A Statistical Study on the Influence of Drilling Process in Delamination Observed in Composite Plates

Abstract

1. Introduction

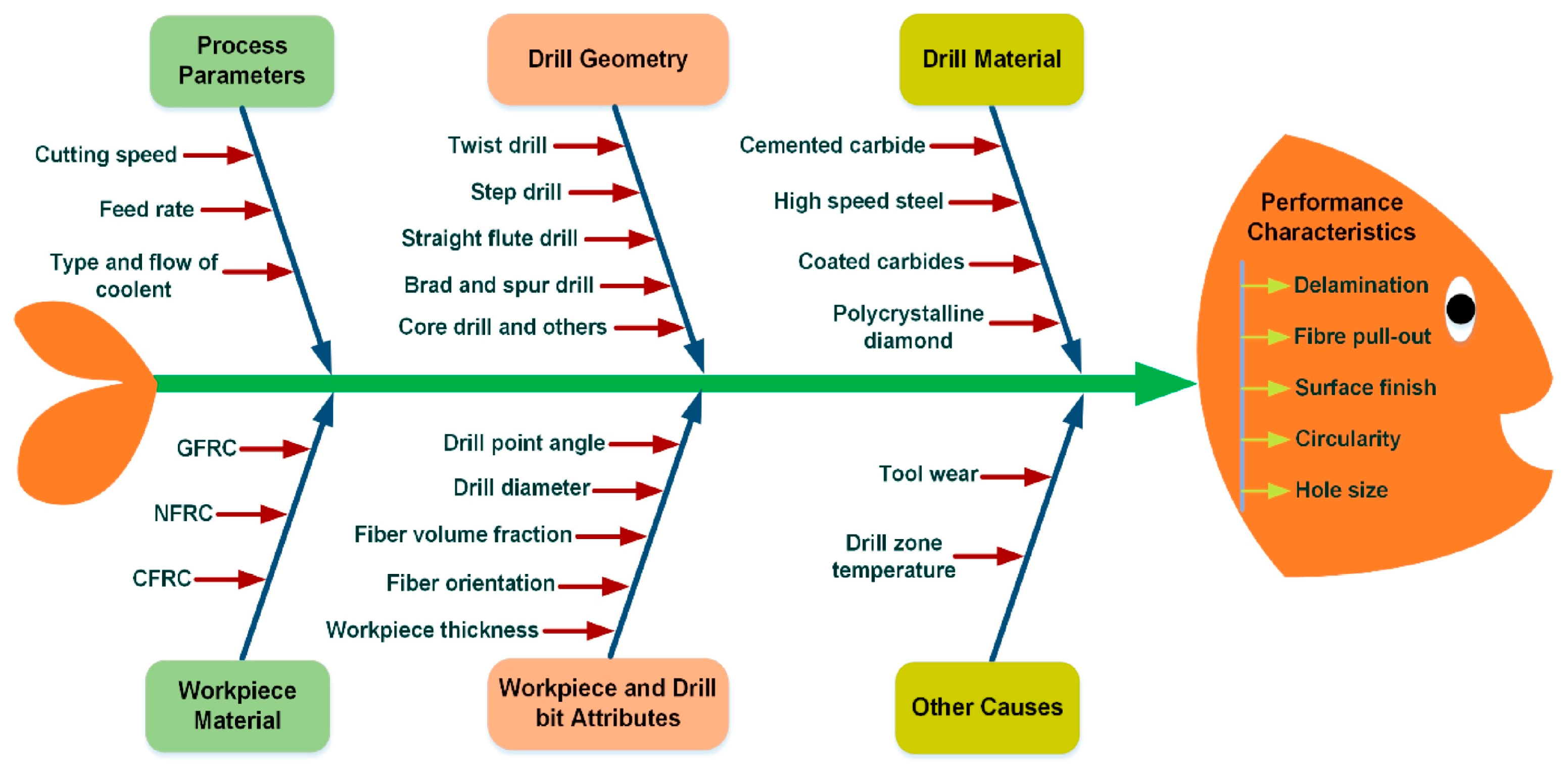

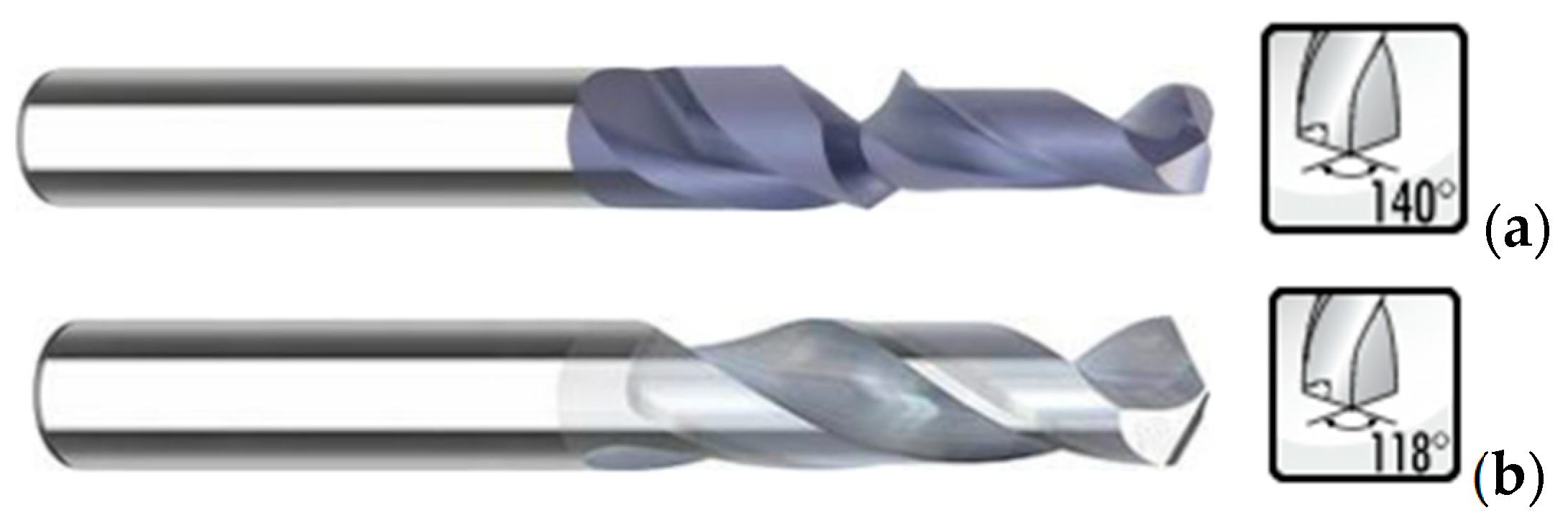

1.1. Composite Plate Drilling

