1. Introduction

Under the coupling effect of temperature, oxygen in the air, ultraviolet light, rainwater, and other natural factors, asphalt mixtures undergo aging. Aging leads to increased brittleness and reduced durability, which significantly diminishes the performance of asphalt pavements, causing issues such as cracking, potholes, and raveling, thereby shortening the service life of asphalt pavements [

1,

2]. Therefore, monitoring and evaluating the aging state of asphalt mixtures are crucial for the timely implementation of appropriate maintenance measures to improve pavement performance and extend its lifespan. Correctly assessing aging is of great importance for researching ways to enhance the aging resistance of asphalt mixtures. Currently, the aging state of asphalt is typically evaluated by extracting asphalt from the mixture using the Abson extraction method, followed by the assessment of the asphalt and its mixture [

3,

4]. However, this traditional extraction method uses chemical reagents (such as trichloroethylene) and involves a heating process that further ages the asphalt, compromising its original properties and failing to accurately reflect the aging state of the asphalt in the mixture. Moreover, the extraction process is complex and time-consuming, and some of the chemical solvents used are harmful to both laboratory personnel and the environment [

5].

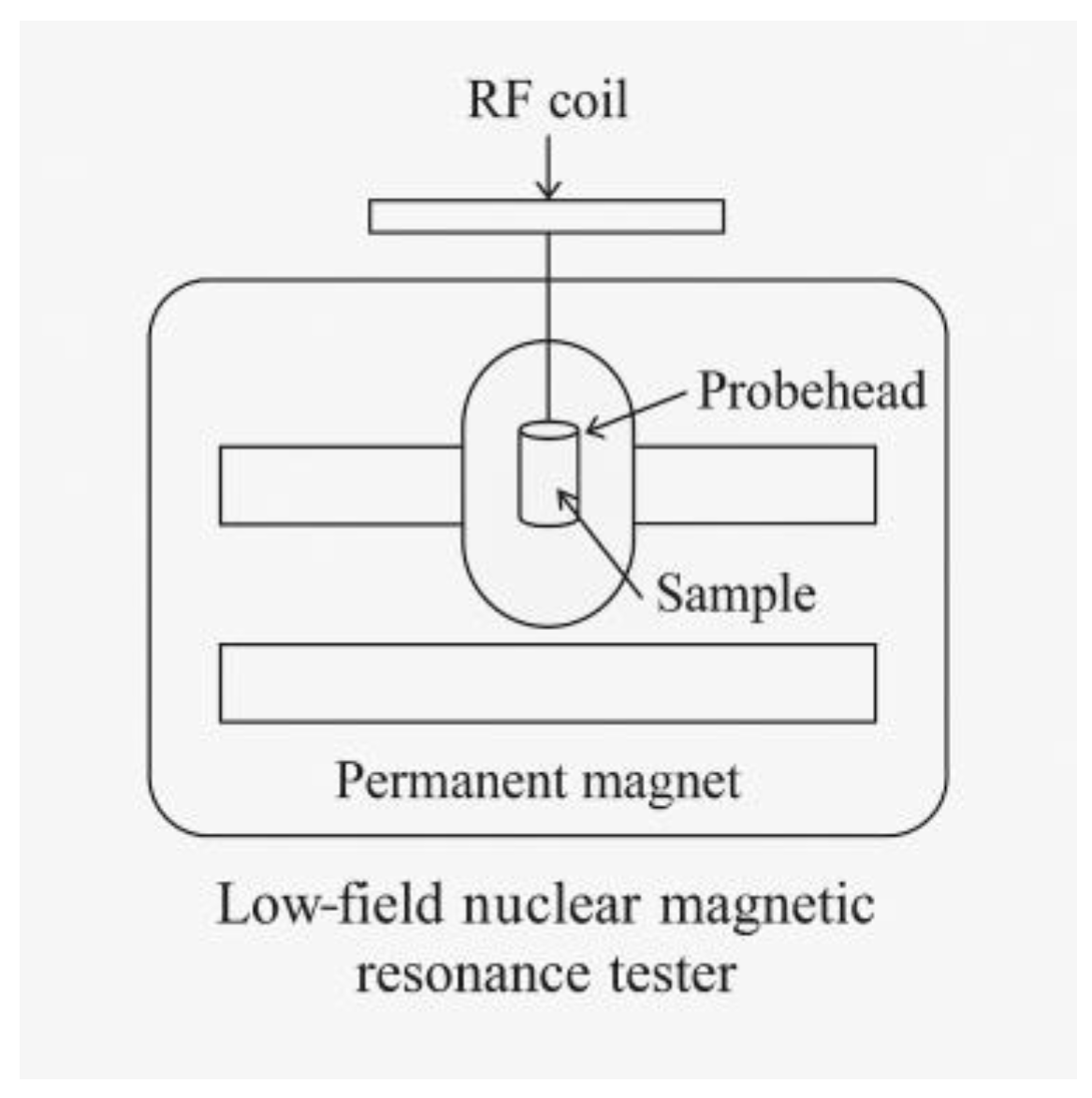

Nuclear magnetic resonance (NMR) spectroscopy detects the interaction between protons in atomic nuclei and an external magnetic field. In recent years, it has been used to analyze the chemical structure of asphalt and infer its aging mechanisms [

