The Preparation and Properties of Ultra-High-Performance Concrete with Aeolian Sand: A Lab Study on the Effect of the Curing Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methodology

2.2.1. Mixture Ratio Design

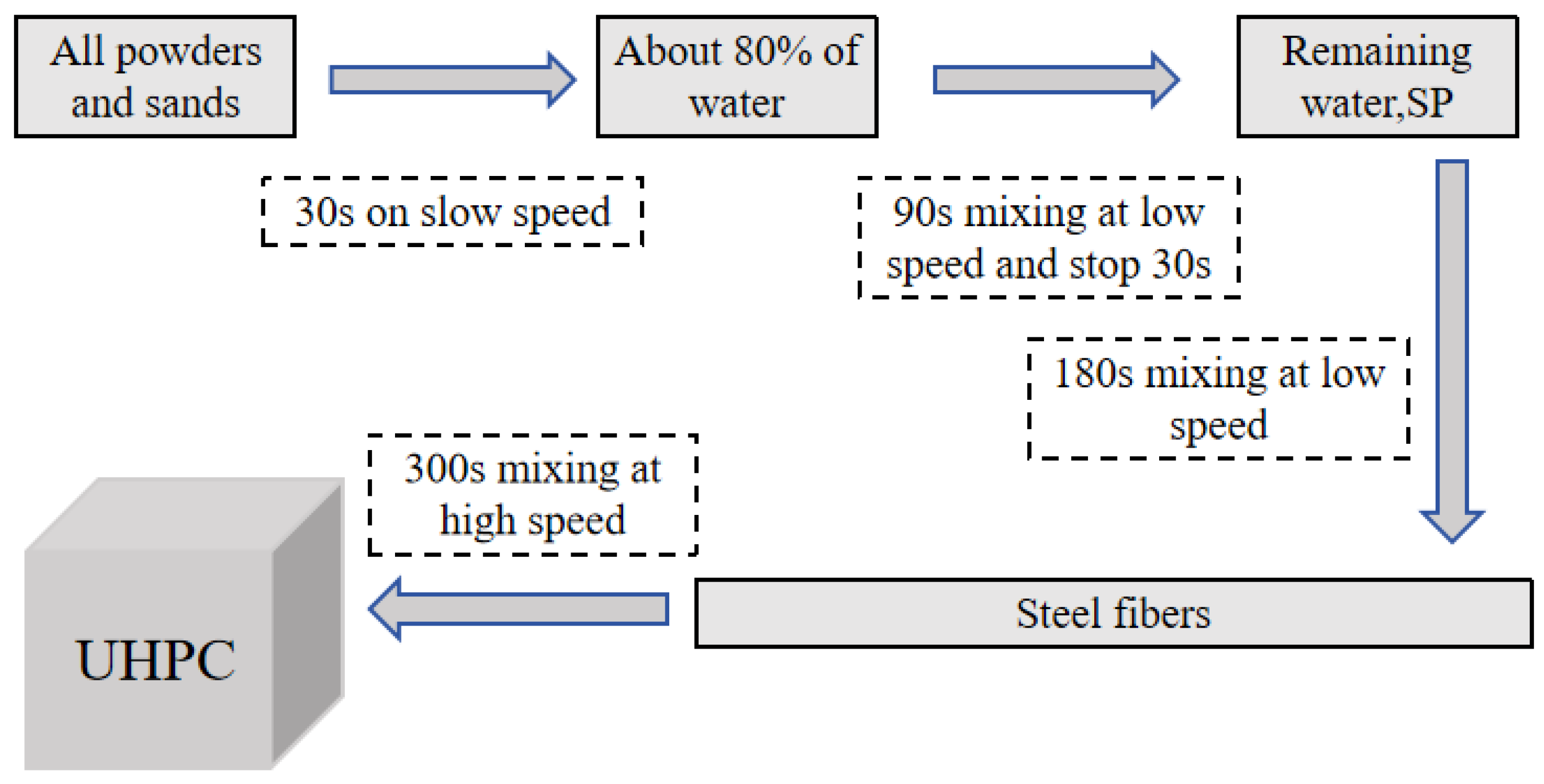

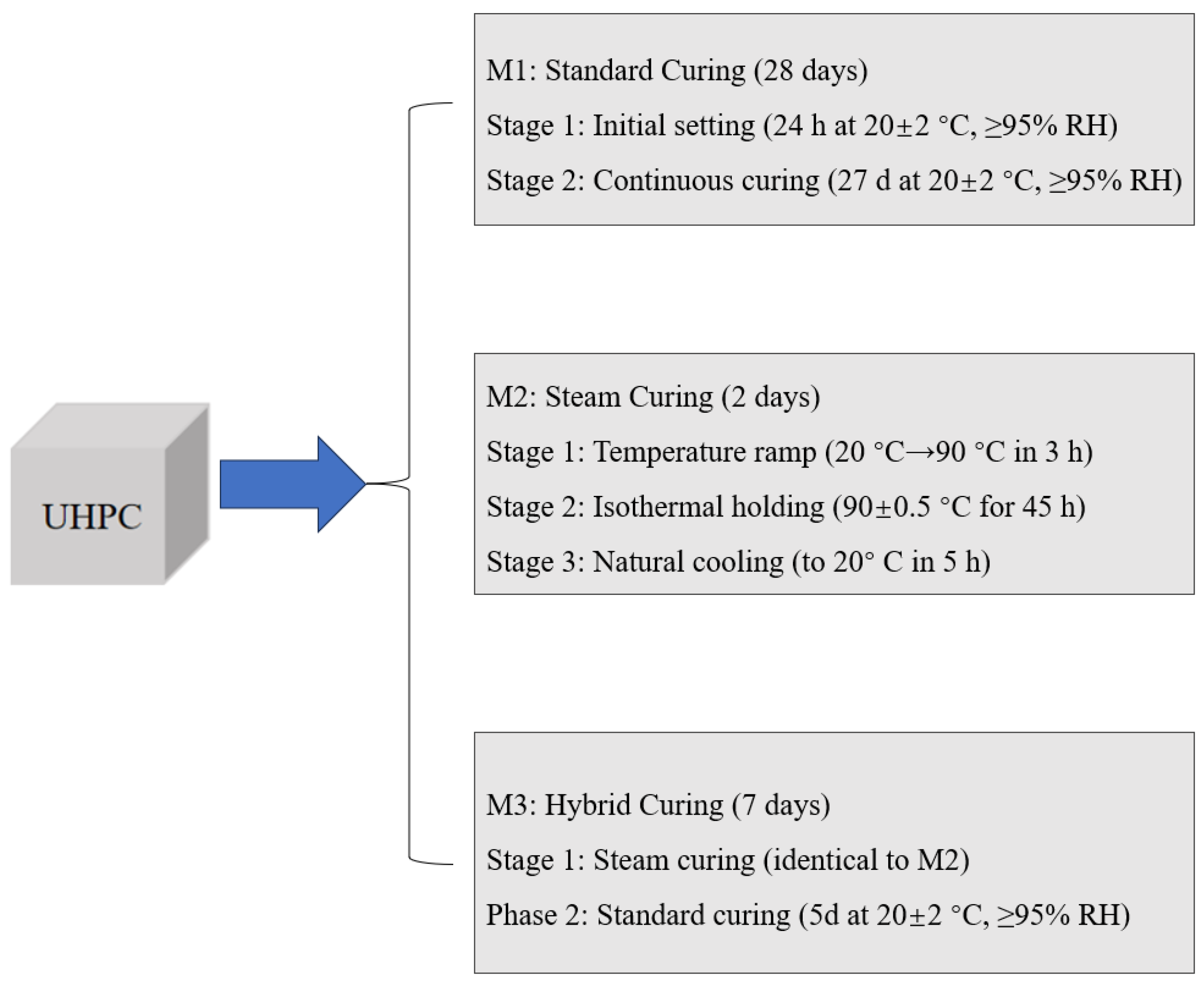

2.2.2. Mixing Procedures and Curing Methods

2.2.3. Fluidity

2.2.4. Mechanical Properties

2.2.5. Autogenous Shrinkage

2.2.6. Mercury Intrusion Porosimetry

2.2.7. Thermogravimetry Analysis

2.2.8. Scanning Electron Microscope

3. Results and Discussion

3.1. Fluidity

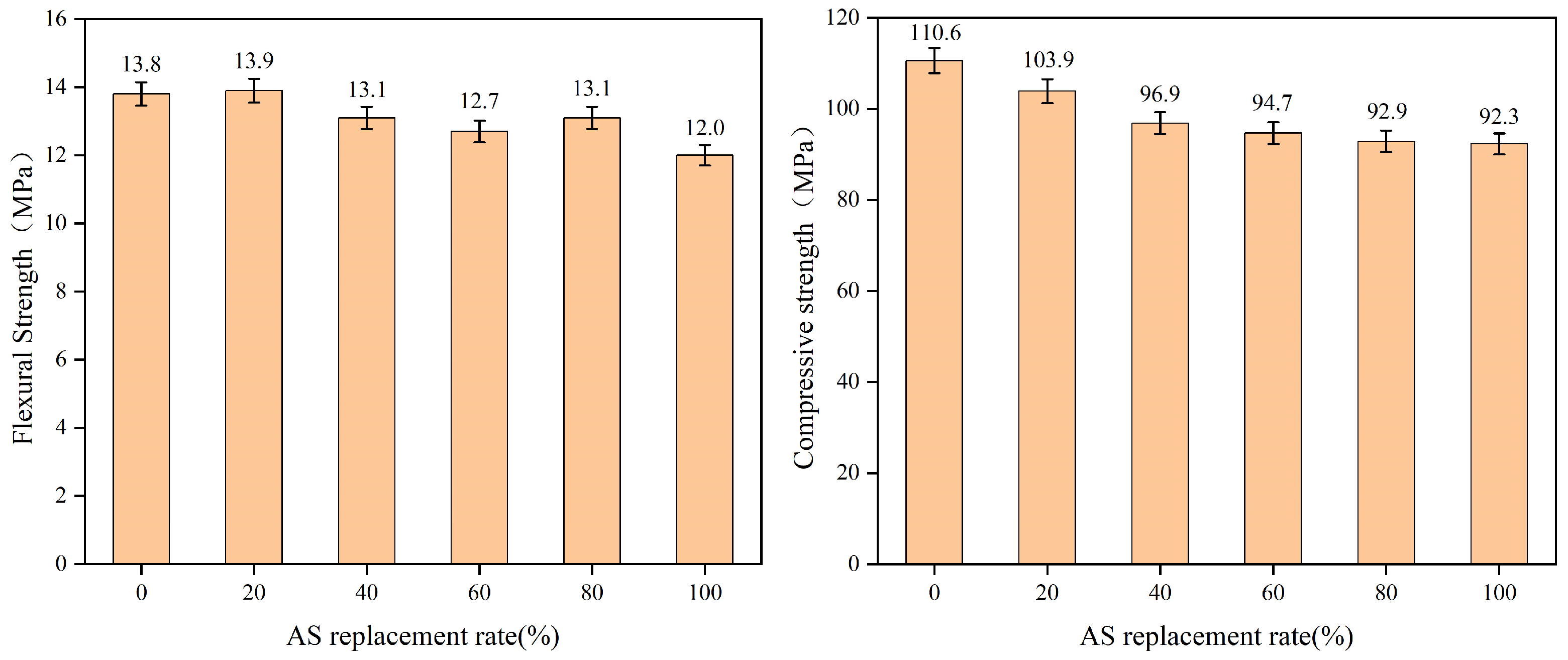

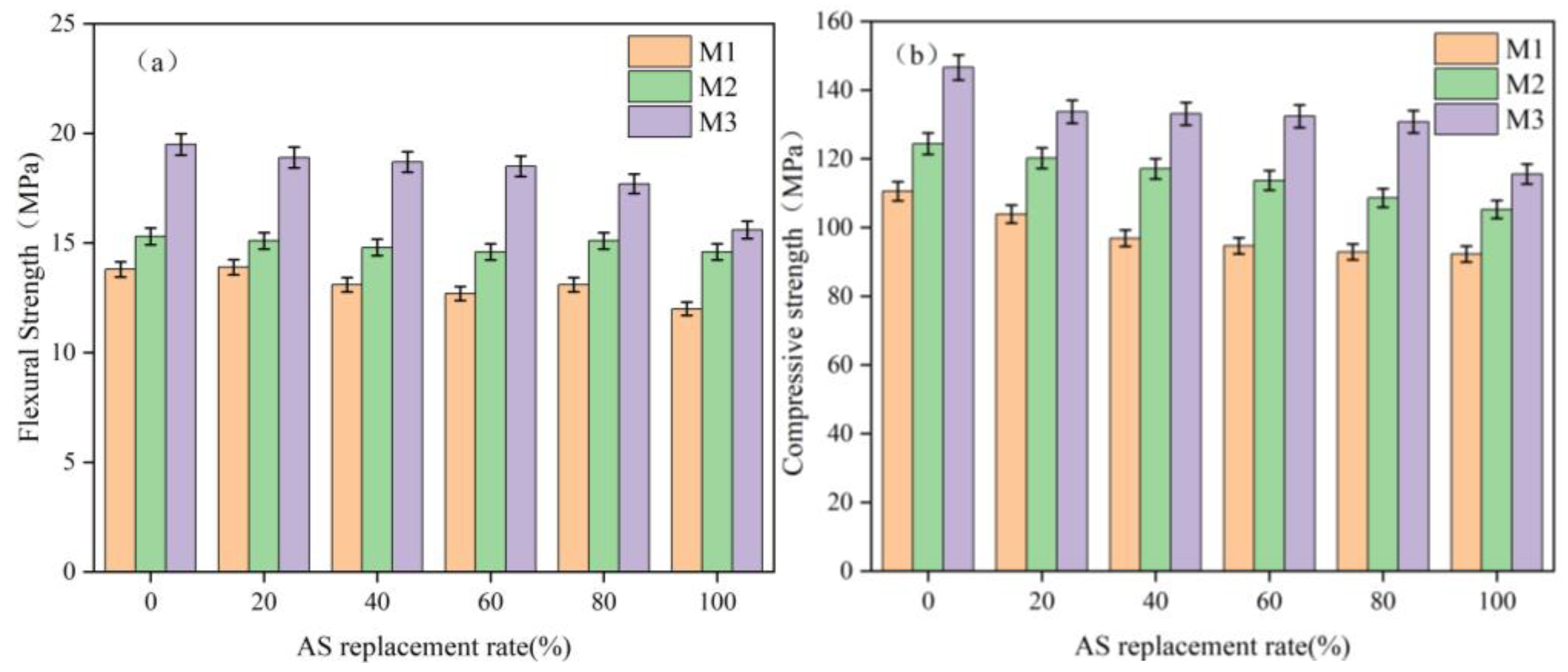

3.2. Mechanical Properties

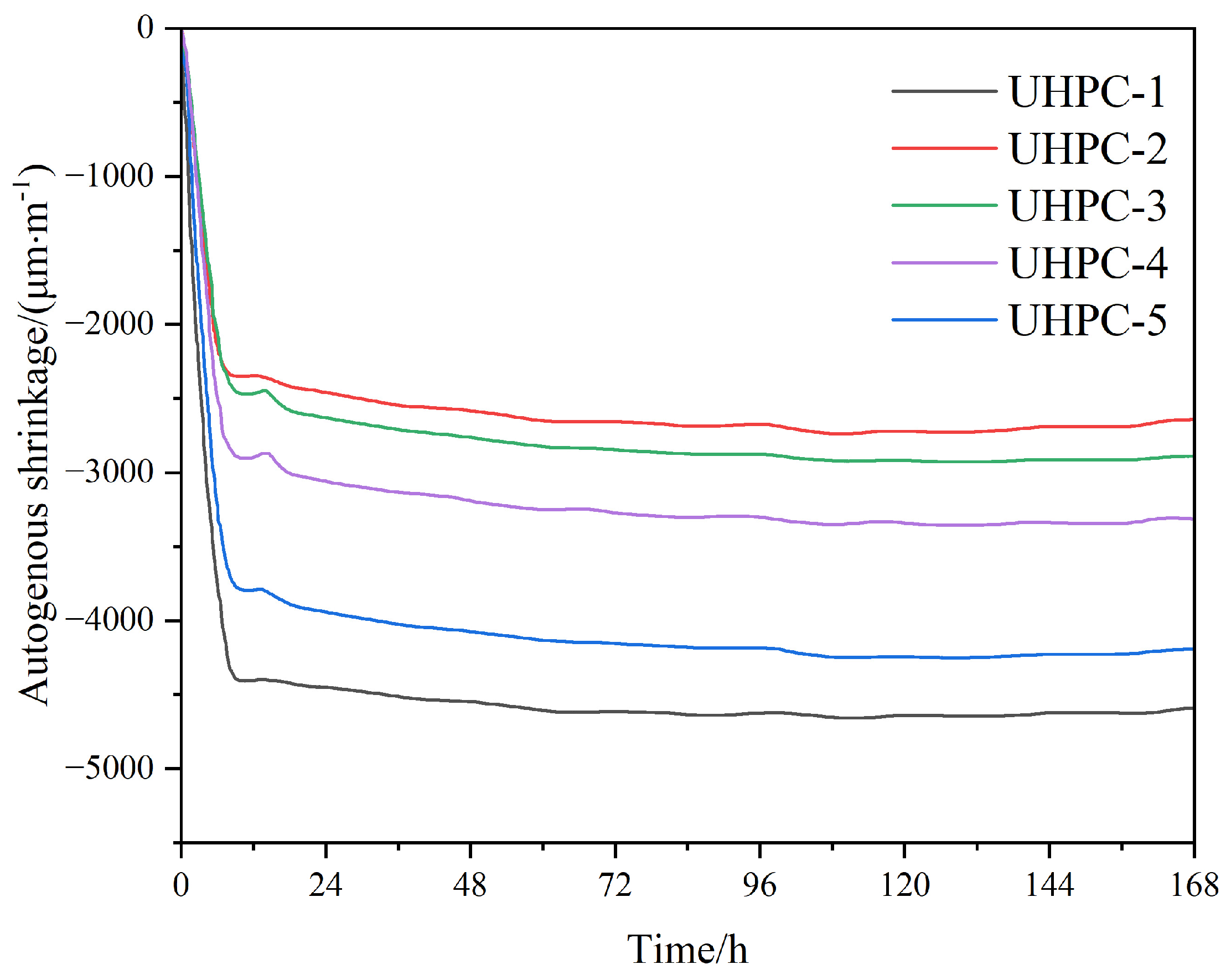

3.3. Autogenous Shrinkage

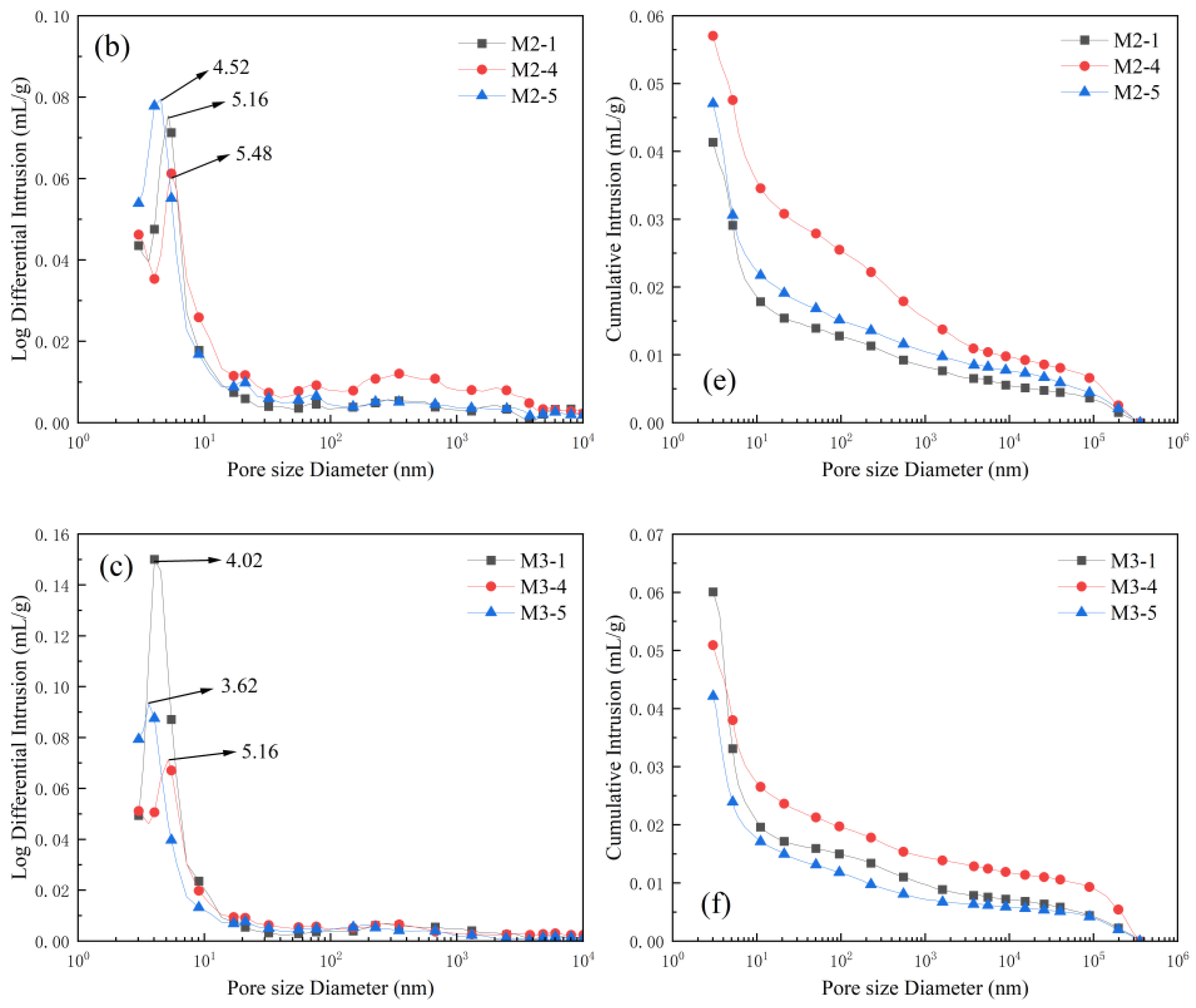

3.4. Pore Structure Analysis

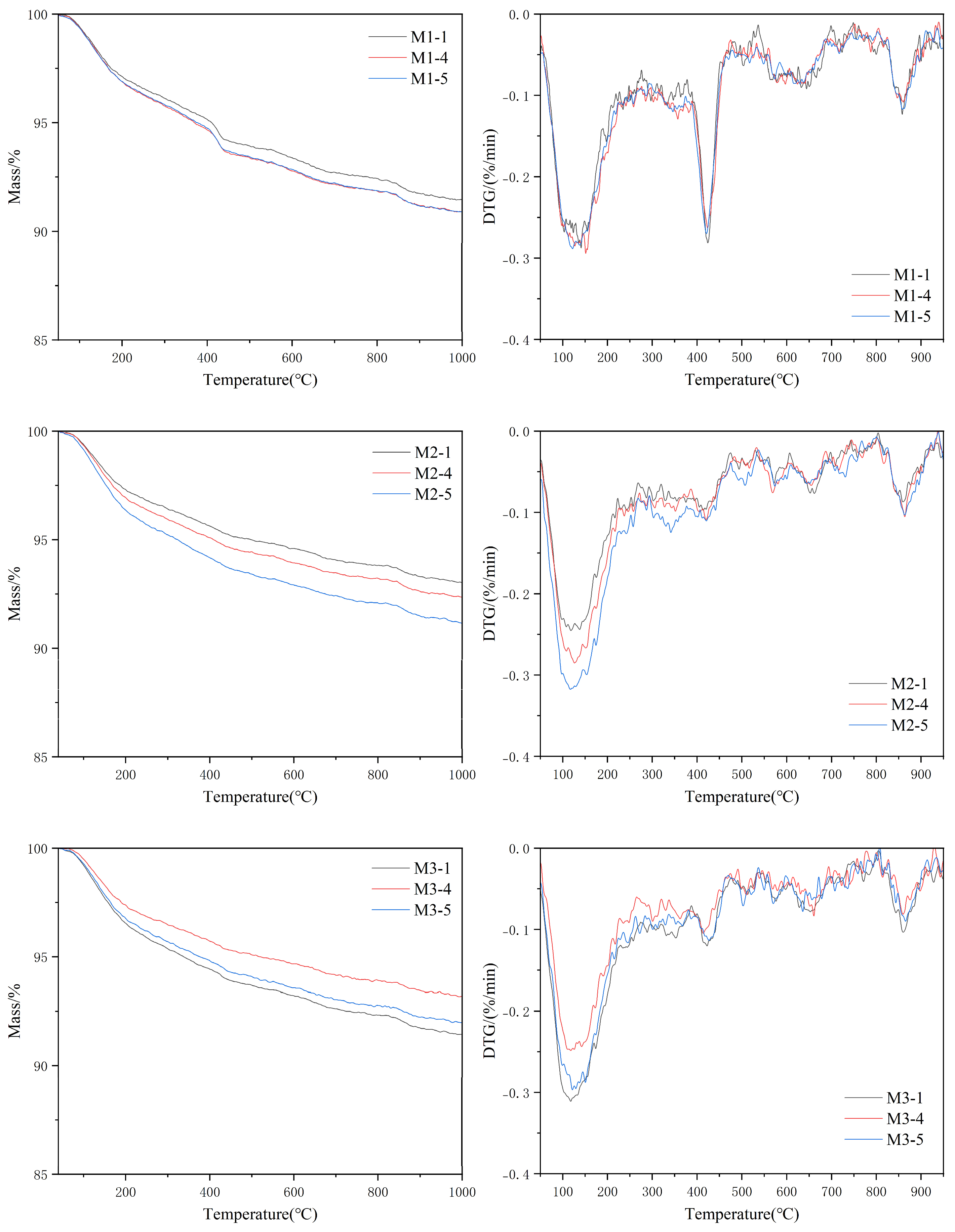

3.5. TG-DTG Analysis

