1. Introduction

Sandwich composite structures (SCSs) are usually composed of fiber-reinforced plastic (FRP) upper and lower face sheets and lightweight core materials. Although this unique design reduces the overall quality of materials, it endows them with high bending stiffness. Moreover, the upper and lower face sheets play a protective and anti-corrosion role for the internal core materials, which is important for marine structures [

1,

2]. Meanwhile, buoyancy materials have been extensively developed and used in the field of deep-sea exploration due to their high strength, resistance to high hydrostatic pressure, and light weight [

3]. SCSs with buoyancy material core (BMC-SCSs) have a wide range of applications in deep-sea structures, since they combine the advantages of both materials. However, with regard to assembly or maintenance operations in the complex and unknown deep-sea environment, collisions and other accidents inevitably occur. In 2007, the Mir submersible collided with a hydrothermal vent structure during a mid-Atlantic Ridge expedition due to operational error. The impact load exhibits typical high-energy and low-velocity characteristics, which can cause extensive internal damage, reduce the stiffness and strength of the composite structure [

4,

5,

6], and potentially lead to catastrophic failure of the overall structure. In current low-velocity impact studies, the energy levels generally range from 10 to 100 Joules. It is still worth exploring whether high-energy low-velocity impacts, such as those more likely encountered by marine structures, can induce new damage modes and mechanisms.

To the best of the authors’ knowledge, and according to the available literature, the impact resistance of BMC-SCSs has been rarely reported. SCSs are commonly used with core materials such as polyurethane (PU) foam, polymethacrylimide (PMI) foam, and various structural grid forms. For instance, Long et al. [

7] conducted systematic experimental and numerical studies on the impact resistance of PU foam/glass fiber-reinforced polymer (GFRP) sandwich structures with different impact energies, foam densities, and layup sequences. It was found that the delamination failure of the upper face sheet follows the behavior typical of composite laminates, while penetration changes the shape of the delamination region. Compared to those with soft cores, sandwich structures with rigid cores are more prone to delamination. Chen et al. [

8] developed a PU foam/GFRP grid sandwich structure, and their experimental results revealed that the damage modes of the sandwich beams were multiple and strongly related to the impact position. Reducing the transverse and longitudinal web spacing and increasing the web thickness can enhance the impact resistance of sandwich structures, with the boundary conditions having a significant effect on the post-damage stage. Lv et al. [

9] performed drop hammer low-velocity impact tests on PMI foam/CFRP grid sandwich structures at different locations, e.g., intersection, web, and center, using different energy levels. The intersection location exhibits the best impact resistance. Morada et al. [

10] investigated sandwich structures consisting of alumina tri-hydrate (ATH)/epoxy core and GFRP panels. Their results indicated that the core material was the main energy absorbing part of the structure. In addition, the peak impact force was approximately proportional to the impact energy. Due to their unique configuration, the impact resistance of grid sandwich structures is closely related to the impact location [

11,

12,

13,

14,

15]. He et al. [

16] conducted experimental and simulation studies on an X-Frame aluminum alloy core/CFRP sandwich structure. In this configuration, under low impact energy at a small-span location, the upper face sheet around the impact area primarily exhibited interlayer delamination. As the impact energy increased, intra-layer damage, e.g., fiber fracture and matrix cracking, became the dominant damage mode. Li et al. [

17] studied a Kagome grid core material sandwich structure and conducted drop hammer experiments with three types of impactors. They found that the shape of the impactor had a significant effect on the damage patterns of the sandwich panels, with the flat impactor causing more severe damage.

The new BMC used in this study is a synthetic material, which is generally made of a resin matrix filled with hollow glass microspheres; changes in the resin matrix properties and hollow glass microsphere content can produce BMCs with different characteristics [

18,

19,

20]. The buoyancy material failure criterion must be analyzed based on its specific composition and experimental results. Li et al. [

21] studied the compression characteristics of an epoxy-based buoyancy material and identified two main coexisting damage modes; one was the fracture of the dominant hollow glass microspheres at the central part, and the other was the formation and propagation of shear cracks from the corners. Furthermore, the increase in the strength of the epoxy matrix with strain rate accounted for the macroscopic strain-rate dependence of the buoyancy material. Zhang et al. [

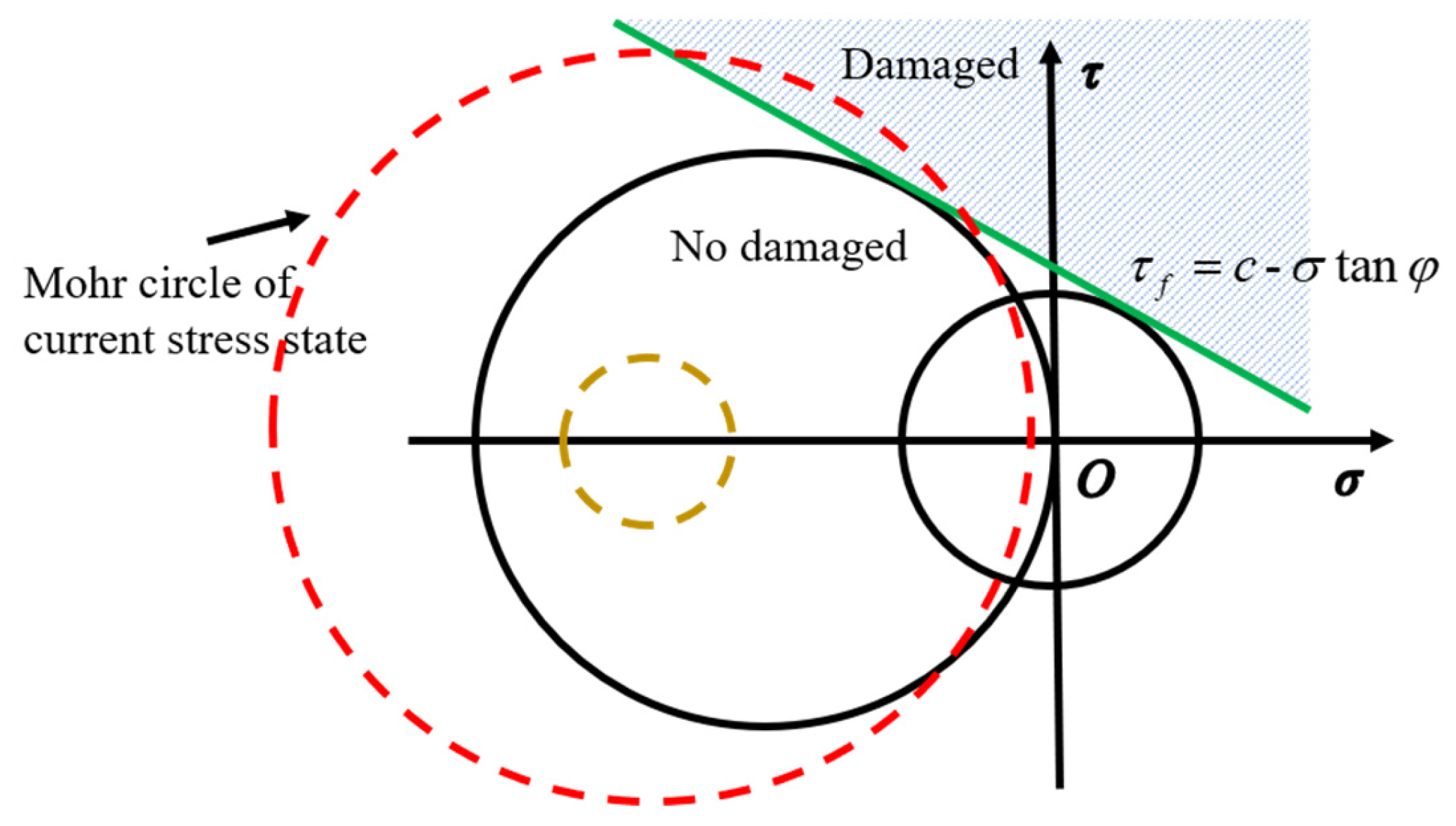

22] conducted similar work on the same system and developed a corresponding finite element (FE) analysis model based on experimental data. Based on uniaxial tensile/compression experimental results, Zhai et al. [

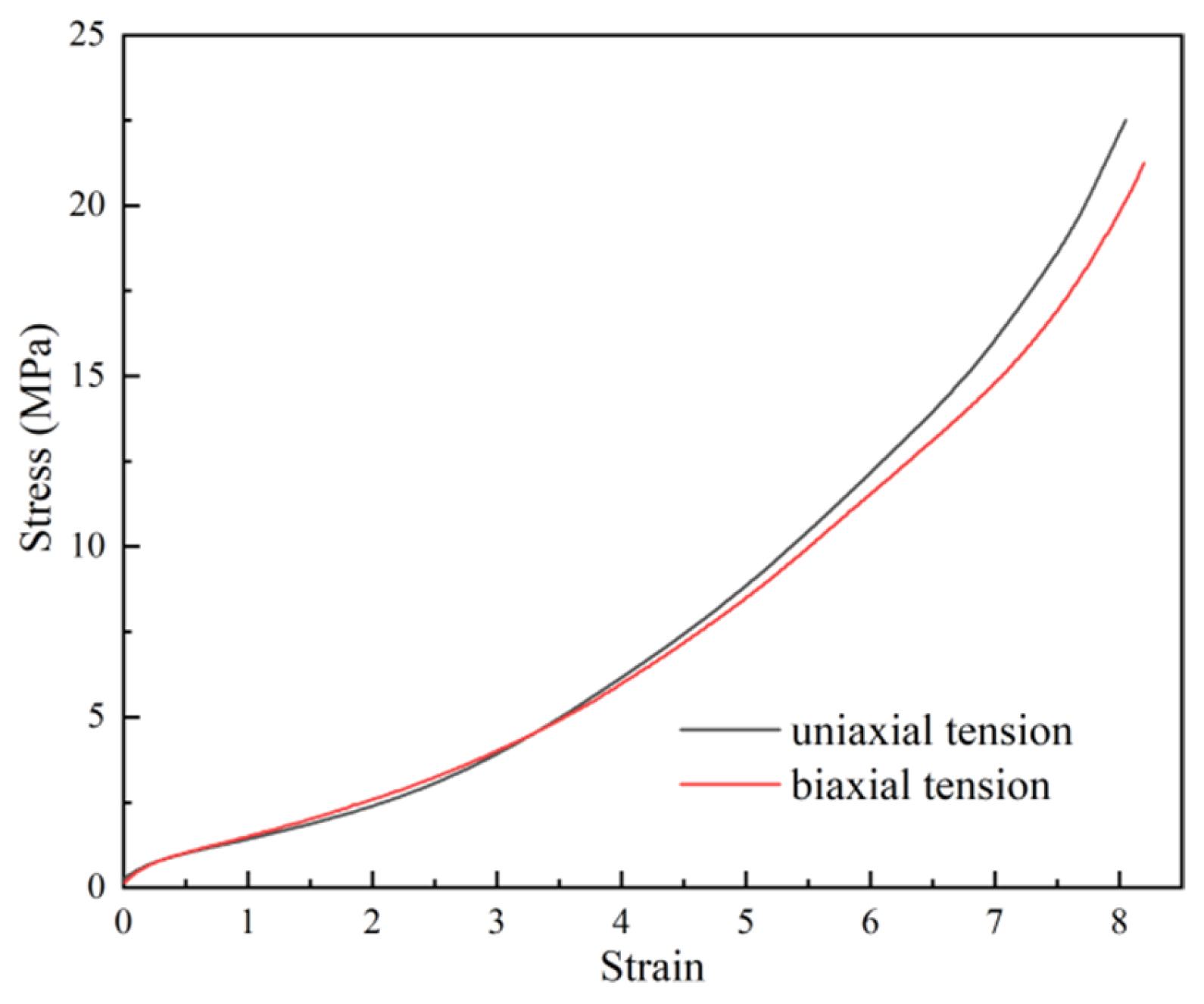

23] established a double Drucker-Prager failure criterion for epoxy-based buoyancy materials considering tensile/compression differences. Gupta et al. [

24] compared the tensile/compression properties of vinyl ester-based buoyancy materials with those of epoxy-based buoyancy materials. They reported that low-cost vinyl ester resins can produce buoyancy materials with properties comparable to those of epoxy-based systems.

