Strengthening of Masonry and Concrete Members with Textile-Reinforced Alkali-Activated Mortars: A Review on the Mechanical Performance

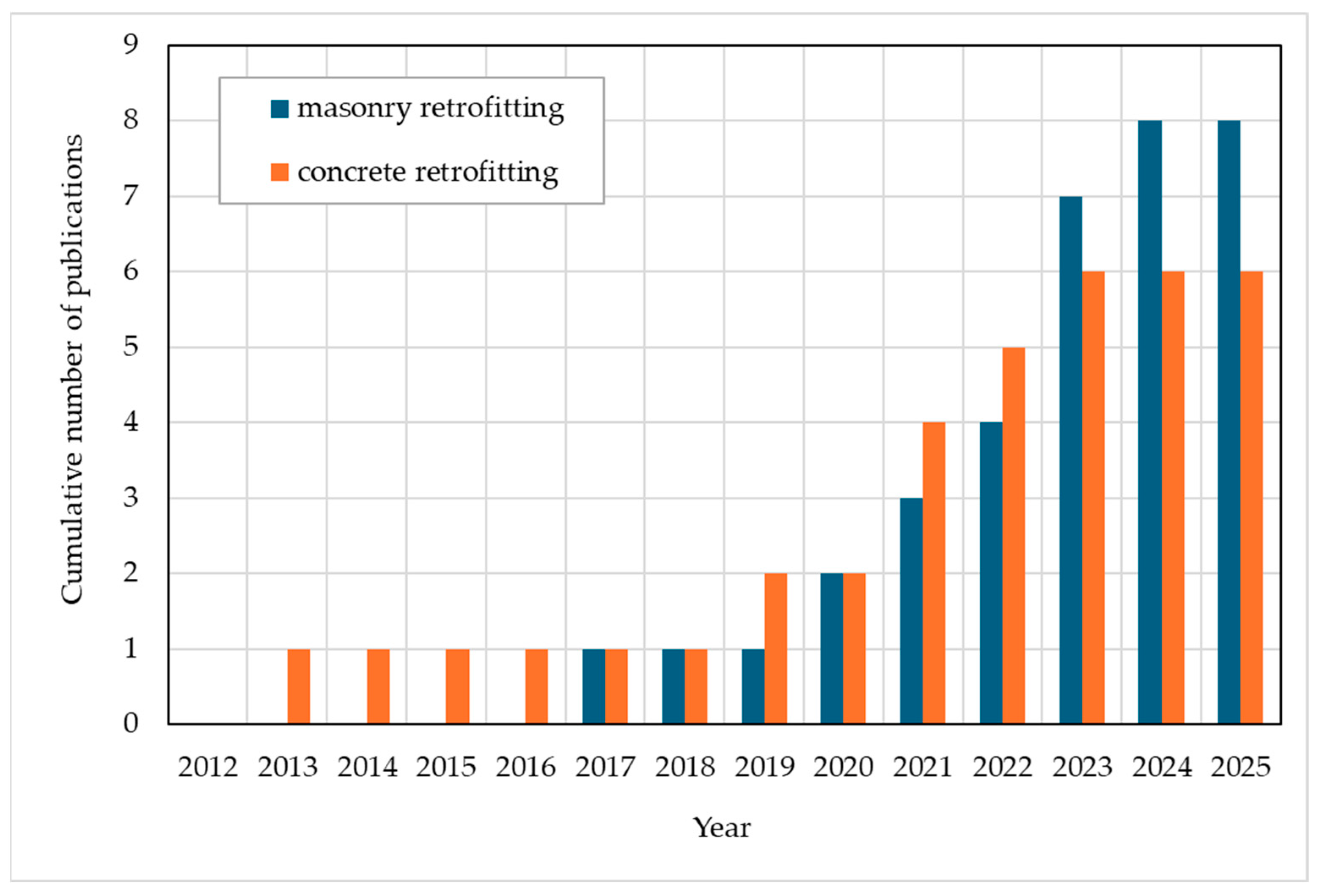

Abstract

1. Introduction

1.1. Retrofitting with Textile-Reinforced Mortars (TRM)

1.2. Retrofitting with Textile-Reinforced Alkali-Activated Mortars (TRAAM)

1.3. Tensile Performance of TRAAM

1.4. Flexural and Impact Performance of TRAAM

1.5. Bond Properties of TRAAM