6]. NMR’s key feature is its ability to qualitatively and quantitatively analyze the composition and structure of substances [

7]. Low-field NMR (LF-NMR) measures spin–spin relaxation (transverse relaxation time, T2) in the sub-microscopic field (between molecules). This method offers the advantages of being non-destructive, low-cost, and efficient. Since its discovery in 1946, NMR has become a valuable tool in physics, chemistry, biology, and medicine [

8]. Recently, LF-NMR has been used to assess the aging state of asphalt mixture samples as a non-destructive, in situ detection method that is gaining increasing attention [

9,

10,

11,

12,

13,

14]. During the aging process of asphalt mixtures, the volatile components of the asphalt decrease, and small molecules aggregate into larger molecules, increasing the viscosity of the asphalt [

14]. Additionally, the oxidation of asphalt leads to the formation of carbonyl (C=O) and sulfoxide (S=O) groups, reducing the Relative Hydrogen Index (RHI) [

12]. In the T2 spectrum of LF-NMR, the transverse relaxation time T2 is related to the viscosity of the measured fluid, while the amplitude is related to the RHI [

12]. Therefore, the NMR spectrum of asphalt reflects its aging degree.

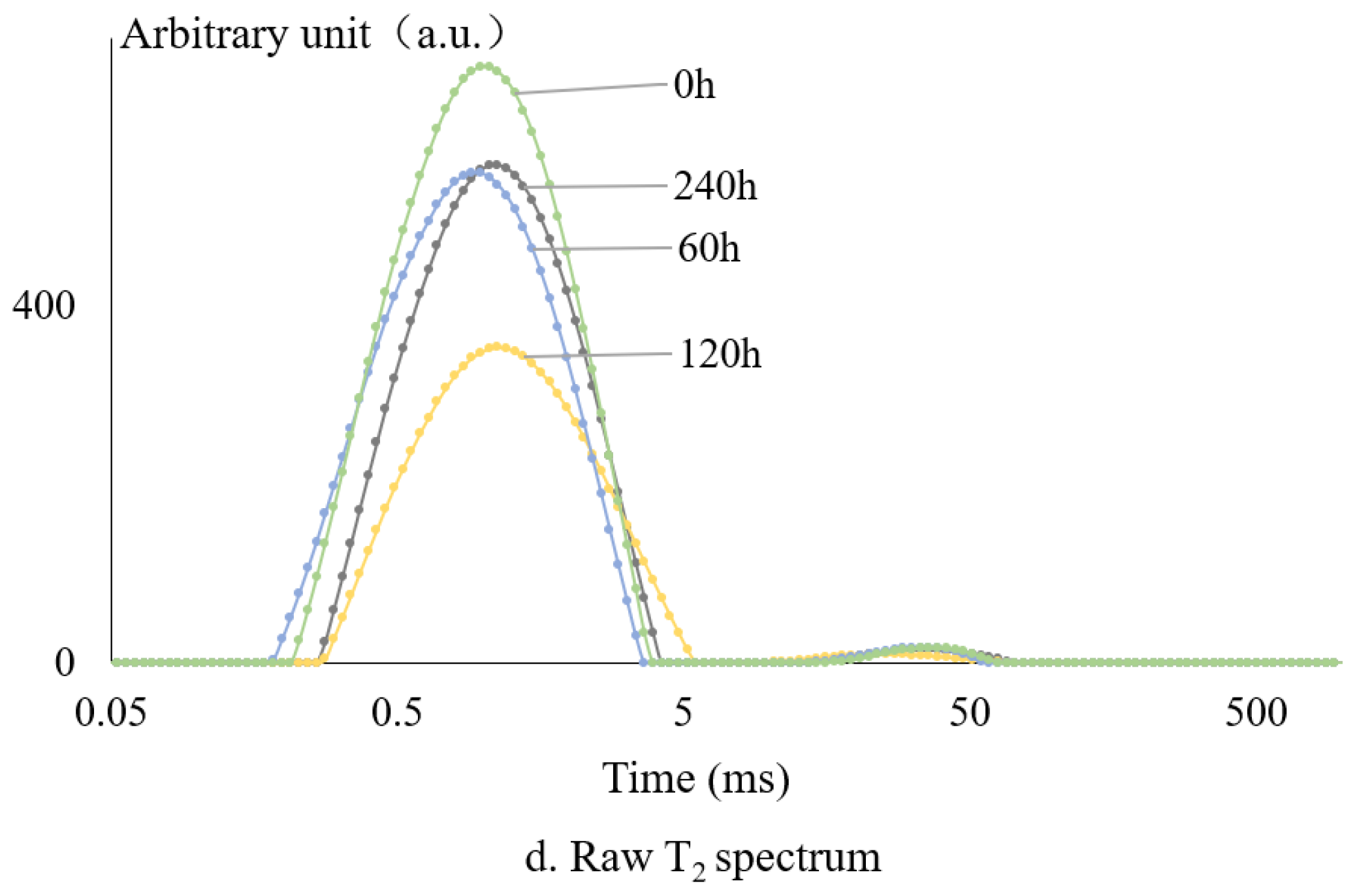

Menapace et al. [

12] applied LF-NMR to study the base asphalt mixtures with different aging times and void ratios. The results showed that as asphalt aging progresses, the transverse relaxation time T2 shortens and the amplitude (RHI) decreases. They established a relationship between RHI and the viscosity of the asphalt binder: As viscosity increases, the volumetric relaxation rate also increases linearly, resulting in a decrease in the measured transverse relaxation time T2 (or RHI).

Menapace proposed that the aging of asphalt binders is related to the Relative Hydrogen Index (RHI) and presented an equation between the RHI and the amplitude of the NMR T2 mapping [

11]:

AI is the amplitude index with the following formula:

The cumulative amplitude is the estimated spin-echo sequence amplitude at t = 0 ms, which is also the sum of all T2 components in the T2 distribution, providing a projection of T2 decay back to t = 0. RHI is proportional to the cumulative amplitude [

