Transforming Agricultural Waste from Mediterranean Fruits into Renewable Materials and Products with a Circular and Digital Approach

Abstract

1. Introduction

2. Agricultural Waste of the Mediterranean Area

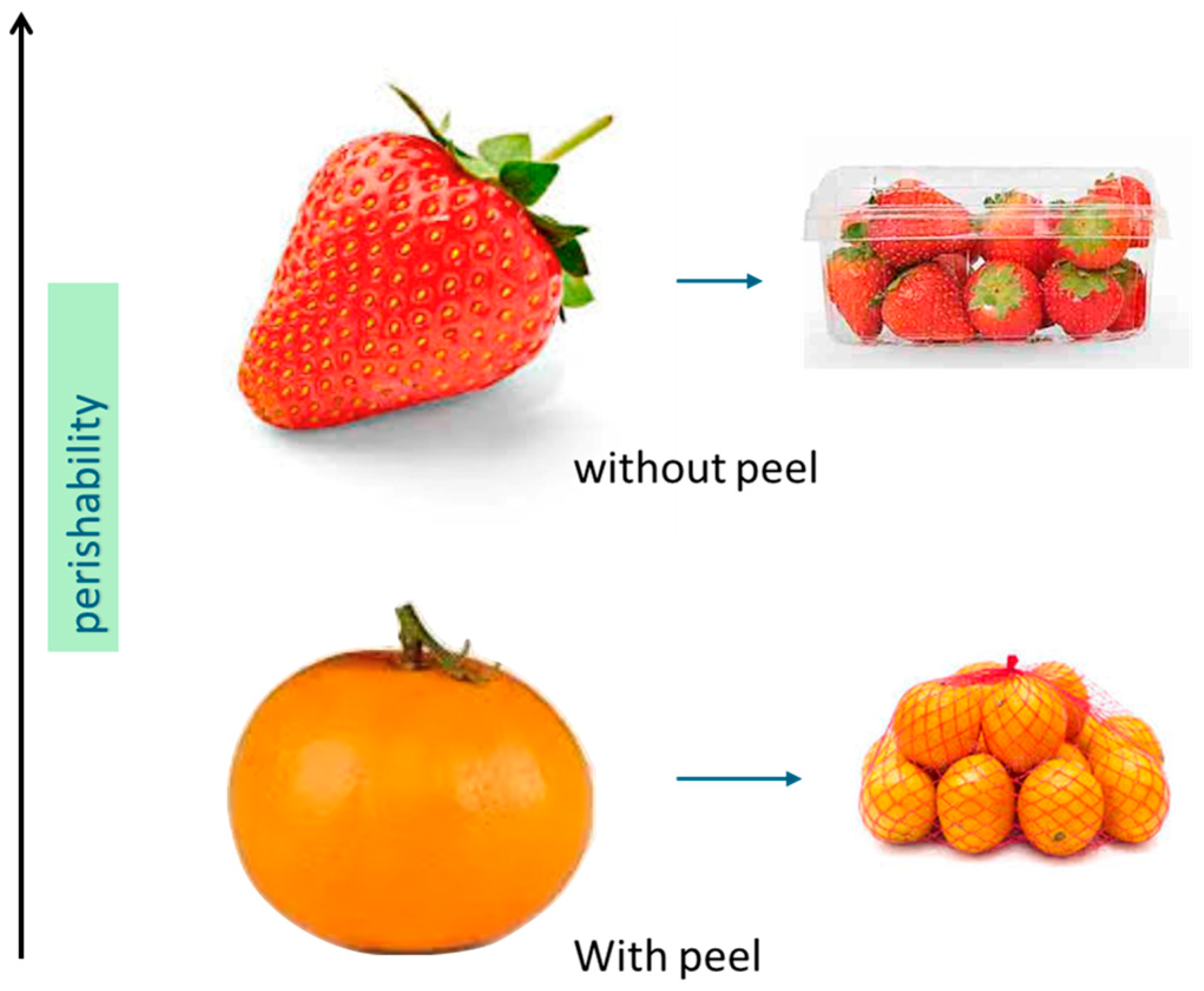

2.1. Perishable Fruits

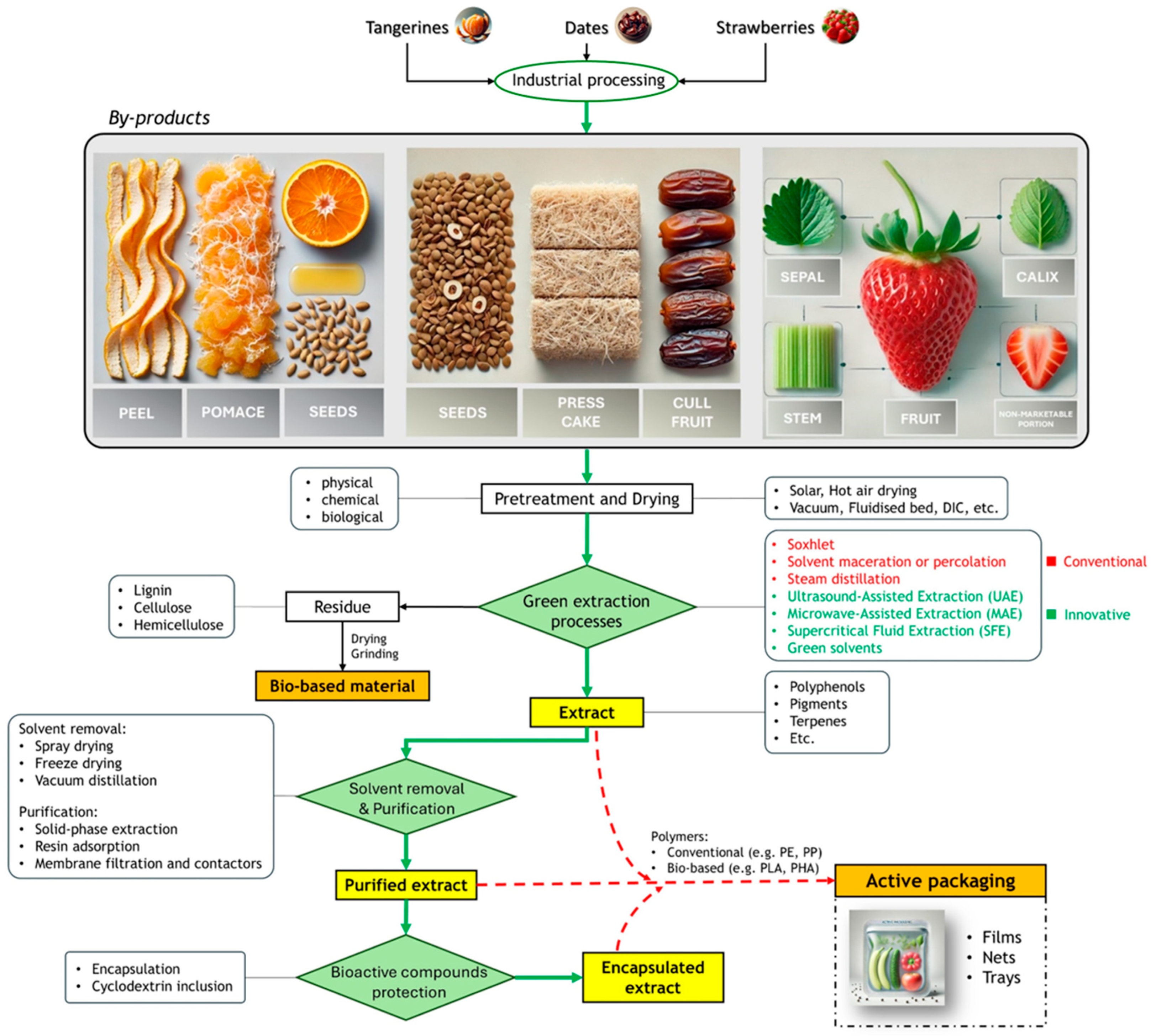

2.2. By-Products of the Food Chain

2.2.1. Fruits Shells and Stones

2.2.2. Pomaces

2.2.3. Peels

2.2.4. Plant Waste Residues

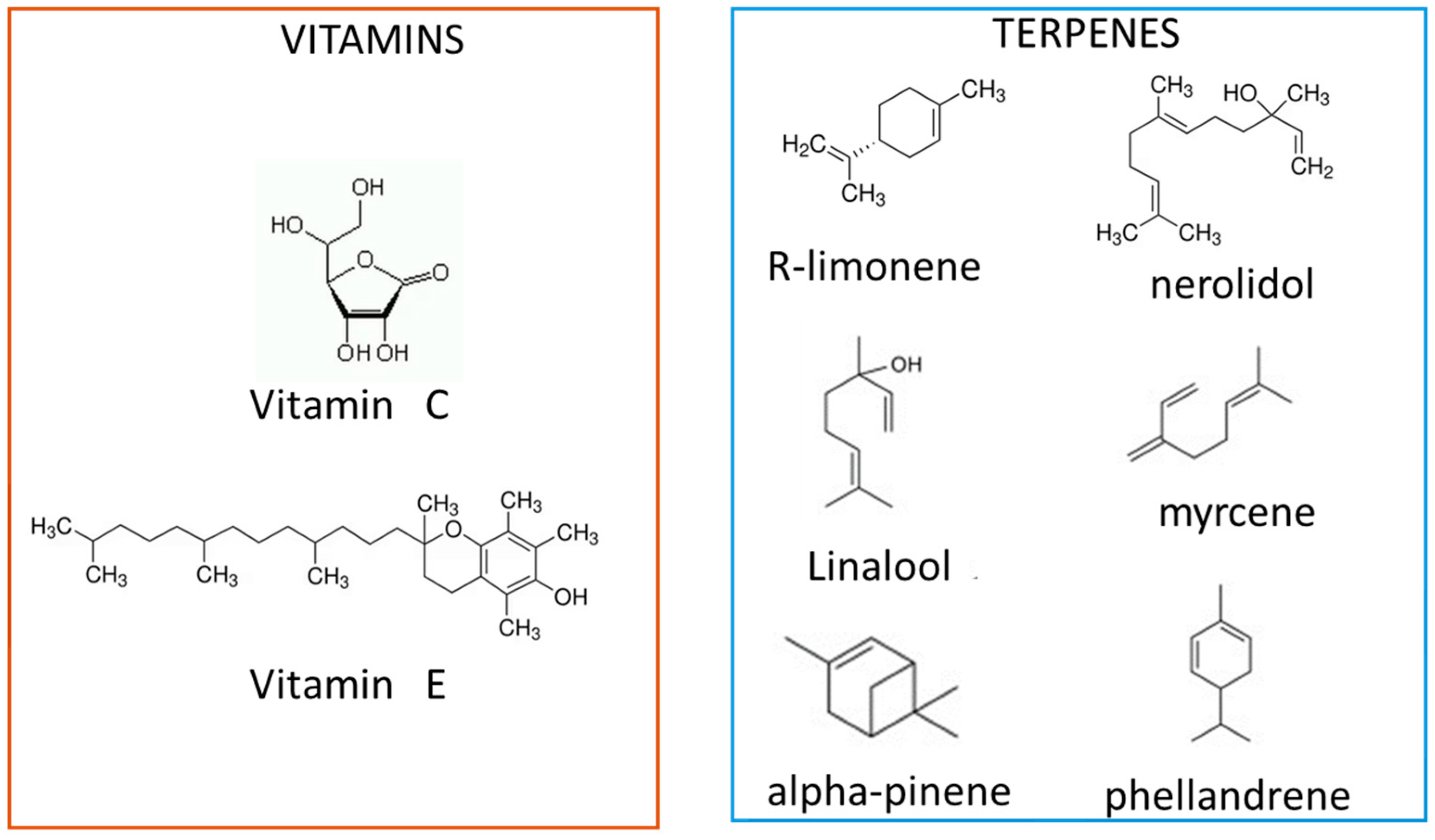

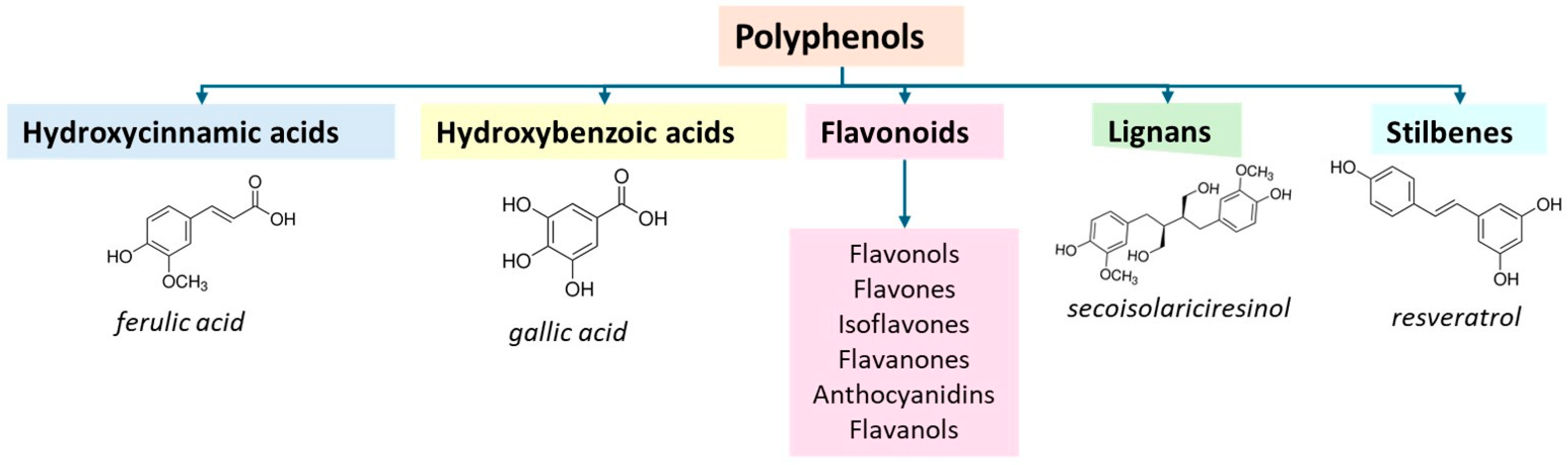

3. Recovery by Extraction of Functional Molecules

3.1. Bioactive Compound Extraction and Purification

3.2. Applications of Extracted Molecules in High-Performance and Added-Value Functional Products

3.2.1. Antioxidant and Anti-Microbial Products

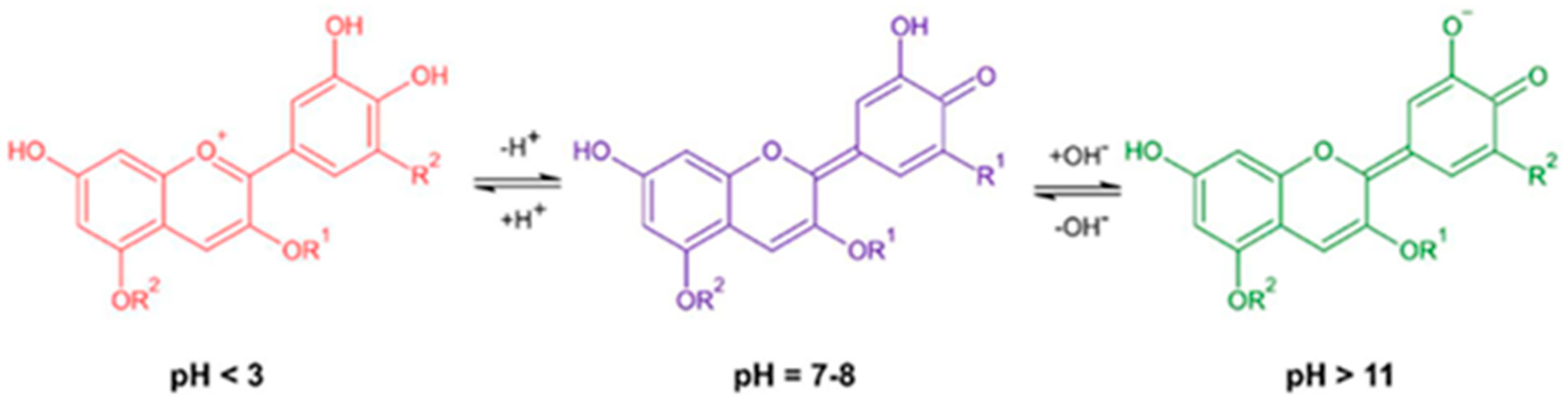

3.2.2. Intelligent Devices

4. Recovery by Production of Composites

4.1. Production of Biocomposites and Their Properties

4.2. Applications in Packaging

4.3. Applications in the Textile Sector

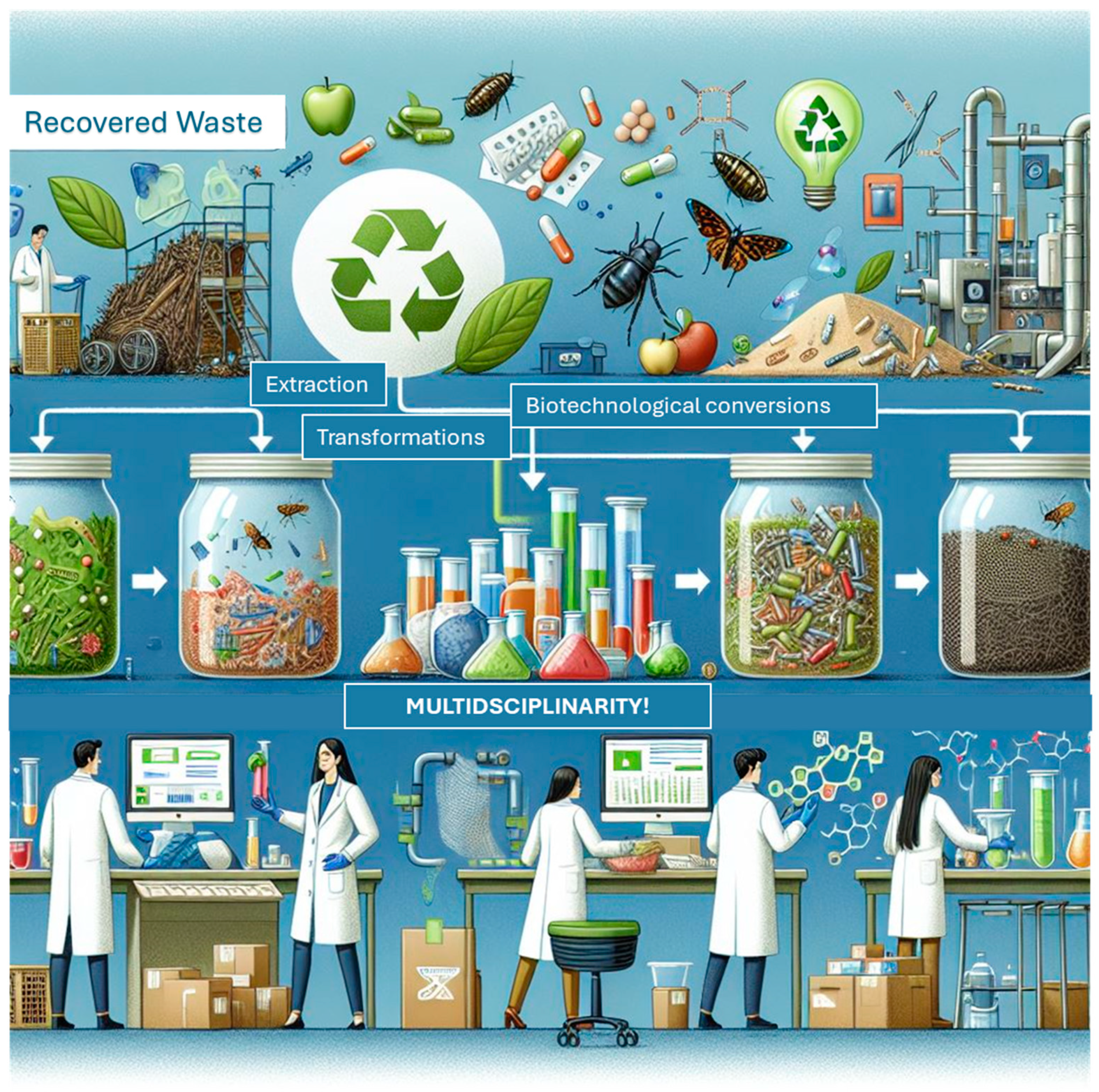

5. Recovery by Bioconversion

5.1. Production of Biopolymers by Microorganisms

5.2. Bioconversion Exploiting Insects

5.3. Mediterranean Food Wastes Valorized Through Their Transformation for Energetic Purposes

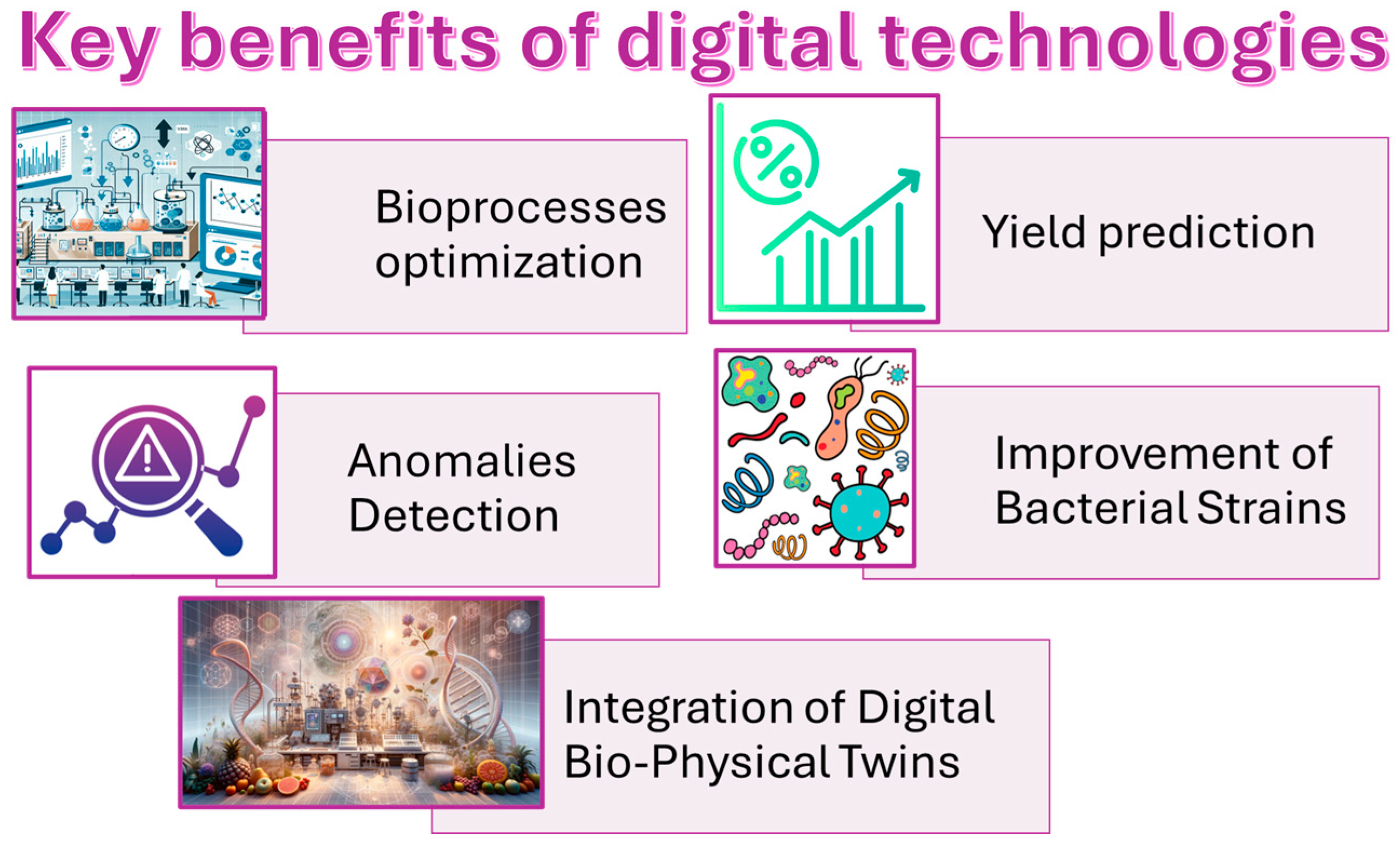

6. Efficiency Gains Through Digitalization

6.1. Artificial Intelligence (AI), Machine Learning, and Internet-of-Things

6.2. Digital Bio-Physical Twins

6.3. Circularity

- Optimization of Bioprocesses: AI, particularly machine learning algorithms, can analyze experimental data and adjust process conditions in real-time, maximizing enzymatic decomposition efficiency and improving yields of valuable compounds.

- Yield Prediction: AI can help predict the quantities of extracted compounds based on the types of agricultural residues, cultivation conditions, and processing parameters, enabling producers to anticipate available raw materials and effectively plan the production of renewable products.

- Early Detection of Anomalies: The use of AI and IoT sensors to monitor processes in real-time allows for the detection of anomalies or inefficiencies in bioprocesses, preventing production losses and enhancing process stability.