1.6. Environmental Properties of TRAAM

1.7. Scope and Objectives of the Present Study

2. Masonry Members

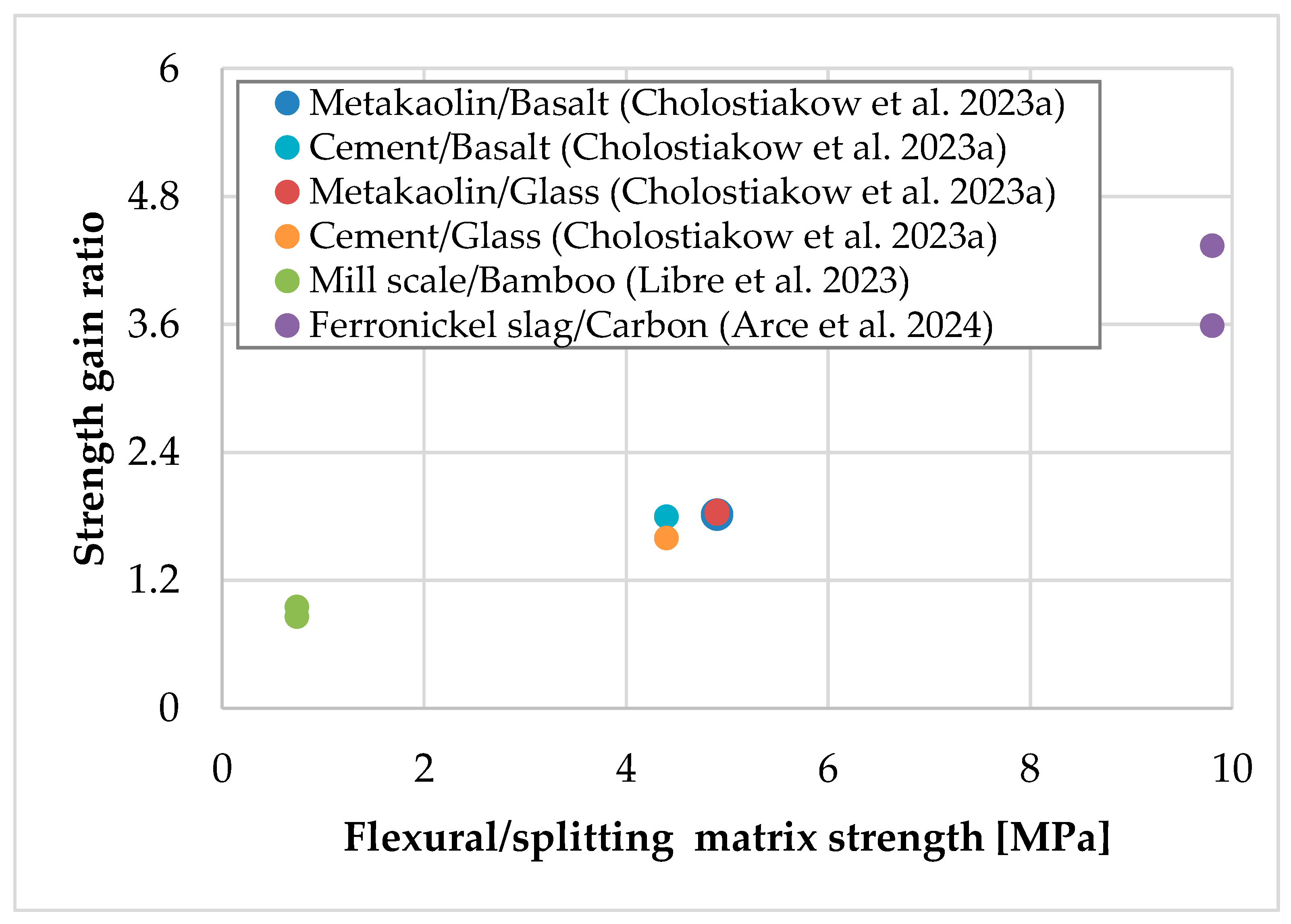

2.1. Upgrading Response to Diagonal Compression

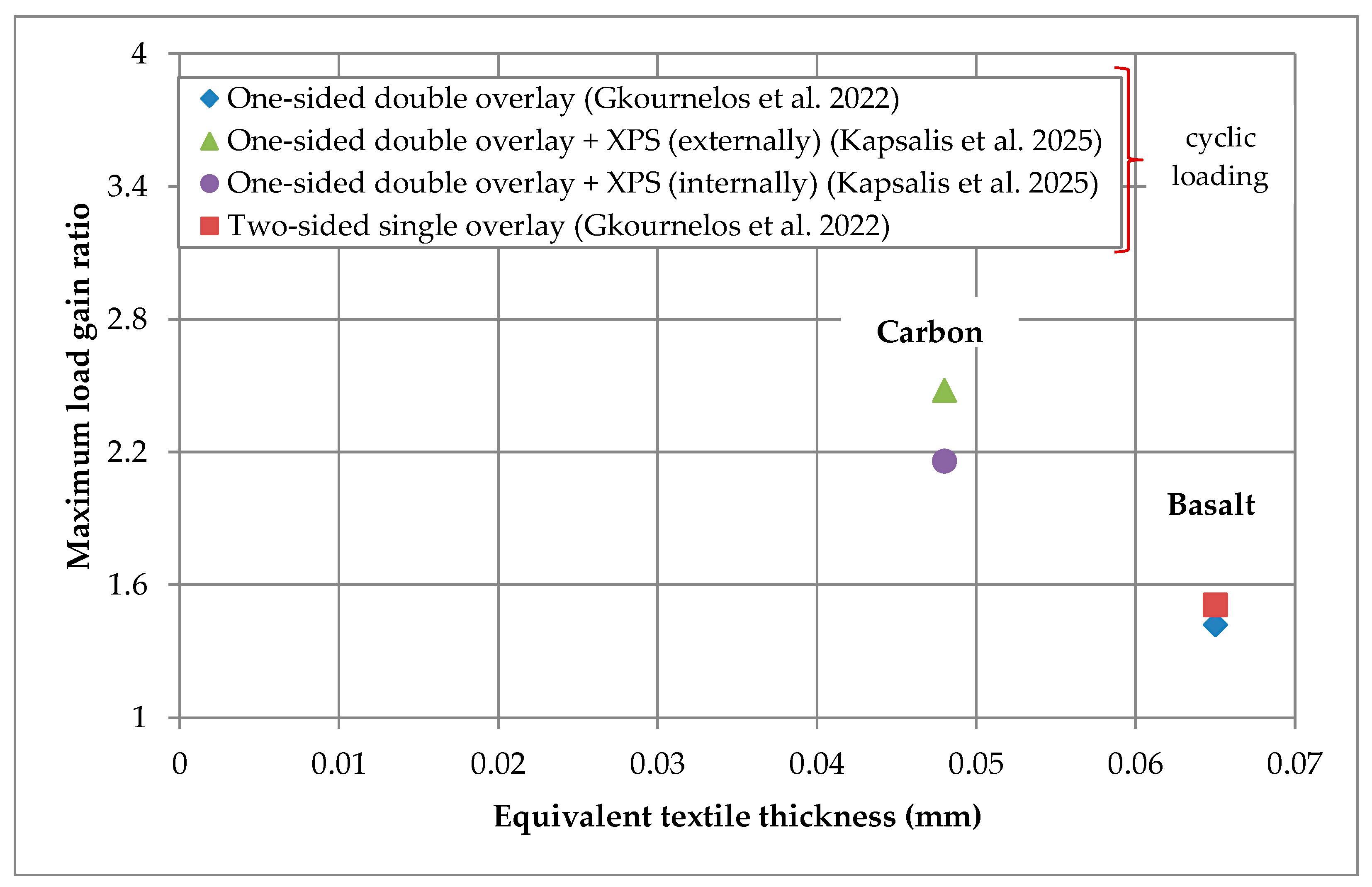

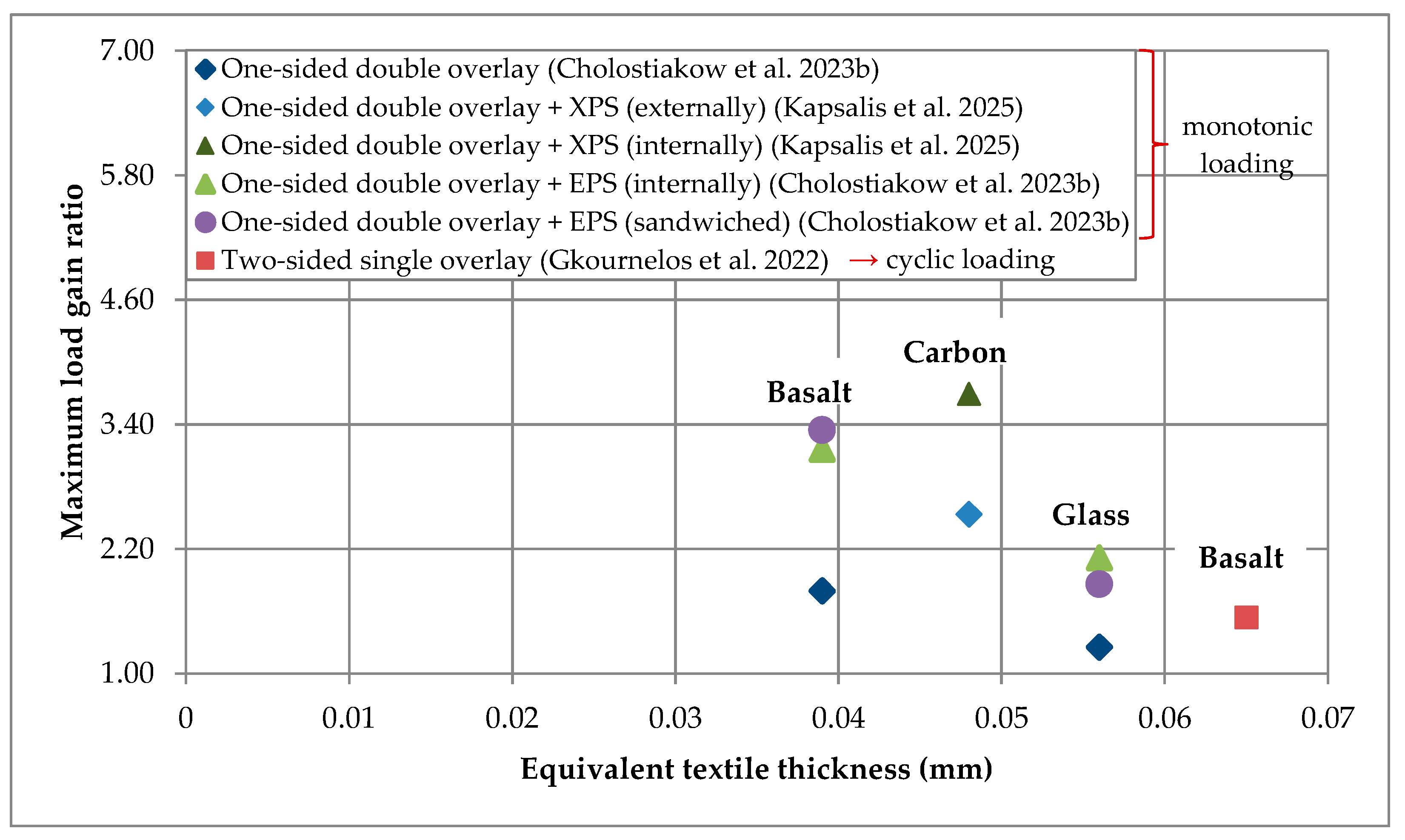

2.2. Upgrading Flexural or Shear Capacity

2.3. Combination of TRAAM with Thermal Insulation

2.4. Lightweight TRAAM

2.5. General Remarks

3. Concrete Members

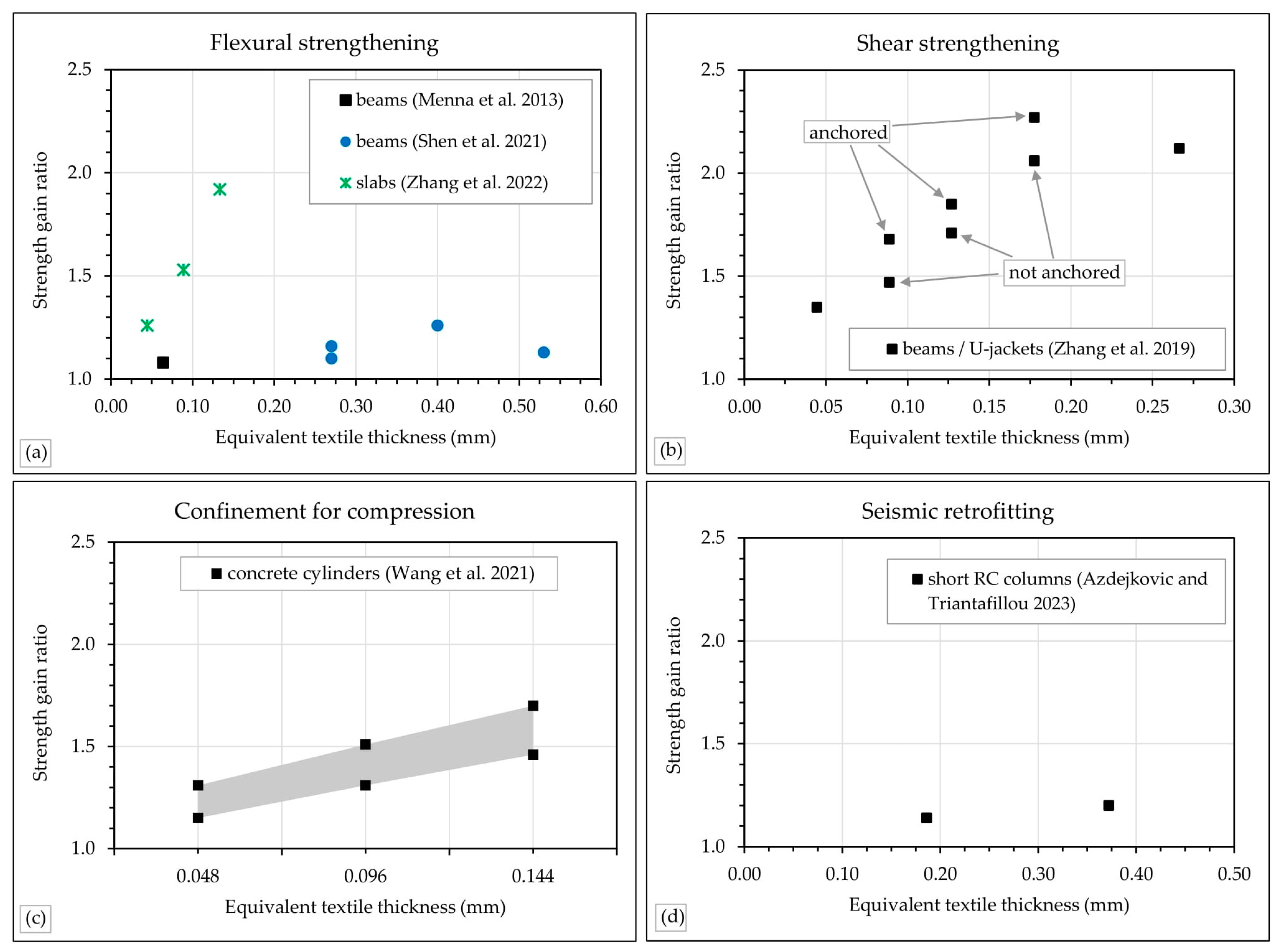

3.1. Upgrading Flexural Capacity

3.2. Upgrading Shear Capacity

3.3. Upgrading Compressive Capacity

3.4. Seismic Retrofitting

3.5. General Remarks

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Triantafillou, T. (Ed.) Textile Fibre Composites in Civil Engineering; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Pacheco-Torgal, F.; Labrincha, J.; Leonelli, C.; Palomo, A.; Chindaprasit, P. (Eds.) Handbook of Alkali-Activated Cements, Mortars and Concretes; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Candamano, S.; Crea, F.; Iorfida, A. Mechanical characterization of basalt fabric-reinforced alkali-activated matrix composite: A preliminary investigation. Appl. Sci. 2020, 10, 2865. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M.A. A new Fabric Reinforced Geopolymer Mortar (FRGM) with mechanical and energy benefits. Fibers 2020, 8, 49. [Google Scholar] [CrossRef]

