473, 323–329. [Google Scholar] [CrossRef]

- Diao, Y.; Ma, M.; Li, G.; Huang, Q.; Wang, K.; Pei, J.; Wang, Q. L12 strengthening of WC-CoNiFe cemented carbides by spark plasma sintering. Ceram. Int. 2024, 50, 56135–56143. [Google Scholar] [CrossRef]

- Li, H.; Zhang, H.; Jiang, Z. Investigation of the effect of partial Co substitution by Ni and Fe on the interface bond strength of WC cemented carbide based on first-principles calculations. Mater. Today Commun. 2024, 40, 109470. [Google Scholar] [CrossRef]

- Schubert, W.D.; Fugger, M.; Wittmann, B.; Useldinger, R. Aspects of sintering of cemented carbides with Fe-based binders. Int. J. Refract. Met. Hard Mater. 2015, 49, 110–123. [Google Scholar] [CrossRef]

- Straumal, B.B.; Konyashin, I. Faceting/roughening of WC/binder interfaces in cemented carbides: A Review. Materials 2023, 16, 3696. [Google Scholar] [CrossRef] [PubMed]

| Designing Cemented Carbides | Proportion | Proportion of Ni and Fe Content | Alloy Compositions | Theoretical Density (g/cm3) | |||

|---|---|---|---|---|---|---|---|

| WC-6Co | WC-NiFe | ||||||

| WC | Ni | Fe | |||||

| H0 | 100 | 0 | 0 | 0 | 0 | 94WC-6Co | 15.23 |

| H1 | 70 | 27.6 | 1.8 | 0.6 | 2.4 wt.% | WC-4.2Co-1.8Ni-0.6Fe | 15.18 |

| H2 | 70 | 27 | 2.25 | 0.75 | 3 wt.% | WC-4.2Co-2.25Ni-0.75Fe | 15.14 |

| H3 | 70 | 26.4 | 2.7 | 0.9 | 3.6 wt.% | WC-4.2Co-2.7Ni-0.9Fe | 15.10 |

| H4 | 70 | 25.8 | 3.15 | 1.05 | 4.2 wt.% | WC-4.2Co-3.15Ni-1.05Fe | 15.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Ye, N.; Zhang, M.; Zhu, Y.; Zhang, C.; Zhu, W.; Zhang, F.; Jiang, J.; Tang, J. Effects of Nickel and Iron Content on the Microstructures and Mechanical Properties of Cemented Carbide with Coarse and Fine-Grained Heterostructures. Materials 2025, 18, 2045. https://doi.org/10.3390/ma18092045

Yang S, Ye N, Zhang M, Zhu Y, Zhang C, Zhu W, Zhang F, Jiang J, Tang J. Effects of Nickel and Iron Content on the Microstructures and Mechanical Properties of Cemented Carbide with Coarse and Fine-Grained Heterostructures. Materials. 2025; 18(9):2045. https://doi.org/10.3390/ma18092045

Chicago/Turabian StyleYang, Shuzhong, Nan Ye, Mingxian Zhang, Yaru Zhu, Chenxin Zhang, Wentan Zhu, Fan Zhang, Jiafa Jiang, and Jiancheng Tang. 2025. "Effects of Nickel and Iron Content on the Microstructures and Mechanical Properties of Cemented Carbide with Coarse and Fine-Grained Heterostructures" Materials 18, no. 9: 2045. https://doi.org/10.3390/ma18092045

APA StyleYang, S., Ye, N., Zhang, M., Zhu, Y., Zhang, C., Zhu, W., Zhang, F., Jiang, J., & Tang, J. (2025). Effects of Nickel and Iron Content on the Microstructures and Mechanical Properties of Cemented Carbide with Coarse and Fine-Grained Heterostructures. Materials, 18(9), 2045. https://doi.org/10.3390/ma18092045