Impact of Processing Parameters on Ti Schottky Contacts on 4H-SiC

Abstract

1. Introduction

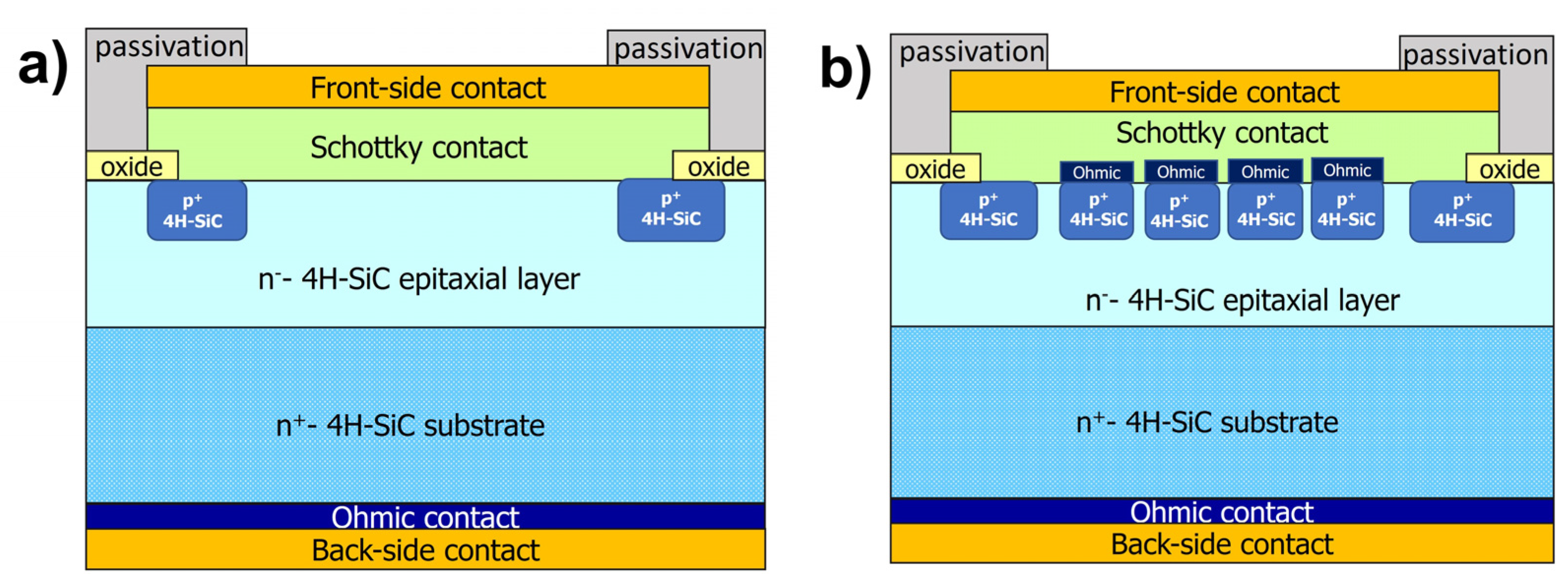

2. Experimental

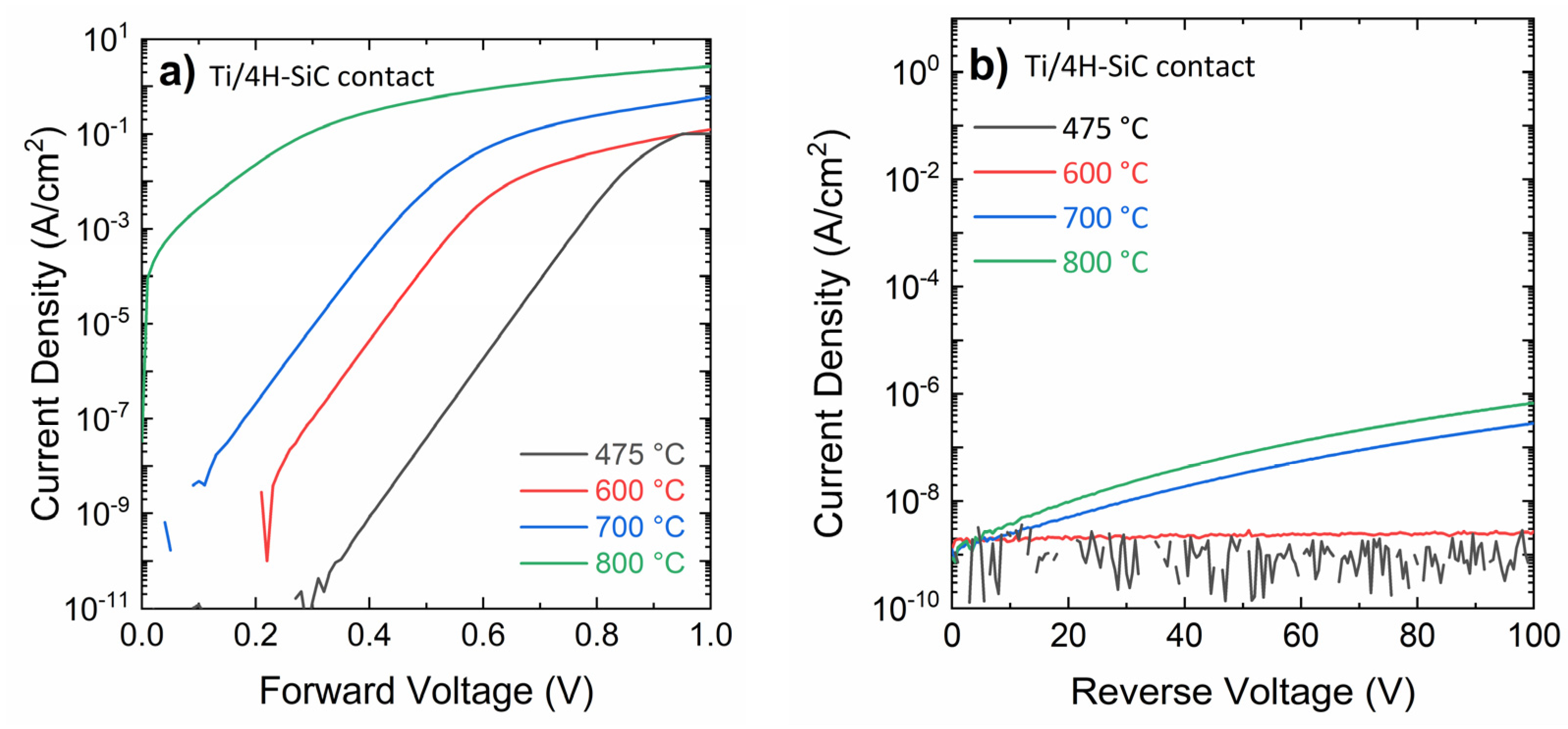

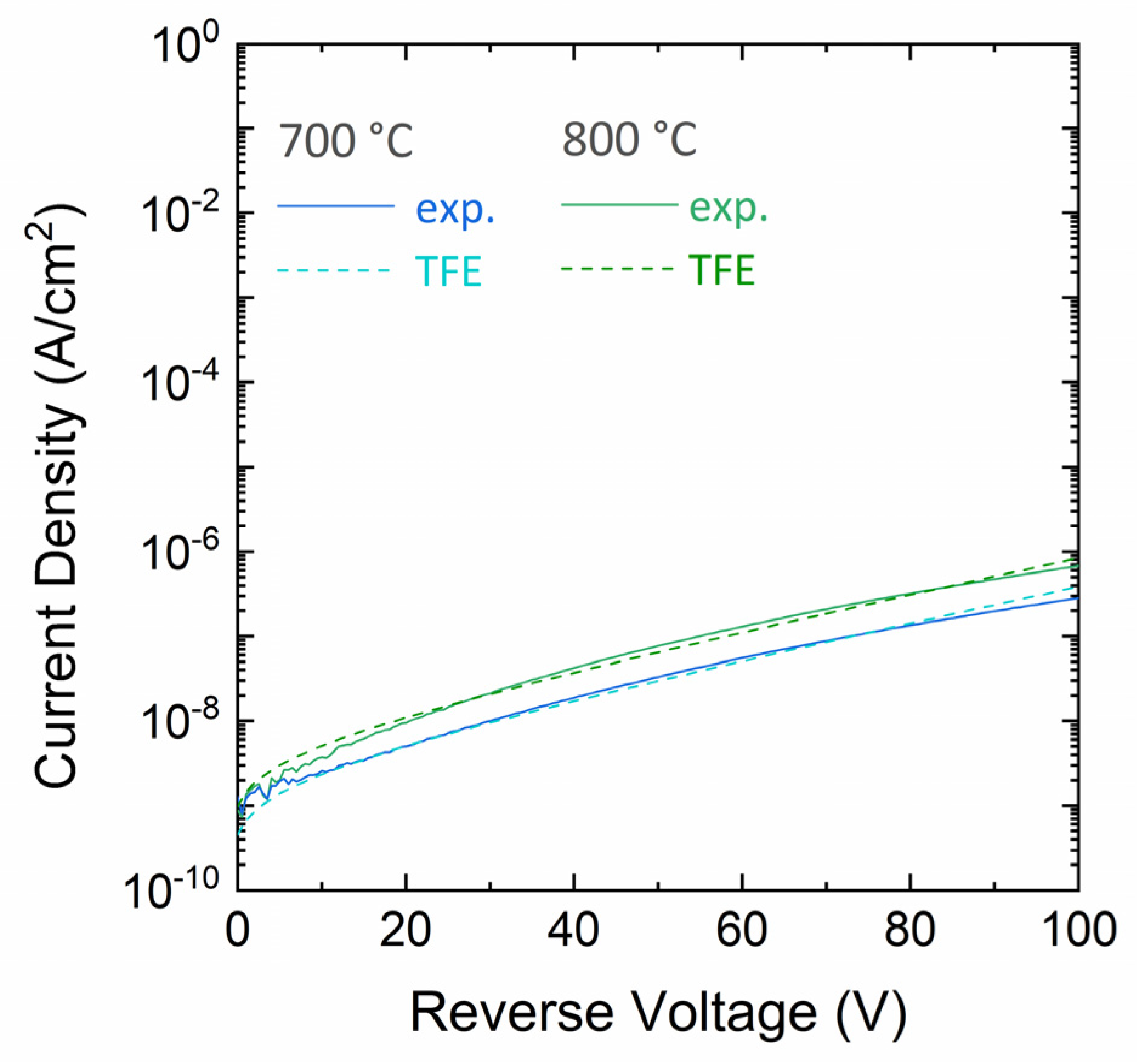

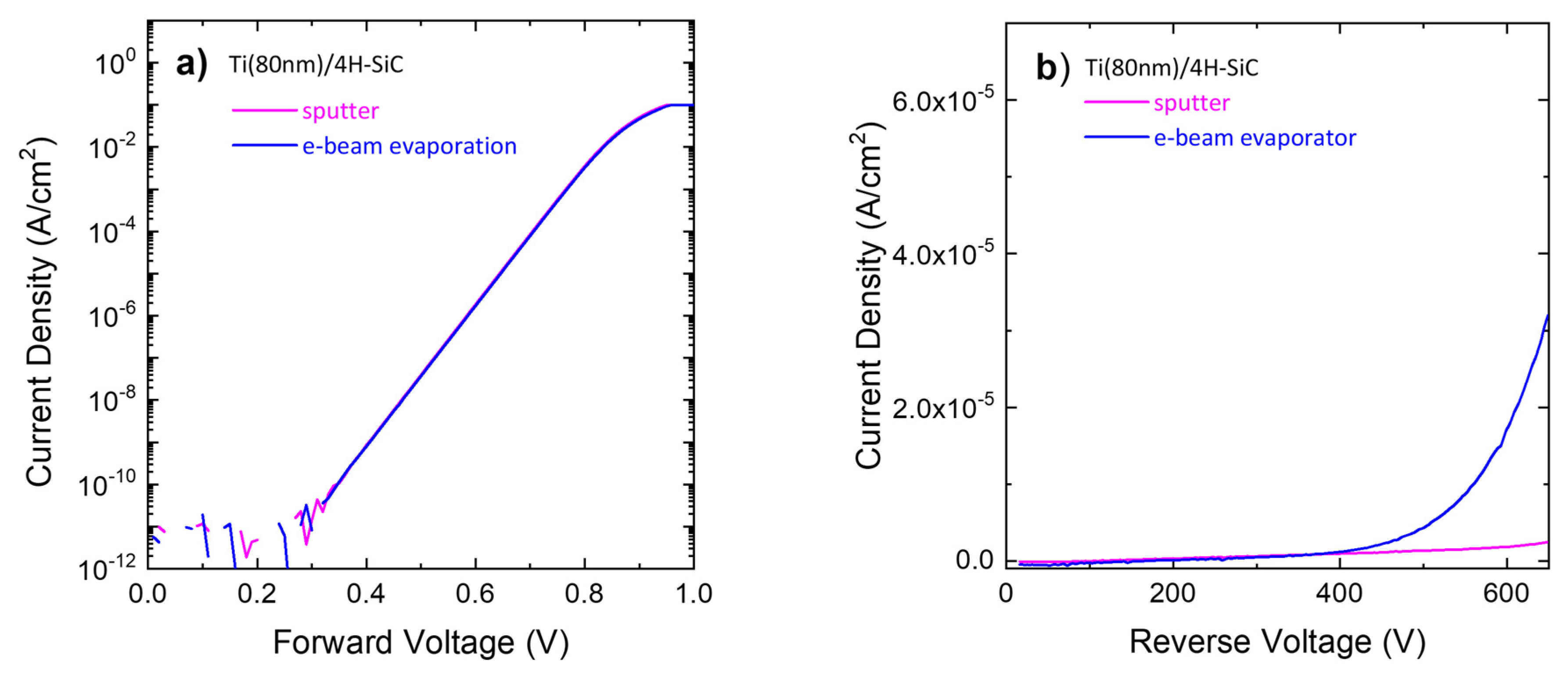

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kimoto, T. Material science and device physics in SiC technology for high-voltage power devices. Jpn. J. Appl. Phys. 2015, 54, 040103. [Google Scholar]

