Paraffin Graphite Composite Spheres for Thermal Energy Management

Abstract

1. Introduction

2. Materials and Methods

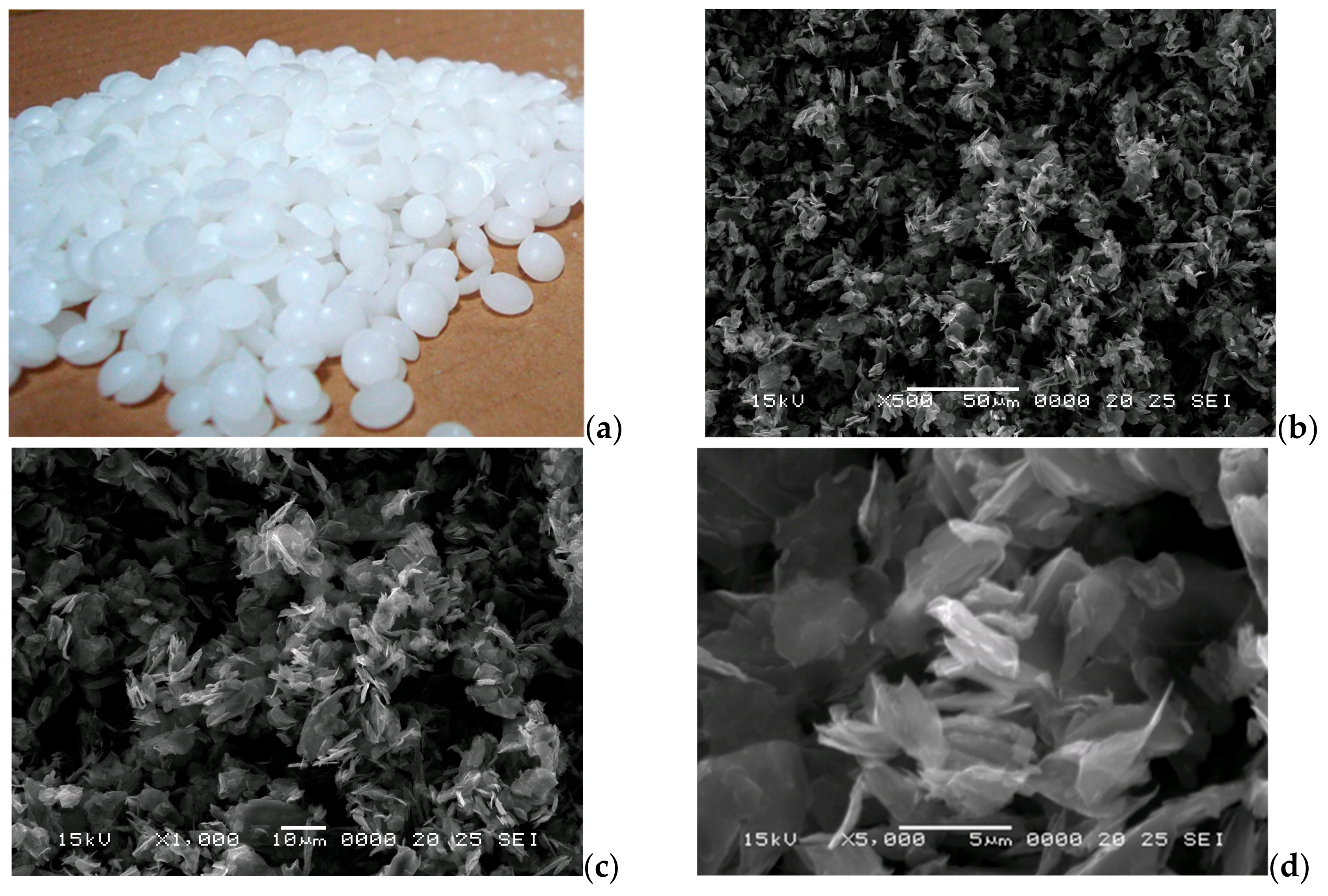

2.1. Paraffin Composite Fabrication and Characterization

2.2. Three D Printing of the Mold

2.3. Injection Moulding of the Composite

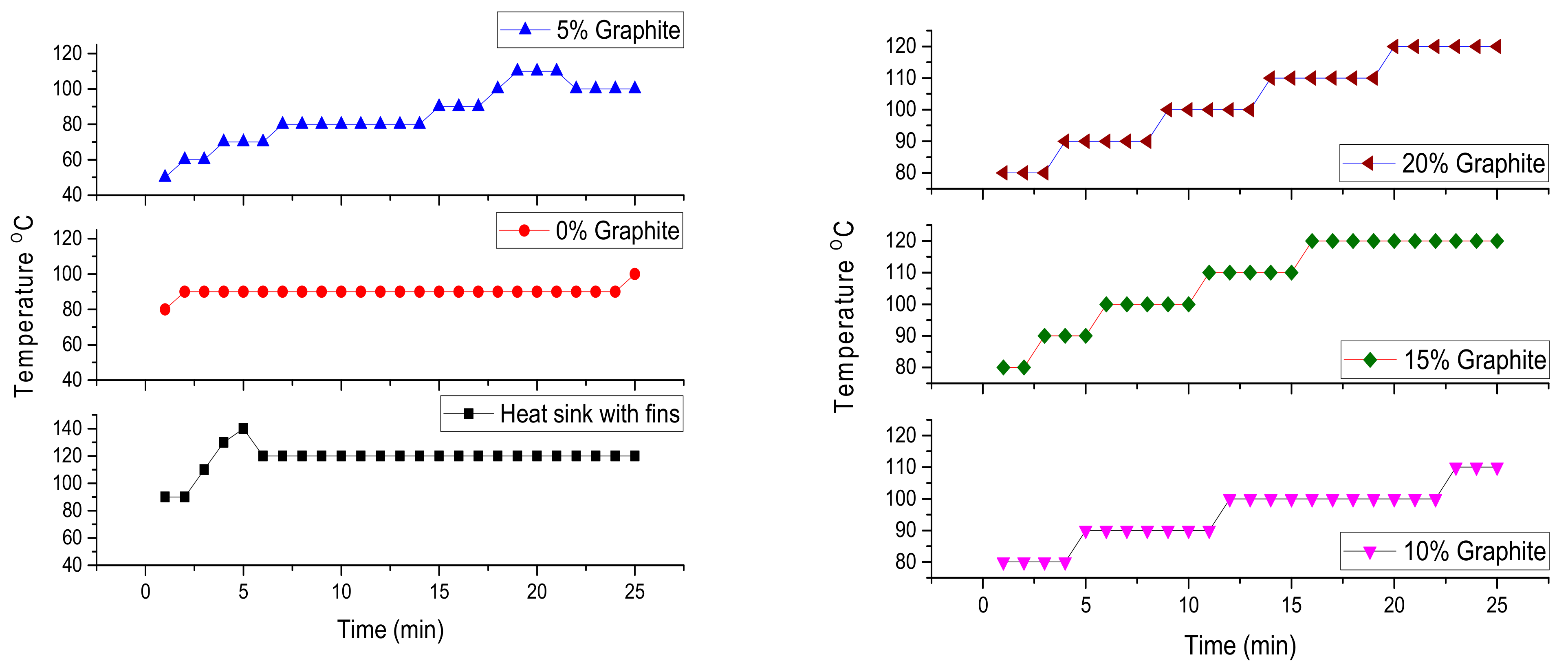

2.4. Assessment of Paraffin Composite for Passive Cooling of Electronic Devices