Given that various types of cracking damage occurred in the buoyancy blocks used in the Jiaolong deep-sea manned submersible during the 35th and 37th China Oceanic Research Expeditions [

25], rubber or polyurea can be used as impact-resistant protective layers for further protection of the BMC-SCS [

26,

27,

28,

29,

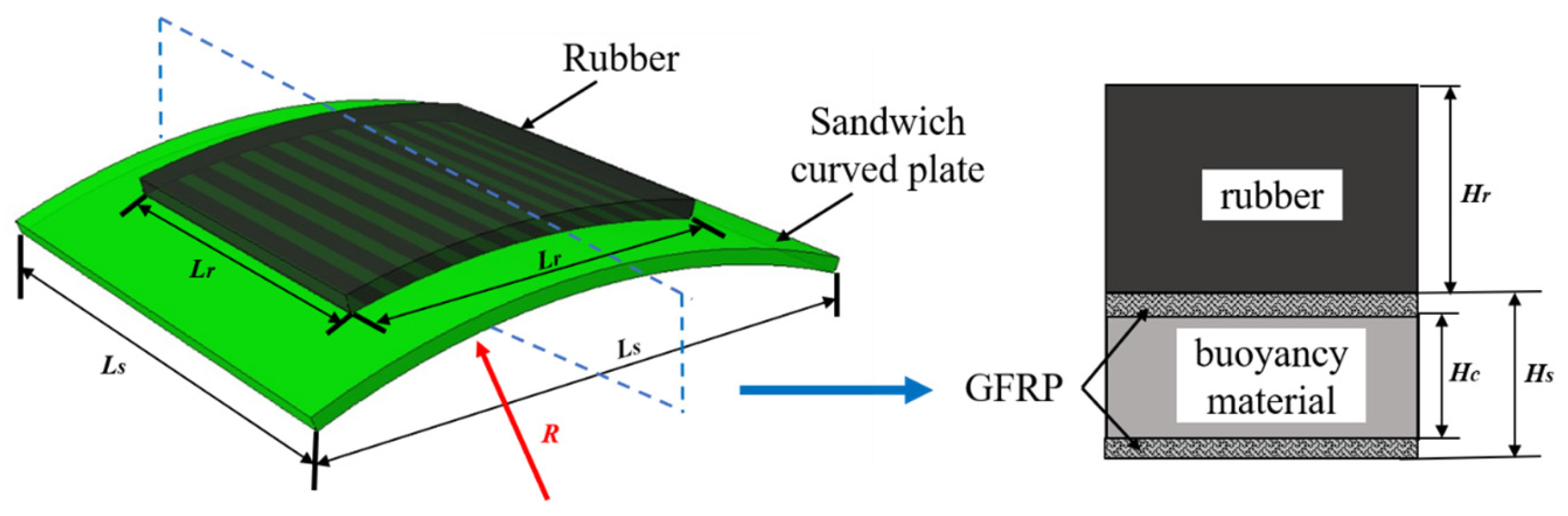

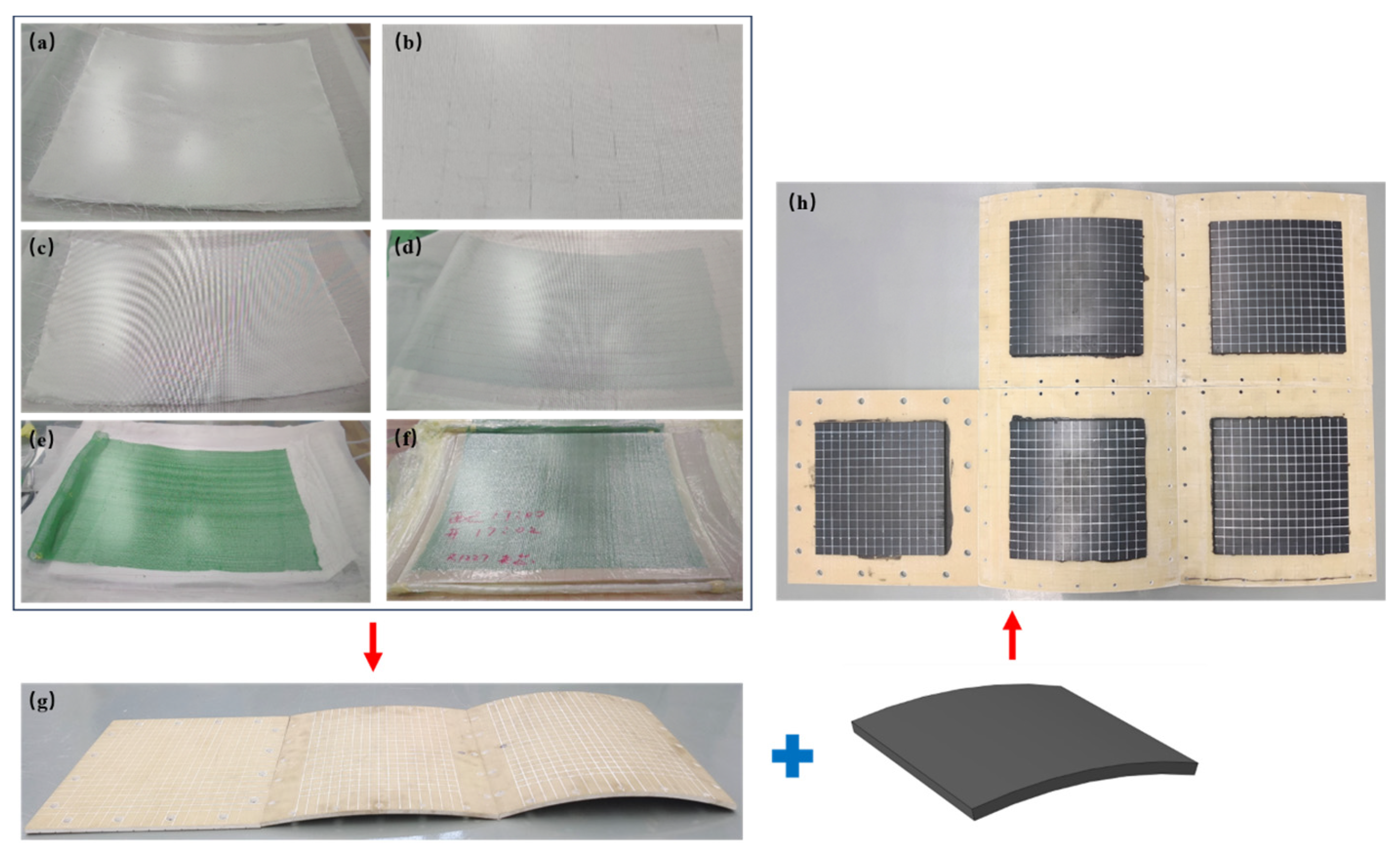

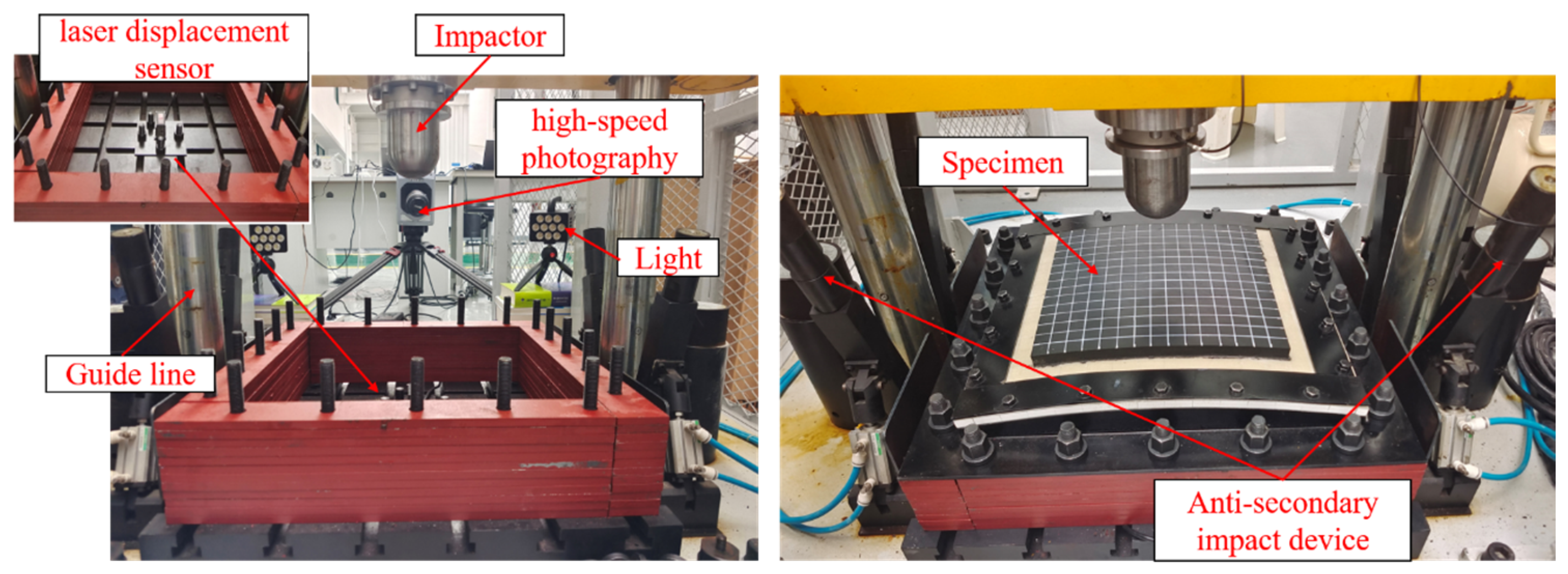

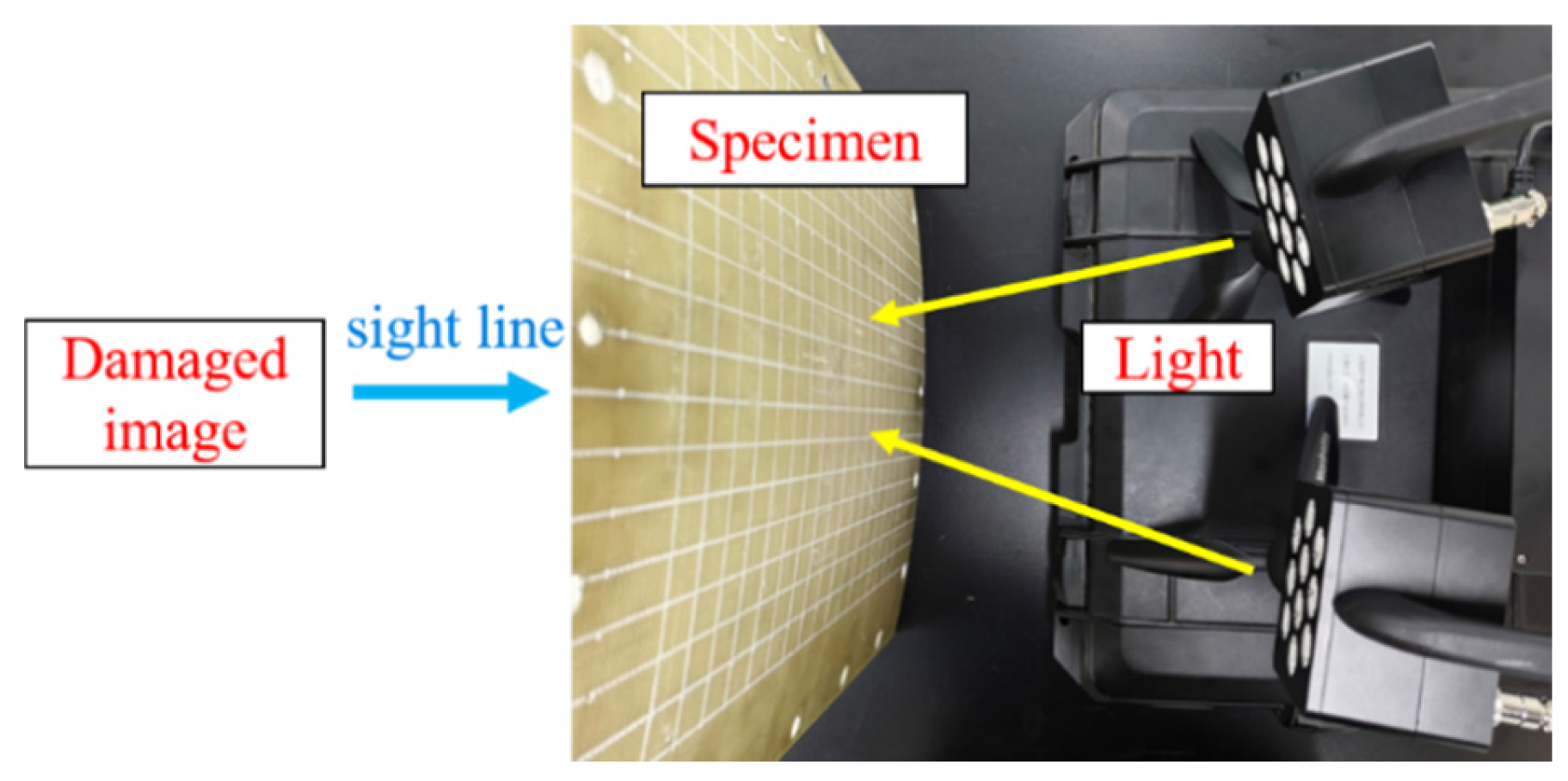

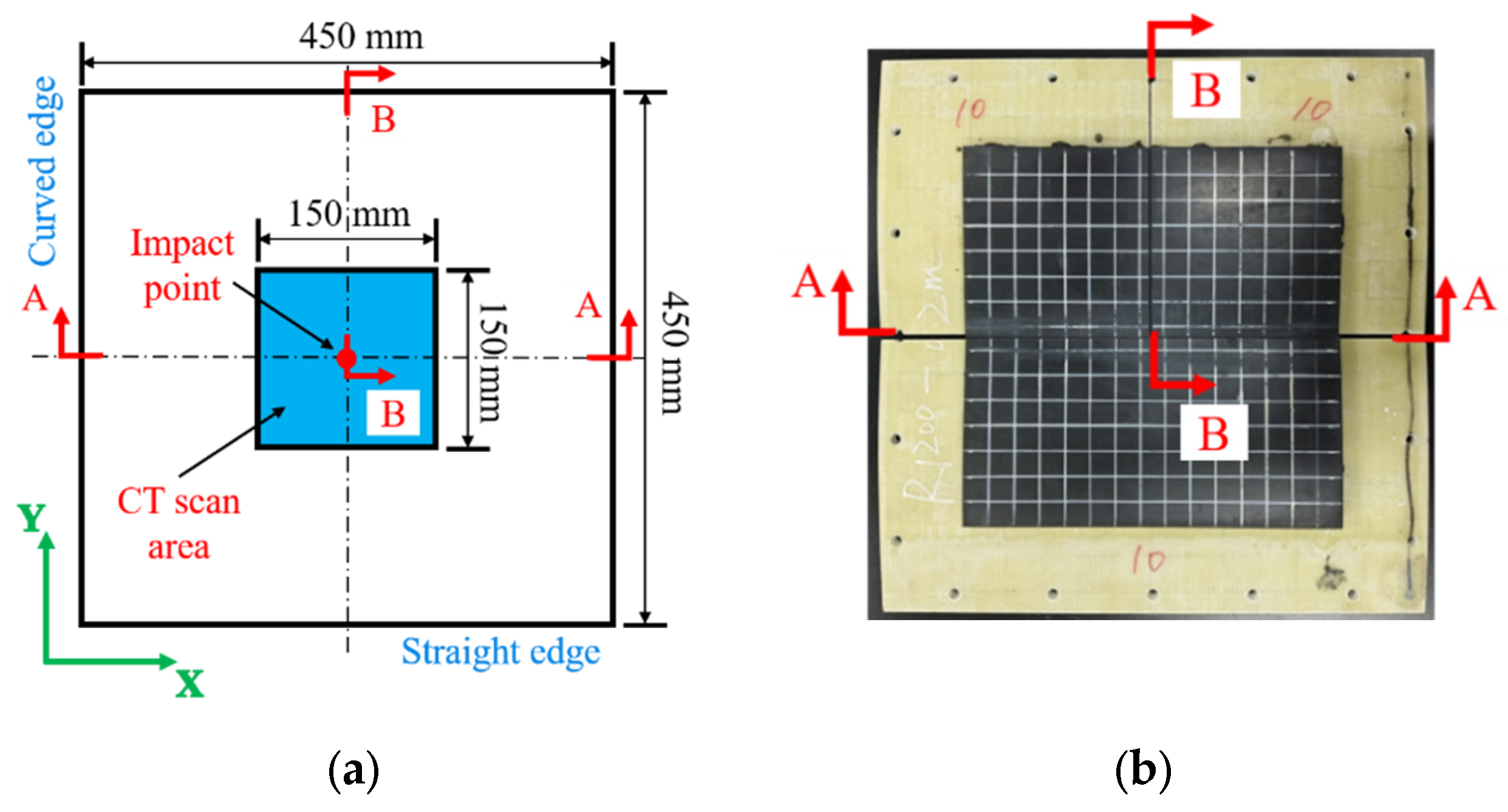

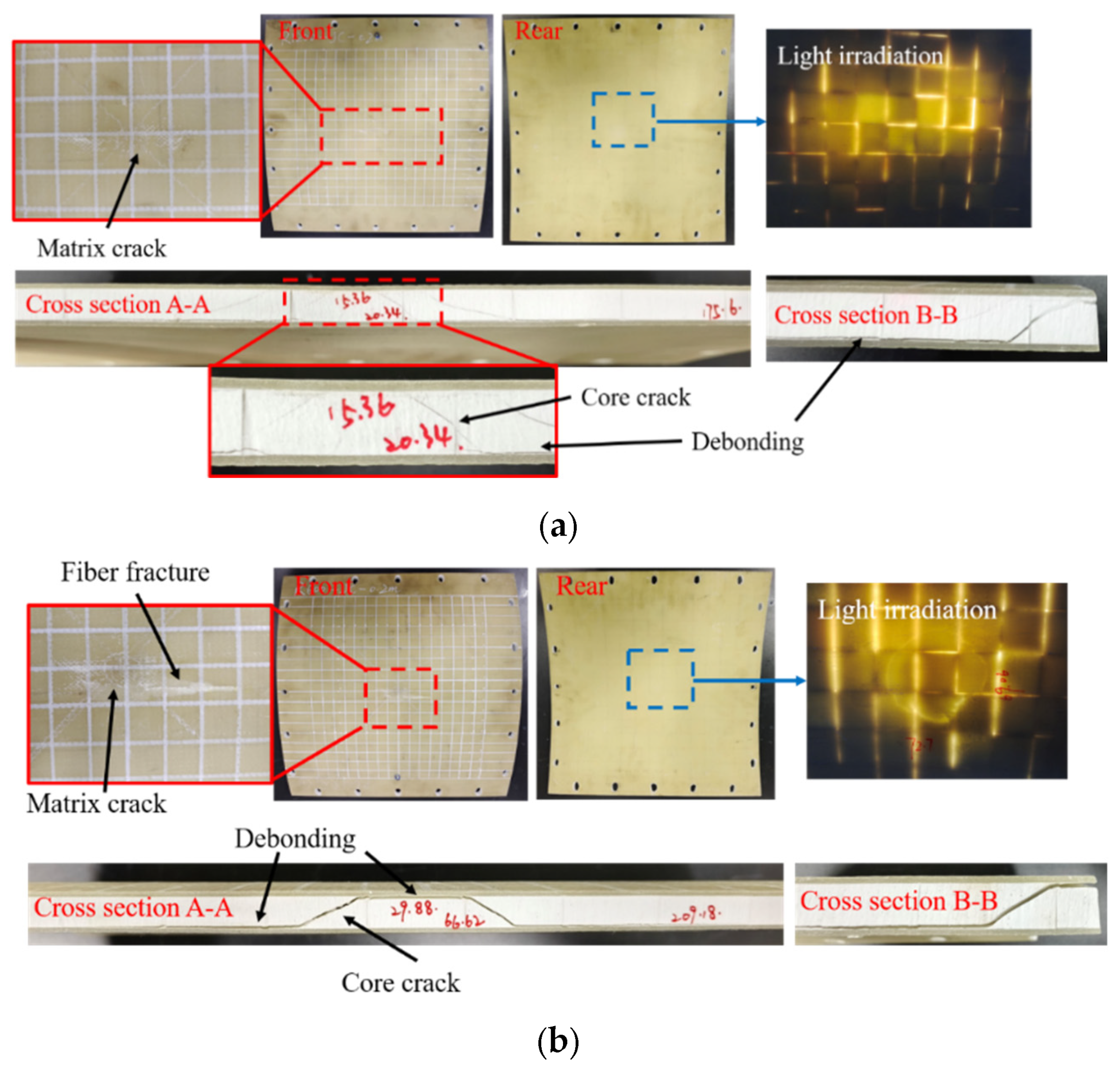

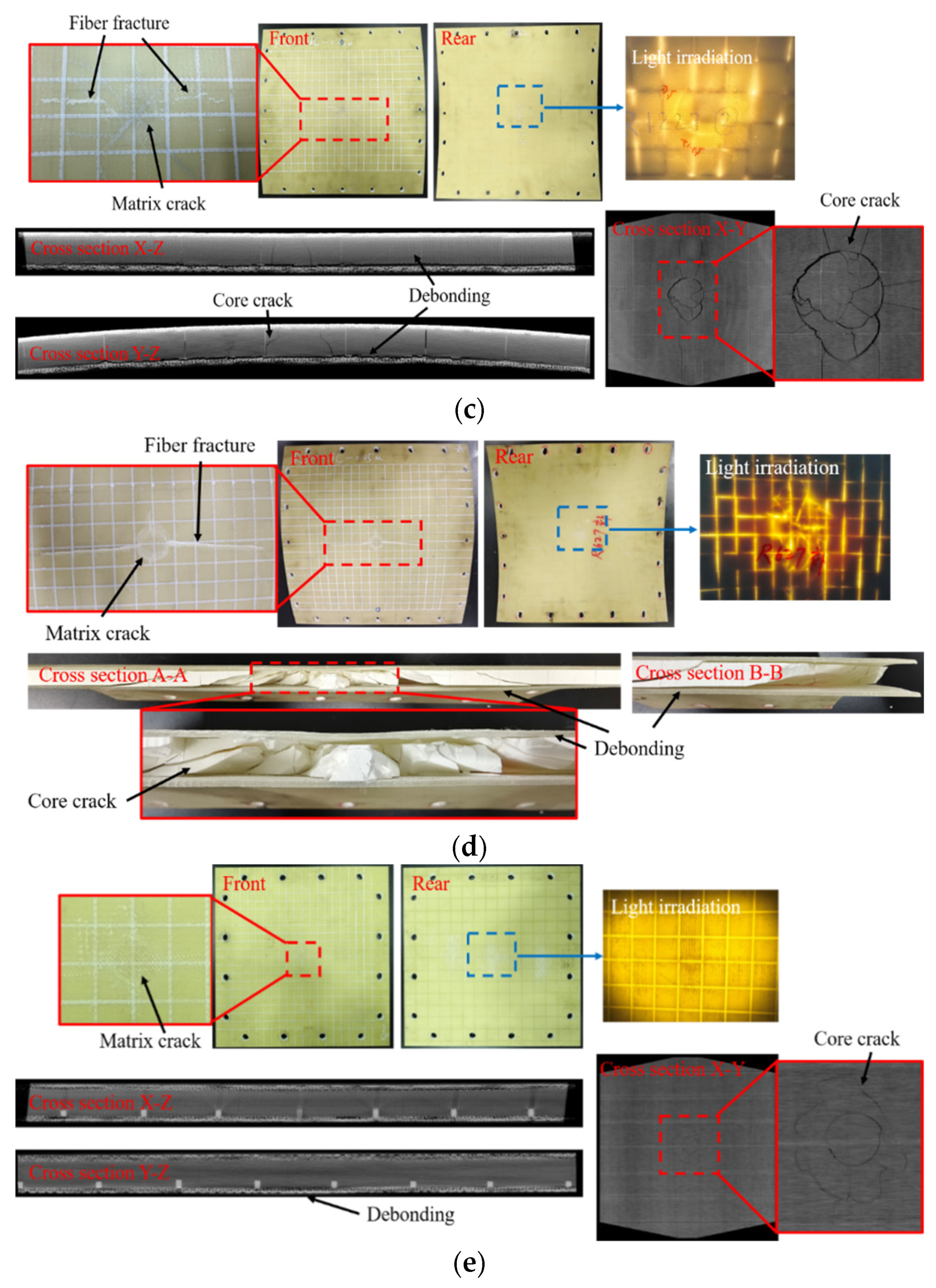

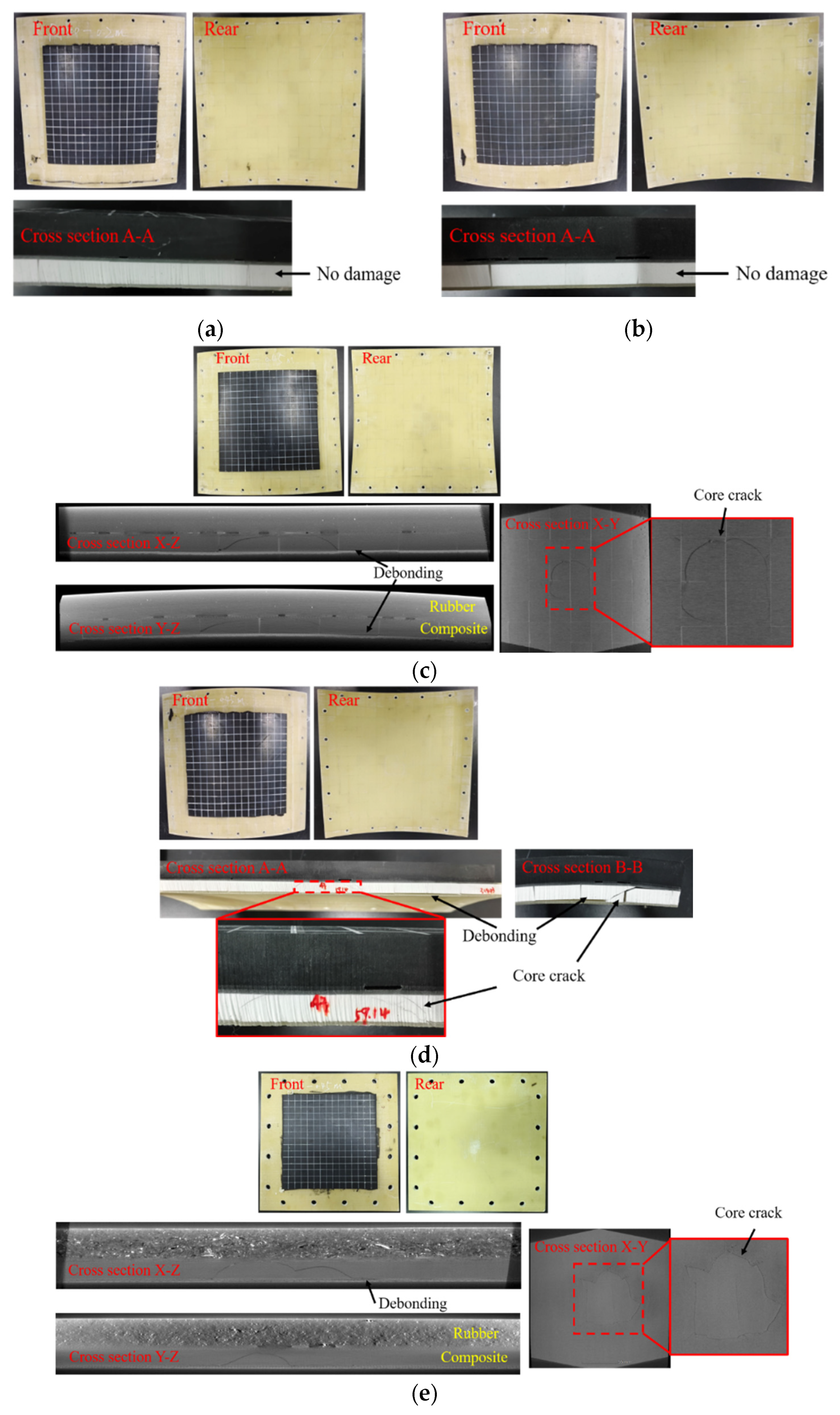