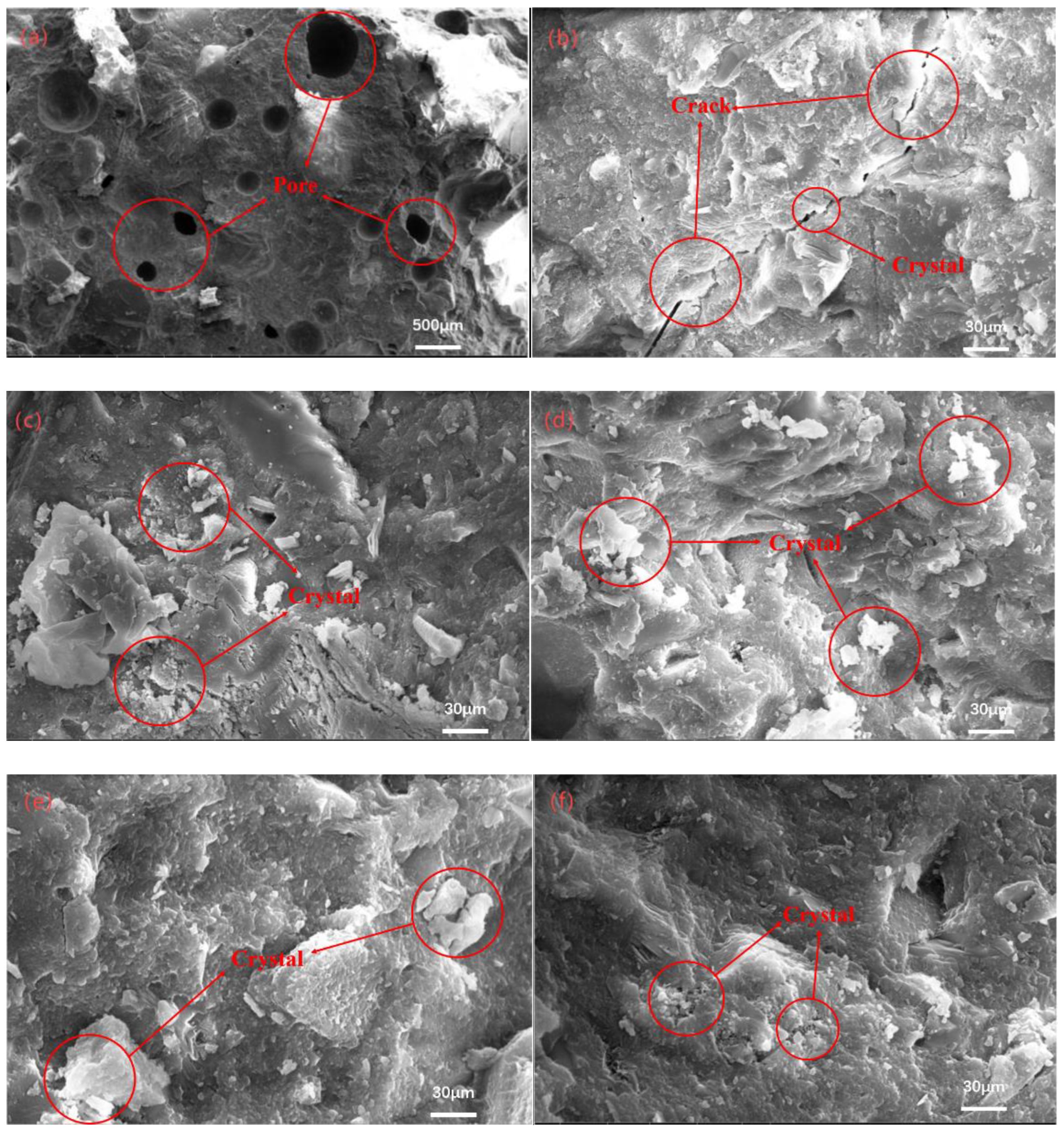

3.6. SEM Analysis

4. Conclusions

- (1)

- A high-density UHPC skeleton was generated using the modified Andreasen and Andersen particle filling model. The deviation of the particle size distribution between the target and mixture curves was small. The combination of the grading of AS and RS with cementitious materials was favorable for obtaining the optimal particle size distribution profile of UHPC.

- (2)

- Under the standard curing regime, UHPC with 60% to 80% AS incorporation increased the degree of flow by 1.7% to 3.0% and reduced the degree of autogenous shrinkage by 13.83% to 34.22% as compared to the blank group. A significant reduction in the flexural and compressive strength of UHPC was observed under the standard 28 d curing regime.

- (3)