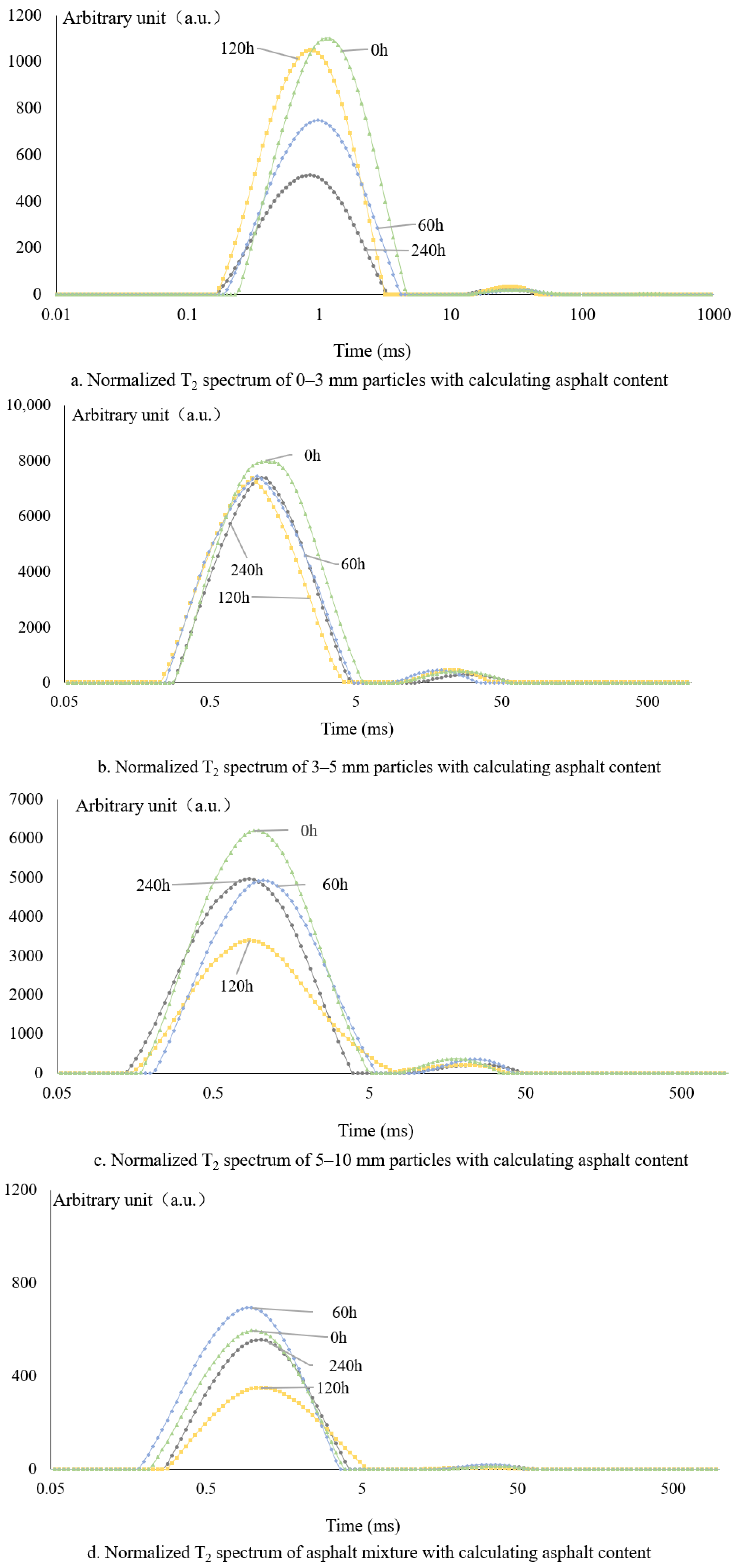

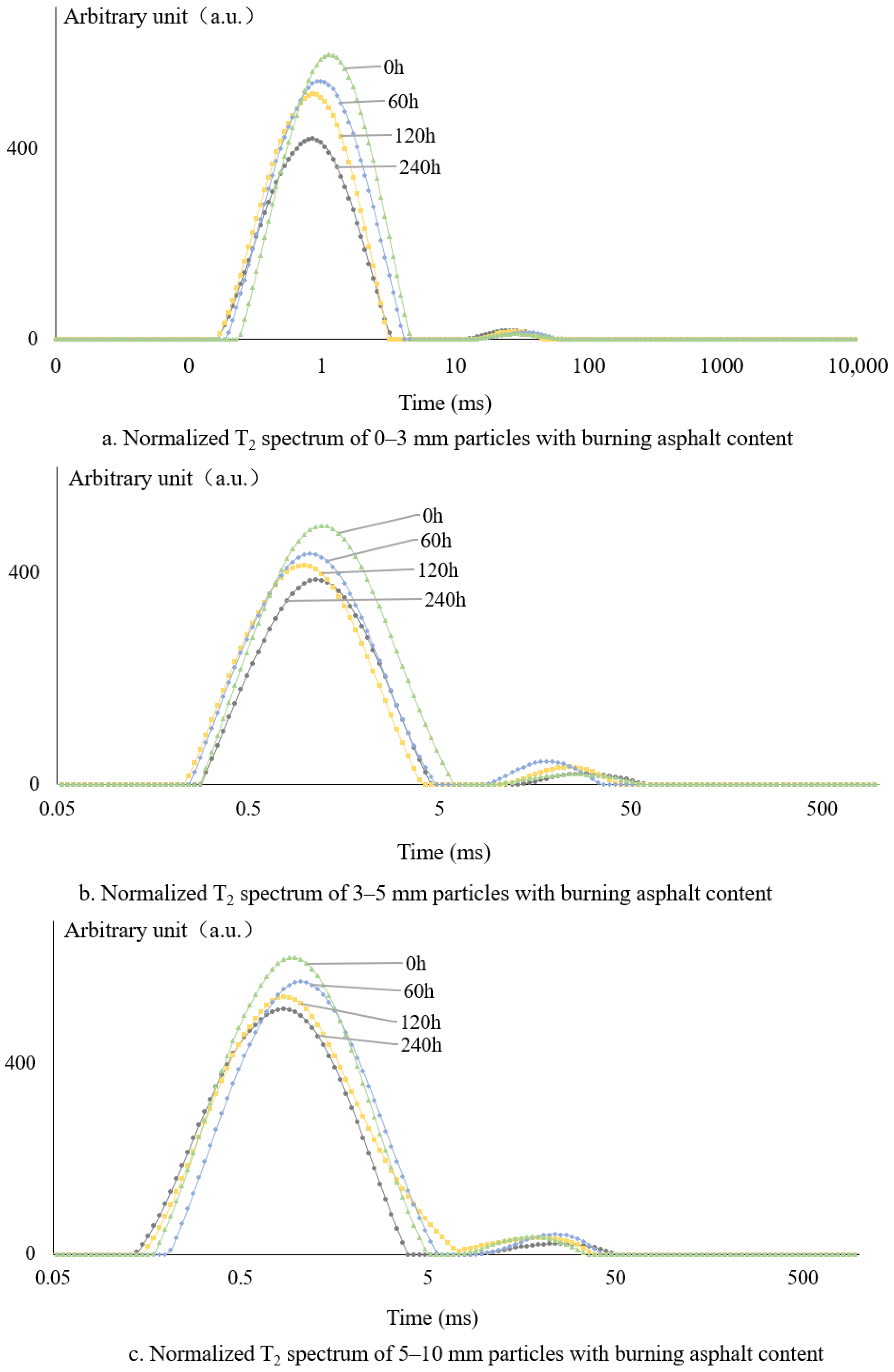

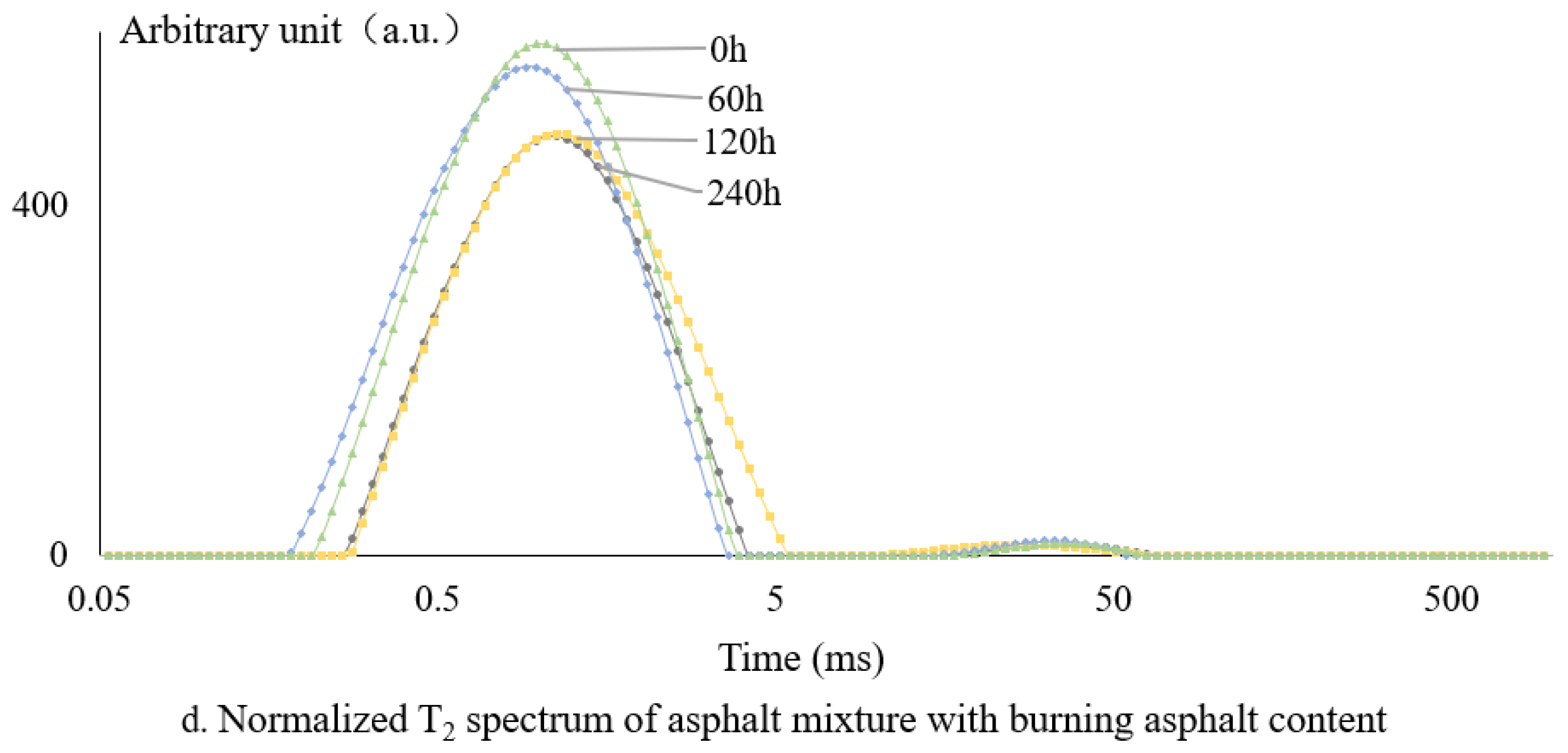

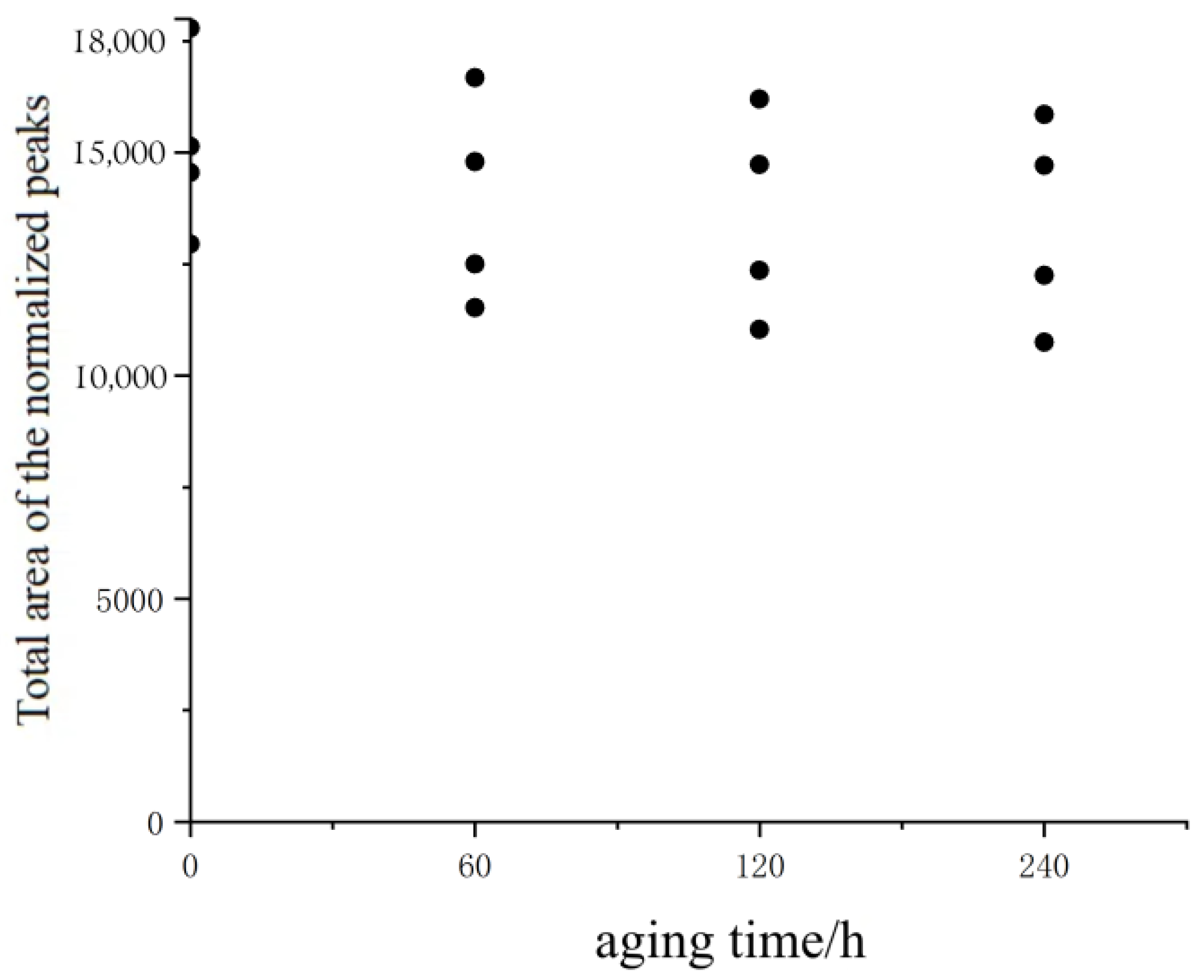

13]. The spin echo decay (SED) curve is transformed into the T2 spectrum via the Fourier transform. According to the calculation formula for RHI and the principles of NMR, the RHI value and the estimated spin-echo sequence amplitude at t = 0 of the normalized T2 spectrum from LF-NMR are consistent, meaning the cumulative amplitude is the sum of all T2 components, i.e., the normalized peak total area [