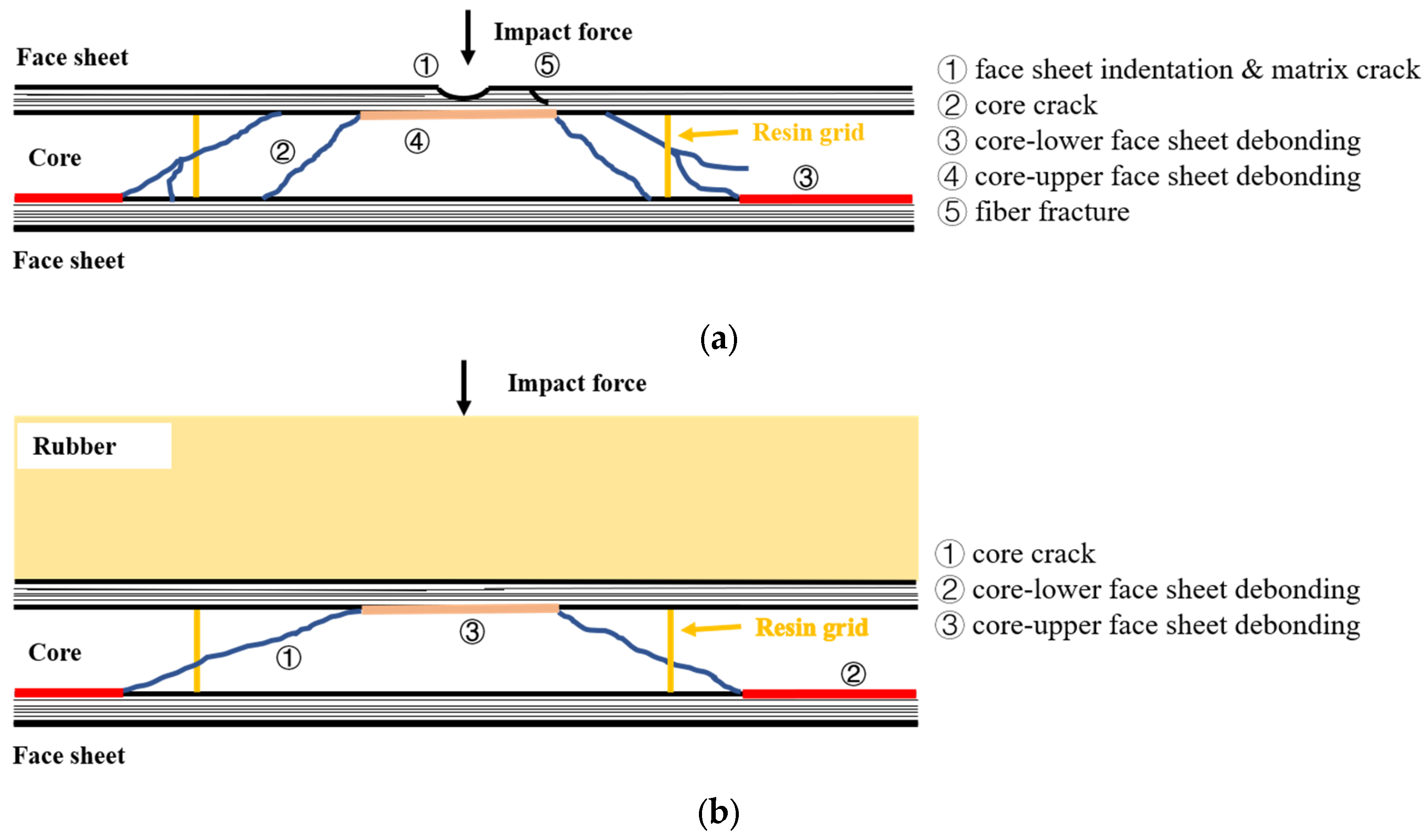

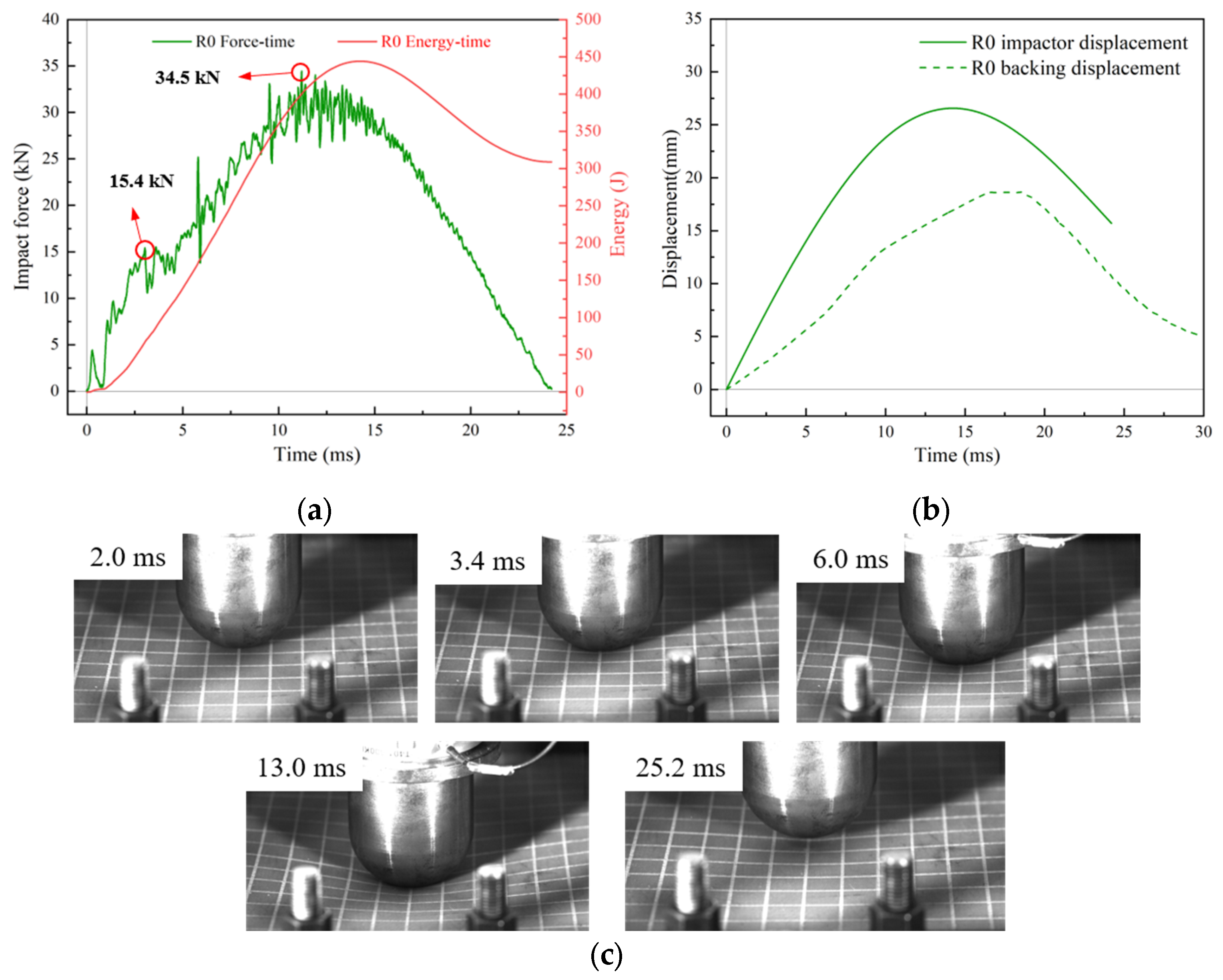

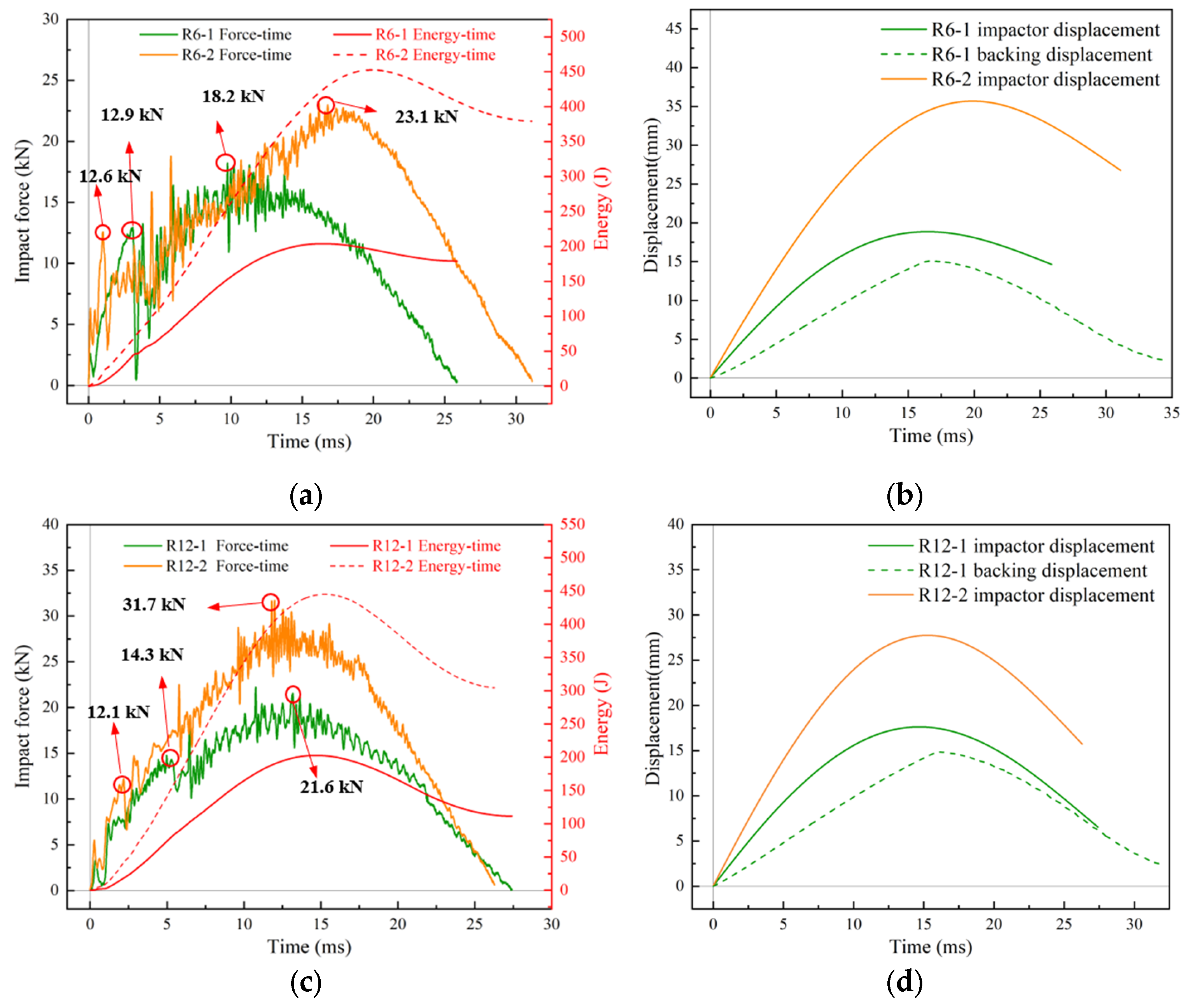

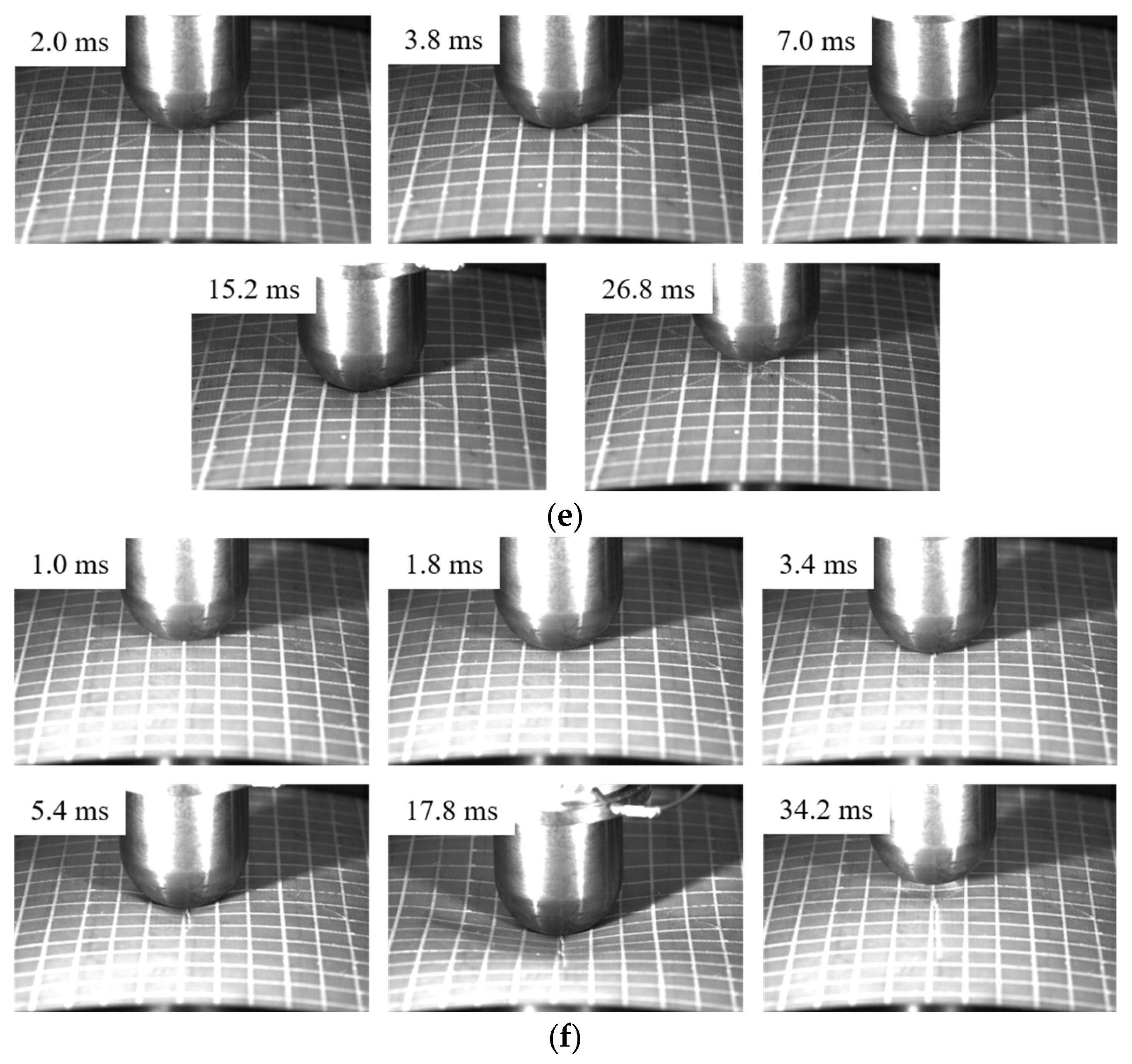

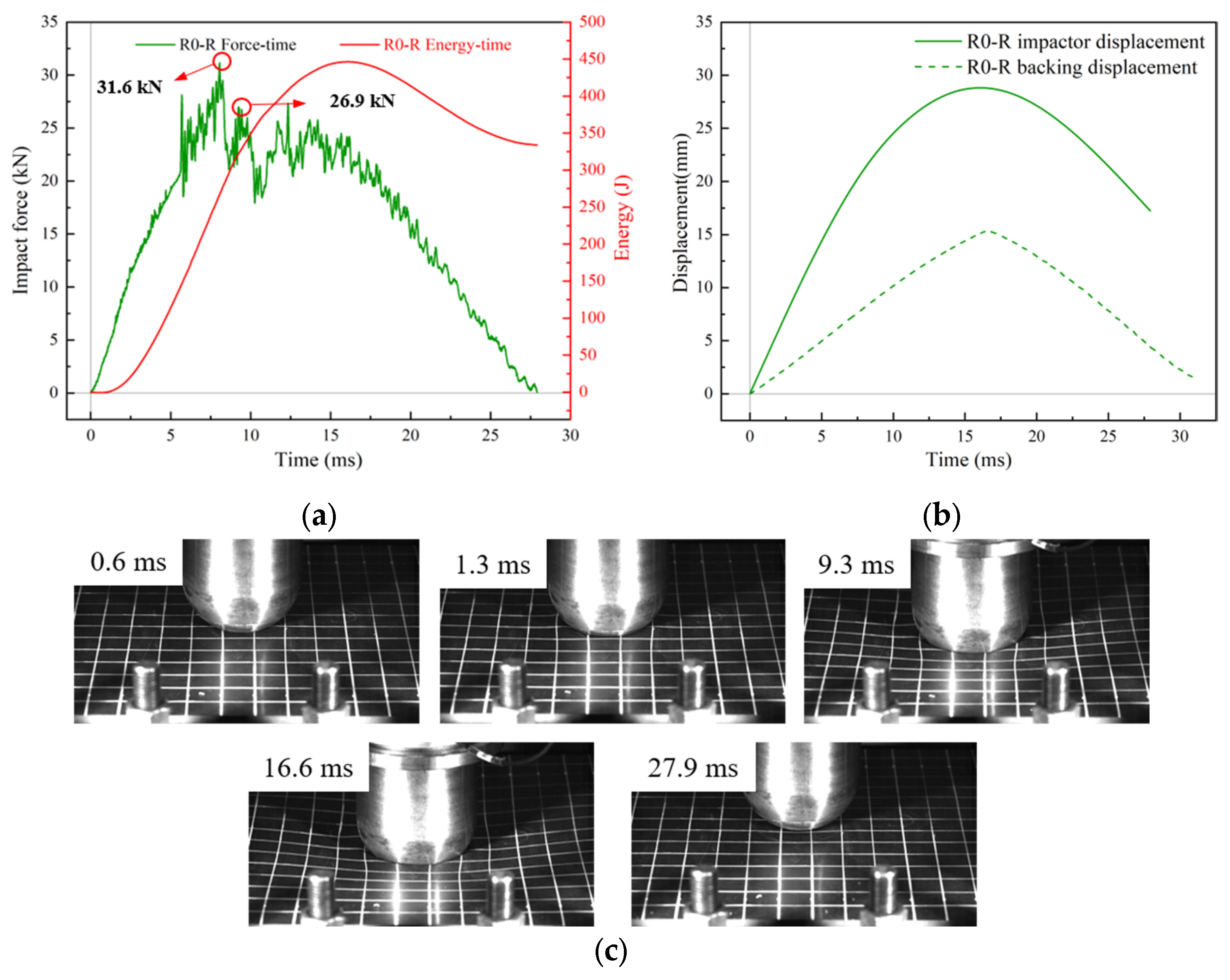

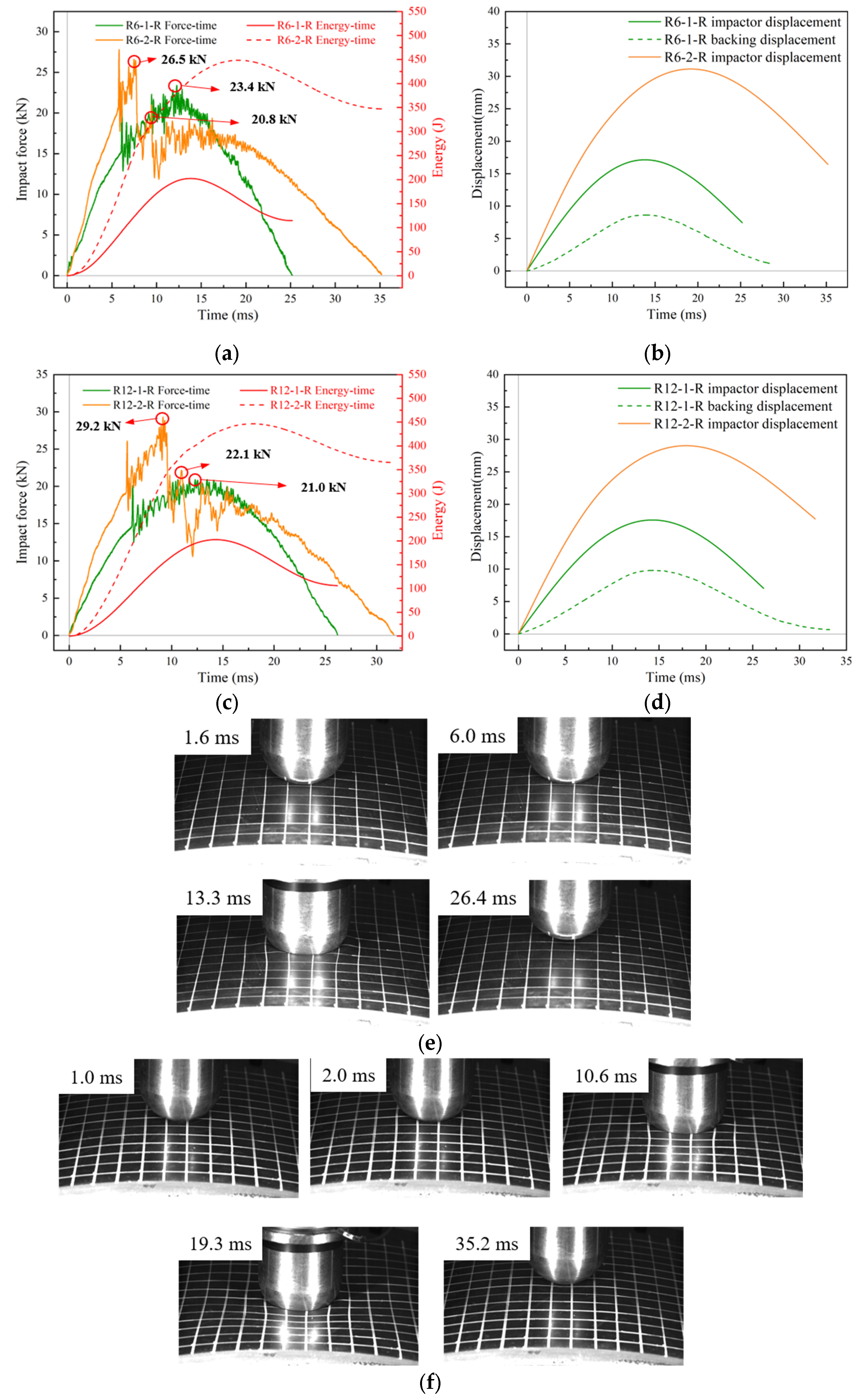

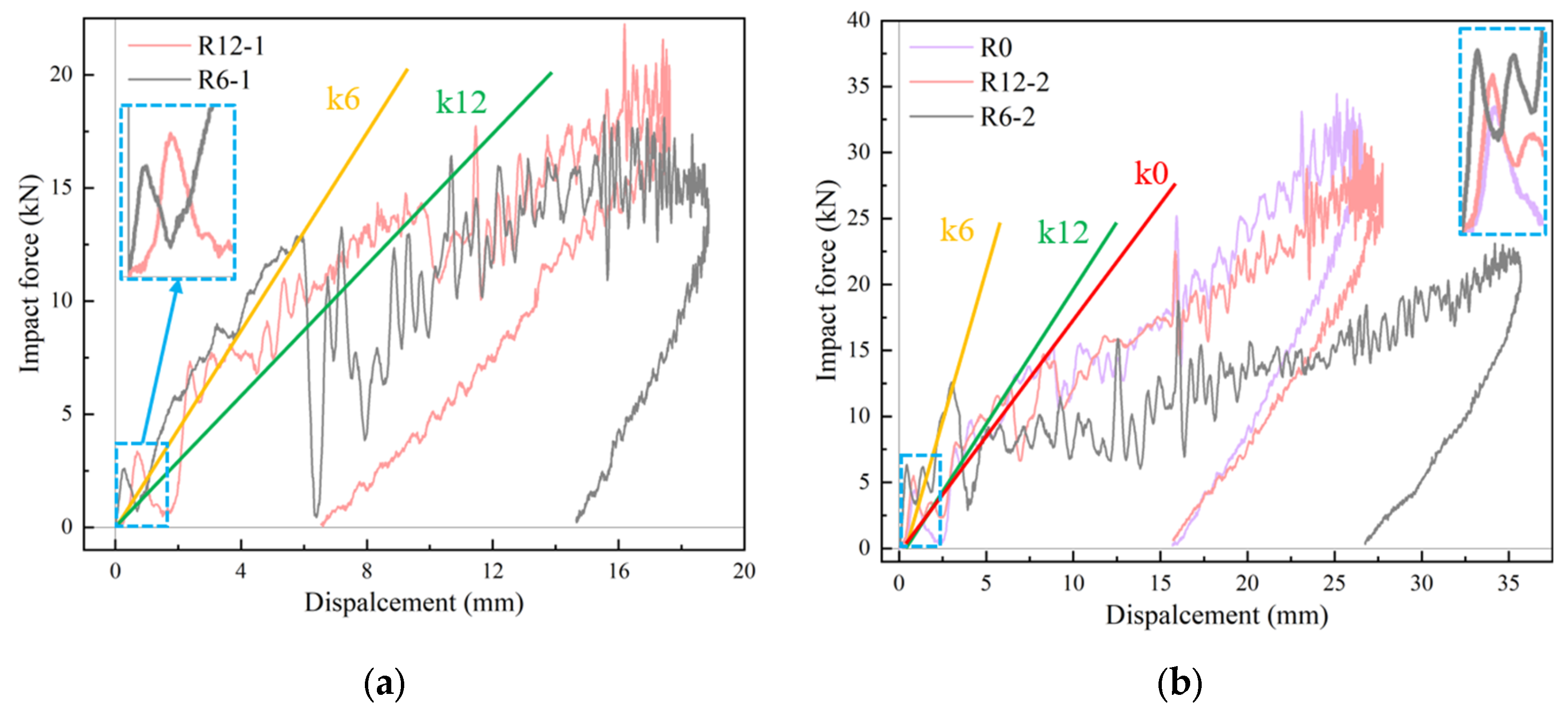