- Under the M3 curing regime (steam curing at 90 °C for 2 d followed by standard curing for up to 7 d), UHPC with 60–80% AS substitution achieved a flexural strength exceeding 18 MPa and a compressive strength over 130 MPa. Notably, the compressive strength of samples with 60% and 80% AS reached 132.4 MPa and 130.8 MPa, respectively. Compared to standard 28 d curing, this hybrid regime reduced porosity by 31.7% (from 13.4% to 9.2%) and increased the gel pore content by nearly 1.5 times (from 23–27% to 58–61%), demonstrating superior matrix densification through accelerated hydration and pozzolanic reactions. These results highlight the feasibility of high-volume AS utilization in UHPC while maintaining exceptional mechanical properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UHPC | Ultra-high-performance concrete |

| AS | Aeolian sand |

| RS | River sand |

References

- Choi, D.; Hong, K.; Ochirbud, M.; Meiramov, D.; Sukontaskuul, P. Mechanical Properties of Ultra-High Performance Concrete (UHPC) and Ultra-High Performance Fiber-Reinforced Concrete (UHPFRC) with Recycled Sand. Int. J. Concr. Struct. Mater. 2023, 17, 67. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K. Effects of saturated lightweight sand content on key characteristics of ultra-high-performance concrete. Cem. Concr. Res. 2017, 101, 46–54. [Google Scholar] [CrossRef]

- Chu, H.; Wang, F.; Wang, L.; Feng, T.; Wang, D. Mechanical Properties and Environmental Evaluation of Ultra-High-Performance Concrete with Aeolian Sand. Materials 2020, 13, 3148. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zheng, W.; Wu, F. Preparation of ultra-high performance concrete containing waste foundry sand and its application in structures. Structures 2023, 58, 105472. [Google Scholar] [CrossRef]

