Performance Evaluation of Warm-Mix Asphalt Binders with an Emphasis on Rutting and Intermediate-Temperature Cracking Resistance

Abstract

1. Introduction

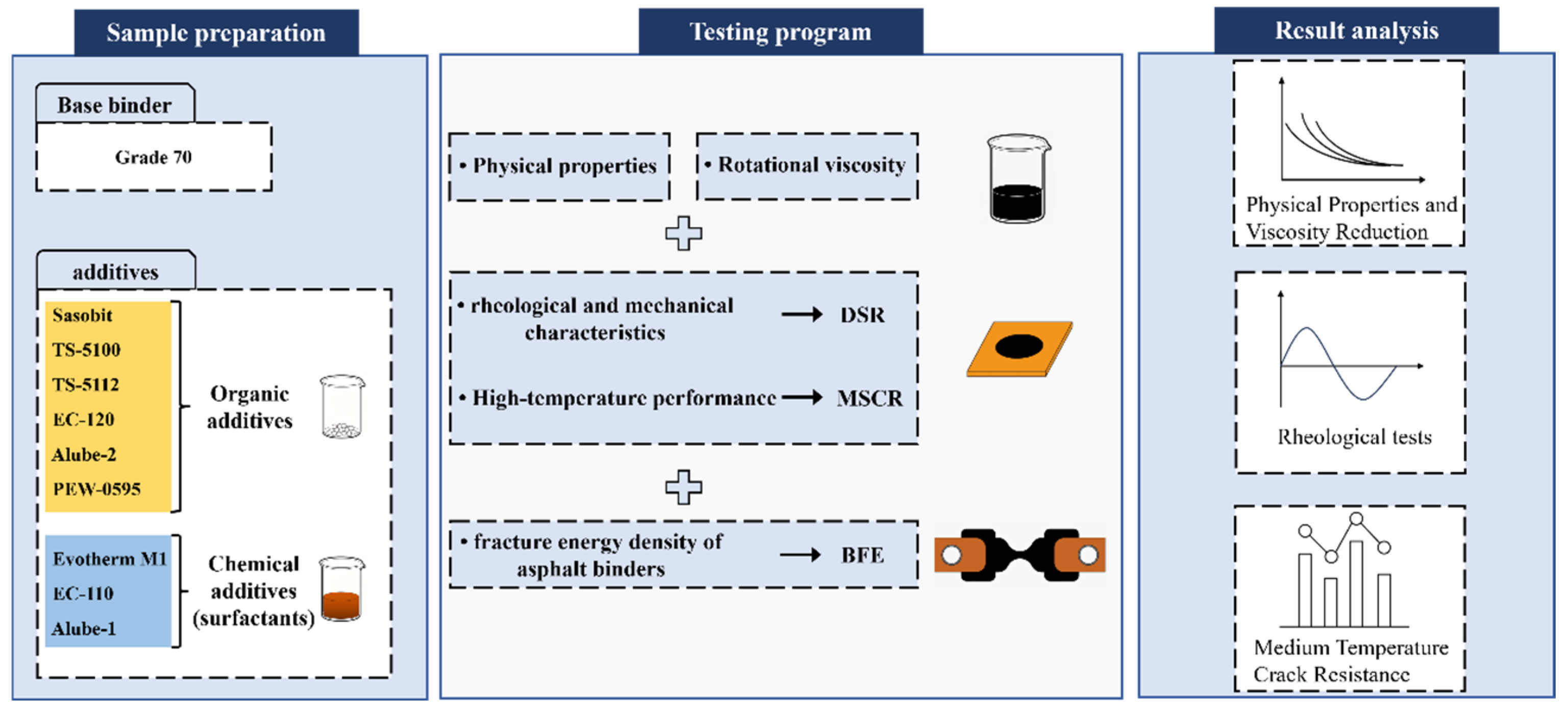

2. Materials and Methods

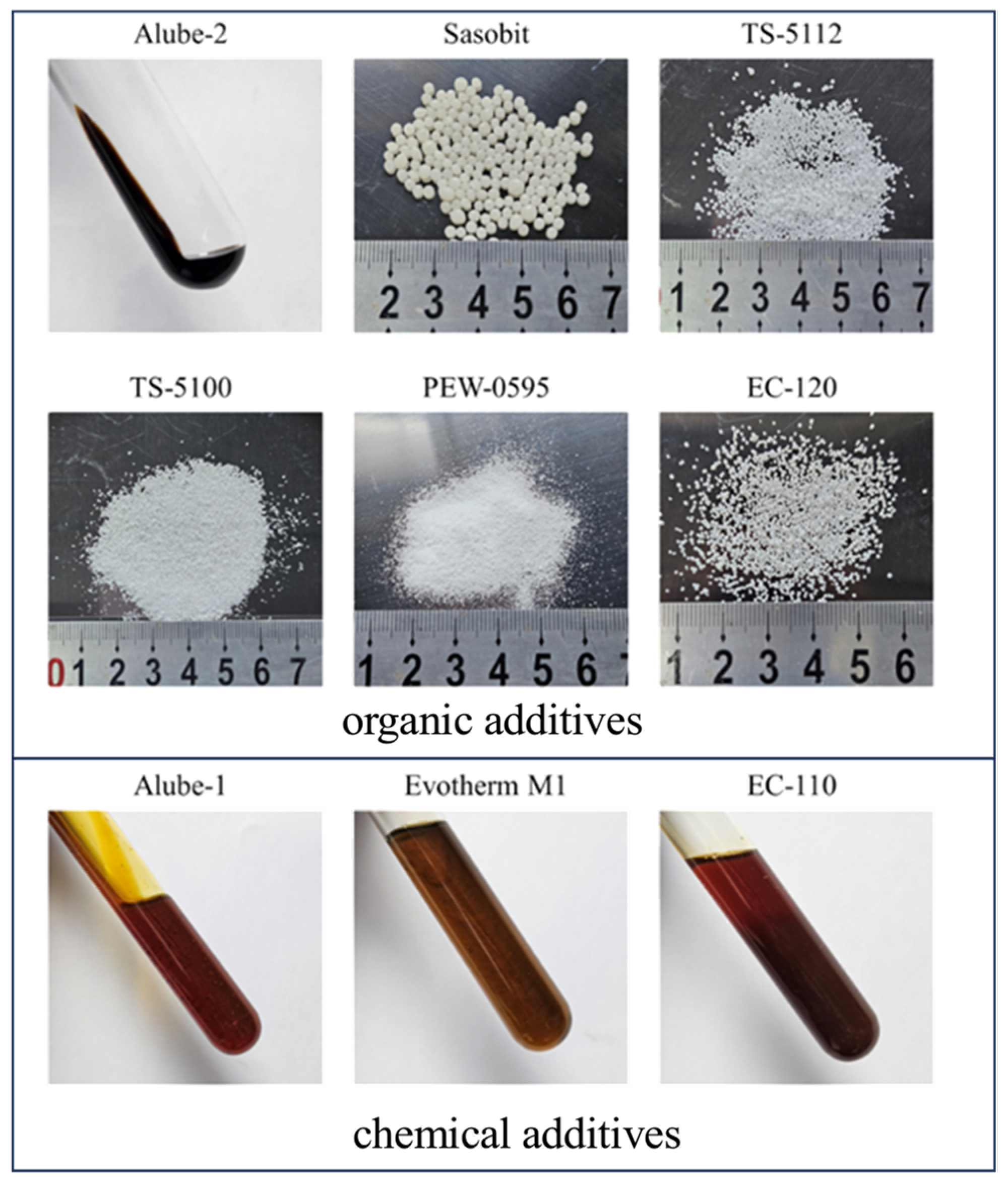

2.1. Materials

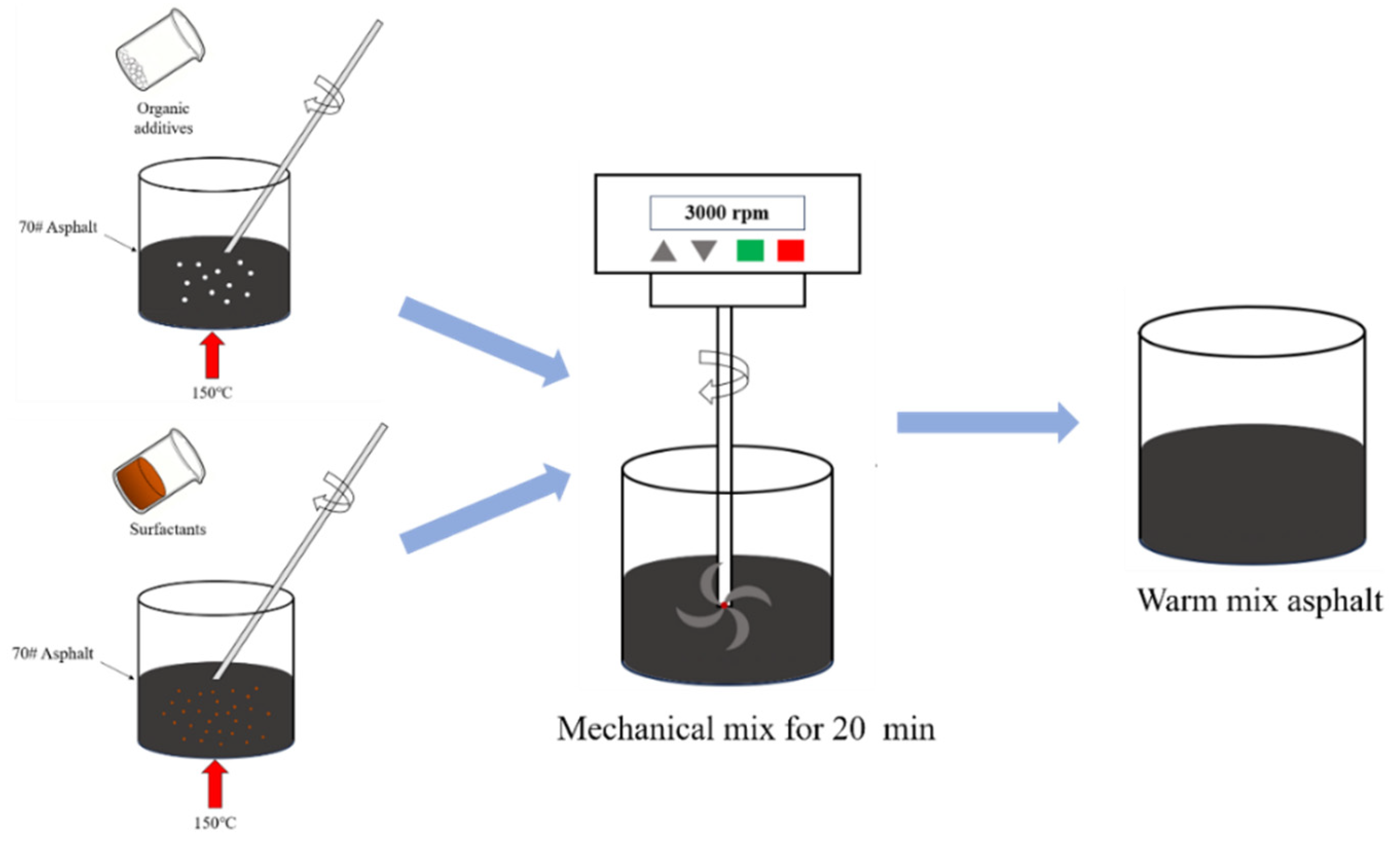

2.2. Preparation of WMA Additive-Modified Asphalt Binders

2.3. The Test Method

