Study on the Road Performance of Terminal Carboxylated Nitrile Rubber-Modified Epoxy Asphalt Permeable Concrete

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Materials

2.2. Preparation of Modified Bitumen

2.3. Asphalt Test Methods

- Tensile TestThe cured modified bitumen was cooled and demolded under standard test conditions (23 °C ± 2 °C) and subsequently maintained at the same temperature for 2 h to ensure uniform conditioning. The tensile test was performed using a universal material testing machine (Shanghai Tuofeng Instruments Technology Co., Ltd, Shanghai, China) with a tensile rate of 500 mm/min ± 50 mm/min. This test was conducted to evaluate the tensile strength and elongation properties of the modified bitumen, providing insights into its mechanical performance under stress.

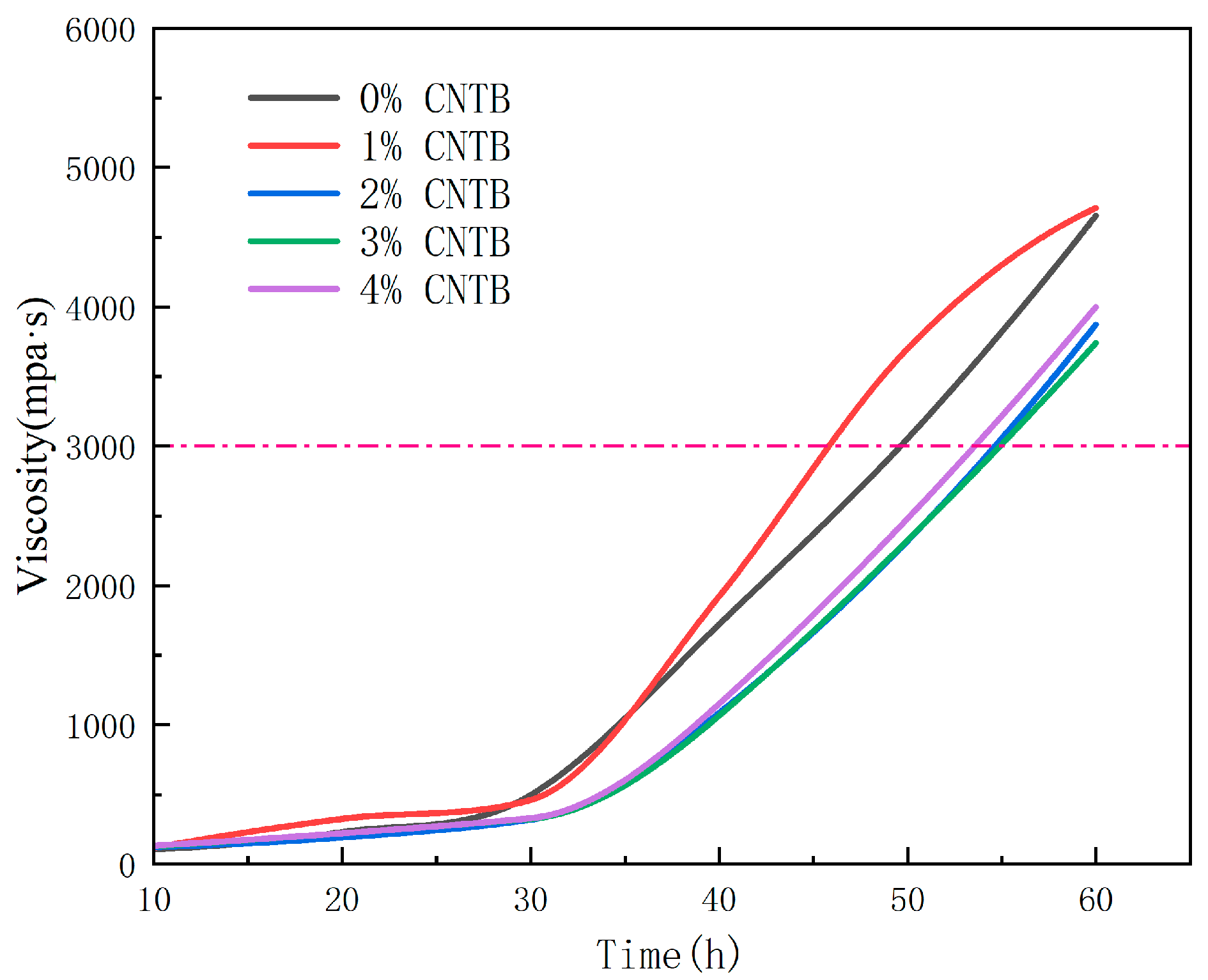

- Brinell Rotational Viscosity TestTo assess the viscosity characteristics of the modified asphalt during construction, the Brinell rotational viscosity test was conducted using a 27-rotor spindle (Shanghai Changji Geological Instruments Co., Ltd, Shanghai, China) at a rotational speed of 100 RPM. The test was performed at a temperature of 120 °C, with the torque range maintained between 10% and 98%. The objective was to determine the target viscosity and the time required to achieve it, which are critical parameters for evaluating the workability and application performance of the modified asphalt.

