Microstructure and Microhardness Research of Steel 304 After Forming Partially Regular Reliefs by Ball Burnishing Operation

Abstract

1. Introduction

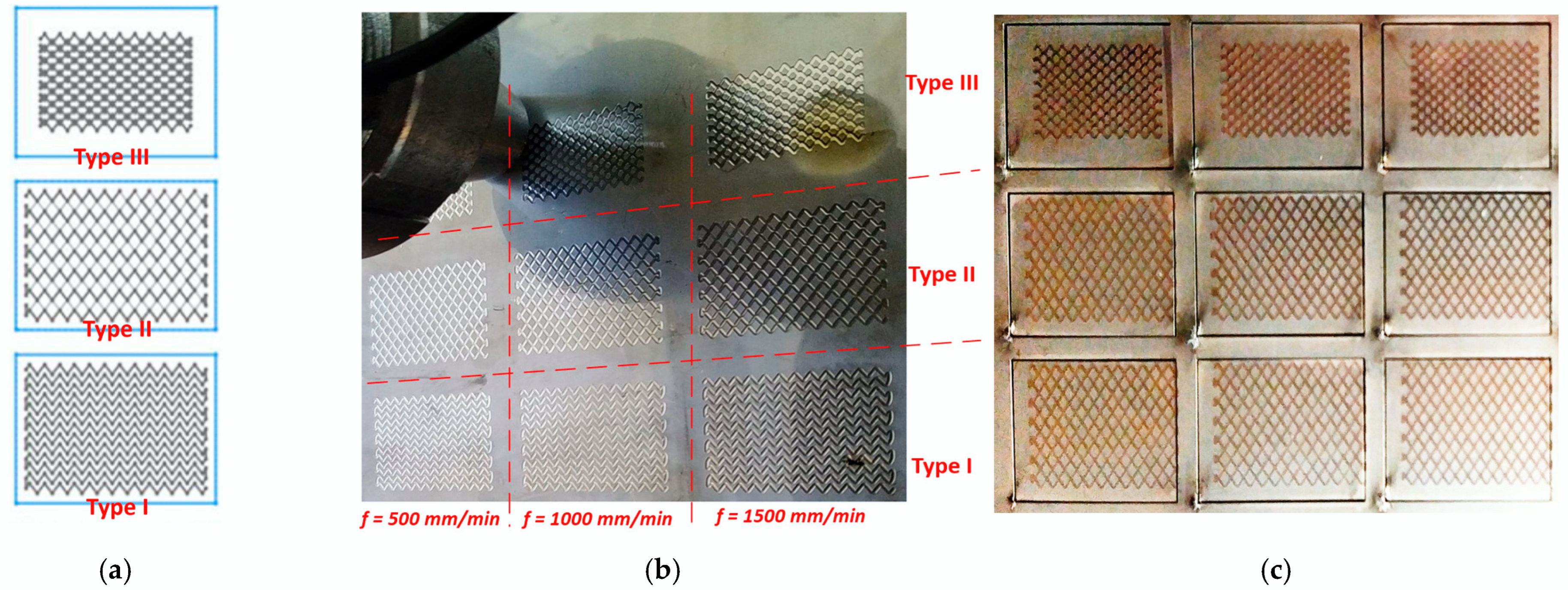

2. Materials and Methods

2.1. Preparing the Test Specimens

