Assessing the Potential of Lateritic Clayey Soils for Road Infrastructure in Tropical Regions

Abstract

1. Introduction

2. Materials and Methods

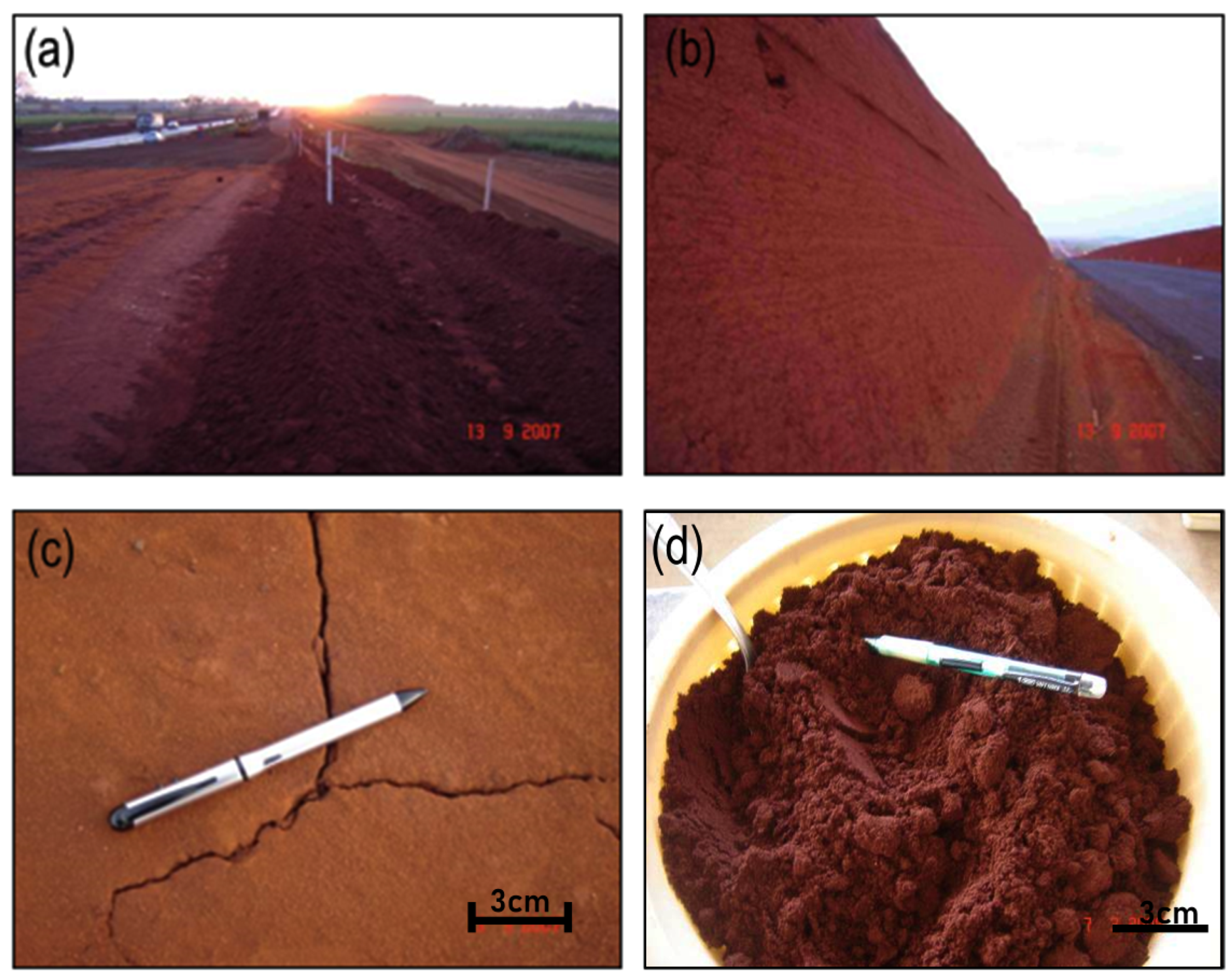

2.1. Materials

2.2. Methods

2.2.1. Sample Preparation

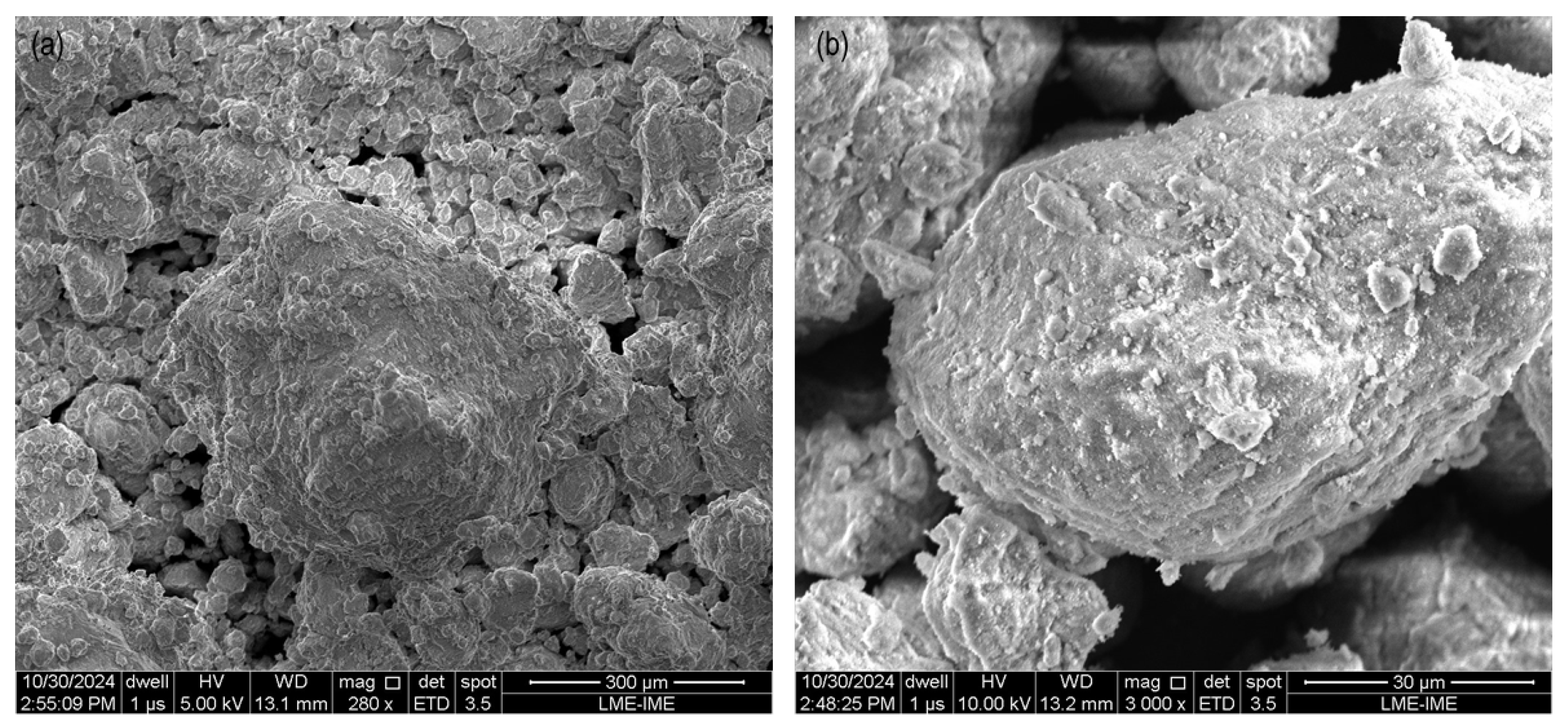

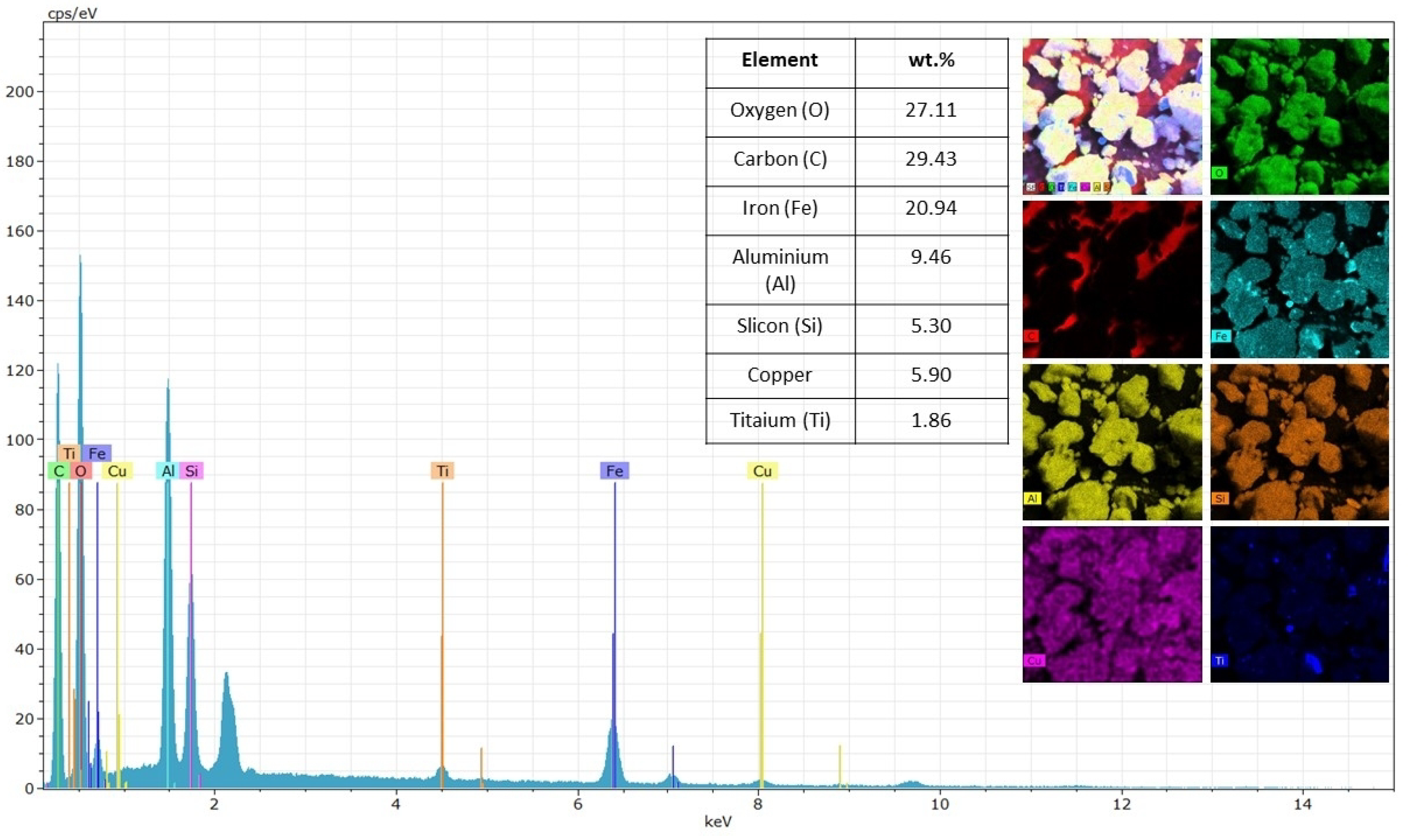

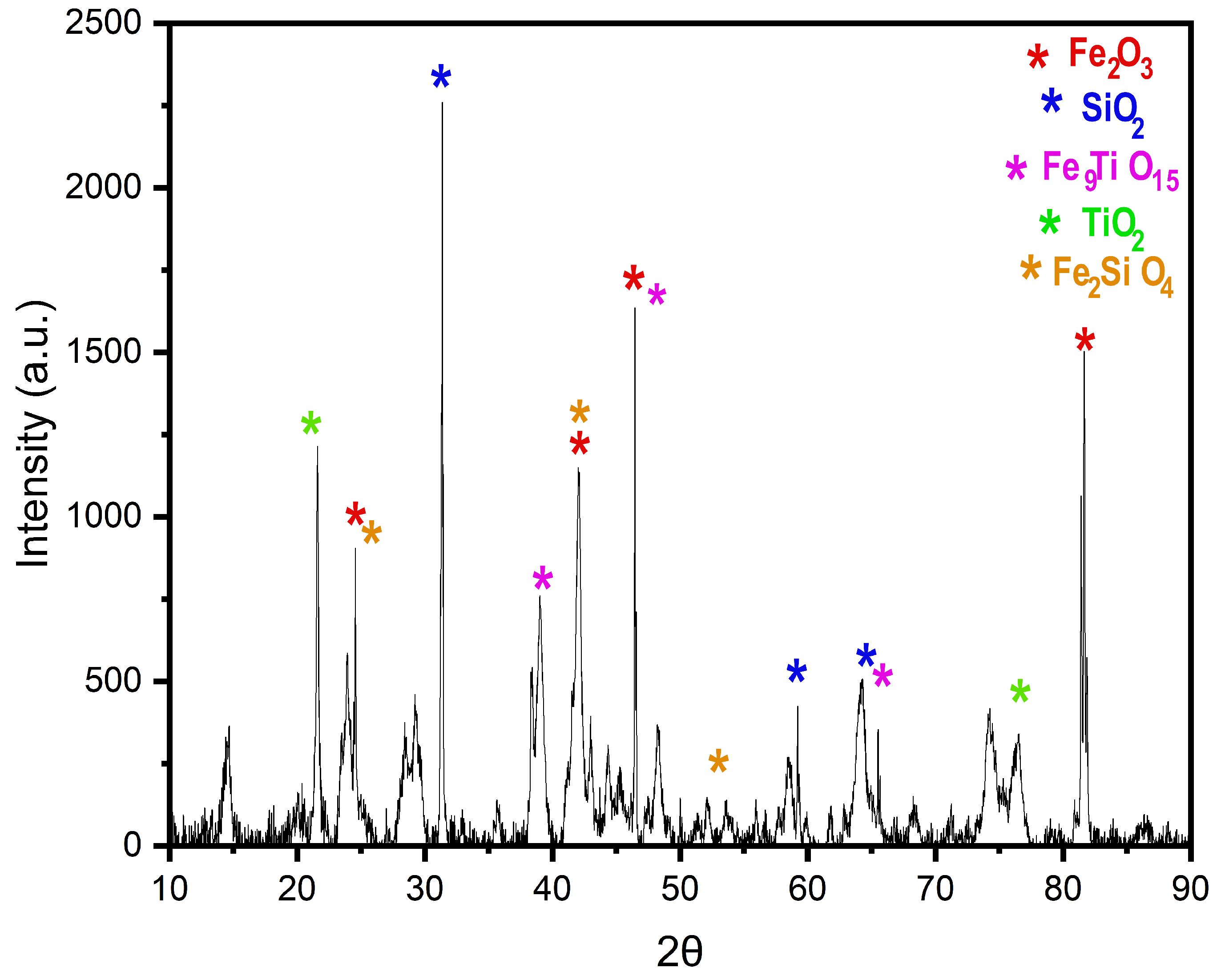

