Influence of Nb Addition on the Microstructure and Mechanical Properties of Laser Powder Bed Fusion-Fabricated Ti6Al4V Alloy

Abstract

1. Introduction

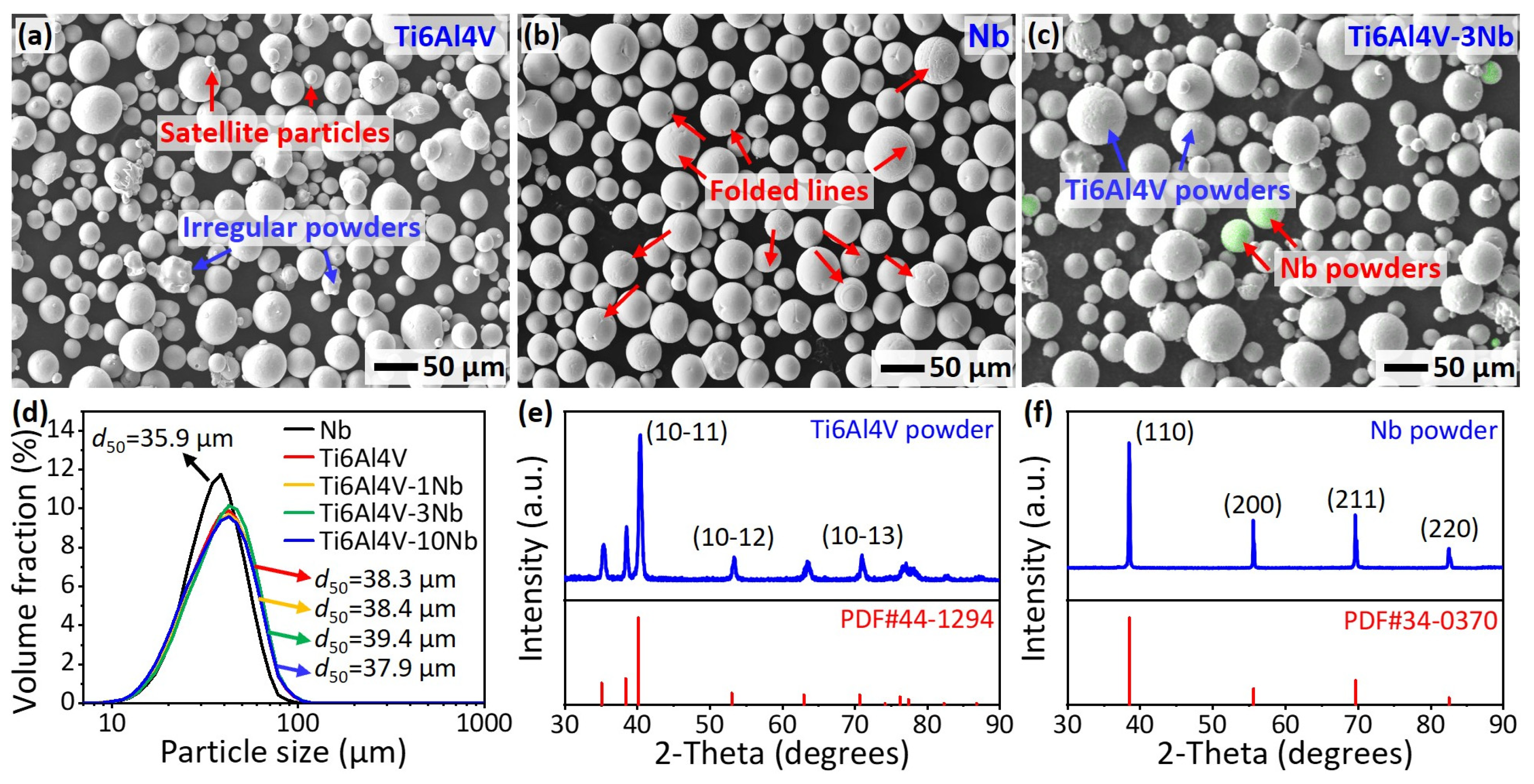

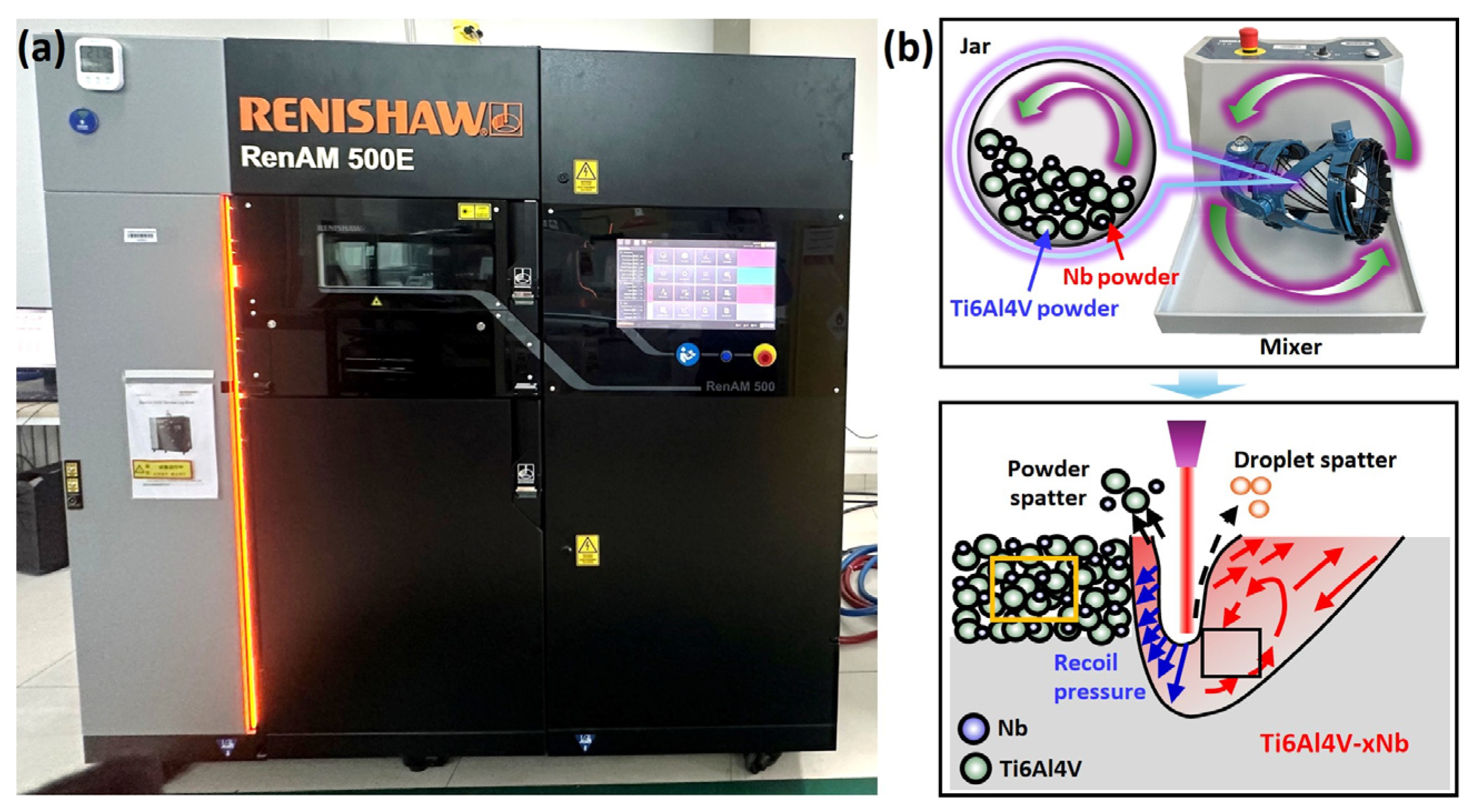

