Performance Evaluation of Asphalt-Pavement Crack-Repair Materials

Abstract

1. Introduction

2. Material Property Requirements

- (1)

- It is required that the joint-filling materials meet many requirements in terms of performance, such as high-temperature stability, corrosion resistance, crack resistance, aging resistance, etc., to ensure the quality of joint filling, that it is adapted to the local temperature environment [24], and that it can maintain stability under conditions such as oil leakage corrosion and have strong resistance to foreign body embedding;

- (2)

- It is required that the filling material meet the requirements of local working conditions and has good construction performance;

- (3)

- The road performance of the repaired joint structure should meet the specifications and other standards to ensure that the road performance and strength performance meet the requirements, increase the service life of the road surface, and improve the driving safety and experience.

3. Test Results

3.1. Material Property Test

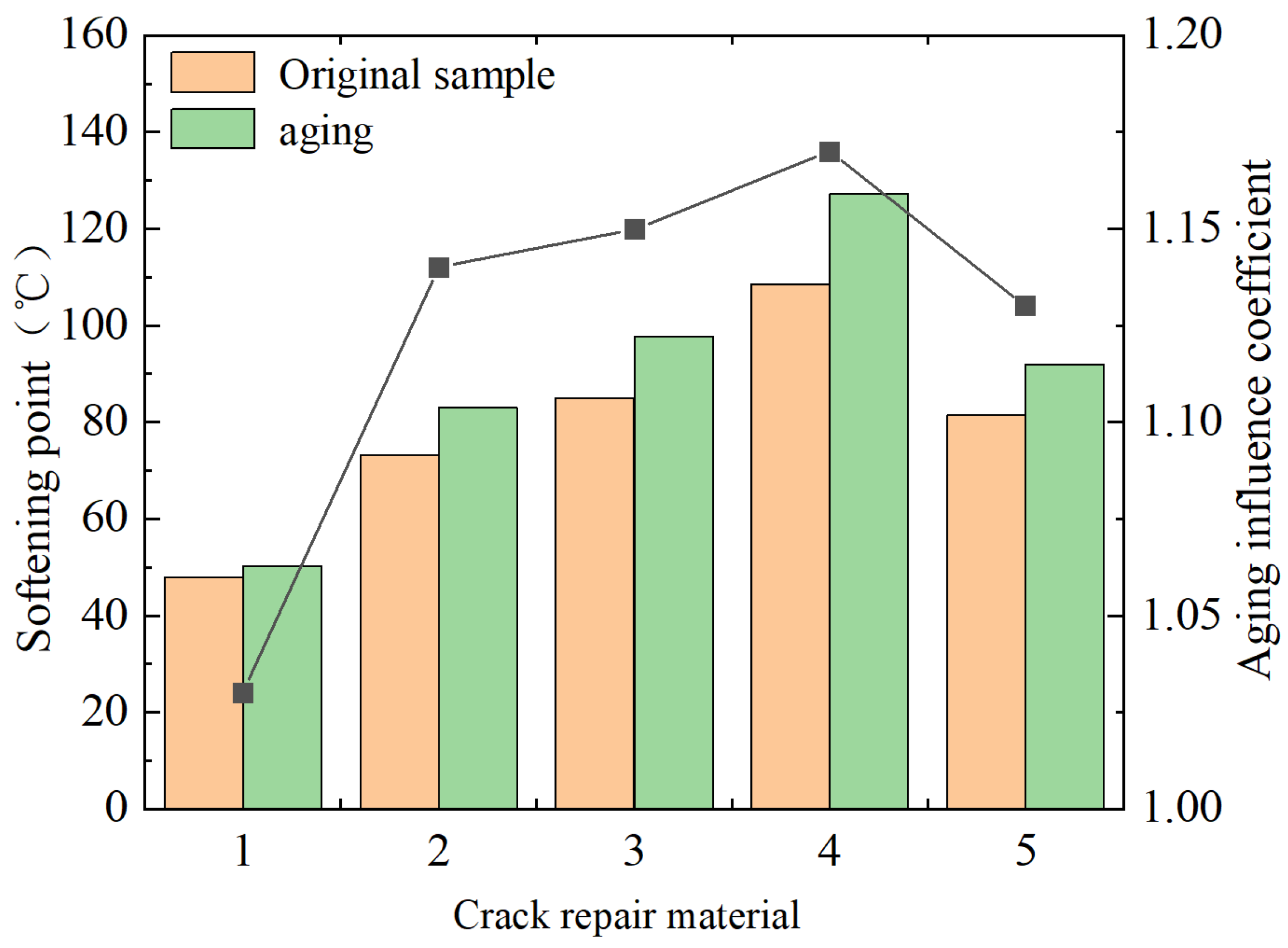

3.1.1. High-Temperature Stability

- (1)

- Softening-point test

- (2)