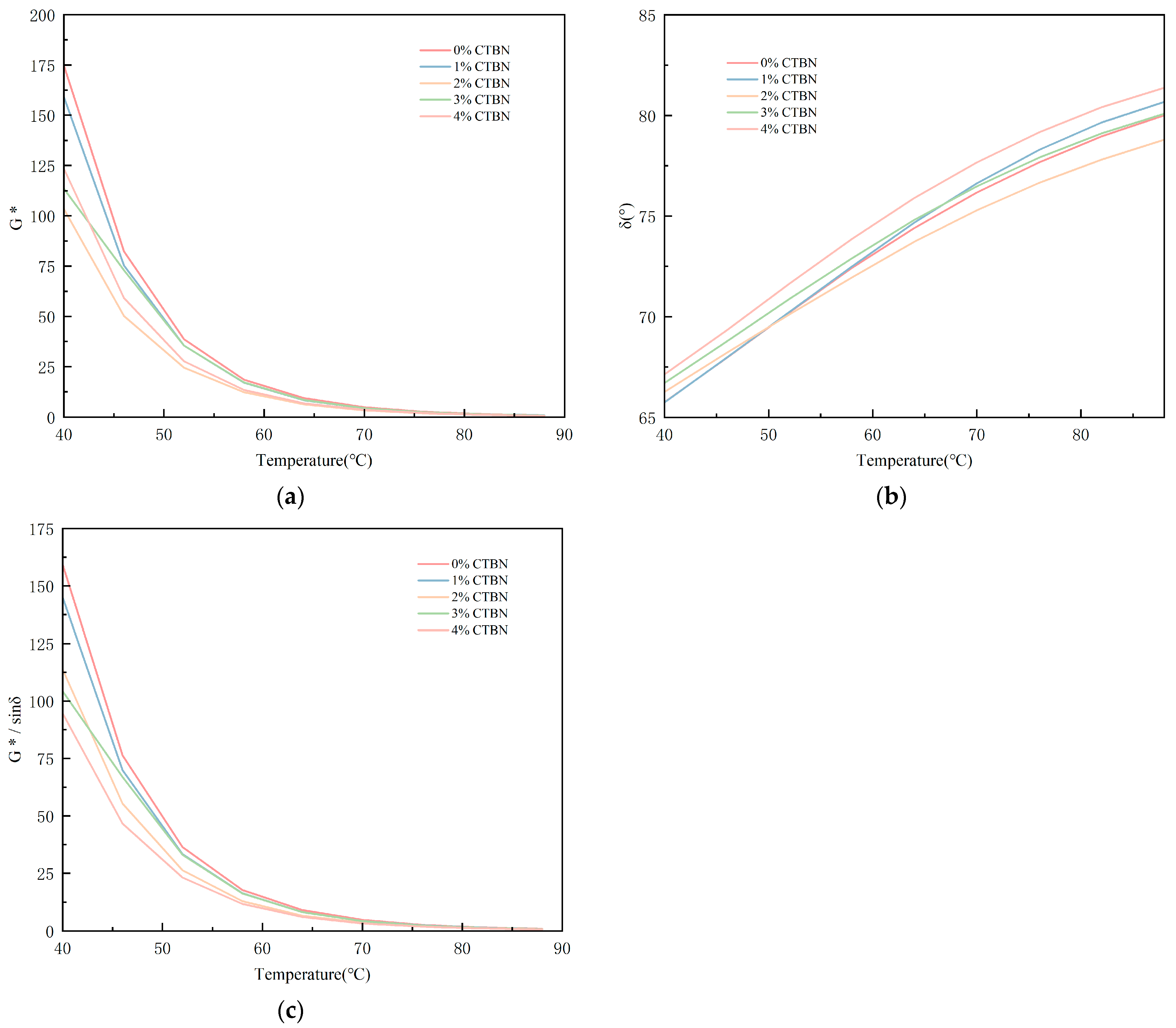

- Temperature Scanning TestThe temperature scanning experiment was performed using Anton Paar’s MCR rheometer (Anton Paar GmbH, Graz, Austria) to analyze the rheological properties of the asphalt binder. The scanning temperature ranged from 40 °C to 82 °C (increments of 6 °C: 40, 46, 52, 58, 64, 70, 76, and 82 °C) at a constant angular velocity of 10 rad/s. This test aimed to measure the high-temperature rutting resistance of the asphalt binder, providing data on its stiffness and deformation behavior under varying thermal conditions.

- Bending Beam Rheometer (BBR) TestThe BBR test was conducted to evaluate the low-temperature cracking resistance of the modified asphalt. Three test temperatures (−12 °C, −18 °C, and −24 °C) were selected to simulate cold climatic conditions. The test measured the creep stiffness (S) and stress relaxation capacity (m) of the asphalt binder, which are critical indicators of its ability to resist thermal cracking and maintain flexibility at low temperatures.

