3.3.4. Simulation Result Analysis

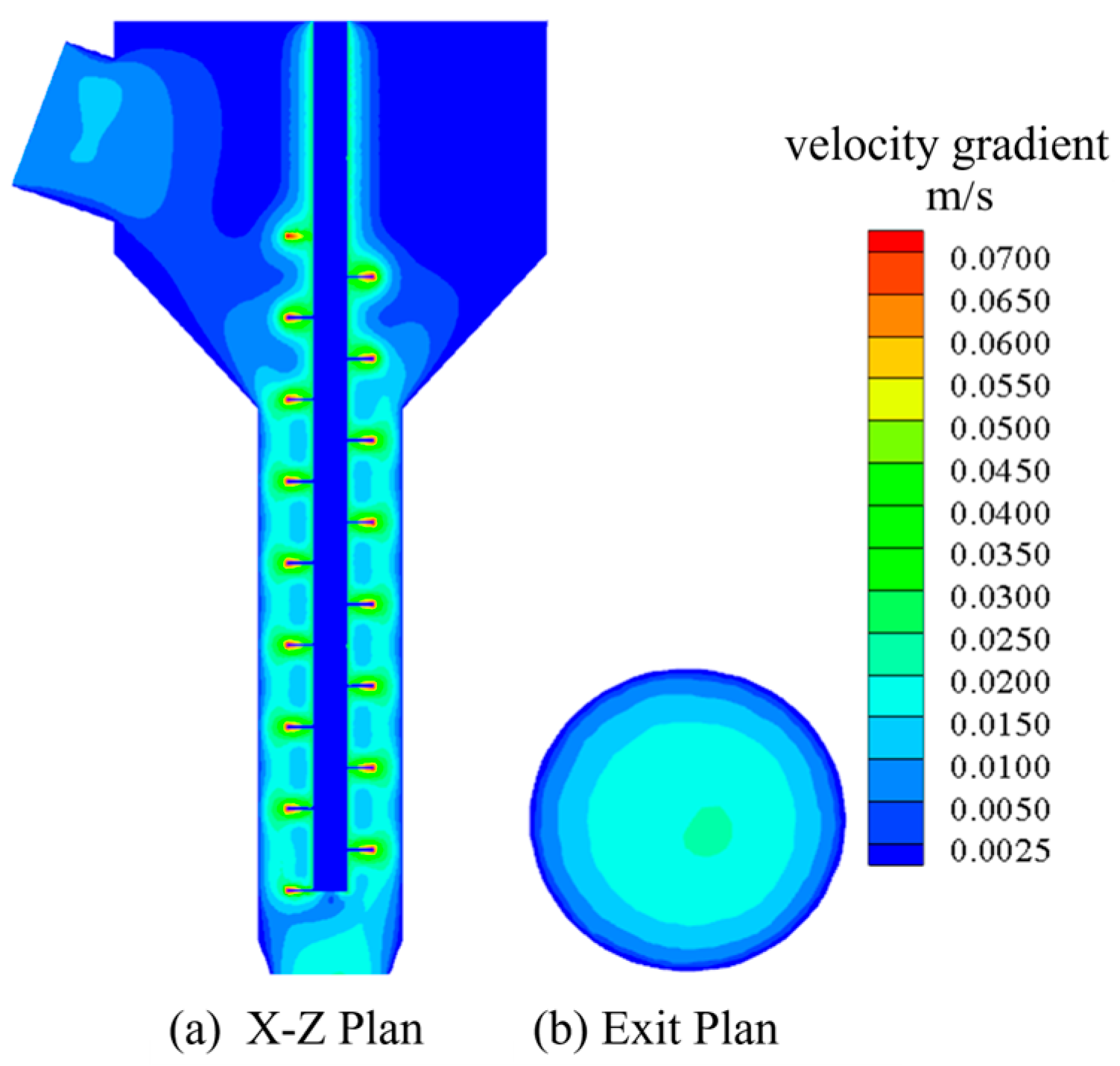

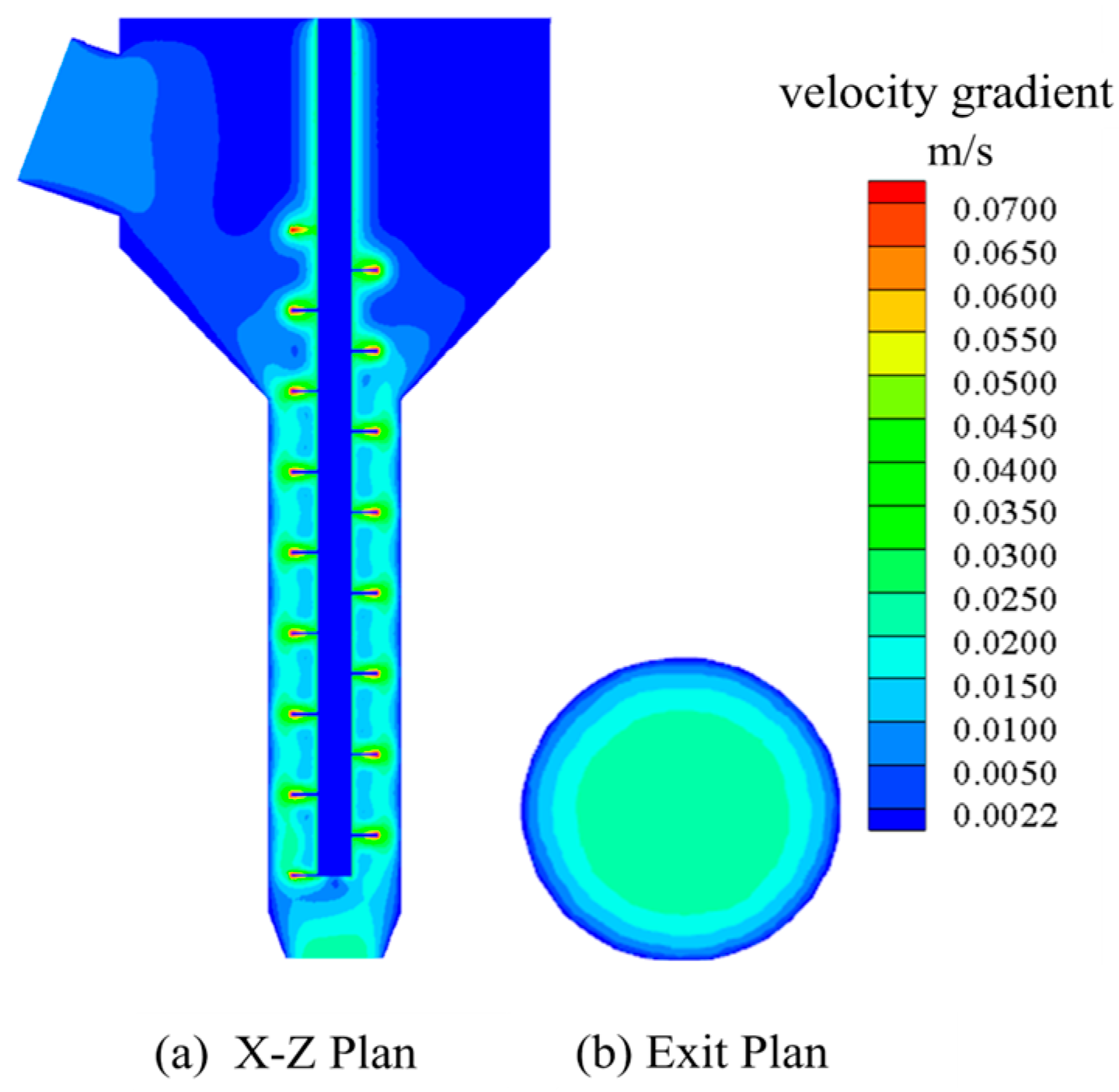

Figure 11 presents the simulation results of Group 1. Specifically,

Figure 11a presents the velocity cloud image perpendicular to the plane at the exit section, and

Figure 11b presents the velocity cloud image at the exit section. It can be seen in

Figure 11 that the flow velocity of concrete slurry from inlet to outlet gradually increases first and then decreases gradually. In the case of rotation of the screw, the velocity of the slurry near the screw is larger because the slurry has a certain viscosity. When the screw is agitated, the slurry near the screw will experience shear, and the movement will be carried out under the action of gravity and shear force. Meanwhile, the shear force of the slurry far from the surface of the screw will gradually decrease, so the velocity of the slurry closer to the surface of the screw will be greater. In addition, it can be seen in