2.2.2. Physical, Chemical, and Mineralogical Characterization

2.2.3. Mechanical Analysis

3. Results and Discussion

3.1. Material Characterization

3.2. Resilient Module (RM)

3.3. Permanent Deformation (PD)

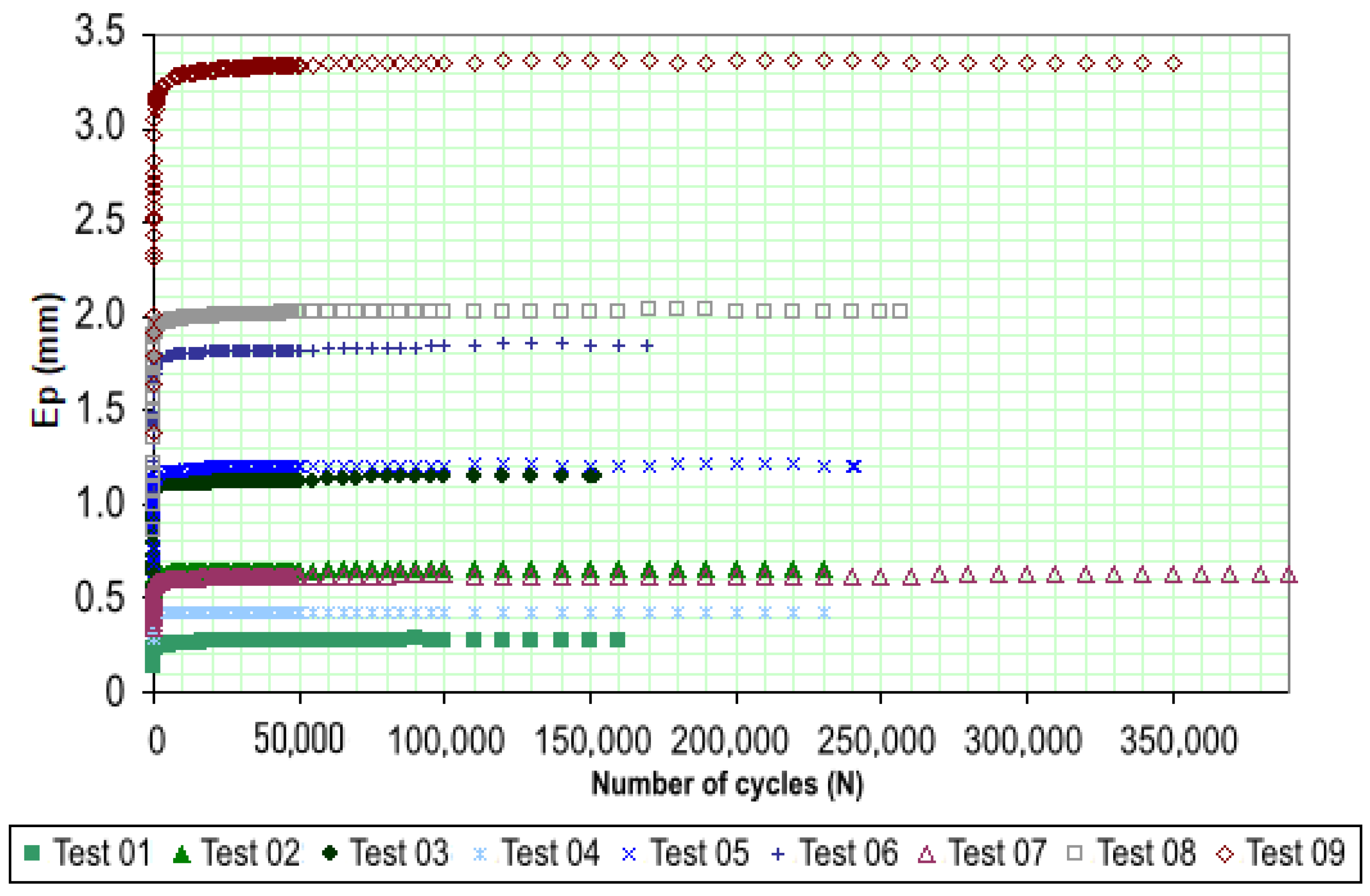

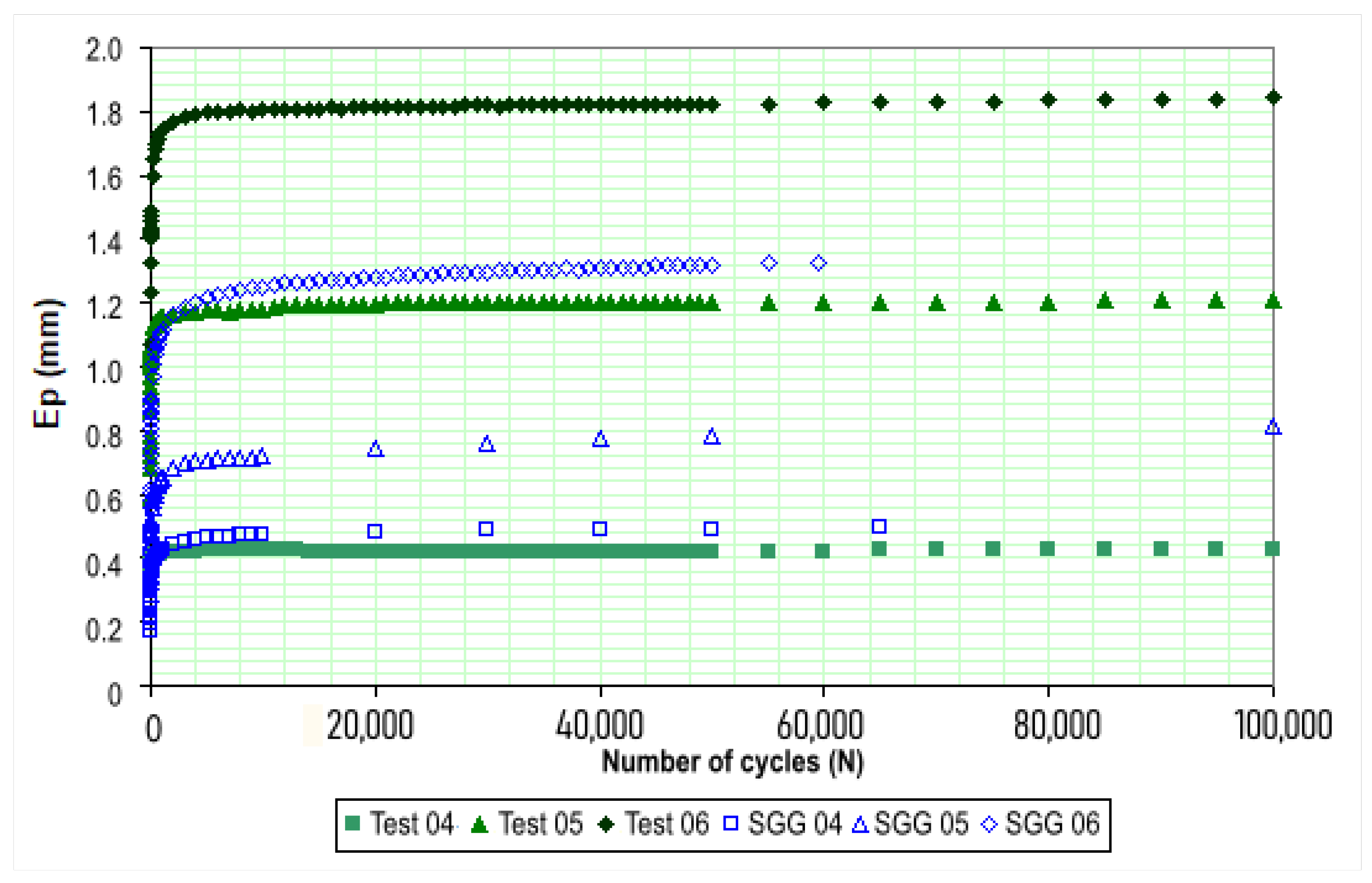

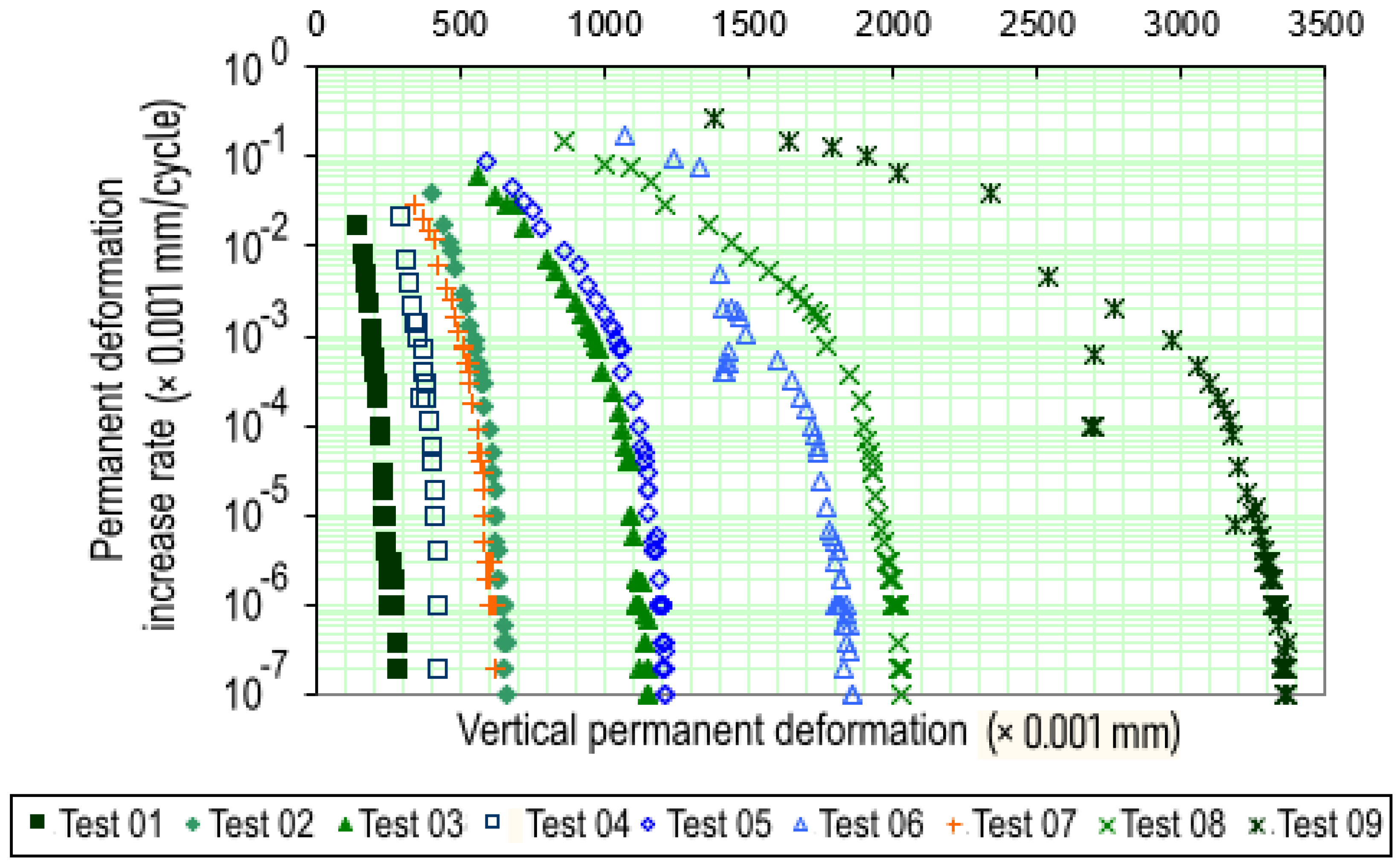

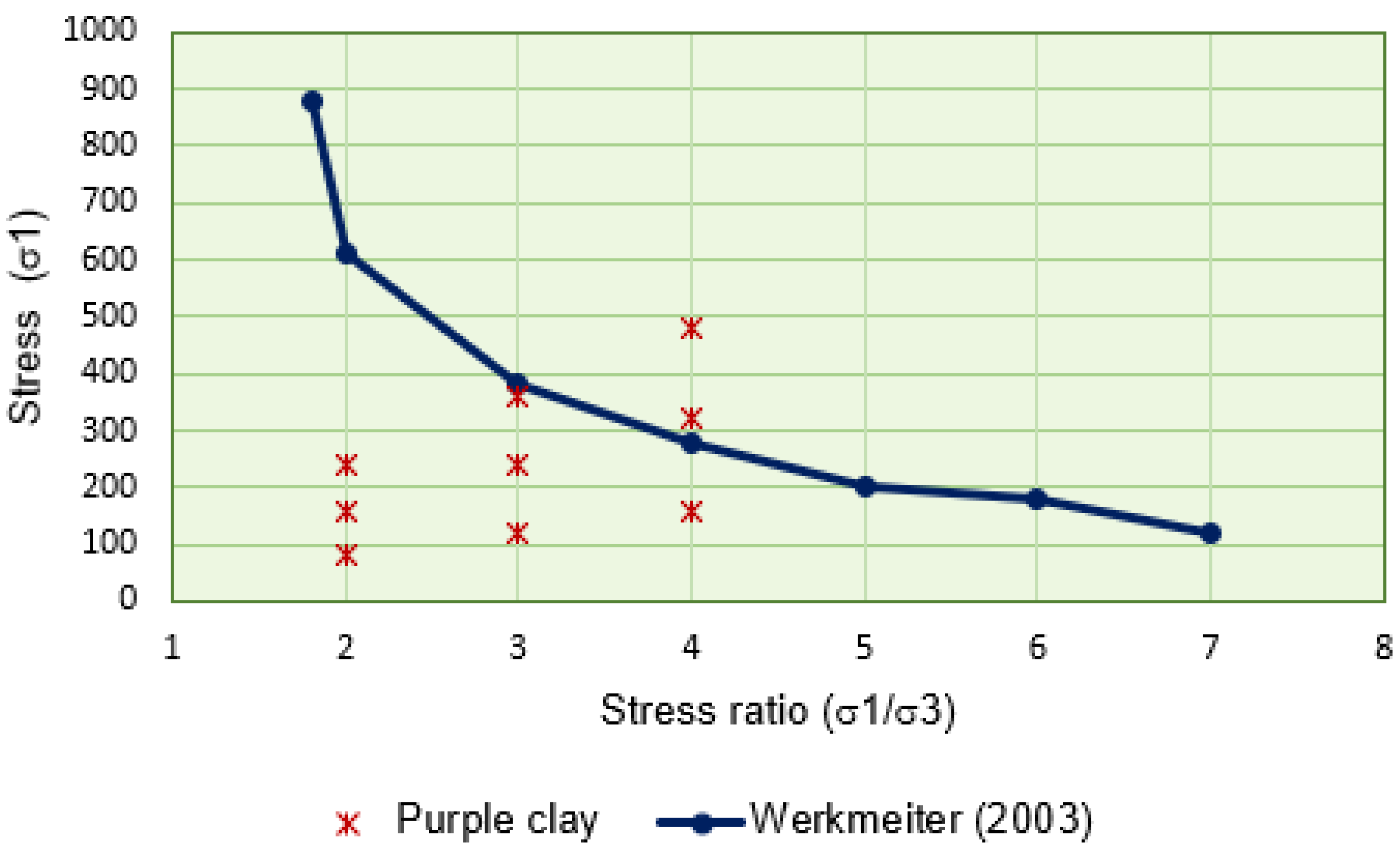

3.4. Shakedown Analysis

4. Conclusions

- Mineralogical analyses revealed a significant presence of iron oxides, such as goethite and hematite, which contribute to the soil’s high density, mechanical strength, and cementation potential. These characteristics suggest that Purple Clay performs well in geotechnical applications, particularly in scenarios requiring long-term stability and resistance.

