Long-Term Behavior and Microstructure of High-Performance Concrete with Coal Slag

Abstract

1. Introduction

2. Research Program

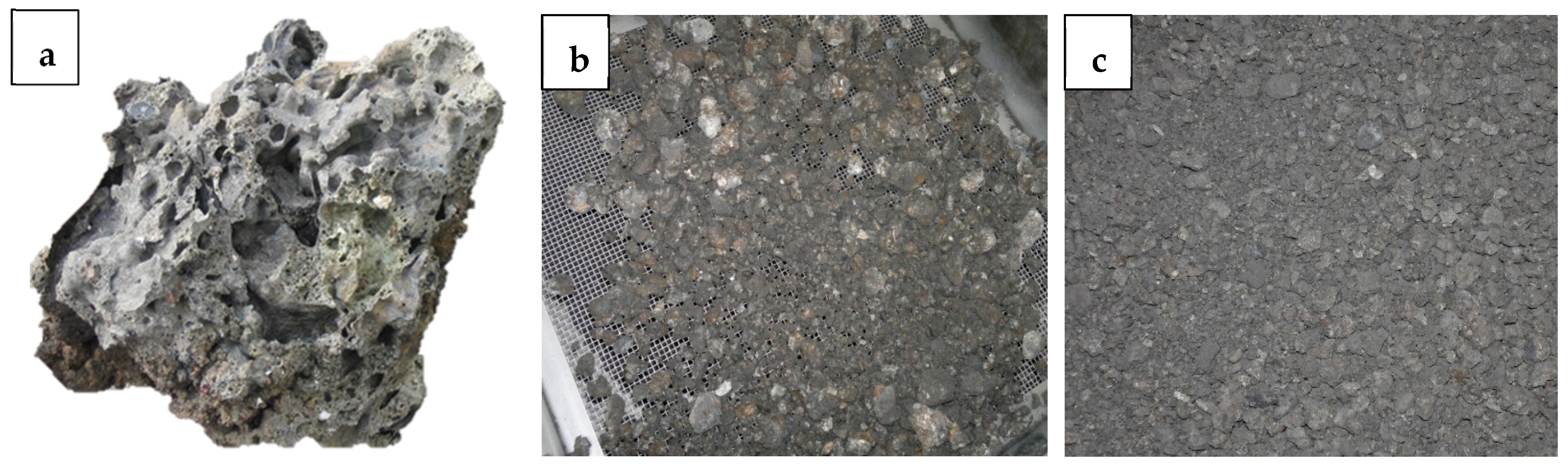

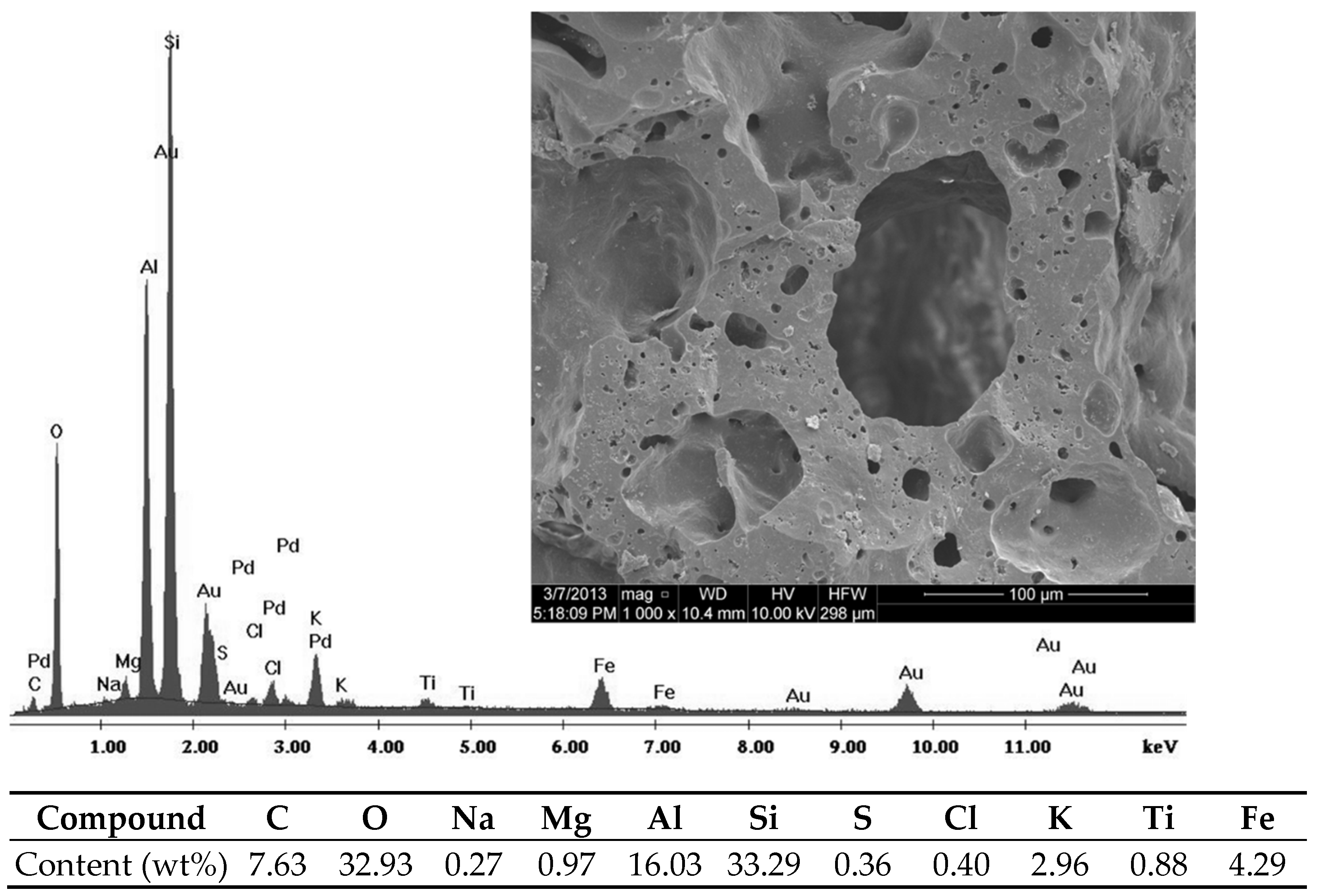

2.1. Characteristics of the Materials

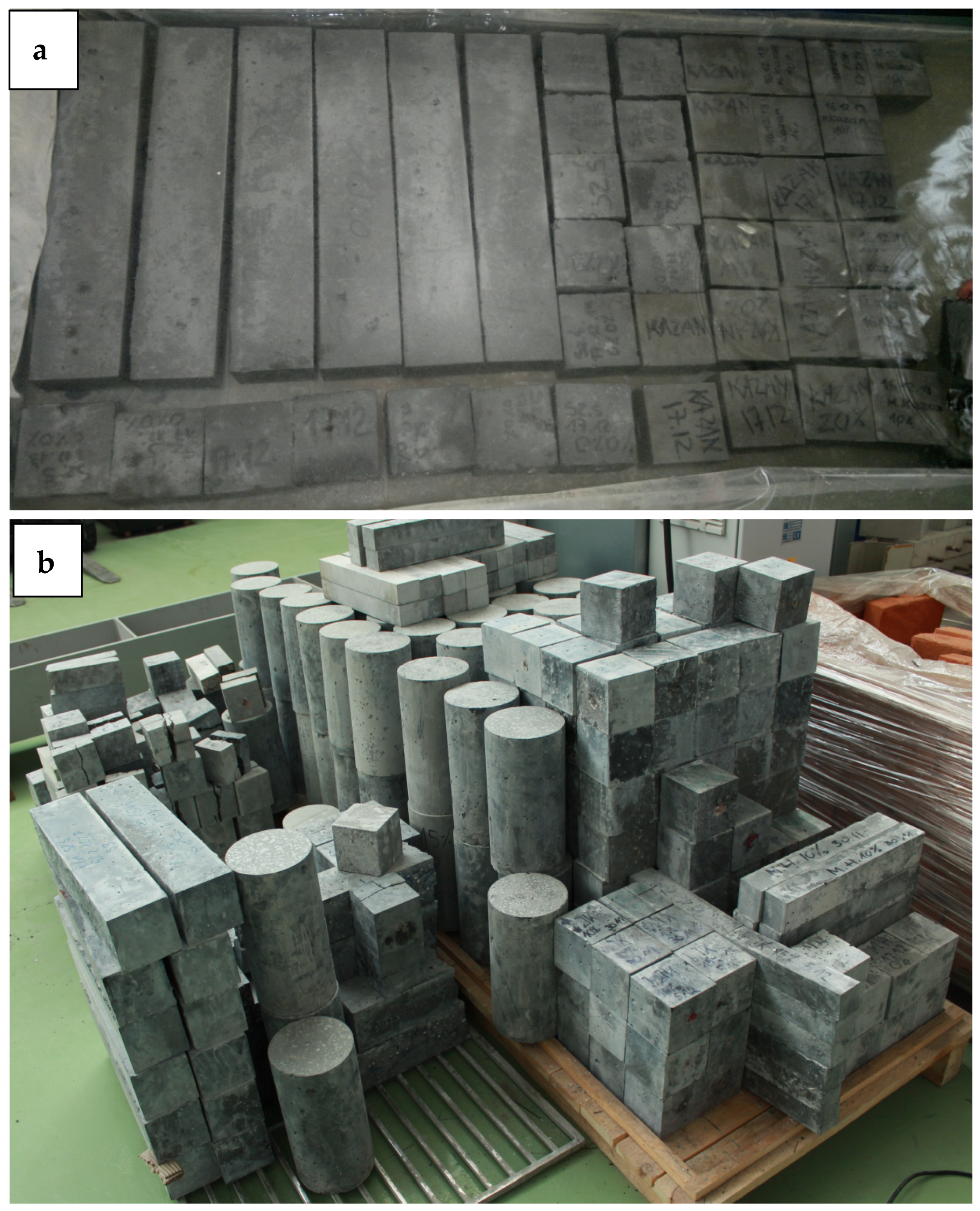

2.2. Mixture Design and Sample Production

2.3. Research Methodology for Hardened HPC Samples