- Improvement of Bacterial Strains: Through genetic data analysis and scenario simulations, AI can identify genes of interest to enhance bacterial strains, increasing their effectiveness in releasing bioactive compounds.

- Integration of Digital Bio-Physical Twins: Digital Bio-Physical Twins facilitate the creation of virtual models of biological processes. These models can simulate and predict outcomes based on various inputs, enabling better decision-making and process optimization.

7. Economic Feasibility, Scalability, Regulatory, and Policy Barriers

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fresán, U.; Martínez-Gonzalez, M.-A.; Sabaté, J.; Bes-Rastrollo, M. The Mediterranean Diet, an Environmentally Friendly Option: Evidence from the Seguimiento Universidad de Navarra (SUN) Cohort. Public Health Nutr. 2018, 21, 1573–1582. [Google Scholar] [CrossRef] [PubMed]

- Antonelli, M.; Basile, L.; Gagliardi, F.; Isernia, P. The Future of the Mediterranean Agri-Food Systems: Trends and Perspectives from a Delphi Survey. Land Use Policy 2022, 120, 106263. [Google Scholar] [CrossRef]

- Liu, Y.; Galani Yamdeu, J.H.; Gong, Y.Y.; Orfila, C. A Review of Postharvest Approaches to Reduce Fungal and Mycotoxin Contamination of Foods. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1521–1560. [Google Scholar] [CrossRef]

- Capone, R.; Bennett, A.; Debs, P.; Bucatariu, C.A.; Bilali, H.E.; Smolak, J.; Lee, W.T.K.; Bottalico, F.; Diei-Ouadi, Y.; Toppe, J. Food Losses and waste: Global overview from a Mediterranean perspective. In Mediterra 2016—Zero Waste in the Mediterranean: Natural Resources, Food and Knowledge; International Centre for Advanced Mediterranean Agronomic Studies (CIHEAM): Paris, France; Food and Agriculture Organisation of the United Nations (FAO): Rome, Italy, 2016; Chapter 9; pp. 193–241. [Google Scholar]

- FAO. State Of Food and Agriculture 2019; Food & Agriculture Org: Rome, Italy, 2019; Available online: https://openknowledge.fao.org/server/api/core/bitstreams/11f9288f-dc78-4171-8d02-92235b8d7dc7/content (accessed on 5 March 2025).

