Hot Deformation Behavior and Microstructure Evolution of Near-α Titanium Alloy TA32 in Dual-Phase Zone

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Preparation

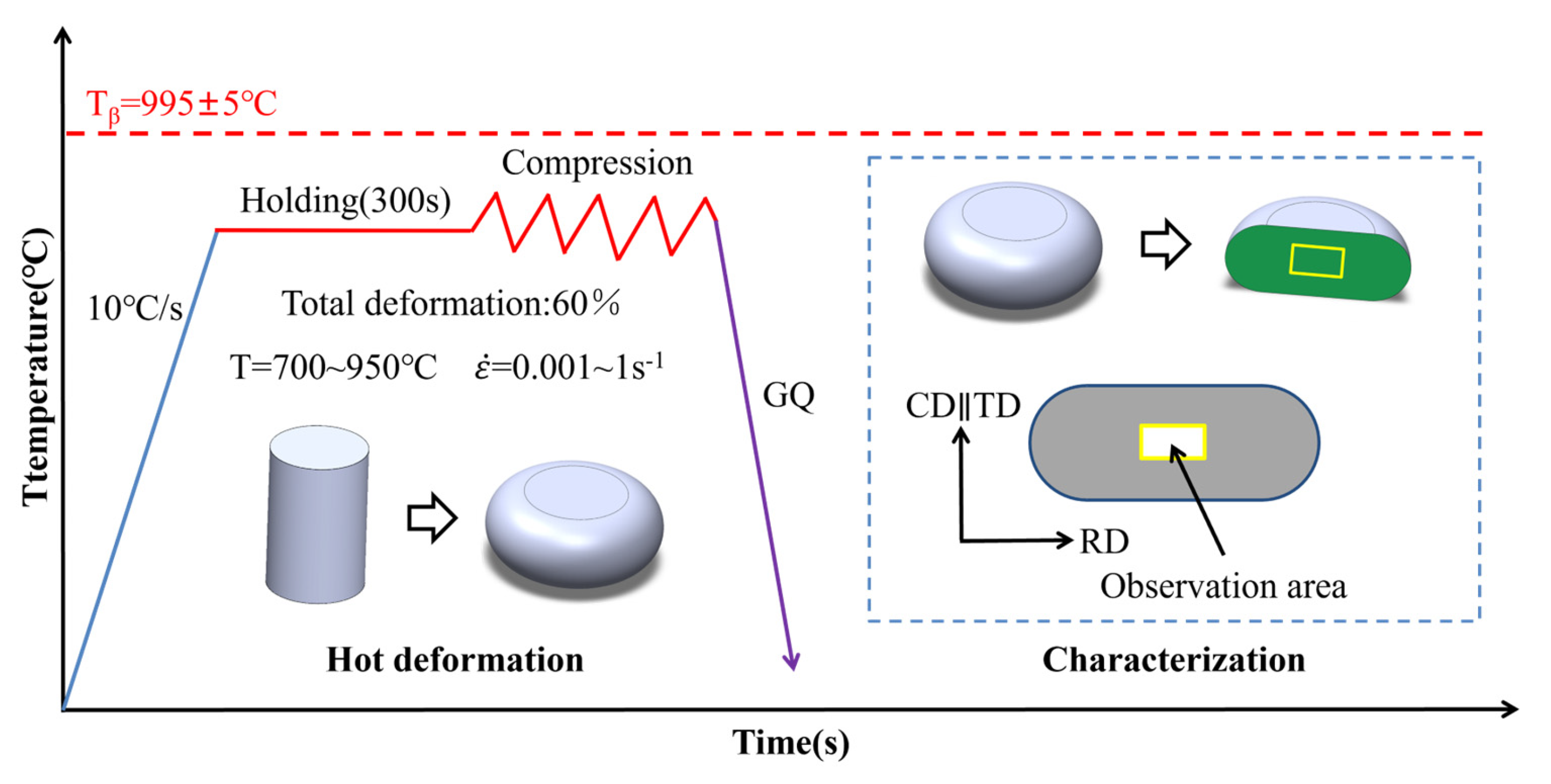

2.2. Thermomechanical Processing Experiments

2.3. Microstructure Characterization

3. Results and Discussion

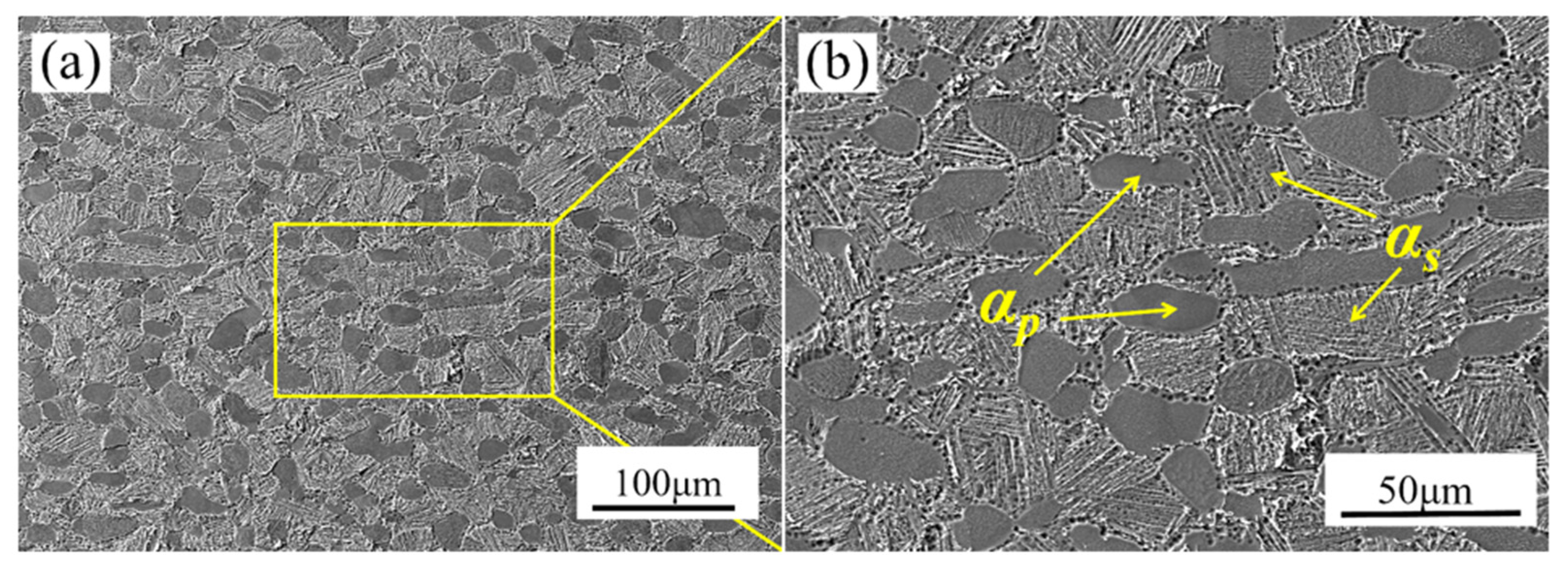

3.1. Initial Microstructure

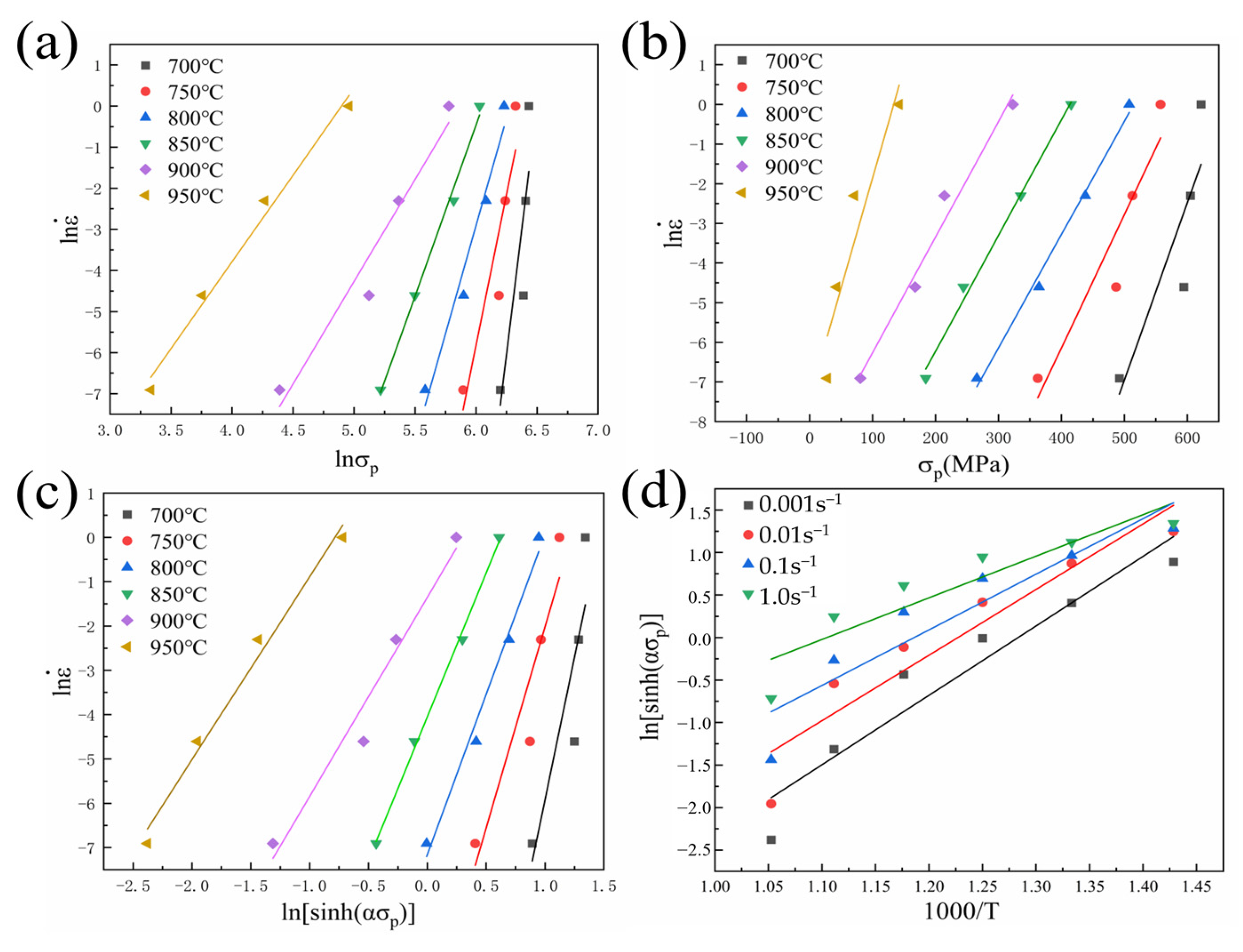

3.2. Constitutive Equation

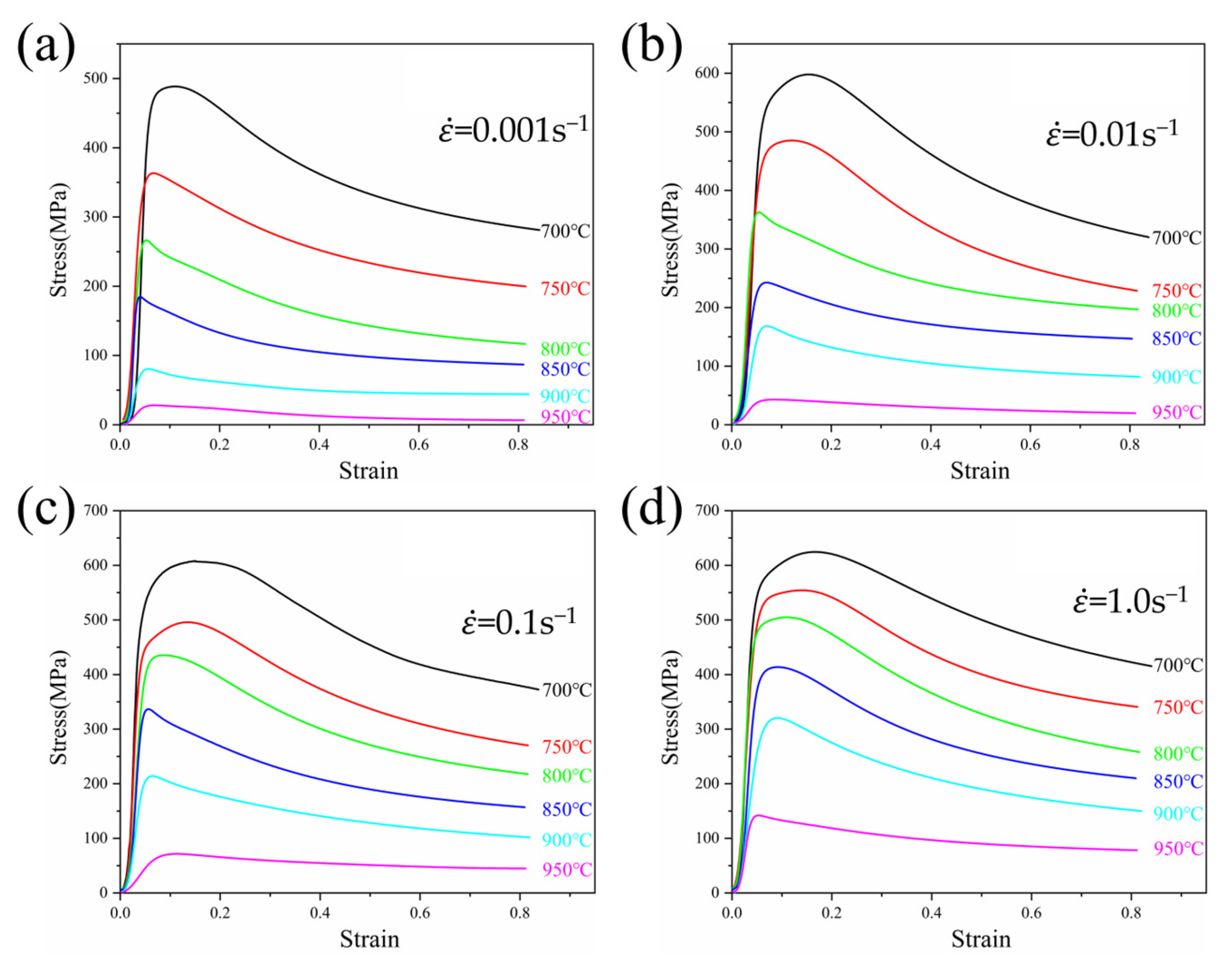

3.2.1. Stress–Strain Curve

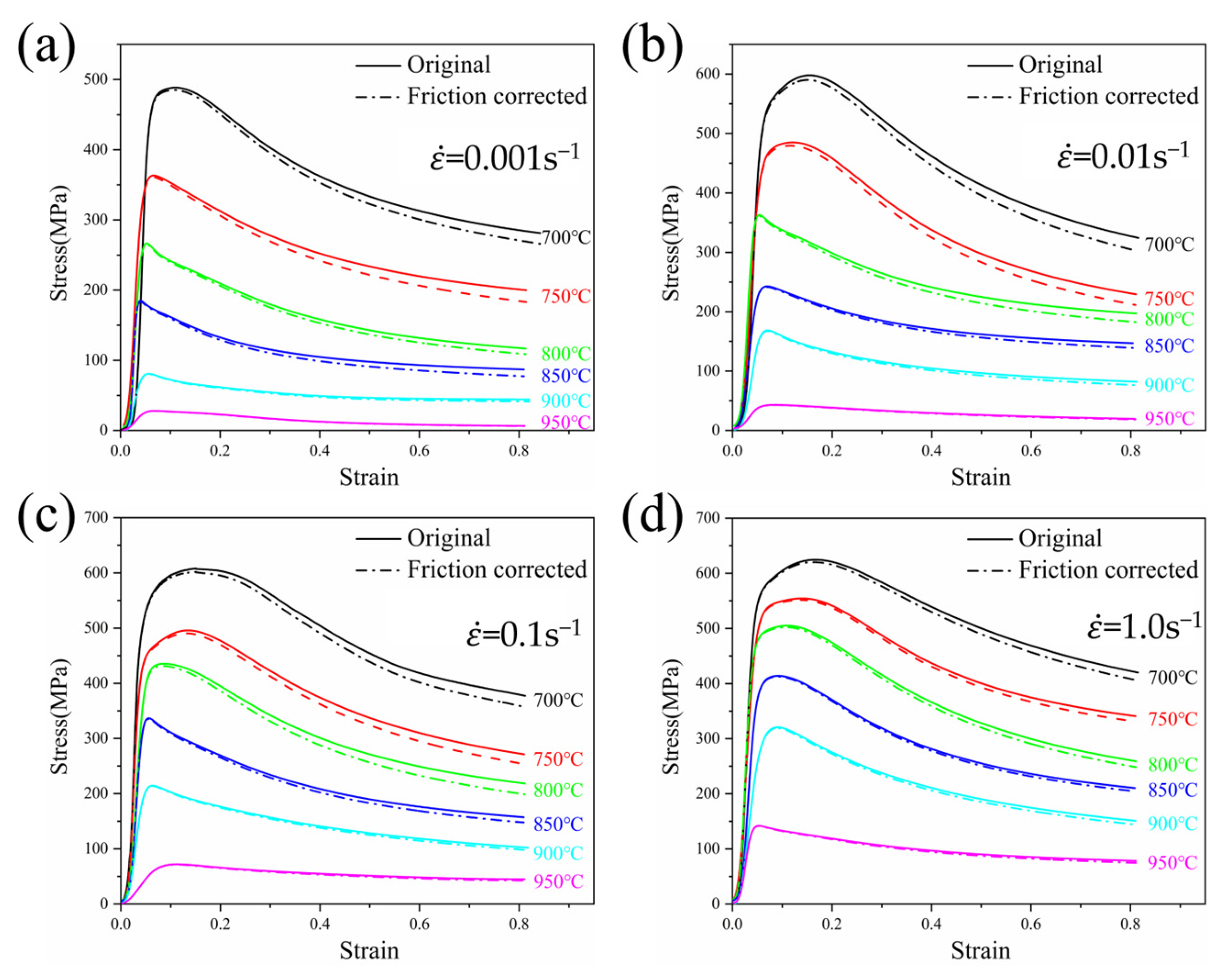

3.2.2. Friction Correction

3.2.3. Temperature Correction

3.2.4. Peak Stress Prediction Model

3.3. Microstructure Evolution

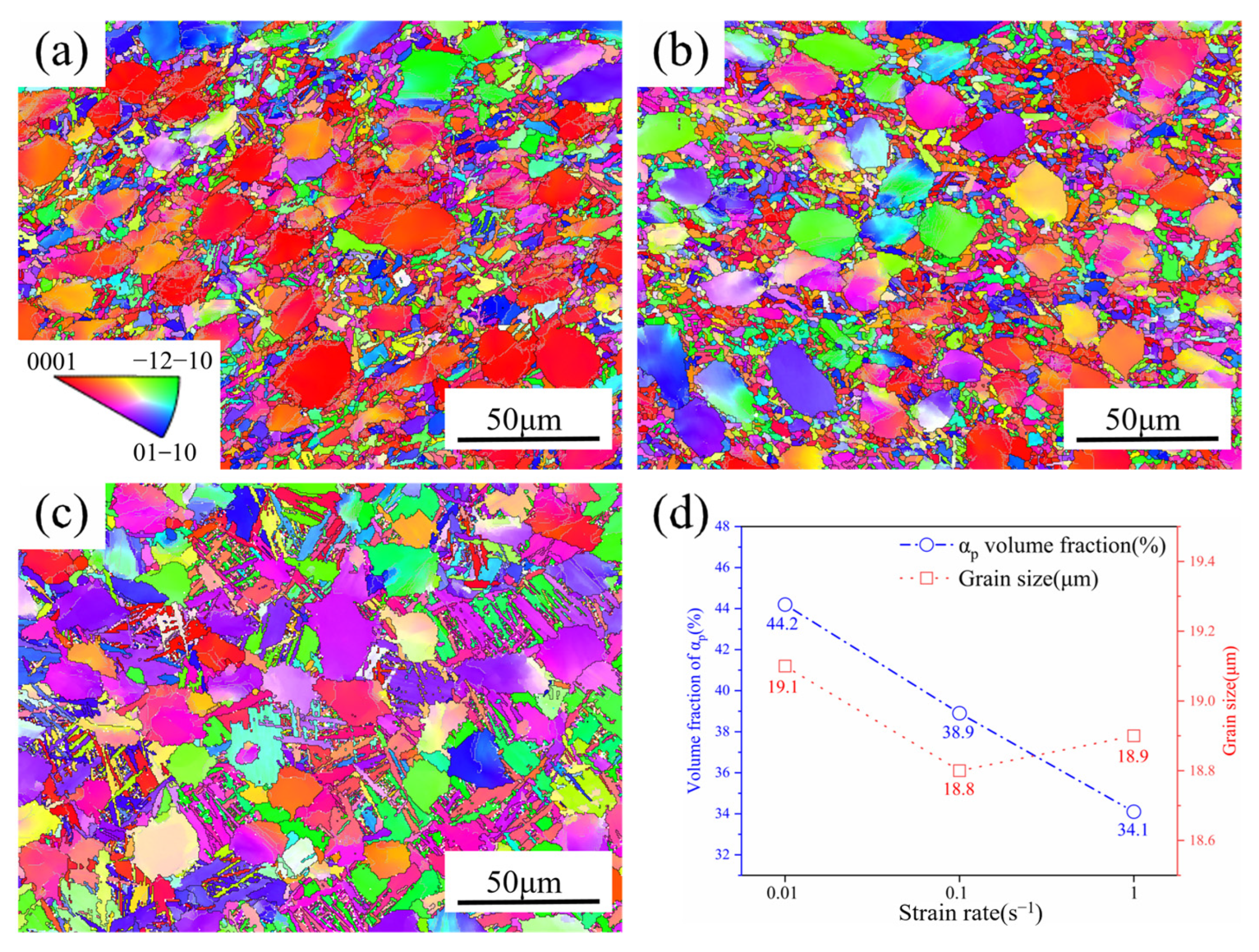

3.3.1. Effect of Strain Rate on Microstructure

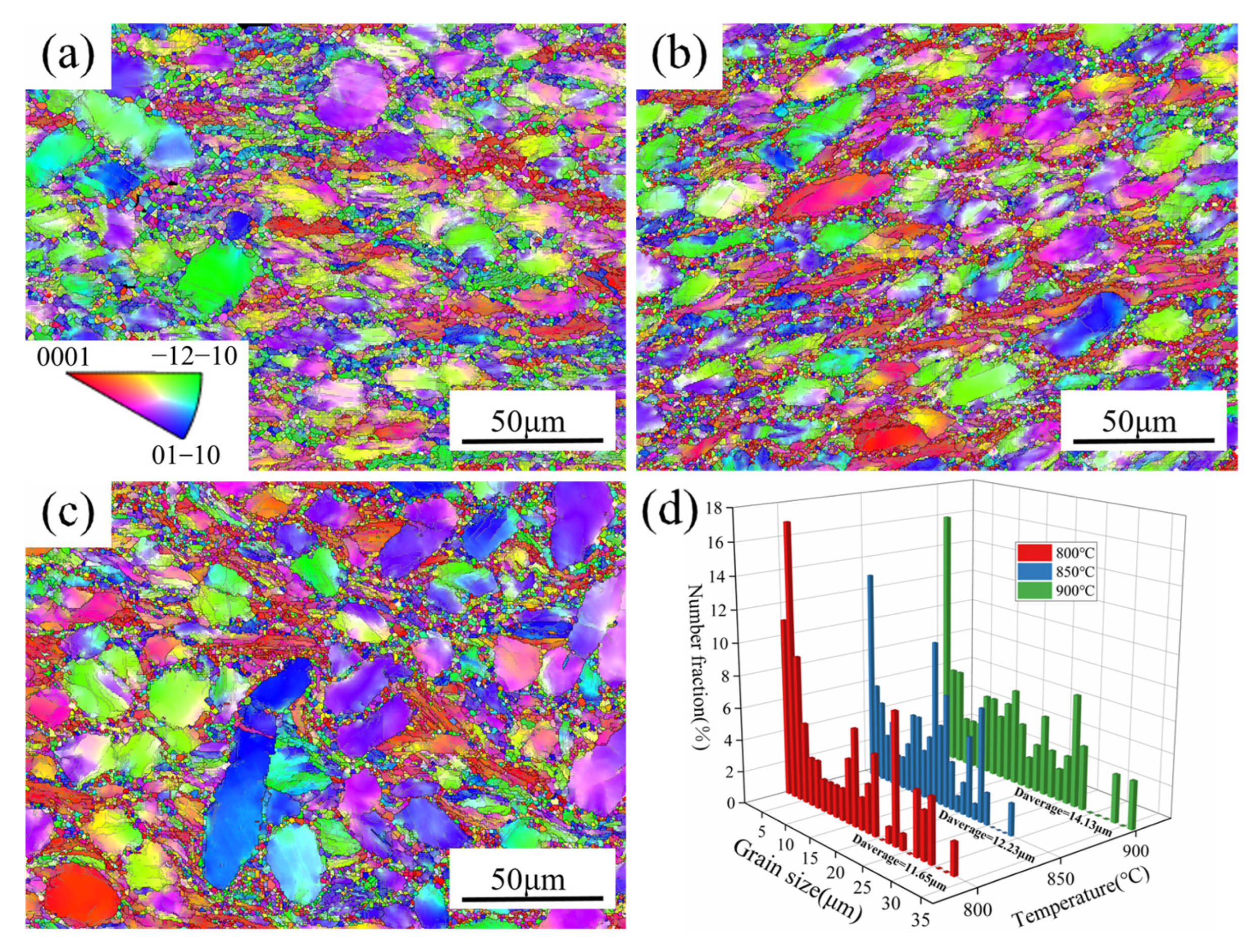