3. Results and Discussion

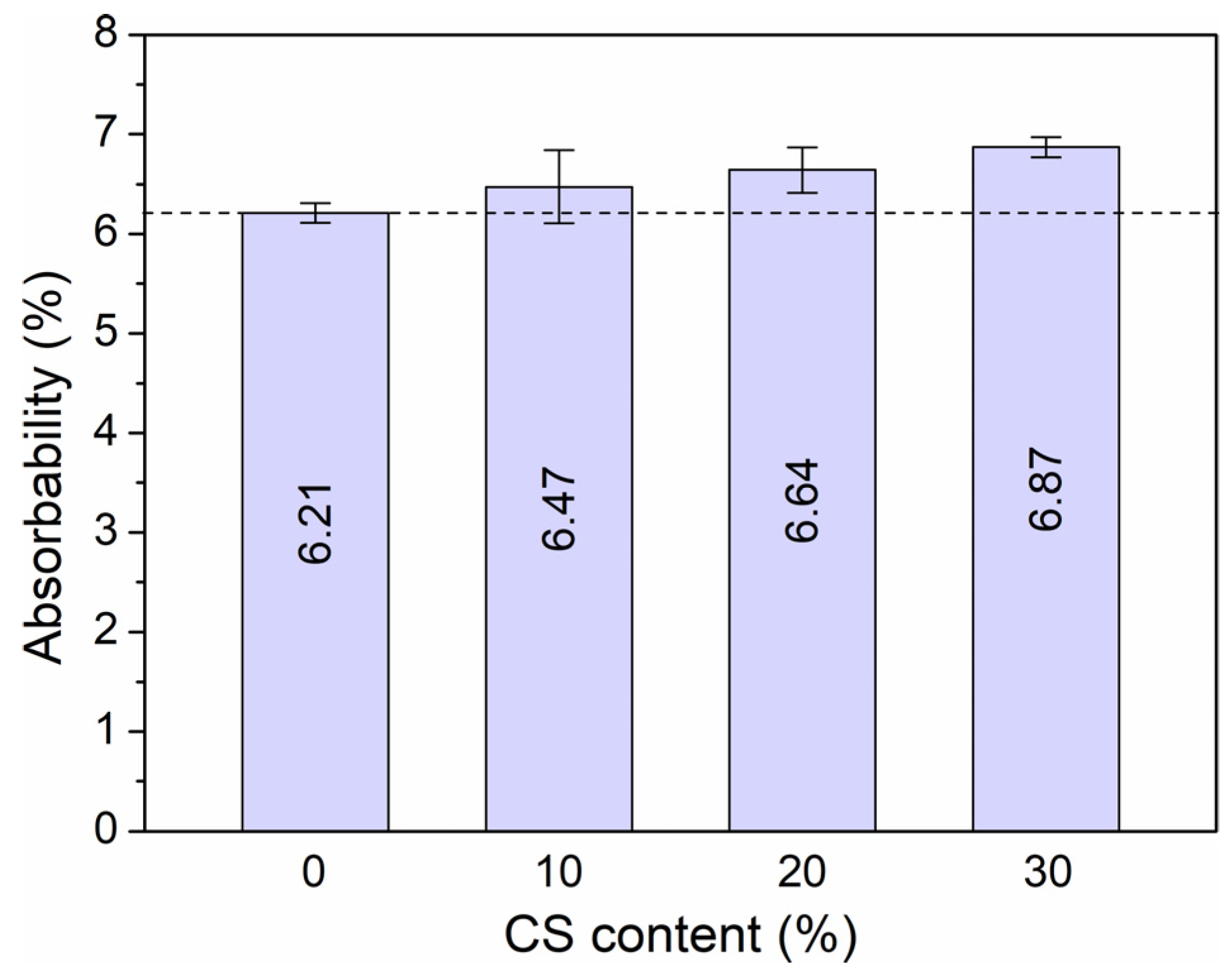

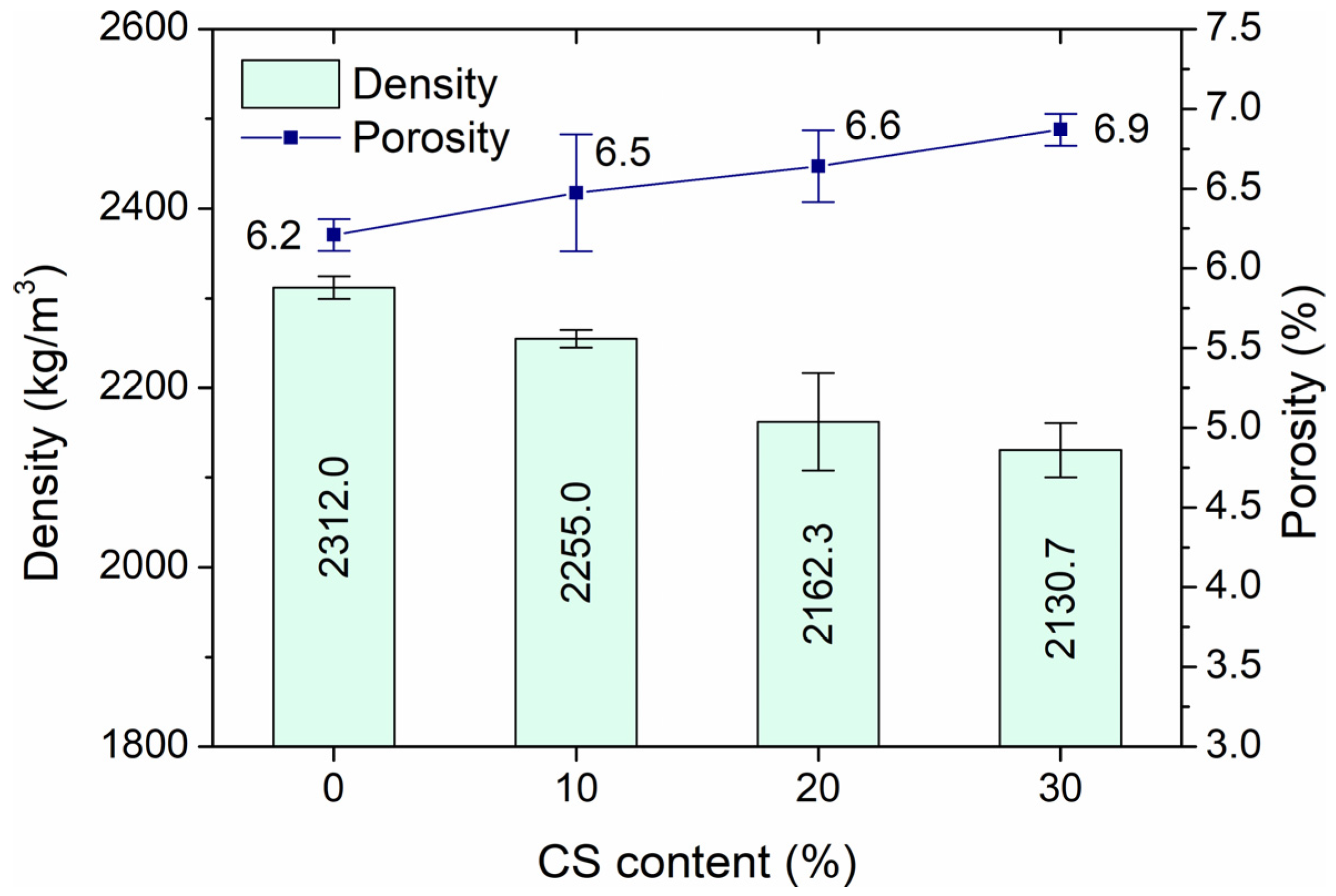

3.1. Absorbability, Density, and Porosity

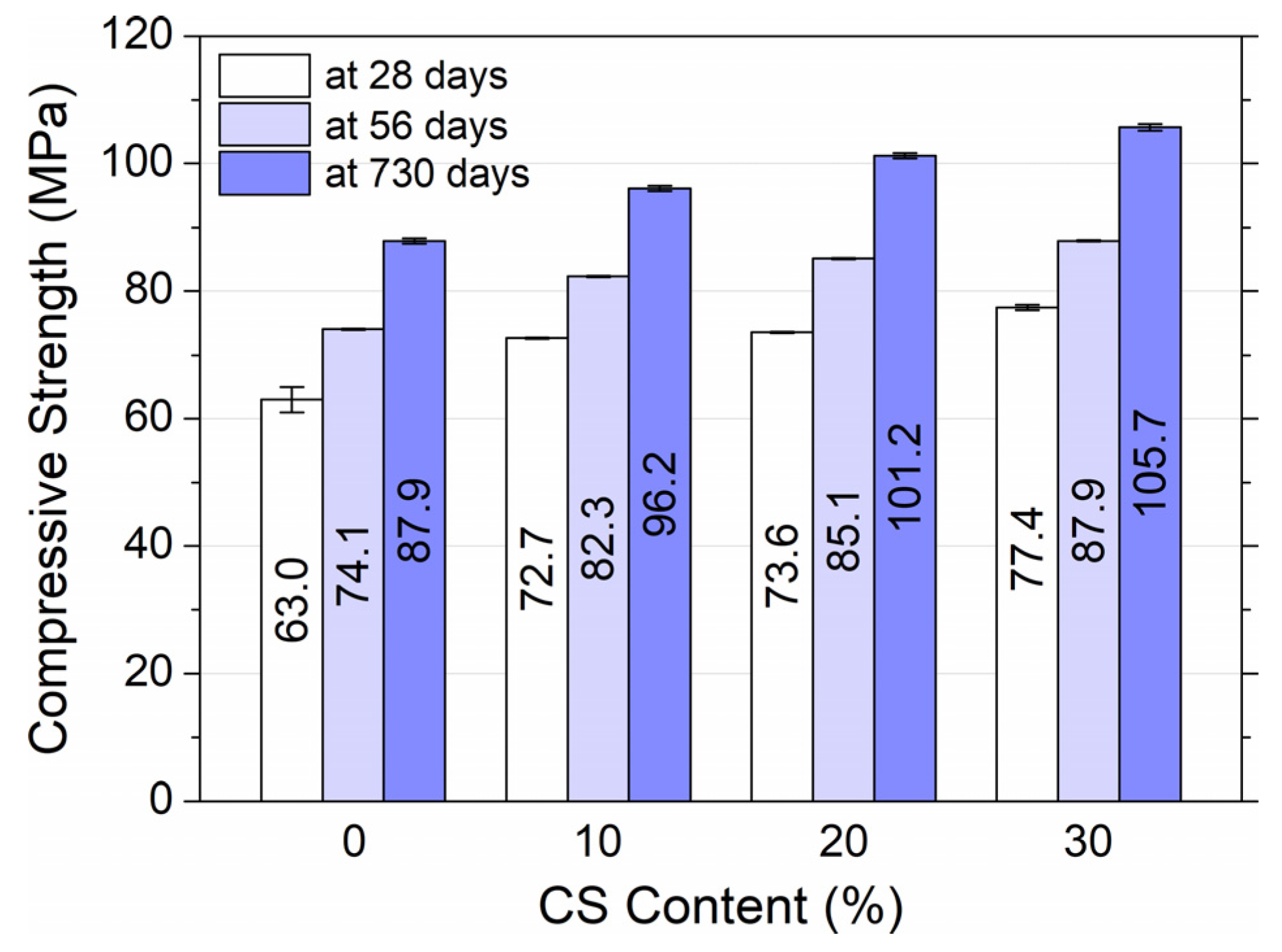

3.2. Compressive Strength

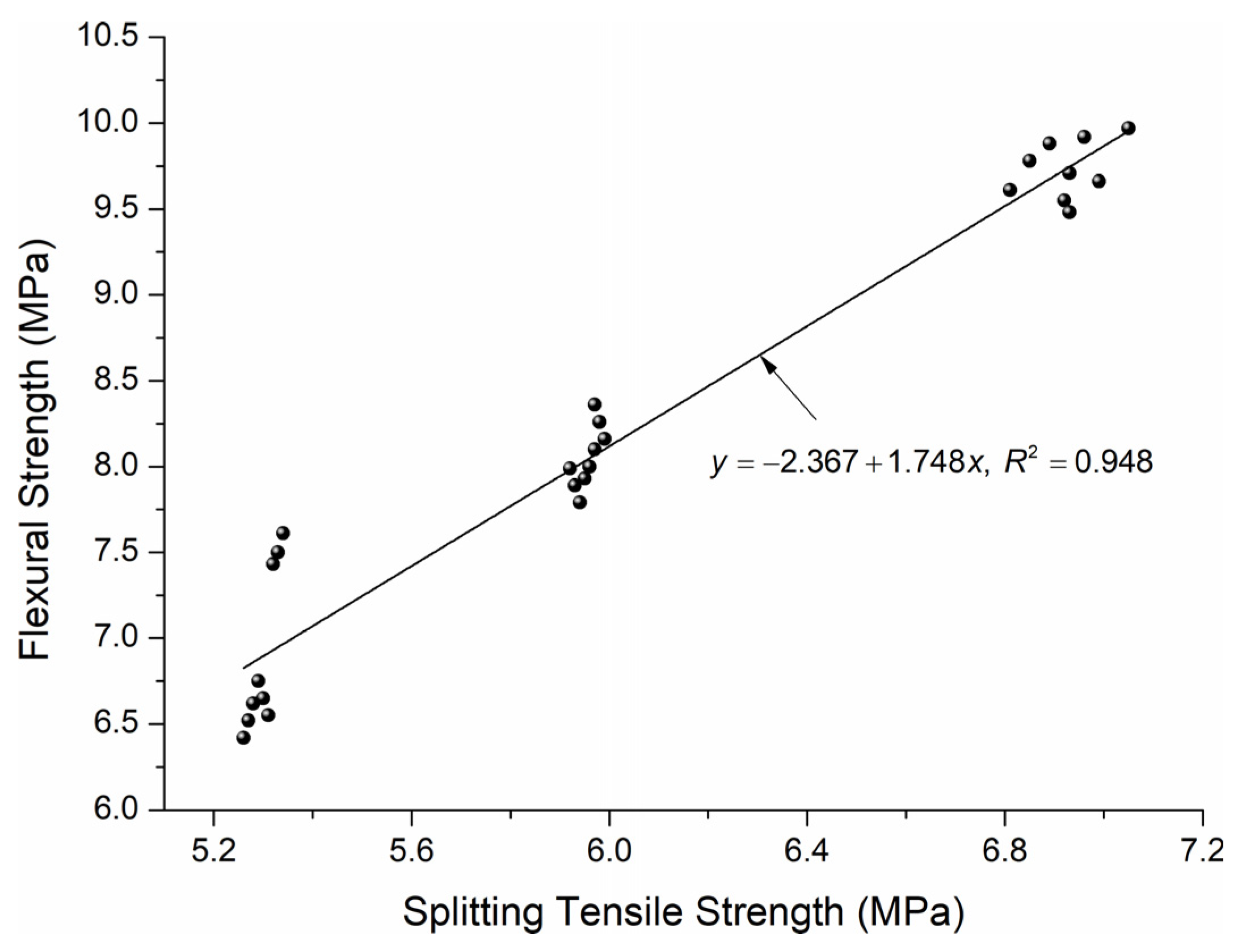

3.3. Flexural Strength

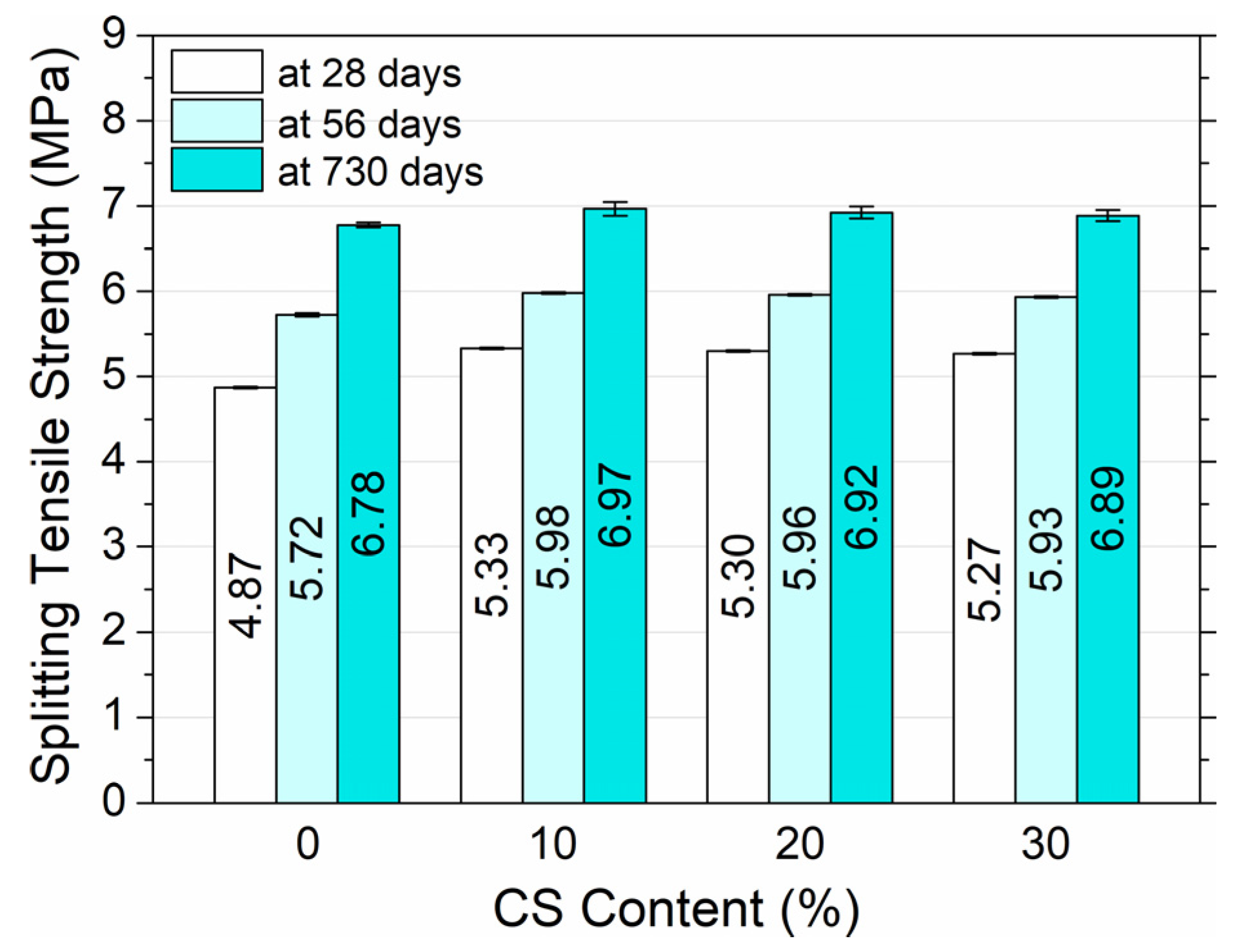

3.4. Splitting Tensile Strength