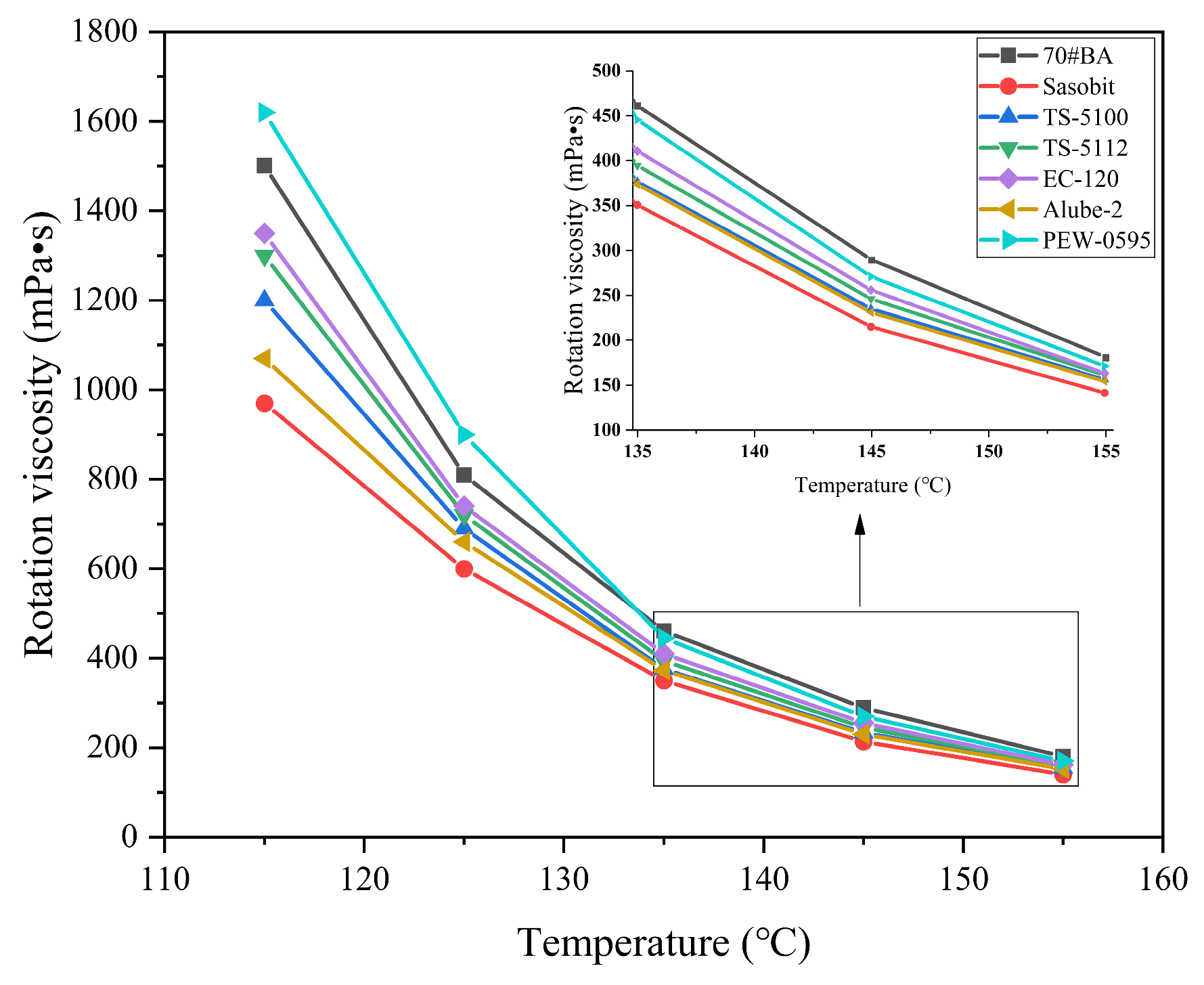

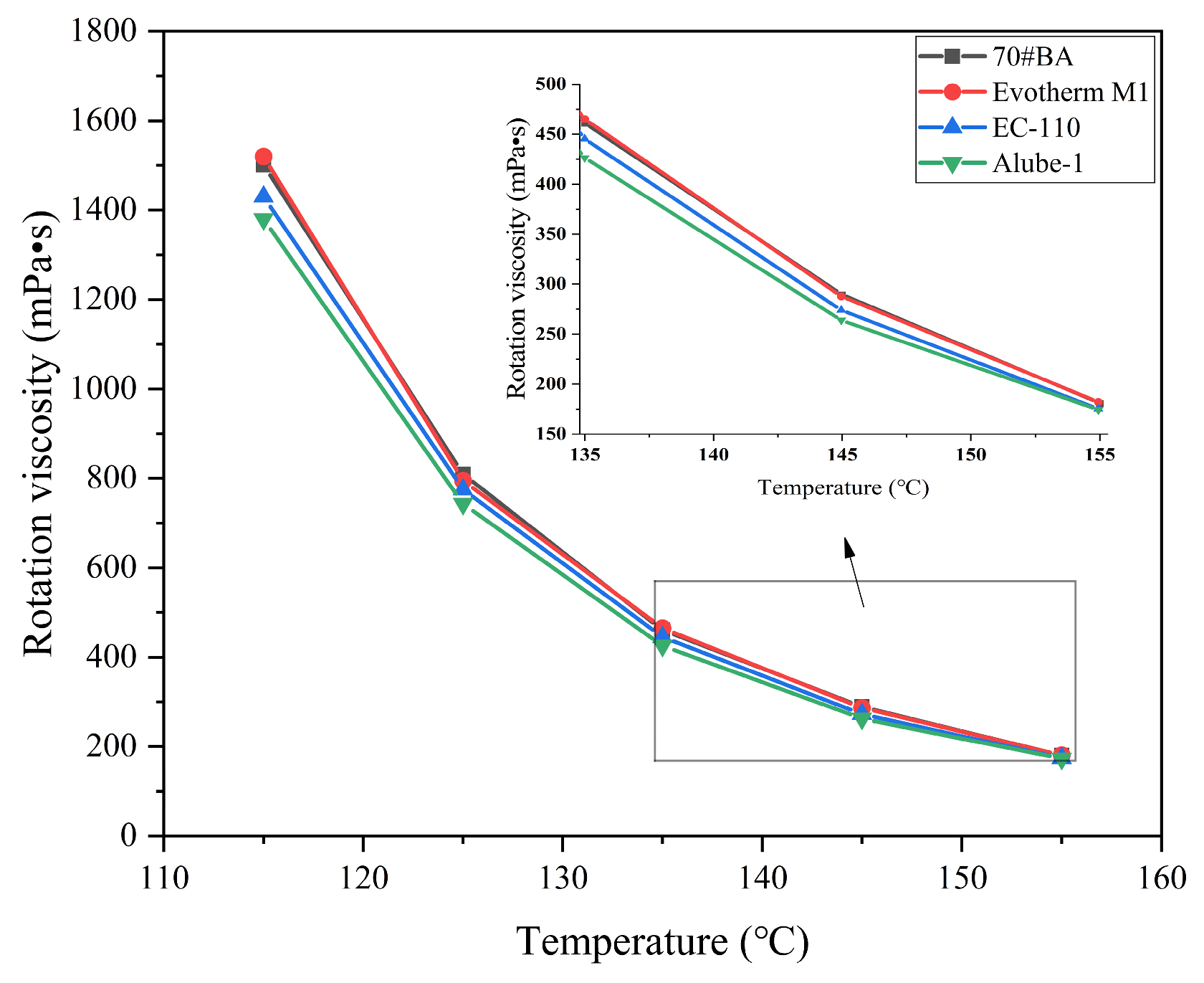

2.3.1. The Rotational Viscosity (RV) Test

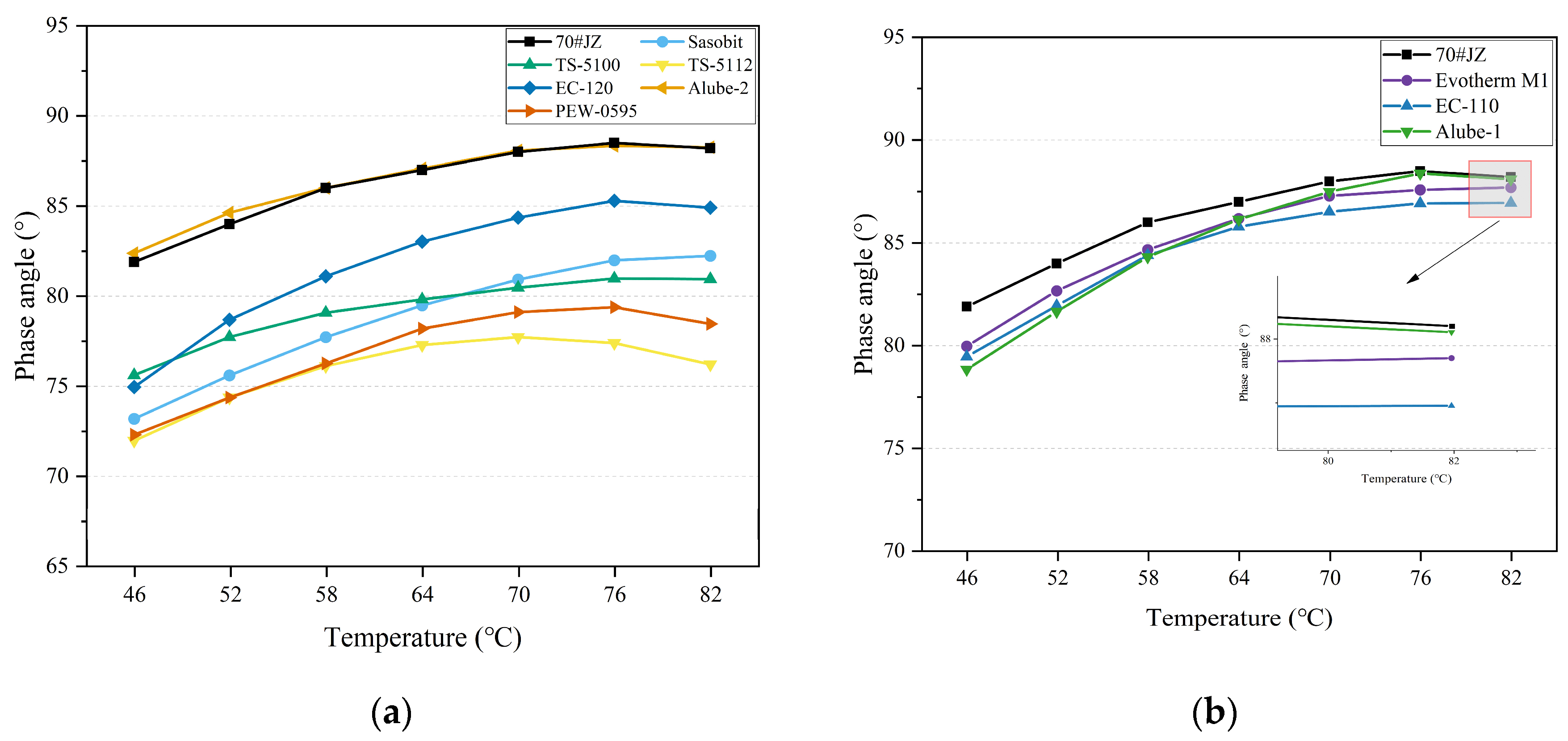

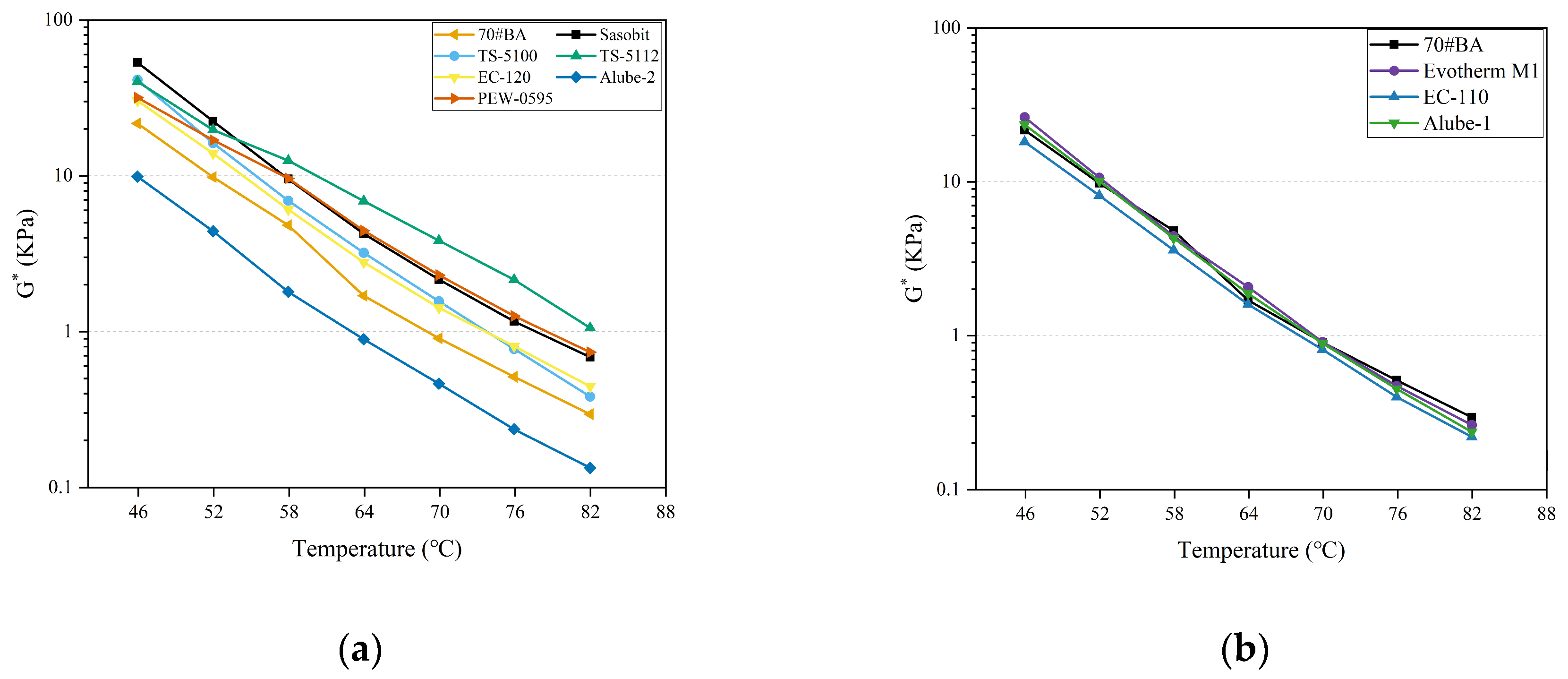

2.3.2. The Temperature Sweep Test

2.3.3. The Multi-Stress Creep Recovery (MSCR) Test

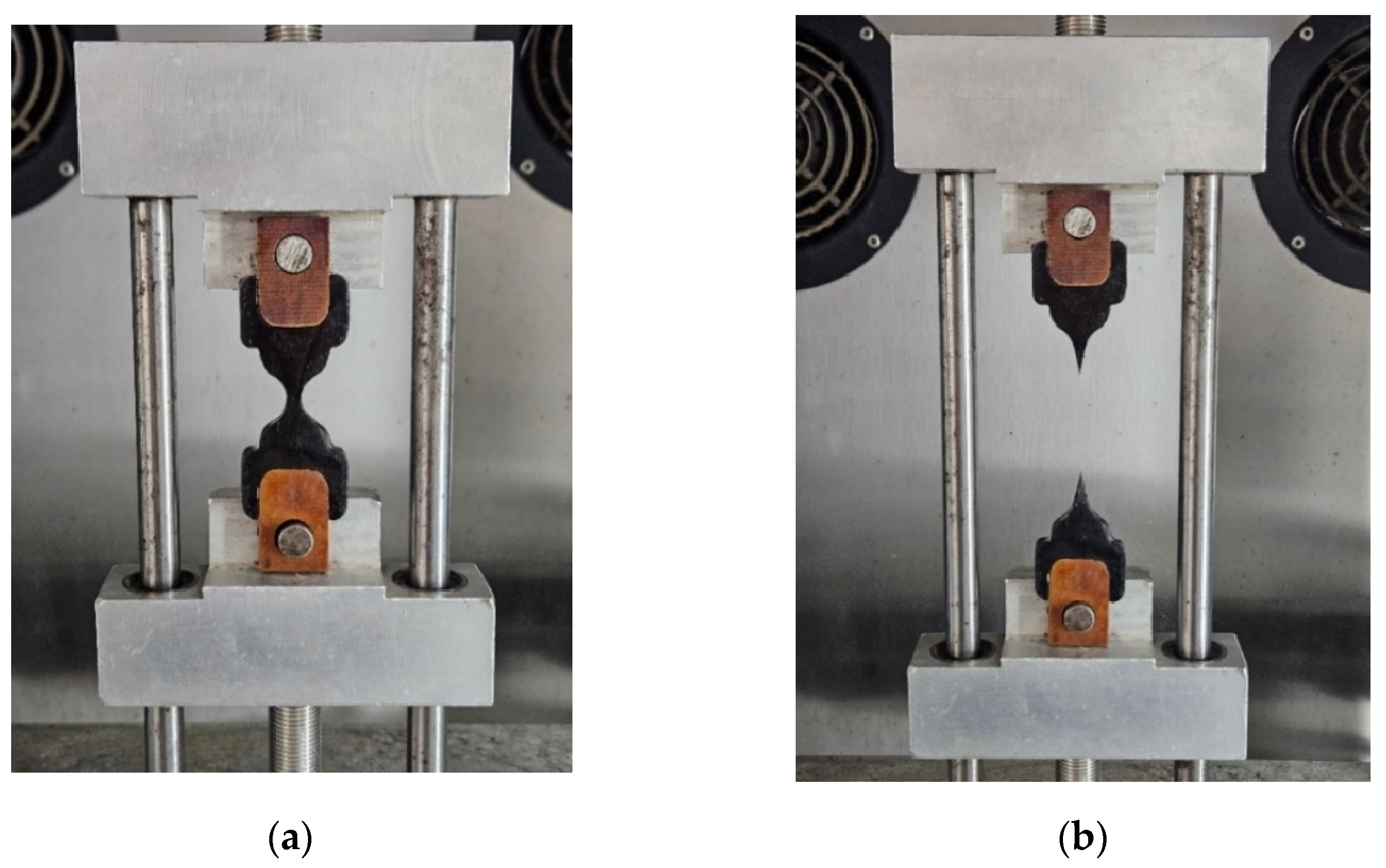

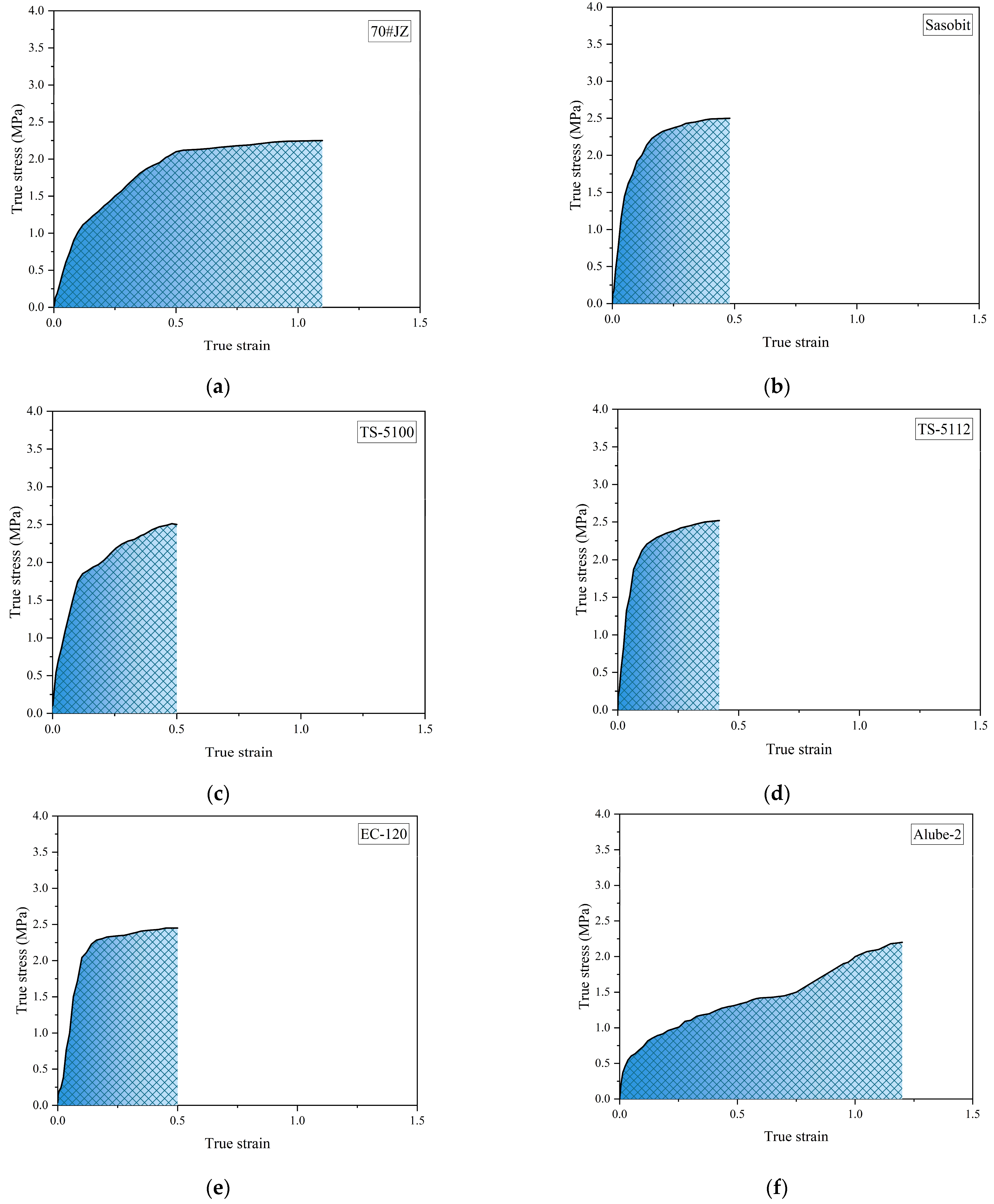