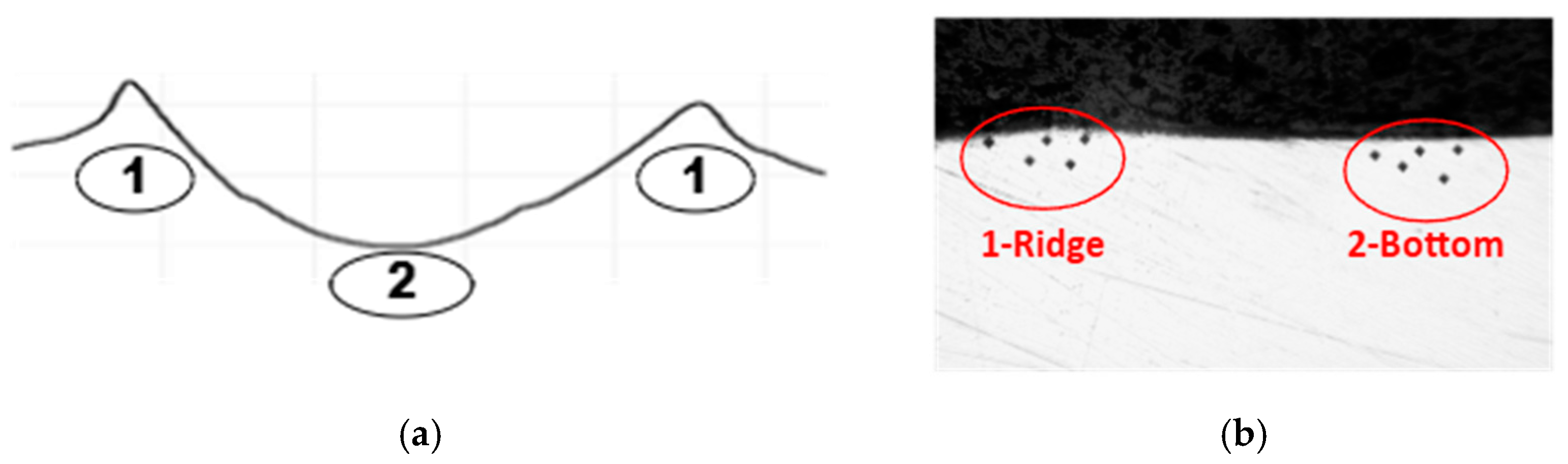

2.2. Initial Microstructure and Microhardness Measurement of the PRR

2.3. Experimental Design Description

3. Results

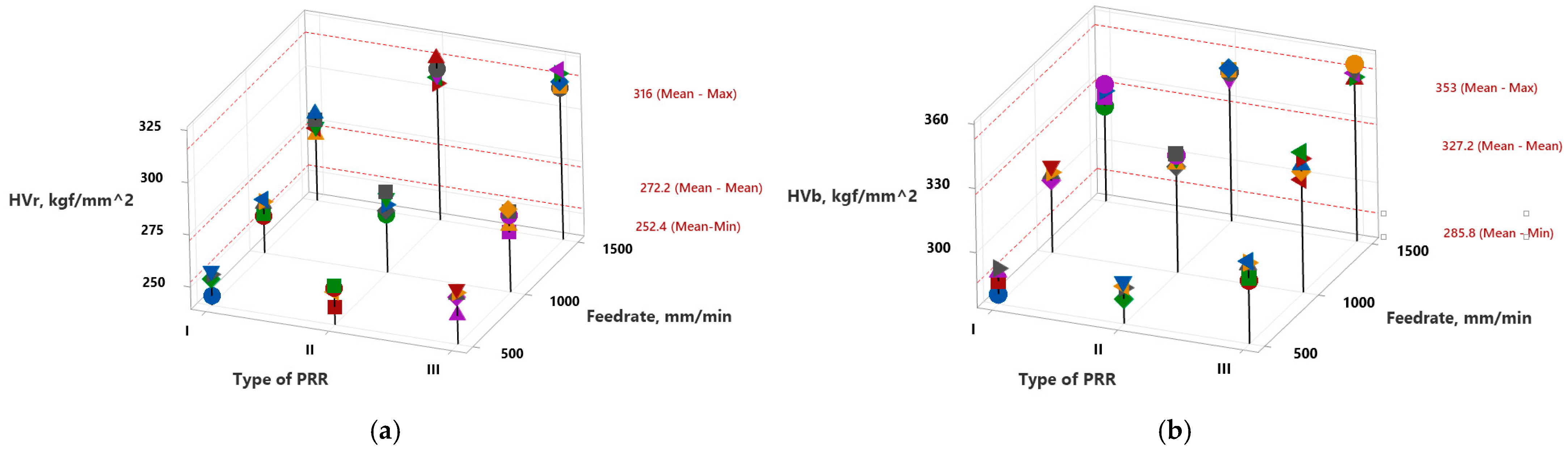

3.1. Results for Microhardness Change

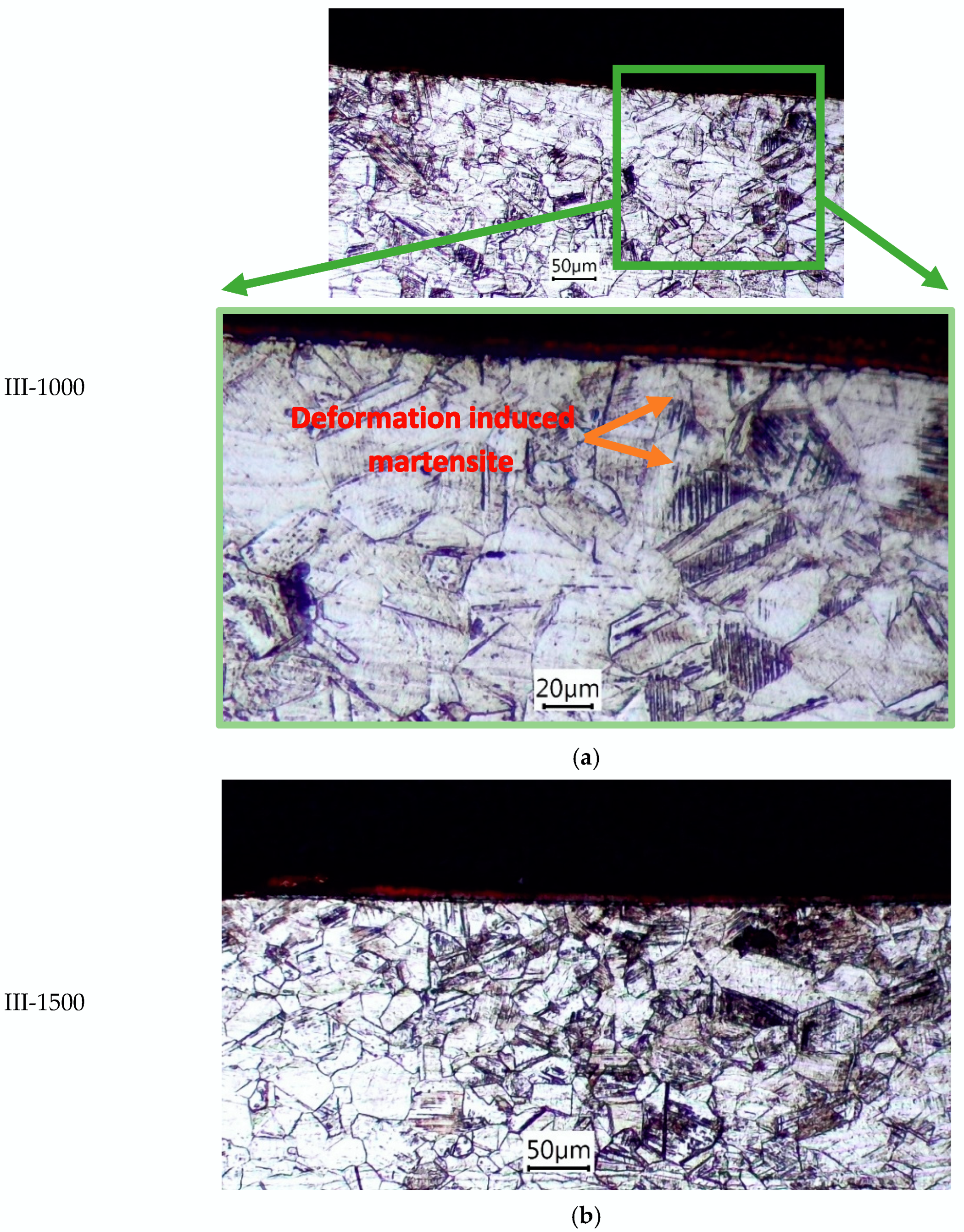

3.2. Microstructure Analysis of the Deformed Surface Layer

4. Derived Regressions Models and Its Statistical Analyses

- -

- The type and parameters of the deforming tool.

- -

- The ball indentation force.

- -

- The feed rate, as demonstrated above.