- Chuah, S.; Duan, W.H.; Pan, Z.; Hunter, E.; Korayem, A.H.; Zhao, X.L.; Collins, F.; Sanjayan, J.G. The properties of fly ash based geopolymer mortars made with dune sand. Mater. Des. 2016, 92, 571–578. [Google Scholar] [CrossRef]

- Jiang, J.; Feng, T.; Chu, H.; Wu, Y.; Wang, F.; Zhou, W.; Wang, Z. Quasi-static and dynamic mechanical properties of eco-friendly ultra-high-performance concrete containing aeolian sand. Cem. Concr. Compos. 2019, 97, 369–378. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Chen, S.; Wang, H.; Liu, G. Multi-scale study on the durability degradation mechanism of aeolian sand concrete under freeze–thaw conditions. Constr. Build. Mater. 2022, 340, 127433. [Google Scholar] [CrossRef]

- Al-Harthy, A.S.; Halim, M.A.; Taha, R.; Al-Jabri, K.S. The properties of concrete made with fine dune sand. Constr. Build. Mater. 2007, 21, 1803–1808. [Google Scholar] [CrossRef]

- Lynda Amel, C.; Kadri, E.-H.; Sebaibi, Y.; Soualhi, H. Dune sand and pumice impact on mechanical and thermal lightweight concrete properties. Constr. Build. Mater. 2017, 133, 209–218. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Liu, X.; Liu, G.; Hu, D.; Meng, X. Time-Varying Compressive Strength Model of Aeolian Sand Concrete considering the Harmful Pore Ratio Variation and Heterogeneous Nucleation Effect. Adv. Civ. Eng. 2019, 2019, 5485630. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Liu, G.; Hu, D.; Ma, X. Multi-scale study on mechanical property and strength prediction of aeolian sand concrete. Constr. Build. Mater. 2020, 247, 118538. [Google Scholar] [CrossRef]

- Bouziani, T.; Benmounah, A.; Bédérina, M. Statistical modelling for effect of mix-parameters on properties of high-flowing sand-concrete. J. Cent. South Univ. 2012, 19, 2966–2975. [Google Scholar] [CrossRef]