15,

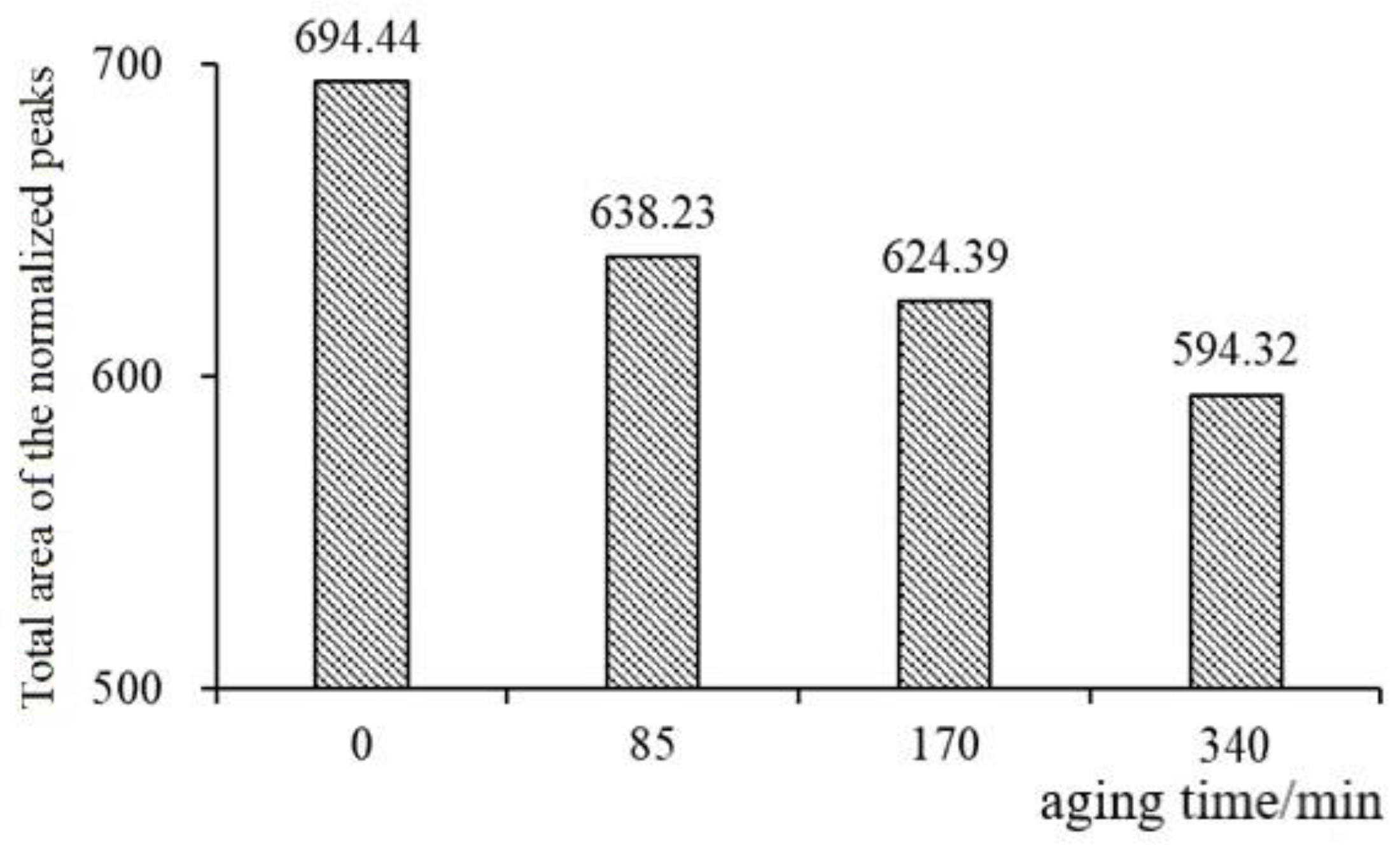

16]. As the degree of aging increases, the normalized peak total area decreases, resulting in a reduction in the cumulative amplitude and RHI.

In existing studies using low-field NMR to detect asphalt and its mixtures, the relaxation peaks of the T2 spectrum have been normalized. The formula for the normalized peak total area (NPA) is as follows [

5,

17]:

In this method, the NMR spectrum of asphalt mixtures primarily originates from the hydrogen signals in the asphalt, with the contribution of aggregate signals being negligible compared to that of the asphalt [

5,

17]. The role of asphalt content is therefore significant.