4.1. Influence on the Microhardness Obtained at the Ridges Area of the PRRs Traces

8.270·PRRI·F500 + 4.330·PRRI·f1000 − 12.600·PRRI·f1500 − 4.930·PRRII·f500 − 0.870·PRRII·f1000 +

5.800·PRRII·f1500 − 3.330·PRRIII·f500 − 3.470·PRRIII·f1000 + 6.800·PRRIII·f1500

4.2. Influence on the Microhardness Obtained at the Bottom Area of the PRRs’ Traces

3.180·PRRI·F500 − 0.090·PRRI·f1000 − 3.090·PRRI·f1500 − 4.890·PRRII·f500 +

2.440·PRRII·f1000 + + 2.440·PRRII·f1500 + 1.710·PRRIII·f500 − 2.360·PRRIII·f1000 + 0.640·PRRIII·f1500

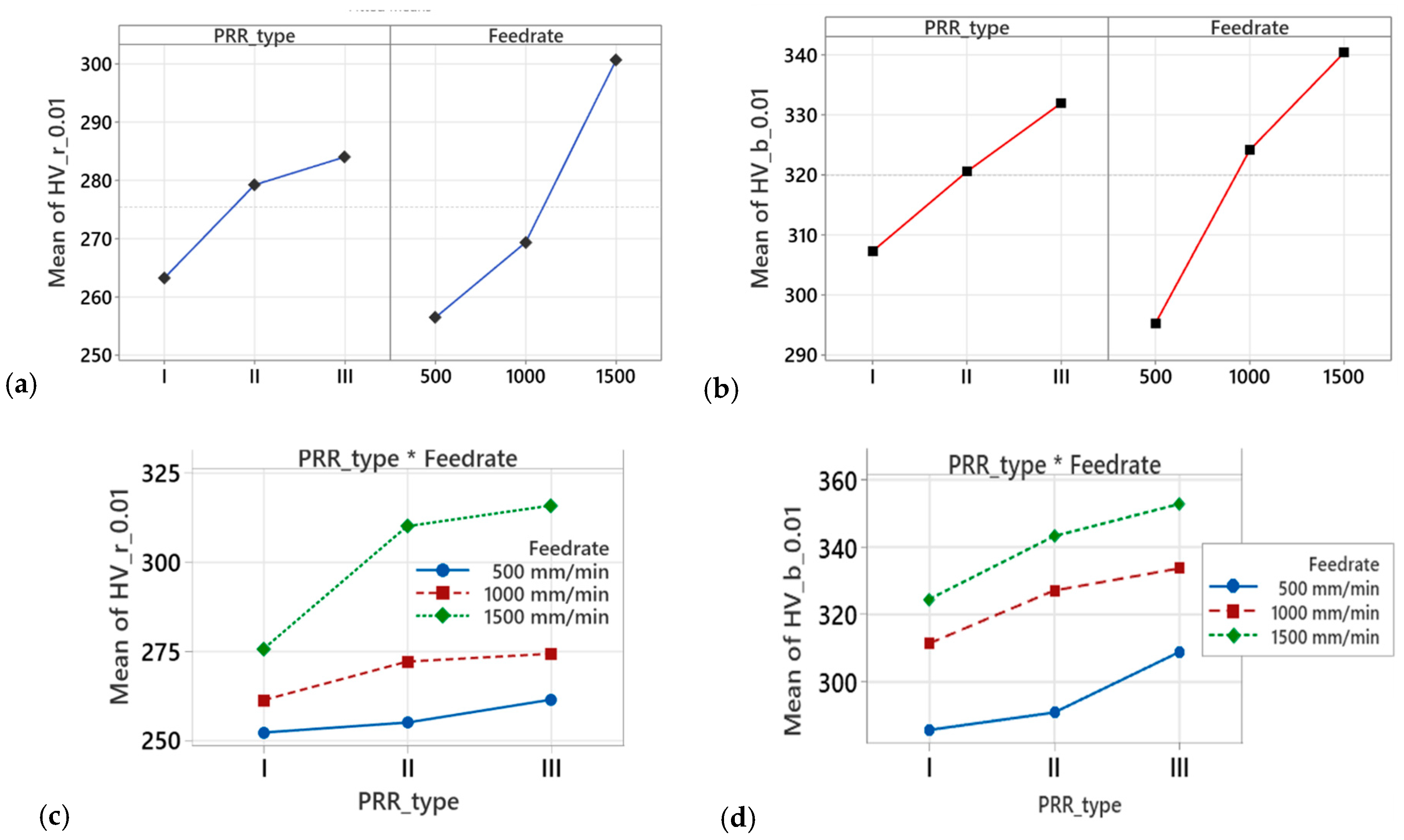

4.3. Main Effects and Interactions Diagrams

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gurey, V.; Hurey, I.; Hurey, T.; Wojtowicz, W. Fatigue Strength of Steel Samples After Friction Treatment. In Proceedings of the Advanced Manufacturing Processes IV. Inter Partner 2022. Lecture Notes in Mechanical Engineering, Odessa, Ukraine, 6–9 September 2022; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Pavlenko, I., Eds.; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Hurey, I.; Hurey, T.; Gurey, V. Wear Resistance of Hardened Nanocrystalline Structures in the Course of Friction of Steel-Grey Cast Iron Pair in Oil-Abrasive Medium. In Proceedings of Advances in Design, Simulation and Manufacturing II. DSMIE 2019, Sumy, Ukraine, 11–14 June 2019; Ivanov, V., Trojanowska, J., Pavlenko, I., Zajac, J., Peraković, D., Eds.; Lecture Notes in Mechanical Engineering. Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Swirad, S. Influence of Ball Burnishing on Lubricated Fretting of the Titanium Alloy Ti6Al4V. Lubricants 2023, 11, 341. [Google Scholar] [CrossRef]

- Mezghani, S.; Demirci, I.; Zahouani, H.; El Mansori, M. The effect of groove texture patterns on piston-ring pack friction. Precis. Eng. 2012, 36, 210–217. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Reverse Problem in Surface Texture Analysis—One-Process Profile Modeling on the Basis of Measured Two-Process Profile after Machining or Wear. Materials 2019, 12, 4169. [Google Scholar] [CrossRef] [PubMed]

- Schneider, Y.G. Service Properties of Parts with Regular Microrelief. Available online: https://books.ifmo.ru/file/pdf/147.pdf (accessed on 23 December 2024).