- Fluidity test

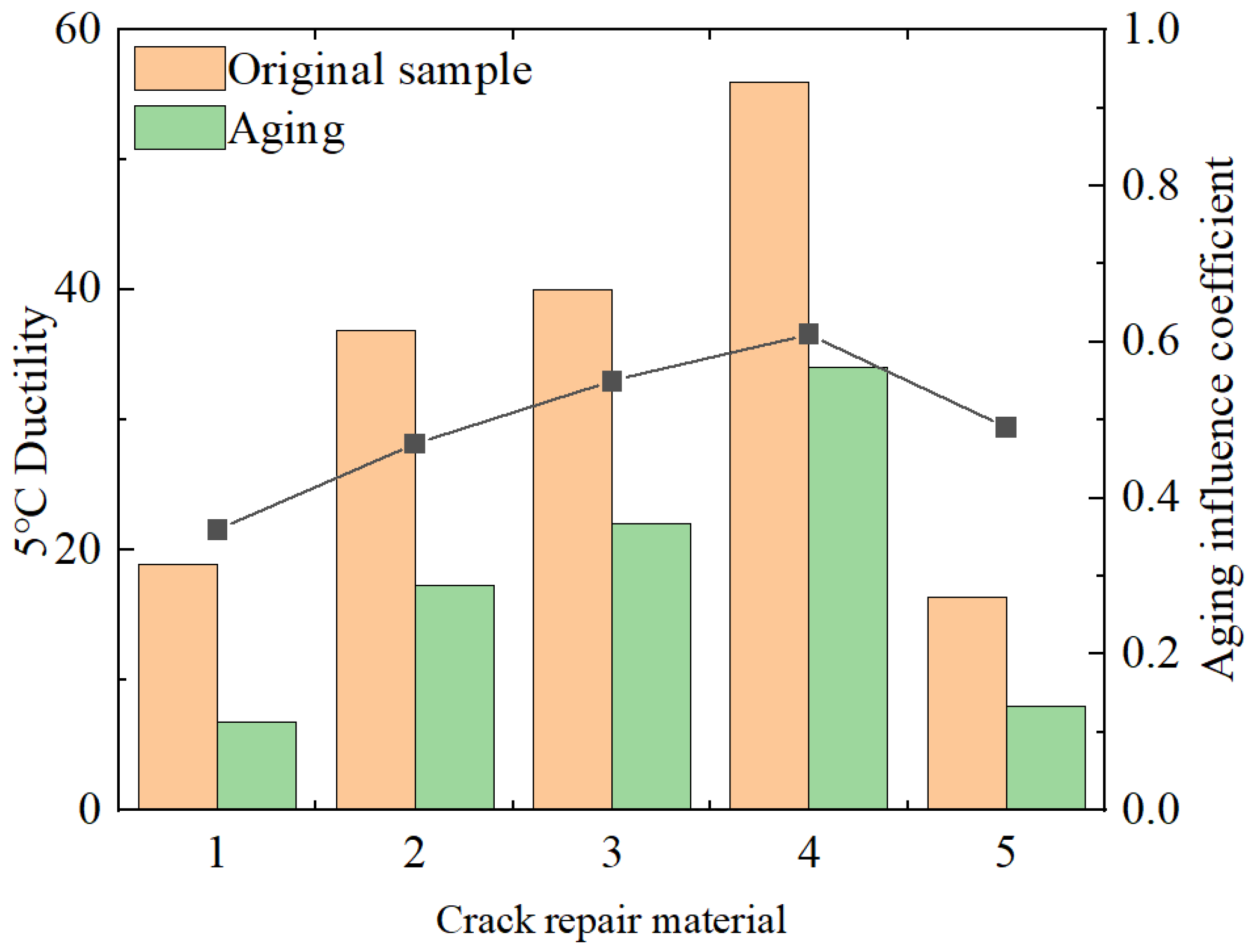

3.1.2. Low-Temperature Crack Resistance

- (1)

- Ductility test (5 °C)

- (2)

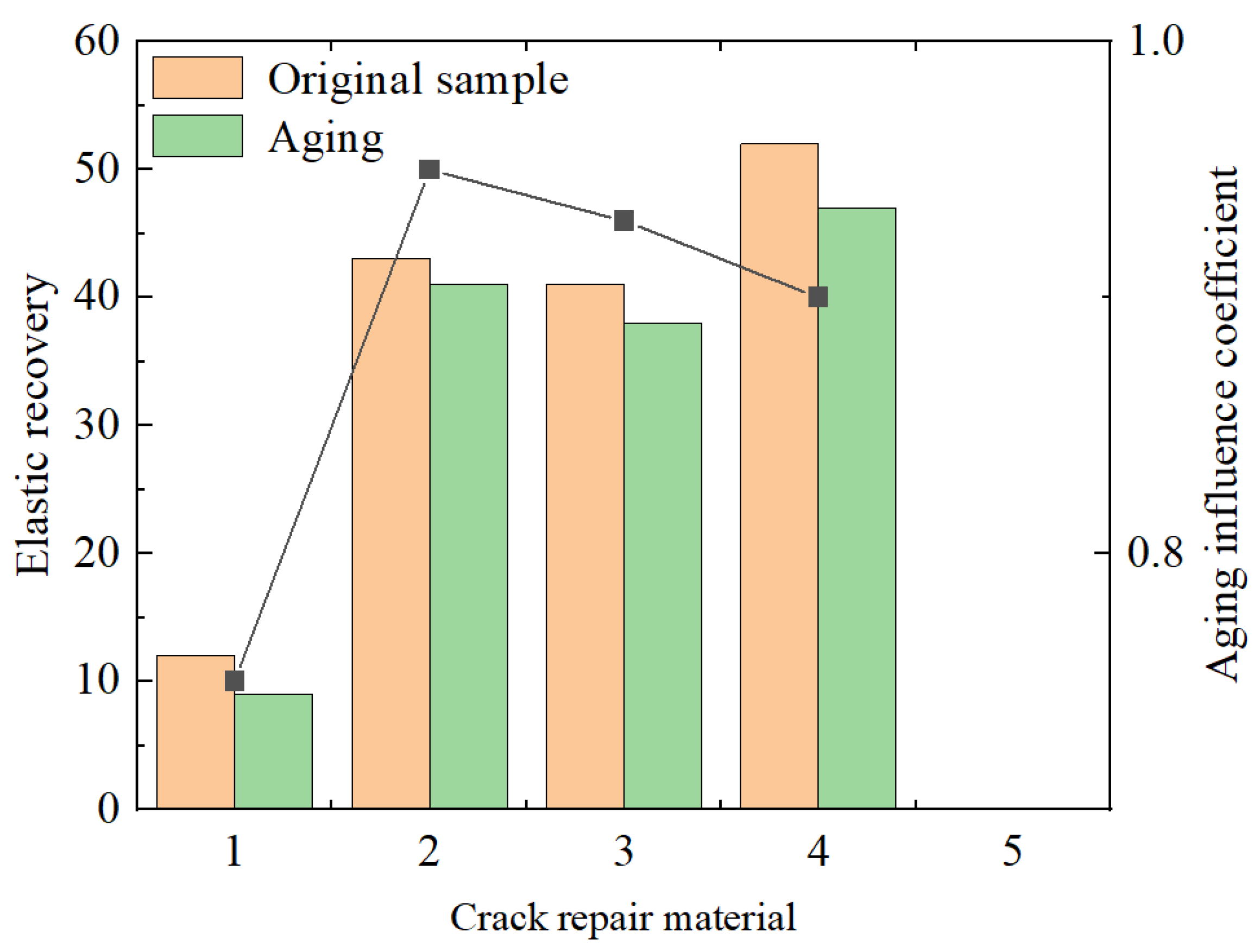

- Elastic recovery test (5 °C)