3. Results

3.1. Thermal Characterization of the Paraffin Composite

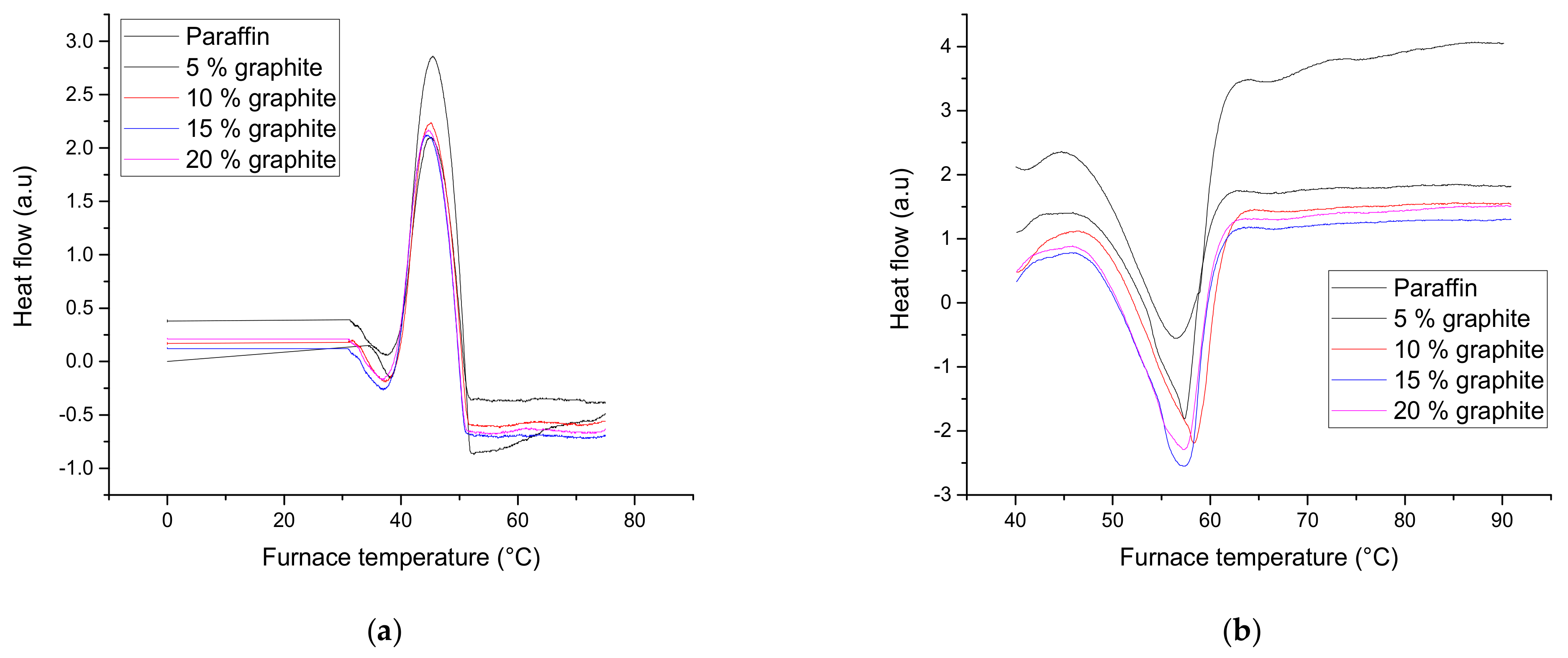

3.1.1. Differential Scanning Calorimetry (DSC)

3.1.2. Thermal Parameters

3.2. Characterizantion of Composite Tested in Simulated Conditions

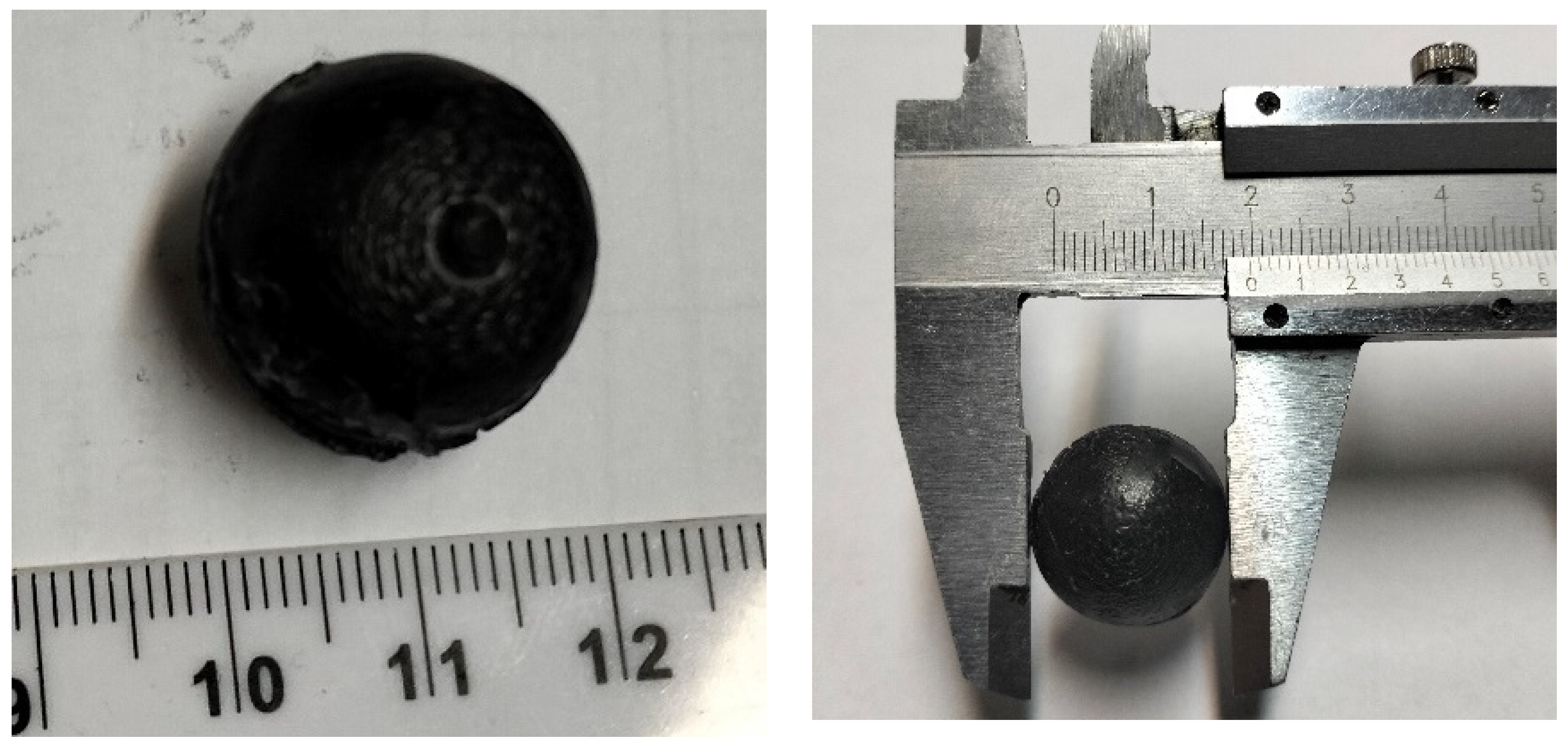

3.3. Prototype Sphere Fabrication by Injection in the Molding of the Paraffin Composite