- Lesyk, D.A.; Martinez, S.; Dzhemelinskyy, V.; Lamikiz, А.; Mordyuk, B.; Prokopenko, G. Surface microrelief and hardness of laser hardened and ultrasonically peened AISI D2 tool steel. Surf. Coat. Technol. 2015, 278, 108–120. [Google Scholar] [CrossRef]

- Zyhulia, S.; Barauskiene, O. Effect of the integrated treatment on the manufacturing of printing cylinders. East.-Eur. J. Enterp. Technol. 2019, 3, 22–28. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V.; Lovell, M.R. Role of Surface Texture, Roughness, and Hardness on Friction During Unidirectional Sliding. Tribol. Lett. 2011, 41, 1–15. [Google Scholar] [CrossRef]

- Pratap, T.; Patra, K. Tribological performances of symmetrically micro-textured Ti-6Al-4V alloy for hip joint. Int. J. Mech. Sci. 2020, 182, 105736. [Google Scholar] [CrossRef]

- Grzesik, W.; Zak, K. Producing high quality hardened parts using sequential hard turning and ball burnishing operations. Precis. Eng. 2013, 37, 849–855. [Google Scholar] [CrossRef]

- Maximov, J.T.; Anchev, A.P.; Duncheva, G.V.; Ganev, N.; Selimov, K.F. Influence of the process parameters on the surface roughness, mi-cro-hardness, and residual stresses in slide burnishing of high-strength aluminum alloys. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3067–3078. [Google Scholar] [CrossRef]

- Luo, H.; Liu, J.; Wang, L.; Zhong, Q. The effect of burnishing parameters on burnishing force and surface microhardness. Int. J. Adv. Manuf. Technol. 2006, 28, 707–713. [Google Scholar] [CrossRef]

- Nagîţ, G.; Slătineanu, L.; Dodun, O.; Rîpanu, M.I.; Mihalache, A.M. Surface layer microhardness and roughness after applying a vibroburnishing process. J. Mater. Res. Technol. 2019, 8, 4333–4346. [Google Scholar] [CrossRef]

- Yuan, X.L.; Sun, Y.W.; Gao, L.S.; Jiang, S.L. Effect of roller burnishing process parameters on the surface roughness and microhard-ness for TA2 alloy. Int. J. Adv. Manuf. Technol. 2016, 85, 1373–1383. [Google Scholar] [CrossRef]

- Cobanoglu, T.; Ozturk, S. Effect of burnishing parameters on the surface quality and hardness. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 286–294. [Google Scholar] [CrossRef]