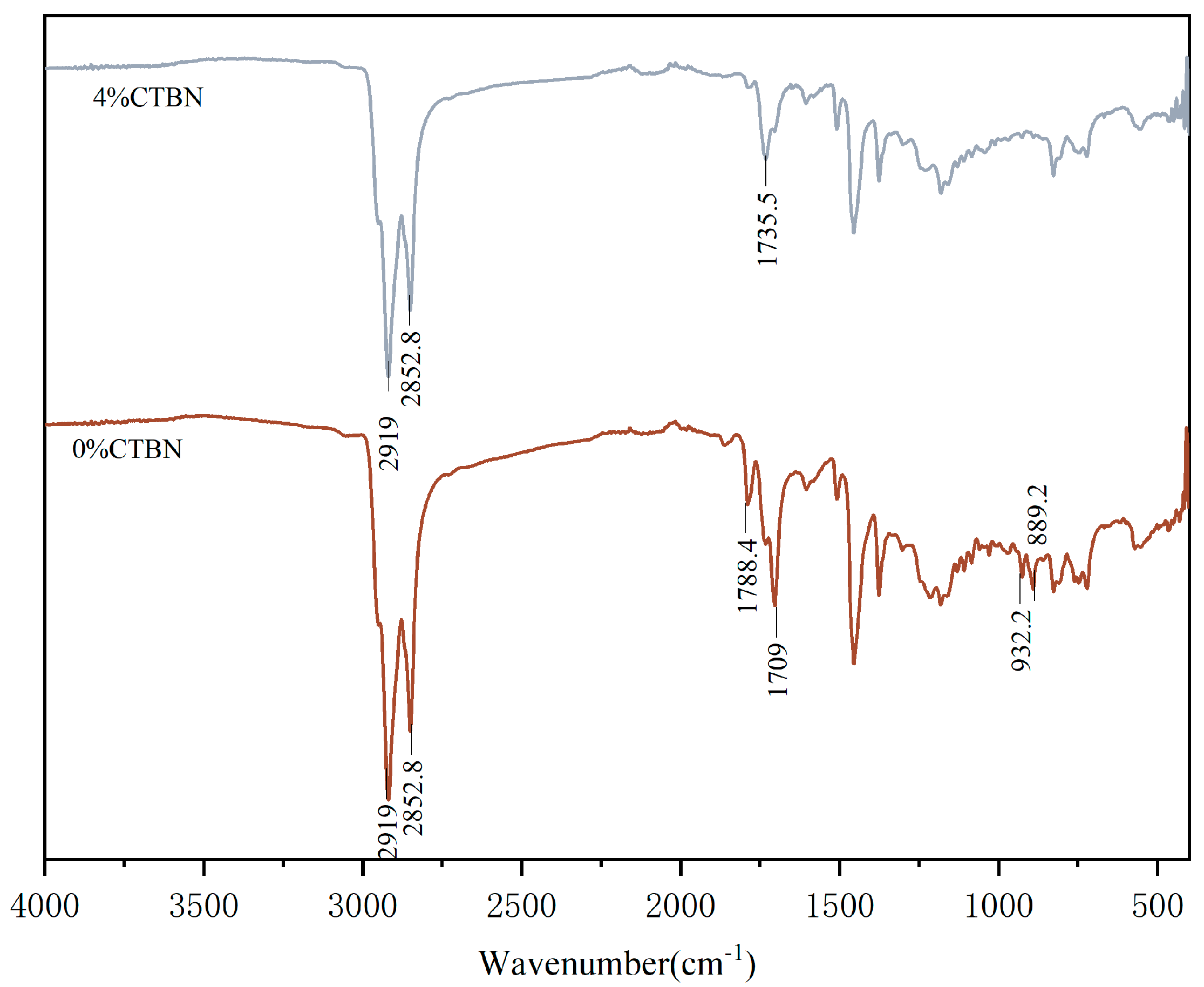

- Fourier Transform Infrared Spectroscopy (FTIR)FTIR analysis was performed to identify the chemical changes and functional group differences between unmodified and CTBN-modified asphalt. The test was conducted over a wavelength range of 400–4000 cm−1, capturing the characteristic absorption peaks associated with specific chemical bonds. This analysis provided insights into the chemical modification mechanism and the interaction between CTBN and the asphalt matrix.