- Seif, E.-S.S.A. Assessing the engineering properties of concrete made with fine dune sands: An experimental study. Arab. J. Geosci. 2011, 6, 857–863. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions: Applied to Ceramic Manufacturing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Yu, R.; van Beers, L.; Spiesz, P.; Brouwers, H.J.H. Impact resistance of a sustainable Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) under pendulum impact loadings. Constr. Build. Mater. 2016, 107, 203–215. [Google Scholar] [CrossRef]

- Spiesz, P.; Yu, Q.L.; Brouwers, H.J.H. Development of cement-based lightweight composites—Part 2: Durability-related properties. Cem. Concr. Compos. 2013, 44, 30–40. [Google Scholar] [CrossRef][Green Version]

- Wang, X.; Yu, R.; Song, Q.; Shui, Z.; Liu, Z.; Wu, S.; Hou, D. Optimized design of ultra-high performance concrete (UHPC) with a high wet packing density. Cem. Concr. Res. 2019, 126, 105921. [Google Scholar] [CrossRef]

- Liu, K.; Yu, R.; Shui, Z.; Yi, S.; Li, X.; Ling, G.; He, Y. Influence of external water introduced by coral sand on autogenous shrinkage and microstructure development of Ultra-High Strength Concrete (UHSC). Constr. Build. Mater. 2020, 252, 119111. [Google Scholar] [CrossRef]

- Brouwers, H.J.H.; Radix, H.J. Self-Compacting Concrete: Theoretical and experimental study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Hunger, M. An Integral Design Concept for Ecological Self-Compacting Concrete. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- Liu, K.; Yu, R.; Shui, Z.; Li, X.; Ling, X.; He, W.; Yi, S.; Wu, S. Effects of Pumice-Based Porous Material on Hydration Characteristics and Persistent Shrinkage of Ultra-High Performance Concrete (UHPC). Materials 2018, 12, 11. [Google Scholar] [CrossRef]

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Standardization Administration of China: Beijing, China, 2005.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2019.

- T/CBMF 37-2018; Ultra-High Performance Concrete. China Building Materials Federation: Beijing, China, 2018.

- ASTM C1698-09; Standard Test Method for Autogenous Strain of Cement Paste and Mortar. American Society for Testing and Materials: West Conshohocken, PA, USA, 2009.

- Luo, F.J.; He, L.; Pan, Z.; Duan, W.H.; Zhao, X.L.; Collins, F. Effect of very fine particles on workability and strength of concrete made with dune sand. Constr. Build. Mater. 2013, 47, 131–137. [Google Scholar] [CrossRef]

- Zhang, M.; Zhu, X.; Shi, J.; Liu, B.; He, Z.; Liang, C. Utilization of desert sand in the production of sustainable cement-based materials: A critical review. Constr. Build. Mater. 2022, 327, 127014. [Google Scholar] [CrossRef]

- Guettala, S.; Mezghiche, B. Compressive strength and hydration with age of cement pastes containing dune sand powder. Constr. Build. Mater. 2011, 25, 1263–1269. [Google Scholar] [CrossRef]

- Wang, T.; Gong, J.; Chen, B.; Gong, X.; Guo, W.; Zhang, Y.; Li, F.; Mo, K.H. Mechanical Properties and Shrinkage of Ultrahigh-Performance Concrete Containing Lithium Carbonate and Nano-Calcium Carbonate. Adv. Civ. Eng. 2021, 2021, 6646272. [Google Scholar] [CrossRef]

- Kang, S.-H.; Hong, S.-G.; Moon, J. The effect of superabsorbent polymer on various scale of pore structure in ultra-high performance concrete. Constr. Build. Mater. 2018, 172, 29–40. [Google Scholar] [CrossRef]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Xiong, X.; Wu, M.; Shen, W.; Li, J.; Zhao, D.; Li, P.; Wu, J. Performance and microstructure of ultra-high-performance concrete (UHPC) with silica fume replaced by inert mineral powders. Constr. Build. Mater. 2022, 327, 126996. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, R.; Shui, Z.; Liu, K. Hydration kinetics and microstructure development of Ultra-High Performance Concrete (UHPC) subjected to microwave pre-curing. Cem. Concr. Compos. 2022, 129, 104484. [Google Scholar] [CrossRef]

- Xu, D.; Tang, J.; Hu, X.; Zhou, Y.; Yu, C.; Han, F.; Liu, J. Influence of silica fume and thermal curing on long-term hydration, microstructure and compressive strength of ultra-high performance concrete (UHPC). Constr. Build. Mater. 2023, 395, 132370. [Google Scholar] [CrossRef]

- Goñi, S.; Puertas, F.; Hernández, M.S.; Palacios, M.; Guerrero, A.; Dolado, J.S.; Zanga, B.; Baroni, F. Quantitative study of hydration of C3S and C2S by thermal analysis. J. Therm. Anal. Calorim. 2010, 102, 965–973. [Google Scholar] [CrossRef]

- Pane, I.; Hansen, W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem. Concr. Res. 2005, 35, 1155–1164. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, L.; Chu, H.; Wang, F.; Ju, S.; Gu, Y. Workability, hydration, microstructure, and mechanical properties of UHPC produced with aeolian sand. J. Sustain. Cem.-Based Mater. 2021, 11, 57–73. [Google Scholar] [CrossRef]

- Zhu, L.; Zheng, M.; Zhang, S.; Zhang, W.; Chen, W.; Ou, Z. Modification and mechanism of polymer in high-performance concrete with full aeolian sand: An integrated macro-to-micro perspective. J. Build. Eng. 2023, 75, 106969. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Wang, F.; Hu, S. The effect of curing regimes on the mechanical properties, nano-mechanical properties and microstructure of ultra-high performance concrete. Cem. Concr. Res. 2019, 118, 1–13. [Google Scholar] [CrossRef]