- Hoekstra, A.Y.; Chapagain, A.K. Water Footprints of Nations: Water Use by People as a Function of Their Consumption Pattern. In Integrated Assessment of Water Resources and Global Change: A North-South Analysis; Craswell, E., Bonnell, M., Bossio, D., Demuth, S., Van De Giesen, N., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 35–48. ISBN 978-1-4020-5591-1. [Google Scholar]

- Lahiri, A.; Daniel, S.; Kanthapazham, R.; Vanaraj, R.; Thambidurai, A.; Peter, L.S. A Critical Review on Food Waste Management for the Production of Materials and Biofuel. J. Hazard. Mater. Adv. 2023, 10, 100266. [Google Scholar] [CrossRef]

- Tang, R.; Liu, Y.; Ma, R.; Zhang, L.; Li, Y.; Li, G.; Wang, D.; Lin, J.; Li, Q.; Yuan, J. Effect of Moisture Content, Aeration Rate, and C/N on Maturity and Gaseous Emissions during Kitchen Waste Rapid Composting. J. Environ. Manag. 2023, 326, 116662. [Google Scholar] [CrossRef]

- Tonini, D.; Albizzati, P.F.; Astrup, T.F. Environmental Impacts of Food Waste: Learnings and Challenges from a Case Study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef]

- Prateep Na Talang, R.; Na Sorn, W.; Polruang, S.; Sirivithayapakorn, S. Alternative Crop Residue Management Practices to Mitigate the Environmental and Economic Impacts of Open Burning of Agricultural Residues. Sci. Rep. 2024, 14, 14372. [Google Scholar] [CrossRef] [PubMed]

- Economou, F.; Chatziparaskeva, G.; Papamichael, I.; Loizia, P.; Voukkali, I.; Navarro-Pedreño, J.; Klontza, E.; Lekkas, D.F.; Naddeo, V.; Zorpas, A.A. The Concept of Food Waste and Food Loss Prevention and Measuring Tools. Waste Manag. Res. J. Sustain. Circ. Econ. 2024, 42, 651–669. [Google Scholar] [CrossRef] [PubMed]

- Miglietta, P.P.; Coluccia, B.; Pacifico, M.A.; Malorgio, G. Tracking on Food and Agriculture-Related SDG Indicators in the Mediterranean Region. New Medit. 2023, 2023, 57–71. [Google Scholar] [CrossRef]

- Schimmenti, E.; Borsellino, V.; Galati, A. Growth of Citrus Production among the Euro-Mediterranean Countries: Political Implications and Empirical Findings. Span. J. Agric. Res. 2013, 11, 561–577. [Google Scholar] [CrossRef]

- Arbonès, G.; De Stefano, L.; Garrido, A. Agricultural Land Use Change and Intensification in Spain: Drivers and Trends (2004–2023). 2024. Available online: https://ssrn.com/abstract=4963512 (accessed on 5 March 2025).

- Consoli, S.; Caggia, C.; Russo, N.; Randazzo, C.L.; Continella, A.; Modica, G.; Cacciola, S.O.; Faino, L.; Reverberi, M.; Baglieri, A.; et al. Sustainable Use of Citrus Waste as Organic Amendment in Orange Orchards. Sustainability 2023, 15, 2482. [Google Scholar] [CrossRef]

- Wedamulla, N.E.; Fan, M.; Choi, Y.-J.; Kim, E.-K. Citrus Peel as a Renewable Bioresource: Transforming Waste to Food Additives. J. Funct. Foods 2022, 95, 105163. [Google Scholar] [CrossRef]

- Gol, N.B.; Patel, P.R.; Rao, T.V.R. Improvement of Quality and Shelf-Life of Strawberries with Edible Coatings Enriched with Chitosan. Postharvest Biol. Technol. 2013, 85, 185–195. [Google Scholar] [CrossRef]

- Vu, K.D.; Hollingsworth, R.G.; Leroux, E.; Salmieri, S.; Lacroix, M. Development of Edible Bioactive Coating Based on Modified Chitosan for Increasing the Shelf Life of Strawberries. Food Res. Int. 2011, 44, 198–203. [Google Scholar] [CrossRef]

- Kelly, K.; Madden, R.; Emond, J.P.; do Nascimento Nunes, M.C. A Novel Approach to Determine the Impact Level of Each Step along the Supply Chain on Strawberry Quality. Postharvest Biol. Technol. 2019, 147, 78–88. [Google Scholar] [CrossRef]

- Petrasch, S.; Knapp, S.J.; van Kan, J.A.L.; Blanco-Ulate, B. Grey Mould of Strawberry, a Devastating Disease Caused by the Ubiquitous Necrotrophic Fungal Pathogen Botrytis Cinerea. Mol. Plant Pathol. 2019, 20, 877–892. [Google Scholar] [CrossRef]

- Alsawmahi, O.N.; Al-Juhaimi, F.Y.; Alhamdan, A.M.; Ghafoor, K.; Mohamed Ahmed, I.A.; Hassan, B.H.; Ehmed, K.A.; Abdelkarim, D.; Younis, M.; Alashmawe, N.; et al. Enzyme Activity, Sugar Composition, Microbial Growth and Texture of Fresh Barhi Dates as Affected by Modified Atmosphere Packaging. J. Food Sci. Technol. 2018, 55, 4492–4504. [Google Scholar] [CrossRef]

- González-Curbelo, M.Á.; Kabak, B. Occurrence of Mycotoxins in Dried Fruits Worldwide, with a Focus on Aflatoxins and Ochratoxin A: A Review. Toxins 2023, 15, 576. [Google Scholar] [CrossRef]

- Manterola-Barroso, C.; Padilla Contreras, D.; Ondrasek, G.; Horvatinec, J.; Gavilán CuiCui, G.; Meriño-Gergichevich, C. Hazelnut and Walnut Nutshell Features as Emerging Added-Value Byproducts of the Nut Industry: A Review. Plants 2024, 13, 1034. [Google Scholar] [CrossRef]

- Solís, A.; Rocha, S.; König, M.; Adam, R.; Garcés, H.O.; Candia, O.; Muñoz, R.; Azócar, L. Preliminary Assessment of Hazelnut Shell Biomass as a Raw Material for Pellet Production. Fuel 2023, 333, 126517. [Google Scholar] [CrossRef]

- Barral-Martinez, M.; Fraga-Corral, M.; Garcia-Perez, P.; Simal-Gandara, J.; Prieto, M.A. Almond By-Products: Valorization for Sustainability and Competitiveness of the Industry. Foods 2021, 10, 1793. [Google Scholar] [CrossRef] [PubMed]

- Prgomet, I.; Gonçalves, B.; Domínguez-Perles, R.; Pascual-Seva, N.; Barros, A. Valorization Challenges to Almond Residues: Phytochemical Composition and Functional Application. Molecules 2017, 22, 1774. [Google Scholar] [CrossRef]

- Fordos, S.; Abid, N.; Gulzar, M.; Pasha, I.; Oz, F.; Shahid, A.; Khan, M.K.I.; Mousavi Khaneghah, A.; Aadil, R.M. Recent Development in the Application of Walnut Processing By-Products (Walnut Shell and Walnut Husk). Biomass Convers. Biorefin. 2023, 13, 14389–14411. [Google Scholar] [CrossRef]

- Li, J.; Cao, L.; Li, B.; Huang, H.; Yu, W.; Sun, C.; Long, K.; Young, B. Utilization of Activated Sludge and Shell Wastes for the Preparation of Ca-Loaded Biochar for Phosphate Removal and Recovery. J. Clean. Prod. 2023, 382, 135395. [Google Scholar] [CrossRef]

- Zhuang, Z.; Liu, Y.; Wei, W.; Shi, J.; Jin, H. Preparation of Biochar Adsorption Material from Walnut Shell by Supercritical CO2 Pretreatment. Biochar 2024, 6, 11. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, C.; Yang, J.; Yan, B.; Liu, J.; Wang, S.; Li, Q.; Zhou, M. Preparation and Characterization of Apricot Kernel Shell Biochar and Its Adsorption Mechanism for Atrazine. Sustainability 2022, 14, 4082. [Google Scholar] [CrossRef]

- Nursiah, C.; Desvita, H.; Elviani, E.; Farida, N.; Muslim, A.; Rosnelly, C.; Mariana, M.; Suhendrayatna, S. Adsorbent Characterization from Cocoa Shell Pyrolysis (Theobroma cacao L.) and Its Application in Mercury Ion Reduction. J. Ecol. Eng. 2023, 24, 366–375. [Google Scholar] [CrossRef]

- Zeghlouli, J.; Schiavone, N.; Askanian, H.; Guendouz, A.; El Modafar, C.; Michaud, P.; Delattre, C. Thermal, Morphological and Mechanical Properties of a BioPE Matrix Composite: Case of Shell, Pulp, and Argan Cake as Biofillers. Materials 2023, 16, 2241. [Google Scholar] [CrossRef]

- Zeghlouli, J.; Christophe, G.; Ogura, K.; Sawamura, N.; Guendouz, A.; Modafar, C.E.; Michaud, P.; Delattre, C. High-Pressure Water Jet System Treatment of Argan Nut Shell and Enzymatic Hydrolysis for Bioethanol Production. Fermentation 2022, 8, 627. [Google Scholar] [CrossRef]

- Zeghlouli, J.; Christophe, G.; Guendouz, A.; El Modafar, C.; Belkamel, A.; Michaud, P.; Delattre, C. Optimization of Bioethanol Production from Enzymatic Treatment of Argan Pulp Feedstock. Molecules 2021, 26, 2516. [Google Scholar] [CrossRef]

- Zeghlouli, J.; Guendouz, A.; Duchez, D.; El Modafar, C.; Michaud, P.; Delattre, C. Valorization of Co-Products Generated by Argan Oil Extraction Process: Application to Biodiesel Production. Biofuels 2022, 13, 771–777. [Google Scholar] [CrossRef]

- Dardick, C.; Callahan, A.M. Evolution of the Fruit Endocarp: Molecular Mechanisms Underlying Adaptations in Seed Protection and Dispersal Strategies. Front. Plant Sci. 2014, 5, 284. [Google Scholar] [CrossRef]

- Ruggiero, A.; Valášek, P.; Müller, M. Exploitation of Waste Date Seeds of Phoenix Dactylifera in Form of Polymeric Particle Biocomposite: Investigation on Adhesion, Cohesion and Wear. Compos. B Eng. 2016, 104, 9–16. [Google Scholar] [CrossRef]

- Djaoudene, O.; Mansinhos, I.; Gonçalves, S.; Jara-Palacios, M.J.; Bachir bey, M.; Romano, A. Phenolic Profile, Antioxidant Activity and Enzyme Inhibitory Capacities of Fruit and Seed Extracts from Different Algerian Cultivars of Date (Phoenix dactylifera L.) Were Affected by in Vitro Simulated Gastrointestinal Digestion. South. Afr. J. Bot. 2021, 137, 133–148. [Google Scholar] [CrossRef]

- Gouw, V.P.; Jung, J.; Simonsen, J.; Zhao, Y. Fruit Pomace as a Source of Alternative Fibers and Cellulose Nanofiber as Reinforcement Agent to Create Molded Pulp Packaging Boards. Compos. Part A Appl. Sci. Manuf. 2017, 99, 48–57. [Google Scholar] [CrossRef]

- Wang, L.; Lee, W.W.; Yang, H.-W.; Ryu, B.M.; Cui, Y.R.; Lee, S.-C.; Lee, T.-G.; Jeon, Y.-J. Protective Effect of Water Extract of Citrus Pomace against AAPH-Induced Oxidative Stress In Vitro in Vero Cells and In Vivo in Zebrafish. Prev. Nutr. Food Sci. 2018, 23, 301–308. [Google Scholar] [CrossRef]

- Iqbal, A.; Schulz, P.; Rizvi, S.S.H. Valorization of Bioactive Compounds in Fruit Pomace from Agro-Fruit Industries: Present Insights and Future Challenges. Food Biosci. 2021, 44, 101384. [Google Scholar] [CrossRef]

- Kumar Gupta, R.; AE Ali, E.; Abd El Gawad, F.; Mecheal Daood, V.; Sabry, H.; Karunanithi, S.; Prakash Srivastav, P. Valorization of Fruits and Vegetables Waste Byproducts for Development of Sustainable Food Packaging Applications. Waste Manag. Bull. 2024, 2, 21–40. [Google Scholar] [CrossRef]

- Shalini, R.; Gupta, D.K. Utilization of Pomace from Apple Processing Industries: A Review. J. Food Sci. Technol. 2010, 47, 365–371. [Google Scholar] [CrossRef]

- Antónia Nunes, M.; Costa, A.S.G.; Bessada, S.; Santos, J.; Puga, H.; Alves, R.C.; Freitas, V.; Oliveira, M.B.P.P. Olive Pomace as a Valuable Source of Bioactive Compounds: A Study Regarding Its Lipid- and Water-Soluble Components. Sci. Total Environ. 2018, 644, 229–236. [Google Scholar] [CrossRef]

- Difonzo, G.; Troilo, M.; Squeo, G.; Pasqualone, A.; Caponio, F. Functional Compounds from Olive Pomace to Obtain High-added Value Foods—A Review. J. Sci. Food Agric. 2021, 101, 15–26. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, S. Potential of Grape Byproducts as Functional Ingredients in Baked Goods and Pasta. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2473–2505. [Google Scholar] [CrossRef] [PubMed]

- Iuga, M.; Mironeasa, S. Use of Grape Peels By-Product for Wheat Pasta Manufacturing. Plants 2021, 10, 926. [Google Scholar] [CrossRef] [PubMed]

- Peralbo-Molina, Á.; Luque de Castro, M.D. Potential of Residues from the Mediterranean Agriculture and Agrifood Industry. Trends Food Sci. Technol. 2013, 32, 16–24. [Google Scholar] [CrossRef]