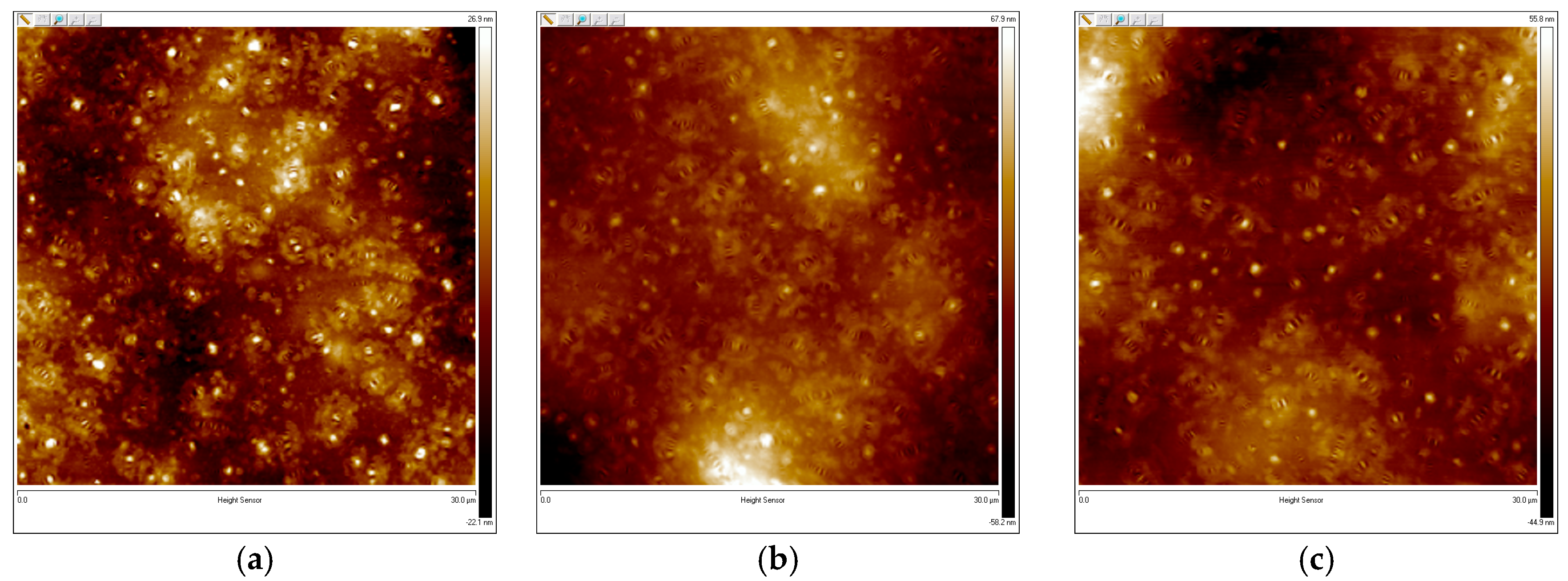

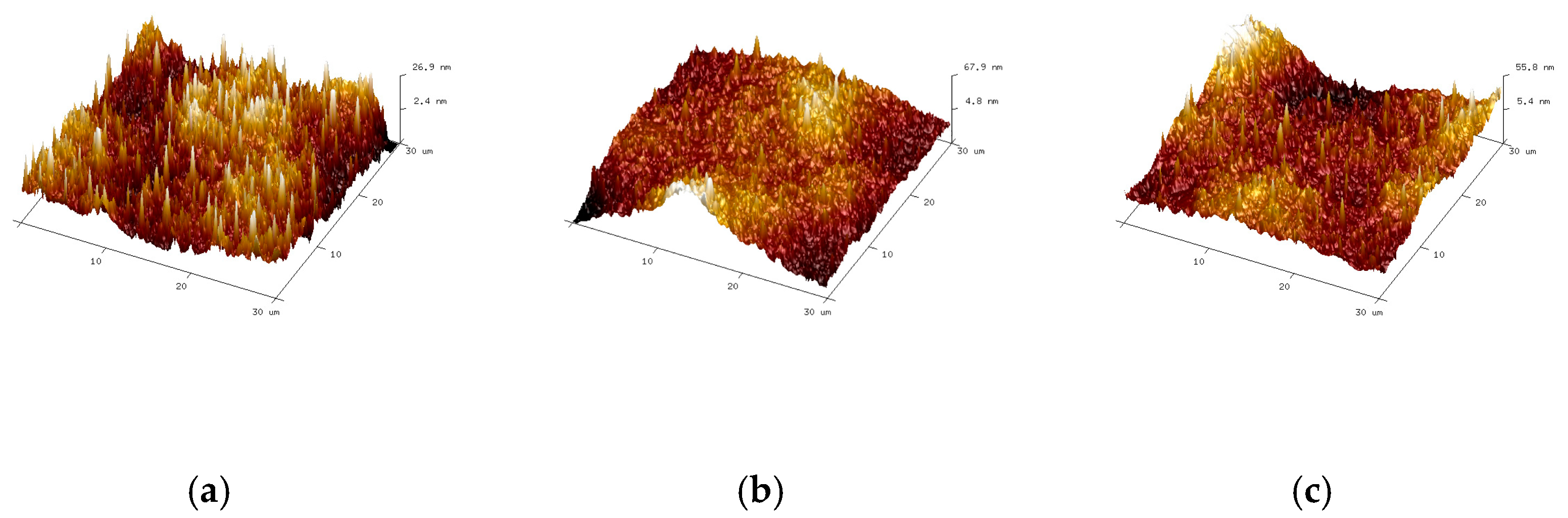

- Atomic Force Microscopy (AFM)AFM was employed to characterize the surface morphology of CTBN-modified bitumen at a test temperature of 25 °C. The microscopic images were captured using the tapping mode of AFM (Bruker Corporation, Billerica, MA, USA) with a scanning range of 30 μm × 30 μm. The test results were analyzed using specialized software (NanoScope Analysis 3.0) to study the microstructure and phase distribution of the modified bitumen, offering a detailed understanding of its surface properties and homogeneity.

2.4. Asphalt Concrete Test Methods

- Indoor Rutting TestThe indoor rutting test was conducted to assess the high-temperature performance of porous asphalt concrete (PAC). The test was performed at a loading rate of 42 cycles per minute, with a tire-applied pressure of 0.7 MPa and a test temperature of 60 °C. The specimens were conditioned at the test temperature for 5 h, followed by an experimental duration of 1 h. This test aimed to measure the rutting depth and deformation resistance of PAC under simulated high-temperature traffic conditions.

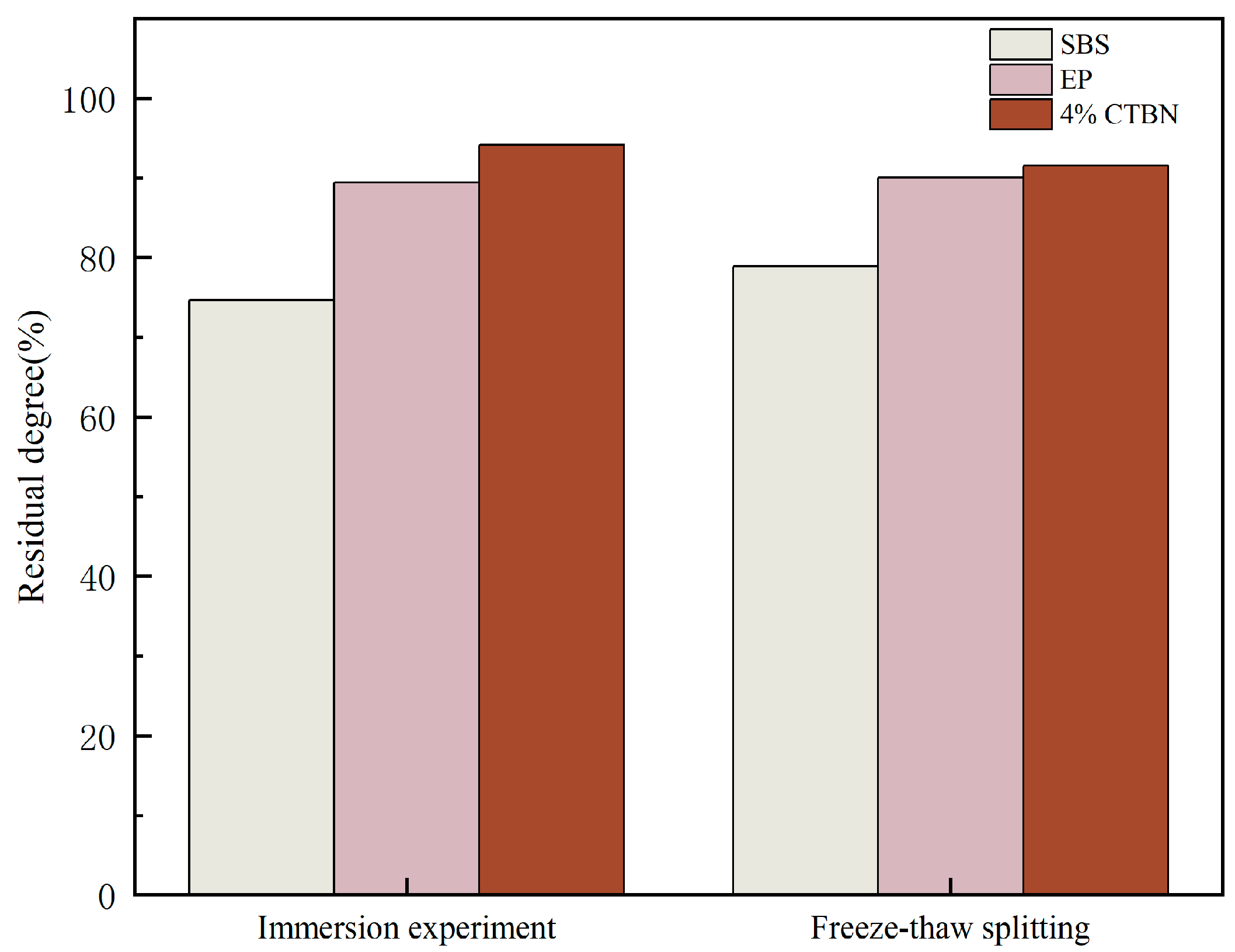

- Water Immersion Marshall TestThe water immersion Marshall test was carried out to evaluate the water stability of PAC. Two groups of Marshall specimens were prepared, each compacted 50 times. One group was immersed in a 60 °C water bath for 0.5 h, while the other group was immersed for 48 h. After immersion, both groups were maintained at 25 °C, and their Marshall stability values were determined. This test provided insights into the durability and resistance of PAC to water-induced damage.