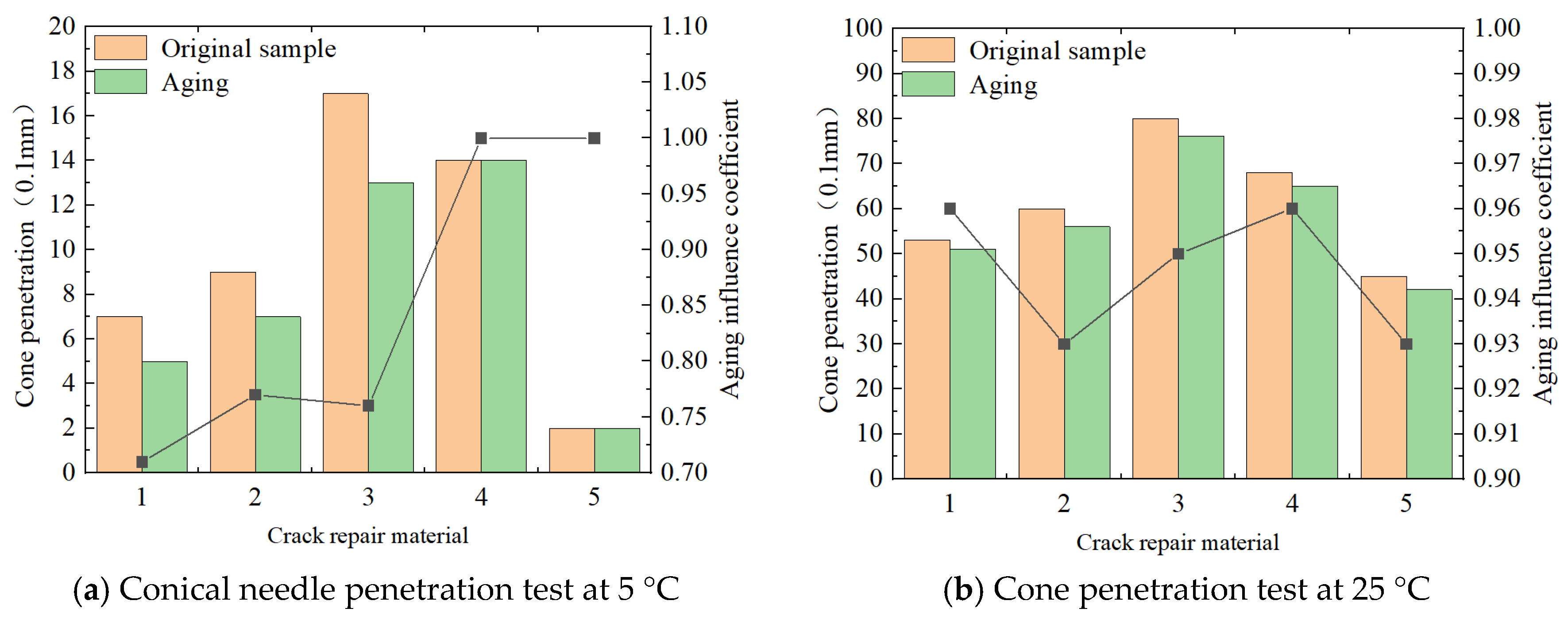

3.1.3. Resistance to Foreign Body Insertion

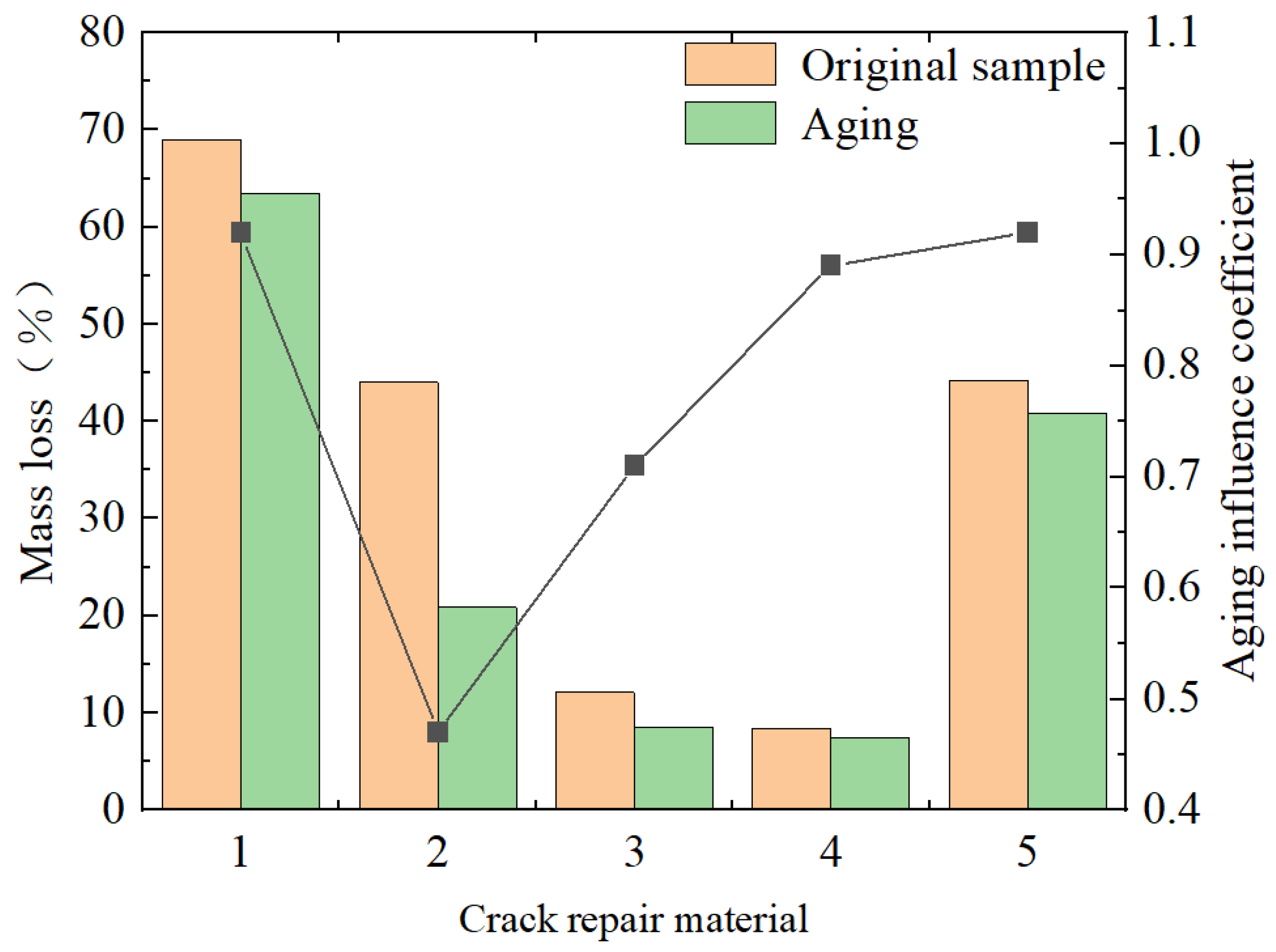

3.1.4. Corrosion Resistance

- α—mass loss (%);

- m1—initial sample mass (g);

- m2—sample residual mass (g).