- Trindade, A.C.; Alcamand, H.; Borges, P.R.; de Andrade Silva, F. Influence of Elevated Temperatures on the Mechanical Behavior of Jute-Textile-Reinforced Geopolymers. J. Ceram. Sci. Technol. 2017, 8, 389–398. [Google Scholar] [CrossRef]

- Le Chi, H.; Louda, P.; Periyasamy, A.P.; Bakalova, T.; Kovacic, V. Flexural behavior of carbon textile-reinforced geopolymer composite thin plate. Fibers 2018, 6, 87. [Google Scholar] [CrossRef]

- Le, C.H.; Louda, P.; Ewa Buczkowska, K.; Dufkova, I. Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers 2021, 13, 751. [Google Scholar] [CrossRef]

- Le Chi, H.; Louda, P.; Le Van, S.; Volesky, L.; Kovacic, V.; Bakalova, T. Composite performance evaluation of basalt textile-reinforced geopolymer mortar. Fibers 2019, 7, 63. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Patel, A. Flexural behavior of hybrid PVA fiber and AR-glass textile reinforced geopolymer composites. Fibers 2018, 6, 2. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Y.; Dai, J.G. Flexural behavior and microstructure of hybrid basalt textile and steel fiber reinforced alkali-activated slag panels exposed to elevated temperatures. Constr. Build. Mater. 2017, 152, 651–660. [Google Scholar] [CrossRef]

- Al-Jaberi, L.A.; Abbas, Z.W.; Al-Kerttani, O.M.; Sarhan, M.M. Bending behavior of fiberglass textile-reinforced thin geopolymer mortar panels. Civ. Environ. Eng. 2022, 18, 280–291. [Google Scholar] [CrossRef]

- Samal, S.; Marvalová, B.; Petríková, I.; Vallons, K.A.; Lomov, S.V.; Rahier, H. Impact and post impact behavior of fabric reinforced geopolymer composite. Constr. Build. Mater. 2016, 127, 111–124. [Google Scholar] [CrossRef]

- Tamburini, S.; Natali, M.; Garbin, E.; Panizza, M.; Favaro, M.; Valluzzi, M.R. Geopolymer matrix for fibre reinforced composites aimed at strengthening masonry structures. Constr. Build. Mater. 2017, 141, 542–552. [Google Scholar] [CrossRef]

- Abu Obaida, F.; El-Maaddawy, T.; El-Hassan, H. Bond behavior of carbon fabric-reinforced matrix composites: Geopolymeric matrix versus cementitious mortar. Buildings 2021, 11, 207. [Google Scholar] [CrossRef]

- Askouni, P.D.; Papanicolaou, C.C.G.; Azdejkovic, L. Experimental investigation of the TRM-to-masonry bond after exposure to elevated temperatures: Cementitious and alkali-activated matrices of various densities. Materials 2021, 15, 140. [Google Scholar] [CrossRef] [PubMed]

- Skyrianou, I.; Papakonstantinou, C.G.; Koutas, L.N. Investigation of the Bond Behaviour Between Geopolymer TRM and Concrete. In Proceedings of the RILEM Spring Convention and Conference, Milan, Italy, 7–12 April 2024; Springer: Cham, Switzerland, 2024; pp. 3–11. [Google Scholar] [CrossRef]

- Donnini, J.; Mobili, A.; Maracchini, G.; Chiappini, G.; Tittarelli, F.; Corinaldesi, V. A multi-performance comparison between lime, cementitious and alkali-activated TRM systems: Mechanical, environmental and energy perspectives. Constr. Build. Mater. 2024, 440, 137396. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A review on properties of fresh and hardened geopolymer mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Arce, A.; Le Galliard, C.; Komkova, A.; Papanicolaou, C.G.; Triantafillou, T.C. Optimal design of ferronickel slag alkali-activated mortar for repair exposed to high thermal load. Mater. Struct. 2023, 56, 34. [Google Scholar] [CrossRef]

- Abulencia, A.B.; Villoria, M.B.D.; Libre, R.G.D., Jr.; Quiatchon, P.R.J.; Dollente, I.J.R.; Guades, E.J.; Promentilla, M.A.B.; Garciano, L.E.O.; Ongpeng, J.M.C. Geopolymers as sustainable material for strengthening and restoring unreinforced masonry structures: A review. Buildings 2021, 11, 532. [Google Scholar] [CrossRef]

- Kryvenko, P.; Rudenko, I.; Sikora, P.; Sanytsky, M.; Konstantynovskyi, O.; Kropyvnytska, T. Alkali-activated cements as sustainable materials for repairing building construction: A review. J. Build. Eng. 2024, 90, 109399. [Google Scholar] [CrossRef]

- Nikravan, M.; Firdous, R.; Stephan, D. Life cycle assessment of alkali-activated materials: A systematic literature review. Low-Carbon Mater. Green Constr. 2023, 1, 13. [Google Scholar] [CrossRef]