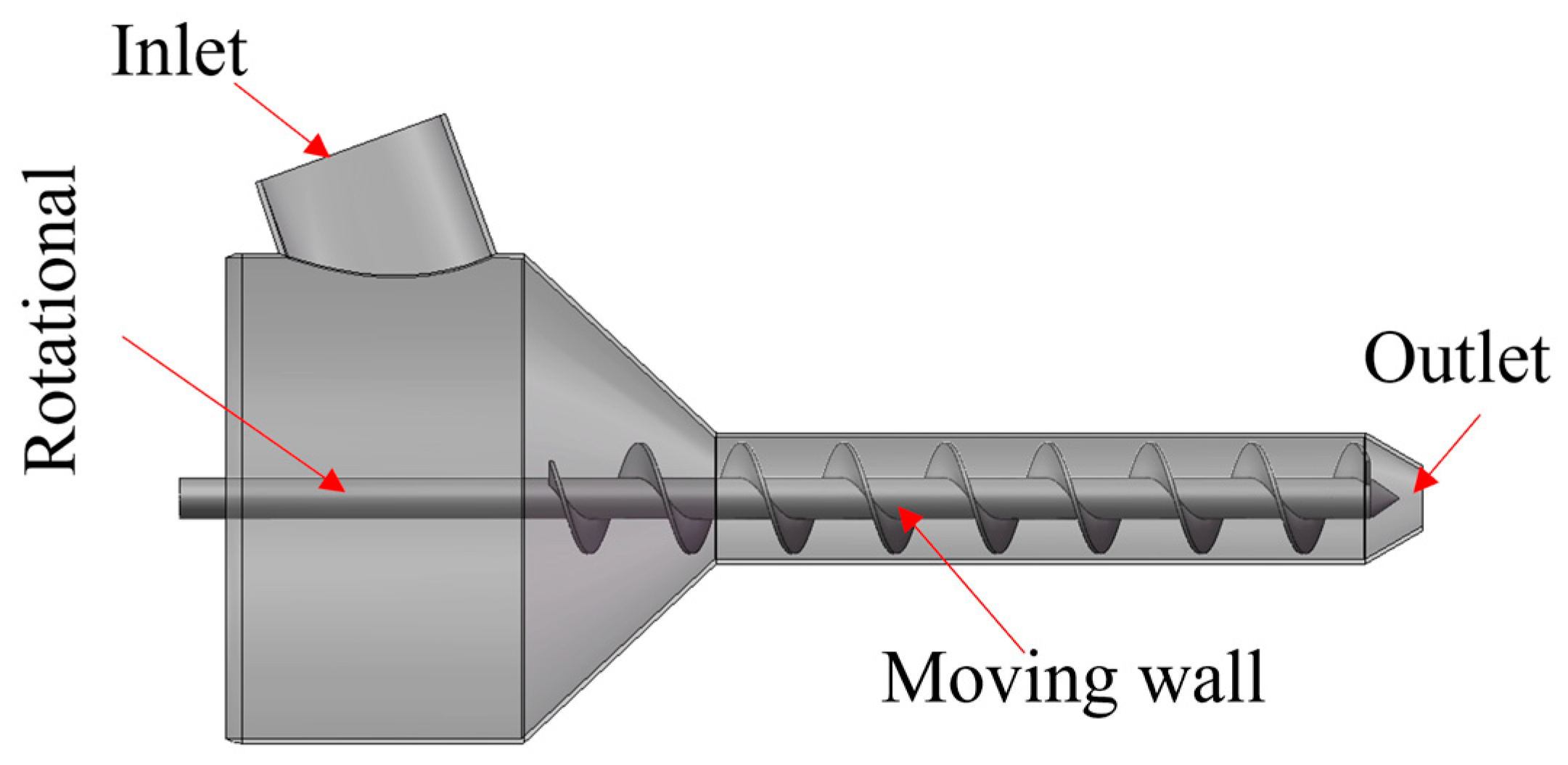

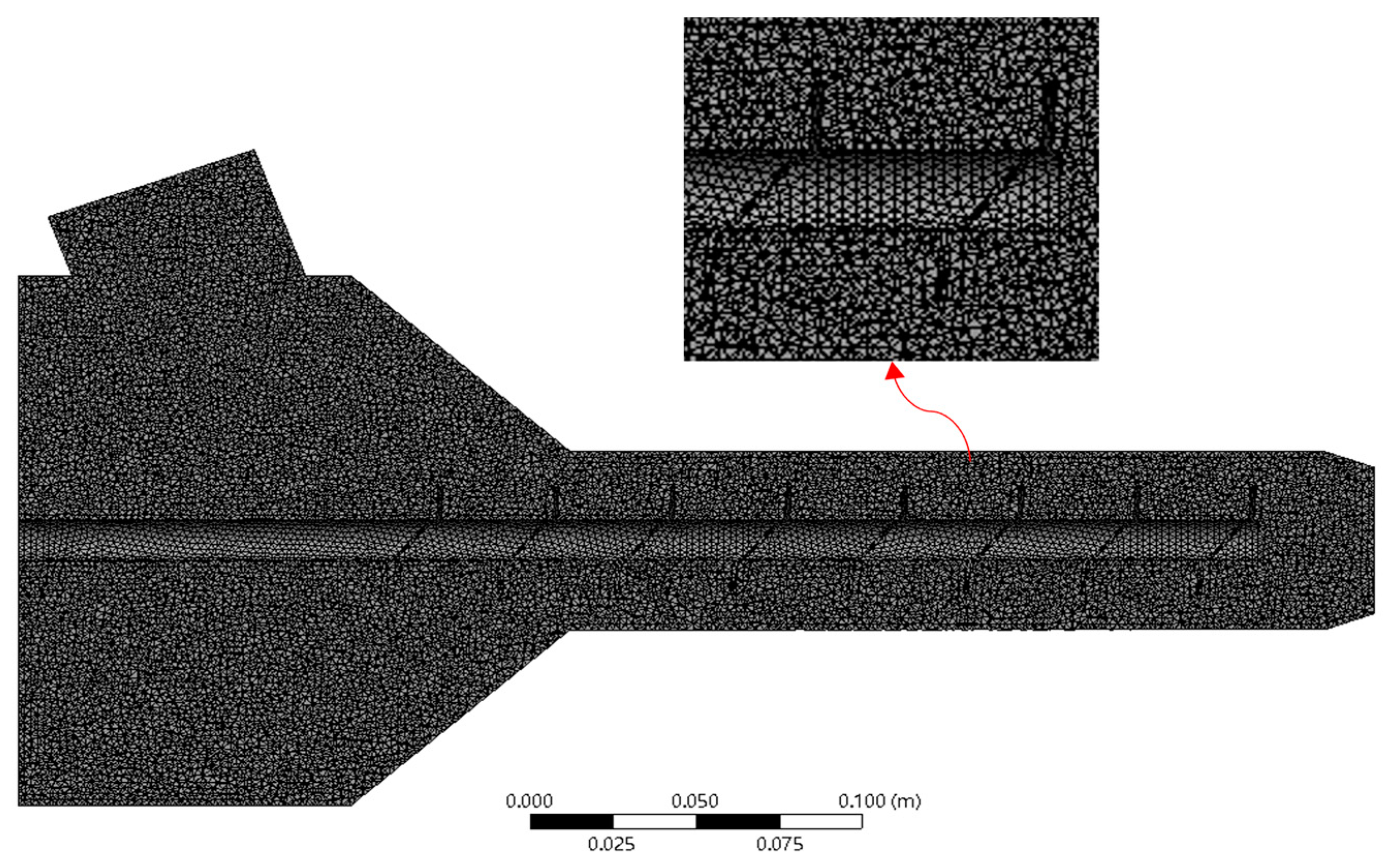

Figure 7 that the velocity distribution of the concrete slurry in the conveying section of the screw has almost no obvious change, which indicates that the screw can keep the speed stable during the extrusion of the slurry and play a certain role in speed regulation.

Figure 12 presents the velocity cloud diagram of the exit section of the other 12 groups of simulation results. It can be seen that there are some differences in the simulation results of different parameter combinations. However, in general, the exit velocity gradually decreases from the center to the outside, with the maximum velocity appearing at the exit center and the minimum velocity appearing at the exit wall. This is because the friction force of the inner wall of the nozzle when the concrete is extruded from the nozzle is encountered. As a result, the concrete speed near the inner wall of the nozzle is smaller, and the speed at the center is larger, resulting in uneven speed at the exit.

In order to make the velocity at the exit section as uniform as possible, the standard deviation of the velocity at each group of exit sections is extracted, which is used as the optimization objective. The smaller the standard deviation is, the more uniform the velocity is. This can ensure the more uniform the velocity of the exit section when the concrete is extruded from the nozzle and ensure the print quality. The orthogonal test results of each group are shown in

Table 6.