- Kimoto, T.; Cooper, J.A. Fundamentals of Silicon Carbide Technology; John Wiley & Sons Pte. Ltd.: Singapore, 2014. [Google Scholar]

- Chen, Y.; Liu, S.; Chen, S.; Yang, B. Diameter enlargement of SiC bulk single crystals based on simulation and experiment. Mater. Sci. Semicond. Proc. 2024, 178, 108414. [Google Scholar]

- Tsuchida, H.; Kanda, T. Advances in fast 4H–SiC crystal growth and defect reduction by high-temperature gas-source method. Mater. Sci. Semicond. Proc. 2024, 176, 108315. [Google Scholar]

- She, X.; Huang, A.Q.; She, X.; Huang, A.Q.; Lucía, Ó.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron 2017, 64, 8193–8205. [Google Scholar]

- Roccaforte, F.; Brezeanu, G.; Gammon, P.M.; Giannazzo, F.; Rascunà, S.; Saggio, M. Schottky contacts to silicon carbide: Physics, technology and applications. In Advancing Silicon Carbide Electronics Technology I; Zekentes, K., Vasilevskiy, K., Eds.; Materials Research Foundations LLC: Millersville, PA, USA, 2018; Volume 37, pp. 127–190. [Google Scholar]

- Vivona, M.; Giannazzo, F.; Roccaforte, F. Materials and Processes for Schottky Contacts on Silicon Carbide. Materials 2022, 15, 298. [Google Scholar] [CrossRef] [PubMed]

- Yakimova, R.; Hemmingsson, C.; Macmillan, M.F.; Yakimov, T.; Janzén, E. Barrier height determination for n-type 4H-SiC Schottky contacts made using various metals. J. Electron. Mater. 1998, 27, 871–875. [Google Scholar] [CrossRef]