1.2. Non-Destructive Testing of Drilled Composite Plates

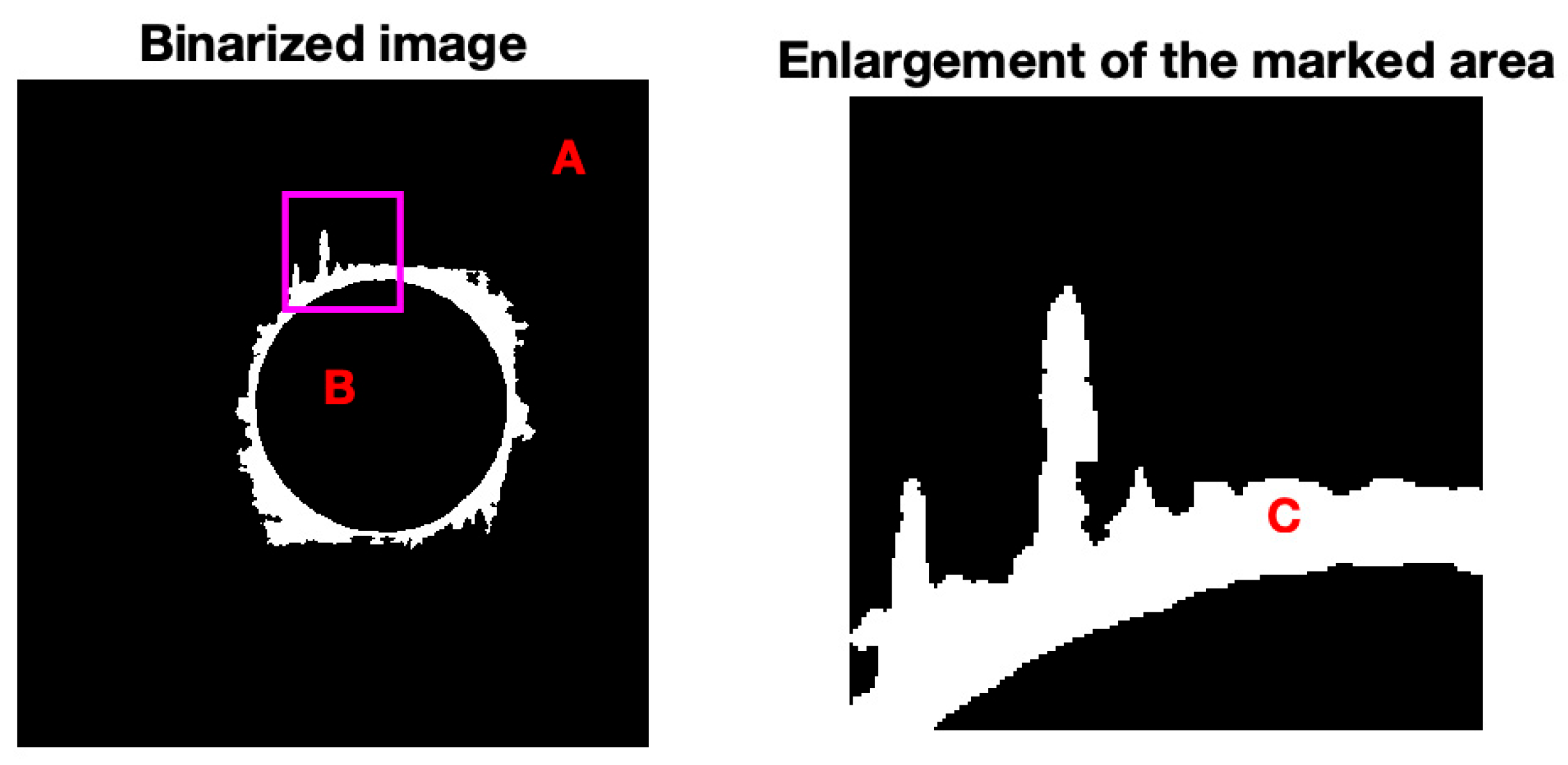

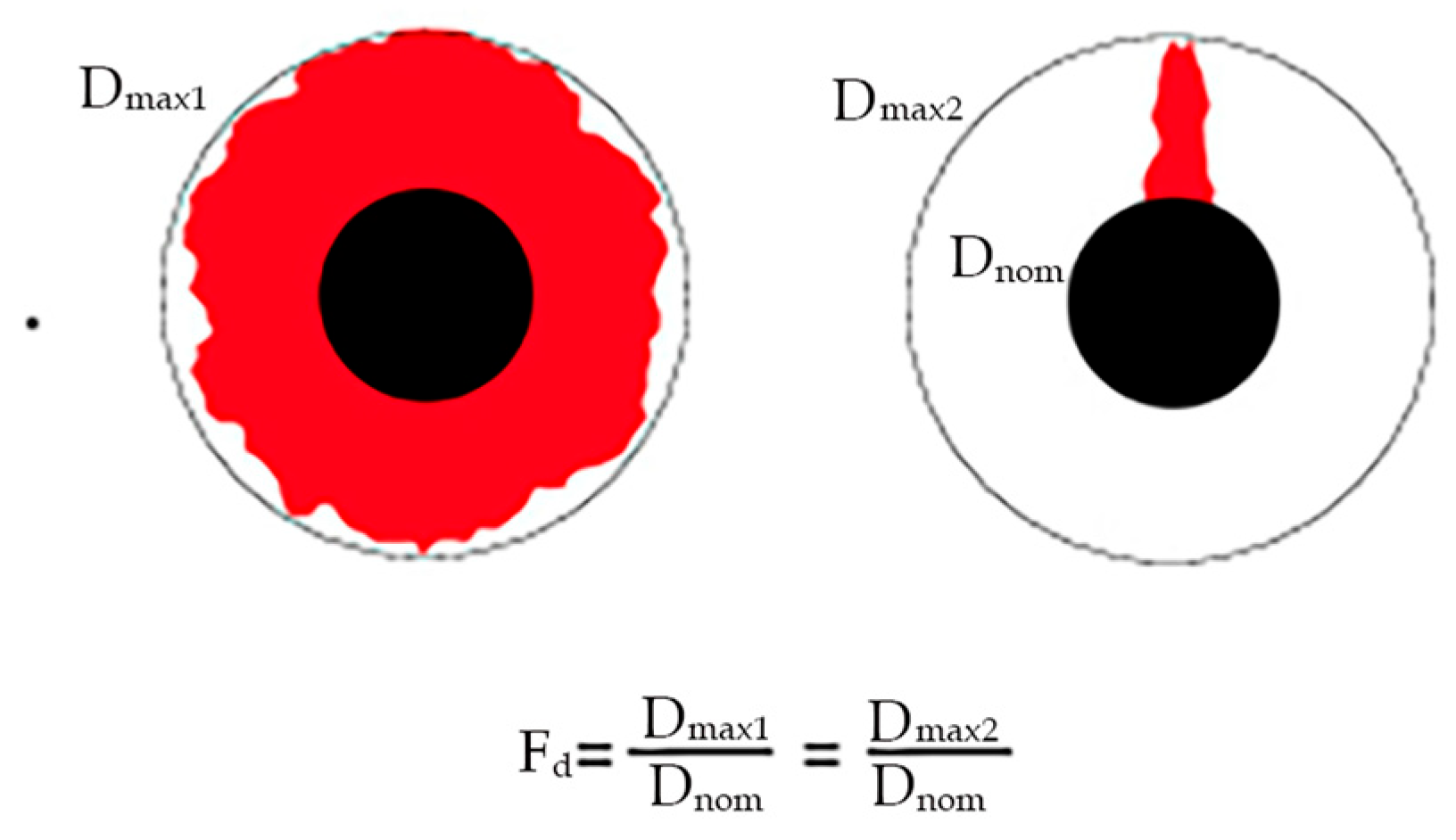

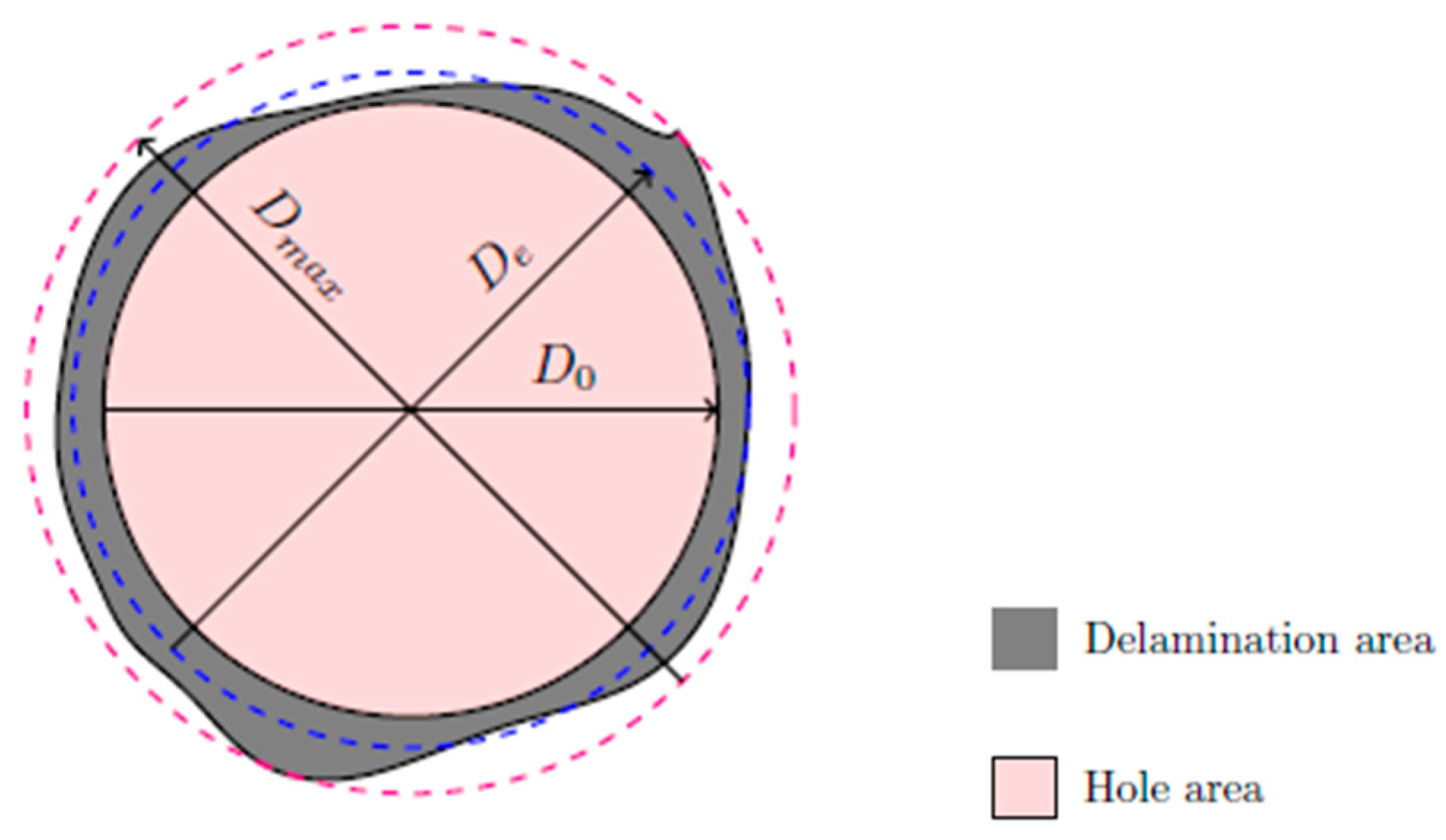

1.3. Image Processing Techniques for Delamination Assessment