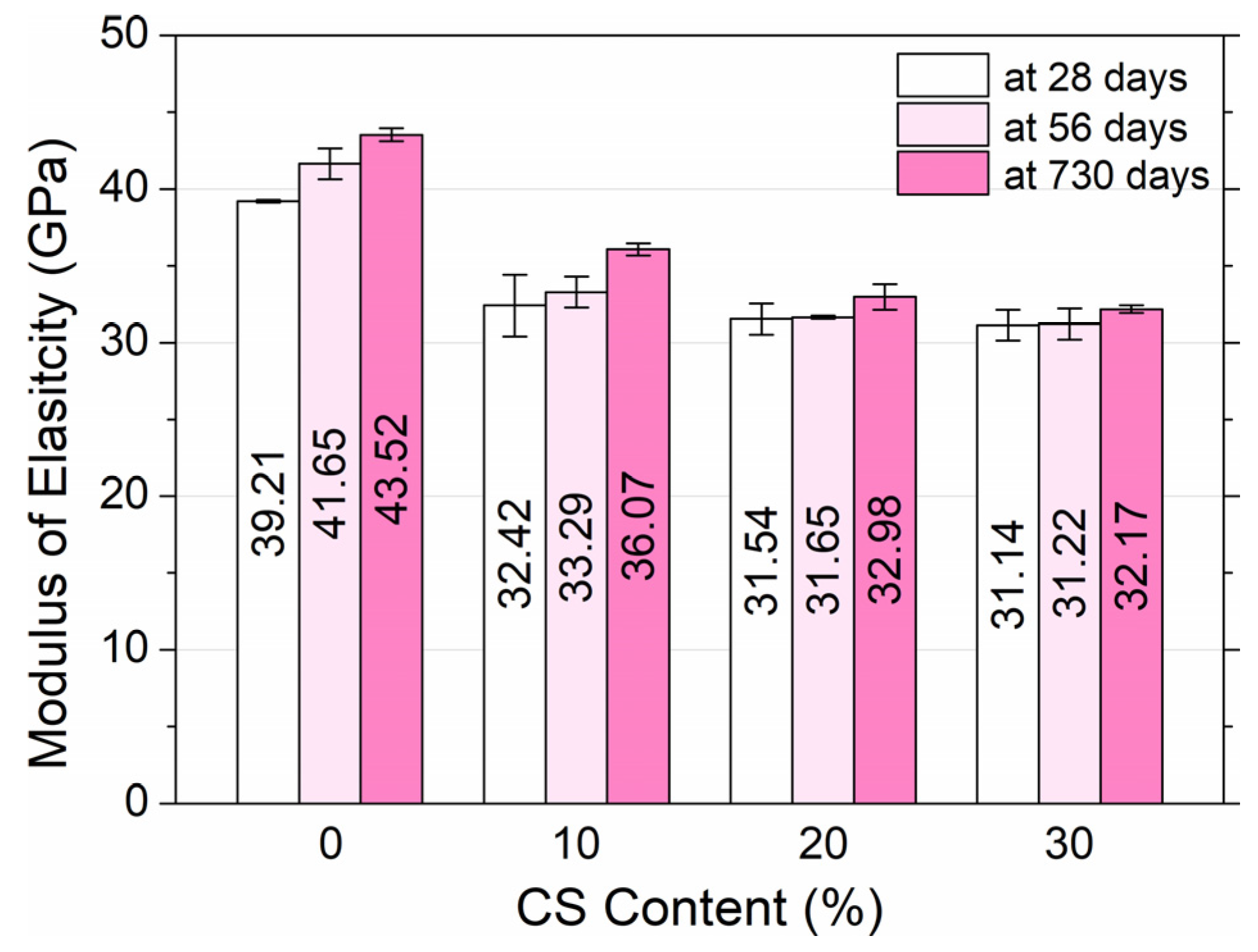

3.5. Modulus of Elasticity

3.6. Ultrasonic Pulse Velocity

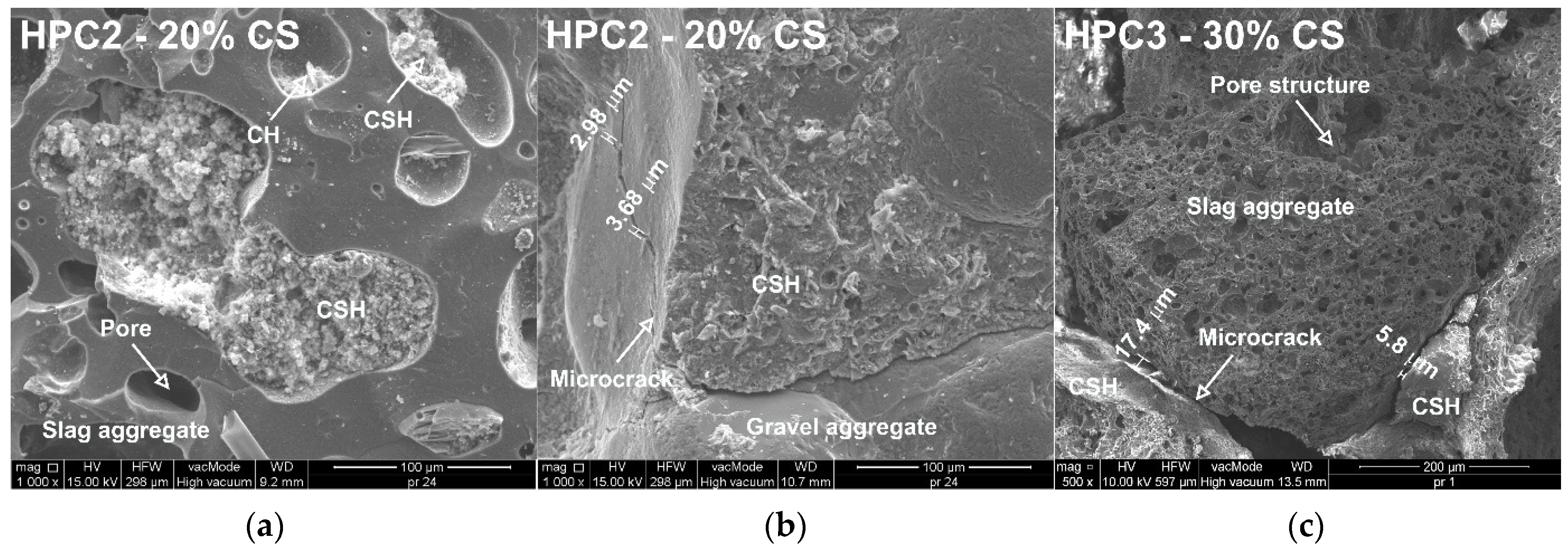

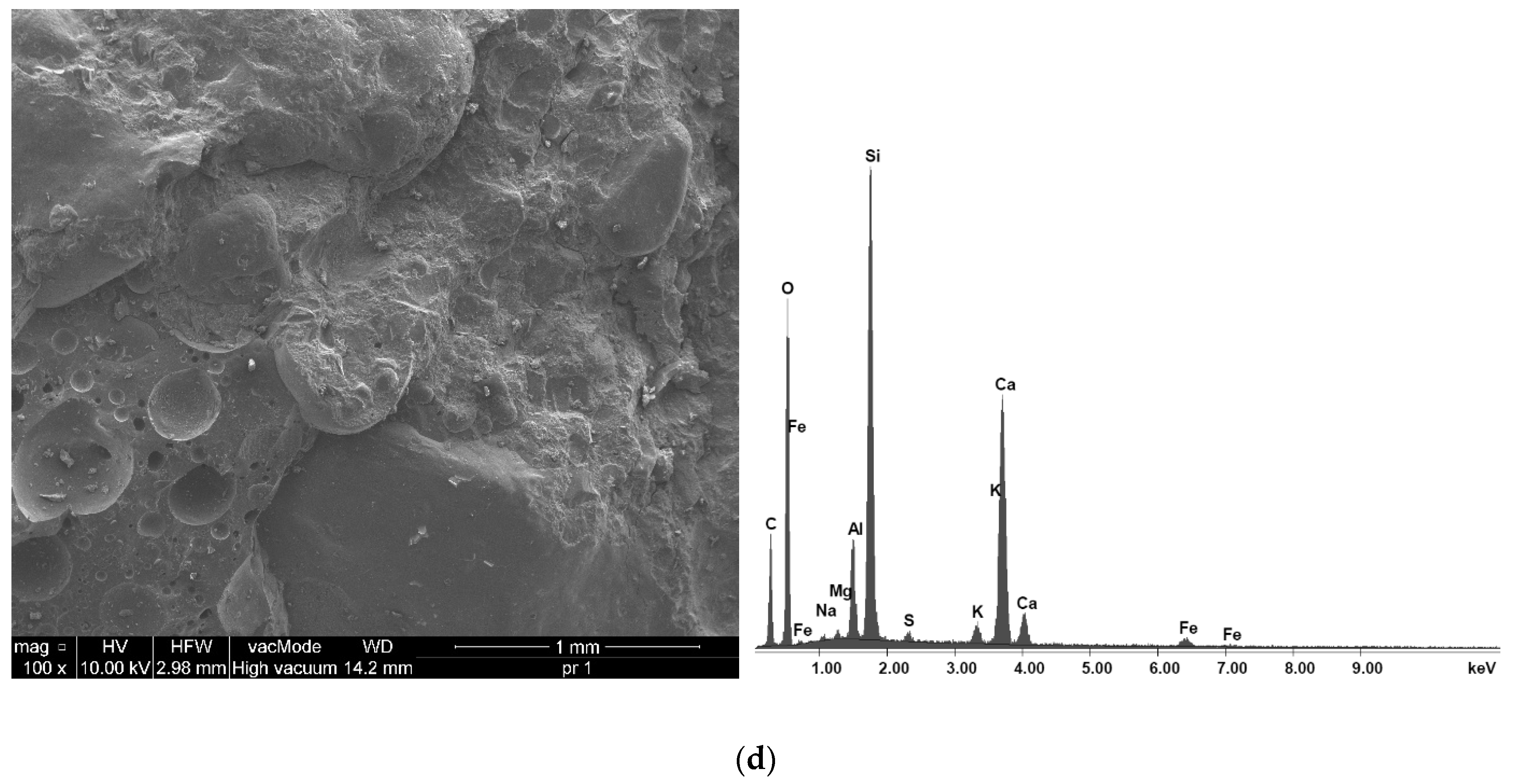

3.7. Microstructure

4. Conclusions

- Porosity and water absorption increase with higher coal slag content. For HPC with 30% CS, porosity and absorption increase by 10.6% and 11.3%, respectively, compared