- Perrone, D.; Naretto, M.; Ferrero, S.; Scaltrito, L.; Pirri, C.F. 4H-SiC Schottky Barrier Diodes Using Mo-, Ti- and Ni-Based Contacts. Mater. Sci. Forum 2009, 615–617, 647–650. [Google Scholar]

- Roccaforte, F.; La Via, F.; Raineri, V.; Pierobon, R.; Zanoni, E. Richardson’s constant in inhomogeneous silicon carbide Schottky contacts. J. Appl. Phys. 2003, 93, 9137–9144. [Google Scholar]

- Vivona, M.; Greco, G.; Bellocchi, G.; Zumbo, L.; Di Franco, S.; Saggio, M.; Rascunà, S.; Roccaforte, F. Electrical properties of inhomogeneous tungsten carbide Schottky barrier on 4H-SiC. J. Phys. D Appl. Phys. 2021, 54, 055101. [Google Scholar]

- Pristavu, G.; Brezeanu, G.; Pascu, R.; Drăghici, F.; Bădilă, M. Characterization of non-uniform Ni/4H-SiC Schottky diodes for improved responsivity in high-temperature sensing. Mater. Sci. Semicond. Process. 2019, 94, 64–69. [Google Scholar]

- Roccaforte, F.; Vivona, M.; Panasci, S.E.; Greco, G.; Fiorenza, P.; Sulyok, A.; Koos, A.; Bela, P.; Giannazzo, F. Schottky contacts on sulfurized silicon carbide (4H-SiC) surface. Appl. Phys. Lett. 2024, 124, 102102. [Google Scholar]

- Rupp, R.; Elpelt, R.; Gerlach, R.; Schomer, R.; Draghici, M. A new SiC diode with significantly reduced threshold voltage. In Proceedings of the 2017 29th International Symposium on Power Semiconductor Devices and IC’s (ISPSD), Sapporo, Japan, 28 May–1 June 2017; pp. 355–358. [Google Scholar]

- Geib, K.M.; Wilson, C.; Long, R.G.; Wilmsen, C.W. Reaction between SiC and W, Mo, and Ta at elevated temperatures. J. Appl. Phys. 1990, 68, 2796–2800. [Google Scholar]

- Zhang, T.; Raynaud, C.; Planson, D. Measure and analysis of 4H-SiC Schottky barrier height with Mo contacts. Eur. Phys. J. Appl. Phys. 2019, 85, 10102. [Google Scholar]

- Ouennoughi, Z.; Toumi, S.; Weiss, R. Study of barrier inhomogeneities using I–V–T characteristics of Mo/4H–SiC Schottky diode. Phys. B Condens. Matter 2015, 456, 176–181. [Google Scholar]

- Berthou, M.; Godignon, P.; Montserrat, J.M.; Millan, J.D.R.; Planson, D. Study of 4H-SiC JBS Diodes Fabricated with Tungsten Schottky Barrier. J. Electron. Mater. 2011, 40, 2355–2362. [Google Scholar]

- Hamida, A.F.; Ouennoughi, Z.; Sellai, A.; Weiss, R.; Ryssel, H. Barrier inhomogeneities of tungsten Schottky diodes on 4H-SiC. Semicond. Sci. Technol. 2008, 23, 045005. [Google Scholar]

- Vivona, M.; Bellocchi, G.; Nigro, R.L.; Rascunà, S.; Roccaforte, F. Electrical evolution of W and WC Schottky contacts on 4H-SiC at different annealing temperatures. Semicond. Sci. Technol. 2022, 37, 015012. [Google Scholar]

- Bellocchi, G.; Vivona, M.; Bongiorno, C.; Badalà, P.; Bassi, A.; Rascuna, S.; Roccaforte, F. Barrier height tuning in Ti/4H-SiC Schottky diodes. Solid-State Electron. 2021, 186, 108042. [Google Scholar]

- Hara, M.; Kaneko, M.; Kimoto, T. Nearly Fermi-level-pinning-free interface in metal/heavily-doped SiC Schottky structures. Jpn. J. Appl. Phys. 2021, 60, SBBD14. [Google Scholar]