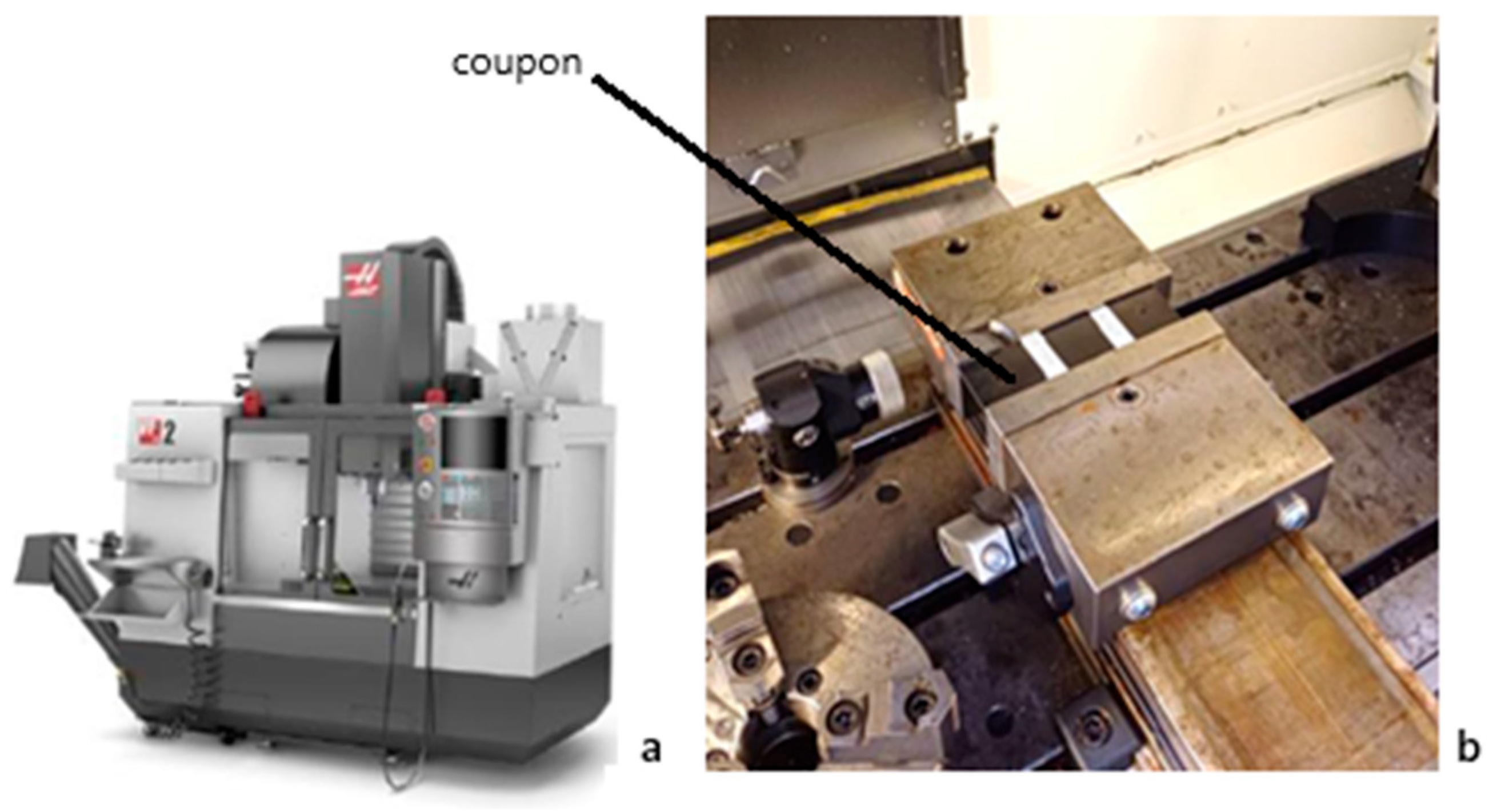

2. Materials and Methods

3. Results and Discussion

3.1. Preliminary Testing

3.2. Delamination Measurement

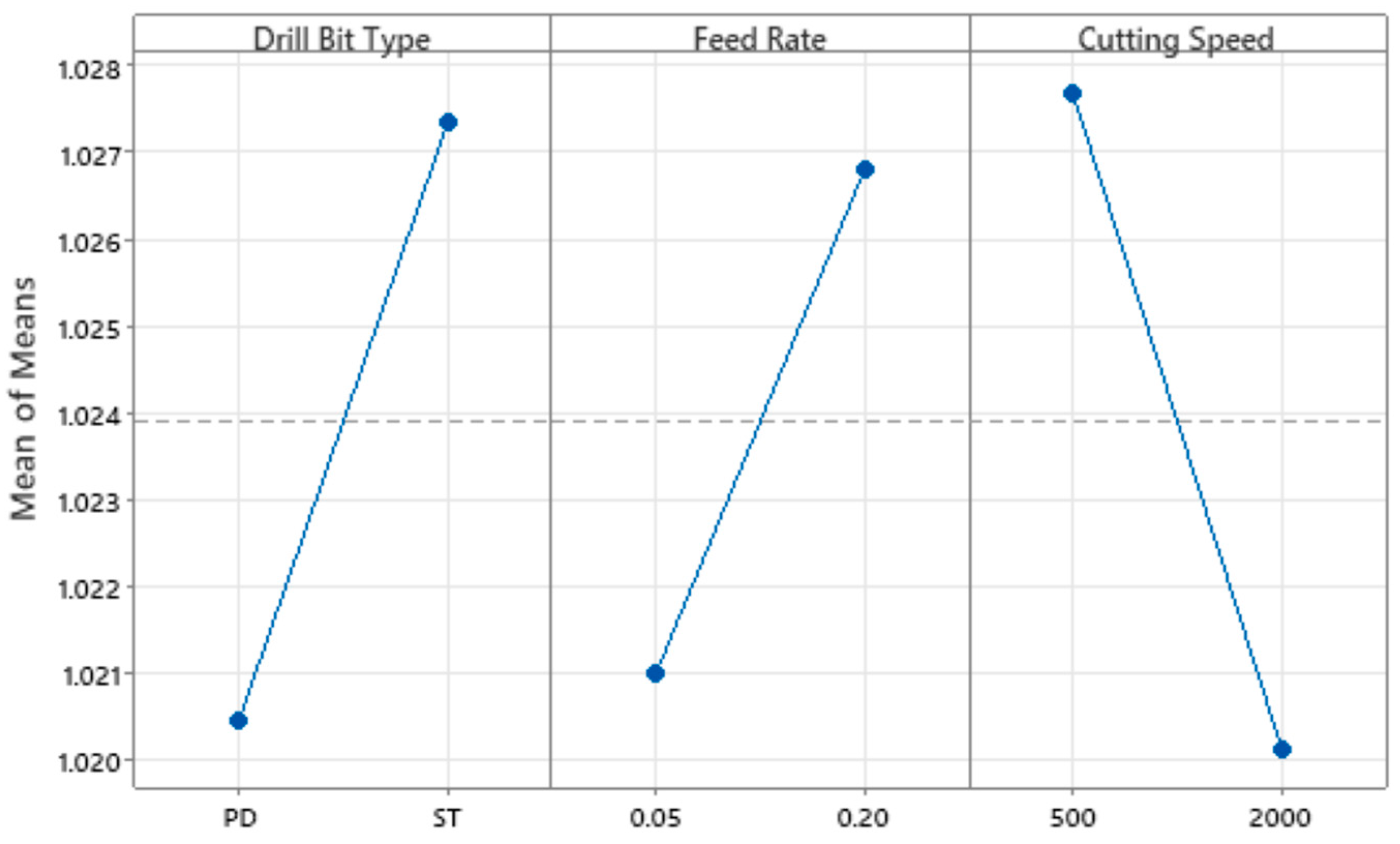

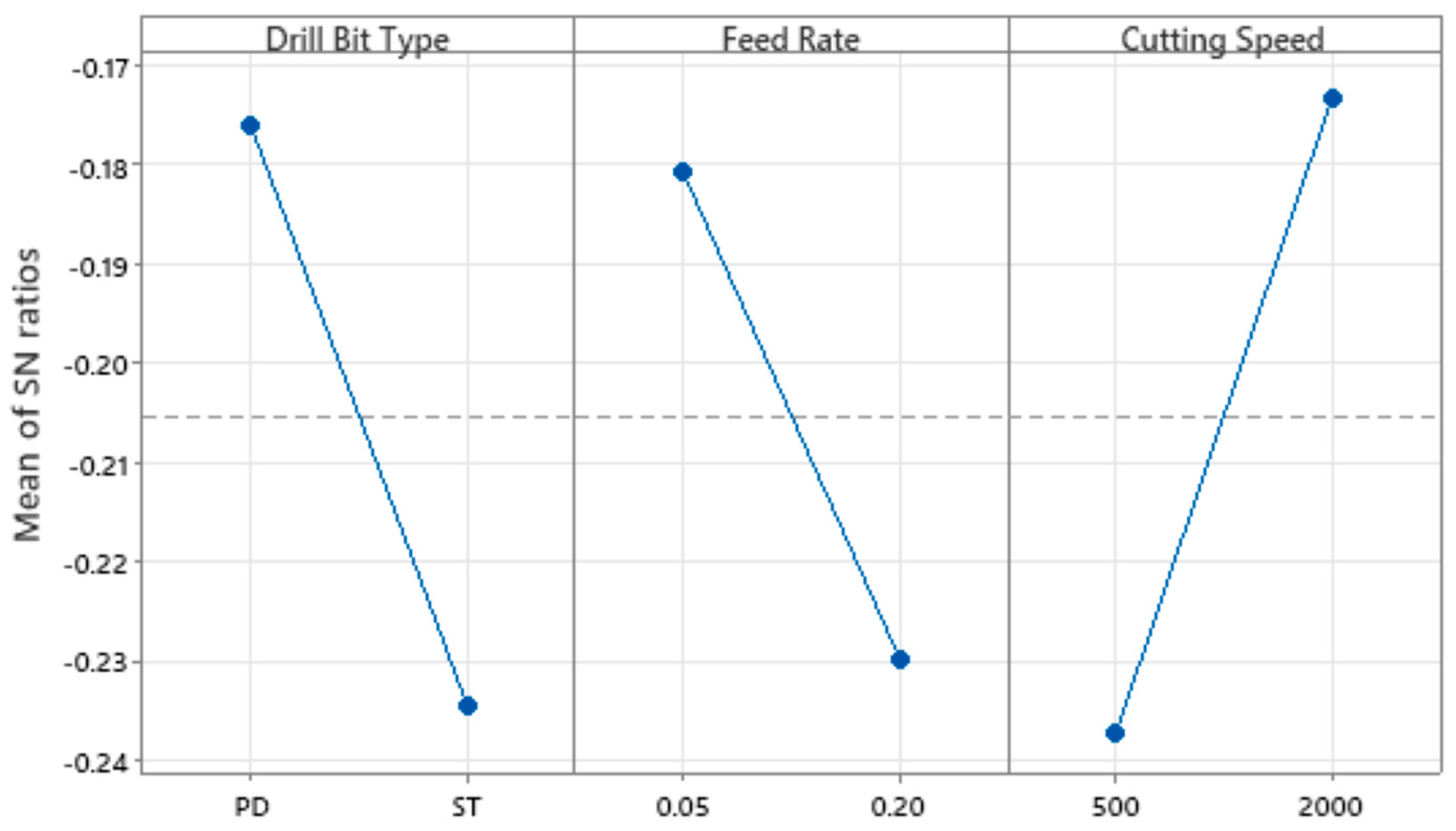

3.3. Taguchi Method Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Continental Reifen Deutschland GmbH. Off-The-Road Tires—Technical Data Book; Continental Reifen Deutschland GmbH: Hannover, Germany, 2019. [Google Scholar]

- Mouritz, A.P.; Gellert, E.; Burchill, P.; Challis, K. Review of advanced composite structures for naval ships and submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Enercom—Production & Sourcing. Available online: https://www.enercon.de/en/company/production-sourcing (accessed on 24 October 2024).