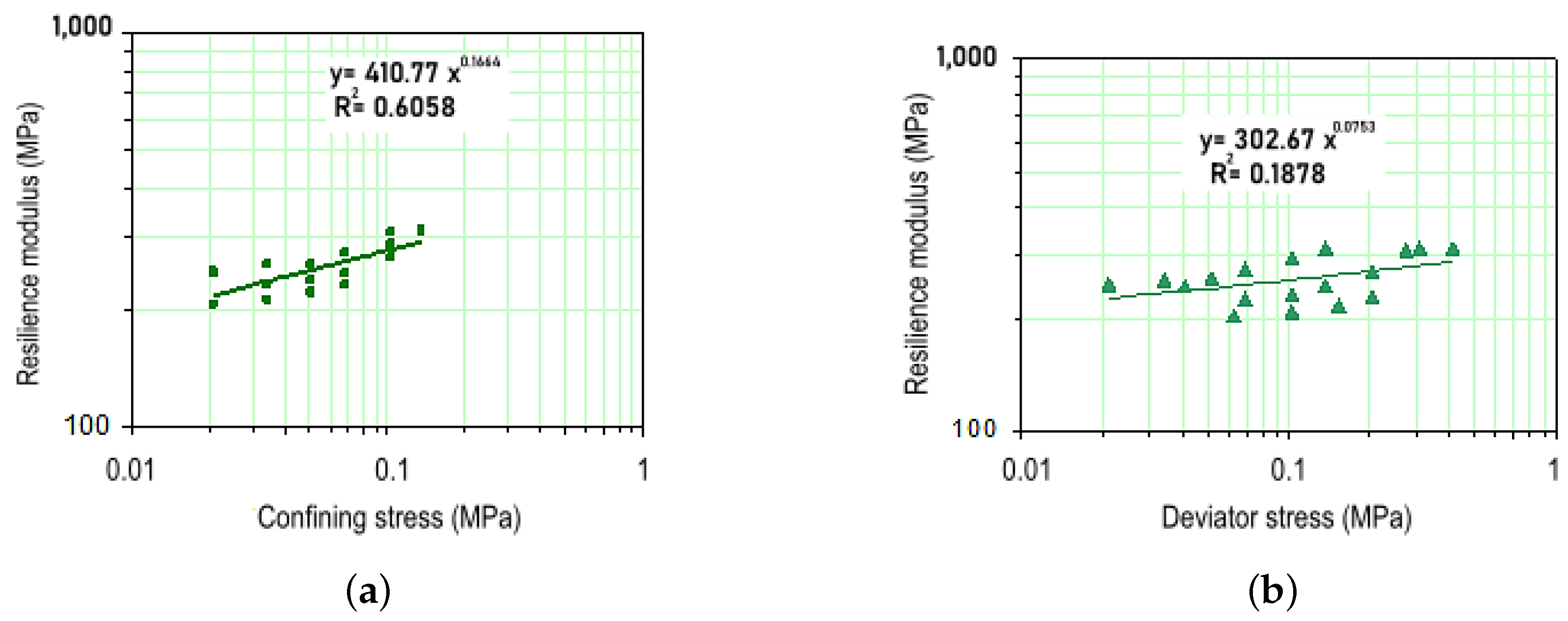

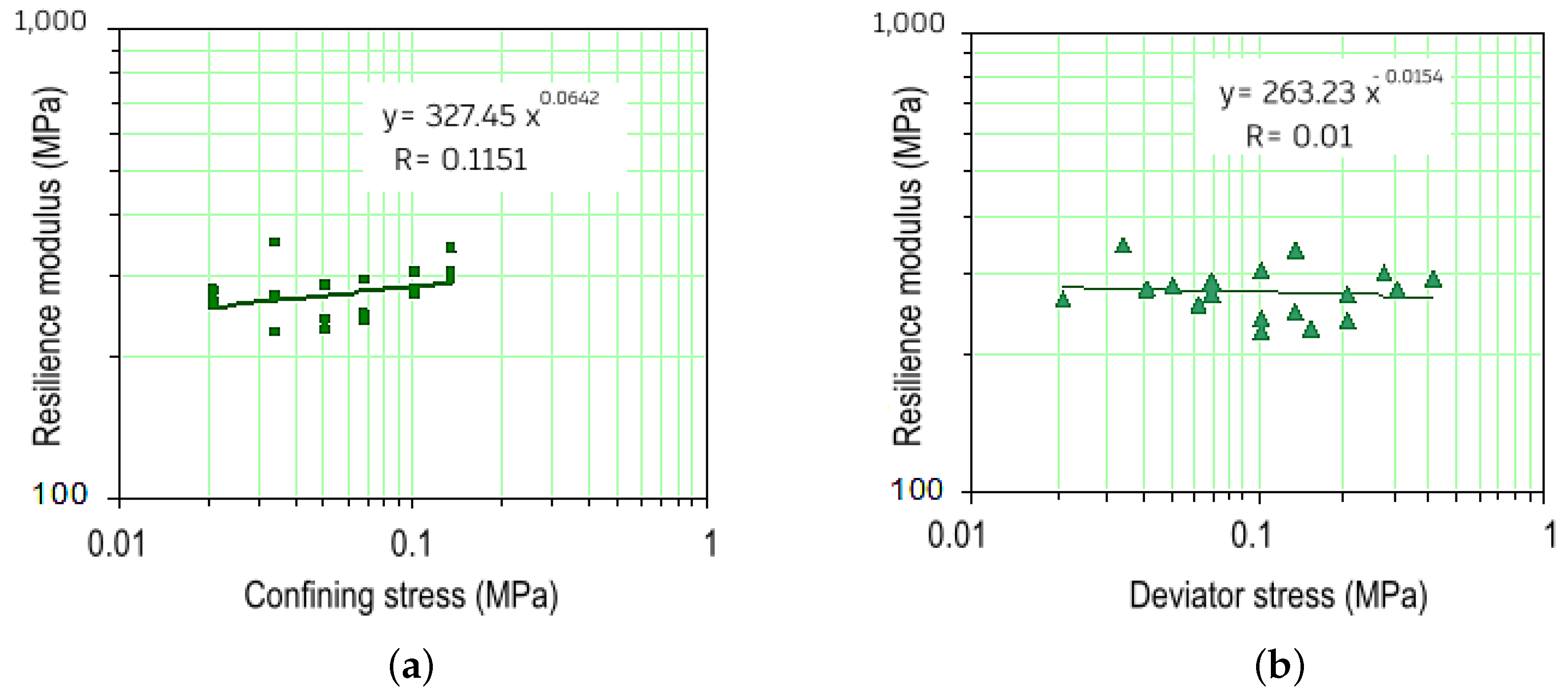

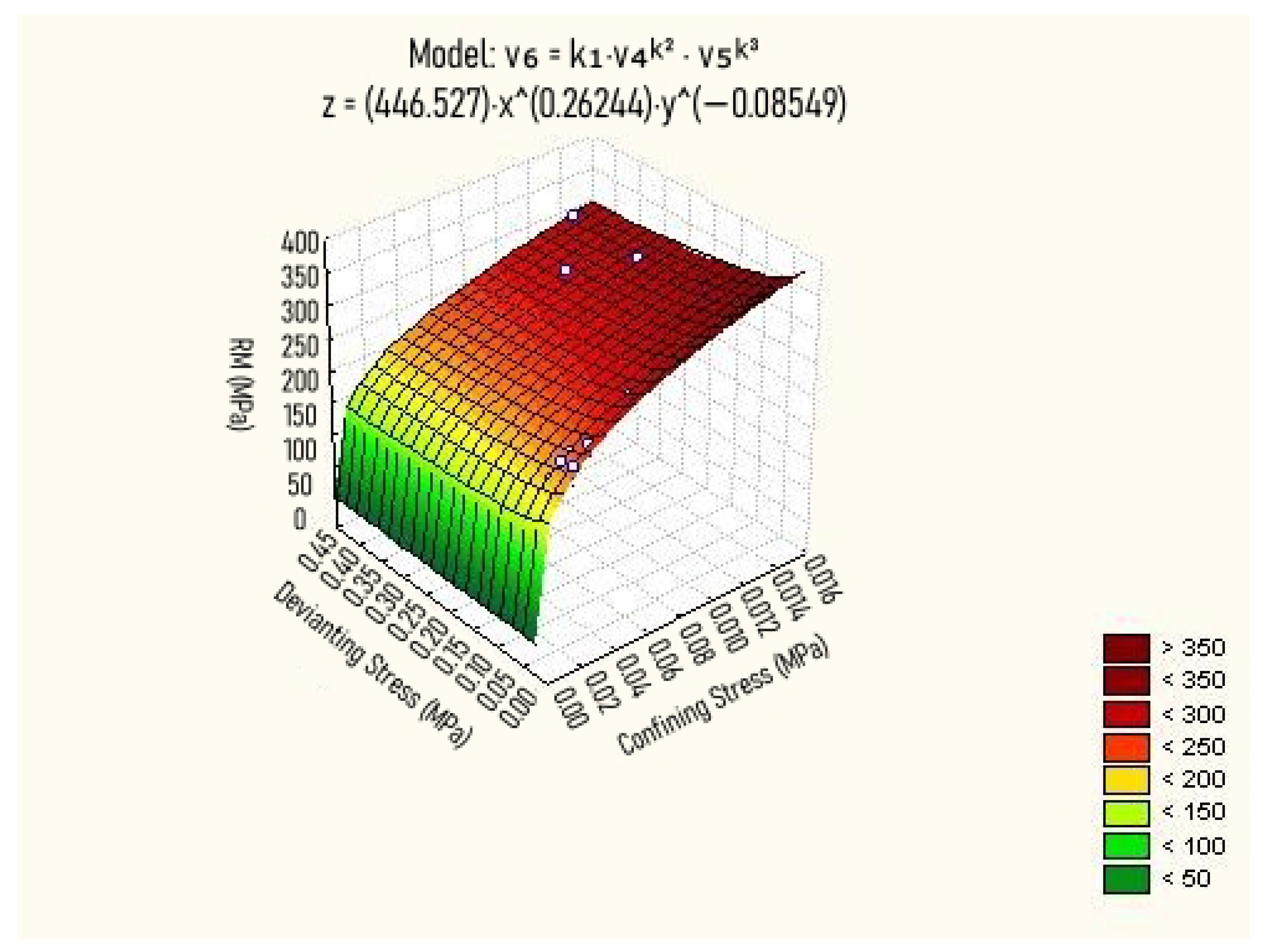

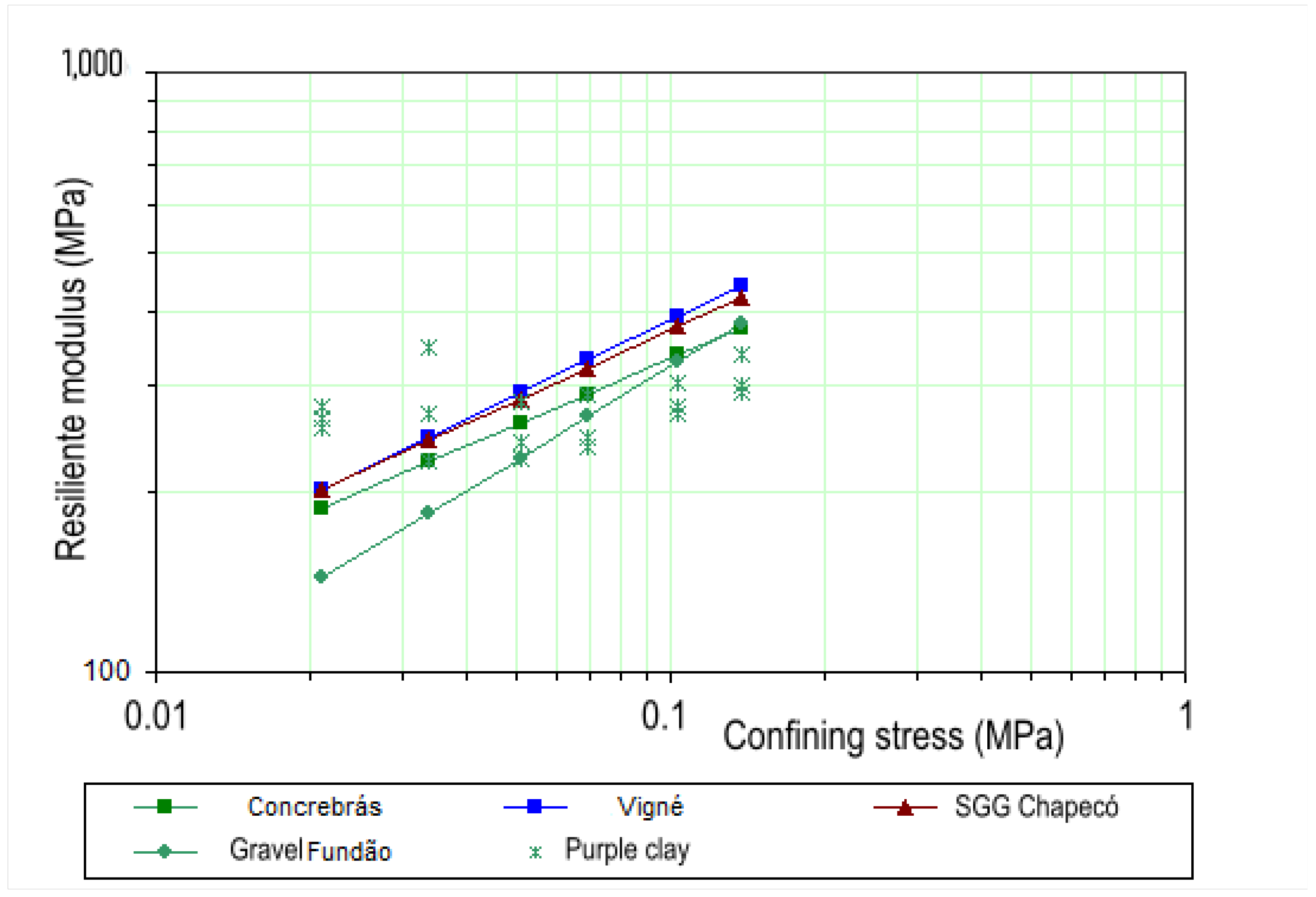

- The resilient modulus (RM) of Purple Clay compacted with energy equivalent to the standard Proctor test was found to be more influenced by confining stress than by deviatoric stress, with the best fit achieved using the combined model. Under these conditions, the average RM was 258 MPa. When compacted with energy equivalent to the intermediate Proctor test, the RM tended to stabilize, reaching an average value of 275 MPa.