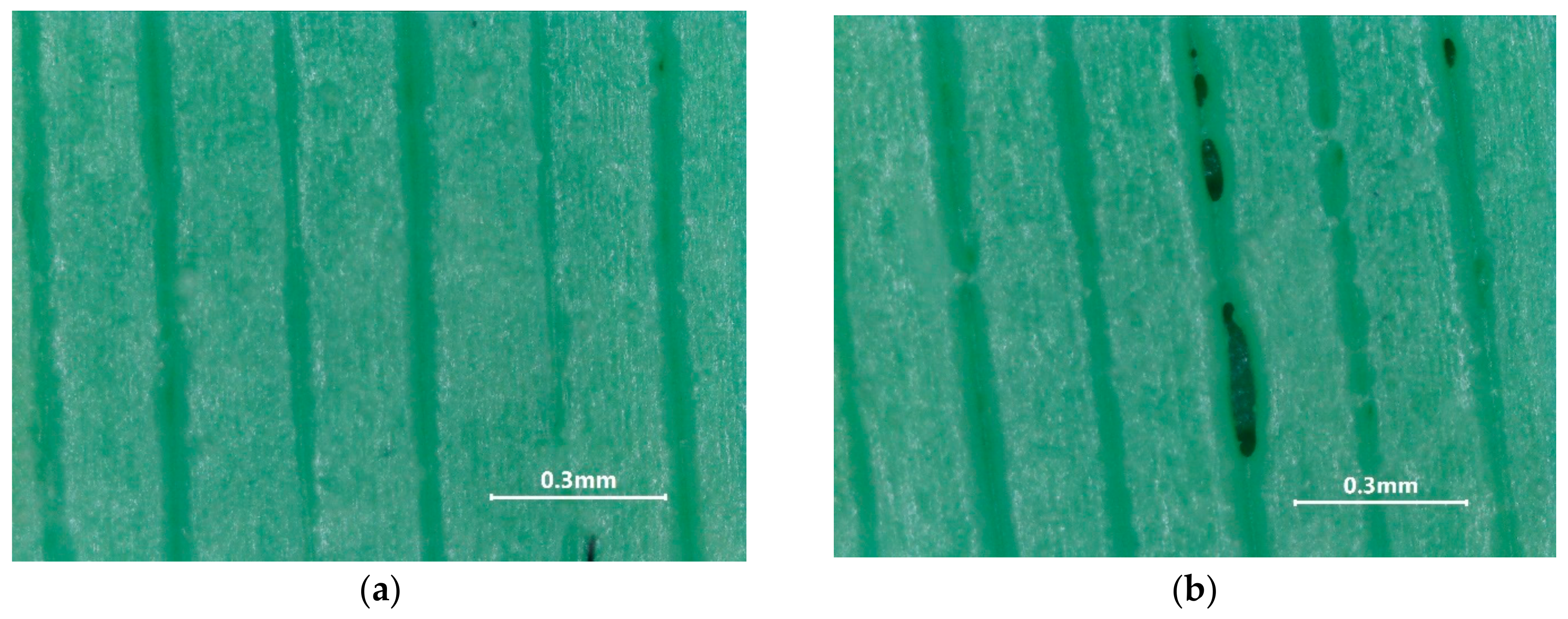

3.3.1. 3D Printing of the Mold

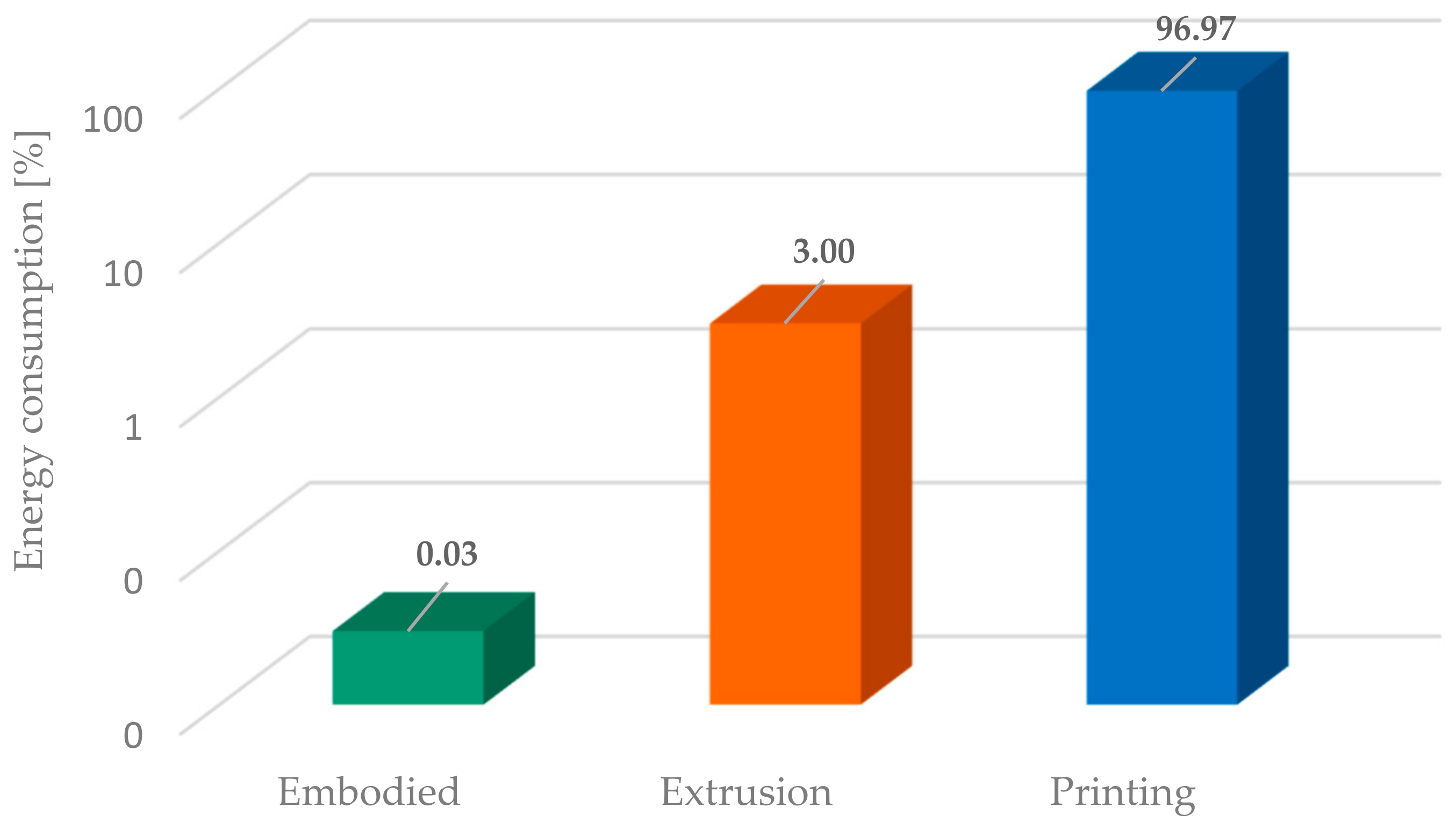

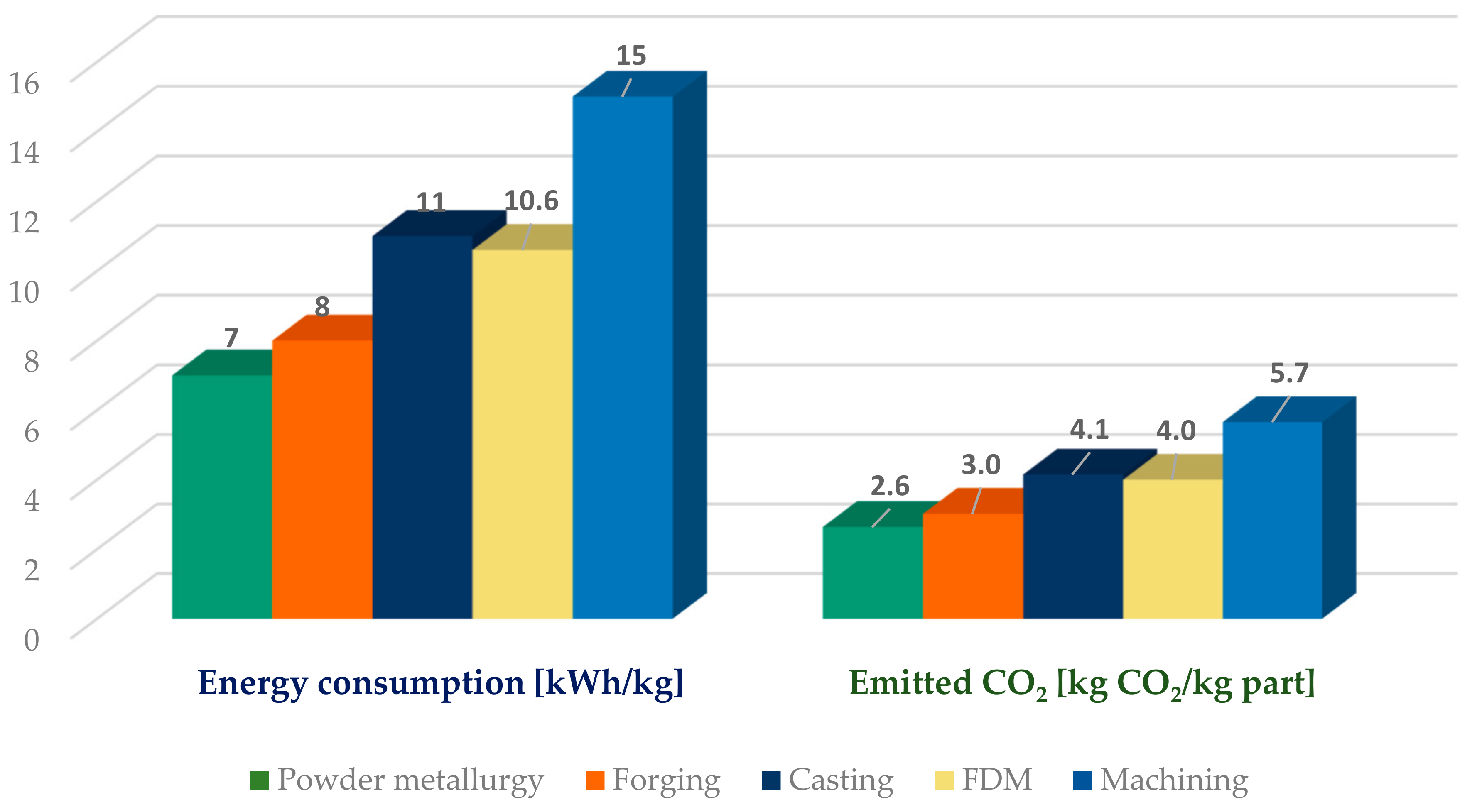

3.3.2. Energy and Eco-Impact Evaluation of 3D Printing of the Mold

3.3.3. Injection of the Paraffin Composite Inside the Molding

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liang, J.; Zhang, X.; Ji, J. Hygroscopic