- Sharma, K.; Mahato, N.; Cho, M.H.; Lee, Y.R. Converting Citrus Wastes into Value-Added Products: Economic and Environmently Friendly Approaches. Nutrition 2017, 34, 29–46. [Google Scholar] [CrossRef]

- Mahato, N.; Sinha, M.; Sharma, K.; Koteswararao, R.; Cho, M.H. Modern Extraction and Purification Techniques for Obtaining High Purity Food-Grade Bioactive Compounds and Value-Added Co-Products from Citrus Wastes. Foods 2019, 8, 523. [Google Scholar] [CrossRef]

- Agourram, A.; Ghirardello, D.; Rantsiou, K.; Zeppa, G.; Belviso, S.; Romane, A.; Oufdou, K.; Giordano, M. Phenolic Content, Antioxidant Potential, and Antimicrobial Activities of Fruit and Vegetable By-Product Extracts. Int. J. Food Prop. 2013, 16, 1092–1104. [Google Scholar] [CrossRef]

- Harholt, J.; Suttangkakul, A.; Vibe Scheller, H. Biosynthesis of Pectin. Plant Physiol. 2010, 153, 384–395. [Google Scholar] [CrossRef]

- Scurria, A.; Albanese, L.; Pagliaro, M.; Zabini, F.; Giordano, F.; Meneguzzo, F.; Ciriminna, R. CytroCell: Valued Cellulose from Citrus Processing Waste. Molecules 2021, 26, 596. [Google Scholar] [CrossRef]

- Santana-Méridas, O.; González-Coloma, A.; Sánchez-Vioque, R. Agricultural Residues as a Source of Bioactive Natural Products. Phytochem. Rev. 2012, 11, 447–466. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. Au 2021. [Google Scholar] [CrossRef]

- García Martín, J.F.; Cuevas, M.; Feng, C.-H.; Álvarez Mateos, P.; Torres García, M.; Sánchez, S. Energetic Valorisation of Olive Biomass: Olive-Tree Pruning, Olive Stones and Pomaces. Processes 2020, 8, 511. [Google Scholar] [CrossRef]

- Stefanidis, S.D.; Kalogiannis, K.G.; Iliopoulou, E.F.; Michailof, C.M.; Pilavachi, P.A.; Lappas, A.A. A Study of Lignocellulosic Biomass Pyrolysis via the Pyrolysis of Cellulose, Hemicellulose and Lignin. J. Anal. Appl. Pyrolysis 2014, 105, 143–150. [Google Scholar] [CrossRef]

- Kabir, F.; Tow, W.W.; Hamauzu, Y.; Katayama, S.; Tanaka, S.; Nakamura, S. Antioxidant and Cytoprotective Activities of Extracts Prepared from Fruit and Vegetable Wastes and By-Products. Food Chem. 2015, 167, 358–362. [Google Scholar] [CrossRef]

- Muthukumaran, S.; Tranchant, C.; Shi, J.; Ye, X.; Xue, S.J. Ellagic Acid in Strawberry (Fragaria spp.): Biological, Technological, Stability, and Human Health Aspects. Food Qual. Saf. 2017, 1, 227–252. [Google Scholar] [CrossRef]

- Riseh, R.S.; Vazvani, M.G.; Hassanisaadi, M.; Thakur, V.K. Agricultural Wastes: A Practical and Potential Source for the Isolation and Preparation of Cellulose and Application in Agriculture and Different Industries. Ind. Crops Prod. 2024, 208, 117904. [Google Scholar] [CrossRef]

- Nayak, A.; Bhushan, B. An Overview of the Recent Trends on the Waste Valorization Techniques for Food Wastes. J. Environ. Manag. 2019, 233, 352–370. [Google Scholar] [CrossRef]

- Faustino, M.; Veiga, M.; Sousa, P.; Costa, E.M.; Silva, S.; Pintado, M. Agro-Food Byproducts as a New Source of Natural Food Additives. Molecules 2019, 24, 1056. [Google Scholar] [CrossRef]

- Selim, S.; Albqmi, M.; Al-Sanea, M.M.; Alnusaire, T.S.; Almuhayawi, M.S.; AbdElgawad, H.; Al Jaouni, S.K.; Elkelish, A.; Hussein, S.; Warrad, M.; et al. Valorizing the Usage of Olive Leaves, Bioactive Compounds, Biological Activities, and Food Applications: A Comprehensive Review. Front. Nutr. 2022, 9, 1008349. [Google Scholar] [CrossRef]

- Jiang, Y.; Lan, W.; Sameen, D.E.; Ahmed, S.; Qin, W.; Zhang, Q.; Chen, H.; Dai, J.; He, L.; Liu, Y. Preparation and Characterization of Grass Carp Collagen-Chitosan-Lemon Essential Oil Composite Films for Application as Food Packaging. Int. J. Biol. Macromol. 2020, 160, 340–351. [Google Scholar] [CrossRef]

- Durmus, M. The Effects of Nanoemulsions Based on Citrus Essential Oils (Orange, Mandarin, Grapefruit, and Lemon) on the Shelf Life of Rainbow Trout (Oncorhynchus mykiss) Fillets at 4 ± 2 °C. J. Food Saf. 2020, 40, e12718. [Google Scholar] [CrossRef]

- Ali, A.; Riaz, S.; Sameen, A.; Naumovski, N.; Iqbal, M.W.; Rehman, A.; Mehany, T.; Zeng, X.-A.; Manzoor, M.F. The Disposition of Bioactive Compounds from Fruit Waste, Their Extraction, and Analysis Using Novel Technologies: A Review. Processes 2022, 10, 2014. [Google Scholar] [CrossRef]

- Dubey, P.; Tripathi, G.; Mir, S.S.; Yousuf, O. Current Scenario and Global Perspectives of Citrus Fruit Waste as a Valuable Resource for the Development of Food Packaging Film. Trends Food Sci. Technol. 2023, 141, 104190. [Google Scholar] [CrossRef]

- Oladzad, S.; Fallah, N.; Mahboubi, A.; Afsham, N.; Taherzadeh, M.J. Date Fruit Processing Waste and Approaches to Its Valorization: A Review. Bioresour. Technol. 2021, 340, 125625. [Google Scholar] [CrossRef]

- De Carnaval, L.S.C.; Jaiswal, A.K.; Jaiswal, S. Agro-Food Waste Valorization for Sustainable Bio-Based Packaging. J. Compos. Sci. 2024, 8, 41. [Google Scholar] [CrossRef]

- Gigante, V.; Panariello, L.; Coltelli, M.-B.; Danti, S.; Obisesan, K.A.; Hadrich, A.; Staebler, A.; Chierici, S.; Canesi, I.; Lazzeri, A.; et al. Liquid and Solid Functional Bio-Based Coatings. Polymers 2021, 13, 3640. [Google Scholar] [CrossRef]

- Apicella, A.; Scarfato, P.; Di Maio, L.; Incarnato, L. Sustainable Active PET Films by Functionalization With Antimicrobial Bio-Coatings. Front. Mater. 2019, 6, 243. [Google Scholar] [CrossRef]

- Li, J.; Sun, H.; Weng, Y. Natural Extracts and Their Applications in Polymer-Based Active Packaging: A Review. Polymers 2024, 16, 625. [Google Scholar] [CrossRef]

- Gomes-Araújo, R.; Martínez-Vázquez, D.G.; Charles-Rodríguez, A.V.; Rangel-Ortega, S.; Robledo-Olivo, A. Bioactive Compounds from Agricultural Residues, Their Obtaining Techniques, and the Antimicrobial Effect as Postharvest Additives. Int. J. Food Sci. 2021, 2021, 9936722. [Google Scholar] [CrossRef]

- Belwal, T.; Cravotto, C.; Prieto, M.A.; Venskutonis, P.R.; Daglia, M.; Devkota, H.P.; Baldi, A.; Ezzat, S.M.; Gómez-Gómez, L.; Salama, M.M.; et al. Effects of Different Drying Techniques on the Quality and Bioactive Compounds of Plant-Based Products: A Critical Review on Current Trends. Dry. Technol. 2022, 40, 1539–1561. [Google Scholar] [CrossRef]

- Gallina, L.; Cravotto, C.; Capaldi, G.; Grillo, G.; Cravotto, G. Plant Extraction in Water: Towards Highly Efficient Industrial Applications. Processes 2022, 10, 2233. [Google Scholar] [CrossRef]

- Sheibani, S.; Jafarzadeh, S.; Qazanfarzadeh, Z.; Osadee Wijekoon, M.M.J.; Mohd Rozalli, N.H.; Mohammadi Nafchi, A. Sustainable Strategies for Using Natural Extracts in Smart Food Packaging. Int. J. Biol. Macromol. 2024, 267, 131537. [Google Scholar] [CrossRef] [PubMed]

- Putnik, P.; Bursać Kovačević, D.; Režek Jambrak, A.; Barba, F.; Cravotto, G.; Binello, A.; Lorenzo, J.; Shpigelman, A. Innovative “Green” and Novel Strategies for the Extraction of Bioactive Added Value Compounds from Citrus Wastes—A Review. Molecules 2017, 22, 680. [Google Scholar] [CrossRef]

- Manjare, S.D.; Dhingra, K. Supercritical Fluids in Separation and Purification: A Review. Mater. Sci. Energy Technol. 2019, 2, 463–484. [Google Scholar] [CrossRef]

- Belwal, T.; Devkota, H.P.; Ramola, S.; Andola, H.C.; Bhatt, I.D. Optimization of Extraction Methodologies and Purification Technologies to Recover Phytonutrients from Food. In Phytonutrients in Food; Elsevier: Amsterdam, The Netherlands, 2020; pp. 217–235. [Google Scholar]

- Chadni, M.; Moussa, M.; Athès, V.; Allais, F.; Ioannou, I. Membrane Contactors-Assisted Liquid-Liquid Extraction of Biomolecules from Biorefinery Liquid Streams: A Case Study on Organic Acids. Sep. Purif. Technol. 2023, 317, 123927. [Google Scholar] [CrossRef]

- Arruda, T.R.; Bernardes, P.C.; e Moraes, A.R.F.; de Soares, N.D.F.F. Natural Bioactives in Perspective: The Future of Active Packaging Based on Essential Oils and Plant Extracts Themselves and Those Complexed by Cyclodextrins. Food Res. Int. 2022, 156, 111160. [Google Scholar] [CrossRef]

- Zabot, G.L.; Schaefer Rodrigues, F.; Polano Ody, L.; Vinícius Tres, M.; Herrera, E.; Palacin, H.; Córdova-Ramos, J.S.; Best, I.; Olivera-Montenegro, L. Encapsulation of Bioactive Compounds for Food and Agricultural Applications. Polymers 2022, 14, 4194. [Google Scholar] [CrossRef]

- Abeyrathne, E.D.N.S.; Nam, K.; Huang, X.; Ahn, D.U. Plant- and Animal-Based Antioxidants’ Structure, Efficacy, Mechanisms, and Applications: A Review. Antioxidants 2022, 11, 1025. [Google Scholar] [CrossRef] [PubMed]

- Iqbal, M.; Kim, K.-H.; Ahn, J. Monoterpenes Released from Fruit, Plant, and Vegetable Systems. Sensors 2014, 14, 18286–18301. [Google Scholar] [CrossRef]

- Aharoni, A.; Giri, A.P.; Verstappen, F.W.A.; Bertea, C.M.; Sevenier, R.; Sun, Z.; Jongsma, M.A.; Schwab, W.; Bouwmeester, H.J. Gain and Loss of Fruit Flavor Compounds Produced by Wild and Cultivated Strawberry Species. Plant Cell 2004, 16, 3110–3131. [Google Scholar] [CrossRef]

- Hardman, W.E. Diet Components Can Suppress Inflammation and Reduce Cancer Risk. Nutr. Res. Pract. 2014, 8, 233. [Google Scholar] [CrossRef] [PubMed]

- Martins, V.G.; Santos, L.G.; Romani, V.P.; Fernandes, S.S. Bio-Based Sensing: Role of Natural Dyes in Food Freshness Indicators. In Bio- And Nano-Sensing Technologies for Food Processing and Packaging; The Royal Society of Chemistry: London, UK, 2022; pp. 37–62. [Google Scholar]

- Echegaray, N.; Guzel, N.; Kumar, M.; Guzel, M.; Hassoun, A.; Lorenzo, J.M. Recent Advancements in Natural Colorants and Their Application as Coloring in Food and in Intelligent Food Packaging. Food Chem. 2023, 404, 134453. [Google Scholar] [CrossRef]

- Álvarez-Martínez, F.J.; Barrajón-Catalán, E.; Herranz-López, M.; Micol, V. Antibacterial Plant Compounds, Extracts and Essential Oils: An Updated Review on Their Effects and Putative Mechanisms of Action. Phytomedicine 2021, 90, 153626. [Google Scholar] [CrossRef] [PubMed]

- Ordoñez, R.; Atarés, L.; Chiralt, A. Biodegradable Active Materials Containing Phenolic Acids for Food Packaging Applications. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3910–3930. [Google Scholar] [CrossRef]

- Reano, A.F.; Domenek, S.; Pernes, M.; Beaugrand, J.; Allais, F. Ferulic Acid-Based Bis/Trisphenols as Renewable Antioxidants for Polypropylene and Poly(Butylene Succinate). ACS Sustain. Chem. Eng. 2016, 4, 6562–6571. [Google Scholar] [CrossRef]

- Aragón-Gutiérrez, A.; Rosa, E.; Gallur, M.; López, D.; Hernández-Muñoz, P.; Gavara, R. Melt-Processed Bioactive EVOH Films Incorporated with Ferulic Acid. Polymers 2020, 13, 68. [Google Scholar] [CrossRef] [PubMed]

- Ordoñez, R.; Atarés, L.; Chiralt, A. Antibacterial Properties of Cinnamic and Ferulic Acids Incorporated to Starch and PLA Monolayer and Multilayer Films. Food Control. 2022, 136, 108878. [Google Scholar] [CrossRef]