3.3.5. Optimization of Printing Nozzle Structure Parameters

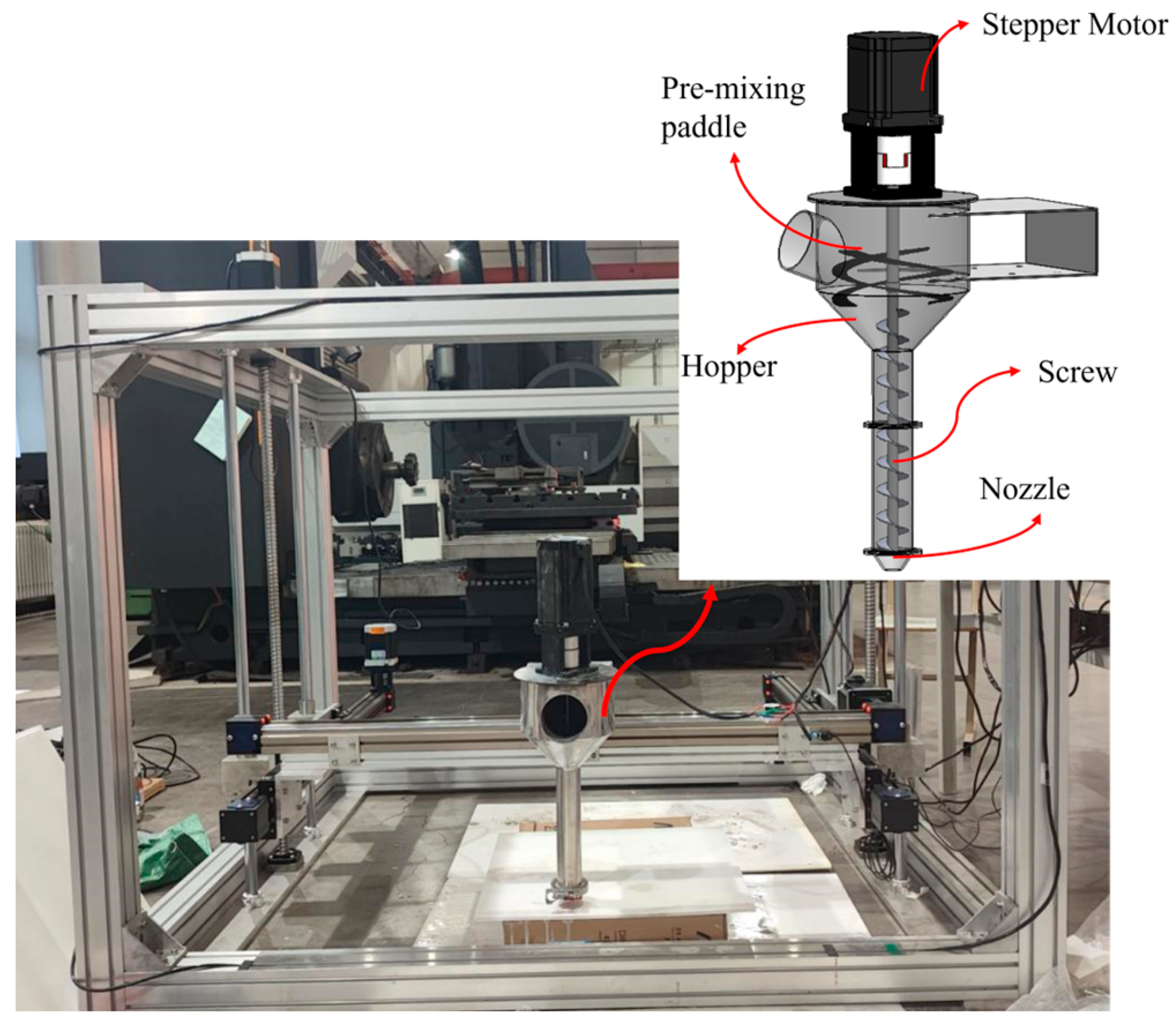

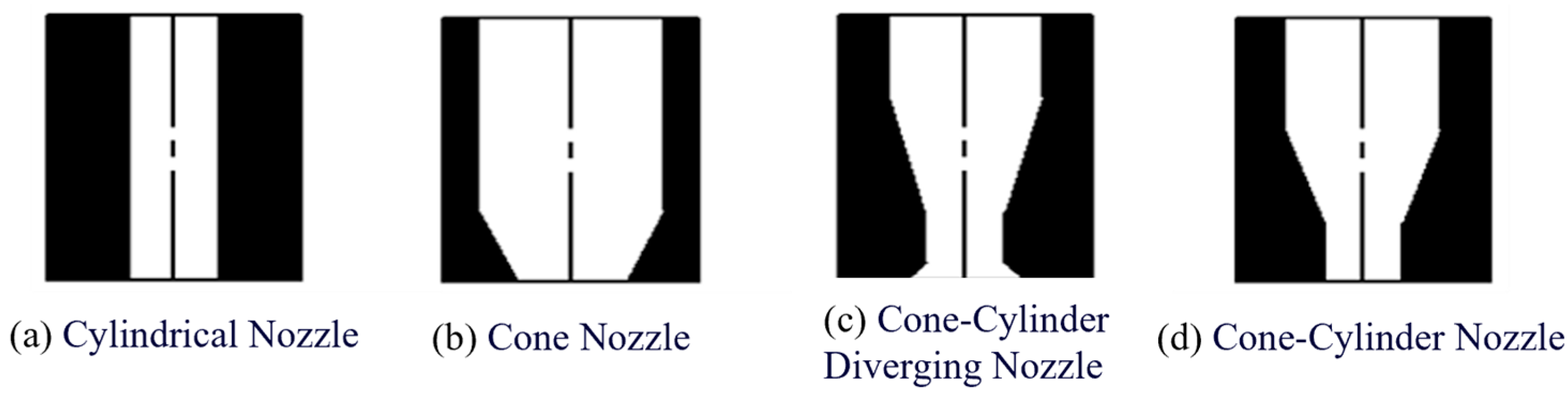

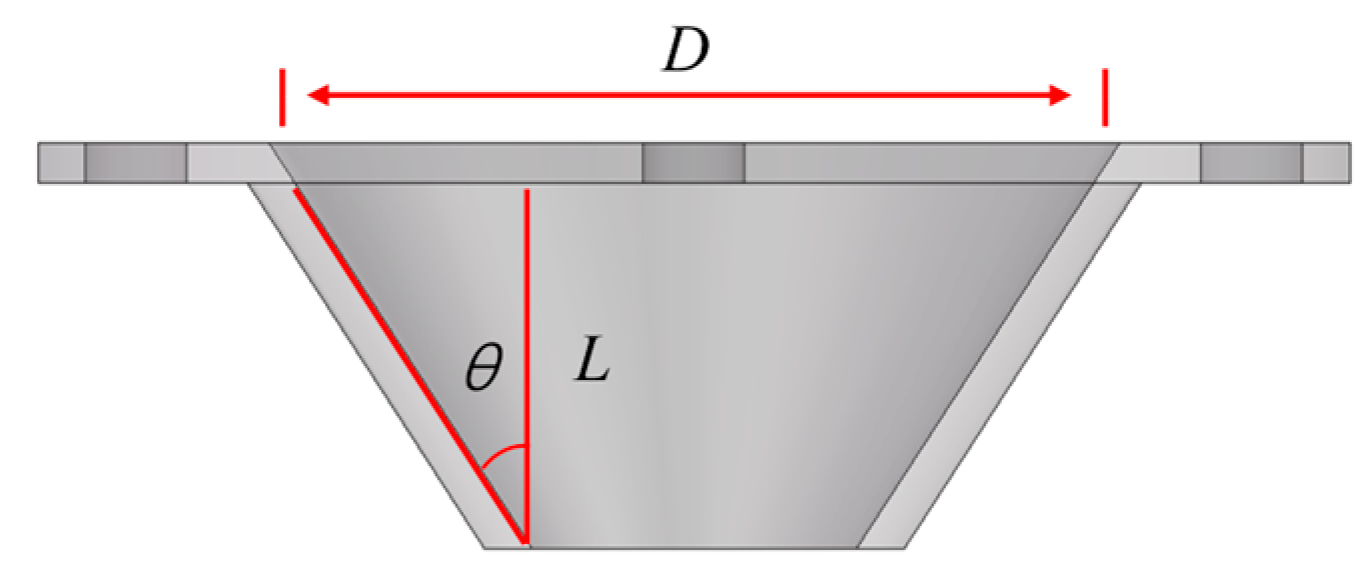

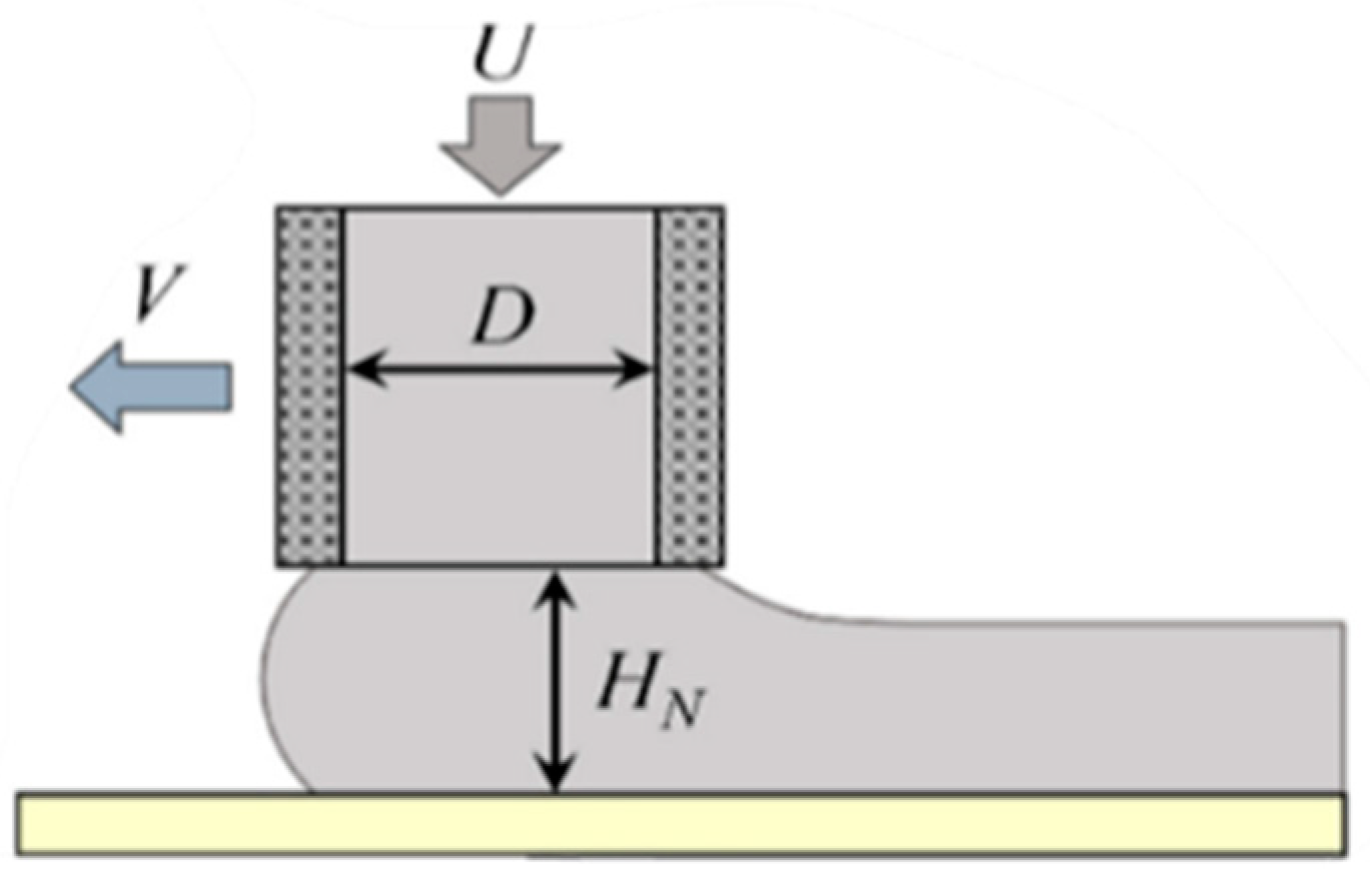

It can be seen in

Figure 7 that the extrusion system has three important parameters, including inlet diameter

D, nozzle inclination angle

θ, and outlet length

L, which determine the extrusion characteristics of the nozzle. This paper adopts response surface methodology to optimize the nozzle structure.