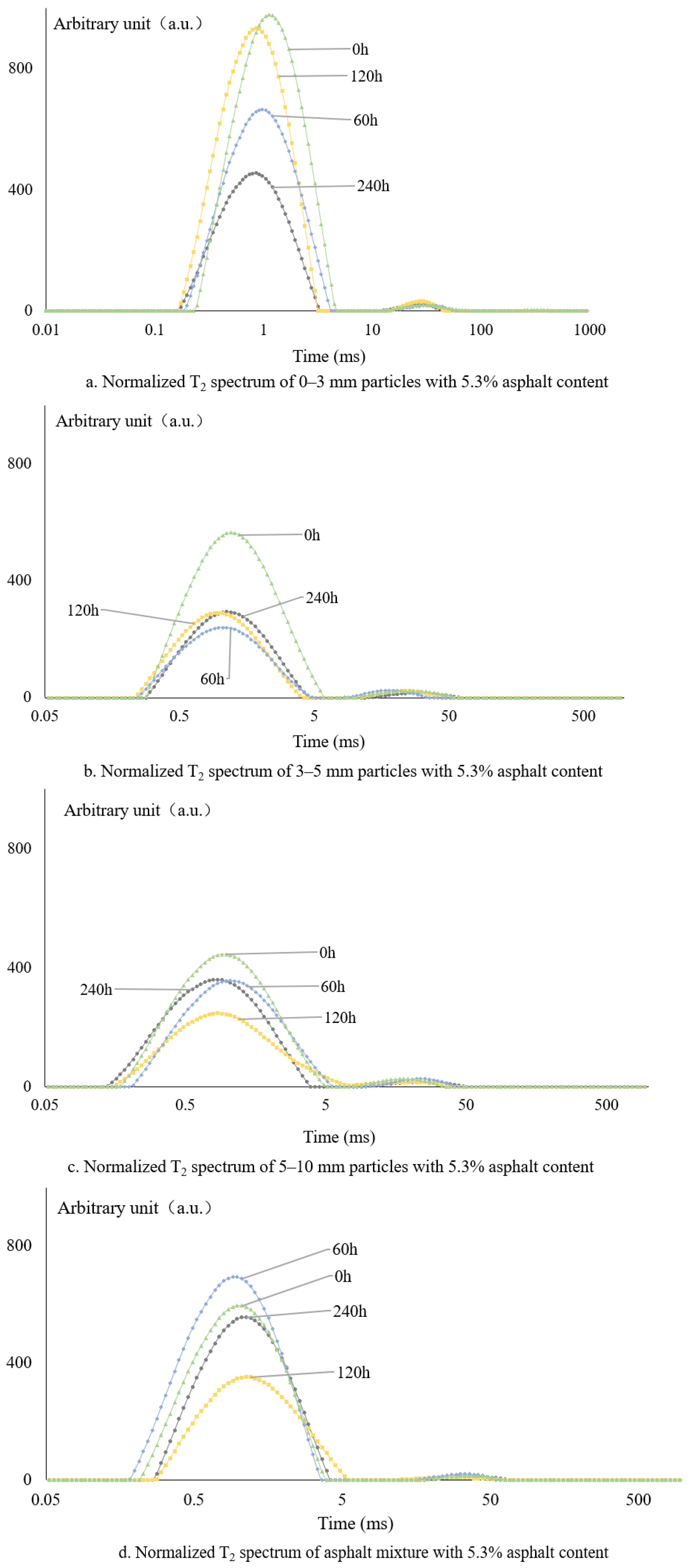

Despite growing interest in applying LF-NMR techniques to asphalt materials, limited attention has been paid to the influence of asphalt content on NMR spectral characteristics. Moreover, few studies have explored the integration of machine learning algorithms to interpret NMR data for asphalt aging evaluation. Addressing these gaps, this study proposes a novel, non-destructive approach that leverages LF-NMR combined with machine learning to assess aging behavior in asphalt mixtures, offering both scientific insight and practical value for long-term pavement performance monitoring. On this basis, the aim of this study is to investigate the impact of asphalt content on the NMR spectrum of mixtures. Specifically, it discusses the designed asphalt content in asphalt mixtures, the calculation of asphalt content for mixtures with different particle sizes, and the effect of measured asphalt content using the ignition method on the spectrum. The relationship between different aging degrees and asphalt content on the normalized peak total area is verified to evaluate asphalt aging.

4. Summary and Conclusions

The purpose of this study is to investigate the influence of the asphalt content on the NMR spectrum of the mixture in order to evaluate the aging degree of the asphalt. Low-field nuclear magnetic resonance (LF-NMR) was detected on the asphalt mixture with the same detection temperature, different particle sizes, and different aging degrees, and the main components of the NMR spectrum were found by a machine learning method and normalized. The asphalt content obtained by three different methods was studied and normalized, especially the law of normalization with aging. The conclusion is drawn from the result analysis:

- (1)

The principal component analysis method in SPSS is used to analyze the parameters that have a great influence on the principal components. From the perspective of the absolute value of the weight coefficient, the peak, normalized peak area, and normalized peak total area affect the first principal component. These three indicators actually influence each other and change together. The total normalized peak area can be used for evaluating the parameters of asphalt mixture aging by low-field NMR.

- (2)