3.2. Road Performance Test

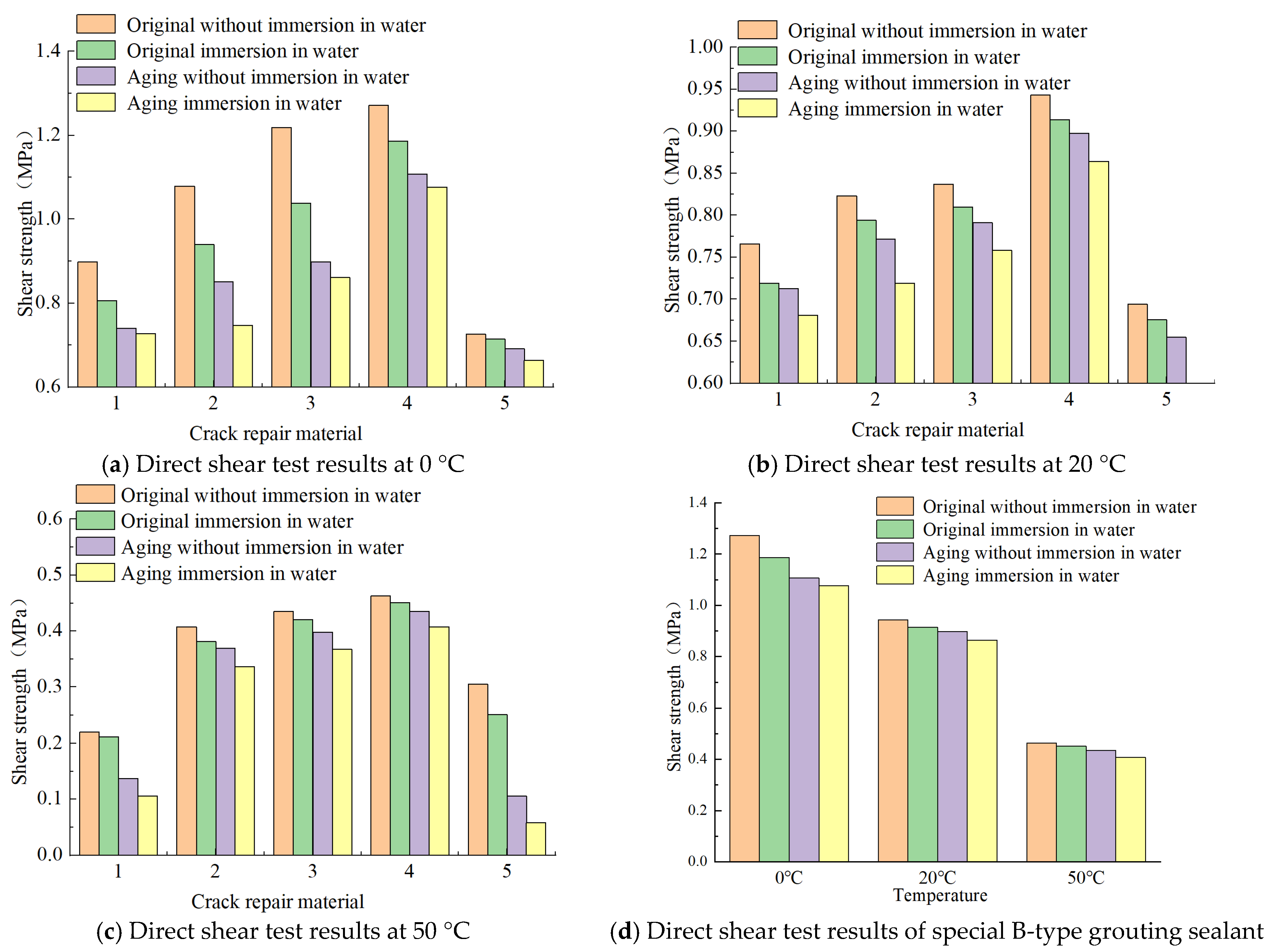

3.2.1. Shear Resistance

- QJ—direct shear strength (MPa);

- PJ—maximum vertical shear stress (kN);

- L1—specimen length (mm);

- L2—specimen width (mm).