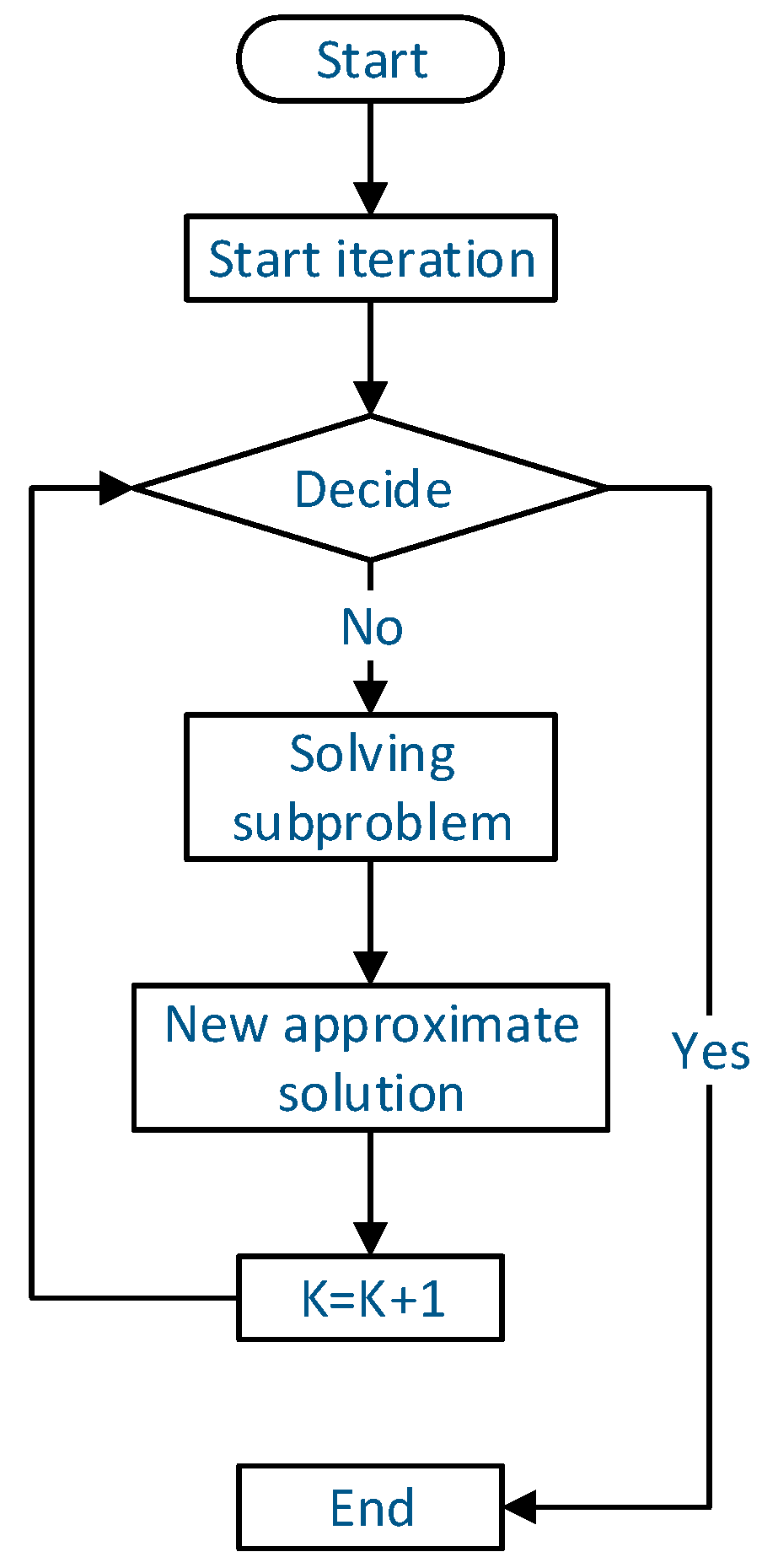

The sequential quadratic programming (SQP) algorithm is an effective algorithm for solving constrained optimization problems of small- and medium-sized programs. Its basic idea is to transform nonlinear optimization problems into a series of quadratic programming subproblems and gradually approach the optimal solution of the original equation by solving these subproblems, as expressed below [

19]:

Its solution process is shown in

Figure 13. Here,

is the iteration point of the current problem, and the linear programming subproblem is obtained by linearization near the current iteration point. The search direction

of the current iteration point is obtained by solving the subproblem, and the step

is determined. The next iteration point

is updated according to the search direction, and the values of the new objective function and constraint function are calculated. Then, it is determined whether the stop criterion is met. If it is met, the iteration will be stopped; otherwise, return to the first step to continue the iteration [

20].

Input the extracted results of the speed standard deviations for each group into the Design-Expert 11 software and then proceed to analyze the data. Various models were utilized to fit the data, and the model with the smallest fitting error was selected. The fitting results for each model are presented in

Table 7 below.

It can be seen in

Table 4 that the 2FI model has high fitting and prediction accuracy at the same time. Therefore, the 2FI model is selected to fit the data, and the influence of three factors, namely, inlet diameter

D, nozzle inclination

θ and outlet length

L, on the standard deviation Std

V of the exit section velocity of the response value is analyzed. The equation after fitting the 2FI model is as follows:

where

ABC represents the inlet diameter

D, the nozzle inclination angle

θ, and the outlet length

L, respectively. The results of ANOVA fitting are shown in

Table 8.

From Equation (6), it can be seen that the coefficient of C is the largest, and the coefficients of A and B have a small difference, indicating that the outlet length L has the greatest influence on the standard deviation of the outlet section velocity, followed by the inlet diameter D. The nozzle inclination angle θ has the least influence.