- Ameri, F.; Zareei, S.A.; Behforouz, B. Zero-cement vs. cementitious mortars: An experimental comparative study on engineering and environmental properties. J. Build. Eng. 2020, 32, 101620. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Kar, A. Environmental impact assessment of alkali-activated mortar with waste precursors and activators. J. Build. Eng. 2021, 44, 103391. [Google Scholar] [CrossRef]

- Cholostiakow, S.; Koutas, L.N.; Papakonstantinou, C.G. Geopolymer versus cement-based textile-reinforced mortar: Diagonal compression tests on masonry walls representative of infills in RC frames. Constr. Build. Mater. 2023, 373, 130836. [Google Scholar] [CrossRef]

- Libre, R.G.D., Jr.; Leaño, J.L., Jr.; Lopez, L.F.; Cacanando, C.J.D.; Promentilla, M.A.B.; Guades, E.J.; Garciano, L.E.O.; Ongpeng, J.M.C. In-Plane Shear Behavior of Unreinforced Masonry Wall Strengthened with Bamboo Fiber Textile-Reinforced Geopolymer Mortar. Buildings 2023, 13, 538. [Google Scholar] [CrossRef]

- Arce, A.; Kapsalis, P.; Papanicolaou, C.G.; Triantafillou, T.C. Diagonal Compression Tests on Unfired and Fired Masonry Wallettes Retrofitted with Textile-Reinforced Alkali-Activated Mortar. J. Compos. Sci. 2024, 8, 14. [Google Scholar] [CrossRef]

- Gkournelos, P.D.; Azdejković, L.D.; Triantafillou, T.C. Innovative and eco-friendly solutions for the seismic retrofitting of natural stone masonry walls with textile reinforced mortar: In-and out-of-plane behavior. J. Compos. Constr. 2022, 26, 04021061. [Google Scholar] [CrossRef]

- Cholostiakow, S.; Skyrianou, I.; Koutas, L.; Papakonstantinou, C. Out-of-plane performance of structurally and energy retrofitted masonry walls: Geopolymer versus cement-based textile-reinforced mortar combined with thermal insulation. Open Res. Eur. 2023, 3, 186. [Google Scholar] [CrossRef]

- Cholostiakow, S.P.; Koutas, L.N.; Papakonstantinou, C.G. Holistic approach to rehabilitation of substandard masonry infilled rc frames. In Proceedings of the 11th International Conference on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2023), Rio de Janeiro, Brazil, 23–26 July 2023. [Google Scholar]

- Kapsalis, P.; Askouni, P.D.; Papanicolaou, C.G.; Triantafillou, T.C. Cementitious versus alkali-activated textile reinforced mortars for combined energy and seismic upgrade of masonry panels. Mater. Struct. 2025, 58, 8. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. Part B Eng. 2013, 45, 1667–1676. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Yan, J.; Kodur, V.; Cao, L. Mechanical behavior of concrete beams shear strengthened with textile reinforced geopolymer mortar. Eng. Struct. 2019, 196, 109348. [Google Scholar] [CrossRef]

- Shen, X.; Chen, W.; Li, B.; Hancock, C.M.; Xu, Y. Flexural strengthening of reinforced concrete beams using fabric reinforced alkali-activated slag matrix. J. Build. Eng. 2021, 33, 101865. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Liu, H.Y.; Kodur, V.; Li, M.Y.; Zhou, Y. Flexural behavior of concrete slabs strengthened with textile reinforced geopolymer mortar. Compos. Struct. 2022, 284, 115220. [Google Scholar] [CrossRef]

- Azdejkovic, L.D.; Triantafillou, T.C. Seismic Retrofit of RC Short Columns with Textile-Reinforced Alkali-Activated or Cement-Based Mortars. J. Compos. Constr. 2023, 27, 04023041. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Y.; Qin, X.; Li, L.; Chen, H.; Cheng, B. Behavior of cement concrete confined by fabric-reinforced geopolymer mortar under monotonic and cyclic compression. Structures 2021, 34, 4731–4744. [Google Scholar] [CrossRef]

- Escrig, C.; Gil, L.; Bernat-Maso, E.; Puigvert, F. Experimental and analytical study of reinforced concrete beams shear strengthened with different types of textile-reinforced mortar. Constr. Build. Mater. 2015, 83, 248–260. [Google Scholar] [CrossRef]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of concrete structures with textile reinforced mortars: State-of-the-art review. J. Compos. Constr. 2019, 23, 03118001. [Google Scholar] [CrossRef]

| Study | Loading | Specimen (Dimensions) {Number} | Matrix Precursor/Activator/Chopped Fibers 1 (Flexural or Splitting Strength|Compressive Strength—MPa) | Textile Treatment/Fibers (tf 2—mm) | Group of Specimens 3 | Failure Mode | Strength Ratio 4 |

|---|---|---|---|---|---|---|---|

| Cholostiakow et al. 2023a [25] | Monotonic | Single-leaf wallettes (700 × 700 × 65) {18} | Metakaolin/potassium silicate/P: (4.9f|46.0) 5 Cement/water/micro PP: (4.4f|24.4) | Coated/basalt or glass (basalt: 0.039; glass: 0.056) | M_BTRAAM2L | Partial TRAAM-to-substrate detachment | 1.82 |