phase change composite material A review. J. Energy Storage 2021, 36, 102395. [Google Scholar] [CrossRef]

- Raj, C.R.; Suresh, S.; Bhavsar, R.R.; Singh, V.K. Recent developments in thermo-physical property enhancement and applications of solid phase change materials. J. Therm. Anal. Calorim. 2020, 139, 3023–3049. [Google Scholar] [CrossRef]

- Yang, X.; Li, D.; Yang, R.; Ma, Y.; Tong, X.; Wu, Y.; Arıcı, M. Comprehensive performance evaluation of double-glazed windows containing hybrid nanoparticle-enhanced phase change material. Appl. Therm. Eng. 2023, 223, 119976. [Google Scholar] [CrossRef]

- Yin, H.; Norouziasas, A.; Hamdy, M. PCM as an energy flexibility asset: How design and operation can be optimized for heating in residential buildings? Energy Build. 2024, 322, 114721. [Google Scholar] [CrossRef]

- Krishnamoorthi, S.; Prabhu, L.; Kuriakose, G.; Harikrishnan, J. Air-cooling system based on phase change materials for a vehicle cabin. Mater. Today Proc. 2021, 45, 5991–5996. [Google Scholar] [CrossRef]

- Mu, M.; Zhang, S.; Yang, S.; Wang, Y. Phase change materials applied in agricultural greenhouses. J. Energy Storage 2022, 49, 104100. [Google Scholar] [CrossRef]