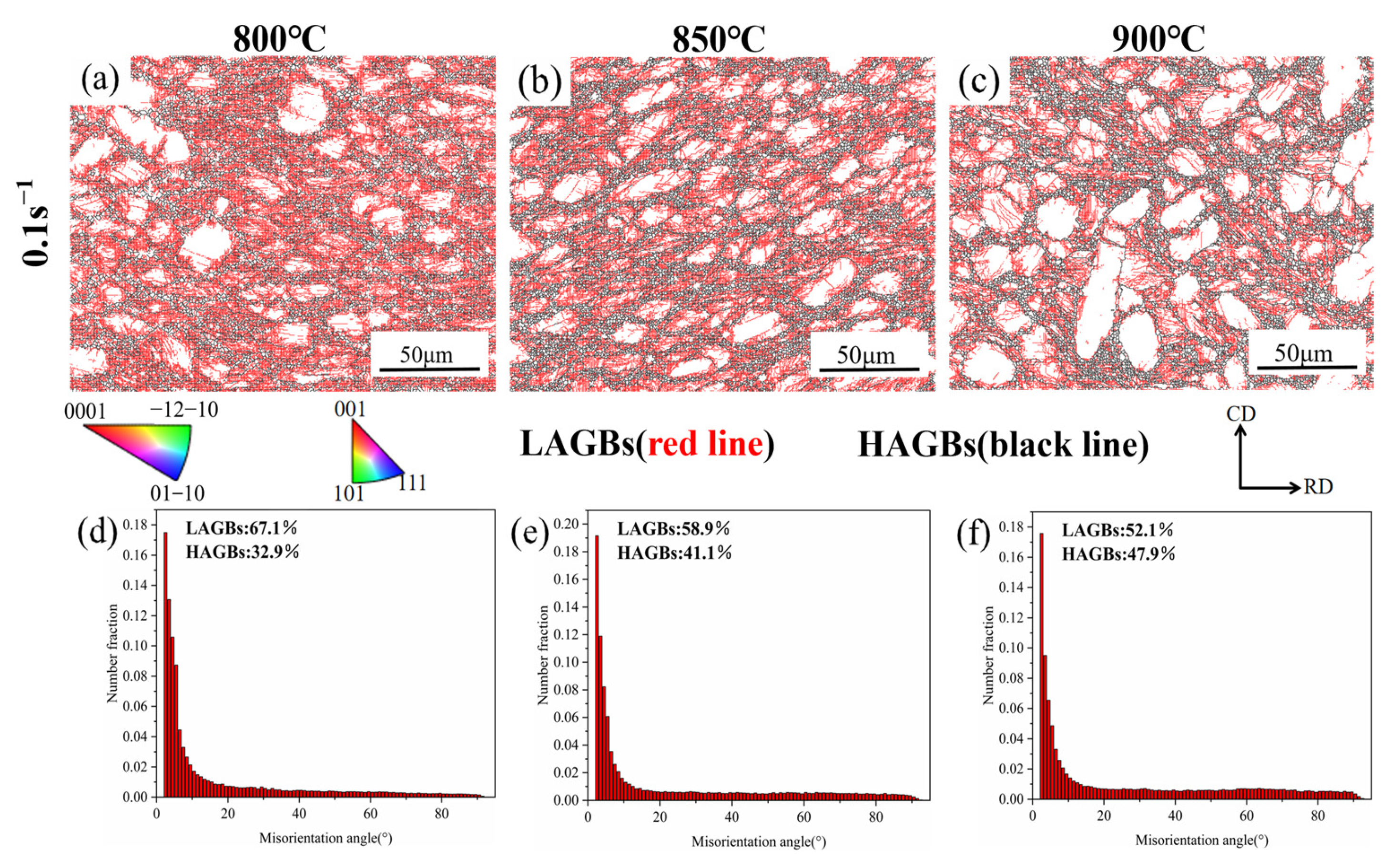

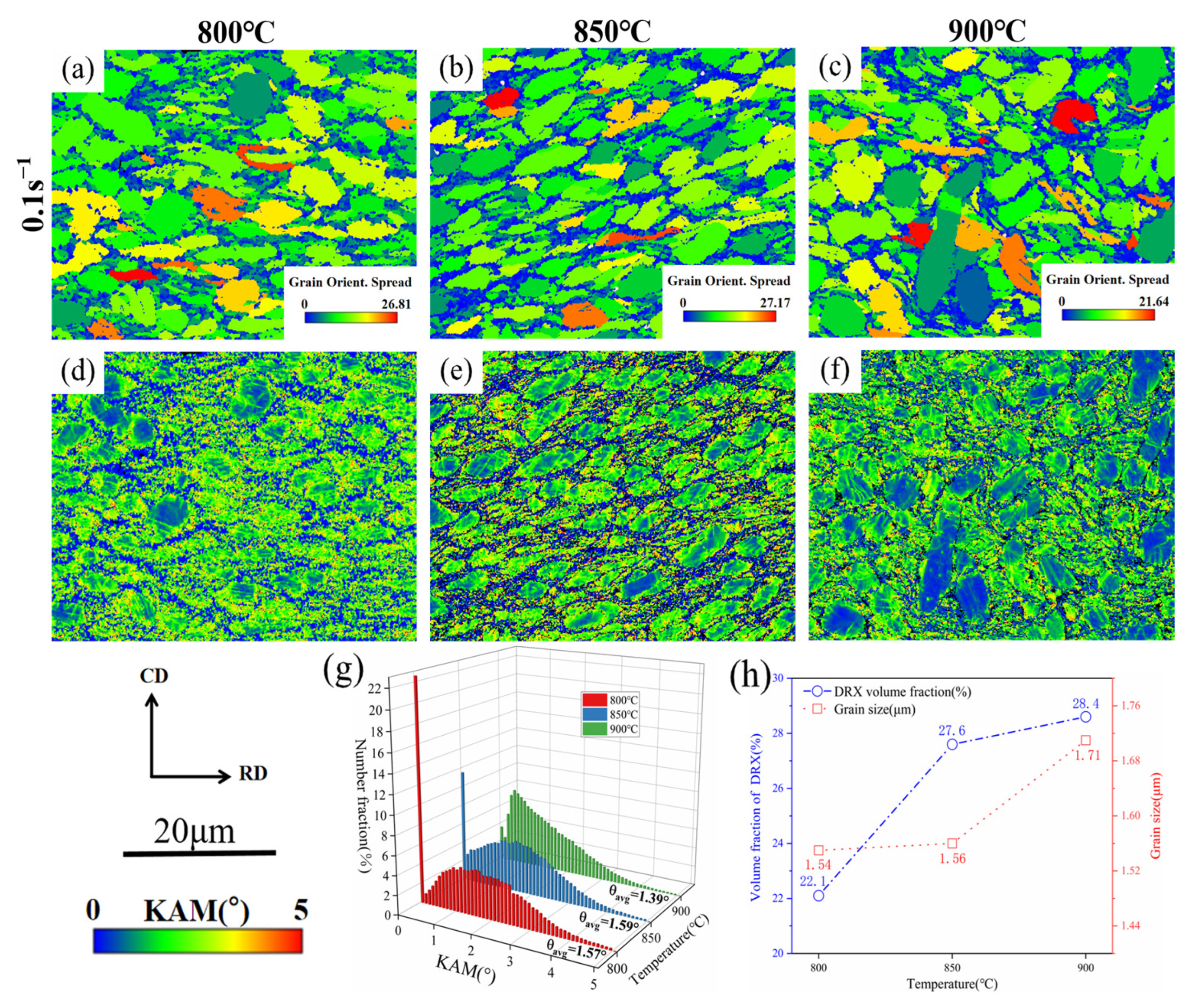

3.3.2. Effect of Deformation Temperature on Microstructure

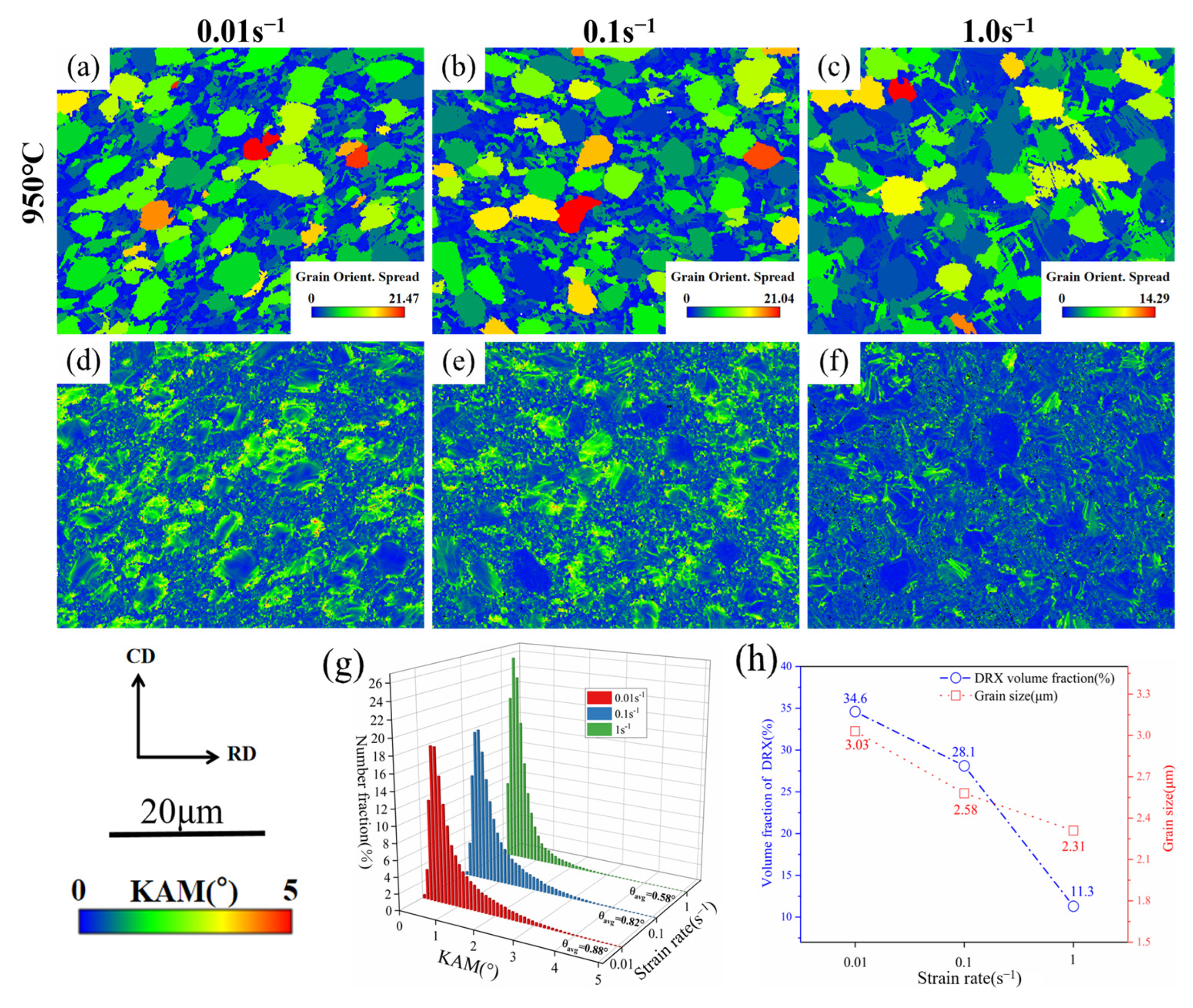

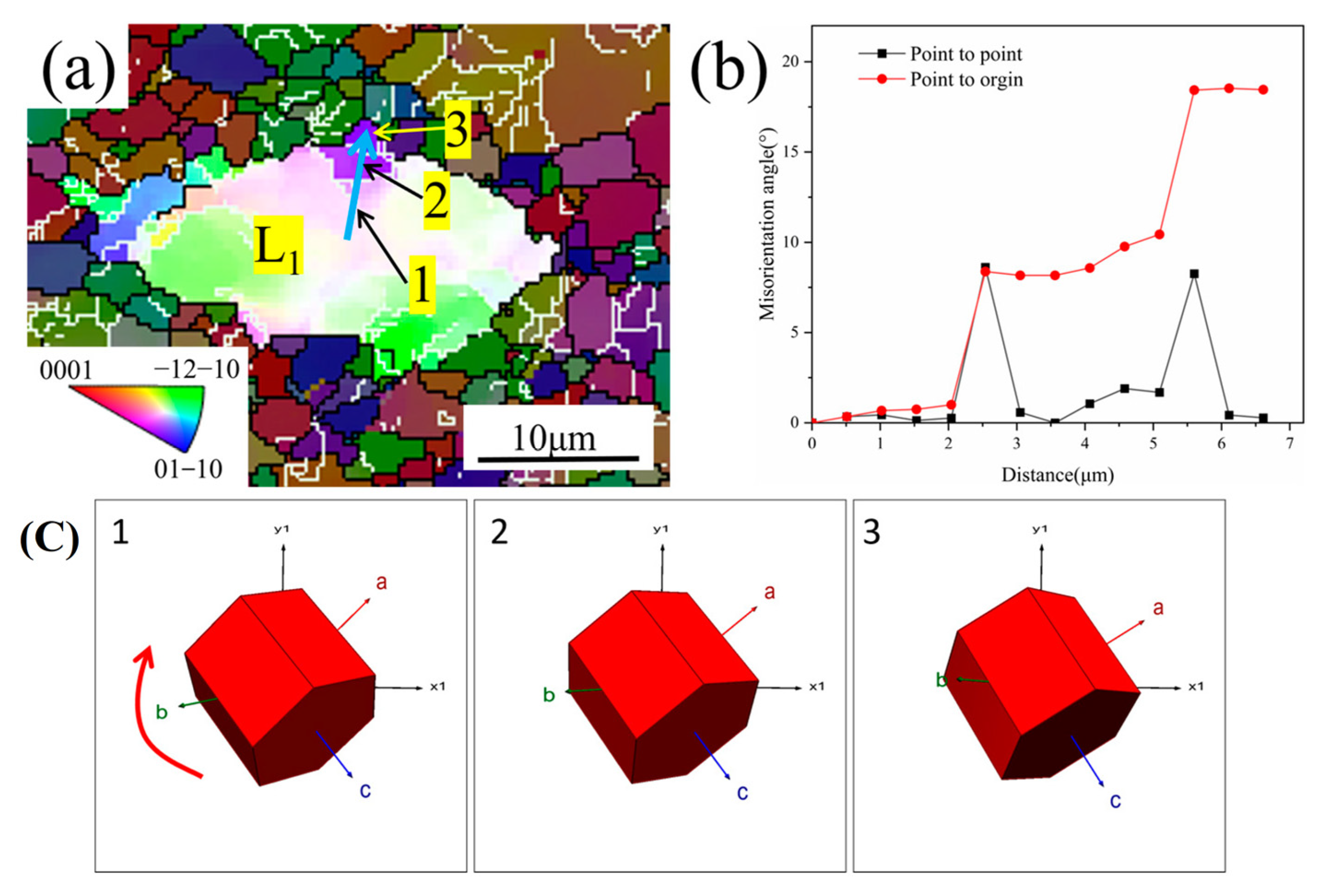

3.4. Analysis of DRX Mechanisms

4. Conclusions

- The flow stress rises quickly to the peak value, and then gradually reduces and eventually stabilizes under the softening impact of DRX at the beginning of deformation.

- The experimental values are significantly lower than the friction-temperature-corrected stress values, and a prediction model for the peak stress of TA32 alloy in the dual-phase zone has been established based on the correction results, as follows:

- At 950 °C temperature deformation, a high strain rate (1.0 s−1) under the adiabatic temperature rise effect is obvious. This condition precipitated a large number of acicular α, which inhibited the nucleation and development of DRX. The main softening mechanism shifted to DRV.

- DRX is the primary mechanism during the thermal deformation process, and the volume fraction and average size of DRX grains rise as temperatures increase. The recrystallization mode is dominated by CDRX with increasing temperatures and decreasing strain rates. At higher strain rates and lower temperatures, the DDRX mechanism exists.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar]

- Jaffee, R.I. The Physical Metallurgy of Titanium Alloys. Prog. Met. Phys. 1958, 7, 65–163. [Google Scholar]

- Zhang, S.; Zhang, H.; Liu, X.; Zhang, S.; Zhang, H.; Liu, X.; Wang, S.; Wang, C.; Zhou, G.; Zhang, S.; et al. Thermal Deformation Behavior Investigation of Ti–10V–5Al-2.5Fe-0.1B Titanium Alloy Based on Phenomenological Constitutive Models and a Machine Learning Method. J. Mater. Res. Technol. 2024, 29, 589–608. [Google Scholar]

- Gronostajski, Z. The Deformation Processing Map for Control of Microstructure in CuAl9.2Fe3 Aluminium Bronze. J. Mater. Process. Technol. 2002, 125–126, 119–124. [Google Scholar]

- Zhang, Z.; Fan, J.; Tang, B.; Kou, H.; Wang, J.; Chen, Z.; Li, J. Microstructure/Texture Evolution Maps to Optimize Hot Deformation Process of Near-α Titanium Alloy. Prog. Nat. Sci. Mater. Int. 2020, 30, 86–93. [Google Scholar]

- Zhang, C.; Yang, Z.; Qu, B.; Lian, Q.; Guo, R.; Zhang, S.; Kong, F.; Cao, P. Superior Strength-Ductility Synergy in a Near-α Titanium Alloy Fabricated by Severe Plastic Deformation at Lower Temperatures. Scr. Mater. 2024, 248, 116140. [Google Scholar]