- Freeze–Thaw Splitting Test

- The freeze–thaw splitting test was performed to assess the resistance of PAC to freeze–thaw cycles. The specimens were divided into two groups: one group was tested directly, while the other group underwent a 15-minute water saturation treatment, followed by 0.5 h of static water immersion, 16 h at −18 °C, and 24 h in a 60 °C water bath. Both groups were then placed in a 25 °C water bath for 2 h before testing. The splitting strength was determined at a loading rate of 50 mm/min and a temperature of 25 °C, providing data on the material’s performance under freeze–thaw conditions.

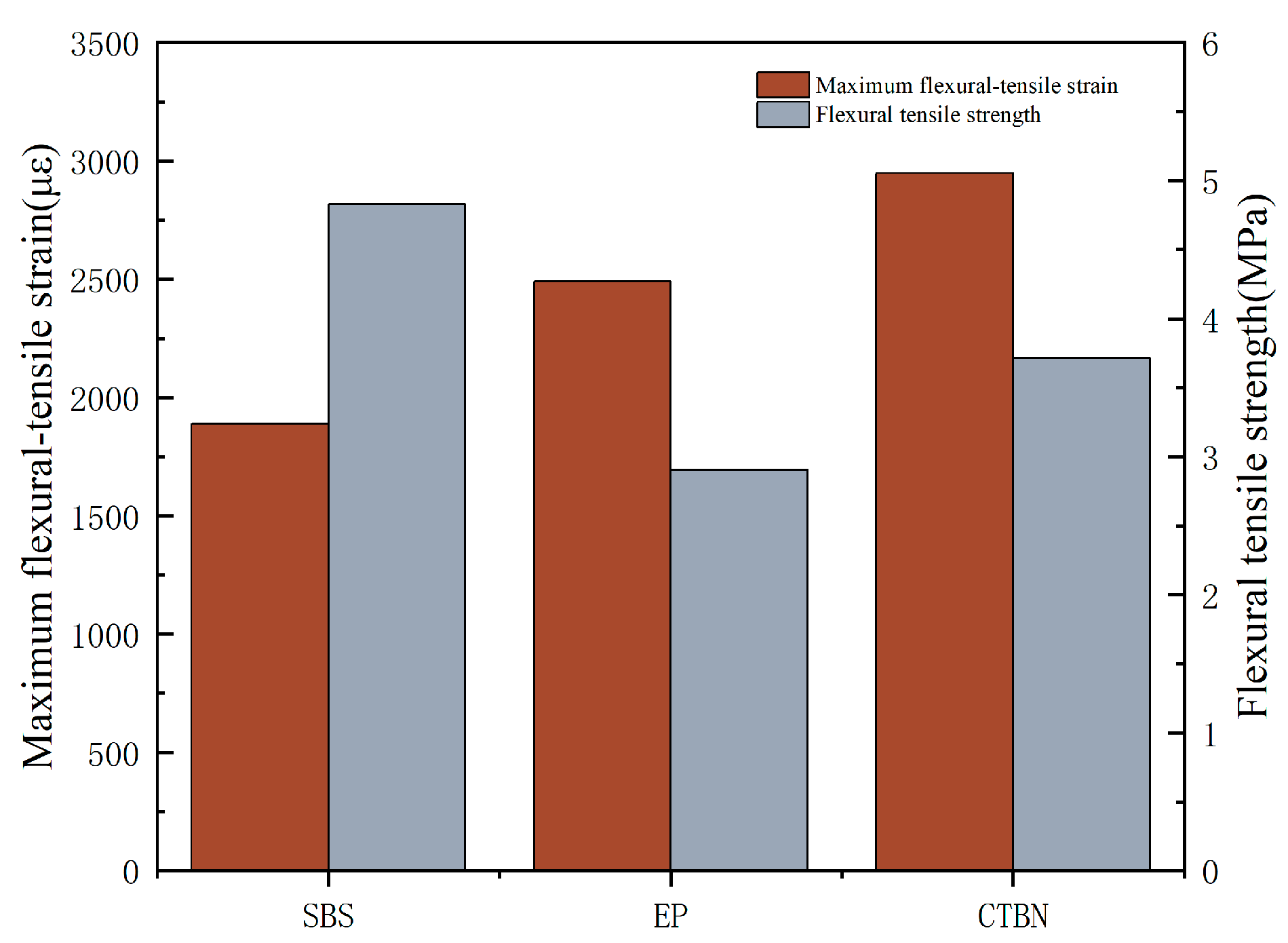

- Low-Temperature Trabecular Bending TestThe low-temperature trabecular bending test was conducted to evaluate the low-temperature performance of PAC. The test specimens had dimensions of 250 mm in length, 30 mm in width, and 35 mm in height, with a span of 200 mm. Prior to testing, the specimens were conditioned at −10 °C for 45 min. The test was performed at a loading rate of 50 mm/min to measure the bending strength and flexibility of PAC under low-temperature conditions, simulating its behavior in cold climates.