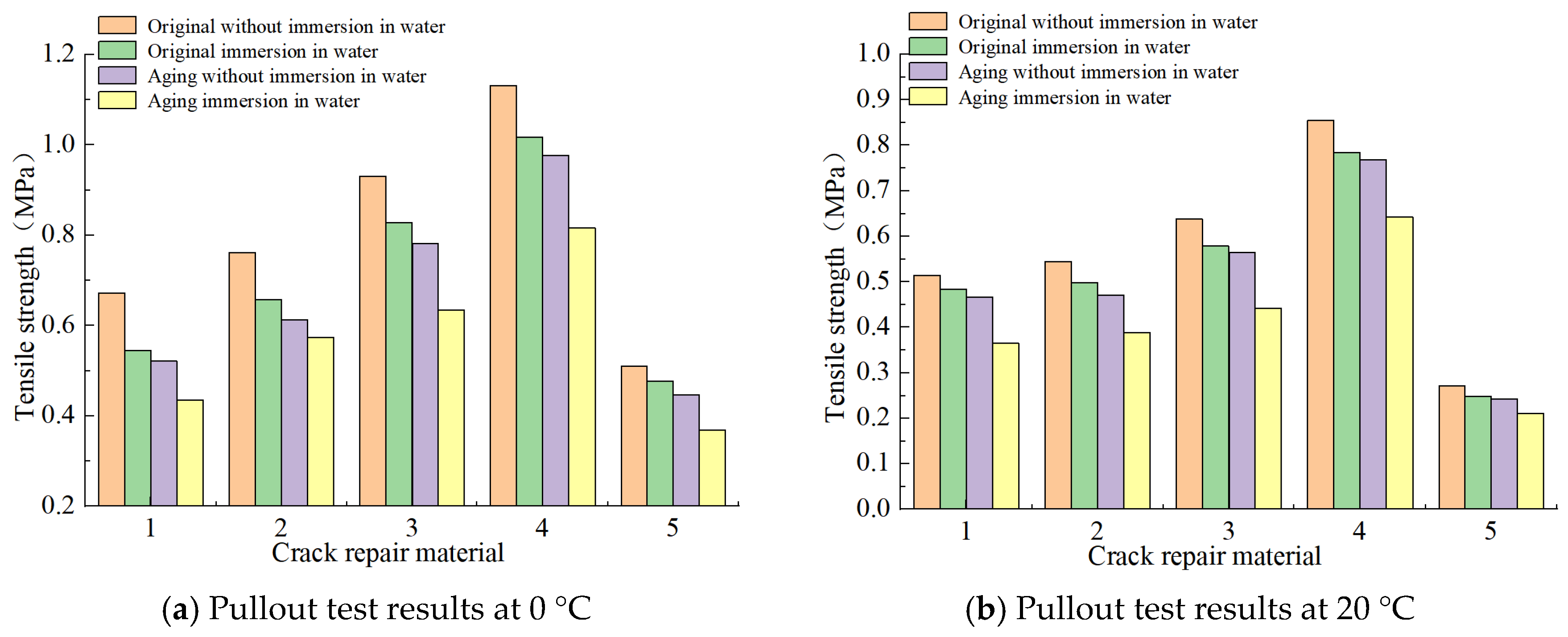

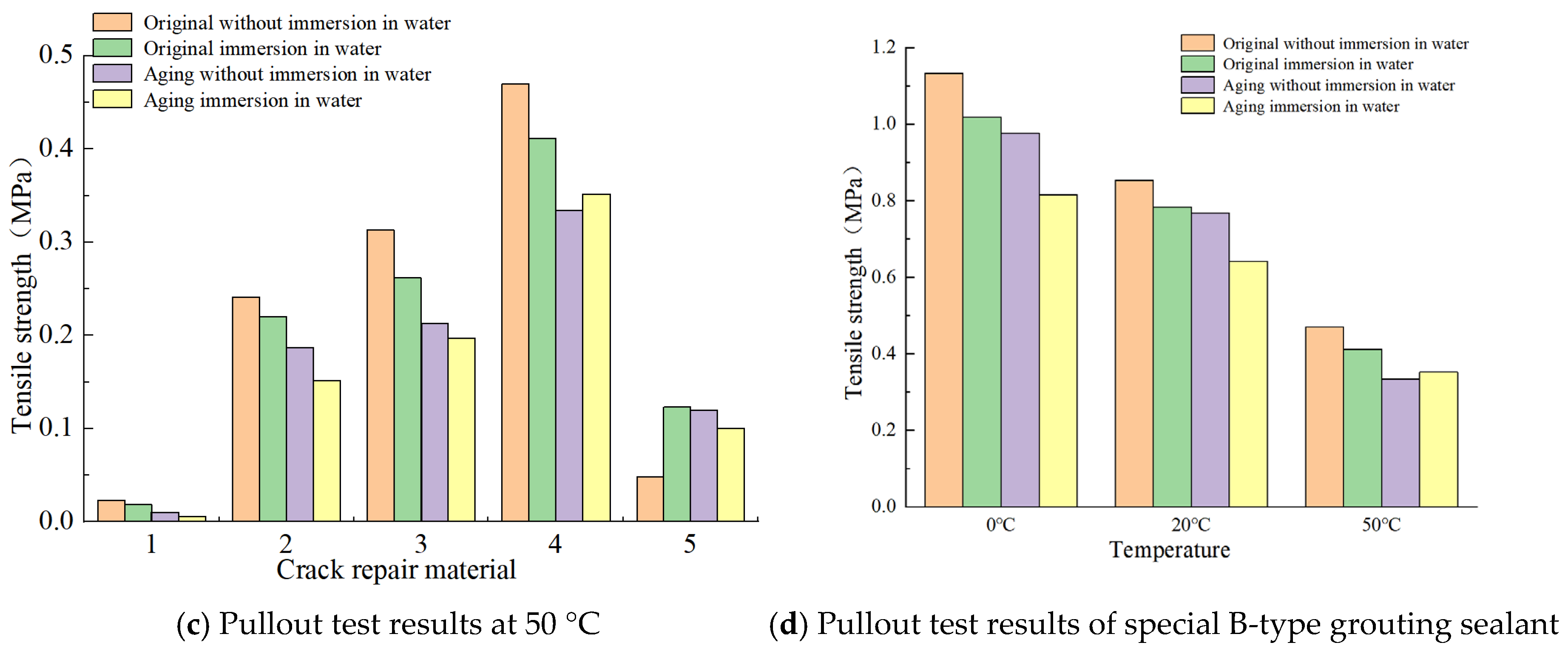

3.2.2. Tensile Property

- QL—tensile strength (MPa);

- PL—maximum vertical tensile stress (kN);

- L1—specimen length (mm);

- L2—specimen width (mm).