- The RM of Purple Clay is of the same order of magnitude as some graded aggregates, based on values reported in the literature.

- The results of the permanent deformation (PD) tests indicate low accumulated PD, except under higher stress levels, where a hypothetical pavement layer composed of Purple Clay could contribute up to 35% of the total admissible rutting value.

- When compared to a graded aggregate from Chapecó, Purple Clay exhibited similar total permanent deformation levels under low-stress conditions but showed slightly higher deformation under higher stress states.

- The PD analysis results suggest that Purple Clay demonstrates good resistance to rutting under repeated loads, with total permanent deformations below 2.0 mm in most tests, indicating a tendency toward shakedown behavior. Although some tests displayed mixed (AB) behavior, Purple Clay’s performance compared favorably to the shakedown limit of a granodiorite-graded aggregate, demonstrating its suitability as a sub-base material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santos, P.R.C.; Daibert, J.D. Soil Analysis: Formation, Classification, and Environmental Conservation, 1st ed.; Érica: São Paulo, Brazil, 2014. [Google Scholar]

- Koshy, S.A.; Praveen, A.; Ajitha, T. Resilient Modulus Prediction of Laterite Soils Under Variable Moisture Levels Using Fuzzy Logic Model. Transp. Infrastruct. Geotechnol. 2022, 9, 583–605. [Google Scholar] [CrossRef]

- Caputo, H.P.; Caputo, A.N. Soil Mechanics: Theory and Applications, 8th ed.; LTC: Rio de Janeiro, Brazil, 2022; p. 12. [Google Scholar]

- de Carvalho, J.C.; de Rezende, L.R.; da F. Cardoso, F.B.; de F.L. Lucena, L.C.; Guimarães, R.C.; Valencia, Y.G. Tropical soils for highway construction: Peculiarities and considerations. Transp. Geotech. 2015, 5, 3–19. [Google Scholar] [CrossRef]

- Nogami, J.S.; Villibor, D.F. Use of lateritic fine-grained soils in road pavement base courses. Geotech. Geol. Eng. 1991, 9, 167–182. [Google Scholar] [CrossRef]

- Sprafke, T.; Kadereit, A.; Lauer, F.; Rodrigues, F.C.G.; Sawakuchi, A.O.; Thiel, C.; van Thuyne, J.; Rodrigues, L.; Santos, T.A.; Zipf, L.; et al. Key processes and timescales of tropical earth formation. Earth-Sci. Rev. 2024, 254, 104804. [Google Scholar] [CrossRef]

- Balan, E.; Allard, T.; Fritsch, E.; Sélo, M.; Falguères, C.; Chabaux, F.; Pierret, M.C.; Calas, G. Formation and evolution of lateritic profiles in the middle Amazon basin: Insights from radiation-induced defects in kaolinite. Geochim. Cosmochim. Acta 2005, 69, 2193–2204. [Google Scholar] [CrossRef]

- National Department of Transportation Infrastructure-DNIT. IPR-726: Basic Guidelines for the Preparation of Road Studies and Projects-Basic Scopes/Service Instructions; National Department of Transportation Infrastructure-DNIT: Rio de Janeiro, Brazil, 2006. [Google Scholar]

- Tardy, Y.; Sarma, V. Petrology of Laterites and Tropical Soils; Oxford and IBH Publishing: Oxford, UK, 1997. [Google Scholar]

- Owoyemi, O.O.; Oladapo, A.G. Variability in the highway geotechnical properties of two residual lateritic soils from central Nigeria. J. Geol. Geophys. 2017, 6, 1000290. [Google Scholar] [CrossRef]

- Onana, V.; Ngo’o Ze, A.; Eko, R.M.; Ntouala, R.; Nanga Bineli, M.; Owoudou, B.N.; Ekodeck, G. Geological identification, geotechnical and mechanical characterization of charnockite-derived lateritic gravels from Southern Cameroon for road construction purposes. Transp. Geotech. 2017, 10, 35–46. [Google Scholar] [CrossRef]

- Olofinyo, O.; Olabode, O.; Fatoyinbo, I. Engineering properties of residual soils in part of southwestern Nigeria: Implications for road foundation. SN Appl. Sci. 2019, 1, 507. [Google Scholar] [CrossRef]

- Honore, T.; Michel, M. Geotechnical characterization of the batoufam lateritic gravels (West Cameroon) for road construction purpose. In Recent Advances in Geo-Environmental Engineering, Geomechanics and Geotechnics, and Geohazards; Kallel, A., Erguler, Z.A., Cui, Z.-D., Karrech, A.L., Karakus, M., Kulatilake, P., Shukla, S.K., Eds.; Springer: Cham, Switzerland, 2019; p. 29. [Google Scholar] [CrossRef]

- Mengue, E.; Mroueh, H.; Lancelot, L.; Medjo Eko, R. Design and parametric study of a pavement foundation layer made of cement-treated fine-grained lateritic soil. Soils Found. 2018, 58, 666–677. [Google Scholar] [CrossRef]

- Katte, V.Y.; Yemeli, C.M.; Kenmoe, O.R.M.; Wouatong, A.S.L. Pavement design with and over lateritic materials from the Mbu–Baforchu area. SN Appl. Sci. 2020, 2, 121. [Google Scholar] [CrossRef]

- Tamba, C.F.; Kengni, L.; Tematio, P.; Manefouet, B.I.; Kenfack, J.V. Assessment of Lateritic Gravelled Materials for Use in Road Pavements in Cameroon. Geotech. Geol. Eng. 2022, 40, 4195–4215. [Google Scholar] [CrossRef]

- Mbengue, M.; Messan, A.; Lawane, A.; Pantet, A. Characterization of the lateritic soil from Kamboinsé (Burkina Faso). In Proceedings of the International RILEM Symposium on Bituminous Materials. ISBM 2020; RILEM Book Series; Di Benedetto, H., Baaj, H., Chailleux, E., Tebaldi, G., Sauzéat, C., Mangiafico, S., Eds.; Springer: Cham, Switzerland, 2022; Volume 27. [Google Scholar] [CrossRef]

- Tamba, C.; François, B.; Fagel, N.; Kengni, L. Geomechanical and thermal properties of lateritic gravels for road pavement design in African tropical environments. Int. J. Pavement Res. Technol. 2024. [Google Scholar] [CrossRef]

- Netterberg, F. Review of Specifications for the Use of Laterite in Road Pavements; Technical Report; Contract: AFCAP/GEN/124; Crown Agents, AFCAP and UKaid: 2014. Available online: https://www.francescomiceli.com/blog/Review_of_Specifications_for_the_Use_of_Laterite_in_Road_Pavements.pdf (accessed on 24 February 2025).

- Kamtchueng, B.T.; Onana, V.L.; Fantong, W.Y.; Ueda, A.; Ntouala, R.F.D.; Wongolo, M.H.D.; Ndongo, G.B.; Ze, A.N.; Kamgang, V.K.B.; Ondoa, J.M. Geotechnical, chemical, and mineralogical evaluation of lateritic soils in a humid tropical area (Mfou, Central Cameroon): Implications for road construction. Geo-Engineering 2015, 6, 1. [Google Scholar] [CrossRef]

- Guimarães, A.; Motta, L.D. A Study on Permanent Deformation of Lateritic Soils Including the Shakedown Concept, 1st ed.; CRC Press: Boca Raton, FL, USA, 2008; p. 8. [Google Scholar]

- Nogami, J.S.; Villibor, D.F. Low-Cost Pavement with Lateritic Soils; Villibor: São Paulo, Brazil, 1995. [Google Scholar]

- DNIT Standard 259/2023; Soils-Classification of Tropical Fine Soils for Road Purposes Using Compacted Test Specimens in Miniature Equipment—Classification. DNIT-National Department of Transport Infrastructure: Rio de Janeiro, Brazil, 2023.