3. Results

3.1. CTBN-Modified Asphalt Material Performance Test Results

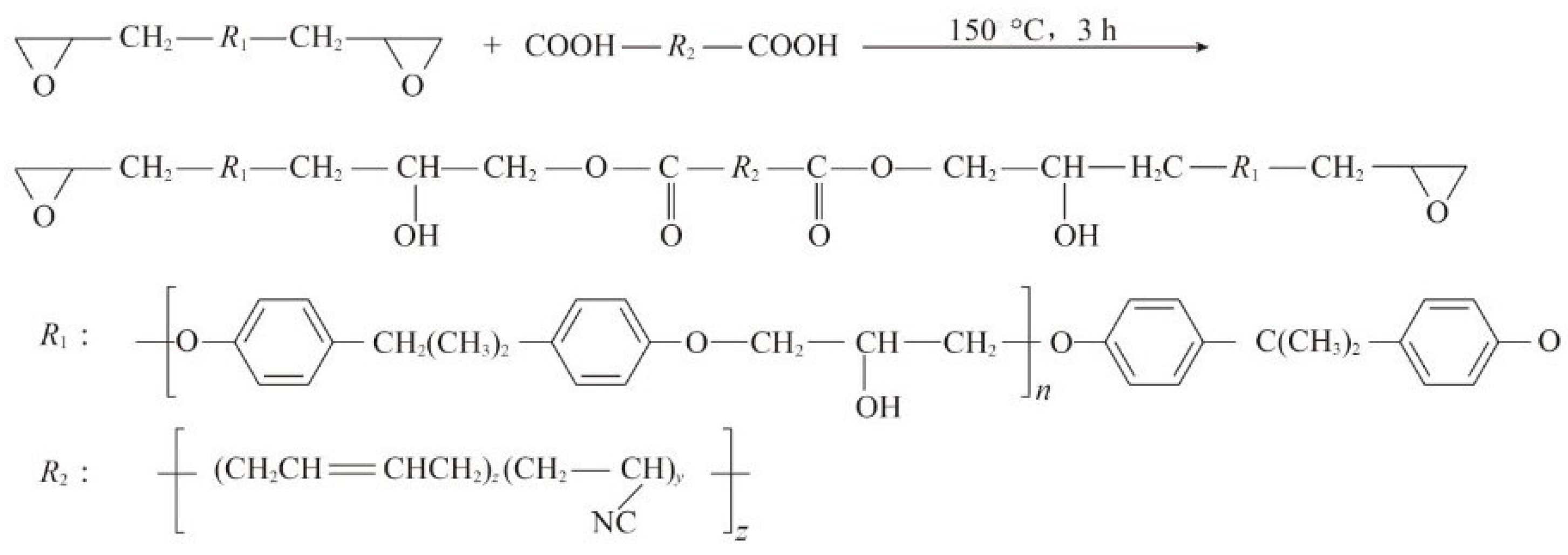

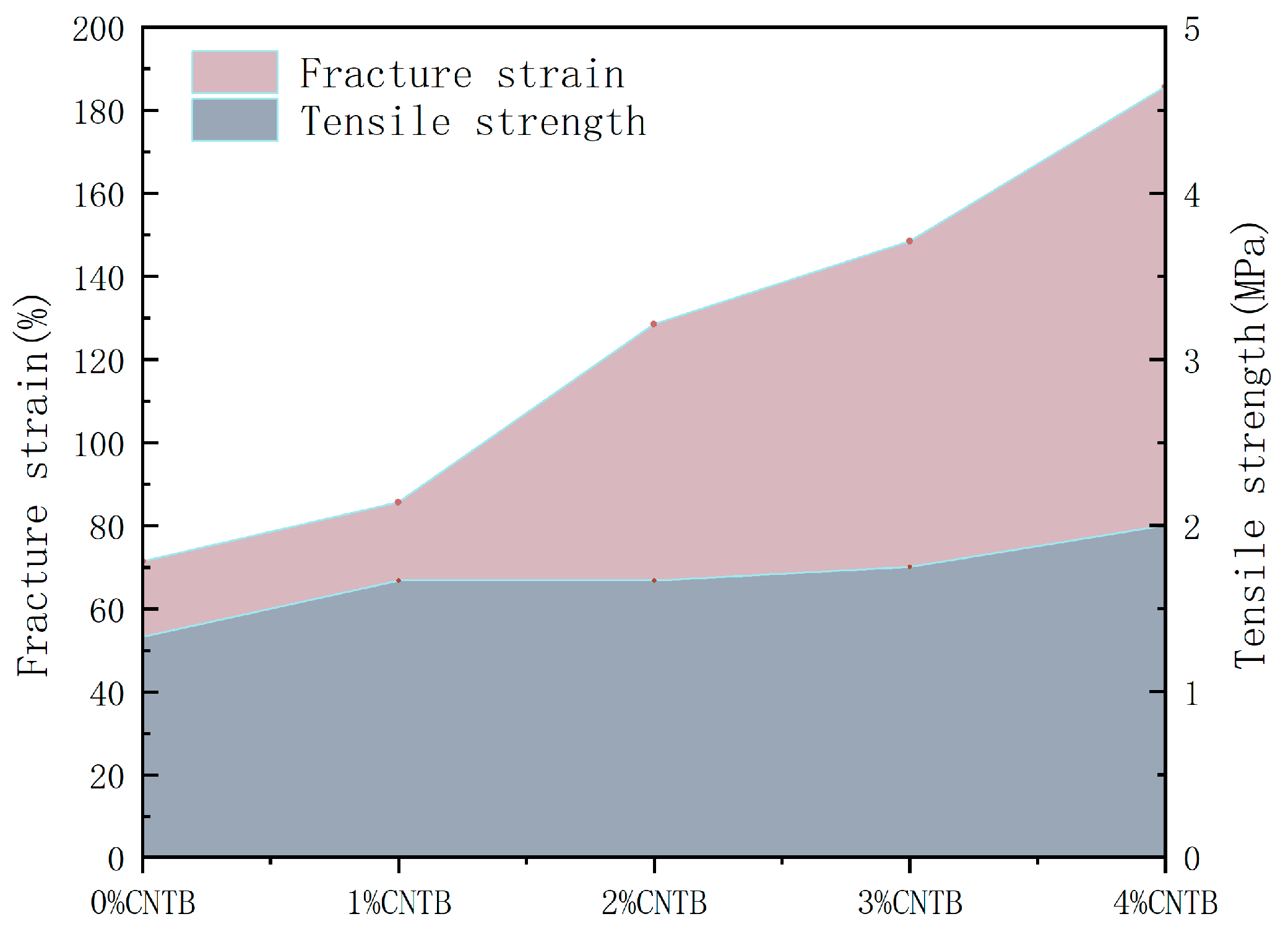

3.1.1. Tensile Test Results

3.1.2. Brinell Rotational Viscosity Test Results

3.1.3. Bending Beam Rheometer Experiment (BBR) Results

3.1.4. Temperature Scanning Experiment Results

3.1.5. Fourier Transform Infrared Spectroscopy (FITR) Test Results

3.1.6. Atomic Force Microscopy (AFM) Test Results

3.2. CTBN-Modified Porous Asphalt Concrete Road Performance Test Results

3.2.1. High-Temperature Properties of Porous Asphalt Concrete

3.2.2. Low-Temperature Properties of Porous Asphalt Concrete

3.2.3. Water Stability Properties of Porous Asphalt Concrete

4. Conclusions

- CTBN significantly enhances the tensile strength and toughness of epoxy asphalt without accelerating the curing time of the epoxy system. While it slightly reduces the high-temperature rutting resistance, it improves the material’s elasticity. Additionally, CTBN effectively enhances the low-temperature cracking resistance of epoxy asphalt, as evidenced by a reduction in the low-temperature stiffness modulus (S) and an improvement in the stress relaxation capacity (m).