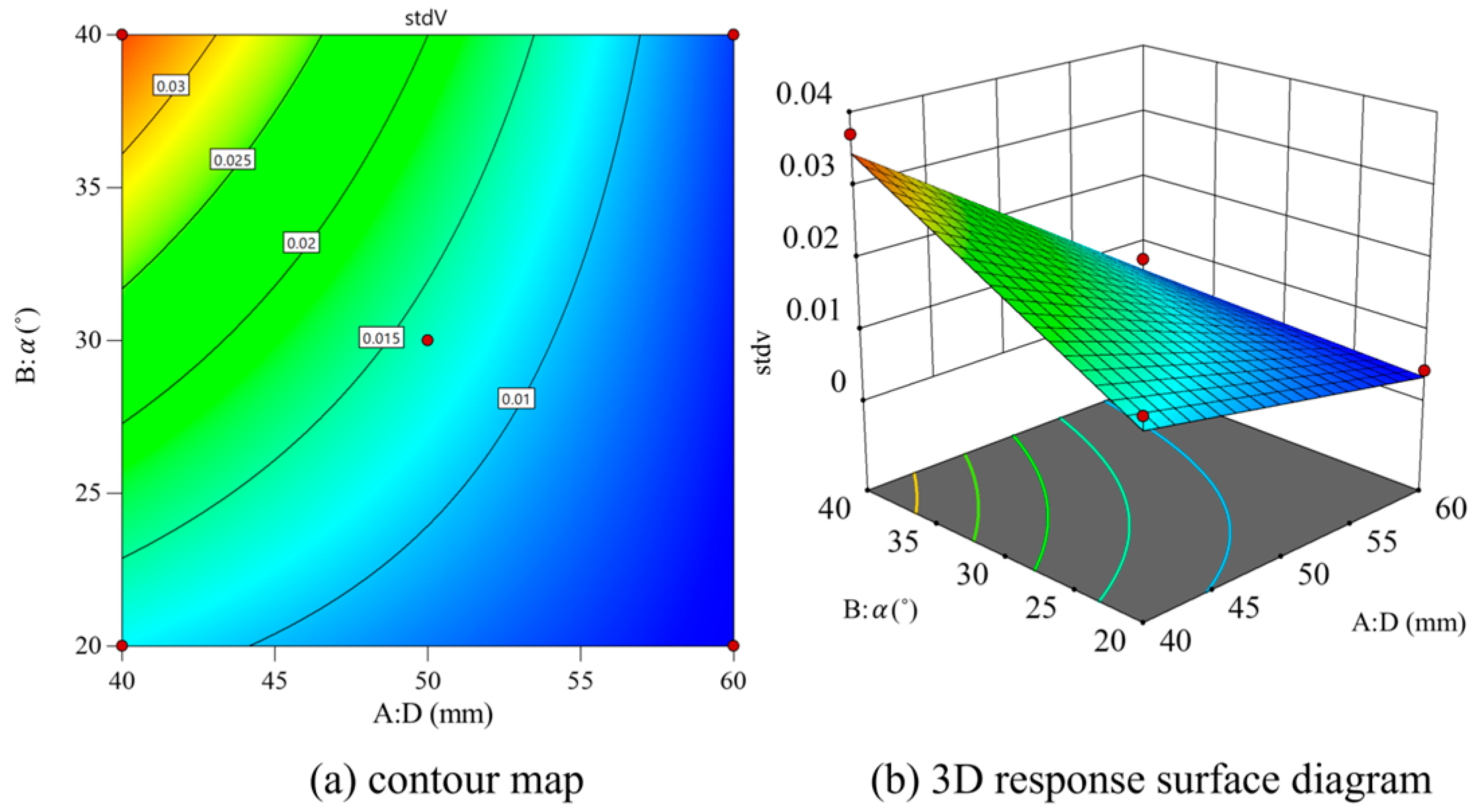

With

D and

θ as variables, and the values of

L fixed, contour and 3D surface maps are drawn as shown in

Figure 14. As the inlet diameter increases, the standard deviation of exit section velocity Std

V gradually decreases. In addition, Std

V increases gradually with the increase in nozzle inclination. As can be seen in the 3D surface diagram, Std

V can be significantly reduced when the inlet diameter is small. When the inlet diameter exceeds 50 mm, Std

V decreases more and more slowly. On the contrary, Std

V can be significantly reduced under a larger nozzle inclination.

With

D and

L as variables, and the

θ values fixed, contour and 3D surface maps were drawn as shown in

Figure 15. Std

V gradually increased with the increase in inlet diameter, and Std