to the reference mix, while the density decreases by up to 7.8%.

- Compressive strength improves significantly with the addition of CS. After 28 days, strength increases range from 15.4% (10% CS) to 22.9% (30% CS), and after 730 days, from 9.4% to 20.2%.

- The flexural and splitting tensile strengths also benefit from CS incorporation, showing consistent growth over time. The splitting tensile strength increases by 8–9% at 28 days and increases by 2–3% at 730 days. Flexural strength improves, especially in the early curing stage, most notably at 10–20% CS.

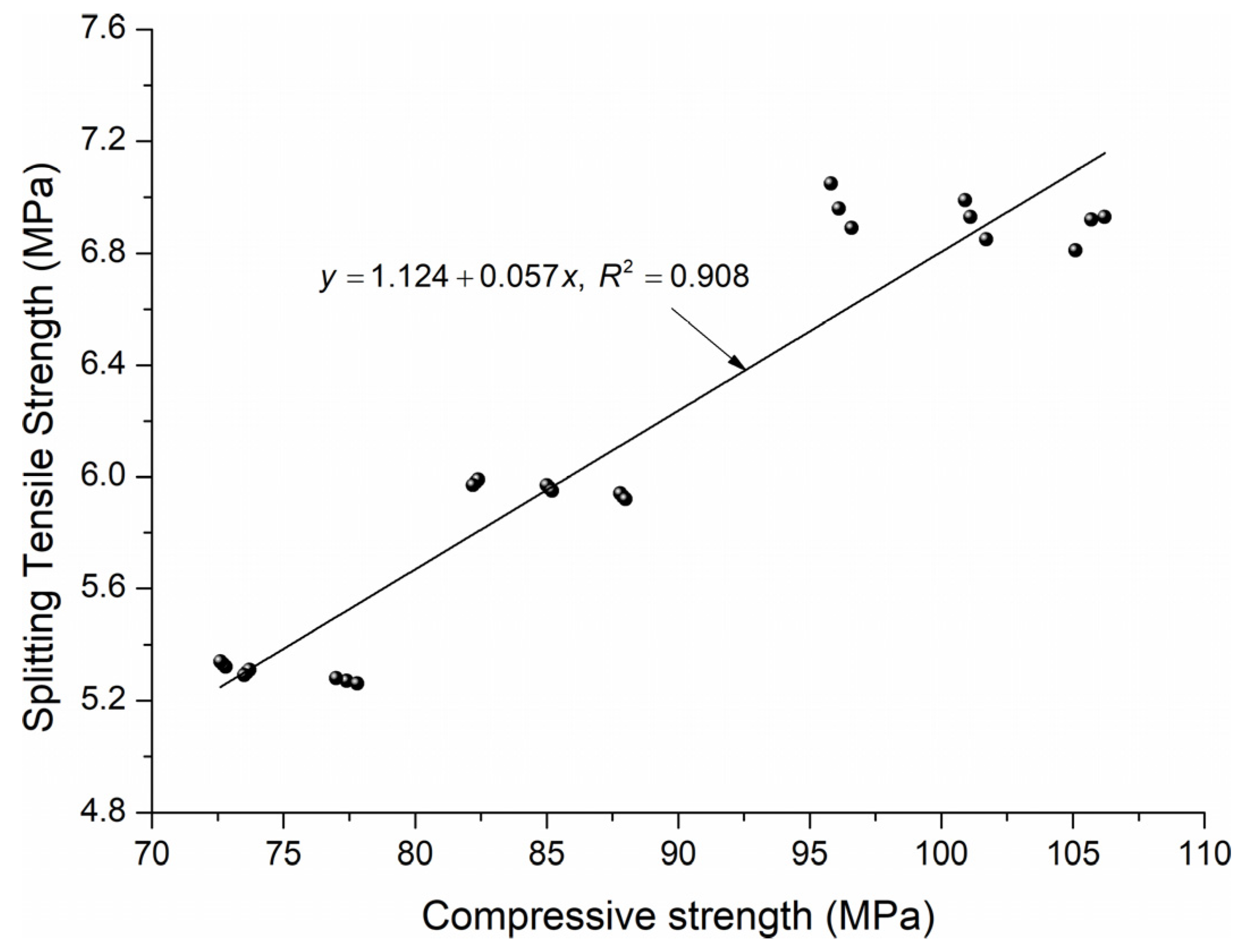

- Statistical relationships are established between compressive, splitting tensile, and flexural strength, allowing performance prediction for mixes with coal slag aggregates.

- The modulus of elasticity decreases both with time and with increasing slag content, which is attributed to the lower stiffness and higher porosity of coal slag compared to natural aggregates.

- Ultrasonic pulse velocity (UPV) values slightly decline with increased CS content but remain within acceptable ranges for good-quality concrete.