- Sharma, S.; Jaiswal, A.K.; Duffy, B.; Jaiswal, S. Ferulic Acid Incorporated Active Films Based on Poly(Lactide)/Poly(Butylene Adipate-Co-Terephthalate) Blend for Food Packaging. Food Packag. Shelf Life 2020, 24, 100491. [Google Scholar] [CrossRef]

- Kahya, N.; Kestir, S.M.; Öztürk, S.; Yolaç, A.; Torlak, E.; Kalaycıoğlu, Z.; Akın-Evingür, G.; Erim, F.B. Antioxidant and Antimicrobial Chitosan Films Enriched with Aqueous Sage and Rosemary Extracts as Food Coating Materials: Characterization of the Films and Detection of Rosmarinic Acid Release. Int. J. Biol. Macromol. 2022, 217, 470–480. [Google Scholar] [CrossRef]

- Kowalska, A.; Kalinowska-Lis, U. 18β-Glycyrrhetinic Acid: Its Core Biological Properties and Dermatological Applications. Int. J. Cosmet. Sci. 2019, 41, 325–331. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Morganti, P.; Castelvetro, V.; Lazzeri, A.; Danti, S.; Benjelloun-Mlayah, B.; Gagliardini, A.; Fusco, A.; Donnarumma, G. Chitin Nanofibril-Nanolignin Complexes as Carriers of Functional Molecules for Skin Contact Applications. Nanomaterials 2022, 12, 1295. [Google Scholar] [CrossRef]

- Miletić, A.; Ristić, I.; Coltelli, M.-B.; Pilić, B. Modification of PLA-Based Films by Grafting or Coating. J. Funct. Biomater. 2020, 11, 30. [Google Scholar] [CrossRef]

- Cicogna, F.; Passaglia, E.; Telleschi, A.; Oberhauser, W.; Coltelli, M.-B.; Panariello, L.; Gigante, V.; Coiai, S. New Functional Bionanocomposites by Combining Hybrid Host-Guest Systems with a Fully Biobased Poly(Lactic Acid)/Poly(Butylene Succinate-Co-Adipate) (PLA/PBSA) Binary Blend. J. Funct. Biomater. 2023, 14, 549. [Google Scholar] [CrossRef]

- Coiai, S.; Campanella, B.; Paulert, R.; Cicogna, F.; Bramanti, E.; Lazzeri, A.; Pistelli, L.; Coltelli, M.-B. Rosmarinic Acid and Ulvan from Terrestrial and Marine Sources in Anti-Microbial Bionanosystems and Biomaterials. Appl. Sci. 2021, 11, 9249. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.-B.; Buchignani, M.; Lazzeri, A. Chitosan and Nano-Structured Chitin for Biobased Anti-Microbial Treatments onto Cellulose Based Materials. Eur. Polym. J. 2019, 113, 328–339. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.-B.; Giangrandi, S.; Garrigós, M.C.; Hadrich, A.; Lazzeri, A.; Cinelli, P. Influence of Functional Bio-Based Coatings Including Chitin Nanofibrils or Polyphenols on Mechanical Properties of Paper Tissues. Polymers 2022, 14, 2274. [Google Scholar] [CrossRef]

- Anushikha; Gaikwad, K.K. Lignin as a UV Blocking, Antioxidant, and Antimicrobial Agent for Food Packaging Applications. Biomass Convers. Biorefin. 2024, 14, 16755–16767. [Google Scholar] [CrossRef]

- Chi, W.; Cao, L.; Sun, G.; Meng, F.; Zhang, C.; Li, J.; Wang, L. Developing a Highly PH-Sensitive ĸ-Carrageenan-Based Intelligent Film Incorporating Grape Skin Powder via a Cleaner Process. J. Clean. Prod. 2020, 244, 118862. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Shi, Q.; Zhang, Y.; Liu, J.; Wu, X.; Fang, Z. Development and Characterization of Active and PH-Sensitive Films Based on Psyllium Seed Gum Incorporated with Free and Microencapsulated Mulberry Pomace Extracts. Food Chem. 2021, 352, 129333. [Google Scholar] [CrossRef]

- Andretta, R.; Luchese, C.L.; Tessaro, I.C.; Spada, J.C. Development and Characterization of PH-Indicator Films Based on Cassava Starch and Blueberry Residue by Thermocompression. Food Hydrocoll. 2019, 93, 317–324. [Google Scholar] [CrossRef]

- Kossyvaki, D.; Contardi, M.; Athanassiou, A.; Fragouli, D. Colorimetric Indicators Based on Anthocyanin Polymer Composites: A Review. Polymers 2022, 14, 4129. [Google Scholar] [CrossRef]

- Mattioli, R.; Francioso, A.; Mosca, L.; Silva, P. Anthocyanins: A Comprehensive Review of Their Chemical Properties and Health Effects on Cardiovascular and Neurodegenerative Diseases. Molecules 2020, 25, 3809. [Google Scholar] [CrossRef] [PubMed]

- Patras, A.; Brunton, N.P.; O’Donnell, C.; Tiwari, B.K. Effect of Thermal Processing on Anthocyanin Stability in Foods; Mechanisms and Kinetics of Degradation. Trends Food Sci. Technol. 2010, 21, 3–11. [Google Scholar] [CrossRef]

- Choi, I.; Lee, J.Y.; Lacroix, M.; Han, J. Intelligent PH Indicator Film Composed of Agar/Potato Starch and Anthocyanin Extracts from Purple Sweet Potato. Food Chem. 2017, 218, 122–128. [Google Scholar] [CrossRef]

- Micó-Vicent, B.; Ramos, M.; Viqueira, V.; Luzi, F.; Dominici, F.; Terenzi, A.; Maron, E.; Hamzaoui, M.; Kohnen, S.; Torre, L.; et al. Anthocyanin Hybrid Nanopigments from Pomegranate Waste: Colour, Thermomechanical Stability and Environmental Impact of Polyester-Based Bionanocomposites. Polymers 2021, 13, 1966. [Google Scholar] [CrossRef] [PubMed]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of Walnut Shells and Silanized Walnut Shells on the Mechanical and Thermal Properties of Rigid Polyurethane Foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Sathiparan, N.; Anburuvel, A.; Selvam, V.V. Utilization of Agro-Waste Groundnut Shell and Its Derivatives in Sustainable Construction and Building Materials—A Review. J. Build. Eng. 2023, 66, 105866. [Google Scholar] [CrossRef]

- Dal Pont, B.; Gigante, V.; Panariello, L.; Canesi, I.; Aliotta, L.; Lazzeri, A. Investigation of Novel Flax Fiber/Epoxy Composites with Increased Biobased Content. Polymers 2023, 15, 4030. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-Mechanical Properties of PLA/Short Flax Fiber Biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Aliotta, L.; Vannozzi, A.; Cinelli, P.; Fiori, S.; Coltelli, M.-B.; Lazzeri, A. Wheat Bran Addition as Potential Alternative to Control the Plasticizer Migration into PLA/PBSA Blends. J. Mater. Sci. 2022, 57, 14511–14527. [Google Scholar] [CrossRef]

- Ortega, F.; Versino, F.; López, O.V.; García, M.A. Biobased Composites from Agro-Industrial Wastes and by-Products. Emergent Mater. 2022, 5, 873–921. [Google Scholar] [CrossRef] [PubMed]

- Baiamonte, M.; Rapisarda, M.; Mistretta, M.C.; Impallomeni, G.; La Mantia, F.P.; Rizzarelli, P. Wood Flour and Hazelnut Shells Polylactide-Based Biocomposites for Packaging Applications: Characterization, Photo-Oxidation, and Compost Burial Degradation. Polym. Compos. 2024, 45, 9802–9818. [Google Scholar] [CrossRef]

- Aliotta, L.; Vannozzi, A.; Bonacchi, D.; Coltelli, M.-B.; Lazzeri, A. Analysis, Development, and Scaling-Up of Poly(Lactic Acid) (PLA) Biocomposites with Hazelnuts Shell Powder (HSP). Polymers 2021, 13, 4080. [Google Scholar] [CrossRef] [PubMed]

- Aliotta, L.; Sergi, C.; Pont, B.D.; Coltelli, M.-B.; Gigante, V.; Lazzeri, A. Sustainable 3D Printed Poly (Lactic Acid) (PLA)/Hazelnut Shell Powder Bio Composites for Design Applications. Mater. Today Sustain. 2024, 26, 100780. [Google Scholar] [CrossRef]

- Pączkowski, P. Properties of Eco-Friendly Composites Based on Post-Consumer Recycled Resin Filled with Walnut Shell Powder. Polymers 2023, 15, 4389. [Google Scholar] [CrossRef]

- Ramos, M.; Dominici, F.; Luzi, F.; Jiménez, A.; Garrigós, M.C.; Torre, L.; Puglia, D. Effect of Almond Shell Waste on Physicochemical Properties of Polyester-Based Biocomposites. Polymers 2020, 12, 835. [Google Scholar] [CrossRef] [PubMed]

- Gorar, A.A.K.; Zhiyi, G.; Wang, Z.; Daham, A.; Wang, J.; Liu, W.; Wang, J.; Derradji, M. Development of Green Composites from Bio-benzoxazine and Epoxy Copolymer Reinforced with Alkali-treated Pine Nut Shell Particles. Polym. Adv. Technol. 2024, 35, e6245. [Google Scholar] [CrossRef]

- Zannini, D.; Dal Poggetto, G.; Malinconico, M.; Santagata, G.; Immirzi, B. Citrus Pomace Biomass as a Source of Pectin and Lignocellulose Fibers: From Waste to Upgraded Biocomposites for Mulching Applications. Polymers 2021, 13, 1280. [Google Scholar] [CrossRef]

- Espinach, F.X.; Espinosa, E.; Reixach, R.; Rodríguez, A.; Mutjé, P.; Tarrés, Q. Study on the Macro and Micromechanics Tensile Strength Properties of Orange Tree Pruning Fiber as Sustainable Reinforcement on Bio-Polyethylene Compared to Oil-Derived Polymers and Its Composites. Polymers 2020, 12, 2206. [Google Scholar] [CrossRef]

- Vallejo, M.; Cordeiro, R.; Dias, P.A.N.; Moura, C.; Henriques, M.; Seabra, I.J.; Malça, C.M.; Morouço, P. Recovery and Evaluation of Cellulose from Agroindustrial Residues of Corn, Grape, Pomegranate, Strawberry-Tree Fruit and Fava. Bioresour. Bioprocess. 2021, 8, 25. [Google Scholar] [CrossRef]

- El Saeidy, E.A. The Usage of Citrus Trees Pruning Outputs for Particleboards Production. Misr J. Agric. Eng. 2016, 33, 1127–1140. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Gulino, E.F. Opuntia Ficus Indica Based Green Composites for NPK Fertilizer Controlled Release Produced by Compression Molding and Fused Deposition Modeling. Compos. Part A Appl. Sci. Manuf. 2022, 159, 107030. [Google Scholar] [CrossRef]

- Gabrielli, S.; Caviglia, M.; Pastore, G.; Marcantoni, E.; Nobili, F.; Bottoni, L.; Catorci, A.; Bavasso, I.; Sarasini, F.; Tirillò, J.; et al. Chemical, Thermal and Mechanical Characterization of Licorice Root, Willow, Holm Oak, and Palm Leaf Waste Incorporated into Maleated Polypropylene (MAPP). Polymers 2022, 14, 4348. [Google Scholar] [CrossRef] [PubMed]

- Maroua, F.; Adnane, L.; Hocine, D. Use of Date Palm Waste to Produce Bio-Composite Material. In Proceedings of the Second International Conference of Innovative Textiles and Developed Materials-ITDM’2, Monastir, Tunisia, 5–6 May 2023; Springer: Singapore, 2024; pp. 147–152. [Google Scholar]

- Umaña, M.; Simal, S.; Dalmau, E.; Turchiuli, C.; Chevigny, C. Evaluation of Different Pectic Materials Coming from Citrus Residues in the Production of Films. Foods 2024, 13, 2138. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Corrado, I.; Di Girolamo, R.; Dal Poggetto, G.; Panzella, L.; Borselleca, E.; Pezzella, C.; Giosafatto, C.V.L. Manufacture of Active Multilayer Films Made of Functionalized Pectin Coated by Polyhydroxyalkanoates: A Fully Renewable Approach to Active Food Packaging. Polymer 2023, 281, 126136. [Google Scholar] [CrossRef]

- Azizah, F.; Nursakti, H.; Ningrum, A. Supriyadi Development of Edible Composite Film from Fish Gelatin–Pectin Incorporated with Lemongrass Essential Oil and Its Application in Chicken Meat. Polymers 2023, 15, 2075. [Google Scholar] [CrossRef]

- Lupidi, G.; Pastore, G.; Marcantoni, E.; Gabrielli, S. Recent Developments in Chemical Derivatization of Microcrystalline Cellulose (MCC): Pre-Treatments, Functionalization, and Applications. Molecules 2023, 28, 2009. [Google Scholar] [CrossRef]

- Wang, L.; Chen, C.; Wang, J.; Gardner, D.J.; Tajvidi, M. Cellulose Nanofibrils versus Cellulose Nanocrystals: Comparison of Performance in Flexible Multilayer Films for Packaging Applications. Food Packag. Shelf Life 2020, 23, 100464. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, Z.; Li, A.; Chen, N.; Rao, J.; Zeng, Q. Nanocellulose Composite Films in Food Packaging Materials: A Review. Polymers 2024, 16, 423. [Google Scholar] [CrossRef]