- Kumar, A.; George, V. Effect of soil parameters on resilient modulus using cyclic tri-axial tests on lateritic subgrade soils from Dakshina Kannada, India. Geotech. Geol. Eng. 2018, 36, 3987–4000. [Google Scholar] [CrossRef]

- Villibor, D.F.; Nogami, J.S.; Cincerre, J.R.; Serra, P.R.M.; Neto, A.Z. Low-Cost Pavement for Urban Roads, 2nd ed.; Arte e Ciência: São Paulo, Brazil, 2009; ISBN 978-85-61165-29-1. [Google Scholar]

- Almeida, B.D.; Coelho, L.M.; Guimarães, A.C.R.; Monteiro, S.N. Effect of sand addition on laterite soil stabilization. Materials 2024, 17, 6033. [Google Scholar] [CrossRef] [PubMed]

- Guimarães, A.C.R.; da Motta, L.M.G.; Castro, C.D. Permanent deformation parameters of fine-grained tropical soils. Road Mater. Pavement Des. 2019, 20, 1664–1681. [Google Scholar] [CrossRef]

- Galhardo, D.; Guimarães, A.; Martins, C.; Narciso, M.; Monteiro, S.; Coelho, L. Influence of Iron Mining Waste Addition as a Sustainable Alternative on the Resilient and Physical Properties of Soils for Pavement Design. Sustainability 2024, 16, 10211. [Google Scholar] [CrossRef]

- Santos, A.R.D.; Pastore, E.L.; Junior, F.A.; Cunha, M.A. Rural Roads: Technical Manual for Conservation and Recovery, 3rd ed.; ABGE—Brazilian Association of Engineering Geology and Environmental Geology; IPT—Institute of Technological Research of the State of São Paulo: São Paulo, Brazil, 2019. [Google Scholar]

- Villibor, D.F.; Alves, D.M.L. Low-Cost Paving for Tropical Regions: Design and Construction, New Considerations, 1st ed.; Tribo da Ilha: Florianópolis, Brazil, 2019. [Google Scholar]

- Witiuk, R.L.; Molin, B.M.G.D.; Guimarães, A.C.R. The influence of particle size distribution on mechanical performance of tropical soils as sub-ballast material. In Proceedings of the 5th International Conference on Transportation Geotechnics (ICTG) 2024, Volume 2; Lecture Notes in Civil Engineering. Rujikiatkamjorn, C., Xue, J., Indraratna, B., Eds.; Springer: Singapore, 2025; Volume 403. [Google Scholar] [CrossRef]

- de Medina, J.; da Motta, L.M.G.; dos Santos, J.D.G. Deformability characteristics of Brazilian laterites. Geotech. Geol. Eng. 2006, 24, 949–971. [Google Scholar] [CrossRef]

- Erlingsson, S.; Rahman, S.; Salour, F. Characteristic of unbound granular materials and subgrades based on multi-stage RLT testing. Transp. Geotech. 2017, 13, 28–42. [Google Scholar] [CrossRef]

- Zago, J.; Pinheiro, R.; Baroni, M.; Specht, L.P.; Delongui, L.; Sagrilo, A.V. Study of the permanent deformation of three soils used in road subgrades in the municipality of Santa Maria-RS, Brazil. Int. J. Pavement Res. Technol. 2021, 14, 729–739. [Google Scholar] [CrossRef]

- Coelho, L.; Guimarães, A.; de Azevedo, A.; Monteiro, S. Sustainable reclaimed asphalt emulsified granular mixture for pavement base stabilization: Prediction of mechanical behavior based on repeated load triaxial tests. Sustainability 2024, 16, 5335. [Google Scholar] [CrossRef]

- Coelho, L.M.; Kox, R.P.; Guimarães, A.C.R.; Travincas, R.; Monteiro, S.N. Influence of curing time on the mechanical behavior of cold recycled bituminous mix in flexible pavement base layer. Appl. Sci. 2024, 14, 7612. [Google Scholar] [CrossRef]

- Lima, C.; Motta, L.; Aragão, F. Effects of compaction moisture content on permanent deformation of soils subjected to repeated triaxial load tests. Transp. Res. Rec. J. Transp. Res. Board 2019, 2673, 466–476. [Google Scholar] [CrossRef]

- da Silva, M.F.; Ribeiro, M.M.P.; Furlan, A.P.; Fabbri, G.T.P. Effect of compaction water content and stress ratio on permanent deformation of a subgrade lateritic soil. Transp. Geotech. 2021, 26, 100443. [Google Scholar] [CrossRef]

- de Freitas, J.B.; de Rezende, L.R.; de F.N. Gitirana, G., Jr. Prediction of the resilient modulus of two tropical subgrade soils considering unsaturated conditions. Eng. Geol. 2020, 270, 105580. [Google Scholar] [CrossRef]

- Sousa, M.A.d.S.; Coutinho, R.Q.; Motta, L.M.G.D. Analysis of the unsaturated behaviour of compacted lateritic fine-grained tropical soils for use in transport infrastructure. Road Mater. Pavement Des. 2021, 24, 31–58. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Filho, J.C.S.; Castro, C.D. Contribution to the use of alternative material in heavy haul railway sub-ballast layer. Transp. Geotech. 2021, 30, 100524. [Google Scholar] [CrossRef]

- KVDP. World Map Indicating Tropics and Subtropics. 2013. Available online: https://en.m.wikipedia.org/wiki/File:World_map_indicating_tropics_and_subtropics.png (accessed on 24 February 2025).

- IBGE-Brazilian Institute of Geography and Statistics; Embrapa—Brazilian Agricultural Research Corporation. Soil Map of Brazil. 2001. Available online: https://www.ibge.gov.br/geociencias/informacoes-ambientais/pedologia/15829-solos.html (accessed on 24 February 2025).

- IBGE. Coordination of Natural Resources and Environmental Studies. In Technical Manual of Pedology, 3rd ed.; Number No. 4 in Ibgeana Collection; Technical Manuals in Geosciences; IBGE: Rio de Janeiro, Brazil, 2015; p. 428. [Google Scholar]

- Soil Survey Staff. Keys to Soil Taxonomy, 13th ed.; USDA Natural Resources Conservation Service, United States Department of Agriculture: Washington, DC, USA, 2022. [Google Scholar]

- Lecomte-Nana, G.L.; Lesueur, E.; Bonnet, J.P.; Lecomte, G. Characterization of a lateritic geomaterial and its elaboration through a chemical route. Constr. Build. Mater. 2009, 23, 1126–1132. [Google Scholar] [CrossRef]

- Marto, A.; Latifi, N.; Eisazadeh, A. Effect of non-traditional additives on engineering and microstructural characteristics of laterite soil. Arab. J. Sci. Eng. 2014, 39, 6949–6958. [Google Scholar] [CrossRef]

- Goel, G.; Kalamdhad, A.S. An investigation on use of paper mill sludge in brick manufacturing. Constr. Build. Mater. 2017, 148, 334–343. [Google Scholar] [CrossRef]

- DNER-ME 083/98; Agregados-Análise Granulométrica. DNER-National Department of Roads and Highways: Brasília, Brazil, 1998.

- DNER-ME 080/94; Solos-Análise Granulométrica por Peneiramento. DNER-National Department of Roads and Highways: Brasília, Brazil, 1994.

- DNIT 443; Pavement-Soils—Compaction Test Using Tripartite Molds. DNIT-National Department of Transport Infrastructure: Rio de Janeiro, Brazil, 2023.

- DNIT Standard 179/2018-IE; Pavement-Soils-Determination of Permanent Deformation-Test Instruction. DNIT-National Department of Transport Infrastructure: Rio de Janeiro, Brazil, 2018.

- DNIT 134; Pavement—Soils—Determination of Resilient Modulus—Test Method. DNIT-National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2018.

- DNIT 179; Pavement—Soils—Determination of Permanent Deformation. DNIT-National Department of Transportation Infrastructure: Rio de Janeiro, Brazil, 2018.

- Chu, X.; Dawson, A.; Thom, N.; Chen, H.; Qin, L. Permanent deformation characteristics of unsaturated subgrade soils under cyclic loading. Case Stud. Constr. Mater. 2024, 20, e03099. [Google Scholar] [CrossRef]

- Dawson, A.; Wellner, F. Plastic Behavior of Granular Materials; Report ARC Project 933 Reference PRG99014; University of Nottingham: Nottingham, UK, 1999. [Google Scholar]

- Werkmeister, S.; Dawson, A.; Wellner, F. Permanent Deformation Behavior of Granular Materials and the Shakedown Concept. Transp. Res. Rec. 2001, 1757, 75–81. [Google Scholar] [CrossRef]

- ISO 14688-1:2017; Geotechnical Investigation and Testing—Identification and Classification of Soil. Part 1: Identification and Description. International Organization for Standardization: Geneva, Switzerland, 2017.