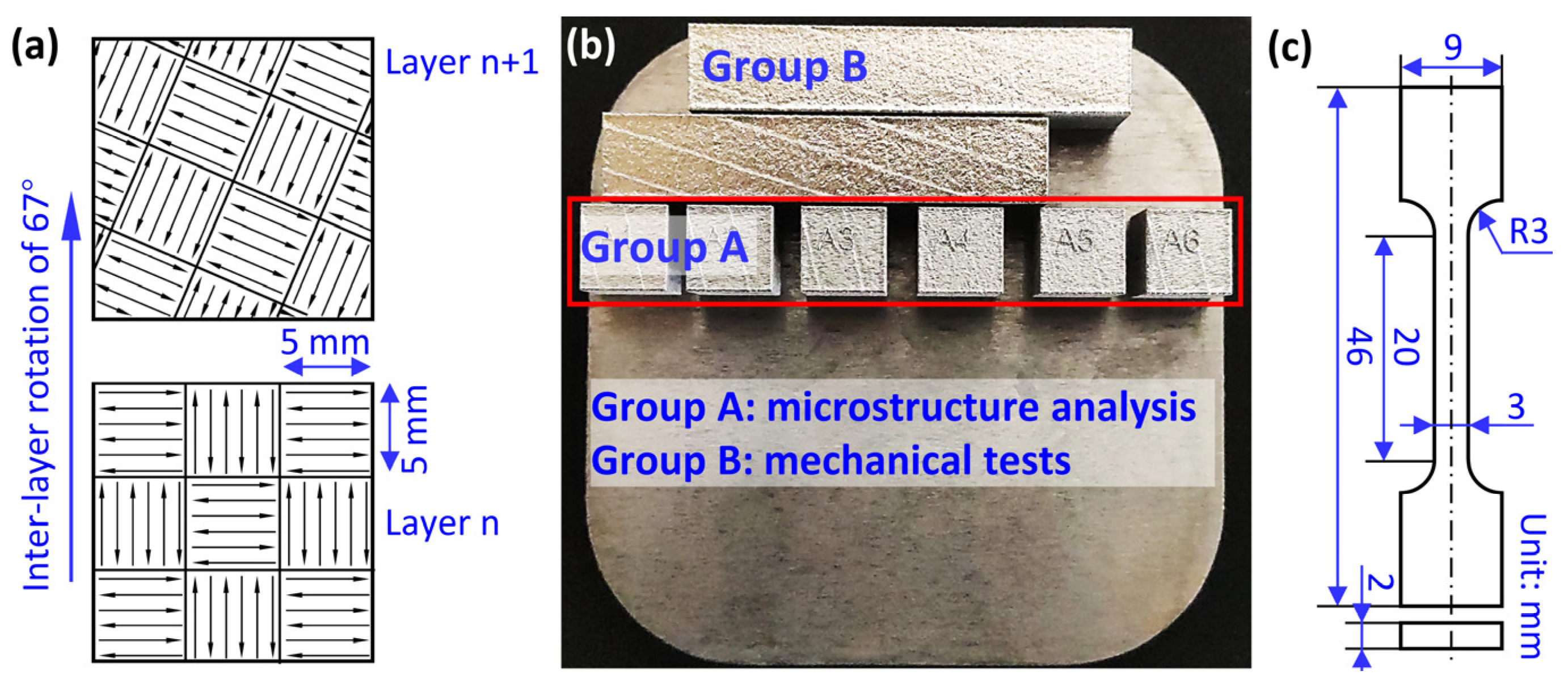

2. Materials and Methods

3. Results and Discussion

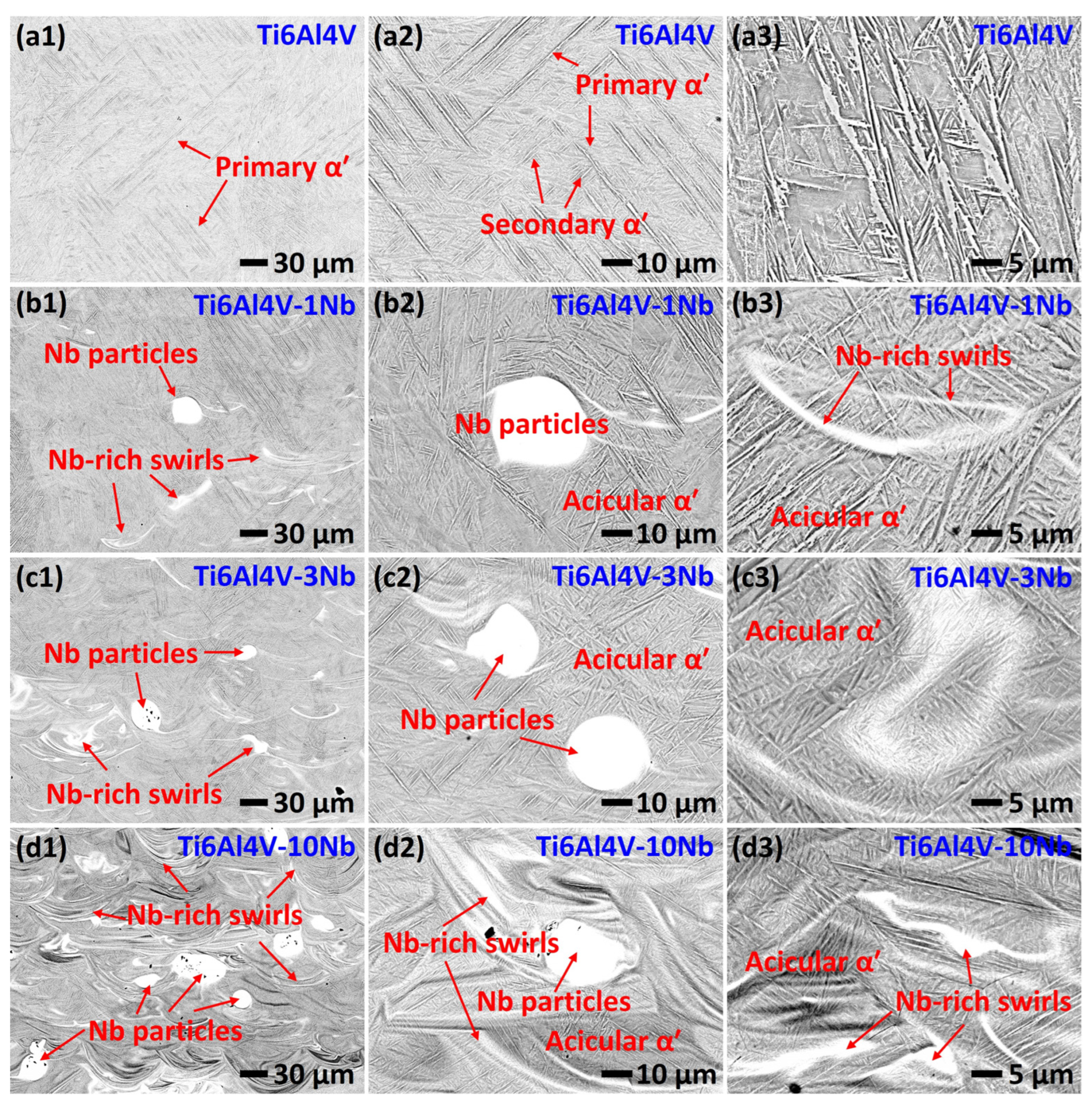

3.1. Microstructure and Elemental Distribution