- Molinari, G.; Gigante, V.; Fiori, S.; Aliotta, L.; Lazzeri, A. Dispersion of Micro Fibrillated Cellulose (MFC) in Poly(Lactic Acid) (PLA) from Lab-Scale to Semi-Industrial Processing Using Biobased Plasticizers as Dispersing Aids. Chemistry 2021, 3, 896–915. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Molinari, G.; D’Ambrosio, R.; Botta, L.; La Mantia, F.P.; Lazzeri, A. Effect of Biobased Plasticizers, Used as Dispersing Aids, on Mechanical, Rheological and Thermal Properties of Micro Fibrillated Cellulose (MFC)/Poly (Lactic Acid) (PLA) Biocomposites over the Time: How MFC Controls the Plasticizer Migration? Cellulose 2023, 30, 2237–2252. [Google Scholar] [CrossRef]

- Apicella, A.; Molinari, G.; Gigante, V.; Pietrosanto, A.; Incarnato, L.; Aliotta, L.; Lazzeri, A. Poly(Lactic Acid) (PLA)/Poly(Butylene Succinate Adipate) (PBSA) Films with Micro Fibrillated Cellulose (MFC) and Cardanol for Packaging Applications. Cellulose 2024, 31, 9173–9190. [Google Scholar] [CrossRef]

- Lu, P.; Guo, M.; Xu, Z.; Wu, M. Application of Nanofibrillated Cellulose on BOPP/LDPE Film as Oxygen Barrier and Antimicrobial Coating Based on Cold Plasma Treatment. Coatings 2018, 8, 207. [Google Scholar] [CrossRef]

- Tayeb, A.H.; Tajvidi, M.; Bousfield, D. Enhancing the Oxygen Barrier Properties of Nanocellulose at High Humidity: Numerical and Experimental Assessment. Sustain. Chem. 2020, 1, 198–208. [Google Scholar] [CrossRef]

- Srivastava, K.R.; Dixit, S.; Pal, D.B.; Mishra, P.K.; Srivastava, P.; Srivastava, N.; Hashem, A.; Alqarawi, A.A.; Abd_Allah, E.F. Effect of Nanocellulose on Mechanical and Barrier Properties of PVA–Banana Pseudostem Fiber Composite Films. Environ. Technol. Innov. 2021, 21, 101312. [Google Scholar] [CrossRef]

- Kumar, S.; Bhowmik, S. Extraction of Bio-Fillers from Natural Solid Wastes (Citrus Limetta Peel) and Characterization of the Physical, Mechanical, and Tribological Performance of Sustainable Biocomposites. J. Mater. Cycles Waste Manag. 2023, 25, 3508–3521. [Google Scholar] [CrossRef]

- Wang, N.; Saleh, A.S.M.; Gao, Y.; Wang, P.; Duan, Y.; Xiao, Z. Effect of Protein Aggregates on Properties and Structure of Rice Bran Protein-Based Film at Different PH. J. Food Sci. Technol. 2019, 56, 5116–5127. [Google Scholar] [CrossRef]

- Ben Shalom, T.; Belsey, S.; Chasnitsky, M.; Shoseyov, O. Cellulose Nanocrystals and Corn Zein Oxygen and Water Vapor Barrier Biocomposite Films. Nanomaterials 2021, 11, 247. [Google Scholar] [CrossRef]

- Gigante, V.; Aliotta, L.; Canesi, I.; Sandroni, M.; Lazzeri, A.; Coltelli, M.-B.; Cinelli, P. Improvement of Interfacial Adhesion and Thermomechanical Properties of PLA Based Composites with Wheat/Rice Bran. Polymers 2022, 14, 3389. [Google Scholar] [CrossRef]

- Abhirami, P.; Modupalli, N.; Natarajan, V. Novel Postharvest Intervention Using Rice Bran Wax Edible Coating for Shelf-life Enhancement of Solanum lycopersicum Fruit. J. Food Process Preserv. 2020, 44, e14989. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, F.; Zhang, P.; Lai, S.; Yang, H. Influence of Rice Bran Wax Coating on the Physicochemical Properties and Pectin Nanostructure of Cherry Tomatoes. Food Bioprocess Technol. 2017, 10, 349–357. [Google Scholar] [CrossRef]

- Ahmed, W.; Haque, A.; Mohibbullah; Khan, S.I.; Islam, M.A.; Mondal, H.T.; Ahmmed, R. A Review on Active Packaging for Quality and Safety of Foods: Current Trends, Applications, Prospects and Challenges. Food Packag. Shelf Life 2022, 33, 100913. [Google Scholar] [CrossRef]

- Thirupathi Vasuki, M.; Kadirvel, V.; Pejavara Narayana, G. Smart Packaging—An Overview of Concepts and Applications in Various Food Industries. Food Bioeng. 2023, 2, 25–41. [Google Scholar] [CrossRef]

- Andrade, M.A.; Barbosa, C.H.; Mariño-Cortegoso, S.; Barbosa-Pereira, L.; Sendón, R.; Buonocore, G.G.; Stanzione, M.; Coelho, A.; Correia, C.B.; Saraiva, M.; et al. LDPE and PLA Active Food Packaging Incorporated with Lemon By-Products Extract: Preparation, Characterization and Effectiveness to Delay Lipid Oxidation in Almonds and Beef Meat. Foods 2023, 12, 2450. [Google Scholar] [CrossRef]

- Khalil, R.K.S.; Sharaby, M.R.; Abdelrahim, D.S. Novel Active Edible Food Packaging Films Based Entirely on Citrus Peel Wastes. Food Hydrocoll. 2023, 134, 107961. [Google Scholar] [CrossRef]

- Yilmaz, B.; Kahraman, K.; Ekici, L. Fabrication of Grape Pomace Extract–Loaded Electrospun Nanofiber Films as Active Packaging Material for Walnut. Food Bioprocess Technol. 2024, 18, 2482–2492. [Google Scholar] [CrossRef]

- Zhao, X.; Tian, R.; Zhou, J.; Liu, Y. Multifunctional Chitosan/Grape Seed Extract/Silver Nanoparticle Composite for Food Packaging Application. Int. J. Biol. Macromol. 2022, 207, 152–160. [Google Scholar] [CrossRef]

- Zidan, N.S.; Aziz albalawi, M.; Alalawy, A.I.; Al-Duais, M.A.; Alzahrani, S.; Kasem, M. Modification of Edible Chitosan/Polyethylene Glycol Films Fortified with Date Palm Fruit Waste Extract as Promising Antimicrobial Food Packaging Materials for Fresh Strawberry Conservation. Eur. Polym. J. 2023, 194, 112171. [Google Scholar] [CrossRef]

- Alparslan, Y.; Yapıcı, H.H.; Metin, C.; Baygar, T.; Günlü, A.; Baygar, T. Quality Assessment of Shrimps Preserved with Orange Leaf Essential Oil Incorporated Gelatin. LWT—Food Sci. Technol. 2016, 72, 457–466. [Google Scholar] [CrossRef]

- Fernandez, C.M.; Alves, J.; Gaspar, P.D.; Lima, T.M.; Silva, P.D. Innovative Processes in Smart Packaging. A Systematic Review. J. Sci. Food Agric. 2023, 103, 986–1003. [Google Scholar] [CrossRef]

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef]

- Oladzadabbasabadi, N.; Mohammadi Nafchi, A.; Ghasemlou, M.; Ariffin, F.; Singh, Z.; Al-Hassan, A.A. Natural Anthocyanins: Sources, Extraction, Characterization, and Suitability for Smart Packaging. Food Packag. Shelf Life 2022, 33, 100872. [Google Scholar] [CrossRef]

- Khan, M.I.; Liu, J. Plant Betalains: Recent Applications in Food Freshness Monitoring Films. Food Packag. Shelf Life 2022, 34, 100921. [Google Scholar] [CrossRef]

- Elhadef, K.; Chaari, M.; Akermi, S.; Ben Hlima, H.; Ennouri, M.; Abdelkafi, S.; Agriopoulou, S.; Ali, D.S.; Boulekbache-Makhlouf, L.; Mellouli, L.; et al. PH-Sensitive Films Based on Carboxymethyl Cellulose/Date Pits Anthocyanins: A Convenient Colorimetric Indicator for Beef Meat Freshness Tracking. Food Biosci. 2024, 57, 103508. [Google Scholar] [CrossRef]

- Oktay, C.; Kahyaoglu, L.N.; Moradi, M. Food Freshness Monitoring Using Poly(Vinyl Alcohol) and Anthocyanins Doped Zeolitic Imidazolate Framework-8 Multilayer Films with Bacterial Nanocellulose beneath as Support. Carbohydr. Polym. 2023, 319, 121184. [Google Scholar] [CrossRef] [PubMed]

- Gupta, D.; Priyadarshi, R.; Tammina, S.K.; Rhim, J.-W.; Agrawal, G. Fruit Processing Wastes as Sustainable Sources to Produce Multifunctional Carbon Quantum Dots for Application in Active Food Packaging. Food Bioprocess Technol. 2025, 18, 2145–2169. [Google Scholar] [CrossRef]

- Oladzadabbasabadi, N.; Dheyab, M.A.; Nafchi, A.M.; Ghasemlou, M.; Ivanova, E.P.; Adhikari, B. Turning Food Waste into Value-Added Carbon Dots for Sustainable Food Packaging Application: A Review. Adv. Colloid. Interface Sci. 2023, 321, 103020. [Google Scholar] [CrossRef]

- Matthes, J.; Schmid, M. Biogenic Raw Materials from Food Waste and By-Products for Smart Packaging Applications. Curr. Opin. Green. Sustain. Chem. 2024, 46, 100894. [Google Scholar] [CrossRef]

- Manshoven, S.; Grossi, F. Textiles and the Environment The Role of Design in Europe’s Circular Economy; European Environment Agency: Copenhagen, Denmark, 2022. [Google Scholar]

- Monseau, S.; Sorsa, K.; Salokangas, H. Cleaner Clothes: The eu Textile Strategy and Sustainability in the Textile Supply Chain. Ga. J. Int’l Comp. L. 2024, 52, 409. [Google Scholar]

- Meksi, N.; Haddar, W.; Hammami, S.; Mhenni, M.F. Olive Mill Wastewater: A Potential Source of Natural Dyes for Textile Dyeing. Ind. Crops Prod. 2012, 40, 103–109. [Google Scholar] [CrossRef]

- Avci, B.B.; Erkan, G. The Investigation of Possible Use of Olive Oil Production Wastes in Wool Dyeing. Dokuz Eylül Üniversitesi Mühendislik Fakültesi Fen Ve Mühendislik Derg. 2023, 25, 569–584. [Google Scholar] [CrossRef]

- Avcı, B.B.; Erkan, G. Zeytinyağı Üretimi Atıklarının Poliamid (6.6) Boyamacılığında Kullanım Olanaklarının Araştırılması. Gazi Üniversitesi Mühendislik Mimar. Fakültesi Derg. 2024, 39, 1673–1692. [Google Scholar] [CrossRef]

- Haddar, W.; Baaka, N.; Meksi, N.; Elksibi, I.; Farouk Mhenni, M. Optimization of an Ecofriendly Dyeing Process Using the Wastewater of the Olive Oil Industry as Natural Dyes for Acrylic Fibres. J. Clean. Prod. 2014, 66, 546–554. [Google Scholar] [CrossRef]

- Erdem İşmal, Ö. A Route from Olive Oil Production to Natural Dyeing: Valorisation of Prina (Crude Olive Cake) as a Novel Dye Source. Color. Technol. 2014, 130, 147–153. [Google Scholar] [CrossRef]

- Akar, T.; Tosun, I.; Kaynak, Z.; Ozkara, E.; Yeni, O.; Sahin, E.N.; Akar, S.T. An Attractive Agro-Industrial by-Product in Environmental Cleanup: Dye Biosorption Potential of Untreated Olive Pomace. J. Hazard. Mater. 2009, 166, 1217–1225. [Google Scholar] [CrossRef] [PubMed]

- Rizzi, V.; D’Agostino, F.; Gubitosa, J.; Fini, P.; Petrella, A.; Agostiano, A.; Semeraro, P.; Cosma, P. An Alternative Use of Olive Pomace as a Wide-Ranging Bioremediation Strategy to Adsorb and Recover Disperse Orange and Disperse Red Industrial Dyes from Wastewater. Separations 2017, 4, 29. [Google Scholar] [CrossRef]

- Yılmaz, F.; Bahtiyari, M.İ. Antibacterial Finishing of Cotton Fabrics by Dyeing with Olive Tree Leaves Fallen during Olive Harvesting. J. Clean. Prod. 2020, 270, 122068. [Google Scholar] [CrossRef]

- Gaminian, H.; Ahvazi, B.; Vidmar, J.J.; Ekuere, U.; Regan, S. Revolutionizing Sustainable Nonwoven Fabrics: The Potential Use of Agricultural Waste and Natural Fibres for Nonwoven Fabric. Biomass 2024, 4, 363–401. [Google Scholar] [CrossRef]

- Biyada, S.; Merzouki, M.; Urbonavičius, J. New Resources for Sustainable Thermal Insulation Using Textile and Agricultural Waste in a New Circular Economy Approach: An Overview. Processes 2023, 11, 2683. [Google Scholar] [CrossRef]

- Guiza, S.; Ghiloufi, K.; Bagane, F.M. Utilization of Waste Tunisian Palm Tree Date as Low-Cost Adsorbent for the Removal of Dyes from Textile Wastewater. Mediterr. J. Chem. 2014, 3, 1044–1052. [Google Scholar]

- Alharbi, H.A.; Hameed, B.H.; Alotaibi, K.D.; Al-Oud, S.S.; Al-Modaihsh, A.S. Recent Methods in the Production of Activated Carbon from Date Palm Residues for the Adsorption of Textile Dyes: A Review. Front. Environ. Sci. 2022, 10, 996953. [Google Scholar] [CrossRef]