- Jiang, B.; Wen, D.; Wang, Q.; Che, J.; Dong, C.; Liaw, P.K.; Xu, F.; Sun, L. Design of Near-α Ti Alloys via a Cluster Formula Approach and Their High-Temperature Oxidation Resistance. J. Mater. Sci. Technol. 2019, 35, 1008–1016. [Google Scholar]

- Tabie, V.M.; Li, C.; Saifu, W.; Li, J.; Xu, X. Mechanical Properties of Near Alpha Titanium Alloys for High-Temperature Applications—A Review. Aircr. Eng. Aerosp. Technol. 2020, 92, 521–540. [Google Scholar]

- Wang, Q.; Liu, X.; Ren, Y.; Song, M.; Baker, I.; Wu, H. Microstructural Evolution and Cryogenic-Normal Temperature Deformation Behavior of the Near-α Titanium Alloy TA15 Fabricated by Laser Powder Bed Fusion. J. Alloys Compd. 2024, 1001, 175075. [Google Scholar]

- Liu, Y.; Li, Z.; Zhao, B.; Sun, C.; Feng, Y. Microstructure Evolution Characteristics of Near-α TA32 Titanium Alloy During Superplastic Tensile Deformation. Mater. Sci. Eng. A 2023, 879, 145264. [Google Scholar]

- Liu, R.; Wang, B.; Hu, S.; Zhang, H.; Feng, P. Unified Modeling of the Microstructure and Densification of TC4 Powder Titanium Alloy During Hot Deformation. J. Mater. Res. Technol. 2023, 24, 4904–4918. [Google Scholar]

- Gao, P.; Zhan, M.; Fan, X.; Lei, Z.; Cai, Y. Hot Deformation Behavior and Microstructure Evolution of TA15 Titanium Alloy with Nonuniform Microstructure. Mater. Sci. Eng. A 2017, 689, 243–251. [Google Scholar]

- Chen, J.; Li, J.; Tang, B.; Chen, Y.; Kou, H. Microstructure and Texture Evolution of a Near β Titanium Alloy Ti-7333 During Continuous Cooling Hot Deformation. Prog. Nat. Sci. Mater. Int. 2019, 29, 50–56. [Google Scholar]