- Sreejith, M.; Rajeev, R.S. Fiber reinforced composites for aerospace and sports applications. In Fiber Reinforced Composites: Constituents, Compatibility, Perspectives and Applications; Woodhead Publishing: Cambridge, UK, 2021; pp. 821–859. [Google Scholar]

- Zimmer, A.; Bachmann, S. Challenges for recycling medium-density fiberboard (MDF). Results Eng. 2023, 19, 101277. [Google Scholar] [CrossRef]

- Composite Panel. Association—Medium Density Fiberboard. Available online: https://www.compositepanel.org/products/medium-density-fiberboard/ (accessed on 21 October 2024).

- Ghabezi, P.; Khoran, M. Optimization of Drilling Parameters in Composite Sandwich Structures (PVC Core). Indian J. Sci. Res. 2014, 2, 173–179. [Google Scholar]

- Ghabezi, P.; Farahani, M.; Shahmirzaloo, A.; Ghorbani, H.; Harrison, N.M. Defect evaluation of the honeycomb structures formed during the drilling process. Int. J. Damage Mech. 2020, 29, 454–466. [Google Scholar]

- Yasar, N.K.; Korkmaz, M.E.; Günay, M. Investigation on hole quality of cutting conditions in drilling of CFRP composite. MATEC Web Conf. 2017, 112, 01013. [Google Scholar] [CrossRef]

- Rajkumar, D.; Ranjithkumar, P.; Jenarthanan, M.P.; Sathiya Narayanan, C. Experimental investigation and analysis of factors influencing delamination and thrust force during drilling of carbon-fibre reinforced polymer composites. Pigment. Resin Technol. 2017, 46, 507–524. [Google Scholar]

- Xu, J.; Li, L.; Geier, N.; Davim, J.P.; Chen, M. Experimental study of drilling behaviors and damage issues for woven GFRP composites using special drills. J. Mater. Res. Technol. 2022, 21, 1256–1273. [Google Scholar]

- Martins, A.; Carvalho, A.; Bragança, I.M.F.; Barbosa, I.C.J.; Barbosa, J.I.; Loja, M.A.R. A Statistical Assessment of Drilling Effects on Glass Fiber-Reinforced Polymeric Composites. Materials 2024, 17, 5631. [Google Scholar] [CrossRef]

- Geng, D.; Liu, Y.; Shao, Z.; Lu, Z.; Cai, J.; Li, X.; Jiang, X.; Zhang, D. Delamination formation, evaluation and suppression during drilling of composite laminates: A review. Compos. Struct. 2019, 216, 168–186. [Google Scholar] [CrossRef]

- Kumar, G.; Rangappa, S.M.; Siengchin, S.; Zafar, S. A review of recent advancements in drilling of fiber-reinforced polymer composites. Compos. Part C Open Access 2022, 9, 100312. [Google Scholar] [CrossRef]

- Xu, J.; Geier, N.; Shen, J.; Krishnaraj, V.; Samsudeensadham, S. A review on CFRP drilling: Fundamental mechanisms, damage issues, and approaches toward high-quality drilling. J. Mater. Res. Technol. 2023, 24, 9677–9707. [Google Scholar]

- Heisel, U.; Pfeifroth, T. Influence of Point Angle on Drill Hole Quality and Machining Forces when Drilling CFRP. CFRP Procedia Cirp 2012, 1, 471–476. [Google Scholar]

- Feito, N.; Díaz-Álvarez, J.; Díaz-Álvarez, A.; Cantero, J.L.; Miguélez, M.H. Experimental Analysis of the Influence of Drill Point Angle and Wear on the Drilling of Woven CFRPs. Materials 2014, 7, 4258–4271. [Google Scholar] [CrossRef]

- Tejas, N.; Rahul, M.C. Effect of Point Angle in Twist Drill Bit on Delamination in CFRP. Mater. Today Proc. 2020, 21, 1278–1282. [Google Scholar]

- Pardo, A.; Le Gall, J.; Heinemann, R.; Bagshaw, L. The impact of tool point angle and interlayer gap width on interface borehole quality in drilling CFRP/titanium stacks. Int. J. Adv. Manuf. Technol. 2021, 114, 159–171. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Tavares, J.M.R.S.; de Albuquerque, V.H.C.; Marques, J.F.S.; Andrade, O.N.G. Drilling Damage in Composite Material. Materials 2014, 7, 3802–3819. [Google Scholar] [CrossRef] [PubMed]

- Silva, P.; Matos, J.E.; Durão, L.M.P. Analysis of damage outcome in the strength of polymer composite materials. J. Compos. Mater. 2019, 53, 547–560. [Google Scholar]

- Camanho, P.P.; Erçin, G.H.; Catalanotti, G.; Mahdi, S.; Linde, P. A finite fracture mechanics model for the prediction of the open-hole strength of composite laminates. Compos. Part A 2012, 43, 1219–1225. [Google Scholar] [CrossRef]

- Bao, H.; Liu, G. Progressive failure analysis on scaled open-hole tensile composite laminates. Compos. Struct. 2016, 150, 173–180. [Google Scholar]

- Waqar, M.; Memon, A.M.; Sabih, M.; Alhems, L.M. Composite pipelines: Analyzing defects and advancements in non-destructive testing techniques. Eng. Fail. Anal. 2024, 157, 107914. [Google Scholar] [CrossRef]

- Kapadia, A. Best Practice Guide Non Destructive Testing of Composite Materials. National Composites Network. Available online: https://avaloncsl.com/wp-content/uploads/2013/01/ncn-best-practice-ndt.pdf (accessed on 12 November 2024).