| M_GTRAAM2L | 1.85 | ||||||

| GTRAAM1L_M_GTRAAM1L | Partial TRAAM-to-substrate detachment + TRAAM failure of TRAAM (fiber rupture or/and fiber slippage within the matrix) | 1.83 | |||||

| M_BTRCM2L | TRCM failure | 1.80 | |||||

| M_GTRCM2L | 1.60 | ||||||

| Libre et al. 2023 [26] | Monotonic | Single-leaf wallettes (350 × 350 × 50) {25} | Mill-scale powder and fly ash/sodium hydroxide and sodium silicate/bamboo (0.74s|3.08) | Immersion in aluminum sulfate solution/bamboo (-) | M_BTRAAM1L | Diagonal cracking (TRAAM failure) or TRAAM-to-substrate detachment (intact TRAAM) | 0.95 |

| BTRAAM1L_M_BTRAAM1L | Diagonal cracking (TRAAM failure) | 0.86 | |||||

| Arce et al. 2024 [27] | Monotonic | Single-leaf wallettes (700 × 700 × 10) {14} | Ferronickel slag and silica fume/potassium silicate and potassium hydroxide (9.8f|77.9) | Dry/carbon (0.048) | M_CTRAAM1L_20 6 | Diagonal cracking, top mortar delamination and—for double TRAAM—extensive detachment at TRAAM-to-substrate interface | 3.59 |

| M_CTRAAM2L_20 | 4.34 | ||||||

| M_CTRAAM1L_300 | 3.38 | ||||||

| M_CTRAAM2L_300 | 3.86 | ||||||

| M_CTRAAM1L_550 | 3.03 | ||||||

| M_CTRAAM2L_550 | 3.93 |

| Study | Test (Loading) | Specimen (Dimensions) {Number} | Matrix Precursor/Activator (Flexural Strength|Compressive Strength—MPa) | Textile Treatment/Fibers (tf 1—mm) | Group of Specimens 2 | Failure Mode | Maxi Mum Load Ratio 3 |

|---|---|---|---|---|---|---|---|

| Gkournelos et al. 2022 [28] | In-plane bending (cyclic) | Slender double-leaf wall (1200 × 400 × 150) {5} | Metakaolin and ladle furnace slag/potassium silicate and potassium hydroxide (5.8|49.2) Lime/water (1.5|4.2) | Coated/basalt or dry/flax basalt: 0.065 flax: 0.229 | BTRAAM1L_M_BTRAAM1L | Textile rupture | 1.51 |

| M_BTRAAM2L | Textile rupture | 1.42 | |||||

| FTRLM3L_M_FTRLM3L | Fiber slippage | 1.55 | |||||

| BTRAAM1L_M_BTRAAM1L-V0 4 | Textile rupture | 0.92 | |||||

| Out-of-plane bending (cyclic) | Slender double-leaf wall (1200 × 400 × 150/22) {5} | BTRAAM1L_M_BTRAAM1L | Textile rupture | 1.54 | |||

| BTRAAM1L_M_BTRAAM1L-th 5 | Textile rupture | 2.50 | |||||

| FTRLM3L_M_FTRLM3L | Fiber slippage | 1.48 | |||||

| FTRLM3L_M_FTRLM3L-th 5 | Textile rupture | 3.18 | |||||

| In-plane shear (cyclic) | Squat double-leaf wall (1000 × 1100 × 150) {4} | BTRAAM1L_M_BTRAAM1L | Textile rupture | 1.62 | |||

| M_BTRAAM2L | Textile rupture | 1.56 | |||||

| FTRLM3L_M_FTRLM3L | Fiber slippage | 1.19 |

| Study | Test (Loading) | Specimen (Dimensions) {Number} | Matrix Precursor/Activator/Chopped Fibers 1 (Flexural Strength|Compressive Strength—MPa) | Textile Treatment/Fibers (tf 2—mm) | Group of Specimens 3 | Failure Mode | Maximum Load [kN] |

|---|---|---|---|---|---|---|---|

| Cholostiakow et al. 2023b [29] | out-of-plane bending (monotonic) | Wall (1090 × 390 × 65) {12} | Metakaolin/potassium silicate/PP (5.5|44.3) Cement/water/micro PP (4.9|22.2) | Coated/basalt or glass (basalt: 0.039; glass: 0.056) | M_GTRCM2L | Shear | 7.62 |

| M_BTRCM2L | Shear | 5.97 | |||||

| M_GTRAAM2L | Fiber slippage/rupture | 4.04 | |||||

| M_BTRAAM2L | Shear | 5.79 | |||||

| M_EPS_GTRCM2L | EPS board debonding | 5.25 | |||||

| M_EPS_BTRCM2L | EPS board debonding | 8.94 | |||||

| M_EPS_GTRAAM2L | Fiber slippage/rupture | 6.82 | |||||

| M_EPS_BTRAAM2L | EPS board debonding | 10.2 | |||||

| M_GTRCM1L_EPS_GTRCM1L | Shear | 11.76 | |||||

| M_BTRCM1L_EPS_BTRCM1L | Shear | 9.52 | |||||

| M_GTRAAM1L_EPS_GTRAAM1L | Fiber slippage/rupture | 6 | |||||

| M_BTRAAM1L_EPS_BTRAAM1L | Shear | 10.8 | |||||

| Cholostiakow et al. 2023c [30] | out-of-plane bending (monotonic) | infill of RC frame (1570 × 250 × 64 ) {2} | Metakaolin/potassium silicate/PP (5.8|42.7) | Coated/basalt (0.039) | CONTROL | Infill’s symmetric cracking | 16.3 |