4. Analysis of Stress State of Crack-Repair Structure

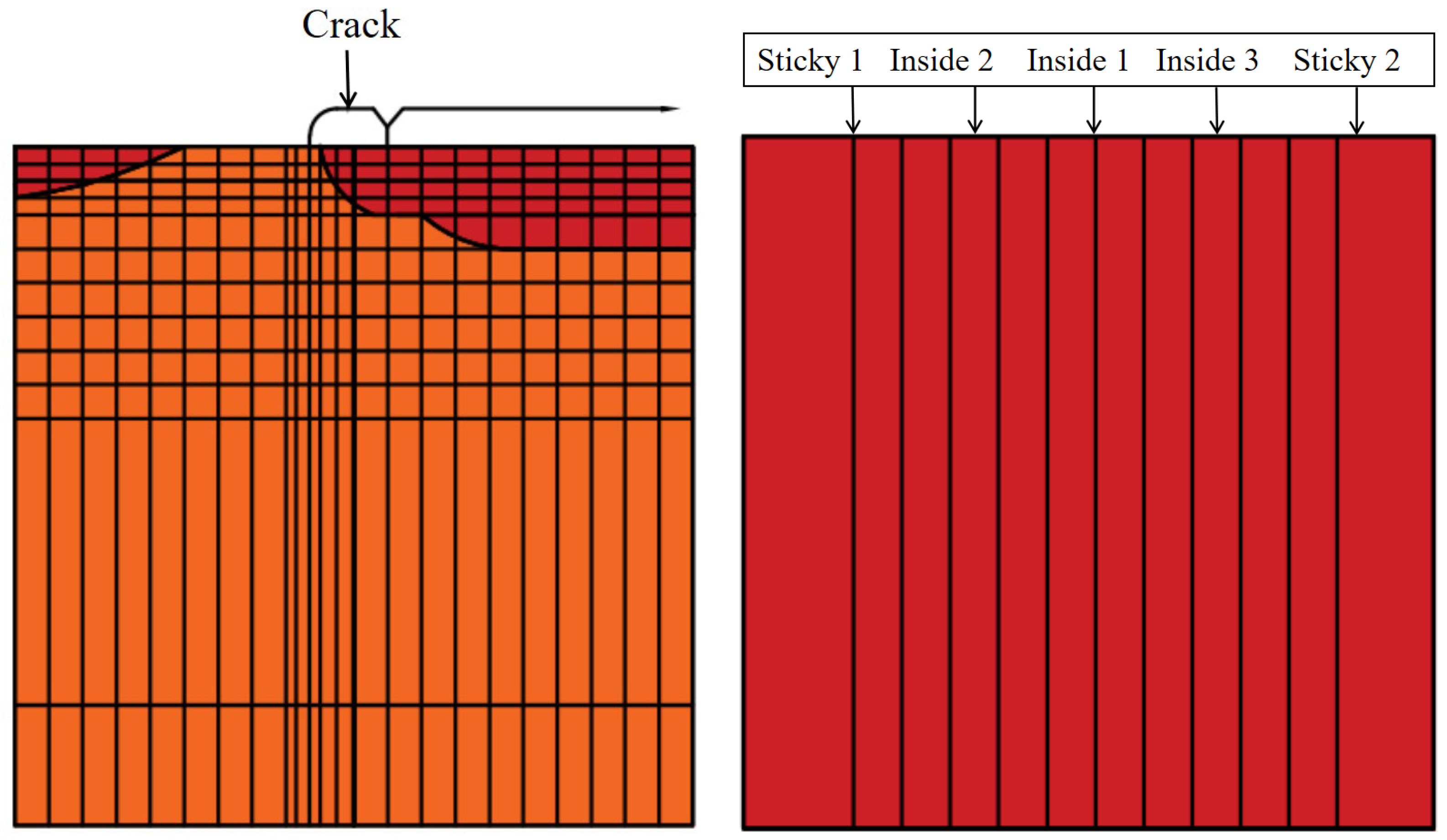

4.1. Finite-Element Model of Asphalt-Pavement Crack-Repair Structure

4.1.1. Structural Layer Parameter

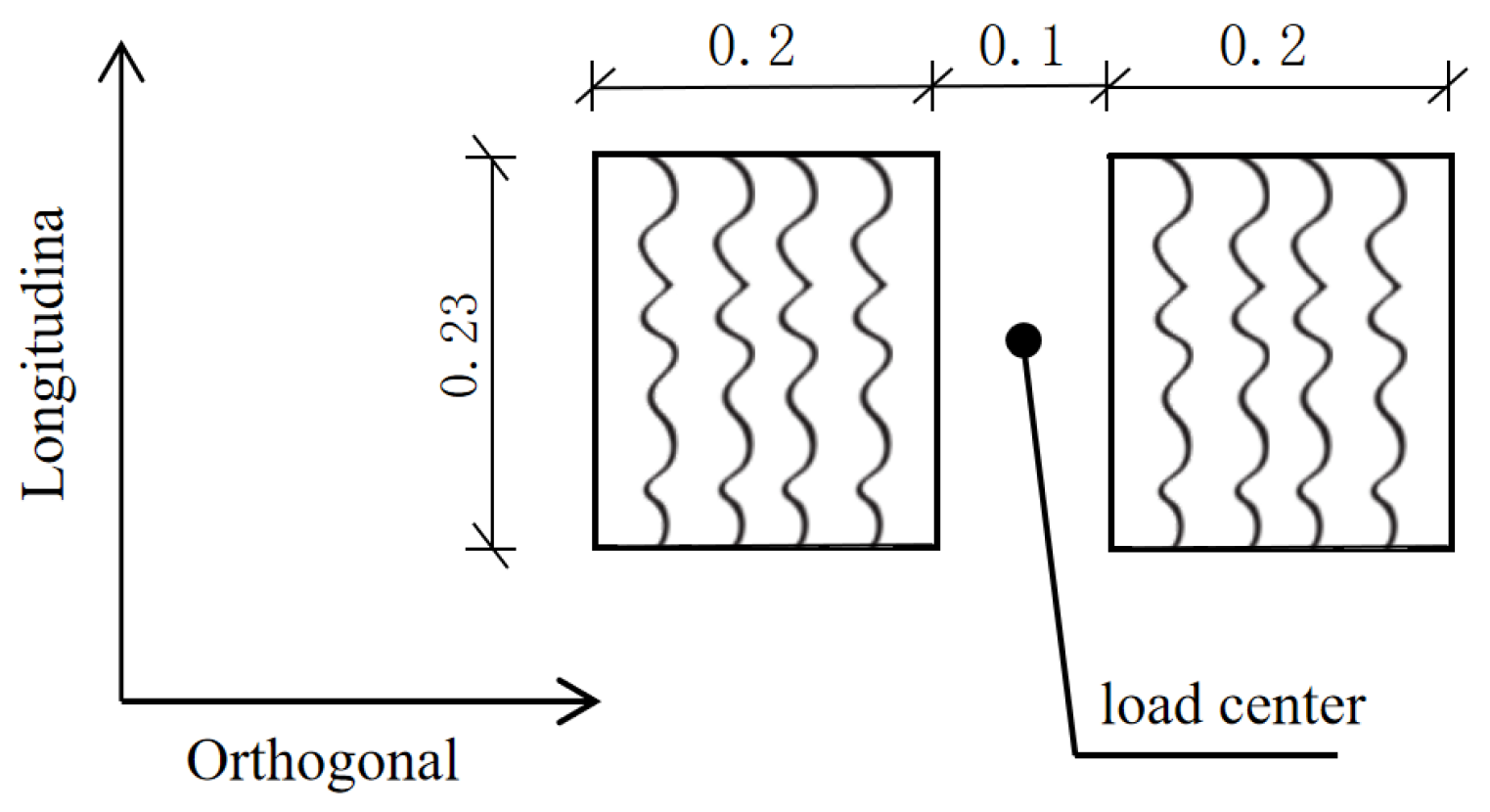

4.1.2. Illustration of Load Effects

4.2. Finite-Element Calculation Results

4.3. Analysis of Calculation Results

5. Conclusions

- (1)

- Special B-type crack sealant (special B-type crack sealant) shows excellent shear performance, tensile performance, and durability under extreme working conditions. Under the high-temperature condition of 50 °C, its measured ratio of shear strength to theoretical maximum shear stress reaches 2.25, which is significantly higher than that of other materials, indicating that it is suitable for heavy traffic roads (such as highways and urban expressways) in high-temperature areas in summer. In the 0 °C low-temperature environment, its tensile strength stress ratio far exceeds that of 70# hot asphalt and room-temperature water-based grouting adhesive, which can effectively inhibit the expansion of low-temperature shrinkage cracks. After thermo-oxidative aging, the shear strength only decreased by about 10%, and the corrosion resistance (mass loss rate < 5%) and the resistance to foreign body embedding ability were better than other materials, verifying the feasibility of its long-life repair.

- (2)

- SBS (Styrene-Butadiene-Styrene block copolymer)-modified asphalt in heating construction materials, at 20 °C room temperature, has a shear strength and tensile strength that can meet the needs of the second level of highway, but its high-temperature performance is significantly weaker than the special materials, so it is recommended to be used for medium traffic volume of the road cyclical repair. Despite the low cost of 70# hot asphalt, because of its high-temperature shear strength (about 1/3 of the special materials), it is recommended for use in medium traffic volume road cyclical repair. However, its high-temperature shear strength and low-temperature tensile strength (0 °C after aging at 0.95 MPa) are lower than the theoretical stress threshold, making it only suitable for low-traffic feeder roads or temporary repair.