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-ray computed tomography of polymer composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Song, X.; Zhou, J.; Zhang, D.; Zhang, S.; Li, P.; Bai, L.; Yang, X.; Du, F.; Wang, J.; Chen, X.; et al. Trans-scale analysis of 3D braided composites with voids based on micro-CT imaging and unsupervised machine learning. Compos. Sci. Technol. 2024, 249, 110494. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar]

- Wang, Y.; Burnett, T.L.; Chai, Y.; Soutis, C.; Hogg, P.J.; Withers, P.J. X-ray computed tomography study of kink bands in unidirectional composites. Compos. Struct. 2017, 160, 917–924. [Google Scholar]

- Coelho, B. Deteção de defeitos em materiais compósitos usando tecnologia de ultrassons. Universidade do Minho, 2020. Available online: https://repositorium.sdum.uminho.pt/handle/1822/65770 (accessed on 22 November 2024). (In Portuguese).

- Xu, C.; Zhang, W.; Wu, C.; Xie, J.; Yin, X.; Chen, G. An improved method of Eddy current pulsed thermography to detect subsurface defects in glass fiber reinforced polymer composites. Compos. Struct. 2020, 242, 112145. [Google Scholar]

- Versaci, M.; Laganà, F.; Morabito, F.C.; Palumbo, A.; Angiulli, G. Adaptation of an Eddy Current Model for Characterizing Subsurface Defects in CFRP Plates Using FEM Analysis Based on Energy Functional. Mathematics 2024, 12, 2854. [Google Scholar] [CrossRef]

- Strąg, M.; Świderski, W. Non-destructive inspection of military-designated composite materials with the use of Terahertz imaging. Compos. Struct. 2023, 306, 116588. [Google Scholar] [CrossRef]

- Besson, A.; Minasyan, A. Terahertz Imaging for Composite Non Destructive Testing. In Proceedings of the 15th Asia Pacific Conference for Non-Destructive Testing, Singapore, 13–17 November 2017; Volume 23. Available online: https://www.ndt.net/?id=22114 (accessed on 15 November 2024).

- Durão, L.M.P.; Tavares, J.M.R.S.; de Albuquerque, V.H.C.; Goncalves, D.J.S. Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos. Struct. 2013, 96, 576–583. [Google Scholar] [CrossRef]

- Silva, D.; Teixeira, J.P.; Machado, C.M. Methodology analysis for evaluation of drilling-induced damage composites. Int. J. Adv. Manuf. Technol. 2014, 71, 1919–1928. [Google Scholar] [CrossRef]

- De Albuquerque, V.H.C.; Tavares, J.M.R.S.; Durão, L.M.P. Evaluation of Delamination Damage on Composite Plates using an Artificial Neural Network for the Radiographic Image Analysis. J. Compos. Mater. 2009, 44, 1139–1159. [Google Scholar] [CrossRef]

- Caggiano, A.; Mattera, G.; Nele, L. Smart Tool Wear Monitoring of CFRP/CFRP Stack Drilling Using Autoencoders and Memory-Based Neural Networks. Appl. Sci. 2023, 13, 3307. [Google Scholar] [CrossRef]

- Chen, W.-C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int. J. Mach. Tools Manuf. 1997, 37, 1097–1108. [Google Scholar] [CrossRef]

- Lissek, F.; Tegas, J.; Kaufeld, M. Damage quantification for machining of CFRP: An introduction about characteristic values considering shape and orientation of drilling-induced delamination. Procedia Eng. 2016, 149, 2–16. [Google Scholar] [CrossRef]

- Davim, J.P.; Campos Rubio, J.; Abrao, A.M. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos. Sci. Technol. 2007, 67, 1939–1945. [Google Scholar] [CrossRef]

- Tsao, C.C.; Kuo, K.L.; Hsu, I.C. Evaluation of a novel approach to a delamination factor after drilling composite laminates using a core-saw drill. Int. J. Adv. Manuf. Technol. 2012, 59, 617–622. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Mi, S.; An, Q.; Chen, M. Study of drilling-induced defects for CFRP composites using new criteria. Compos. Struct. 2018, 201, 1076–1087. [Google Scholar] [CrossRef]

- Durão, L.M.P.; Gonçalves, D.J.; Tavares, J.M.R.; de Albuquerque, V.H.C.; Marques, A.T. Comparative analysis of drills for composite laminates. J. Compos. Mater. 2011, 46, 1649–1659. [Google Scholar] [CrossRef]

- Wang, G.D.; Kirwa, M.S. Comparisons of the use of twist, pilot-hole and step-drill on influence of carbon fiber-reinforced polymer drilling hole quality. J. Compos. Mater. 2018, 52, 1465–1480. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C.C. Effects of special drill bits on drilling-induced delamination of composite materials. Int. J. Mach. Tools Manuf. 2006, 46, 1403–1416. [Google Scholar] [CrossRef]

- Tsao, C.C. The effect of pilot hole on delamination when core drilling composite materials. Int. J. Mach. Tools Manuf. 2006, 46, 1653–1661. [Google Scholar]

- Durão, L.M.P.; Matos, J.E.; Loureiro, N.C.; Esteves, J.L.; Fernandes, S.C.F. Damage Propagation by Cyclic Loading in Drilled Carbon/Epoxy Plates. Materials 2023, 16, 2688. [Google Scholar] [CrossRef] [PubMed]

- Roy, R.K. A Primer on the Taguchi Method—Google Books. Available online: https://books.google.pt/books?id=OUI54mrYdqIC&printsec=frontcover&hl=pt-PT#v=onepage&q&f=false (accessed on 13 December 2024).

- Taguchi Robust Design and Loss Function. Available online: https://sixsigmastudyguide.com/taguchi-robust-design/ (accessed on 16 December 2024).