| M_BTRAAM1L_EPS_BTRAAM1L | Detachment of TRAAM from beam | 46 | |||||

| Kapsalis et al. 2025 [31] | out-of-plane bending (monotonic) | Wall (1300 × 400 × 85) {8} | Ferronickel slag and silica fume/potassium silicate and potassium hydroxide (7.7|79.7) Cement/water (3.2|9.6) | Dry/carbon (0.048 mm) | CONTROL | Wall splitting | 4.79 |

| M_CTRCM2L_XPS | Wall’s flexural craking + textile-to-matrix detachment | 16.36 | |||||

| M_CTRAAM2L_XPS | 12.14 | ||||||

| M_XPS_CTRAAM2L | Fibers’ rupture + textile-to-matrix detachment | 17.68 | |||||

| in-plane bending (cyclic) | CONTROL | Flexural cracks near mid-span | 11.15 | ||||

| M_CTRCM2L_XPS | Textile-to-matrix detachment near mid-span | 25.02 | |||||

| M_CTRAAM2L_XPS | Textile-to-matrix detachment near mid-span + fibers’ rupture | 27.6 | |||||

| M_XPS_CTRAAM2L | Fibers’ rupture | 24.1 |

| Study | Test (Loading) | Specimens {Number} | Matrix Precursor/Activator/Chopped Fibers 1 (Flexural Strength|Compressive Strength—MPa) | Textile Treatment/Fibers (tf 2—mm) | Failure Mode | Strength Ratio | Deformation Ratio |

|---|---|---|---|---|---|---|---|

| Menna et al. 2013 [32] | Flexure (4-point bending/static) | Full-scale beams {5} | Metakaolin/sodium hydroxide and sodium silicate (not provided|98) | Dry/Carbon (0.064) | Concrete crushing; textile-to-matrix debonding | 1.08 | 0.97 |

| Zhang et al. 2019 [33] | Shear (4-point bending/static) | Mid-scale beams {10} | Metakaolin and fly ash/potassium silicate (7.5|43.3) | Dry/Carbon (0.044–0.266) | TRAAM-to-substrate debonding; concrete cover delamination; fiber rupture at shear cracks | 1.35–2.27 | |

| Shen et al. 2021 [34] | Flexure (4-point bending/static) | Mid-scale beams {7} | Blast furnace slag and fly ash/sodium hydroxide and sodium silicate/PP (not provided|53.5) | Not provided/Carbon (0.27–0.53) | Slippage and rupture of fibers | 1.10–1.26 | |

| Wang et al. 2021 [37] | Compression (monotonic and cyclic) | Cylinders 150 × 300 {28} | Blast furnace slag and fly ash/sodium hydroxide and sodium silicate/PVA (not provided|25–55) | Epoxy resin impregnated/Basalt (0.048–0.144) | Textile-to-matrix debonding; fiber rupture; crushing of concrete core | 1.15–1.70 | 1.54–3.49 |

| Zhang et al. 2022 [35] | Flexure (4-point bending/static) | Full-scale one-way slabs {8} | Metakaolin and fly ash/potassium silicate (7.0|45.1) | Dry/Carbon (0.044–0.133) | Fiber slippage and rupture | 1.26–1.92 | 0.74–>0.87 |

| Azdejkovic and Triantafillou 2023 [36] | Shear (lateral/cyclic) | Mid-scale short columns {7} | Metakaolin, ladle furnace slag and fly ash/potassium silicate and potassium hydroxide/PVA (6.8|40.7) | Dry/Carbon (0.186–0.372) | Fiber rupture in abrupt shear failures | 1.14–1.20 | 2.58–5.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Askouni, P.D.; Kapsalis, P.; Papanicolaou, C.G.; Triantafillou, T.C. Strengthening of Masonry and Concrete Members with Textile-Reinforced Alkali-Activated Mortars: A Review on the Mechanical Performance. Materials 2025, 18, 1517. https://doi.org/10.3390/ma18071517

Askouni PD, Kapsalis P, Papanicolaou CG, Triantafillou TC. Strengthening of Masonry and Concrete Members with Textile-Reinforced Alkali-Activated Mortars: A Review on the Mechanical Performance. Materials. 2025; 18(7):1517. https://doi.org/10.3390/ma18071517

Chicago/Turabian StyleAskouni, Paraskevi D., Panagiotis Kapsalis, Catherine G. Papanicolaou, and Thanasis C. Triantafillou. 2025. "Strengthening of Masonry and Concrete Members with Textile-Reinforced Alkali-Activated Mortars: A Review on the Mechanical Performance" Materials 18, no. 7: 1517. https://doi.org/10.3390/ma18071517

APA StyleAskouni, P. D., Kapsalis, P., Papanicolaou, C. G., & Triantafillou, T. C. (2025). Strengthening of Masonry and Concrete Members with Textile-Reinforced Alkali-Activated Mortars: A Review on the Mechanical Performance. Materials, 18(7), 1517. https://doi.org/10.3390/ma18071517