- (3)

- Room-temperature construction materials, such as water-based grouting adhesives, demonstrate good wettability under wet conditions. Their high-temperature shear and tensile strength (3.08 MPa) are insufficient to withstand dynamic vehicle loads. They exhibit poor low-temperature elastic recovery rates (<40%) and aging resistance, with strength decay exceeding 50%. Due to these limitations, these materials are only suitable for emergency seepage control or short-term crack closure after rain or snow events.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Yang, Y. Study on the performance of the investigation and repair material of asphalt pavement crack diseases. IOP Conf. Ser. Mater. Sci. Eng. 2019, 490, 022030. [Google Scholar]

- Yao, H.; Wang, Y.; Ma, P.; Li, X.; You, Z. A literature review: Asphalt pavement repair technologies and materials. Proc. Inst. Civ. Eng.-Eng. Sustain. 2023, 177, 259–273. [Google Scholar]

- He, Y.; Li, Y.; Zhang, J.; Xiong, K.; Huang, G.; Hu, Q.; Zhao, X. Performance evolution mechanism and affecting factors of emulsified asphalt cold recycled mixture performance: A state-of art review. Constr. Build. Mater. 2024, 411, 134545. [Google Scholar]

- Gnatenko, R.; Tsyrkunova, K.; Zhdanyuk, V. Technological sides of crack sealing in asphalt pavements. Transp. Res. Procedia 2016, 14, 804–810. [Google Scholar]

- Xiong, K.; Zhang, J.; He, Y.; Li, J.; Zhang, M.; Li, R.; Pei, J.; Li, Y.; Lyu, L. Introducing the mineral powder to strengthen polyurethane grouting materials for crack repair of asphalt pavements. Constr. Build. Mater. 2024, 453, 139023. [Google Scholar]

- Franesqui, M.A.; Yepes, J.; García-González, C. Top-down cracking self-healing of asphalt pavements with steel filler from industrial waste applying microwaves. Constr. Build. Mater. 2017, 149, 612–620. [Google Scholar]

- Zhu, Z.; Xiao, P.; Kang, A.; Wu, Z.; Kou, C.; Ren, Z. Research on the road performance of self-adhesive basalt fiber geotextiles based on the background of long-life pavements. Constr. Build. Mater. 2023, 392, 131776. [Google Scholar] [CrossRef]

- Tabakovic, A.; Post, W.; Cantero, D.; Copuroglu, O.; Garcia, S.J.; Schlangen, E. The reinforcement and healing of asphalt mastic mixtures by rejuvenator encapsulation in alginate compartmented fibres. Smart Mater. Struct. 2016, 25, 084003. [Google Scholar]

- Franesqui, M.A.; Gallego, J. Inspection and depth sizing of surface-initiated cracking for preventive maintenance of asphalt pavements. Int. J. Pavement Eng. 2023, 24, 2083617. [Google Scholar]

- JT/T 740-2015; Pavement Heating Sealant. People’s Transportation Press: Beijing, China, 2015.

- Sun, H.D.; Fan, W.Y.; Shi, J.T. Study on adhesive property of SAC-sealant for cracks in asphalt pavement. J. China Univ. Pet. (Ed. Nat. Sci.) 2016, 40, 159–165. [Google Scholar]

- Song, L.; Guo, S.; Xia, H.; Li, X.; Niu, Y. Study on deformation recovery properties and shape memory mechanism of epoxy resin/SBS composite modified asphalt for crack repair. Constr. Build. Mater. 2025, 464, 140155. [Google Scholar]

- Wang, S.; Li, Y.; Wei, Z.; Gao, Y.; Jia, Y.; Liu, M.; Zhang, Z.; Ou, Z. Effects of Periodically Changing Temperatures on the Bond Interface between Crack Sealant and Repaired Pavement. J. Transp. Eng. Part B Pavements 2024, 150, 04024003. [Google Scholar]

- Li, Y.; Li, X.; Tan, Y. Effect of aging on fatigue performance of cement emulsified asphalt repair material. Constr. Build. Mater. 2021, 292. [Google Scholar]

- Castillo, C.A.; Hand, A.J.; Sebaaly, P.E.; Hajj, E.Y.; Piratheepan, M. Evaluation of Cracking Resistance of Tire Rubber-Modified Asphalt Mixtures. J. Transp. Eng. Part B Pavements 2021, 147, 04021019. [Google Scholar]

- Wei, J. Research on Causes of Cracks in Asphalt Pavement of Highways and Repair Techniques. Transp. Sci. Manag. 2024, 5, 29–32. [Google Scholar]

- Zhao, J.; Liu, K.; Liu, H.; Ding, W.; Pang, H. Optimization of crack healing in steel bridge deck asphalt pavement based on the microwave heating technology. Therm. Sci. Eng. Prog. 2023, 46, 102159. [Google Scholar]

- Fang, Y.F.; Ma, B.; Wei, K.; Wang, L.; Kang, X.X.; Chang, X.G. Orthogonal experimental analysis of the material ratio and preparation technology of single-component epoxy resin for asphalt pavement crack repair. Constr. Build. Mater. 2021, 288, 123074. [Google Scholar]

- Guo, S.; Xu, Z.; Li, X.; Zhu, P. Detection and Characterization of Cracks in Highway Pavement with the Amplitude Variation of GPR Diffracted Waves: Insights from Forward Modeling and Field Data. Remote Sens. 2022, 14, 976. [Google Scholar] [CrossRef]

- Zhu, H.; Wei, G.; Ma, D.; Yu, X.; Xu, Z.; Wang, H. 3D digital modelling and identification of pavement typical internal defects based on GPR measured data. Road Mater. Pavement Des. 2024, 25, 2283–2302. [Google Scholar] [CrossRef]

- Zhu, H.; Wei, G.; Ma, D.; Yu, X.; Dong, C. Research on the detection and identification method of internal cracks in semi-rigid base asphalt pavement based on three-dimensional ground penetrating radar. Measurement 2025, 244, 116486. [Google Scholar]

- Solla, M.; Lagüela, S.; González-Jorge, H.; Arias, P. Approach to identify cracking in asphalt pavement using GPR and infrared thermographic methods: Preliminary findings. NDT E Int. 2014, 62, 55–65. [Google Scholar]

- Tong, Z.; Gao, J.; Zhang, H. Recognition, location, measurement, and 3D reconstruction of concealed cracks using convolutional neural networks. Constr. Build. Mater. 2017, 146, 775–787. [Google Scholar]

- Remišová, E.; Decký, M.; Podolka, L.; Kováč, M.; Vondráčková, T.; Bartuška, L. Frost Index from Aspect of Design of Pavement Construction in Slovakia. Procedia Earth Planet. Sci. 2015, 15, 3–10. [Google Scholar]

- JTG E20-2011; Test Specification for Asphalt and Asphalt Mixture in Highway Engineering. People’s Transportation Press: Beijing, China, 2011.