- Chen, W.; Zhou, G. Numerical investigation on thermal performance of a solar greenhouse with synergetic energy release of short- and long-term PCM storage. Sol. Energy 2024, 269, 112313. [Google Scholar] [CrossRef]

- Thaler, S.M.; Zwatz, J.; Nicolay, P.; Hauser, R.; Lackner, R. An Innovative Heating Solution for Sustainable Agriculture: A Feasibility Study on the Integration of Phase Change Materials as Passive Heating Elements. Appl. Sci. 2024, 14, 7419. [Google Scholar] [CrossRef]

- Liao, J.; Yang, C.; Yang, H. Experimental study and information entropy analysis on periodic performance of a PCM thermal management system for blade servers in data centers. Int. J. Therm. Sci. 2023, 188, 108216. [Google Scholar] [CrossRef]

- Nirwan, A.; Gupta, D.; Matta, R.; Kumar, R.; Mondal, B. Evaluation of heat transfer performance of PCM based composites for thermal management of electronics. Mater. Today Proc. 2022, 57, 954–957. [Google Scholar]

- Liu, Y.; Zheng, R.; Li, J. High latent heat phase change materials (PCMs) with low melting temperature for thermal management and storage of electronic devices and power batteries: Critical review. Renew. Sustain. Energy Rev. 2022, 168, 112783. [Google Scholar] [CrossRef]

- Chang, S.; Zhang, L.; Li, X.; Liu, B.; Meng, Y.; Hu, H. Experimental study of novel paraffin-fatty acid eutectic mixtures for thermal management of electronic devices. J. Energy Storage 2024, 84, 110846. [Google Scholar] [CrossRef]

- Huang, S.; Long, C.; Hu, Z.; Xu, Y.; Zhang, B.; Zhi, C. Thermal Performance of Heat Sink Filled with Double-Porosity Porous Aluminum Skeleton/Paraffin Phase Change Material. Micromachines 2024, 15, 806. [Google Scholar] [CrossRef] [PubMed]

- Joseph, M.; Sajith, V. Graphene enhanced paraffin nanocomposite-based hybrid cooling system for thermal management of electronics. Appl. Therm. Eng. 2019, 163, 114342. [Google Scholar] [CrossRef]

- Zhao, J.; Chen, Y.; Chen, M. Battery thermal management with a modified metal alloy/expanded graphite/paraffin composite phase change material. J. Energy Storage 2025, 113, 115652. [Google Scholar] [CrossRef]

- Liu, X.; Liu, X.; Chen, Z.; Huang, Y. Experimental study on the temperature control characteristics of graphite foam-based composite phase change materials. Energy 2024, 299, 131394. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Ma, K.; Mao, Q.; Shi, Y. A simulation study of HS-PCM thermal management performance for electronic device. J. Energy Storage 2024, 97, 112971. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Kurajica, S.; Šipušić, J. Thermophysical Comparison of Five Commercial Paraffin Waxes as Latent Heat Storage Materials. Chem. Biochem. Eng. Q. 2010, 24, 129. [Google Scholar]

- Zhang, P.; Meng, Z.N.; Zhu, H.; Wang, Y.L.; Peng, S.P. Melting heat transfer characteristics of a composite phase change material fabricated by paraffin and metal foam. Appl. Energy 2017, 185, 1971–1983. [Google Scholar] [CrossRef]

- Yang, B.; Cao, Y.; Zhang, R.; Yu, X. Experimental investigation on the stability and heat transfer enhancement of phase change materials composited with nanoparticles and metal foams. J. Energy Storage 2024, 89, 111826. [Google Scholar] [CrossRef]

- Bharathiraja, R.; Ramkumar, T.; Selvakumar, M.; Radhika, N. Thermal characteristics enhancement of Paraffin Wax Phase Change Material (PCM) for thermal storage applications. Renew. Energy 2024, 222, 119986. [Google Scholar] [CrossRef]

- Thalmaier, G.; Cobîrzan, N.; Fechete-Tutunaru, L.V.; Balan, M.C. Recycled Aluminum Paraffin Composite for Passive Cooling Application in Buildings. Materials 2025, 18, 728. [Google Scholar] [CrossRef] [PubMed]

- Salunkhe, P.B.; Shembekar, P.S. A review on effect of phase change material encapsulation on the thermal performance of a system. Renew. Sustain. Energy Rev. 2012, 16, 5603–5616. [Google Scholar] [CrossRef]

- Yu, D.-H.; He, Z.-Z. Shape-remodeled macrocapsule of phase change materials for thermal energy storage and thermal management. Appl. Energy 2019, 247, 503–516. [Google Scholar] [CrossRef]