- CTBN-modified epoxy asphalt undergoes chemical modification, wherein the reaction between CTBN and epoxy resin generates new functional groups. This alters the overall distribution of the epoxy asphalt, increasing its fluidity and homogeneity, thereby providing a theoretical basis for the improvement in macroscopic performance.

- Compared to EPAC and SPAC, CEPAC exhibits superior high-temperature performance, low-temperature performance, and water stability due to the formation of a stable “sea-island structure”. Although its low-temperature tensile strain is slightly inferior to that of SPAC, CEPAC is more suitable as a pavement material for permeable pavements in cold regions when considering overall performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Falegnami, A.; Romano, E.; Tomassi, A. The emergence of the GreenSCENT competence framework: A constructivist approach: The GreenSCENT theory. In The European Green Deal in Education; Routledge: London, UK, 2024; pp. 204–216. [Google Scholar]

- Xu, J.; Hong, B.; Lu, G.; Li, T.; Wang, S.; Wang, C.; Wang, D. Carboxylated Styrene-Butadiene Latex (XSB) in Asphalt Modification Towards Cleaner Production and Enhanced Performance of Pavement in Cold Regions. J. Clean. Prod. 2022, 372, 133653. [Google Scholar] [CrossRef]

- Zhang, S.; Teng, J.; He, Z.; Liu, Y.; Liang, S.; Yao, Y.; Sheng, D. Canopy Effect Caused by Vapour Transfer in Covered Freezing Soils. Géotechnique 2016, 66, 927–940. [Google Scholar] [CrossRef]

- Hu, K.; Chen, Y.; Chen, G.; Duan, Y.; Yu, C. Proposed Cool Coatings with High Near-Infrared Reflectance and Heat Insulation for Asphalt Pavement. Coatings 2021, 11, 85. [Google Scholar] [CrossRef]

- Sheng, D.; Zhang, S.; Niu, F.; Cheng, G. A Potential New Frost Heave Mechanism in High-Speed Railway Embankments. Géotechnique 2014, 64, 144–154. [Google Scholar] [CrossRef]

- Luo, T.; Qu, X.; Wang, N.; Chen, H.; Yao, Y. Pot Cover Effect and Its Prevention: An Experimental Study in the Field. Cold Reg. Sci. Technol. 2019, 167, 102845. [Google Scholar] [CrossRef]

- Wei, S.; Ma, M.; Guo, Y.; Zhang, C. Numerical analysis of the influence of foundation replacement materials on the hydrothermal variation and deformation process of highway subgrades in permafrost regions. Water 2022, 14, 2642. [Google Scholar] [CrossRef]

- Dong, F.; Zhao, W.; Zhang, Y.; Wei, J.; Fan, W.; Yu, Y.; Wang, Z. Influence of SBS and Asphalt on SBS Dispersion and the Performance of Modified Asphalt. Constr. Build. Mater. 2014, 62, 1–7. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, C.; Lv, S.; Ge, D.; Ju, Z.; Fan, G. Research on Rheological Properties of CNT-SBR Modified Asphalt. Constr. Build. Mater. 2022, 361, 129587. [Google Scholar] [CrossRef]

- Fan, X.; Lu, W.; Lv, S.; He, F. Improvement of Low-Temperature Performance of Buton Rock Asphalt Composite Modified Asphalt by Adding Styrene-Butadiene Rubber. Materials 2019, 12, 2358. [Google Scholar] [CrossRef]

- Wang, T.; Xiao, F.; Amirkhanian, S.; Huang, W.; Zheng, M. A Review on Low-Temperature Performances of Rubberized Asphalt Materials. Constr. Build. Mater. 2017, 145, 483–505. [Google Scholar] [CrossRef]

- Li, X.; Pei, J.; Shen, J.; Li, R. Experimental Study on the High-Temperature and Low-Temperature Performance of Polyphosphoric Acid/Styrene-Butadiene-Styrene Composite-Modified Asphalt. Adv. Mater. Sci. Eng. 2019, 2019, 6384360. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Wang, H.; Guo, Y.; Wu, H. Effect of Basalt Fiber on the Low-Temperature Performance of an Asphalt Mixture in a Heavily Frozen Area. Constr. Build. Mater. 2020, 253, 119080. [Google Scholar] [CrossRef]

- Zhao, L.; Xu, G.; Zhang, M. Low-Temperature Creep Properties for Fibre–Asphalt Mixtures. Proc. Inst. Civ. Eng. Transp. 2017, 170, 152–157. [Google Scholar] [CrossRef]

- Xiang, Q.; Xiao, F. Applications of Epoxy Materials in Pavement Engineering. Constr. Build. Mater. 2020, 235, 117529. [Google Scholar] [CrossRef]

- Qian, Z.; Lu, Q. Design and Laboratory Evaluation of Small Particle Porous Epoxy Asphalt Surface Mixture for Roadway Pavements. Constr. Build. Mater. 2015, 77, 110–116. [Google Scholar] [CrossRef]

- Zhao, K.; Song, S.; Yang, W.; Li, G.; Guo, F. Adhesion Properties of Recycled High-Viscosity Asphalt–Aggregate Interface under Dynamic Water Erosion. Materials 2023, 16, 6203. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.; Yuan, D.; Xing, C.; Zhang, B.; Xiao, J.; Wang, T.; Wu, W. Experimental Study of Epoxy Asphalt Binder and Porous Epoxy Asphalt Concrete. J. Clean. Prod. 2023, 420, 138373. [Google Scholar] [CrossRef]

- Li, L.; Guo, Z.; Ran, L.; Zhang, J. Study on low-temperature cracking performance of asphalt under heat and light together conditions. Materials 2020, 13, 1541. [Google Scholar] [CrossRef]

- Mansour, G.; Tsongas, K.; Tzetzis, D. Investigation of the Dynamic Mechanical Properties of Epoxy Resins Modified with Elastomers. Compos. Part B Eng. 2016, 94, 152–159. [Google Scholar] [CrossRef]