3.2. Phase Composition and Crystallography

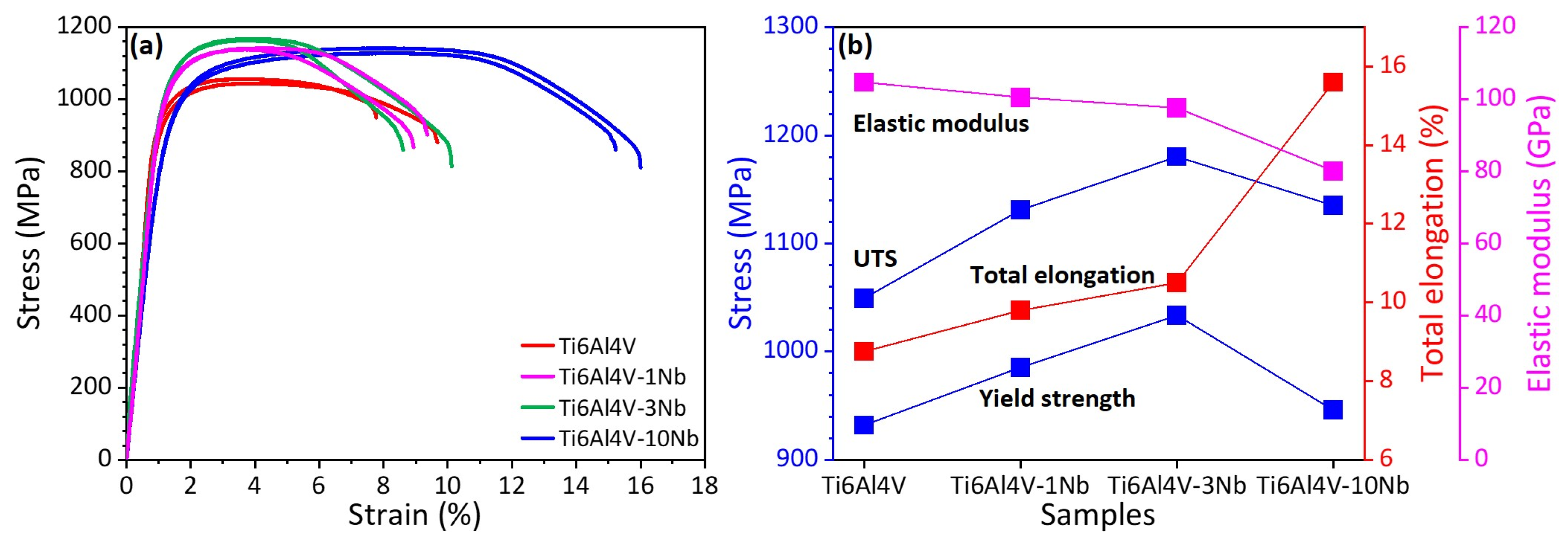

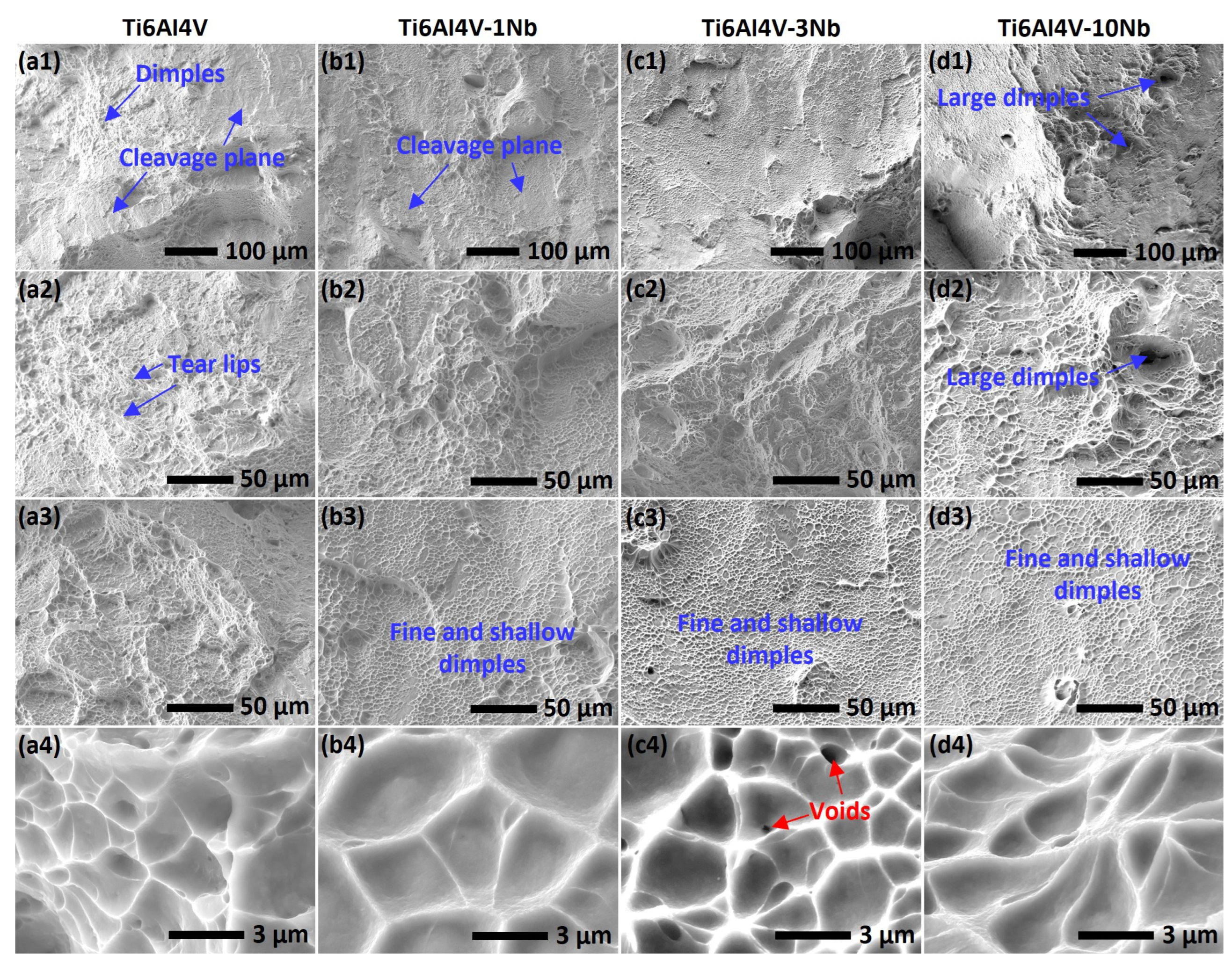

3.3. Mechanical Properties and Fractography

4. Conclusions

- The powder mixture shows good printability. Dense and defect-free Ti6Al4V-xNb alloys are produced successfully. Although the distribution of Nb is highly heterogeneous, no solidification cracks or secondary intermetallics were detected in the Nb-rich areas.