- Chen, Z.; Xu, L.; Cao, S.; Yang, J.; Zheng, Y.; Xiao, S.; Tian, J.; Chen, Y. Characterization of Hot Deformation and Microstructure Evolution of a New Metastable β Titanium Alloy. Trans. Nonferrous Met. Soc. China 2022, 32, 1513–1529. [Google Scholar]

- Hua, K.; Xue, X.; Kou, H.; Fan, J.; Tang, B.; Li, J. Characterization of Hot Deformation Microstructure of a Near Beta Titanium Alloy Ti-5553. J. Alloys Compd. 2014, 615, 531–537. [Google Scholar]

- Gao, P.F.; Guo, J.; Zhan, M.; Lei, Z.N.; Fu, M.W. Microstructure and Damage Based Constitutive Modelling of Hot Deformation of Titanium Alloys. J. Alloys Compd. 2020, 831, 154851. [Google Scholar]

- Yang, X.; Wang, Y.; Dong, X.; Peng, C.; Ji, B.; Xu, Y.; Li, W. Hot Deformation Behavior and Microstructure Evolution of the Laser Solid Formed TC4 Titanium Alloy. Chin. J. Aeronaut. 2021, 34, 163–182. [Google Scholar]

- Xiao, Y.; Deng, Y.; An, Y.; Yuan, L.; Zhan, X.; Wang, B. Strain Rate Affects the Deformation Mechanism of a Ti-55511 Titanium Alloy: Modeling of Constitutive Model and 3D Processing Map Using Machine Learning. Mater. Today Commun. 2024, 40, 109881. [Google Scholar]

- Shen, Z.; Wu, R.; Yuan, C.; Jiao, W. Comparative Study of Metamodeling Methods for Modeling the Constitutive Relationships of the TC6 Titanium Alloy. J. Mater. Res. Technol. 2021, 10, 188–204. [Google Scholar]

- Wang, L.; Li, W.; Luan, S.; Jin, P.; Wang, J.; Ren, Q.; Zhu, L. Study on Hot Deformation Behavior of As-Cast Ti-5Al-5Mo-5V-1Cr-1Fe Titanium Alloy in (α + β) Phase Region. Mater. Today Commun. 2023, 35, 105797. [Google Scholar]

- Wang, Y.; Li, Z.; Wang, H.; Hou, M.; Yu, K.; Xu, Y.; Xiao, H. Flow Behavior and Dynamic Recrystallization Mechanism of a New Near-Alpha Titanium Alloy Ti-0.3Mo-0.8Ni-2Al-1.5Zr. J. Mater. Res. Technol. 2024, 30, 3863–3876. [Google Scholar]

- Li, C.; Muhammad, I.S.; Lang, L.; Guo, Y.; Li, X.; Alexandrova, S.; Zhang, D. Hot Deformation Behavior and Strain Compensation Constitutive Model of Equiaxed Fine Grain Diffusion-Welded Micro-Duplex TC4 Titanium Alloy. Chin. J. Aeronaut. 2023, 36, 510–522. [Google Scholar]

- Lu, T.; Dan, Z.; Li, T.; Dai, G.; Sun, Y.; Guo, Y.; Li, K.; Yi, D.; Chang, H.; Zhou, L. Flow Softening and Microstructural Evolution of Near β Titanium Alloy Ti-35421 During Hot Compression Deformation in the α+β Region. J. Mater. Res. Technol. 2022, 19, 2257–2274. [Google Scholar]

- Chai, Z.; Wang, W.Y.; Ren, Y.; Wang, X.; Zhang, Y.; Sun, F.; Hao, F.; Li, J. Hot Deformation Behavior and Microstructure Evolution of TC11 Dual-Phase Titanium Alloy. Mater. Sci. Eng. A 2024, 898, 146331. [Google Scholar]

- Han, L.; Zhang, H.; Wang, C.; Zhou, G.; Zhang, S.; Chen, L. Dynamic Recrystallization Behavior of β Grains in Hot Deformed Ti-6Mo-5V-3Al-2Fe Alloy. Int. J. Adv. Manuf. Technol. 2023, 1–10. [Google Scholar] [CrossRef]

- Yu, R.; Chen, Q.; Zhang, X.; Zhang, H.; Hao, J.; Li, J. Constitutive Model and Microstructure Evolution of a Novel TG6 High-Temperature Titanium Alloy During Hot Deformation. J. Mater. Eng. Perform. 2022, 31, 833–848. [Google Scholar]

- Wang, J.; Wang, K.; Lu, S.; Li, X.; OuYang, D.; Qiu, Q. Softening Mechanism and Process Parameters Optimization of Ti-4.2Al-0.005B Titanium Alloy During Hot Deformation. J. Mater. Res. Technol. 2022, 17, 1842–1851. [Google Scholar]

- Ebrahimi, R.; Najafizadeh, A. A New Method for Evaluation of Friction in Bulk Metal Forming. J. Mater. Process. Technol. 2004, 152, 136–143. [Google Scholar]

- Sellars, C.M.; McTegart, W.J. On the Mechanism of Hot Deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar]

- Mahadule, D.; Kumar, D.; Dandekar, T.R.; Khatirkar, R.K.; Suwas, S. Modelling of Flow Stresses During Hot Deformation of Ti–6Al–4Mo–1V–0.1Si Alloy. J. Mater. Res. 2023, 38, 3750–3763. [Google Scholar]

- Kapoor, K.; Ravi, P.; Naragani, D.; Park, J.S.; Almer, J.D.; Sangid, M.D. Strain Rate Sensitivity, Microstructure Variations, and Stress-Assisted β→α′′ Phase Transformation Investigation on the Mechanical Behavior of Dual-Phase Titanium Alloys. Mater. Charact. 2020, 166, 110410. [Google Scholar] [CrossRef]

- Cao, S.; Han, J.; Wang, H.; Xiao, S.; Chen, Y.; Jia, Y. Microstructure Evolution and Phase Transformation Mechanism of Ti–46Al–8Nb–2.5V Alloy Based on Phase Transformation Geometric Models. J. Mater. Res. Technol. 2023, 27, 6135–6147. [Google Scholar] [CrossRef]

- Shahmir, H.; Nili-Ahmadabadi, M.; Kim, H.S.; Langdon, T.G. Significance of Adiabatic Heating on Phase Transformation in Titanium-Based Alloys During Severe Plastic Deformation. Mater. Charact. 2023, 203, 113091. [Google Scholar] [CrossRef]

- Wang, L.; Fan, X.; Yu, J.; Lu, F.; Zhan, M.; Chen, Q. Insight into the Multi-Hierarchical Interactions Between α and β Phases During Hot Deformation of Near-β Titanium Alloy. Mater. Sci. Eng. A 2024, 903, 146649. [Google Scholar] [CrossRef]

- Guan, X.R.; Chen, Q.; Qu, S.J.; Cao, G.J.; Wang, H.; Ran, X.D.; Feng, A.H.; Chen, D.L. High-Strain-Rate Deformation: Stress-Induced Phase Transformation and Nanostructures in a Titanium Alloy. Int. J. Plast. 2023, 169, 103707. [Google Scholar] [CrossRef]

- He, L.; Su, H.; Xu, J.; Zhang, L. Inverse Identification of Constitutive Parameters of Ti2AlNb Intermetallic Alloys Based on Cooperative Particle Swarm Optimization. Chin. J. Aeronaut. 2018, 31, 1774–1785. [Google Scholar]

- Deng, H.; Zheng, Z.; Song, W.; Tan, X.; Liang, X.; Li, H.; Li, H. Constitutive Model and Microstructure Evolution of Thermal Deformation Behavior of In Situ TiB2p/Al-Zn-Mg-Cu Composites with High Zn Content. Mater. Today Commun. 2024, 41, 110308. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Q.; Zhang, J.; Xu, K.; Xue, Y. Effect of Multi-Pass Deformation on Hot Flow Behavior and Microstructure Evolution Mechanism of Ti–6Al–4V Alloy Fabricated by Hot Isostatic Pressing. J. Mater. Res. Technol. 2022, 17, 2229–2248. [Google Scholar]