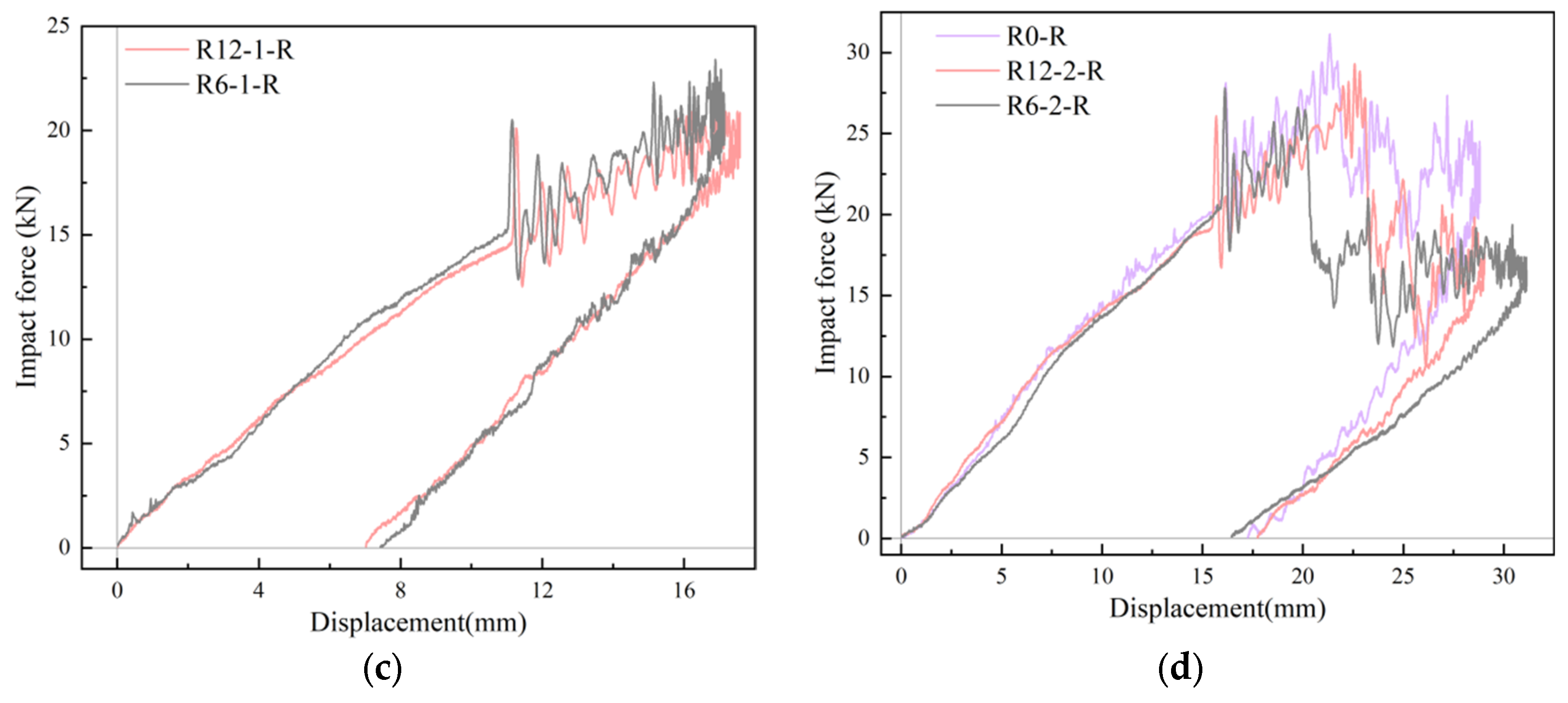

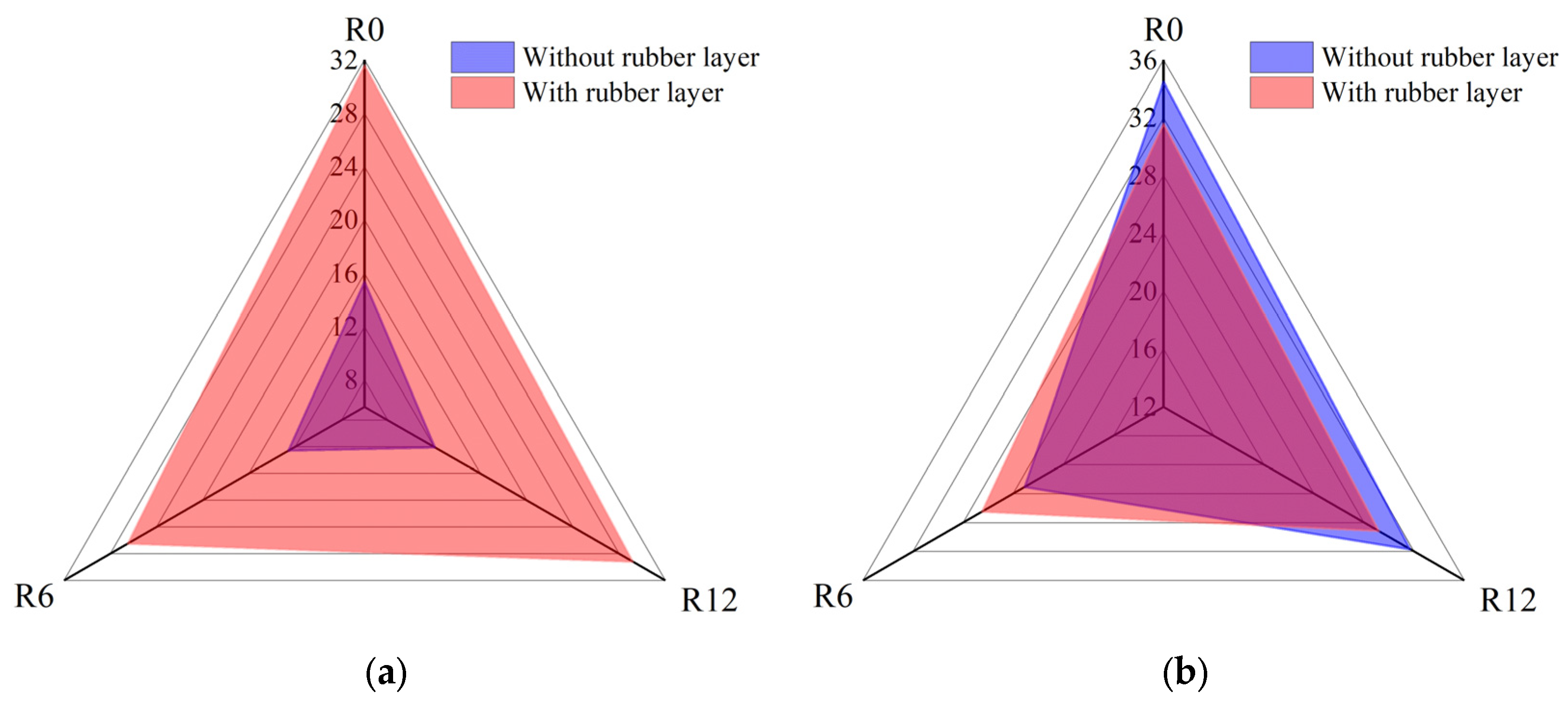

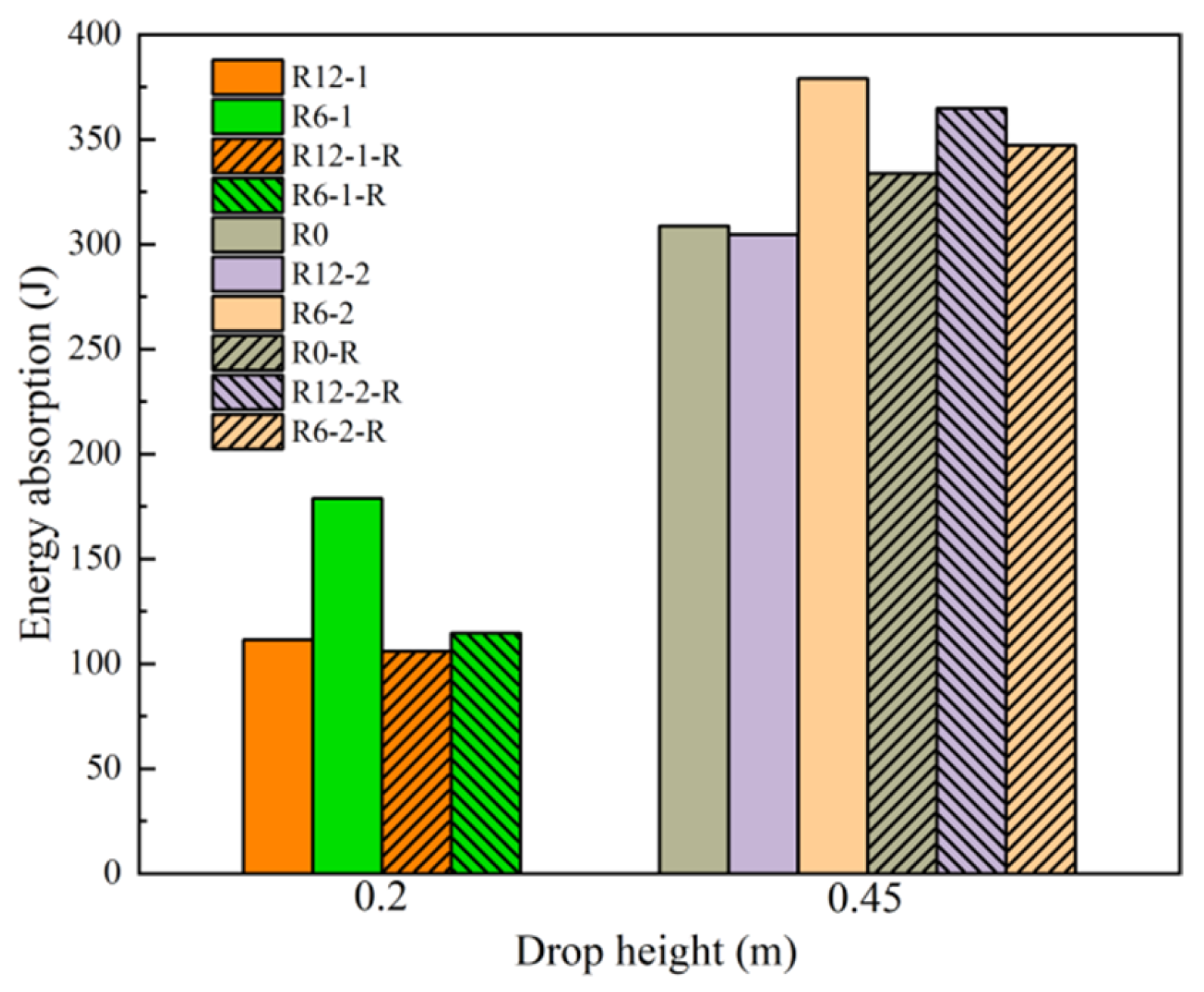

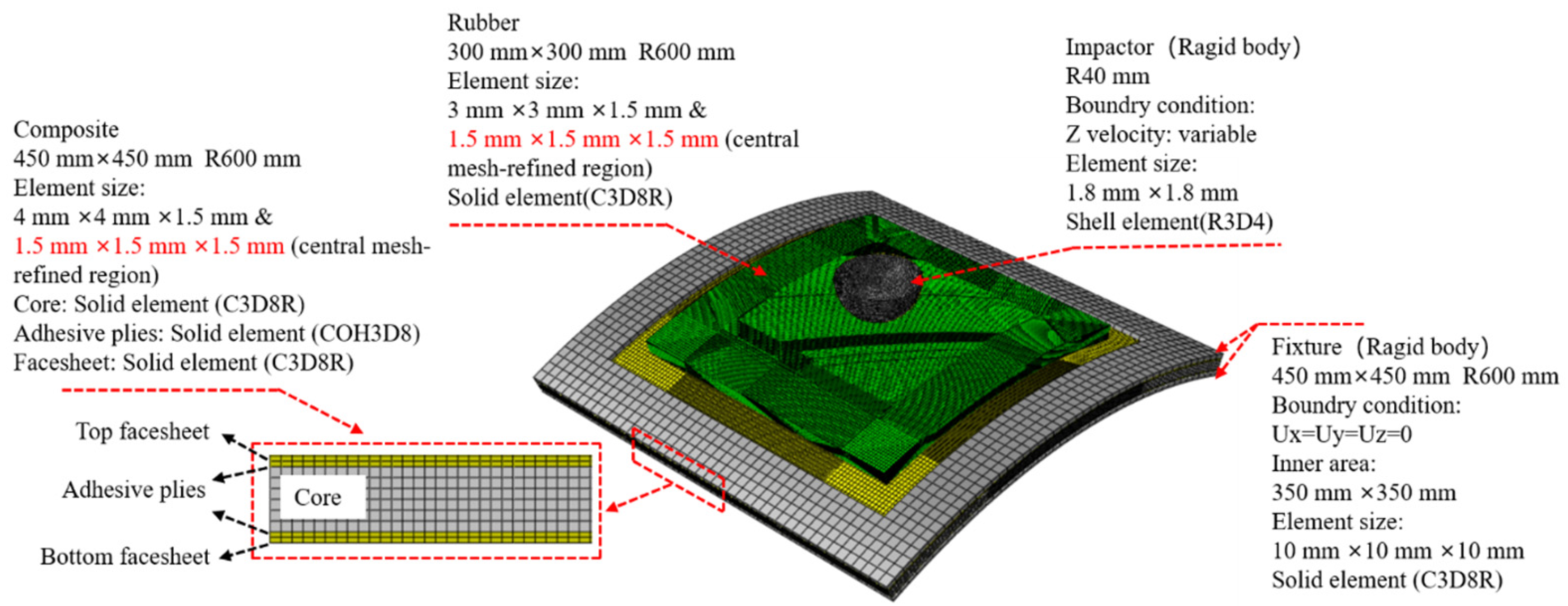

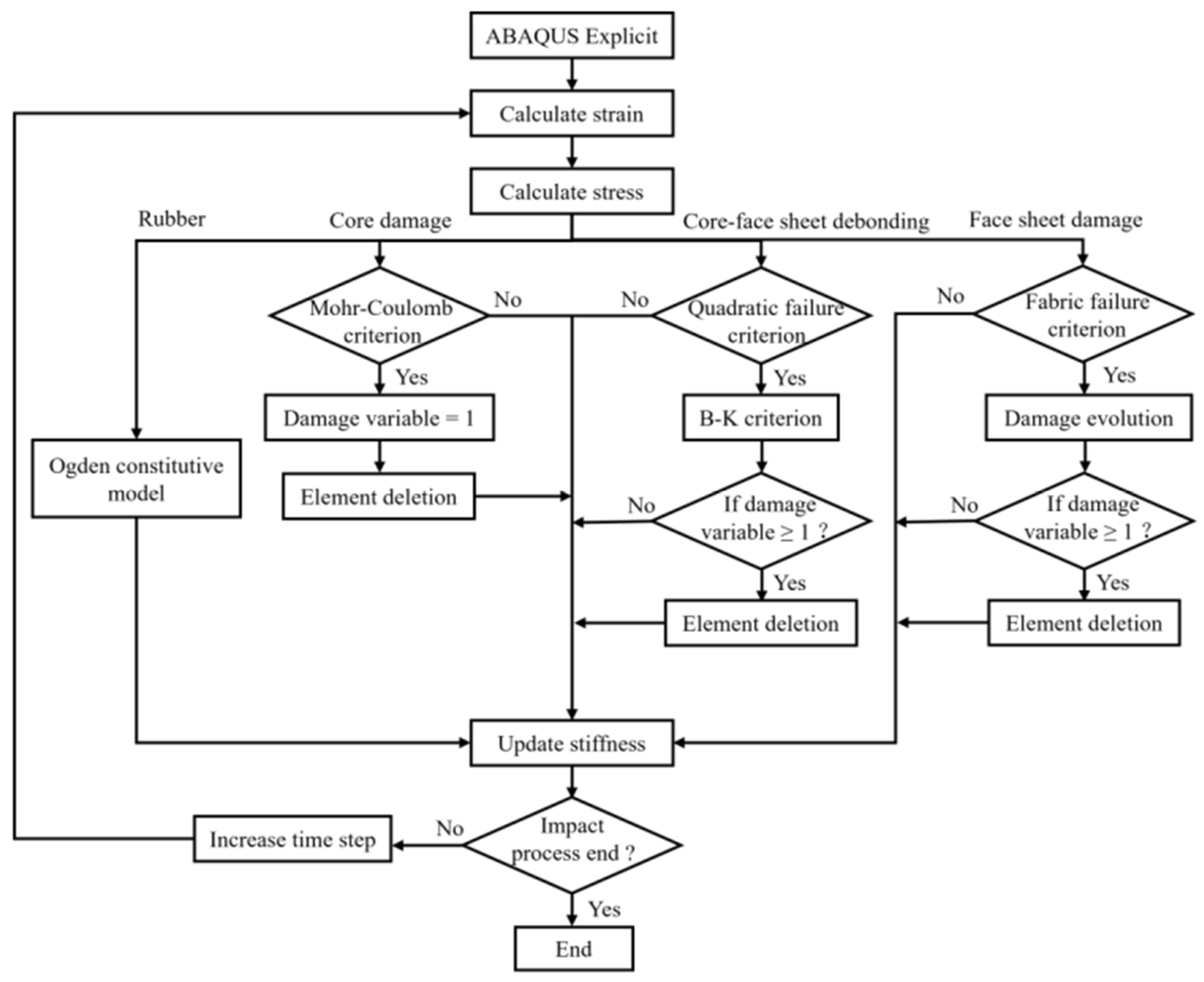

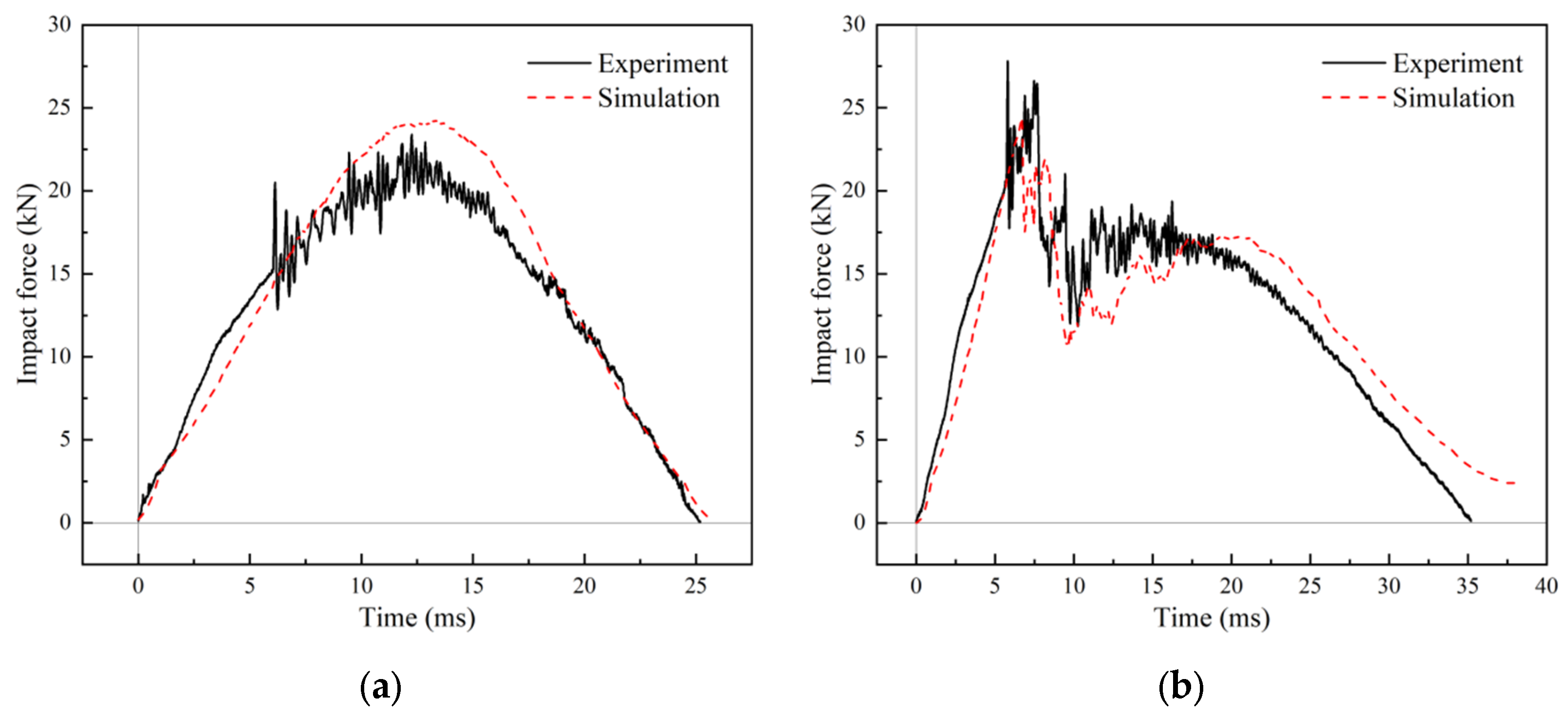

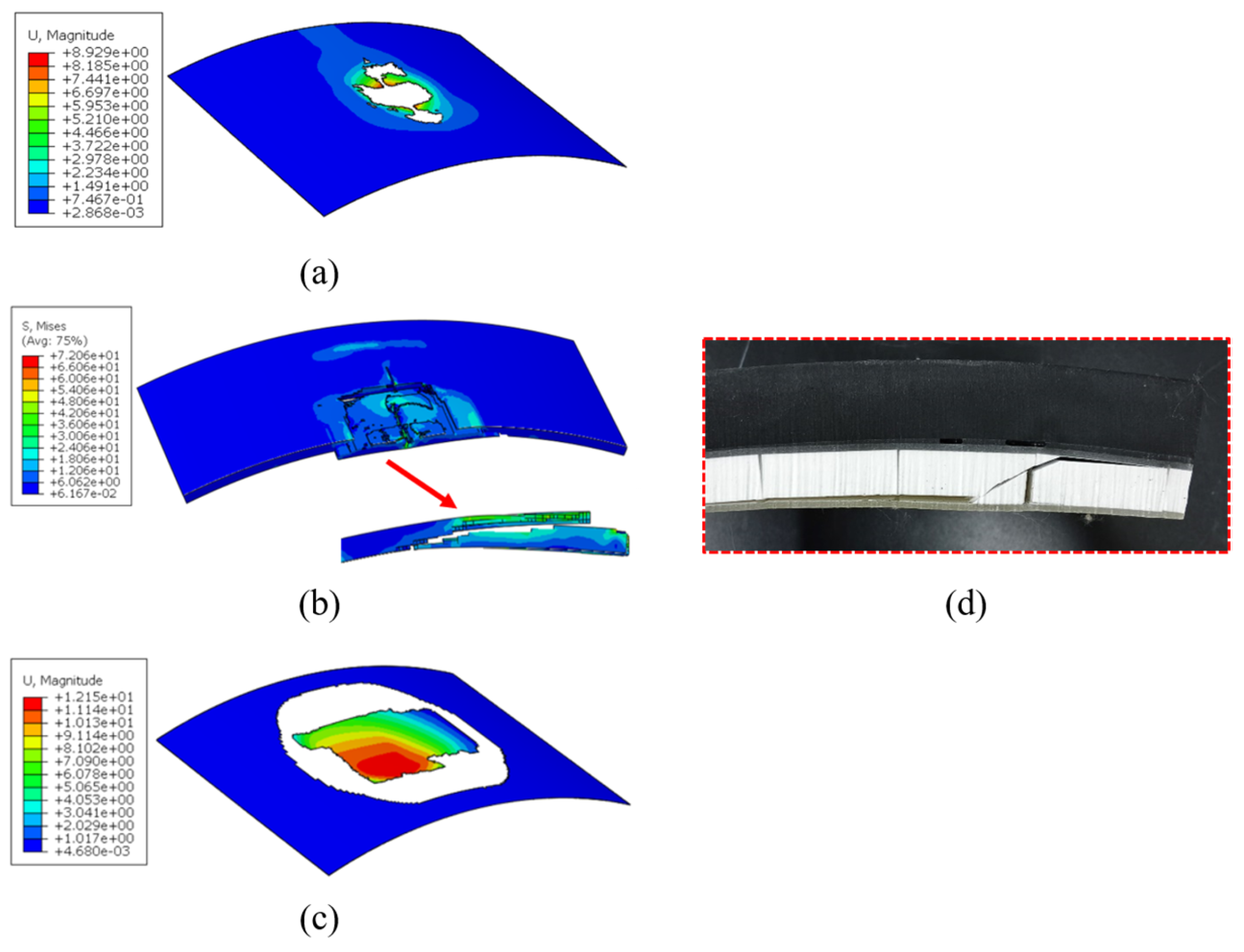

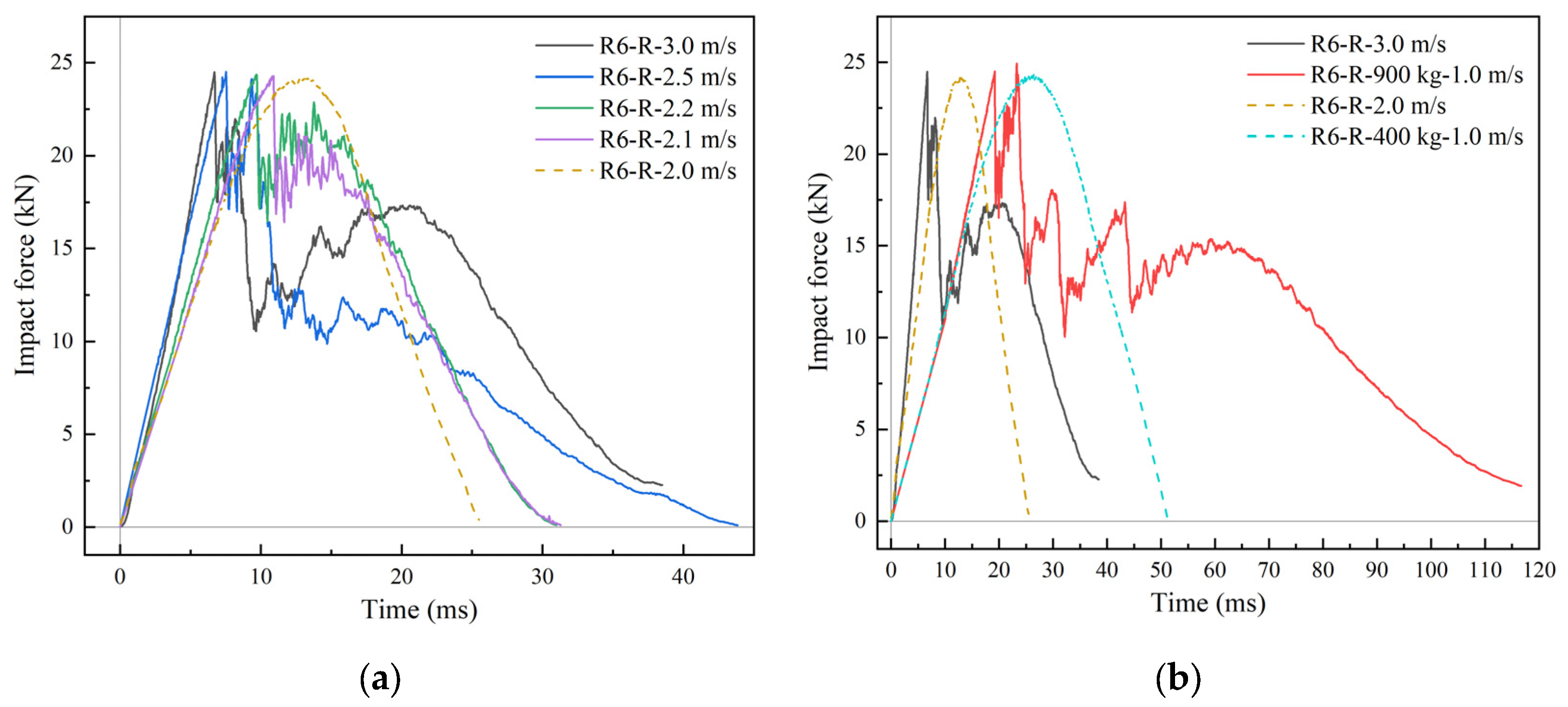