- The Ti6Al4V-xNb alloys are mainly in α’ martensite phase, even with the addition of 10 wt.% Nb, mainly due to the low content of Nb solute in the matrix. A narrow area with graded Nb content is detected around the partially melted Nb particles, and β phase is suggested to form in this area.

- Large columnar prior β grains are formed in the L-PBF-fabricated Ti6Al4V alloy. The prior β grain is refined gradually with the increase in Nb addition, since the partially melted Nb particles promote largely the heterogeneous nucleation during L-PBF.

- The ductility of the Ti6Al4V-xNb alloy benefits largely from Nb addition. Good ductility (total elongation of 15.6%) and high strength (UTS of 1135 MPa) are obtained with the addition of 10 wt.% Nb (i.e., the Ti6Al4V-10Nb alloy).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lutjering, G.; Williams, J.C. Titanium; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Ahmed, T.; Rack, H.J. Phase Transformations during Cooling in α + β Titanium Alloys. Mater. Sci. Eng. A 1998, 243, 206–211. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive Manufacturing of Biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Thouas, G.A. Metallic Implant Biomaterials. Mater. Sci. Eng. R 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Gu, K.; Wang, J.; Zhou, Y. Effect of Cryogenic Treatment on Wear Resistance of Ti–6Al–4V Alloy for Biomedical Applications. J. Mech. Behav. Biomed. Mater. 2014, 30, 131–139. [Google Scholar] [CrossRef]

- Li, S.J.; Yang, R.; Li, S.; Hao, Y.L.; Cui, Y.Y.; Niinomi, M.; Guo, Z.X. Wear Characteristics of Ti–Nb–Ta–Zr and Ti–6Al–4V Alloys for Biomedical Applications. Wear 2004, 257, 869–876. [Google Scholar] [CrossRef]

- Su, J.; Jiang, F.; Teng, J.; Chen, L.; Yan, M.; Requena, G.; Zhang, L.-C.; Wang, Y.M.; Okulov, I.V.; Zhu, H.; et al. Recent Innovations in Laser Additive Manufacturing of Titanium Alloys. Int. J. Extrem. Manuf. 2024, 6, 032001. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, G.; Liu, B. Chip Formation Characteristics in the Machining of Titanium Alloys: A Review. Int. J. Mach. Mach. Mater. 2016, 18, 155. [Google Scholar] [CrossRef]

- Sivarupan, T.; Bermingham, M.; Ng, C.-H.; Sun, S.; Dargusch, M. A Review of the Use of Cryogenic Coolant during Machining Titanium Alloys. Sustain. Mater. Technol. 2024, 40, e00946. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Mitra, I.; Avila, J.D.; Upadhyayula, M.; Bose, S. Porous Metal Implants: Processing, Properties, and Challenges. Int. J. Extrem. Manuf. 2023, 5, 032014. [Google Scholar] [CrossRef]

- Li, X.; Zhang, B.; Jakobi, T.; Yu, Z.; Ren, L.; Zhang, Z. Laser-Based Bionic Manufacturing. Int. J. Extrem. Manuf. 2024, 6, 042003. [Google Scholar] [CrossRef]

- Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-Structure-Performance Integrated Laser-Metal Additive Manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef] [PubMed]

- Hollander, D.A.; Von Walter, M.; Wirtz, T.; Sellei, R.; Schmidt-Rohlfing, B.; Paar, O.; Erli, H.-J. Structural, Mechanical and in Vitro Characterization of Individually Structured Ti–6Al–4V Produced by Direct Laser Forming. Biomaterials 2006, 27, 955–963. [Google Scholar] [CrossRef] [PubMed]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A Study of the Microstructural Evolution during Selective Laser Melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of Titanium Alloys Fabricated Using Rapid Prototyping Technologies—Electron Beam Melting and Laser Beam Melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the Texture Formation of Selective Laser Melted Ti-6Al-4V. Metall. Mater. Trans. A 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat Treatment of Ti6Al4V Produced by Selective Laser Melting: Microstructure and Mechanical Properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Lu, S.L.; Zhang, Z.J.; Liu, R.; Zhou, X.H.; Wang, X.G.; Zhang, B.N.; Zhao, X.M.; Eckert, J.; Zhang, Z.F. Optimal Tensile Properties of Laser Powder Bed Fusion Hereditary Basket-Weave Microstructure in Additive Manufactured Ti6Al4V. Addit. Manuf. 2022, 59, 103092. [Google Scholar] [CrossRef]