- SEM/EDX microstructural analysis confirms that hydration products (CSH, CH) partially fill the pores of slag grains and contribute to matrix densification, improving overall cohesion and strength development.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Russell, H.G.; Chairman; Anderson, A.R.; Banning, J.O.; Cantor, I.G.; Carrasquillo, R.; Cook, J.E.; Frantz, G.; Hester, W.; Anderson, D.; et al. ACI, A. 363R-92, State-of-the-art report on high-strength concrete (reapproved in 1997). Comput. Sci. 1998, 363, 92. [Google Scholar]

- Seleem, H.E.-D.H.; Rashad, A.M.; El-Sabbagh, B.A. Durability and strength evaluation of high-performance concrete in marine structures. Constr. Build. Mater. 2010, 24, 878–884. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Kansal, C.M.; Singla, S.; Garg, R. Effect of Silica Fume & Steel Slag on Nano-silica based High-Performance Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 961, 012012. [Google Scholar]

- Brescia-Norambuena, L.; González, M.; Avudaiappan, S.; Saavedra Flores, E.I.; Grasley, Z. Improving concrete underground mining pavements performance through the synergic effect of silica fume, nanosilica, and polypropylene fibers. Constr. Build. Mater. 2021, 285, 122895. [Google Scholar] [CrossRef]

- Hu, H.; Yao, W.; Wei, Y. Recycling waste dolomite powder in cement paste: Early hydration process, microscale characteristics, and life-cycle assessment. Sci. Total Environ. 2023, 902, 166008. [Google Scholar] [CrossRef]

- Smarzewski, P.; Błaszczyk, K. Influence of Cement Kiln Dust on Long-Term Mechanical Behavior and Microstructure of High-Performance Concrete. Materials 2024, 17, 833. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Yavuz, D.; Tawfik, T.A.; Smarzewski, P.; Guler, S. Enhancing Concrete Performance through Sustainable Utilization of Class-C and Class-F Fly Ash: A Comprehensive Review. Sustainability 2024, 16, 4905. [Google Scholar] [CrossRef]

- Liu, Y.; Hao, W.; He, W.; Meng, X.; Shen, Y.; Du, T.; Wang, H. Influence of dolomite rock powder and iron tailings powder on the electrical resistivity, strength and microstructure of cement pastes and concrete. Coatings 2022, 12, 95. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Łagód, G.; Suchorab, Z. Evaluation of the contact angle of hydrophobised lightweight aggregate concrete with sewage sludge. Ecol. Chem. Eng. 2015, 22, 625–635. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Yavuz, D.; Tawfik, T.A.; Smarzewski, P.; Guler, S. Examining the Workability, Mechanical, and Thermal Characteristics of Eco-Friendly, Structural Self-Compacting Lightweight Concrete Enhanced with Fly Ash and Silica Fume. Materials 2024, 17, 3504. [Google Scholar] [CrossRef]

- Liu, Q.; Lin, W.; Xi, L. Enhanced Mechanical Properties of Alkali-Activated Dolomite Dust Emulsified Asphalt Composites. Sci. Rep. 2024, 14, 31582. [Google Scholar] [CrossRef]

- Sales, A.; De Souza, F.R. Concretes and Mortars Recycled with Water Treatment Sludge and Construction and Demolition Rubble. Constr. Build. Mater. 2009, 23, 2362–2370. [Google Scholar] [CrossRef]

- McNeil, K.; Kang, T.H.-K. Recycled Concrete Aggregates: A Review. Int. J. Concr. Struct. Mater. 2013, 7, 61–69. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Durability Performance of High-Performance Concrete Made with Recycled Aggregates, Fly Ash and Densified Silica Fume. Cem. Concr. Compos. 2018, 93, 63–74. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy; COM(2015) 614 Final; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Roszak, W.; Kubiczek, F. Concretes Made of Lightweight Aggregates; Arkady: Warsaw, Poland, 1989. (In Polish) [Google Scholar]

- Strzałkowska, E. Characteristics of Physicochemical and Mineralogical Properties of Selected Coal Combustion By-Products; Silesian University of Technology Publishing House: Gliwice, Poland, 2011. (In Polish) [Google Scholar]

- Regulation of the Council of Ministers of 2 January 2007 on the Requirements for the Content of Natural Radioactive Isotopes of Potassium K-40, Radium Ra-226, and Thorium Th-228 in Raw Materials and Materials Used in Buildings Intended for the Stay of People and Livestock, as Well as in Industrial Waste Used in Construction, and the Control of the Content of These Isotopes. Atomic Law 2004, 161, 1689. (In Polish)

- Bouguerra, A.; Ledhem, A.; de Barquin, F.; Dheilly, R.M.; Queneudec, M. Effect of Microstructure on the Mechanical and Thermal Properties of Lightweight Concrete Prepared from Clay, Cement, and Wood Aggregate. Cem. Concr. Res. 1998, 28, 1179–1190. [Google Scholar] [CrossRef]

- Steiger, R.W.; Hurd, M.K. Lightweight Insulating Concrete for Floors and Roof Decks. Concr. Constr. 1978, 23, 411–422. [Google Scholar]

- Thomas, M.D.A.; Hopkins, D.S.; Perreault, M.; Cail, K. Ternary Cement in Canada. Concr. Int. 2007, 29, 59–64. [Google Scholar]

- Lewicki, B. (Ed.) Concrete Construction, Vol. 4—Lightweight Concretes; Arkady: Warsaw, Poland, 1967. (In Polish) [Google Scholar]

- Kim, H.K.; Lee, H.K. Use of Power Plant Bottom Ash as Fine and Coarse Aggregates in High-Strength Concrete. Constr. Build. Mater. 2011, 25, 1115–1122. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Nagaraj, T.S.; Bhavanishankar, S.; Ramalinga Reddy, B.M. Proportioning Cement-Based Composites with Burnt Coal Cinder. Mater. Struct. 2007, 40, 543–552. [Google Scholar] [CrossRef]

- Muthusamy, K.; Ahmad, S.W.; Hashim, M.H.; Mohamad, N.; Kirgiz, M.S.; Kamarudin, M.A.A.; Ravindran, G. Sulphate Resistance of Lightweight Aggregate Concrete Comprising Sieved Palm Oil Fuel Ash as Fine Aggregate Replacement. Mater. Today Proc. 2022, 66, 2536–2540. [Google Scholar] [CrossRef]

- Syarif, M.; Kirgiz, M.S.; de Sousa Galdino, A.G.; El Naggar, M.H.; Mirza, J.; Khatib, J.; Kenai, S.; Nehdi, M.; Kinuthia, J.; Khitab, A.; et al. Development and Assessment of Cement and Concrete Made of the Burning of Quinary By-Product. J. Mater. Res. Technol. 2021, 15, 3708–3721. [Google Scholar] [CrossRef]

- Kirgiz, M.S.; de Sousa Galdino, A.G.; Kinuthia, J.; Khitab, A.; Ul Hassan, M.I.; Khatib, J.; El Naggar, H.; Thomas, C.; Mirza, J.; Kenai, S.; et al. Synthesis, Physico-Mechanical Properties, Material Processing, and Math Models of Novel Superior Materials Doped with Flake of Carbon and Colloid Flake of Carbon. J. Mater. Res. Technol. 2021, 15, 4993–5009. [Google Scholar] [CrossRef]

- Ma, H.; Zhu, H.; Wu, C.; Chen, H.; Sun, J.; Liu, J. Study on Compressive Strength and Durability of Alkali-Activated Coal Gangue-Slag Concrete and Its Mechanism. Powder Technol. 2020, 368, 112–124. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, T.; Zhang, Y.; Zhu, Z. Effects of Loading Rate and Notch Geometry on Dynamic Fracture Behavior of Rocks Containing Blunt V-Notched Defects. Rock Mech. Rock Eng. 2024, 57, 2501–2521. [Google Scholar] [CrossRef]

- Zhang, Z.; Nie, B.; Ma, C.; Liu, X.; Li, Y.; Li, C. A Study of High-Intensity High Voltage Electric Pulse Fracturing—A Perspective on the Energy Distribution of Shock Waves. Geoenergy Sci. Eng. 2025, 249, 213791. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Q.; Wang, H.; Chen, X. Strain Characteristics and Energy Dissipation Laws of Gas-Bearing Coal during Impact Fracture Process. Energy 2022, 242, 123028. [Google Scholar] [CrossRef]

- PN-EN 197-1:2012; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 196-6:2019-01; Methods of Testing Cement—Part 6: Determination of Fineness. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 196-1:2016-07; Methods of Testing Cement—Part 1: Determination of Strength. Polish Committee for Standardization: Warsaw, Poland, 2016.