- Vida-Simiti, I.; Jumate, N.; Thalmaier, G.; Sechel, N.; Moldovan, V. Study of gradual porous metallic membranes obtained by powder sedimentation. J. Porous Mater. 2012, 19, 21–27. [Google Scholar] [CrossRef]

- Thalmaier, G.Y.; Sechel, N.A.; Vida-Simiti, I. Heat Transfer Enhancement of Paraffin Phase Change Composite Material Using Recycled Aluminum Sawing Chips. JOM 2019, 71, 1049–1055. [Google Scholar] [CrossRef]

- Bastos, J.; Monforti-Ferrario, F.; Melica, G. GHG Emission Factors for Electricity Consumption. European Commission. Joint Research Centre (JRC) 2024, [Dataset] PID. Available online: http://data.europa.eu/89h/919df040-0252-4e4e-ad82-c054896e1641 (accessed on 17 January 2025).

- Ali, M.A.; Fayaz; Viegas, R.F.; Kumar, M.B.S.; Kannapiran, R.K.; Feroskhan, M. Enhancement of heat transfer in paraffin wax PCM using nano graphene composite for industrial helmets. J. Energy Storage 2019, 26, 100982. [Google Scholar] [CrossRef]

- Chen, Y.; Tian, C.; Tu, Y.; Zhang, Z.; Wu, Y.; Wang, D.; Yan, W. Paraffin/graphite/boron nitride composite as a novel phase change material for rapid heat absorption in battery thermal management technology. Int. J. Heat. Mass. Transf. 2024, 235, 126214. [Google Scholar]

- Zhou, G.; Qiao, Y. Study on Heat Transfer of Copper Foam Microstructure in Phase Change Materials. Sustainability 2025, 17, 1681. [Google Scholar] [CrossRef]

- Elbadawi, M.; Basit, A.W.; Gaisford, S. Energy consumption and carbon footprint of 3D printing in pharmaceutical manufacture. Int. J. Pharm. 2023, 639, 122926. [Google Scholar] [CrossRef]

- Kim, J.; Shin, D.; Jang, A.; Sun, C.; Chang, J. 3D Printed Injection Molding for Prototyping Batch Fabrication of Macroscale Graphene/Paraffin Spheres for Thermal Energy Management. JOM 2019, 71, 4569–4577. [Google Scholar] [CrossRef]

- Garg, M.; Rani, R.; Meena, V.K.; Singh, S. Significance of 3D printing for a sustainable environment. Mater. Today Sustain. 2023, 23, 100419. [Google Scholar] [CrossRef]

- Enemuoh, E.U.; Menta, V.G.; Abutunis, A.; O’Brien, S.; Kaya, L.I.; Rapinac, J. Energy and Eco-Impact Evaluation of Fused Deposition Modeling and Injection Molding of Polylactic Acid. Sustainability 2021, 13, 1875. [Google Scholar] [CrossRef]

- Kruzhanov, V.; Arnhold, V. Energy consumption in powder metallurgical manufacturing. Powder Metall. 2012, 55, 14–21. [Google Scholar] [CrossRef]

| Graphite Content (vol. %) | 0 | 5 | 10 | 15 | 20 |

|---|---|---|---|---|---|

| Thermal conductivity (W/mK) | 0.25 | 0.74 | 0.88 | 1.15 | 2.72 |

| Specific heat (J/kgK) | 2144 | 2114 | 2082 | 2048 | 2012 |

| Thermal diffusivity (m2/s) | 1.3 | 3.9 | 4.6 | 5.9 | 13.7 |

| Density (kg/m3) | 897 | 925 | 955 | 987 | 1020 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thalmaier, G.; Cobîrzan, N.; Sechel, N.A.; Vida-Simiti, I. Paraffin Graphite Composite Spheres for Thermal Energy Management. Materials 2025, 18, 1482. https://doi.org/10.3390/ma18071482

Thalmaier G, Cobîrzan N, Sechel NA, Vida-Simiti I. Paraffin Graphite Composite Spheres for Thermal Energy Management. Materials. 2025; 18(7):1482. https://doi.org/10.3390/ma18071482

Chicago/Turabian StyleThalmaier, Gyorgy, Nicoleta Cobîrzan, Niculina A. Sechel, and Ioan Vida-Simiti. 2025. "Paraffin Graphite Composite Spheres for Thermal Energy Management" Materials 18, no. 7: 1482. https://doi.org/10.3390/ma18071482

APA StyleThalmaier, G., Cobîrzan, N., Sechel, N. A., & Vida-Simiti, I. (2025). Paraffin Graphite Composite Spheres for Thermal Energy Management. Materials, 18(7), 1482. https://doi.org/10.3390/ma18071482