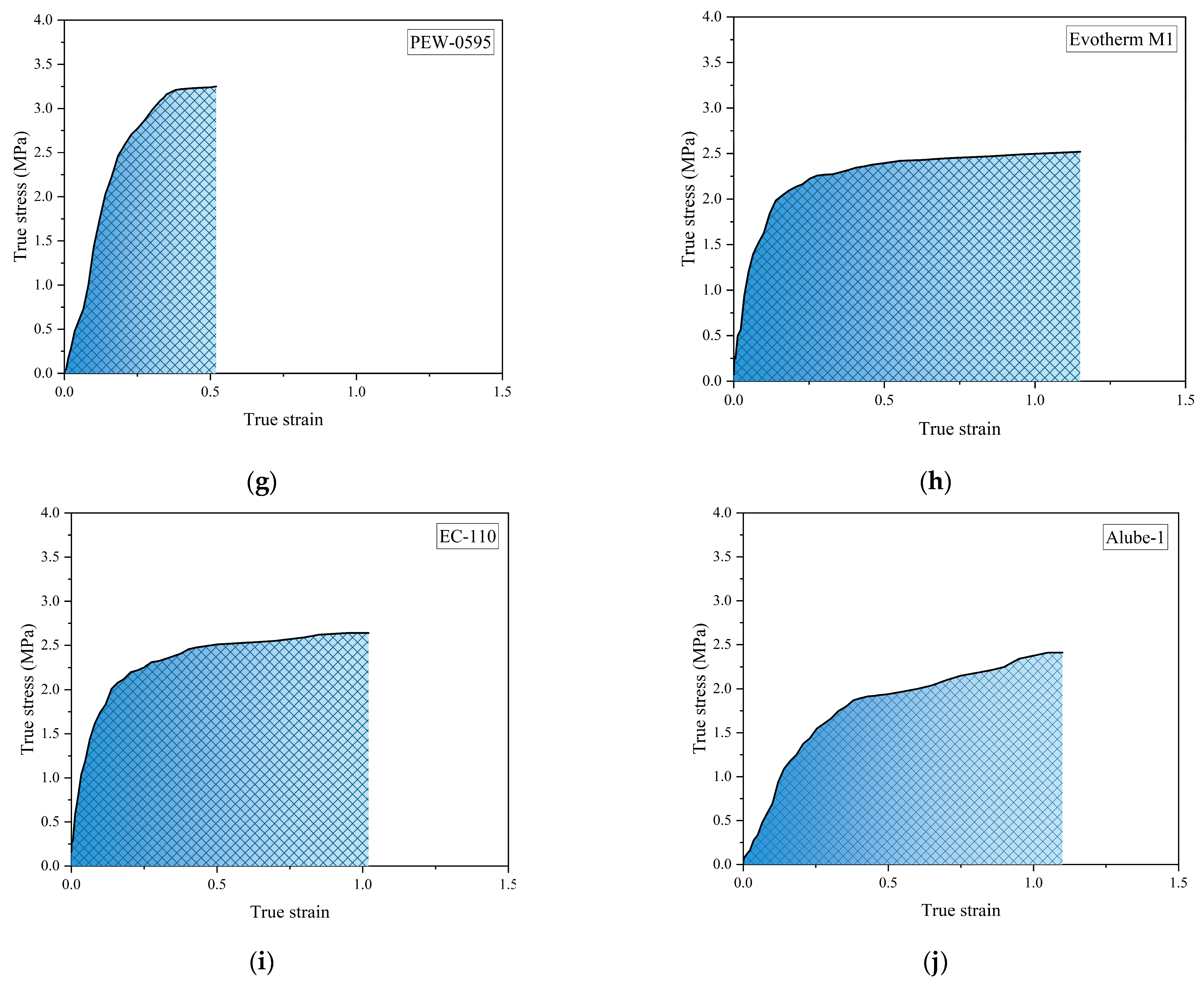

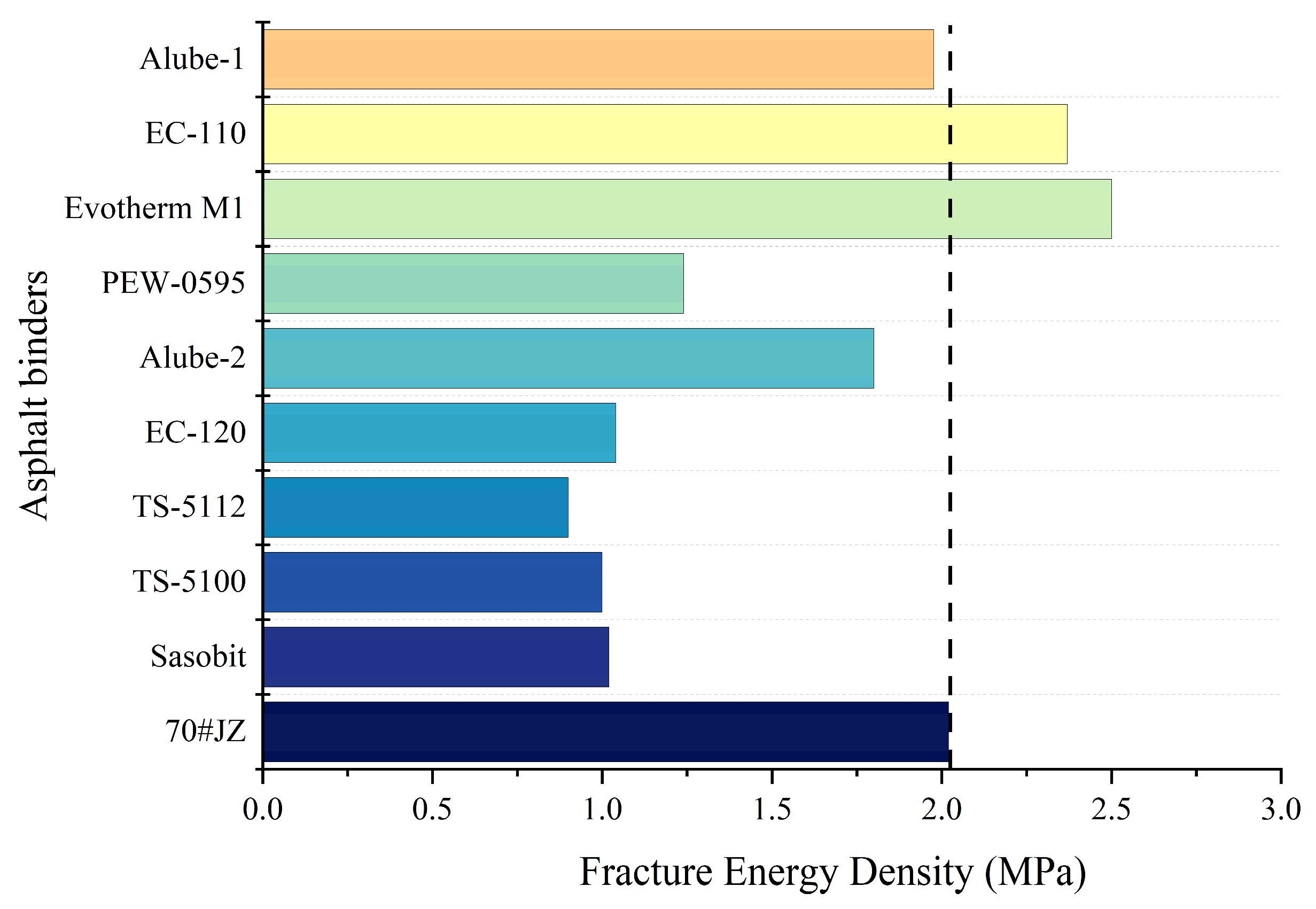

2.3.4. The Binder Fracture Energy (BFE) Test

3. Results

3.1. Viscosity-Reducing Effect

3.2. High-Temperature Rutting Resistance

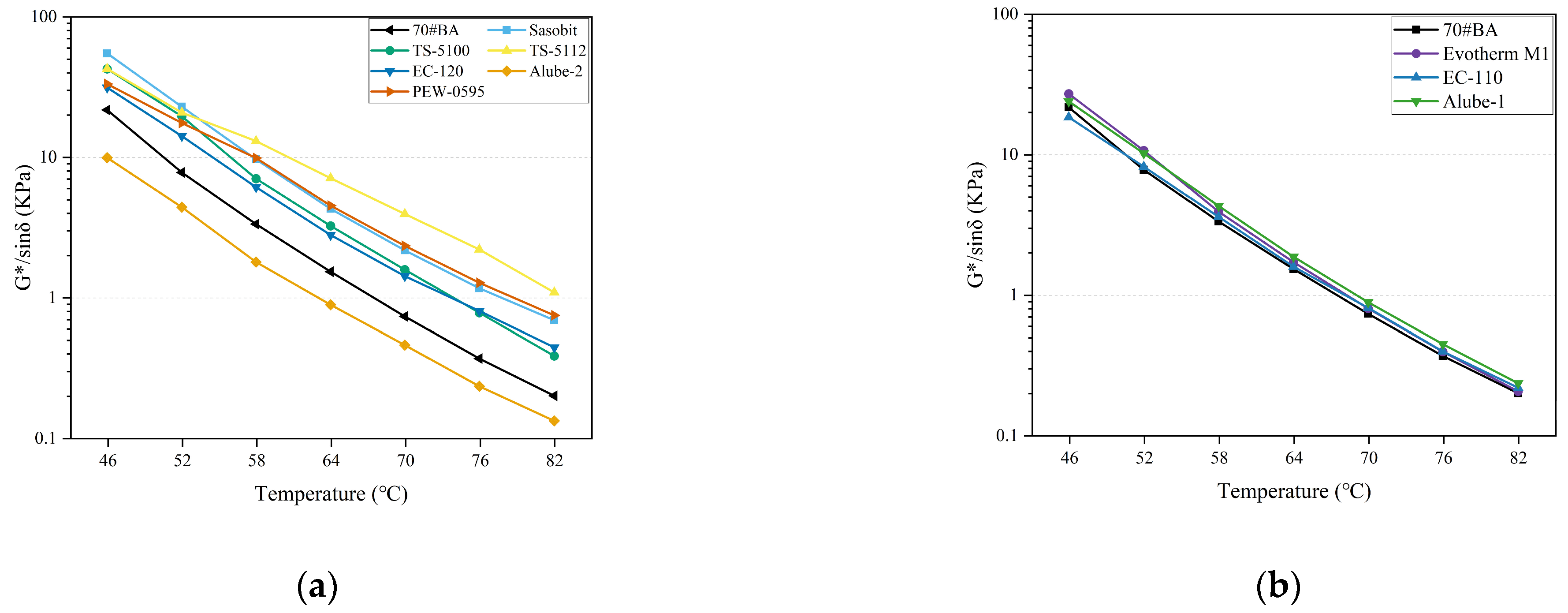

3.2.1. Temperature Sweep Tests

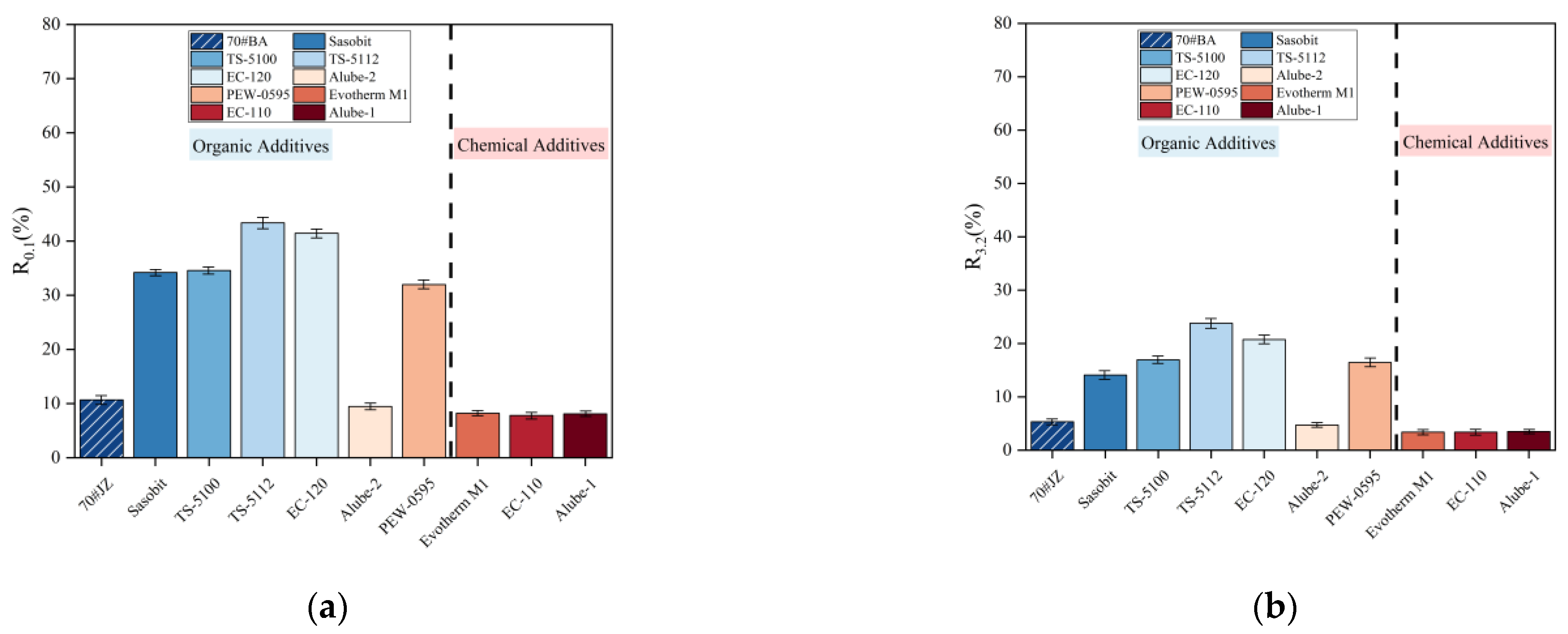

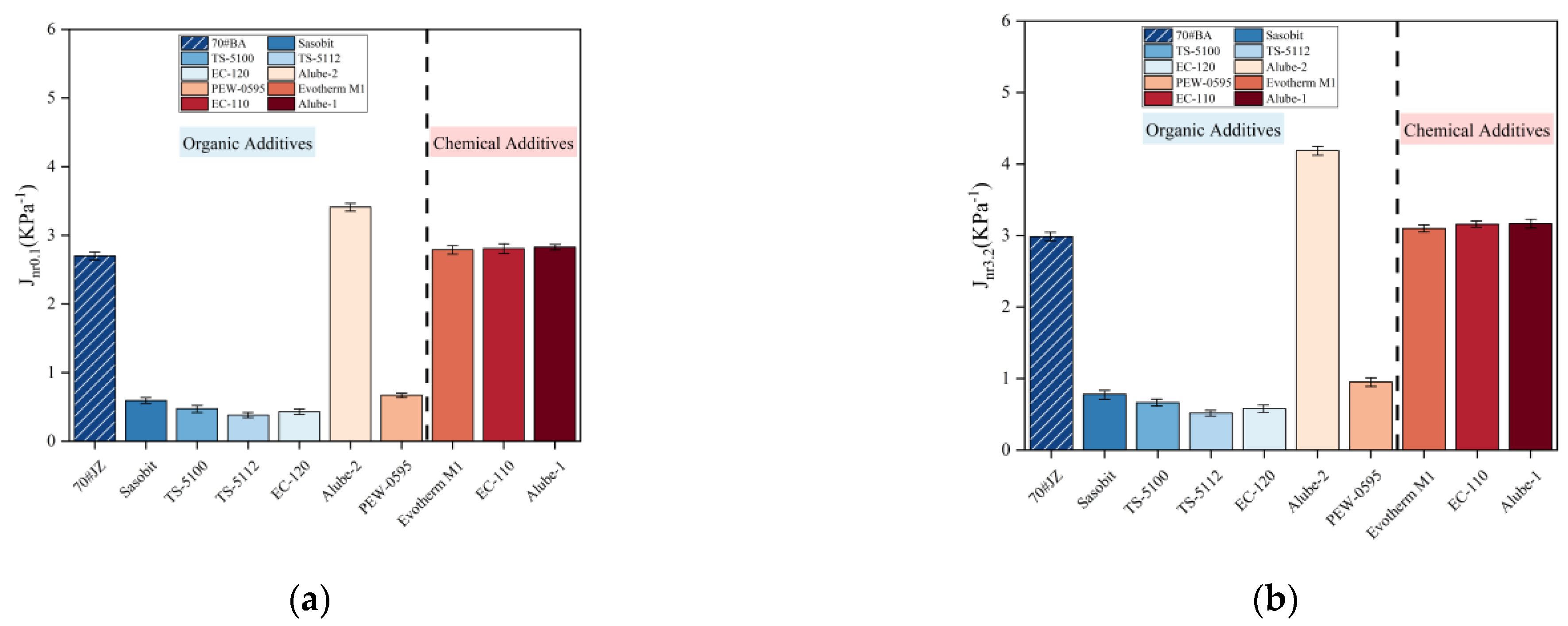

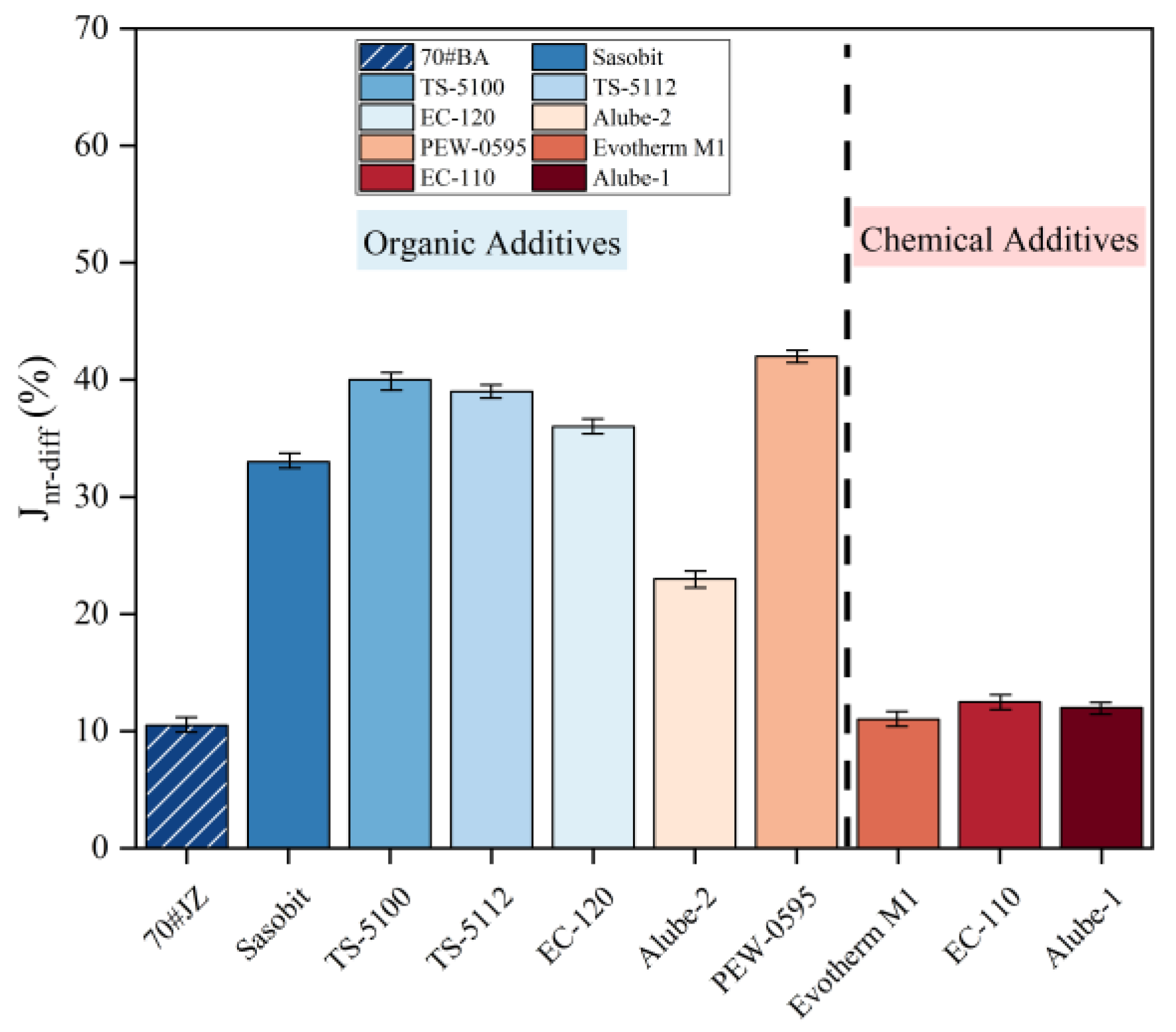