Due to the different particle size, the asphalt content of the asphalt mixture of the same weight is different. This result is proved by both the calculation method and the combustion method, that is, the smaller the particle size of the sample, the greater the asphalt content. The asphalt content of the asphalt mixture is close to and less than the asphalt content during mixing. The asphalt content obtained by the three methods used in this study strongly influenced the normalization of the NMR spectra.

- (3)

As the aging time increases from 0 h to 60 h, 120 h and 240 h, the three-graded particles of asphalt mixture (0–3 mm, 3–5 mm, 5–10 mm) and the NMR spectrum approach the total area of the normalized peak, which are clearly related to the asphalt content.

To validate and contextualize the present findings, a comparative analysis with previous literature was conducted. Similar to earlier studies [

5,

10,

11,

12,

13,

17,

19], the aging of asphalt mixtures led to a notable shift in the T

2 relaxation peaks toward shorter relaxation times, reflecting increased molecular rigidity and reduced proton mobility. However, this study further demonstrates that the magnitude and pattern of these spectral shifts are significantly influenced by the asphalt content, which has not been sufficiently emphasized in prior work. In particular, higher asphalt content mitigated the extent of aging-induced T

2 peak reduction, suggesting a buffering effect attributable to the increased binder phase. While the overall trends are consistent with previous reports, a few discrepancies were observed—primarily in the relative prominence of certain peaks—which can likely be attributed to differences in raw materials, sample preparation methods, and aging protocols. These variations highlight the necessity of considering mixture composition when interpreting NMR spectra in asphalt aging studies.

These findings indicate that the combination of LF-NMR and machine learning provides a promising non-destructive approach for road engineers to assess asphalt aging in situ. While the observed trends in spectral responses are generally applicable across mixtures, the method may require calibration when applied to different asphalt binders or aggregate gradations. Future studies will aim to extend this approach to modified asphalts and field-aged specimens, further enhancing its practical relevance and reliability in diverse engineering contexts.