- Baaka, N.; Haddar, W.; Ben Ticha, M.; Mhenni, M.F. Eco-Friendly Dyeing of Modified Cotton Fabrics with Grape Pomace Colorant: Optimization Using Full Factorial Design Approach. J. Nat. Fibers 2019, 16, 652–661. [Google Scholar] [CrossRef]

- Fonseca, F.D.; Symochko, L.; Pinheiro, M.N.C. Grape Pomace (Vitis vinifera L.) Waste Valorization: Assessing Its Potential as a Sustainable Natural Dye for Textiles Applications. Sustainability 2024, 16, 3167. [Google Scholar] [CrossRef]

- Baaka, N.; Ben Ticha, M.; Haddar, W.; Amorim, M.T.P.; Mhenni, M.F. Upgrading of UV Protection Properties of Several Textile Fabrics by Their Dyeing with Grape Pomace Colorants. Fibers Polym. 2018, 19, 307–312. [Google Scholar] [CrossRef]

- Sachidhanandham, A. Textiles from Orange Peel Waste. Sci. Technol. Dev. J. 2020, 23, 508–516. [Google Scholar] [CrossRef]

- Ahmad, T.; Danish, M.; Dadi, M.; Siraj, K.; Sundaram, T.; Raj, D.S.; Majeed, S.; Ramasamy, S. Potentials of Orange Wastes in Wastewater Treatment Technology: A Comprehensive Review. J. Water Process Eng. 2024, 67, 106113. [Google Scholar] [CrossRef]

- Dulo, B.; De Somer, T.; Phan, K.; Roosen, M.; Githaiga, J.; Raes, K.; De Meester, S. Evaluating the Potential of Natural Dyes from Nutshell Wastes: Sustainable Colouration and Functional Finishing of Wool Fabric. Sustain. Mater. Technol. 2022, 34, e00518. [Google Scholar] [CrossRef]

- Moussa, I.; Khiari, R.; Moussa, A.; Mortha, G.; Mhenni, M.F. New Lignins with Antioxidant Activity Extracted from Almond By-Products. J. Text. Inst. 2022, 113, 1731–1738. [Google Scholar] [CrossRef]

- Saharan, B.S.; Kamal, N.; Badoni, P.; Kumar, R.; Saini, M.; Kumar, D.; Sharma, D.; Tyagi, S.; Ranga, P.; Parshad, J.; et al. Biopolymer and Polymer Precursor Production by Microorganisms: Applications and Future Prospects. J. Chem. Technol. Biotechnol. 2024, 99, 17–30. [Google Scholar] [CrossRef]

- Chen, C.; Chen, X.; Liu, L.; Wu, J.; Gao, C. Engineering Microorganisms to Produce Bio-Based Monomers: Progress and Challenges. Fermentation 2023, 9, 137. [Google Scholar] [CrossRef]

- Thamarai, P.; Vickram, A.S.; Saravanan, A.; Deivayanai, V.C.; Evangeline, S. Recent Advancements in Biosynthesis, Industrial Production, and Environmental Applications of Polyhydroxyalkanoates (PHAs): A Review. Bioresour. Technol. Rep. 2024, 27, 101957. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Danti, S.; De Clerck, K.; Lazzeri, A.; Morganti, P. Pullulan for Advanced Sustainable Body- and Skin-Contact Applications. J. Funct. Biomater. 2020, 11, 20. [Google Scholar] [CrossRef] [PubMed]

- Teno, J.; Pardo-Figuerez, M.; Hummel, N.; Bonin, V.; Fusco, A.; Ricci, C.; Donnarumma, G.; Coltelli, M.-B.; Danti, S.; Lagaron, J.M. Preliminary Studies on an Innovative Bioactive Skin Soluble Beauty Mask Made by Combining Electrospinning and Dry Powder Impregnation. Cosmetics 2020, 7, 96. [Google Scholar] [CrossRef]

- Bhatia, S.K. Microbial Biopolymers: Trends in Synthesis, Modification, and Applications. Polymers 2023, 15, 1364. [Google Scholar] [CrossRef]

- Sharma, M.; Tellili, N.; Kacem, I.; Rouissi, T. Microbial Biopolymers: From Production to Environmental Applications—A Review. Appl. Sci. 2024, 14, 5081. [Google Scholar] [CrossRef]

- Scudder, G.G.E. The Importance of Insects. In Insect Biodiversity; Wiley: Hoboken, NJ, USA, 2017; pp. 9–43. [Google Scholar]

- Snell-Rood, E. Interdisciplinarity: Bring Biologists into Biomimetics. Nature 2016, 529, 277–278. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Harahap, I.A.; Osei-Owusu, J.; Saikia, T.; Wu, Y.S.; Fernando, I.; Perestrelo, R.; Câmara, J.S. Bioconversion of Organic Waste by Insects—A Comprehensive Review. Process Saf. Environ. Prot. 2024, 187, 1–25. [Google Scholar] [CrossRef]

- Mannucci, A.; Panariello, L.; Abenaim, L.; Coltelli, M.B.; Ranieri, A.; Conti, B.; Santin, M.; Castagna, A. From Food Waste to Functional Biopolymers: Characterization of Chitin and Chitosan Produced from Prepupae of Black Soldier Fly Reared with Different Food Waste-Based Diets. Foods 2024, 13, 278. [Google Scholar] [CrossRef]

- Scieuzo, C.; Franco, A.; Salvia, R.; Triunfo, M.; Addeo, N.F.; Vozzo, S.; Piccolo, G.; Bovera, F.; Ritieni, A.; Francia, A.D.; et al. Enhancement of Fruit Byproducts through Bioconversion by Hermetia illucens (Diptera: Stratiomyidae). Insect Sci. 2023, 30, 991–1010. [Google Scholar] [CrossRef]

- Scala, A.; Cammack, J.A.; Salvia, R.; Scieuzo, C.; Franco, A.; Bufo, S.A.; Tomberlin, J.K.; Falabella, P. Rearing Substrate Impacts Growth and Macronutrient Composition of Hermetia illucens (L.) (Diptera: Stratiomyidae) Larvae Produced at an Industrial Scale. Sci. Rep. 2020, 10, 19448. [Google Scholar] [CrossRef]

- Franco, A.; Rinaldi, R.; Giglio, F.; Ianniciello, D.; Boschi, A.; Scieuzo, C.; Salvia, R.; Falabella, P. Edible Insects: An Overview on Farming, from Processing Procedures to Environmental Impact, with a Glimpse to Traditional Recipes and to Future Cultured Meat. Entomol. Gen. 2024, 44, 813–831. [Google Scholar] [CrossRef]

- Magee, K.; Halstead, J.; Small, R.; Young, I. Valorisation of Organic Waste By-Products Using Black Soldier Fly (Hermetia illucens) as a Bio-Convertor. Sustainability 2021, 13, 8345. [Google Scholar] [CrossRef]

- Taufek, N.M.; Mohamad Zulkifli, N.F.N.; Hamizah, A.N. Upcycling of Food Waste Generated from the Fresh Market by Utilising Black Soldier Fly Larvae: Influence on Growth, Bioconversion, and Nutritional Composition. J. Environ. Manag. 2024, 349, 119467. [Google Scholar] [CrossRef]

- Tschirner, M.; Simon, A. Influence of Different Growing Substrates and Processing on the Nutrient Composition of Black Soldier Fly Larvae Destined for Animal Feed. J. Insects Food Feed. 2015, 1, 249–259. [Google Scholar] [CrossRef]

- Surendra, K.C.; Tomberlin, J.K.; van Huis, A.; Cammack, J.A.; Heckmann, L.-H.L.; Khanal, S.K. Rethinking Organic Wastes Bioconversion: Evaluating the Potential of the Black Soldier Fly (Hermetia illucens (L.)) (Diptera: Stratiomyidae) (BSF). Waste Manag. 2020, 117, 58–80. [Google Scholar] [CrossRef]

- Rehman, K.U.; Hollah, C.; Wiesotzki, K.; Rehman, R.; Rehman, A.U.; Zhang, J.; Zheng, L.; Nienaber, T.; Heinz, V.; Aganovic, K. Black Soldier Fly, Hermetia illucens as a Potential Innovative and Environmentally Friendly Tool for Organic Waste Management: A Mini-Review. Waste Manag. Res. J. A Sustain. Circ. Econ. 2023, 41, 81–97. [Google Scholar] [CrossRef]

- Setti, L.; Francia, E.; Pulvirenti, A.; De Leo, R.; Martinelli, S.; Maistrello, L.; Macavei, L.I.; Montorsi, M.; Barbi, S.; Ronga, D. Bioplastic Film from Black Soldier Fly Prepupae Proteins Used as Mulch: Preliminary Results. Agronomy 2020, 10, 933. [Google Scholar] [CrossRef]

- Triunfo, M.; Tafi, E.; Guarnieri, A.; Salvia, R.; Scieuzo, C.; Hahn, T.; Zibek, S.; Gagliardini, A.; Panariello, L.; Coltelli, M.B.; et al. Characterization of Chitin and Chitosan Derived from Hermetia illucens, a Further Step in a Circular Economy Process. Sci. Rep. 2022, 12, 6613. [Google Scholar] [CrossRef]

- Triunfo, M.; Guarnieri, A.; Ianniciello, D.; Coltelli, M.B.; Salvia, R.; Scieuzo, C.; De Bonis, A.; Falabella, P. A Comprehensive Characterization of Hermetia illucens Derived Chitosan Produced through Homogeneous Deacetylation. Int. J. Biol. Macromol. 2024, 271, 132669. [Google Scholar] [CrossRef]

- Lomonaco, G.; Franco, A.; De Smet, J.; Scieuzo, C.; Salvia, R.; Falabella, P. Larval Frass of Hermetia illucens as Organic Fertilizer: Composition and Beneficial Effects on Different Crops. Insects 2024, 15, 293. [Google Scholar] [CrossRef]

- Triunfo, M.; Tafi, E.; Guarnieri, A.; Scieuzo, C.; Hahn, T.; Zibek, S.; Salvia, R.; Falabella, P. Insect Chitin-Based Nanomaterials for Innovative Cosmetics and Cosmeceuticals. Cosmetics 2021, 8, 40. [Google Scholar] [CrossRef]

- Desai, N.; Rana, D.; Salave, S.; Gupta, R.; Patel, P.; Karunakaran, B.; Sharma, A.; Giri, J.; Benival, D.; Kommineni, N. Chitosan: A Potential Biopolymer in Drug Delivery and Biomedical Applications. Pharmaceutics 2023, 15, 1313. [Google Scholar] [CrossRef] [PubMed]

- Rajkumar, D.S.R.; Keerthika, K.; Vijayaragavan, V. Chitosan-Based Biomaterial in Wound Healing: A Review. Cureus 2024, 16, e55193. [Google Scholar] [CrossRef]

- Abenaim, L.; Conti, B. Chitosan as a Control Tool for Insect Pest Management: A Review. Insects 2023, 14, 949. [Google Scholar] [CrossRef]

- Bhatt, P.; Joshi, S.; Urper Bayram, G.M.; Khati, P.; Simsek, H. Developments and Application of Chitosan-Based Adsorbents for Wastewater Treatments. Environ. Res. 2023, 226, 115530. [Google Scholar] [CrossRef] [PubMed]

- Shcherban, A.B. Chitosan and Its Derivatives as Promising Plant Protection Tools. Vavilov J. Genet. Breed. 2023, 27, 1010–1021. [Google Scholar] [CrossRef]

- Tafi, E.; Triunfo, M.; Guarnieri, A.; Ianniciello, D.; Salvia, R.; Scieuzo, C.; Ranieri, A.; Castagna, A.; Lepuri, S.; Hahn, T.; et al. Preliminary Investigation on the Effect of Insect-Based Chitosan on Preservation of Coated Fresh Cherry Tomatoes. Sci. Rep. 2023, 13, 7030. [Google Scholar] [CrossRef]

- Triunfo, M.; Guarnieri, A.; Ianniciello, D.; Coviello, L.; Vitti, A.; Nuzzaci, M.; Salvia, R.; Scieuzo, C.; Falabella, P. Hermetia illucens, an Innovative and Sustainable Source of Chitosan-Based Coating for Postharvest Preservation of Strawberries. iScience 2023, 26, 108576. [Google Scholar] [CrossRef]

- Weng, S.; Marcet, I.; Rendueles, M.; Díaz, M. Insect-Derived Materials for Food Packaging-A Review. Food Packag. Shelf Life 2023, 38, 101097. [Google Scholar] [CrossRef]

- Guarnieri, A.; Triunfo, M.; Ianniciello, D.; Tedesco, F.; Salvia, R.; Scieuzo, C.; Schmitt, E.; Capece, A.; Falabella, P. Insect-Derived Chitosan, a Biopolymer for the Increased Shelf Life of White and Red Grapes. Int. J. Biol. Macromol. 2024, 275, 133149. [Google Scholar] [CrossRef]

- Vitti, A.; Coviello, L.; Triunfo, M.; Guarnieri, A.; Scieuzo, C.; Salvia, R.; Falabella, P.; Nuzzaci, M. In Vitro Antifungal Activity and in Vivo Edible Coating Efficacy of Insect-Derived Chitosan against Botrytis Cinerea in Strawberry. Int. J. Biol. Macromol. 2024, 279, 135158. [Google Scholar] [CrossRef]

- Islam, N.F.; Gogoi, B.; Saikia, R.; Yousaf, B.; Narayan, M.; Sarma, H. Encouraging Circular Economy and Sustainable Environmental Practices by Addressing Waste Management and Biomass Energy Production. Reg. Sustain. 2024, 5, 100174. [Google Scholar] [CrossRef]

- Vasileiadou, A. From Organic Wastes to Bioenergy, Biofuels, and Value-Added Products for Urban Sustainability and Circular Economy: A Review. Urban. Sci. 2024, 8, 121. [Google Scholar] [CrossRef]