3.2.2. MSCR Tests

3.3. BFE Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sukhija, M.; Saboo, N. A comprehensive review of warm mix asphalt mixtures-laboratory to field. Constr. Build. Mater. 2020, 274, 121781. [Google Scholar] [CrossRef]

- Cheraghian, G.; Cannone Falchetto, A.; You, Z.; Chen, S.; Kim, Y.S.; Westerhoff, J.; Moon, K.H.; Wistuba, M.P. Warm mix asphalt technology: An up to date review. J. Clean. Prod. 2020, 268, 122128. [Google Scholar] [CrossRef]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Ghabchi, R.; Rani, S.; Zaman, M.; Ali, S.A. Effect of WMA additive on properties of PPA-modified asphalt binders containing anti-stripping agent. Int. J. Pavement Eng. 2021, 22, 418–431. [Google Scholar] [CrossRef]

- Şahan, N.; Kumandaş, A.; Kabadayı, E.; Çavdar, E.; Oruç, Ş. The use of wax-based additives in bitumen modification: A systematic quantitative literature review. Constr. Build. Mater. 2023, 407, 133423. [Google Scholar] [CrossRef]

- Canestrari, F.; Graziani, A.; Valter, P.; Bahia, H.U. Rheological properties of bituminous binders with synthetic wax. Int. J. Pavement Res. Technol. 2013, 6, 15–21. [Google Scholar]

- Jamaloei, M.H.; Esfahani, M.A.; Torkaman, M.F. Rheological and mechanical properties of bitumen modified with sasobit, polyethylene, paraffin, and their mixture. J. Mater. Civ. Eng. 2019, 31, 04019119. [Google Scholar] [CrossRef]

- Zhang, K.; Luo, Y.; Chen, F.; Han, F. Performance evaluation of new warm mix asphalt and water stability of its mixture based on laboratory tests. Constr. Build. Mater. 2020, 241, 118017. [Google Scholar] [CrossRef]