V gradually increased with the increase in

L. It can be seen in the 3D response surface diagram that the outlet length can reduce Std

V in small cases; however, Std

V increases more obviously when the nozzle length increases.

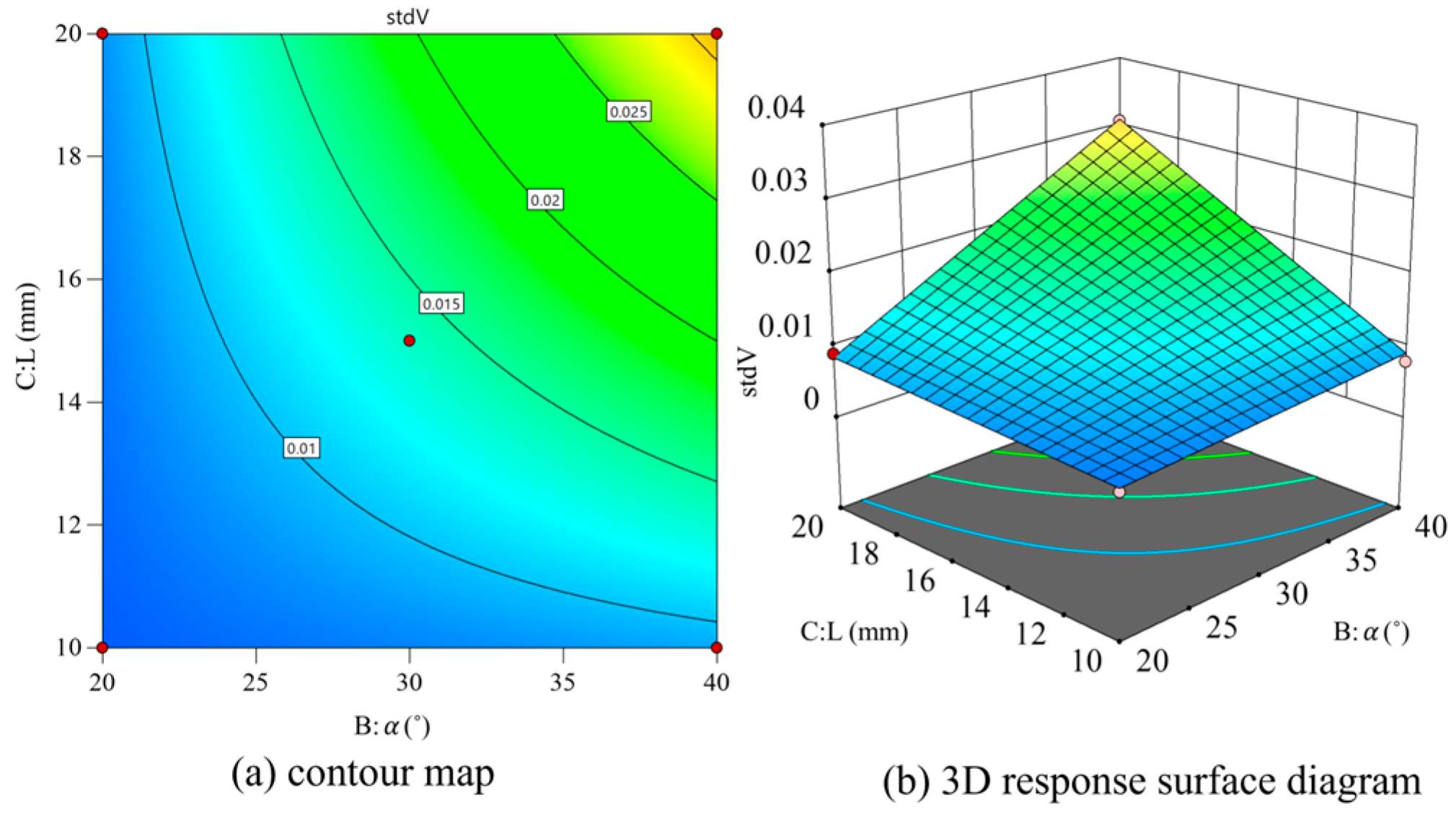

With

θ and

L as variables and fixed

D values, contour and 3D surface maps are drawn as shown in

Figure 16. Std

V gradually increases with the increase in the nozzle inclination angle and outlet length. As can be seen in the 3D response surface diagram, Std

V can be significantly increased when the nozzle inclination and outlet length are both large values. When they are gradually reduced, Std

V also gradually decreases, and the reduction amplitude is gradually smaller.