- Zhu, C.; Yi, T.; Lin, X.; Bai, G.; Liu, C. Feasibility analysis of treating aeolian sand and recycled mixed powder as environmentally friendly materials in the ultra-high-performance concrete. Dev. Built Environ. 2023, 15, 100212. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, B.; Xie, J.; Xue, Z.; Huang, K.; Tan, J. Effects of recycled sand and nanomaterials on ultra-high performance concrete: Workability, compressive strength and microstructure. Constr. Build. Mater. 2023, 378, 131180. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P.-M.; Li, X.-G. Physical and mechanical properties of styrene–butadiene rubber emulsion modified cement mortars. Cem. Concr. Res. 2005, 35, 900–906. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. Microstructure of ultra-high-performance concrete (UHPC)—A review study. J. Build. Eng. 2022, 50, 104118. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, X.; Creighton, A.T.; Peterson, M.M. Effect of styrene–butadiene rubber latex on the chloride permeability and microstructure of Portland cement mortar. Constr. Build. Mater. 2009, 23, 2283–2290. [Google Scholar] [CrossRef]

| Substance | Cement | Slag | SF |

|---|---|---|---|

| CaO | 62.05 | 38.80 | 1.25 |

| SiO2 | 21.94 | 32.27 | 94.44 |

| Al2O3 | 5.82 | 16.17 | 0.35 |

| Fe2O3 | 2.63 | 0.41 | 0.14 |

| K2O | 0.67 | 0.56 | 0.37 |

| Na2O | 0.19 | 0.46 | 0.19 |

| SO3 | 2.09 | 2.67 | 0.12 |

| MgO | 2.82 | 7.25 | 0.56 |

| TiO2 | 0.30 | 0.77 | 0.10 |

| MnO | 0.09 | 0.20 | 0.01 |

| P2O5 | 0.06 | - | 0.39 |

| Cl− | 0.10 | 0.03 | 0.05 |

| Other | 1.24 | 0.41 | 2.04 |

| Group | Cement | SF | Slag | RS 2 | RS 1 | AS | Water | SP | LSF (Vol.%) |

|---|---|---|---|---|---|---|---|---|---|

| UHPC-1 | 774.7 | 166.0 | 166.0 | 169.3 | 959.6 | 0 | 210.3 | 22.1 | 0.65 |

| UHPC-2 | 774.7 | 166.0 | 166.0 | 169.3 | 767.7 | 191.9 | 210.3 | 22.1 | 0.65 |

| UHPC-3 | 774.7 | 166.0 | 166.0 | 169.3 | 575.7 | 383.8 | 210.3 | 22.1 | 0.65 |

| UHPC-4 | 774.7 | 166.0 | 166.0 | 169.3 | 383.8 | 575.7 | 210.3 | 22.1 | 0.65 |

| UHPC-5 | 774.7 | 166.0 | 166.0 | 169.3 | 191.9 | 767.7 | 210.3 | 22.1 | 0.65 |

| UHPC-6 | 774.7 | 166.0 | 166.0 | 169.3 | 0 | 959.6 | 210.3 | 22.1 | 0.65 |

| Sample Code | AS Substitution Rate | Curing Regime | Description |

|---|---|---|---|

| UHPC-1–UHPC-6 | 0–100% | M1, M2, or M3 | See Table 2 for mix proportions; curing regimes defined in Section 2.2.2 |

| M1 | N/A | Standard (20 °C, 28 d) | Control curing condition |

| M2 | N/A | Steam (90 °C, 2 d) | High-temperature accelerated curing |

| M3 | N/A | Steam (2 d) + standard curing (5 d) | Hybrid curing for optimized hydration |

| Specimen | Porosity/% | Aperture Distribution/% | |||

|---|---|---|---|---|---|

| (0, 10) nm | [10, 100] nm | (100, 5000] nm | >5000 nm | ||

| M1-1 | 12.24 | 28 | 50 | 13 | 9 |

| M1-4 | 13.72 | 27 | 47 | 17 | 9 |

| M1-5 | 13.43 | 23 | 50 | 17 | 10 |

| M2-1 | 12.15 | 54 | 16 | 15 | 15 |

| M2-4 | 11.94 | 52 | 16 | 14 | 18 |

| M2-5 | 10.24 | 52 | 16 | 15 | 17 |

| M3-1 | 12.08 | 66 | 10 | 12 | 12 |

| M3-4 | 10.87 | 61 | 13 | 12 | 14 |

| M3-5 | 9.17 | 58 | 14 | 14 | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Zhao, B.; Zhu, J.; He, C.; Ge, Y.; Wu, Y.; Zhu, Y.; Dan, J.; Zhou, Y.; Li, X. The Preparation and Properties of Ultra-High-Performance Concrete with Aeolian Sand: A Lab Study on the Effect of the Curing Method. Materials 2025, 18, 2031. https://doi.org/10.3390/ma18092031

Lv Y, Zhao B, Zhu J, He C, Ge Y, Wu Y, Zhu Y, Dan J, Zhou Y, Li X. The Preparation and Properties of Ultra-High-Performance Concrete with Aeolian Sand: A Lab Study on the Effect of the Curing Method. Materials. 2025; 18(9):2031. https://doi.org/10.3390/ma18092031

Chicago/Turabian StyleLv, Yang, Boyu Zhao, Jie Zhu, Chenhao He, Yunlu Ge, Yuanshuai Wu, Yanchao Zhu, Jianming Dan, Yang Zhou, and Xiangguo Li. 2025. "The Preparation and Properties of Ultra-High-Performance Concrete with Aeolian Sand: A Lab Study on the Effect of the Curing Method" Materials 18, no. 9: 2031. https://doi.org/10.3390/ma18092031

APA StyleLv, Y., Zhao, B., Zhu, J., He, C., Ge, Y., Wu, Y., Zhu, Y., Dan, J., Zhou, Y., & Li, X. (2025). The Preparation and Properties of Ultra-High-Performance Concrete with Aeolian Sand: A Lab Study on the Effect of the Curing Method. Materials, 18(9), 2031. https://doi.org/10.3390/ma18092031