- Roccaforte, F.; Vivona, M.; Greco, G.; Lyle, L.A.M.; Sarkar, B.; Porter, L.M. Contacts to wide band gap (WBG) and ultra-wide band gap (UWBG) semiconductors for power electronics devices. In Comprehensive Semiconductor Science and Technology, 2nd ed.; Fornari, R., Ed.; Elsevier: London, UK, 2025; Volume 2, pp. 605–665. [Google Scholar] [CrossRef]

- Nakamura, T.; Miyanagi, T.; Kamata, I.; Jikimoto, T.; Tsuchida, H. A 4.15 kV 9.07-Ω cm2 4H-SiC Schottky-barrier diode using Mo contact annealed at high temperature. IEEE Electron. Device Lett. 2005, 26, 99–101. [Google Scholar]

- Oder, T.N.; Kundeti, K.C.; Borucki, N.; Isukapati, S.B. Effects of deposition temperature on the electrical properties of Ti/SiC Schottky barrier diodes. AIP Adv. 2017, 7, 125311. [Google Scholar]

- Kim, D.H.; Lee, J.H.; Moon, J.H.; Oh, M.S.; Song, H.K.; Yim, J.H.; Lee, J.B.; Kim, H.J. Improvement of the reverse characteristics of Ti/4H-SiC Schottky barrier diodes by thermal treatments. Solid State Phenom. 2007, 124–126, 105–108. [Google Scholar]

- Vassilevski, K.V.; Horsfall, A.B.; Johnson, C.M.; Wright, N.G.; O’Neill, A.G. 4H-SiC Rectifiers with Dual Metal Planar Schottky Contacts. IEEE Trans. Electron. Dev. 2022, 49, 947–949. [Google Scholar]

- Alexandrov, P.; Wright, W.; Pan, M.; Weiner, M.; Jiao, L.; Zhao, J.H. Demonstration of high voltage (600–1300 V), high current (10–140 A), fast recovery 4H-SiC p-i-n/Schottky (MPS) barrier diodes. Solid-State Electron. 2003, 47, 263–269. [Google Scholar]

- Singh, R.; Capell, D.C.; Hefner, A.R.; Lai, J.; Palmour, J.W. High-power 4H-SiC JBS rectifiers. IEEE Trans. Electron. Devices 2002, 49, 2054–2063. [Google Scholar]

- Dahlquist, F.; Lendenmann, H.; Östling, M. A High Performance JBS Rectifier—Design Considerations. Mater. Sci. Forum 2001, 353–356, 683–686. [Google Scholar]

- Sze, S.M.; Kwok, K.N. Physics of Semiconductor Devices; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Treu, M.; Rupp, R.; Kapels, H.; Bartsch, W. Temperature Dependence of Forward and Reverse Characteristics of Ti, W, Ta and Ni Schottky Diodes on 4H-SiC. Mater. Sci. Forum 2001, 353–356, 679–682. [Google Scholar]

- Padovani, F.A.; Stratton, R. Field and thermionic-field emission in Schottky barriers. Solid-State Electron. 1966, 9, 695–707. [Google Scholar]

- Kocher, M.; Rommel, M.; Michalowski, P.; Erlbacher, T. Mechanisms of Ohmic Contact Formation of Ti/Al-Based Metal Stacks on p-Doped 4H-SiC. Materials 2022, 15, 50. [Google Scholar]

- Frazzetto, A.; Giannazzo, F.; Lo Nigro, R.; Di Franco, S.; Bongiorno, C.; Saggio, M.; Zanetti, E.; Raineri, V.; Roccaforte, F. Nanoscale electro-structural characterisation of ohmic contacts formed on p-type implanted 4H-SiC. Nanoscale Res. Lett. 2011, 6, 158. [Google Scholar]

- Frazzetto, A.; Giannazzo, F.; Lo Nigro, R.; Raineri, V.; Roccaforte, F. Structural and transport properties in alloyed Ti/Al Ohmic contacts formed on p-type Al-implanted 4H-SiC annealed at high temperature. J. Phys. D: Appl. Phys. 2011, 44, 255302. [Google Scholar] [CrossRef]