- ISO 527-1; Plastics—Determination of tensile properties. Part 1: General principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- Hocheng, H.; Dharan, C.K.H. Delamination during drilling in composite laminates. J. Eng. Ind. 1990, 112, 236–239. [Google Scholar]

- Karpat, Y.; Karagüzel, U.; Bahtiyar, O. A thermo-mechanical model of drill margin-borehole surface interface contact conditions in dry drilling of thick CFRP laminates. Int. J. Mach. Tools Manuf. 2020, 154, 103565. [Google Scholar]

- Wysmulski, P. Failure Mechanism of Tensile CFRP Composite Plates with Variable Hole Diameter. Materials 2023, 16, 4714. [Google Scholar] [CrossRef]

- ASTM D5961; Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates. ASTM International: West Conshohocken, PA, USA, 2017.

| Coupon ID | Drill Geometry | Feed Rate mm/rev | Spindle Speed rpm |

|---|---|---|---|

| 1–PD0505 | Pilot hole drilling | 0.05 | 500 |

| 2-PD0520 | Pilot hole drilling | 0.05 | 2000 |

| 3-PD2005 | Pilot hole drilling | 0.20 | 500 |

| 4-PD2020 | Pilot hole drilling | 0.20 | 2000 |

| 5-ST0505 | Step drill | 0.05 | 500 |

| 6-ST0520 | Step drill | 0.05 | 2000 |

| 7-ST2005 | Step drill | 0.20 | 500 |

| 8-ST2020 | Step drill | 0.20 | 2000 |

| Test | Units | Value |

|---|---|---|

| 0° Tensile Strength | MPa | 2207 |

| 90° Tensile Strength | MPa | 81 |

| 0° Tensile Modulus | GPa | 141 |

| 90° Tensile Modulus | GPa | 10 |

| 0° Compression Strength | MPa | 1531 |

| 0° Compression Modulus | GPa | 128 |

| 0° ILSS | MPa | 128 |

| In-plane Shear Strength | MPa | 114 |

| Test | Units | Average | Std Dev |

|---|---|---|---|

| Tensile Strength | MPa | 971.44 | 82.09 |

| Tensile Modulus | GPa | 66.55 | 2.34 |

| Coupon ID | Hole Area | Damage Area | Fed |

|---|---|---|---|

| 1-PD0505 | 28.227 | 1.312 | 1.023 |

| 2-PD0520 | 28.456 | 0.759 | 1.013 |

| 3-PD2005 | 28.566 | 1.552 | 1.027 |

| 4-PD2020 | 28.547 | 1.097 | 1.019 |

| 5-ST0505 | 28.248 | 1.694 | 1.029 |

| 6-ST0520 | 28.365 | 1.154 | 1.020 |

| 7-ST2005 | 28.492 | 1.832 | 1.032 |

| 8-ST2020 | 28.571 | 1.121 | 1.028 |

| Average PD | 28.449 | 1.180 | 1.022 |

| Average ST | 28.419 | 1.450 | 1.028 |

| Source | DF | SQ Seq | SQ(aj) | QM(aj) | F | p |

|---|---|---|---|---|---|---|

| Drill type | 1 | 0.000094 | 0.000094 | 0.000094 | 214.36 | 0.043 |

| Feed rate | 1 | 0.000067 | 0.000067 | 0.000067 | 152.60 | 0.051 |

| Cut speed | 1 | 0.000113 | 0.000113 | 0.000113 | 257.40 | 0.040 |

| Drill*Feed | 1 | 0.000000 | 0.000000 | 0.000000 | 0.98 | 0.504 |

| Drill*speed | 1 | 0.000004 | 0.000004 | 0.000004 | 9.09 | 0.204 |

| Feed*speed | 1 | 0.000005 | 0.000005 | 0.000005 | 10.86 | 0.188 |

| Residual error | 1 | 0.000000 | 0.000000 | 0.000000 | ||

| TOTAL | 7 | 0.000284 |

| Source | DF | SQ Seq | SQ(aj) | QM(aj) | F | p |

|---|---|---|---|---|---|---|

| Drill type | 1 | 0.006808 | 0.006808 | 0.006808 | 231.74 | 0.042 |

| Feed rate | 1 | 0.004790 | 0.004790 | 0.004790 | 163.06 | 0.050 |

| Cut speed | 1 | 0.008221 | 0.008221 | 0.008221 | 279.83 | 0.038 |

| Drill*Feed | 1 | 0.000031 | 0.000031 | 0.000031 | 1.04 | 0.494 |

| Drill*speed | 1 | 0.000302 | 0.000302 | 0.000302 | 10.28 | 0.192 |

| Feed*speed | 1 | 0.000364 | 0.000364 | 0.000364 | 12.38 | 0.176 |

| Residual error | 1 | 0.000029 | 0.000029 | 0.000029 | ||

| TOTAL | 7 | 0.020544 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cerqueira, H.R.C.; Matos, J.E.; Esteves, J.L.; Fernandes, S.C.F.; Durão, L.M.P. A Statistical Study on the Influence of Drilling Process in Delamination Observed in Composite Plates. Materials 2025, 18, 1595. https://doi.org/10.3390/ma18071595

Cerqueira HRC, Matos JE, Esteves JL, Fernandes SCF, Durão LMP. A Statistical Study on the Influence of Drilling Process in Delamination Observed in Composite Plates. Materials. 2025; 18(7):1595. https://doi.org/10.3390/ma18071595

Chicago/Turabian StyleCerqueira, Hugo R. C., João E. Matos, José L. Esteves, Susana C. F. Fernandes, and Luis M. P. Durão. 2025. "A Statistical Study on the Influence of Drilling Process in Delamination Observed in Composite Plates" Materials 18, no. 7: 1595. https://doi.org/10.3390/ma18071595

APA StyleCerqueira, H. R. C., Matos, J. E., Esteves, J. L., Fernandes, S. C. F., & Durão, L. M. P. (2025). A Statistical Study on the Influence of Drilling Process in Delamination Observed in Composite Plates. Materials, 18(7), 1595. https://doi.org/10.3390/ma18071595