- Li, K.; Yang, J.; Yi, Y.; Liu, X.; Liu, Y.; Zhang, L.-C.; Zhang, W.; Li, W.; Chen, D.; Zhou, S. Enhanced Strength-Ductility Synergy and Mechanisms of Heterostructured Ti6Al4V-Cu Alloys Produced by Laser Powder Bed Fusion. Acta Mater. 2023, 256, 119112. [Google Scholar] [CrossRef]

- Becker, T.H.; Kumar, P.; Ramamurty, U. Fracture and Fatigue in Additively Manufactured Metals. Acta Mater. 2021, 219, 117240. [Google Scholar] [CrossRef]

- Kumar, P.; Ramamurty, U. Microstructural Optimization through Heat Treatment for Enhancing the Fracture Toughness and Fatigue Crack Growth Resistance of Selective Laser Melted Ti 6Al 4V Alloy. Acta Mater. 2019, 169, 45–59. [Google Scholar] [CrossRef]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.-P.; Van Humbeeck, J. Effects of Build Orientation and Heat Treatment on the Microstructure and Mechanical Properties of Selective Laser Melted Ti6Al4V Lattice Structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Qiu, C.; Adkins, N.J.E.; Attallah, M.M. Microstructure and Tensile Properties of Selectively Laser-Melted and of HIPed Laser-Melted Ti–6Al–4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V Alloy Produced by Selective Laser Melting of Prealloyed Powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Qu, Z.; Zhang, Z.; Liu, R.; Xu, L.; Zhang, Y.; Li, X.; Zhao, Z.; Duan, Q.; Wang, S.; Li, S.; et al. High Fatigue Resistance in a Titanium Alloy via Near-Void-Free 3D Printing. Nature 2024, 626, 999–1004. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive Manufacturing of Ultrafine-Grained High-Strength Titanium Alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, Z.; Yang, T.; Kong, H.; Luan, J.; Wang, A.; Wang, D.; Kuo, W.; Wang, Y.; Liu, C.-T. In Situ Design of Advanced Titanium Alloy with Concentration Modulations by Additive Manufacturing. Science 2021, 374, 478–482. [Google Scholar] [CrossRef]

- Zhang, J.; Bermingham, M.J.; Otte, J.; Liu, Y.; Hou, Z.; Yang, N.; Yin, Y.; Bayat, M.; Lin, W.; Huang, X.; et al. Ultrauniform, Strong, and Ductile 3D-Printed Titanium Alloy through Bifunctional Alloy Design. Science 2024, 383, 639–645. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Microstructure and Mechanical Properties of a Novel β Titanium Metallic Composite by Selective Laser Melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Yang, H.; Han, Y. Enhanced Corrosion Fatigue Strength of Additively Manufactured Graded Porous Scaffold-Coated Ti-6Al-7Nb Alloy. J. Mater. Sci. Technol. 2025, 212, 192–206. [Google Scholar] [CrossRef]

- Challis, V.J.; Xu, X.; Halfpenny, A.; Cramer, A.D.; Saunders, M.; Roberts, A.P.; Sercombe, T.B. Understanding the Effect of Microstructural Texture on the Anisotropic Elastic Properties of Selective Laser Melted Ti-24Nb-4Zr-8Sn. Acta Mater. 2023, 254, 119021. [Google Scholar] [CrossRef]

- Wang, L.; Xie, L.; Lv, Y.; Zhang, L.-C.; Chen, L.; Meng, Q.; Qu, J.; Zhang, D.; Lu, W. Microstructure Evolution and Superelastic Behavior in Ti-35Nb-2Ta-3Zr Alloy Processed by Friction Stir Processing. Acta Mater. 2017, 131, 499–510. [Google Scholar] [CrossRef]

- Zheng, Y.; Xu, P. Effect of Nb Content on Phase Transformation and Comprehensive Properties of TiNb Alloy Coating. Coatings 2023, 13, 1186. [Google Scholar] [CrossRef]

- Sehhat, M.H.; Chandler, J.; Yates, Z. A Review on ICP Powder Plasma Spheroidization Process Parameters. Int. J. Refract. Met. Hard Mater. 2022, 103, 105764. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, G.; Zhang, T.; Li, D.; Zhang, J.; Liu, S.; Chen, C.; Zhou, K. Effect of CH4 on Plasma Spheroidization of Tantalum Powder. Powder Technol. 2024, 437, 119523. [Google Scholar] [CrossRef]

- Iovane, P.; Borriello, C.; Pandolfi, G.; Portofino, S.; De Girolamo Del Mauro, A.; Sico, G.; Tammaro, L.; Fedele, N.; Galvagno, S. Spheroidization of Alumina Powders for Additive Manufacturing Applications by DC Plasma Technology. Molecules 2025, 30, 453. [Google Scholar] [CrossRef]

- Wei, H.L.; Mukherjee, T.; Zhang, W.; Zuback, J.S.; Knapp, G.L.; De, A.; DebRoy, T. Mechanistic Models for Additive Manufacturing of Metallic Components. Prog. Mater. Sci. 2021, 116, 100703. [Google Scholar] [CrossRef]

- Xi, R.; Jiang, H.; Li, G.; Kustov, S.; Zhang, Z.; Wei, H.; Liu, Z.; Zhao, G.; Van Humbeeck, J.; Wang, X. In-Situ Alloying of NiTiNb Ternary Shape Memory Alloys via Laser Powder Bed Fusion Using Pre-Alloyed NiTi and Elemental Nb Powders: Microstructure, Phase Transformation Behavior and Functional Properties. Addit. Manuf. 2024, 79, 103933. [Google Scholar] [CrossRef]