- Gu, A.; Liang, G. Thermal Stability and Kinetics Analysis of Rubber-modified Epoxy Resin by High-resolution Thermogravimetric Analysis. J. Appl. Polym. Sci. 2003, 89, 3594–3600. [Google Scholar] [CrossRef]

- Wu, S.; He, R.; Chen, H.; Luo, Y. Low temperature characteristics of asphalt mixture based on the semi-circular bend and thermal stress restrained specimen test in alpine cold regions. Constr. Build. Mater. 2021, 311, 125300. [Google Scholar] [CrossRef]

- Xu, J.; Fan, Z.; Lin, J.; Liu, P.; Wang, D.; Oeser, M. Study on the Effects of Reversible Aging on the Low Temperature Performance of Asphalt Binders. Constr. Build. Mater. 2021, 295, 123604. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, H.; Zhang, N.; Weng, L. The Preparation and Application of CTBN Modified Epoxy Adhesive. Pigment Resin Technol. 2015, 44, 358–363. [Google Scholar] [CrossRef]

- Zhang, H.L.; Wang, H.C.; Yu, J.Y. Effect of Aging on Morphology of Organo-Montmorillonite Modified Bitumen by Atomic Force Microscopy. J. Microsc. 2011, 242, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Nazzal, M.D.; Mogawer, W.; Kaya, S.; Bennert, T. Multiscale Evaluation of the Composite Asphalt Binder in High-Reclaimed Asphalt Pavement Mixtures. J. Mater. Civ. Eng. 2014, 26, 04014019. [Google Scholar] [CrossRef]

- Yan, K.; Shi, J.; Shi, K.; Wang, M.; Li, G.; Hong, Z. Effects of the Chemical Structure of Curing Agents on Rheological Properties and Microstructure of WER Emulsified Asphalt. Constr. Build. Mater. 2022, 347, 128531. [Google Scholar] [CrossRef]

- Gan, X.; Chen, P.; Yu, B.; Zhang, W. Study on the Performances of Waste Battery Powder Modified Asphalt and Asphalt Mixture. Polymers 2022, 14, 5409. [Google Scholar] [CrossRef]

- Ji, X.; Li, J.; Zhai, X.; Zou, H.; Chen, B. Application of atomic force microscope to investigate the surface micro-adhesion properties of asphalt. Materials 2020, 13, 1736. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Yu, T.; Liu, Z. Microstructural characteristics of differently aged asphalt samples based on atomic force microscopy (AFM). Constr. Build. Mater. 2020, 255, 119388. [Google Scholar] [CrossRef]

- Ma, T.; Ding, X.; Zhang, D.; Huang, X.; Chen, J. Experimental Study of Recycled Asphalt Concrete Modified by High-Modulus Agent. Constr. Build. Mater. 2016, 128, 128–135. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, W.; Wu, S. Analysis on Factors Affecting Moisture Stability of Steel Slag Asphalt Concrete Using Grey Correlation Method. J. Clean. Prod. 2023, 397, 136490. [Google Scholar] [CrossRef]

| Material | Technical Indicators | Value |

|---|---|---|

| 90# Matrix Asphalt Bonding Agent | Needle penetration (25 °C, 100 g, 5 s)/0.1 mm | 89 |

| Softening point (TR&B)/°C | 51 | |

| Elongation (15 °C, 5 cm/min)/cm | 121 | |

| Dynamic viscosity (60 °C)/Pa·s | 199 | |

| epoxy resin | Epoxy equivalent/(g/mol) | 185 |

| Inorganic chlorine value/(mg/kg) | 7 |

| Material | Technical Indicators | Value |

|---|---|---|

| Methyl tetrahydrophthalic anhydride | Viscosity (25 °C)/mPa⋅s | 41 |

| Anhydride base content/% | 42.3 | |

| Free acid/% | 0.1 | |

| C12-14 alkyl glycidyl ethers | Viscosity (25 °C)/mPa⋅s | 8.4 |

| Epoxy equivalent/(ep/100 g) | 0.33 | |

| Hydrolyzed oxygen/ppm | 370 |

| Material | Coarse Aggregate | Fine Aggregate | Mineral Powder |

|---|---|---|---|

| Relative apparent density/(g/cm3) | 2.821 | 2.740 | 2.685 |

| Crushing value/% | 10.5 | / | / |

| Water absorption/% | 0.4 | 1.0 | / |

| Needle flake content/% | 5.9 | 14.7 | / |

| Mixture | Passing (by Mass) Under Different Sieve Sizes (mm)% | Binder Content/% | Void Ratio/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |||

| SBS | 100.0 | 95.0 | 69.0 | 21.0 | 19.2 | 14.5 | 10.0 | 6.80 | 5.2 | 4.5 | 5.0 | 18.2 |

| EP (EP + CTBN) | 100.0 | 95.0 | 69.0 | 21.0 | 19.2 | 14.5 | 10.0 | 6.80 | 5.2 | 4.5 | 5.0 | 18.3 |

| Type of Asphalt | Displacement (mm) | Dynamic Stability (Times/mm) | |

|---|---|---|---|

| 45 min | 60 min | ||

| SPAC | 12.29 | 12.54 | 2550.6 |

| EPAC | 1.07 | 1.11 | 14,318.2 |

| CEPAC | 0.49 | 0.525 | 18,529.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, W.; Zhang, S. Study on the Road Performance of Terminal Carboxylated Nitrile Rubber-Modified Epoxy Asphalt Permeable Concrete. Materials 2025, 18, 1691. https://doi.org/10.3390/ma18081691

Shan W, Zhang S. Study on the Road Performance of Terminal Carboxylated Nitrile Rubber-Modified Epoxy Asphalt Permeable Concrete. Materials. 2025; 18(8):1691. https://doi.org/10.3390/ma18081691

Chicago/Turabian StyleShan, Wei, and Shenru Zhang. 2025. "Study on the Road Performance of Terminal Carboxylated Nitrile Rubber-Modified Epoxy Asphalt Permeable Concrete" Materials 18, no. 8: 1691. https://doi.org/10.3390/ma18081691

APA StyleShan, W., & Zhang, S. (2025). Study on the Road Performance of Terminal Carboxylated Nitrile Rubber-Modified Epoxy Asphalt Permeable Concrete. Materials, 18(8), 1691. https://doi.org/10.3390/ma18081691