- Lee, W.-S.; Lin, C.-F. Impact properties and microstructure evolution of 304L stainless steel. Mater. Sci. Eng. A 2001, 308, 124–135. [Google Scholar] [CrossRef]

- Hedayati, A.; Najafizadeh, A.; Kermanpur, A.; Forouzan, F. The effect of cold rolling regime on microstructure and mechanical properties of AISI 304L stainless steel. J. Mater. Process. Technol. 2010, 210, 1017–1022. [Google Scholar] [CrossRef]

- Slavov, S.; Markov, O. A Tool for Ball Burnishing with Ability for Wire and Wireless Monitoring of the Deforming Force Values. Acta Technica Na-pocensis-Series: APPLIED MATHEMATICS, MECHANICS, and ENGINEERING 2023, vol. 65, no. 4S. Available online: https://atna-mam.utcluj.ro/index.php/Acta/article/view/2066 (accessed on 5 January 2025).

- ISO 6507-1:2023; “Metallic materials — Vickers hardness test — Part 1: Test method”. Technical Committee ISO/TC 164/SC 3 of ISO; ISO: Geneva, Switzerland, 2023; p. 35.

- Slavov, S.D.; Dimitrov, D.M.; Konsulova-Bakalova, M.I. Advances in burnishing technology. In Advanced Machining and Finishing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 481–525. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Chausov, M.; Maruschak, P.; Pylypenko, A.; Shmanenko, V.; Brezinová, J.; Lisnichuk, M. The effects of cryogenic treatment and impact-oscillatory loading on changes in the mechanical properties and structural condition of stainless steel 12Kh18N10T. Mater. Sci. Eng. A 2024, 913, 147007. [Google Scholar] [CrossRef]

- Minitab 22 Support-Minitab. Available online: https://support.minitab.com/en-us/minitab/21/ (accessed on 7 January 2025).

| Mechanical Properties | ||||

|---|---|---|---|---|

| Material | Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elongation A, % | HV0.01 |

| AISI 304 | 372 ± 10 | 710 ± 12 | 31.2 ± 0.8 | 205 ± 12 |

| Material | Cr | Mn | Mo | Ni | Si | Fe |

|---|---|---|---|---|---|---|

| AISI 304 | 18.23 | 1.76 | 0.27 | 8.33 | 0.38 | 71.03 |

| NO. | Type of PRR | Feed Rate, fin.i. [mm/min] | , [kgf/mm2] | , [kgf/mm2] | , [kgf/mm2] | , [kgf/mm2] |