- Abi-Tannous, T.; Soueidan, M.; Ferro, G.; Lazar, M.; Toury, B.; Beaufort, M.F.; Barbot, J.F.; Penuelas, J.F.; Planson, D. Parametric investigation of the formation of epitaxial Ti3SiC2 on4H-SiC from Al-Ti annealing. Appl. Surf. Sci. 2015, 347, 186–192. [Google Scholar] [CrossRef]

- Shilpa, A.; Murty, N.V.L.N. Alphavoltaic Performance of 4H-SiC Schottky Barrier Diodes. IEEE Trans. Nucl. Sci. 2024, 71, 2507–2514. [Google Scholar] [CrossRef]

- Hernández-Acosta, M.A.; Martínez-Gutiérrez, H.; Martínez-González, C.L.; Torres-SanMiguel, C.R.; Trejo-Valdez, M.; Torres-Torres, C. Fractional and chaotic electrical signatures exhibited by random carbon nanotube networks. Phys. Scr. 2018, 93, 125801. [Google Scholar] [CrossRef]

- Ramzan, M.W.; Riaz, K.; Mehmood, M.Q.; Zubair, M.; Massoud, Y. Generalized fractional Wentzel–Kramers–Brillouin approximation for electron tunnelling across rough metal interface. Proc. R. Soc. A 2023, 479, 20220600. [Google Scholar] [CrossRef]

- Tung, R.T. Electron transport at metal-semiconductor interfaces: General theory. Phys. Rev. B 1992, 45, 13509–13523. [Google Scholar] [CrossRef]

- Werner, J.H.; Güttler, H.H. Barrier inhomogeneities at Schottky contacts. J. Appl. Phys. 1991, 69, 1522–1533. [Google Scholar] [CrossRef]

| Metal (Thickness) | Contact Fabrication Conditions | ΦB | Reference |

|---|---|---|---|

| Ti (n.r.) | e-beam evaporation, annealing at 500 °C and 600 °C; for 10 min in Ar | 1.15–1.22 eV | [24] |

| Ti (200 nm) | Sputter deposition with substrate T ranging from 28 °C to 500 °C; annealing for 60 h at 500 °C in vacuum | 0.83–1.13 eV | [25] |

| Ti (100 nm) | e-gun evaporation, annealing at 500 °C and 750 °C for 2 min in N2 | 1.23–1.33 eV | [26] |

| Ti (100 nm) | Deposition, annealing at 450 °C and 650 °C for 0.5 and 1 h in vacuum | 1.27 eV | [27] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vivona, M.; Bellocchi, G.; Puglisi, V.; Bongiorno, C.; Adamo, S.; Giannazzo, F.; Rascunà, S.; Roccaforte, F. Impact of Processing Parameters on Ti Schottky Contacts on 4H-SiC. Materials 2025, 18, 1447. https://doi.org/10.3390/ma18071447

Vivona M, Bellocchi G, Puglisi V, Bongiorno C, Adamo S, Giannazzo F, Rascunà S, Roccaforte F. Impact of Processing Parameters on Ti Schottky Contacts on 4H-SiC. Materials. 2025; 18(7):1447. https://doi.org/10.3390/ma18071447

Chicago/Turabian StyleVivona, Marilena, Gabriele Bellocchi, Valeria Puglisi, Corrado Bongiorno, Salvatore Adamo, Filippo Giannazzo, Simone Rascunà, and Fabrizio Roccaforte. 2025. "Impact of Processing Parameters on Ti Schottky Contacts on 4H-SiC" Materials 18, no. 7: 1447. https://doi.org/10.3390/ma18071447

APA StyleVivona, M., Bellocchi, G., Puglisi, V., Bongiorno, C., Adamo, S., Giannazzo, F., Rascunà, S., & Roccaforte, F. (2025). Impact of Processing Parameters on Ti Schottky Contacts on 4H-SiC. Materials, 18(7), 1447. https://doi.org/10.3390/ma18071447