- Nogami, J.S.; Cozzolino, V.M.N.; Villibor, D.F. Meaning of Coefficients and Index of MCT Soil Classification for Tropical Soils. In Proceedings of the 12th International Conference on Soil Mechanics and Foundation Engineering, Rio de Janeiro, Brazil, 13–18 August 1989. [Google Scholar]

- Sivarajasingham, S.; Alexander, L.; Cady, J.; Cline, M. Laterite. In Advances in Agronomy; Norman, A., Ed.; Academic Press: Cambridge, MA, USA, 1962; Volume 14, pp. 1–60. [Google Scholar]

- Blight, G. General Report/Discussion Session 6—Invited Lecture: Design Assessment of Saprolite Sand Laterites. In Proceedings of the 12th International Conference on Soil Mechanics and Foundation Engineering, International Society for Soil Mechanics and Geotechnical Engineering (ISSMGE), Rio De Janeiro, Brazil, 13–18 August 1989; pp. 2477–2484. [Google Scholar]

- Sunil, B.; Krishnappa, H. Effect of drying on the index properties of lateritic soils. Geotech. Geol. Eng. 2012, 30, 869–879. [Google Scholar] [CrossRef]

- Gidigasu, M. Degree of weathering in the identification of laterite materials for engineering purposes—A review. Eng. Geol. 1974, 8, 213–266. [Google Scholar] [CrossRef]

- Barbosa, V.; Marques, M.; Guimarães, A. Prediction of soil swelling potential using soil classification properties. Geotech. Geol. Eng. 2023, 41, 4445–4457. [Google Scholar] [CrossRef]

- Santha Kumar, G.; Saini, P.; Deoliya, R.; Mishra, A.K.; Negi, S. Characterization of laterite soil and its use in construction applications: A review. Resour. Conserv. Recycl. Adv. 2022, 16, 200120. [Google Scholar] [CrossRef]

- Santana, L.H.S.; Guimarães, A.C.R.; Marques, M.E.S. Tropical Compacted Residual Soils Erodibility: A Case Study on the West-East Integration Railway (FIOL). Geociências 2024, 43, 17–27. [Google Scholar] [CrossRef]

- Benatti, J.C.B.; Miguel, M.G. A proposal of structural models for colluvial and lateritic soil profile from southwestern Brazil on the basis of their collapsible behavior. Eng. Geol. 2013, 153, 1–11. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Lima, C.D.A.D.; Aragão, F.T.S.; Motta, L.M.G.D.; Santos, J.T.A.D. Mechanical characterization of an alternative laterite gravel used as pavement material. Soils Rocks 2024, 47, 1–13. [Google Scholar] [CrossRef]

- Oguntayo, O.D.; Olufawoye, L.K.; Ogundipe, O.M.; Aladegboye, O.; Awolusi, T.F.; Ejigboye, O.P.; Oguntayo, B.Y. Characterization of Soils for Road Works: Case Study of Borrow Pits in Kwara State, Nigeria. In Proceedings of the Recent Research on Geotechnical Engineering, Remote Sensing, Geophysics and Earthquake Seismology; Springer: Cham, Switzerland, 2024; pp. 107–111. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, W.; Zhu, Z.D.; Li, N.; Pu, S.Y.; Wan, Y.; Huo, W.W. Triaxial Mechanical Characteristics and Microscopic Mechanism of Graphene-Modified Cement Stabilized Expansive Soil. KSCE J. Civ. Eng. 2022, 26, 96–106. [Google Scholar] [CrossRef]

- Samb, F.; Fall, M.; Berthaud, Y.; Bâ, M. Resilient Modulus of Compacted Lateritic Soils from Senegal at OPM Conditions. Geomaterials 2013, 3, 165–171. [Google Scholar] [CrossRef]

- Ki, B.I.J.; Ba, M.; Coulibaly, M. Modelling of the Resilient Modulus (Mr) of Lateritic Soils in Tropical Africa (Burkina Faso and Senegal): Determination of Model Parameters K1, K2 and K3 (Thom and Brown (1987), Uzan (1985) and the NCHRP 1-28A (2004) (National Cooperative Highway Research Program). Lond. J. Eng. Res. 2022, 22, 449U. [Google Scholar]

- Moreira, C.; Guimarães, A.; Nascimento, F.; dos Santos, J. Evaluation of Fine-Grained Tropical Soils’ Resilient Behaviour for Pavement Design. In Proceedings of the 5th International Conference on Transportation Geotechnics (ICTG) 2024, Volume 4; Lecture Notes in Civil Engineering; Rujikiatkamjorn, C., Xue, J., Indraratna, B., Eds.; Springer: Singapore, 2025; Volume 405. [Google Scholar] [CrossRef]

- Neto, L.A.; Bernucci, L.B.; Nogami, J.S. Proposal for a Method of Flexible Pavement Design for Low Traffic Volume Roads Using Lateritic Soils. Doctoral Thesis, Polytechnic School of the University of São Paulo, São Paulo, Brazil, 5 January 1998. Available online: https://www.teses.usp.br/teses/disponiveis/3/3138/tde-21082024-104123/pt-br.php (accessed on 24 February 2025). [CrossRef]

- Ramos, C.R. Study for the Development of a Flexible Pavement Catalog for the Municipality of Rio de Janeiro. Master’s Thesis, Federal University of Rio de Janeiro, COPPE, Rio de Janeiro, Brazil, 2003; 301p. [Google Scholar]

- Guimarães, A.C.R.; Motta, L.M.G. Evaluation of the Deformability of a Graded Gravel Using Triaxial Tests with Repeated Loads. In Proceedings of the XIV Brazilian Conference on Soil Mechanics and Geotechnical Engineering (COBRAMSEG), Búzios, Brazil, 23–26 August 2008. [Google Scholar]

- Wahab, N.A.; Roshan, M.J.; Rashid, A.S.A.; Hezmi, M.A.; Jusoh, S.N.; Norsyahariati, N.D.N.; Tamassoki, S. Strength and Durability of Cement-Treated Lateritic Soil. Sustainability 2021, 13, 6430. [Google Scholar] [CrossRef]

- Caro, S.; Agudelo, J.P.; Caicedo, B.; Orozco, L.F.; Patiño, F.; Rodado, N. Advanced characterisation of cement-stabilised lateritic soils to be used as road materials. Int. J. Pavement Eng. 2019, 20, 1425–1434. [Google Scholar] [CrossRef]

- Pascoal, P.T.; Sagrilo, A.V.; Baroni, M.; Specht, L.P.; da Silva Pereira, D. Lateritic soil deformability regarding the variation of compaction energy in the construction of pavement subgrade. Soils Rocks 2023, 46, e2023009922. [Google Scholar] [CrossRef]

- Werkmeister, S.; Ralf, N.; Dawson, A.R.; Wellner, F. Deformation Behavior of Granular Materials Under Repeated Dynamic Load. J. Environ. Geomech. Monte Verit. 2002, 128, 215–223. [Google Scholar]

- BS EN 13286-7; Unbound and Hydraulically Bound Mixtures—Part 7: Cyclic Load Triaxial Test for Unbound Mixtures. CEN: Washington, DC, USA, 2004.

| Test | Stress (MPa) | Stress Ratio (/) | N | |

|---|---|---|---|---|

| 1 | 0.040 | 0.040 | 1 | 160.000 |

| 2 | 0.080 | 2 | 230.000 | |

| 3 | 0.120 | 3 | 150.000 | |

| 4 | 0.080 | 0.080 | 1 | 230.000 |

| 5 | 0.160 | 2 | 240.000 | |

| 6 | 0.240 | 3 | 169.000 | |

| 7 | 0.120 | 0.120 | 1 | 390.000 |

| 8 | 0.240 | 2 | 257.000 | |

| 9 | 0.360 | 3 | 340.000 | |

| Grain Composition (%) | ||||||

|---|---|---|---|---|---|---|

| Material | Clay | Silt | Sand | Stony | ||

| Fine | Medium | Coarse | ||||

| Purple Clay | 37 | 25 | 29 | 8 | 1 | 0 |

| Sample | pH | %P | Sulphuric Attack | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| H2O | KCL 1 M | SiO2 % | Al2O3 % | Fe2O3 % | TiO2 % | K2O % | Res % | Ki | Kr | ||

| Clay | 5.52 | 5.71 | 8.39 | 13 | 20.1 | 25.5 | 4.2 | 0.02 | 24.6 | 1.1 | 0.61 |

| Soil | RM (MPa) | |

|---|---|---|

| Base (100% PI) | Subgrade (100% PN) | |

| LG’ | 100 | 90–160 |

| LG’ | 200 | 110–220 |

| LA’ | 220–300 | 160–220 |

| LA’ | 220–300 | - |

| LA’ | 270 | 170 |

| LA | 240 | - |

| Purple Clay from this study | 275 | 258 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guimarães, A.C.R.; Povuação, A.M.; Nascimento, G.d.C.; Monteiro, S.N.; Coelho, L.M. Assessing the Potential of Lateritic Clayey Soils for Road Infrastructure in Tropical Regions. Materials 2025, 18, 1804. https://doi.org/10.3390/ma18081804

Guimarães ACR, Povuação AM, Nascimento GdC, Monteiro SN, Coelho LM. Assessing the Potential of Lateritic Clayey Soils for Road Infrastructure in Tropical Regions. Materials. 2025; 18(8):1804. https://doi.org/10.3390/ma18081804

Chicago/Turabian StyleGuimarães, Antônio Carlos Rodrigues, Albeds Mesquita Povuação, Gabriel de Carvalho Nascimento, Sergio Neves Monteiro, and Lisley Madeira Coelho. 2025. "Assessing the Potential of Lateritic Clayey Soils for Road Infrastructure in Tropical Regions" Materials 18, no. 8: 1804. https://doi.org/10.3390/ma18081804

APA StyleGuimarães, A. C. R., Povuação, A. M., Nascimento, G. d. C., Monteiro, S. N., & Coelho, L. M. (2025). Assessing the Potential of Lateritic Clayey Soils for Road Infrastructure in Tropical Regions. Materials, 18(8), 1804. https://doi.org/10.3390/ma18081804