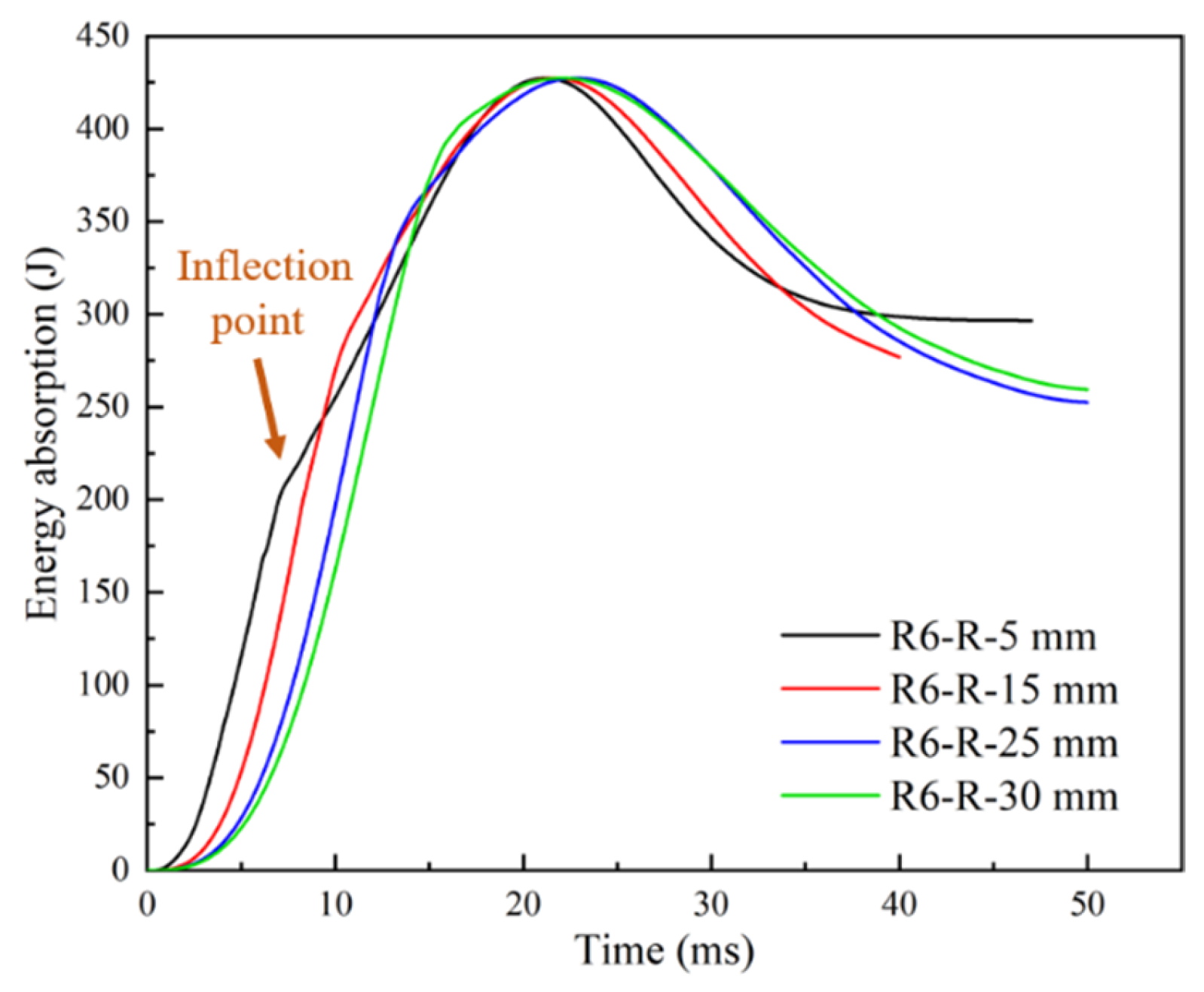

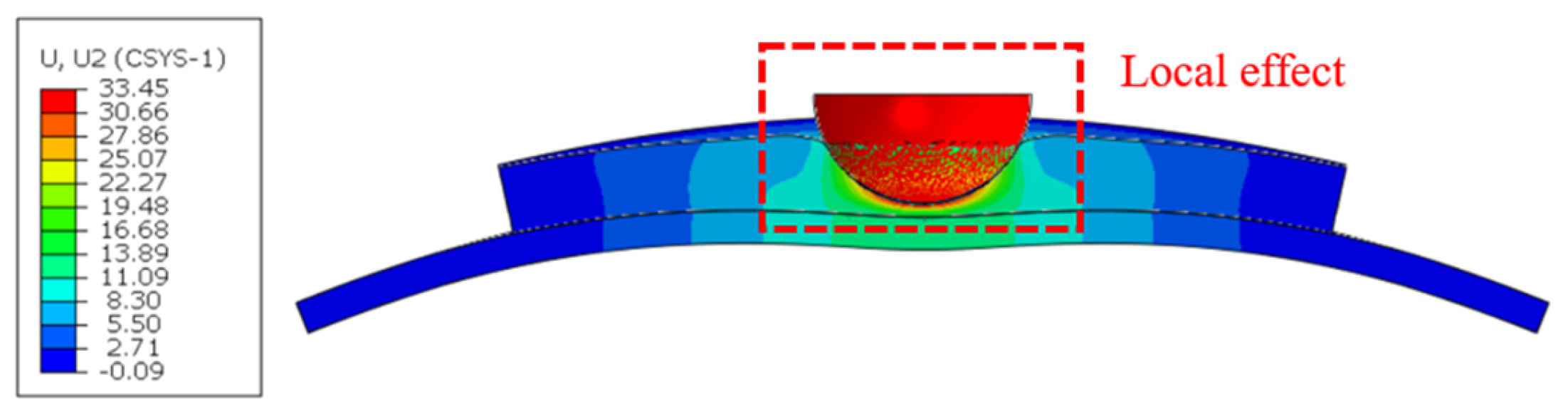

30]. Therefore, this paper proposes a rubber-coated (RC) BMC-SCS (RC-BMC-SCS) for deep-sea marine structures and investigates its impact resistance characteristics. The impact process is captured by force sensors, laser displacement sensors, and high-speed cameras. The damage morphology of the sandwich structure after impact is analyzed via waterjet cutting or computerized tomography (CT) technology. The effects of curvature and impact energy on the impact resistance of the sandwich structure are discussed, and the protection mechanism of the rubber is analyzed. Subsequently, a low-velocity impact FE model of a typical specimen is developed based on the experimental results, revealing the damage mechanism of the sandwich structure. Using this model, further efforts are made to explore the relationship between impact resistance and the impact energy or thickness of the rubber.