- Saxena, S.; Moharil, M.P.; Jadhav, P.V.; Ghodake, B.; Deshmukh, R.; Ingle, A.P. Transforming Waste into Wealth: Leveraging Nanotechnology for Recycling Agricultural Byproducts into Value-Added Products. Plant Nano Biol. 2025, 11, 100127. [Google Scholar] [CrossRef]

- Manara, P.; Vamvuka, D.; Sfakiotakis, S.; Vanderghem, C.; Richel, A.; Zabaniotou, A. Mediterranean Agri-Food Processing Wastes Pyrolysis after Pre-Treatment and Recovery of Precursor Materials: A TGA-Based Kinetic Modeling Study. Food Res. Int. 2015, 73, 44–51. [Google Scholar] [CrossRef]

- Demichelis, F.; Lenzuni, M.; Converti, A.; Del Borghi, A.; Freyria, F.S.; Gagliano, E.; Mancini, M.; Toscano, G.; Mazzoni, E.; Reguzzi, M.C.; et al. Agro-Food Waste Conversion into Valuable Products in the Italian Scenario: Current Practices and Innovative Approaches. J. Environ. Chem. Eng. 2025, 13, 115458. [Google Scholar] [CrossRef]

- Antonopoulou, G.; Ntaikou, I.; Pastore, C.; di Bitonto, L.; Bebelis, S.; Lyberatos, G. An Overall Perspective for the Energetic Valorization of Household Food Waste Using Microbial Fuel Cell Technology of Its Extract, Coupled with Anaerobic Digestion of the Solid Residue. Appl. Energy 2019, 242, 1064–1073. [Google Scholar] [CrossRef]

- Ma, Y.; Cai, W.; Liu, Y. An Integrated Engineering System for Maximizing Bioenergy Production from Food Waste. Appl. Energy 2017, 206, 83–89. [Google Scholar] [CrossRef]

- Hamed, M.A.; El-Habibi, M.F.; Sababa, R.Z.; Al-Hanjori, M.; Abunasser, B.S.; Abu-Naser, S.S. Artificial Intelligence in Agriculture: Enhancing Productivity and Sustainability; International Journal of Engineering and Information Systems: Bowling Green, KY, USA, 2024; Volume 8. [Google Scholar]

- Mehryar, M.; Rostamizadeh, A.; Talwalkar, A. Foundations of Machine Learning, 2nd ed.; MIT Press, Ed.; MIT: Cambridge, MA, USA, 2018; ISBN 9780262039406. [Google Scholar]

- Russel, N.; Norvig, P. Artificial Intelligence A Modern Approach, 3rd ed.; Prentice Hall Series in Artificial Intelligence; Prentice-Hall: Saddle River, NJ, USA, 2010; ISBN 0-13-604259-7. [Google Scholar]

- Li, C.; He, P.; Peng, W.; Lü, F.; Du, R.; Zhang, H. Exploring Available Input Variables for Machine Learning Models to Predict Biogas Production in Industrial-Scale Biogas Plants Treating Food Waste. J. Clean. Prod. 2022, 380, 135074. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep Learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep Learning in Neural Networks: An Overview. Neural Netw. 2015, 61, 85–117. [Google Scholar] [CrossRef] [PubMed]

- Krupitzer, C.; Stein, A. Unleashing the Potential of Digitalization in the Agri-Food Chain for Integrated Food Systems. Annu. Rev. Food Sci. Technol. 2024, 15, 307–328. [Google Scholar] [CrossRef] [PubMed]

- Allioui, H.; Mourdi, Y. Exploring the Full Potentials of IoT for Better Financial Growth and Stability: A Comprehensive Survey. Sensors 2023, 23, 8015. [Google Scholar] [CrossRef] [PubMed]

- Barandun, G.; Gonzalez-Macia, L.; Lee, H.S.; Dincer, C.; Güder, F. Challenges and Opportunities for Printed Electrical Gas Sensors. ACS Sens. 2022, 7, 2804–2822. [Google Scholar] [CrossRef]

- Ghaani, M.; Cozzolino, C.A.; Castelli, G.; Farris, S. An Overview of the Intelligent Packaging Technologies in the Food Sector. Trends Food Sci. Technol. 2016, 51, 1–11. [Google Scholar] [CrossRef]

- Krupitzer, C. Generative Artificial Intelligence in the Agri-Food Value Chain—Overview, Potential, and Research Challenges. Front. Food Sci. Technol. 2024, 4, 1473357. [Google Scholar] [CrossRef]

- Stark, R.; Damerau, T. Digital Twin. In CIRP Encyclopedia of Production Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–8. [Google Scholar]

- Henrichs, E.; Noack, T.; Pinzon Piedrahita, A.M.; Salem, M.A.; Stolz, J.; Krupitzer, C. Can a Byte Improve Our Bite? An Analysis of Digital Twins in the Food Industry. Sensors 2021, 22, 115. [Google Scholar] [CrossRef]

- Krupitzer, C.; Noack, T.; Borsum, C. Digital Food Twins Combining Data Science and Food Science: System Model, Applications, and Challenges. Processes 2022, 10, 1781. [Google Scholar] [CrossRef]

- Alloun, W.; Berkani, M.; Benaissa, A.; Shavandi, A.; Gares, M.; Danesh, C.; Lakhdari, D.; Ghfar, A.A.; Chaouche, N.K. Waste Valorization as Low-Cost Media Engineering for Auxin Production from the Newly Isolated Streptomyces Rubrogriseus AW22: Model Development. Chemosphere 2023, 326, 138394. [Google Scholar] [CrossRef]

- Alloun, W.; Calvio, C. Bio-Driven Sustainable Extraction and AI-Optimized Recovery of Functional Compounds from Plant Waste: A Comprehensive Review. Fermentation 2024, 10, 126. [Google Scholar] [CrossRef]

- Plazzotta, S.; Manzocco, L. Food Waste Valorization. In Saving Food; Galanakis, C.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 279–313. [Google Scholar]

- Paini, J.; Benedetti, V.; Ail, S.S.; Castaldi, M.J.; Baratieri, M.; Patuzzi, F. Valorization of Wastes from the Food Production Industry: A Review Towards an Integrated Agri-Food Processing Biorefinery. Waste Biomass Valorization 2022, 13, 31–50. [Google Scholar] [CrossRef]

- Thomchick, E.; Jacobson, M.; Ruamsook, K. Bioeconomy Bright Spots, Challenges, and Key Factors Going Forward: Perceptions of Bioeconomy Stakeholders. EFB Bioeconomy J. 2024, 4, 100068. [Google Scholar] [CrossRef]

- Available online: https://Graded.It/Portfolio_item/Progetto-Green-Farm/ (accessed on 5 March 2025).

- Available online: https://Www.Project-Provide.Eu/ (accessed on 5 March 2025).

- Titone, V.; Mistretta, M.C.; Botta, L. Adding Mandarin Peel Waste to a Biodegradable Polymeric Matrix: Reinforcement or Degradation Effect? Polymers 2024, 16, 3172. [Google Scholar] [CrossRef] [PubMed]

- Galanakis, C.M. Recovery of High Added-Value Components from Food Wastes: Conventional, Emerging Technologies and Commercialized Applications. Trends Food Sci. Technol. 2012, 26, 68–87. [Google Scholar] [CrossRef]

- Mirabella, N.; Castellani, V.; Sala, S. Current Options for the Valorization of Food Manufacturing Waste: A Review. J. Clean. Prod. 2014, 65, 28–41. [Google Scholar] [CrossRef]

- Gullón, P.; Gullón, B.; Astray, G.; Carpena, M.; Fraga-Corral, M.; Prieto, M.A.; Simal-Gandara, J. Valorization of By-Products from Olive Oil Industry and Added-Value Applications for Innovative Functional Foods. Food Res. Int. 2020, 137, 109683. [Google Scholar] [CrossRef]

| Component | Weight Percentage (%) |

|---|---|

| Moisture | 40–70 |

| Residual oil | 2–8 |

| Total Organic Matter | 85–95 |

| Crude Fiber | 25–45 |

| Proteins | 3–10 |

| Ash | 2–5 |

| Polysaccharides and Sugars | 20–40 |

| Lignin | 10–30 |

| Polyphenols | 1–5 |

| Minerals | Traces |

| Material Used as Filler | Matrix | Shape of the Reinforcement | Key Findings |

|---|---|---|---|

| Hazelnut Shell (HS, HSP) | PLA (Polylactic Acid) | Powder | Increased stiffness but reduced tensile strength; improved UV resistance; semi-industrial production feasible; potential for 3D printing. |

| Walnut Shell (WSP) | Fossil-based thermoplastics | Powder | Often used in durable applications like furniture and automotive. |

| Almond Shell (ASP) | Biobased thermoplastics | Powder | Increased mechanical properties |

| Citrus Pomance | Polysaccharide-based biocomposites | Fibers of pectin and cellulose | Used for biodegradable mulching films; enhanced biodegradation |

| Orange Tree Pruinings | BIO-PE (Biopolyethylene) | Fibers | Improved tensile strength and Young’s modulus; potential PP replacement |

| Citrus Branches | Urea-formaldehyde resin | Shives | Viable substitute for flax in particleboard production |

| Opuntia Ficus Indica (OFI) | Biodegradable polymers | Particles | Green composite for controlled-release fertilizers |

| Lignocellulosic Waste | Polypropylene (PP) | Willow, holm oak, palm leaf, licorice root | Increased tensile and flexural strength |

| Date Palm Waste (DPW) | Polyvinyl acetate (PVA) | Leaflet fibers | Good mechanical properties confirmed via three-point bending tests |

| Derived Substance | Application | Function | Key Findings |

|---|---|---|---|

| Pectin (citrus waste) | Films, coatings, edible films | Oxygen barrier, reduced water solubility with crosslinking | Poor water vapor barrier, improved with PHA or multivalent ions |

| Cellulose and derivatives (plant waste) | Films, coatings, fillers, active packaging | Improved gas barriers, mechanical stability | Nanocellulose improves barrier properties but is sensitive to humidity |

| Citrus peel waste | Filler for bioepoxy | Increased mechanical strength and thermal stability | Used in biocomposites |

| Zein (corn or rice bran proteins) | Films, coatings | Water vapor and oxygen barrier (with crosslinking agents) | Improvements only with crosslinking and specific composition ratios |

| Waxes (rice bran wax) | Coatings | Fruit freshness preservation, reduced weight loss | Used for tomato storage |

| Extracts from waste (lemon, grape seed, date) | Active packaging | Antimicrobial and antioxidant properties | Extends food shelf life |

| Natural colorants (purple sweet potato, red cabbage, berries, beetroot) | Intelligent packaging | Freshness indicators with pH-based color change | Used to monitor meat and fish freshness |

| Agricultural Waste | Application | Key Findings |

|---|---|---|

| Olive Mill Wastewater | Natural dye for wool fabrics | Olive mill wastewater can successfully dye wool fabrics dark brown with high color yield, also effective for acrylic and polyamide fibers in eco-friendly dyeing. |

| Olive Pomace | Dye for textiles & adsorbent for wastewater | Olive pomace contains natural pigments for dyeing natural fibers and can adsorb synthetic dyes, reducing environmental pollution while repurposing industrial byproducts. |

| Olive Pomace & Date Palm Fibers | Nonwoven fabrics and composite textiles | Olive pomace and date palm fibers used to create nonwoven fabrics with excellent insulation properties, also showing potential for composite textiles. |

| Date Palm Fibers | Adsorbent for textile wastewater | Date palm fibers effectively adsorb dyes from textile wastewater, helping in pollution control. |

| Grape Pomace | Natural dye for cotton and wool | Grape pomace used as a natural dye for cotton and wool, providing UV protection and effective dyeing properties with various mordants. |

| Nutshells (Peanut, Cashew, etc.) | Dye source for wool fabrics | Nutshells (peanut, cashew, coconut, macadamia) used as a dye source for wool fabrics, providing effective coloration, UV protection, and fastness without mordants. |

| Almond By-products | Lignin extraction for textile industry | Lignin extracted from almond by-products can be incorporated into textile fibers, enhancing durability, UV resistance, and microbial growth prevention. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castagna, A.; Aboudia, A.; Guendouz, A.; Scieuzo, C.; Falabella, P.; Matthes, J.; Schmid, M.; Drissner, D.; Allais, F.; Chadni, M.; et al. Transforming Agricultural Waste from Mediterranean Fruits into Renewable Materials and Products with a Circular and Digital Approach. Materials 2025, 18, 1464. https://doi.org/10.3390/ma18071464

Castagna A, Aboudia A, Guendouz A, Scieuzo C, Falabella P, Matthes J, Schmid M, Drissner D, Allais F, Chadni M, et al. Transforming Agricultural Waste from Mediterranean Fruits into Renewable Materials and Products with a Circular and Digital Approach. Materials. 2025; 18(7):1464. https://doi.org/10.3390/ma18071464

Chicago/Turabian StyleCastagna, Antonella, Aouatif Aboudia, Amine Guendouz, Carmen Scieuzo, Patrizia Falabella, Julia Matthes, Markus Schmid, David Drissner, Florent Allais, Morad Chadni, and et al. 2025. "Transforming Agricultural Waste from Mediterranean Fruits into Renewable Materials and Products with a Circular and Digital Approach" Materials 18, no. 7: 1464. https://doi.org/10.3390/ma18071464

APA StyleCastagna, A., Aboudia, A., Guendouz, A., Scieuzo, C., Falabella, P., Matthes, J., Schmid, M., Drissner, D., Allais, F., Chadni, M., Cravotto, C., Senge, J., Krupitzer, C., Canesi, I., Spinelli, D., Drira, F., Ben Hlima, H., Abdelkafi, S., Konstantinou, I., ... Coltelli, M.-B. (2025). Transforming Agricultural Waste from Mediterranean Fruits into Renewable Materials and Products with a Circular and Digital Approach. Materials, 18(7), 1464. https://doi.org/10.3390/ma18071464