- Liu, C.; Wu, X.; Zhang, D.; Yao, Q. Research on the Influence Law of Thermal Oxidative Aging Temperature on the Properties of Polymer Modified Asphalt. China Adhes. 2024, 33, 57–62+67. [Google Scholar]

- Zhang, H.; Duan, H.; Zhu, C.; Chen, Z.; Luo, H. Mini-review on the application of nanomaterials in improving anti-aging properties of asphalt. Energy Fuels 2021, 35, 11017–11036. [Google Scholar]

- Zhou, W.; Li, D.; Wan, J. Research on the High Temperature Performance of Pourable Asphalt Pavement Materials. Highway 2020, 65, 91–94. [Google Scholar]

- Andrews, J.K.; Radhakrishnan, V.; Koshy, R.Z.; Prasad, C.S.R.K. Performance prediction of emulsion treated base layer mixes using indirect tensile strength and resilient modulus test parameters. Innov. Infrastruct. Solut. 2024, 9, 429. [Google Scholar]

- Huang, B.; Zhou, Z.F.; Jia, H.C. Dynamic Response of Semi-Rigid Base Asphalt Pavement. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2014, 33, 47–51+74. [Google Scholar]

- JTG D50-2006; Highway Asphalt Pavement Design Specifications. People’s Transportation Press: Beijing, China, 2017.

| Structural Layer | Material | Thickness (m) | Temperature (°C) | Elastic Modulus (Mpa) |

|---|---|---|---|---|

| Surface layer | Asphalt concrete | 0.18 | 0 | 2200 |

| 20 | 1200 | |||

| 50 | 500 | |||

| Base | Cement-stabilized macadam | 0.30 | 20 | 4500 |

| Subbase | Lime-fly ash stabilized soil | 0.30 | 800 | |

| Soil foundation | Backfill soil | 5.00 | 50 | |

| Inside the crack | Repair materials | 0.18 | 0 | 280 |

| 20 | 150 | |||

| 50 | 70 |

| State of Temperature | Maximum Shear Stress (Mpa) | Maximum Tensile Stress (Mpa) | Maximum Compressive Stress (Mpa) |

|---|---|---|---|

| Low-temperature state | 0.603 | 0.4580 | 1.249 |

| Normal-temperature state | 0.576 | 0.0489 | 1.137 |

| High-temperature conditions | 0.206 | 0.0393 | 0.237 |

| Material | Temperature (°C) | Measured Shear Strength (Mpa)/Theoretical Maximum Shear Stress (Mpa) | |||

|---|---|---|---|---|---|

| Original Without Immersion in Water | Original Immersion in Water | Aging Without Immersion in Water | Aging Immersion in Water | ||

| 70# | 0 | 1.49 | 1.33 | 1.23 | 1.21 |

| 20 | 1.33 | 1.25 | 1.24 | 1.18 | |

| 50 | 1.07 | 1.03 | 0.67 | 0.51 | |

| SBS | 0 | 1.80 | 1.55 | 1.41 | 1.23 |

| 20 | 1.43 | 1.38 | 1.32 | 1.25 | |

| 50 | 1.97 | 1.85 | 1.79 | 1.64 | |

| Special A-type grouting sealant | 0 | 2.02 | 1.72 | 1.49 | 1.43 |

| 20 | 1.45 | 1.41 | 1.37 | 1.32 | |

| 50 | 2.11 | 2.04 | 1.93 | 1.79 | |

| Special B-type grouting sealant | 0 | 2.11 | 1.97 | 1.84 | 1.78 |

| 20 | 1.64 | 1.59 | 1.56 | 1.50 | |

| 50 | 2.25 | 2.19 | 2.11 | 1.98 | |

| Water-based grouting sealant at normal temperature | 0 | 1.20 | 1.18 | 1.15 | 1.01 |

| 20 | 1.20 | 1.17 | 1.14 | 1.03 | |

| 50 | 1.48 | 1.22 | 0.51 | 0.28 | |

| Material | Temperature (°C) | Measured Tensile Strength (Mpa)/Theoretical Maximum Tensile Stress (Mpa) | |||

|---|---|---|---|---|---|

| Original Without Immersion in Water | Original Immersion in Water | Aging Without Immersion in Water | Aging Immersion in Water | ||

| 70# | 0 | 1.47 | 1.19 | 1.14 | 0.95 |

| 20 | 10.49 | 9.86 | 9.51 | 7.45 | |

| 50 | 0.59 | 0.46 | 0.26 | 0.15 | |

| SBS | 0 | 1.66 | 1.44 | 1.34 | 1.25 |

| 20 | 11.08 | 10.16 | 9.61 | 7.91 | |

| 50 | 6.18 | 5.64 | 4.79 | 3.87 | |

| Special A-type grouting sealant | 0 | 2.03 | 1.81 | 1.71 | 1.38 |

| 20 | 13.02 | 11.82 | 11.53 | 9.00 | |

| 50 | 8.03 | 6.72 | 5.46 | 5.05 | |

| Special B-type grouting sealant | 0 | 2.47 | 2.22 | 2.13 | 1.78 |

| 20 | 17.43 | 16.00 | 15.67 | 13.10 | |

| 50 | 12.05 | 10.56 | 8.56 | 7.74 | |

| Water-based grouting sealant at normal temperature | 0 | 1.11 | 1.04 | 0.98 | 0.80 |

| 20 | 5.55 | 5.06 | 4.94 | 4.31 | |

| 50 | 3.79 | 3.75 | 3.08 | 2.56 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Wang, H.; Liu, S.; Yang, D.; Xiong, Y. Performance Evaluation of Asphalt-Pavement Crack-Repair Materials. Materials 2025, 18, 1611. https://doi.org/10.3390/ma18071611

Liu C, Wang H, Liu S, Yang D, Xiong Y. Performance Evaluation of Asphalt-Pavement Crack-Repair Materials. Materials. 2025; 18(7):1611. https://doi.org/10.3390/ma18071611

Chicago/Turabian StyleLiu, Congying, Hongchang Wang, Song Liu, Dagang Yang, and Yue Xiong. 2025. "Performance Evaluation of Asphalt-Pavement Crack-Repair Materials" Materials 18, no. 7: 1611. https://doi.org/10.3390/ma18071611

APA StyleLiu, C., Wang, H., Liu, S., Yang, D., & Xiong, Y. (2025). Performance Evaluation of Asphalt-Pavement Crack-Repair Materials. Materials, 18(7), 1611. https://doi.org/10.3390/ma18071611