The optimization of printing nozzle parameters is a multi-variable, constrained, and nonlinear minimization problem. In order to make the extruded concrete more uniform, the optimization goal is to minimize the velocity standard deviation of the exit section. Then the objective function is expressed as follows:

The value range of inlet diameter

D, nozzle inclination angle

θ, and outlet length

L is expressed as follows:

In addition, the value of Std

V should be positive, so the value range of

std V is expressed as follows:

Input the fitted equation for the velocity standard deviation of the exit section, along with the value range of each parameter, into the Optimization Toolbox in MATLAB R2022b to solve this problem. Set the initial point as (40, 30, 20), and obtain the optimal solution as follows: D = 55 mm, θ = 20°, L = 34 mm. Here, the objective function value Std V is 1.9 × 10−3.

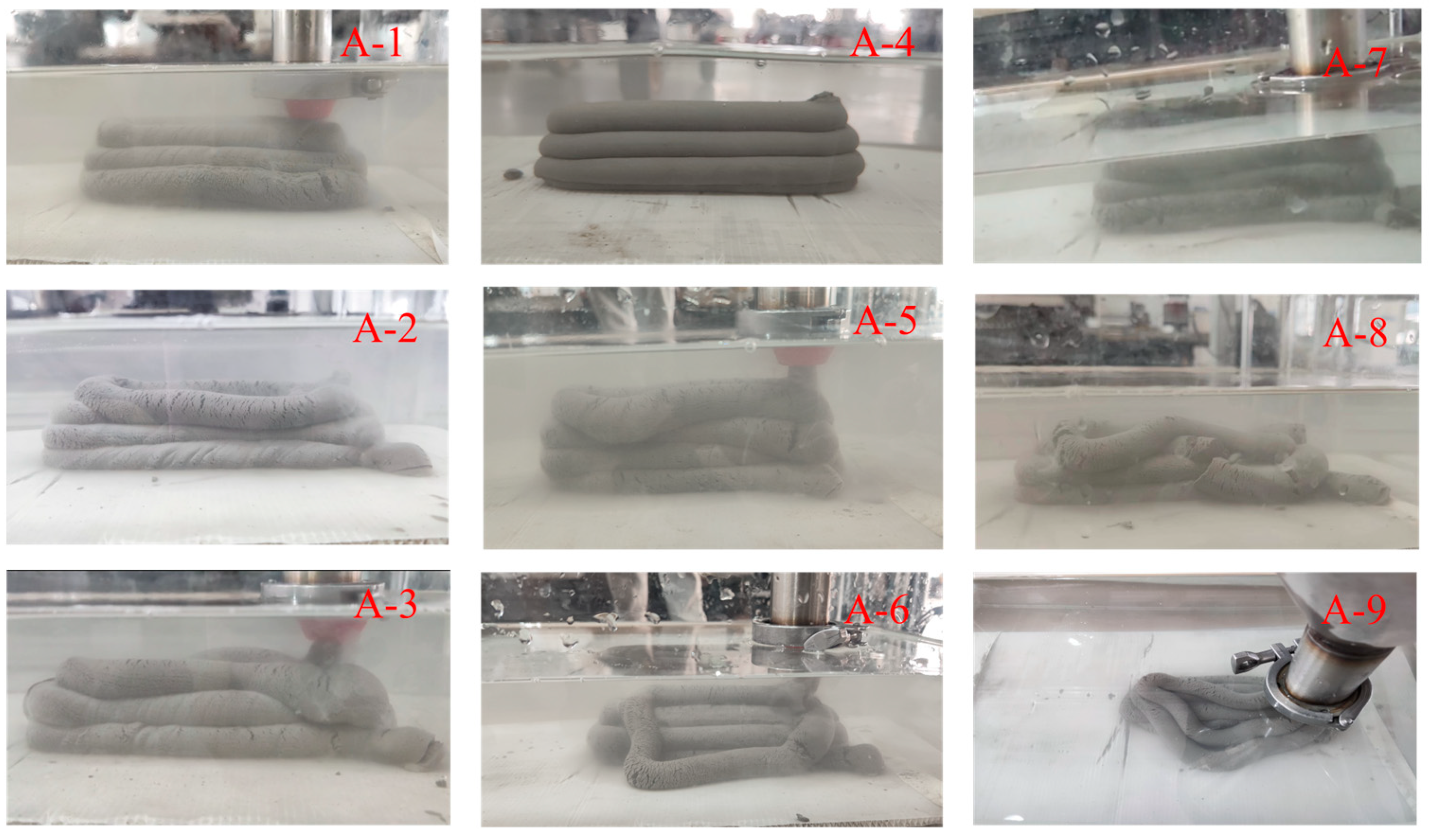

The extrusion mechanism model with optimal structural parameters was established for simulation, and the parameter settings were the same as above. The calculation results of optimal structural parameters are shown in

Figure 17 below.

Figure 17a shows the velocity distribution of the X-Z plane section, and

Figure 17b shows the velocity distribution of the exit section. The velocity standard deviation of the exit section was extracted and compared with the group with the smallest velocity standard deviation in

Table 3. The comparison results are shown in

Table 9.

It can be seen in

Table 6 that the velocity variance of the exit section of the optimized scheme is smaller than the result of the optimal scheme in the test in

Table 9. Specifically, it is reduced by 34.8%, which indicates that the optimization of nozzle structure parameters using this method is effective.