- Jiang, H.; Wang, X.; Xi, R.; Li, G.; Wei, H.; Liu, J.; Zhang, B.; Kustov, S.; Vanmeensel, K.; Van Humbeeck, J.; et al. Size Effect on the Microstructure, Phase Transformation Behavior, and Mechanical Properties of NiTi Shape Memory Alloys Fabricated by Laser Powder Bed Fusion. J. Mater. Sci. Technol. 2023, 157, 200–212. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and Control of Martensite in Ti-6Al-4V Alloy Produced by Selective Laser Melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Bilous, O.O.; Artyukh, L.V.; Bondar, A.A.; Velikanova, T.Y.; Burka, M.P.; Brodnikovskyi, M.P.; Fomichov, O.S.; Tsyganenko, N.I.; Firstov, S.O. Effect of Boron on the Structure and Mechanical Properties of Ti–6Al and Ti–6Al–4V. Mater. Sci. Eng. A 2005, 402, 76–83. [Google Scholar] [CrossRef]

- Xi, R.; Jiang, H.; Li, G.; Zhang, Z.; Wei, H.; Zhao, G.; Van Humbeeck, J.; Wang, X. Effect of Solution Treatment on the Microstructure, Phase Transformation Behaviour and Functional Properties of NiTiNb Ternary Shape Memory Alloys Fabricated via Laser Powder Bed Fusion in-Situ Alloying. Int. J. Extrem. Manuf. 2024, 6, 045002. [Google Scholar] [CrossRef]

- Korneva, A.; Straumal, B.; Gornakova, A.; Kilmametov, A.; Gondek, Ł.; Lityńska-Dobrzyńska, L.; Chulist, R.; Pomorska, M.; Zięba, P. Formation and Thermal Stability of the ω-Phase in Ti–Nb and Ti–Mo Alloys Subjected to HPT. Materials 2022, 15, 4136. [Google Scholar] [CrossRef]

- Bonisch, M. Structural Properties, Deformation Behavior and Thermal Stability of Martensitic Ti-Nb Alloys. Ph.D. Thesis, Technische Universität Dresden: Dresden, Germany, 2016. [Google Scholar]

- Zhang, Y.; Liu, H.; Jin, Z. Thermodynamic Assessment of the Nb-Ti System. Calphad 2001, 25, 305–317. [Google Scholar] [CrossRef]

- Talbot, C.E.P.; Church, N.L.; Hildyard, E.M.; Connor, L.D.; Miller, J.R.; Jones, N.G. On the Stability and Formation of the α″ and ω Phases in Ti-Nb Alloys upon Cooling. Acta Mater. 2024, 262, 119409. [Google Scholar] [CrossRef]

- Su, Y.; Liang, C.; Sun, X.; Zhang, H.; Liang, Q.; Zheng, Y.; Hao, Y.; Yang, R.; Wang, D.; Banerjee, D.; et al. Composition-Dependent Shuffle-Shear Coupling and Shuffle-Regulated Strain Glass Transition in Compositionally Modulated Ti-Nb Alloys. Acta Mater. 2023, 246, 118697. [Google Scholar] [CrossRef]

- Li, Z.; Qiu, J.; Xu, H.; Dong, A.; He, L.; Zhu, G.; Du, D.; Xing, H.; Liu, X.; Sun, B. Characteristics of β-Type Ti-41Nb Alloy Produced by Laser Powder Bed Fusion: Microstructure, Mechanical Properties and in Vitro Biocompatibility. J. Mater. Sci. Technol. 2022, 124, 260–272. [Google Scholar] [CrossRef]

- Glavicic, M.G.; Kobryn, P.A.; Bieler, T.R.; Semiatin, S.L. An Automated Method to Determine the Orientation of the High-Temperature Beta Phase from Measured EBSD Data for the Low-Temperature Alpha-Phase in Ti–6Al–4V. Mater. Sci. Eng. A 2003, 351, 258–264. [Google Scholar] [CrossRef]

- Thijs, L.; Montero Sistiaga, M.L.; Wauthle, R.; Xie, Q.; Kruth, J.-P.; Van Humbeeck, J. Strong Morphological and Crystallographic Texture and Resulting Yield Strength Anisotropy in Selective Laser Melted Tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ishimoto, T.; Hibino, S.; Yasutomi, J.; Narushima, T.; Nakano, T. Unique Crystallographic Texture Formation in Inconel 718 by Laser Powder Bed Fusion and Its Effect on Mechanical Anisotropy. Acta Mater. 2021, 212, 116876. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, J.; Zhang, L.; Zhang, Y.; Song, B.; Wang, X.; Fan, J.; Liu, Q.; Shi, Y. Laser Powder Bed Fusion Additive Manufacturing of NiTi Shape Memory Alloys: A Review. Int. J. Extrem. Manuf. 2023, 5, 032001. [Google Scholar] [CrossRef]