- Yang, S.; Yan, K.; He, W.; Wang, Z. Effects of Sasobit and Deurex additives on asphalt binders at midrange and high temperatures. Int. J. Pavement Eng. 2019, 20, 1400–1407. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, J.; Ding, H.; Xie, Q.; Qiu, Y. Evaluation of physical hardening of wax-based warm mix asphalt binders from low-temperature rheological properties. Constr. Build. Mater. 2024, 419, 135496. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Q.; Lin, Y.; Dong, N. Effect of wax additives on asphalt rheological behavior as road paving material. Mater. Today Commun. 2023, 37, 107044. [Google Scholar] [CrossRef]

- Zelelew, H.; Paugh, C.; Corrigan, M.; Belagutti, S.; Ramakrishnareddy, J. Laboratory evaluation of the mechanical properties of plant-produced warm-mix asphalt mixtures. Road Mater. Pavement Des. 2013, 14, 49–70. [Google Scholar] [CrossRef]

- Tasdemir, Y. High temperature properties of wax modified binders and asphalt mixtures. Constr. Build. Mater. 2009, 23, 3220–3224. [Google Scholar] [CrossRef]

- Pereira, R.; Almeida-Costa, A.; Duarte, C.; Benta, A. Warm mix asphalt: Chemical additives’ effects on bitumen properties and limestone aggregates mixture compactibility. Int. J. Pavement Res. Technol. 2018, 11, 285–299. [Google Scholar] [CrossRef]

- Bazzaz, M.; Darabi, M.K.; Little, D.N.; Garg, N. Effect of Evotherm-M1 on properties of asphaltic materials used at NAPMRC testing facility. J. Test. Eval. 2019, 48, 2256–2269. [Google Scholar]

- Luo, J.; Yang, Y.; Huang, W.; Xie, C.; Chen, J.; Liu, H.; Ren, T.; Huang, X. Physical, rheological, and microsurface characteristics of high-viscosity binder modified with WMA agents. Adv. Mater. Sci. Eng. 2022, 2022, 5098250. [Google Scholar] [CrossRef]

- Jamshidi, A.; Golchin, B.; Hamzah, M.O.; Turner, P. Selection of type of warm mix asphalt additive based on the rheological properties of asphalt binders. J. Clean. Prod. 2015, 100, 89–106. [Google Scholar] [CrossRef]

- Wagh, V.P.; Sukhija, M.; Gupta, A. Exploring the consequences of reduced aging on the performance of warm mix asphalt binders. Int. J. Pavement Eng. 2023, 24, 2270768. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, W.; Shen, S.; Li, X.; Muhunthan, B.; Mohammad, L.N. Field-aged asphalt binder performance evaluation for Evotherm warm mix asphalt: Comparisons with hot mix asphalt. Constr. Build. Mater. 2017, 156, 574–583. [Google Scholar] [CrossRef]

- Pandey, A.; Singh, S.K.; Islam, S.S.; Ransingchung R. N., G.D.; Raju, S.; Ravindranath, S.S. Rheological analysis of performance grade rutting and fatigue cracking criteria in asphalt binders. Int. J. Pavement Res. Technol. 2023, 16, 66–81. [Google Scholar] [CrossRef]

- AASHTO T316; Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- AASHTO T315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T350; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- AASHTO TP127; Determining the Fracture Energy Density of Asphalt Binder Using the Binder Fracture Energy (BFE) Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2019.

- Chen, Y.; Dong, S.; Wang, H.; Gao, R.; You, Z. Using surface free energy to evaluate the fracture performance of asphalt binders. Constr. Build. Mater. 2020, 240, 118004. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Hasan, M.R.M.; Diab, A.; Shao, H.; Chen, S.; Ge, D. Environmental and mechanical performance of crumb rubber modified warm mix asphalt using Evotherm. J. Clean. Prod. 2017, 159, 346–358. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Moreno-Navarro, F.; Rubio-Gámez, M.C. Study of surfactant additives for the manufacture of warm mix asphalt: From laboratory design to asphalt plant manufacture. Appl. Sci. 2017, 7, 745. [Google Scholar] [CrossRef]

- Shi, J.; Fan, W.; Wang, T.; Zhao, P.; Che, F. Evaluation of the physical performance and working mechanism of asphalt containing a surfactant warm mix additive. Adv. Mater. Sci. Eng. 2020, 2020, 8860466. [Google Scholar] [CrossRef]

- Kumar, R.; Saboo, N.; Kumar, P.; Chandra, S. Effect of warm mix additives on creep and recovery response of conventional and polymer modified asphalt binders. Constr. Build. Mater. 2017, 138, 352–362. [Google Scholar] [CrossRef]

- Bennert, T.; Reinke, G.; Mogawer, W.; Mooney, K. Assessment of Workability and Compactability of Warm-Mix Asphalt. Transp. Res. Rec. 2010, 2180, 36–47. [Google Scholar] [CrossRef]

- AASHTO M332; Standard Specification for Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

| Type | Penetration Value/0.1 mm | Softening Point/°C | Ductility at 10 °C/cm |

|---|---|---|---|

| 70#JZ | 67 | 47.5 | 31.5 |

| Alube-2 | 71 | 45 | 32.7 |

| Sasobit | 49 | 70.2 | 7.8 |

| TS-5112 | 43 | 71.5 | 6.3 |

| TS-5100 | 46 | 63.7 | 6.5 |

| PEW-0595 | 47 | 68.4 | 6.9 |

| EC-120 | 45 | 67.5 | 7.4 |

| Alube-1 | 64 | 47.1 | 24.9 |

| Evotherm-M1 | 64 | 47.6 | 25.8 |

| EC-110 | 65 | 48.2 | 24.5 |

| WMA Additive Type | Physical State | Color | Molecular Weight (g/mol) | Melting Point (°C) | Dosage (%) | Manufacturer |

|---|---|---|---|---|---|---|

| Alube-2 | Liquid | Black | - | - | 5 | Xinli Highway Material Co., (Chengdu, China) |

| Sasobit | Solid particle | Off-white to pale brown | Approx. 1000 | 100–110 | 3 | Sasol-Wax Co., (Hamburg, Germany) |

| TS-5112 | Solid powder | White | 1300–1500 | 109–115 | 3 | Tianshi Material Technology Co., (Nanjing, China) |

| TS-5100 | Solid powder | White | 700–1100 | 102–107 | 3 | Tianshi Material Technology Co., (Nanjing, China) |

| PEW-0595 | Solid powder | White | 1500–5000 | 137 | 3 | Tianshi Material Technology Co., (Nanjing, China) |

| EC-120 | Tiny tablet and granular solid | White | Approx. 1000 | 100–110 | 3 | Haichuan Material Technology Co., (Shenzhen, China) |

| Alube-1 | Liquid | Brown | - | - | 0.5 | Xinli Highway Material Co., (Chengdu, China) |

| Evotherm M1 | Liquid | Dark amber liquid | - | - | 0.8 | Ingevity Co., (Zhuhai, China) |

| EC-110 | Liquid | Brown | - | - | 0.3 | Haichuan Material Technology Co., (Shenzhen, China) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, J.; Chen, Y.; Jing, L.; Song, H.; Liu, Z. Performance Evaluation of Warm-Mix Asphalt Binders with an Emphasis on Rutting and Intermediate-Temperature Cracking Resistance. Materials 2025, 18, 1571. https://doi.org/10.3390/ma18071571

Pang J, Chen Y, Jing L, Song H, Liu Z. Performance Evaluation of Warm-Mix Asphalt Binders with an Emphasis on Rutting and Intermediate-Temperature Cracking Resistance. Materials. 2025; 18(7):1571. https://doi.org/10.3390/ma18071571

Chicago/Turabian StylePang, Jiangbo, Yu Chen, Longfei Jing, Haoran Song, and Ziyang Liu. 2025. "Performance Evaluation of Warm-Mix Asphalt Binders with an Emphasis on Rutting and Intermediate-Temperature Cracking Resistance" Materials 18, no. 7: 1571. https://doi.org/10.3390/ma18071571

APA StylePang, J., Chen, Y., Jing, L., Song, H., & Liu, Z. (2025). Performance Evaluation of Warm-Mix Asphalt Binders with an Emphasis on Rutting and Intermediate-Temperature Cracking Resistance. Materials, 18(7), 1571. https://doi.org/10.3390/ma18071571