|---|---|---|---|---|---|---|

| 1 | I | 500 | 244 | 252.4 | 289 | 285.8 |

| 2 | I | 500 | 256 | 279 | ||

| 3 | I | 500 | 254 | 285 | ||

| 4 | I | 500 | 256 | 291 | ||

| 5 | I | 500 | 252 | 285 | ||

| 6 | I | 1000 | 265 | 261.4 | 311 | 311.4 |

| 7 | I | 1000 | 263 | 312 | ||

| 8 | I | 1000 | 257 | 308 | ||

| 9 | I | 1000 | 258 | 315 | ||

| 10 | I | 1000 | 264 | 311 | ||

| 11 | I | 1500 | 278 | 275.8 | 319 | 324.6 |

| 12 | I | 1500 | 281 | 326 | ||

| 13 | I | 1500 | 274 | 329 | ||

| 14 | I | 1500 | 271 | 326 | ||

| 15 | I | 1500 | 275 | 323 | ||

| 16 | II | 500 | 248 | 255.2 | 292 | 291.0 |

| 17 | II | 500 | 258 | 286 | ||

| 18 | II | 500 | 257 | 291 | ||

| 19 | II | 500 | 258 | 292 | ||

| 20 | II | 500 | 255 | 294 | ||

| 21 | II | 1000 | 278 | 272.2 | 324 | 327.2 |

| 22 | II | 1000 | 275 | 328 | ||

| 23 | II | 1000 | 272 | 330 | ||

| 24 | II | 1000 | 267 | 325 | ||

| 25 | II | 1000 | 269 | 329 | ||

| 26 | II | 1500 | 312 | 310.2 | 341 | 343.4 |

| 27 | II | 1500 | 317 | 341 | ||

| 28 | II | 1500 | 309 | 345 | ||

| 29 | II | 1500 | 305 | 344 | ||

| 30 | II | 1500 | 308 | 346 | ||

| 31 | III | 500 | 253 | 261.6 | 312 | 309.0 |

| 32 | III | 500 | 266 | 313 | ||

| 33 | III | 500 | 262 | 304 | ||

| 34 | III | 500 | 264 | 305 | ||

| 35 | III | 500 | 263 | 311 | ||

| 36 | III | 1000 | 268 | 274.4 | 334 | 333.8 |

| 37 | III | 1000 | 278 | 340 | ||

| 38 | III | 1000 | 276 | 337 | ||

| 39 | III | 1000 | 271 | 327 | ||

| 40 | III | 1000 | 279 | 331 | ||

| 41 | III | 1500 | 315 | 316.0 | 350 | 353.0 |

| 42 | III | 1500 | 321 | 357 | ||

| 43 | III | 1500 | 312 | 354 | ||

| 44 | III | 1500 | 319 | 351 | ||

| 45 | III | 1500 | 313 | 353 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Model | 8 | 20,971.2 | 96.80% | 20,971.2 | 2621.40 | 135.98 | 0.000 |

| Linear | 4 | 19,101.3 | 88.17% | 19,101.3 | 4775.33 | 247.71 | 0.000 |

| PRR_type | 2 | 3558.4 | 16.42% | 3558.4 | 1779.20 | 92.29 | 0.000 |

| Feed rate | 2 | 15,542.9 | 71.74% | 15,542.9 | 7771.47 | 403.13 | 0.000 |

| Two-Way Interactions | 4 | 1869.9 | 8.63% | 1869.9 | 467.47 | 24.25 | 0.000 |

| PRR_typeFeed rate | 4 | 1869.9 | 8.63% | 1869.9 | 467.47 | 24.25 | 0.000 |

| Error | 36 | 694.0 | 3.20% | 694.0 | 19.28 | ||

| Total | 44 | 21,665.2 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Model | 8 | 20,527.6 | 97.84% | 20,527.6 | 2565.96 | 203.47 | 0.000 |

| Linear | 4 | 20,205.7 | 96.30% | 20,205.7 | 5051.42 | 400.55 | 0.000 |

| PRR_type | 2 | 4572.0 | 21.79% | 4572.0 | 2286.02 | 181.27 | 0.000 |

| Feed rate | 2 | 15,633.6 | 74.51% | 15,633.6 | 7816.82 | 619.84 | 0.000 |

| Two-Way Interactions | 4 | 322.0 | 1.53% | 322.0 | 80.49 | 6.38 | 0.001 |

| PRR_typeFeed rate | 4 | 322.0 | 1.53% | 322.0 | 80.49 | 6.38 | 0.001 |

| Error | 36 | 454.0 | 2.16% | 454.0 | 12.61 | ||

| Total | 44 | 20,981.6 | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slavov, S.D.; Dimitrov, D.M.; Mincheva, D.Y.; Dzyura, V.; Maruschak, P.; Semehen, V. Microstructure and Microhardness Research of Steel 304 After Forming Partially Regular Reliefs by Ball Burnishing Operation. Materials 2025, 18, 1565. https://doi.org/10.3390/ma18071565

Slavov SD, Dimitrov DM, Mincheva DY, Dzyura V, Maruschak P, Semehen V. Microstructure and Microhardness Research of Steel 304 After Forming Partially Regular Reliefs by Ball Burnishing Operation. Materials. 2025; 18(7):1565. https://doi.org/10.3390/ma18071565

Chicago/Turabian StyleSlavov, Stoyan Dimitrov, Diyan Minkov Dimitrov, Desislava Yordanova Mincheva, Volodymyr Dzyura, Pavlo Maruschak, and Volodymyr Semehen. 2025. "Microstructure and Microhardness Research of Steel 304 After Forming Partially Regular Reliefs by Ball Burnishing Operation" Materials 18, no. 7: 1565. https://doi.org/10.3390/ma18071565

APA StyleSlavov, S. D., Dimitrov, D. M., Mincheva, D. Y., Dzyura, V., Maruschak, P., & Semehen, V. (2025). Microstructure and Microhardness Research of Steel 304 After Forming Partially Regular Reliefs by Ball Burnishing Operation. Materials, 18(7), 1565. https://doi.org/10.3390/ma18071565