- Instruction of the Institute of Building Technology (ITB) No. 234/2003. Tests of Natural Radioactivity of Raw Materials and Building Materials; Institute of Building Technology: Warsaw, Poland, 2003. (In Polish) [Google Scholar]

- Smarzewski, P.; Barnat-Hunek, D.; Jezierski, W. The Possibility of Using Boiler Slag as Coarse Aggregate in High Strength Concrete. KSCE J. Civ. Eng. 2017, 22, 1816–1826. [Google Scholar] [CrossRef]

- Smarzewski, P. Mechanical and Microstructural Studies of High Performance Concrete with Condensed Silica Fume. Appl. Sci. 2023, 13, 2510. [Google Scholar] [CrossRef]

- PN-EN 13755:2008; Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure. Polish Committee for Standardization: Warsaw, Poland, 2008.

- PN-EN 12390-3:2019-07; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 12390-3:2011; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2011.

- PN-EN 12390-6:2011; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2011.

- ASTM C469/C469M-14; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014.

- PN-EN 12390-5:2011; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. Polish Committee for Standardization: Warsaw, Poland, 2011.

- Maierhofer, C.; Reinhardt, H.-W.; Dobmann, G. Non-Destructive Evaluation of Reinforced Concrete Structures; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- PN-EN 13791:2019-12; Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components. Polish Committee for Standardization: Warsaw, Poland, 2019.

- Bouzoubaa, N.; Bilodeau, A.; Sivasudaram, V.; Fournier, B.; Golden, D.M. Development of Ternary Blends for High-Performance Concrete. ACI Mater. J. 2004, 101, 19–29. [Google Scholar]

- Gesoglu, M.; Guneyisi, E.; Ozbay, E. Properties of Self-Compacting Concretes Made with Binary, Ternary and Quaternary Cementitious Blends of Fly Ash, Blast Furnace Slag and Silica Fume. Constr. Build. Mater. 2009, 23, 1847–1854. [Google Scholar] [CrossRef]

- Bagheri, A.R.; Zanganeh, H.; Moalemi, M.M. Mechanical and Durability Properties of Ternary Concretes Containing Silica Fume and Low Reactivity Blast Furnace Slag. Cem. Concr. Compos. 2012, 34, 663–670. [Google Scholar] [CrossRef]

- Park, S.B.; Jang, Y.I.; Lee, J.; Lee, B.J. An Experimental Study on the Hazard Assessment and Mechanical Properties of Porous Concrete Utilizing Coal Bottom Ash Coarse Aggregate in Korea. J. Hazard. Mater. 2009, 166, 348–355. [Google Scholar] [CrossRef]

- Ostle, B. Engineering Statistics: The Industrial Experience; Wadsworth Publishing Company: Belmont, CA, USA, 1996. [Google Scholar]

- Malhotra, V.M. Testing Hardened Concrete: Nondestructive Methods; Noyes Publications: Park Ridge, NJ, USA, 1976. [Google Scholar]

- Adegoke, H.A.; Ikumapayi, C.M. Effects of Induction Furnace Slag on the Durability Properties of Concrete. Constr. Build. Mater. 2024, 419, 135263. [Google Scholar] [CrossRef]

| Material Characteristics | Cement | Microsilica |

|---|---|---|

| Specific surface area (m2/kg) | 398.5 | 17,000 |

| Water demand (%) | 28 | — |

| Start of setting (min) | 190 | — |

| End of setting (min) | 250 | — |

| Volume stability acc. to Le Chateliere (mm) | 0 | — |

| Compressive strength at 2 days (MPa) | 30.4 | — |

| Compressive strength at 28 days (MPa) | 59.2 | — |

| Flexural strength at 2 days (MPa) | 5.4 | — |

| Composition (%) | ||

| SiO2 | 20.46 | 94.80 |

| Al2O3 | 4.15 | 1.30 |

| Fe2O3 | 3.37 | 0.83 |

| CaO | 65.10 | 0.56 |

| MgO | 1.21 | 0.71 |

| SO3 | 2.58 | — |

| K2O | 0.46 | 1.26 |

| Na2O | 0.24 | 0.41 |

| Cl | 0.09 | — |

| Loss in ignition | 3.44 | 0.12 |

| Insoluble matter | 0.29 | — |

| Sample Description | Concentrations of Natural Radioactive Isotopes (Bq/kg) | Activity Indicators | Gamma Radiation Dose Rate Value | |||

|---|---|---|---|---|---|---|

| Potassium K-40 | Rad Ra-226 | Thorium Th-228 | f1 | f2 (Bq/kg) | nGy/h | |

| Coal slag | 565 ± 60 | 122.1 ± 15.1 | 99.4 ± 8.9 | 1.09 ± 0.05 | 122.1 ± 15.1 | 142.4 |

| Mix ID | Coal Slag | Aggregate | Cement (kg) | Water (L) | Microsilica (kg) | SP (kg) | ||

|---|---|---|---|---|---|---|---|---|

| Portion (%) | Weight (kg) | Sand (kg) | Gravel (kg) | |||||

| HPC0 | 0 | – | 539 | 1229 | 372 | 186 | 18.6 | 5.9 |

| HPC1 | 10 | 123 | 1106 | |||||

| HPC2 | 20 | 246 | 983 | |||||

| HPC3 | 30 | 369 | 860 | |||||

| Formula | Atom [%] | |||

|---|---|---|---|---|

| HPC2_1 20% CS | HPC2_2 20% CS | HPC2_3 20% CS | HPC3 30% CS | |

| Calcium | 6.43 | 0.23 | 0.32 | 7.04 |

| Carbon | 32.35 | 26.04 | 29.64 | 31.81 |

| Silicon | 9.15 | 1.37 | 7.60 | 11.95 |

| Iron | 2.93 | 27.12 | 8.02 | 0.49 |

| Aluminum | 3.87 | 0.76 | 3.78 | 2.47 |

| Oxygen | 42.98 | 43.72 | 48.03 | 45.11 |

| Sodium | 0.40 | 0.00 | 0.17 | 0.20 |

| Magnesium | 0.72 | 0.21 | 1.41 | 0.23 |

| Sulfur | 0.18 | 0.18 | 0.09 | 0.23 |

| Chlorine | 0.07 | 0.14 | 0.16 | — |

| Potassium | 0.73 | 0.14 | 0.60 | 0.48 |

| Titanium | 0.18 | 0.07 | 0.18 | — |

| Calcium/Silicon ratio | 0.70 | 0.17 | 0.04 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smarzewski, P. Long-Term Behavior and Microstructure of High-Performance Concrete with Coal Slag. Materials 2025, 18, 2585. https://doi.org/10.3390/ma18112585

Smarzewski P. Long-Term Behavior and Microstructure of High-Performance Concrete with Coal Slag. Materials. 2025; 18(11):2585. https://doi.org/10.3390/ma18112585

Chicago/Turabian StyleSmarzewski, Piotr. 2025. "Long-Term Behavior and Microstructure of High-Performance Concrete with Coal Slag" Materials 18, no. 11: 2585. https://doi.org/10.3390/ma18112585

APA StyleSmarzewski, P. (2025). Long-Term Behavior and Microstructure of High-Performance Concrete with Coal Slag. Materials, 18(11), 2585. https://doi.org/10.3390/ma18112585