- Wang, L.; Li, W.; Jin, P.; Wang, J.; Ren, Q.; Zhu, L. Revealing Hot Deformation Behavior and Optimizing Process Parameters of As-Cast Ti–5Al–5Mo–5V–1Cr–1Fe Alloy. J. Mater. Res. Technol. 2023, 23, 3602–3616. [Google Scholar]

- Liu, Y.; Sun, P.; Wang, M.; Li, H.; Li, Q. Microstructure Evolution and Recrystallization Mechanisms of a Fine-Grained Nickel-Based Superalloy During Thermal Deformation Process. Intermetallics 2024, 173, 108406. [Google Scholar]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Flow Behavior and Globularization Kinetics During Hot Working of Ti–6Al–4V with a Colony Alpha Microstructure. Mater. Sci. Eng. A 1999, 263, 257–271. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.; Chen, X.; Bao, J.; Chen, Z. Effect of Sn Addition on the Deformation Behavior and Microstructural Evolution of Mg-Gd-Y-Zr Alloy During Hot Compression. Mater. Sci. Eng. A 2021, 826, 142026. [Google Scholar] [CrossRef]

- Yu, Y.; Yan, H.; Zhu, H.; Chen, J.; Xia, W.; Liang, T.; Su, B.; Song, M. Hot Deformation Behavior and Microstructure Evolution of TC17 Alloy with Lamellar and β Treated Starting Microstructures During Stepped Strain Rate Compression. J. Alloys Compd. 2023, 957, 170465. [Google Scholar] [CrossRef]

- Xia, J.; Chai, L.; Wu, H.; Zhi, Y.; Gou, Y.; Huang, W.; Guo, N. EBSD Study of Microstructural and Textural Changes of Hot-Rolled Ti–6Al–4V Sheet After Annealing at 800 °C. Acta Metall. Sin. Engl. Lett. 2018, 31, 1215–1223. [Google Scholar] [CrossRef]

- Yang, Q.; Ma, M.; Tan, Y.; Xiang, S.; Zhao, F.; Liang, Y. Microstructure and Texture Evolution of TB8 Titanium Alloys During Hot Compression. Rare Met. 2021, 40, 2917–2926. [Google Scholar] [CrossRef]

- Ji, H.; Peng, Z.; Huang, X.; Wang, B.; Xiao, W.; Wang, S. Dynamic Recrystallization of Ti-6Al-4V Titanium Alloy Based on Cellular Automata. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 237, 1442–1459. [Google Scholar] [CrossRef]

- Yu, Y.; Yan, H.; Zhu, H.; Chen, J.; Xia, W.; Sun, Y.; Su, B.; Deng, Y.; Song, M. Dynamic Recrystallization Behavior and Mechanism of Bimodal TC17 Titanium Alloy During High Strain Rate Hot Compression. Mater. Today Commun. 2023, 34, 105255. [Google Scholar] [CrossRef]

- Li, C.; Cui, Y.; Zheng, W.; Song, L.; Wu, Y.; Wu, Y.; Yu, C.; Hui, X. Unveiling the Dynamic Softening Mechanism via Micromechanical Behavior for a Near-β Titanium Alloy Deformed at a High Strain Rate. J. Mater. Res. Technol. 2023, 26, 9392–9405. [Google Scholar] [CrossRef]

- Shams, S.A.A.; Mirdamadi, S.; Abbasi, S.M.; Kim, D.; Lee, C.S. Mechanism of Martensitic to Equiaxed Microstructure Evolution During Hot Deformation of a Near-Alpha Ti Alloy. Metall. Mater. Trans. A 2017, 48, 2979–2992. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, B.; Yu, H.; Yang, H.; Liu, Q.; Ning, Y. Microstructure Evolution and Underlying Mechanisms During the Hot Deformation of 718Plus Superalloy. Mater. Sci. Eng. A 2020, 784, 139334. [Google Scholar] [CrossRef]

- Tiamiyu, A.A.; Pang, E.L.; Chen, X.; LeBeau, J.M.; Nelson, K.A.; Schuh, C.A. Nanotwinning-Assisted Dynamic Recrystallization at High Strains and Strain Rates. Nat. Mater. 2022, 21, 786–794. [Google Scholar] [PubMed]

- Germain, L.; Gey, N.; Humbert, M.; Bocher, P.; Jahazi, M. Analysis of Sharp Microtexture Heterogeneities in a Bimodal IMI 834 Billet. Acta Mater. 2005, 53, 3535–3543. [Google Scholar]

- Li, Y.; Fang, H.; Chen, R.; Ding, X.; Sun, S.; Zhu, B.; Xue, X.; Guo, J. A Comparative Analysis of a Unique DRX Process in Achieving a Homogeneous Distribution of β Grains in the Single Phase Region of As-Cast Ti644321 Alloy. Mater. Charact. 2024, 207, 113505. [Google Scholar]

| Element | Al | Sn | Zr | Mo | Nb | Ta | Si | Ti |

|---|---|---|---|---|---|---|---|---|

| Content | 5.5 | 3.5 | 3.0 | 1 | 0.5 | 0.7 | 0.3 | 85.5 |

| Strain Rate (s−1) | Temperature of Deformation (°C) | |||||

|---|---|---|---|---|---|---|

| 700 | 750 | 800 | 850 | 900 | 950 | |

| 0.001 | 1.249 | 1.371 | 1.336 | 1.463 | 1.306 | 1.117 |

| 0.01 | 1.253 | 1.275 | 1.304 | 1.367 | 1.330 | 1.197 |

| 0.1 | 1.255 | 1.217 | 1.313 | 1.311 | 1.319 | 1.376 |

| 1 | 1.065 | 1.066 | 1.203 | 1.232 | 1.368 | 1.258 |

| Strain Rate (s−1) | Temperature of Deformation (°C) | |||||

|---|---|---|---|---|---|---|

| 700 | 750 | 800 | 850 | 900 | 950 | |

| 0.001 | 492.02 | 362.55 | 265.67 | 184.52 | 80.58 | 28.04 |

| 0.01 | 594.32 | 486.67 | 364.47 | 244.06 | 167.72 | 42.81 |

| 0.1 | 604.95 | 512.75 | 437.89 | 335.61 | 214.02 | 71.36 |

| 1 | 621.82 | 557.51 | 507.68 | 415.34 | 322.86 | 142.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Meng, Y.; Cheng, Y.; Wang, R.; Liu, X. Hot Deformation Behavior and Microstructure Evolution of Near-α Titanium Alloy TA32 in Dual-Phase Zone. Materials 2025, 18, 1476. https://doi.org/10.3390/ma18071476

Jiang J, Meng Y, Cheng Y, Wang R, Liu X. Hot Deformation Behavior and Microstructure Evolution of Near-α Titanium Alloy TA32 in Dual-Phase Zone. Materials. 2025; 18(7):1476. https://doi.org/10.3390/ma18071476

Chicago/Turabian StyleJiang, Jiajun, Yi Meng, Yingxu Cheng, Ruiqi Wang, and Xingang Liu. 2025. "Hot Deformation Behavior and Microstructure Evolution of Near-α Titanium Alloy TA32 in Dual-Phase Zone" Materials 18, no. 7: 1476. https://doi.org/10.3390/ma18071476

APA StyleJiang, J., Meng, Y., Cheng, Y., Wang, R., & Liu, X. (2025). Hot Deformation Behavior and Microstructure Evolution of Near-α Titanium Alloy TA32 in Dual-Phase Zone. Materials, 18(7), 1476. https://doi.org/10.3390/ma18071476