- Jiang, M.; Jiang, H.; Xi, R.; Ren, D.; Ji, H.; Lei, J.; Wang, X. Superior Superelasticity of Laser Powder Bed Fusion Fabricated NiTi Alloys Achieved by Post Heat Treatment. Scr. Mater. 2025, 257, 116476. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, Q.; Liang, X.; Wang, X.; Li, G.; Vanmeensel, K.; Xie, J. Alloy Design for Laser Powder Bed Fusion Additive Manufacturing: A Critical Review. Int. J. Extrem. Manuf. 2024, 6, 022002. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and Heterogeneity of Microstructure and Mechanical Properties in Metal Additive Manufacturing: A Critical Review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Gao, T.; Zhang, S.; Liu, G.; Sun, Q.; Liu, J.; Sun, Q.; Sun, J.; Wang, Z.; Liu, X.; Wang, X. A High Strength AlSi10Mg Alloy Fabricated by Laser Powder Bed Fusion with Addition of Al Ti C B Master Alloy Powders. Materialia 2021, 16, 101103. [Google Scholar] [CrossRef]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; Van Humbeeck, J.; Kruth, J.-P. Selective Laser Melting of Nano-TiB2 Decorated AlSi10Mg Alloy with High Fracture Strength and Ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Singla, A.K.; Banerjee, M.; Sharma, A.; Singh, J.; Bansal, A.; Gupta, M.K.; Khanna, N.; Shahi, A.S.; Goyal, D.K. Selective Laser Melting of Ti6Al4V Alloy: Process Parameters, Defects and Post-Treatments. J. Manuf. Process. 2021, 64, 161–187. [Google Scholar] [CrossRef]

- Romero Reséndiz, L.; Sánchez Cano, T.; Naeem, M.; Ur Rehman, A.; Salamci, E.; Torres Mendoza, V.; Degalez Duran, E.; Bazán Díaz, L.; Salamci, M.U. Mechanical and Electrochemical Properties Comparison of Additively Manufactured Ti-6Al-4V Alloys by Electron Beam Melting and Selective Laser Melting. J. Mater. Eng. Perform. 2024, 33, 9028–9038. [Google Scholar] [CrossRef]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A Review of the As-Built SLM Ti-6Al-4V Mechanical Properties towards Archieving Fatigue Resistant Designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Liu, Y.; Cao, G.; Zhang, L.-C. Influence of Nb on the Β→α″ Martensitic Phase Transformation and Properties of the Newly Designed Ti–Fe–Nb Alloys. Mater. Sci. Eng. C 2016, 60, 503–510. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.C.; Liu, Y.J.; Liang, S.X.; Zhang, Y.S.; Wang, L.Q.; Sercombe, T.B.; Zhang, L.C. Comparison of Microstructure and Mechanical Behavior of Ti-35Nb Manufactured by Laser Powder Bed Fusion from Elemental Powder Mixture and Prealloyed Powder. J. Mater. Sci. Technol. 2022, 105, 1–16. [Google Scholar] [CrossRef]

- Glassman, A.H.; Bobyn, J.D.; Tanzer, M. New Femoral Designs: Do They Influence Stress Shielding? Clin. Orthop. Relat. Res. 2006, 453, 64–74. [Google Scholar] [CrossRef]

- Hao, Y.L.; Zhang, Z.B.; Li, S.J.; Yang, R. Microstructure and Mechanical Behavior of a Ti–24Nb–4Zr–8Sn Alloy Processed by Warm Swaging and Warm Rolling. Acta Mater. 2012, 60, 2169–2177. [Google Scholar] [CrossRef]

- Bai, Y.; Deng, Y.; Zheng, Y.; Li, Y.; Zhang, R.; Lv, Y.; Zhao, Q.; Wei, S. Characterization, Corrosion Behavior, Cellular Response and in Vivo Bone Tissue Compatibility of Titanium–Niobium Alloy with Low Young’s Modulus. Mater. Sci. Eng. C 2016, 59, 565–576. [Google Scholar] [CrossRef]

- Luo, Z.C.; Huang, M.X. Revealing the Fracture Mechanism of Twinning-Induced Plasticity Steels. Steel Res. Int. 2018, 89, 1700433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Wan, M.; Gao, N.; Jiang, H.; Chen, T.; Zhao, P.; Liu, Z.; Jiao, Q.; Lv, B.; Han, Q.; et al. Influence of Nb Addition on the Microstructure and Mechanical Properties of Laser Powder Bed Fusion-Fabricated Ti6Al4V Alloy. Materials 2025, 18, 1803. https://doi.org/10.3390/ma18081803

Zhang B, Wan M, Gao N, Jiang H, Chen T, Zhao P, Liu Z, Jiao Q, Lv B, Han Q, et al. Influence of Nb Addition on the Microstructure and Mechanical Properties of Laser Powder Bed Fusion-Fabricated Ti6Al4V Alloy. Materials. 2025; 18(8):1803. https://doi.org/10.3390/ma18081803

Chicago/Turabian StyleZhang, Bo, Min Wan, Na Gao, Hao Jiang, Tuokuan Chen, Peng Zhao, Zhenzhen Liu, Qingyuan Jiao, Baoguo Lv, Quanquan Han, and et al. 2025. "Influence of Nb Addition on the Microstructure and Mechanical Properties of Laser Powder Bed Fusion-Fabricated Ti6Al4V Alloy" Materials 18, no. 8: 1803. https://doi.org/10.3390/ma18081803

APA StyleZhang, B., Wan, M., Gao, N., Jiang, H., Chen, T., Zhao, P., Liu, Z., Jiao, Q., Lv, B., Han, Q., & Wang, X. (2025). Influence of Nb Addition on the Microstructure and Mechanical Properties of Laser Powder Bed Fusion-Fabricated Ti6Al4V Alloy. Materials, 18(8), 1803. https://doi.org/10.3390/ma18081803