Electrospun Silver-Modified PZT/PVDF Composites for High-Performance Piezoelectric Energy Harvester

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of pPZT@Ag

2.3. Preparation of pPZT@Ag/PVDF PEHs

2.4. Characterization

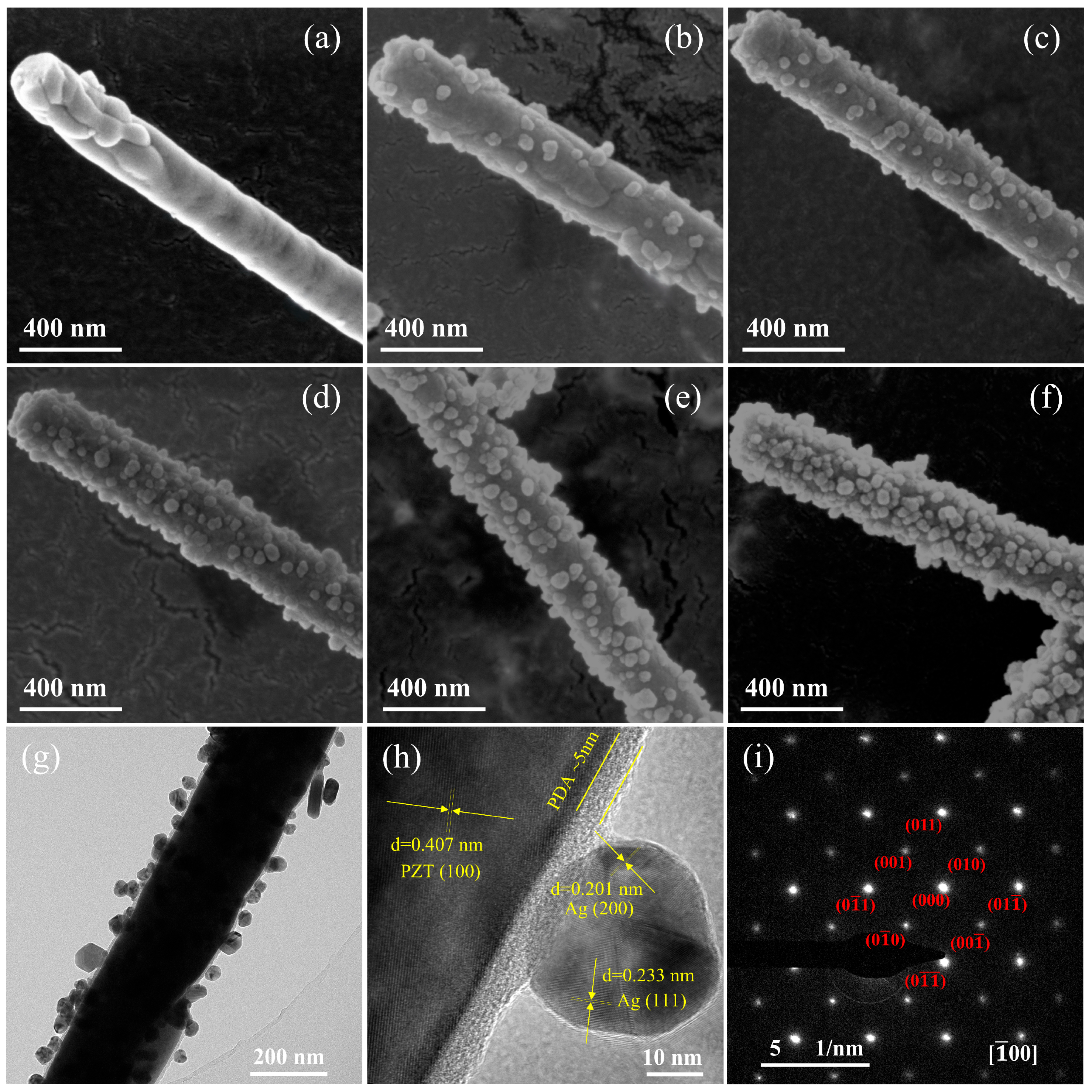

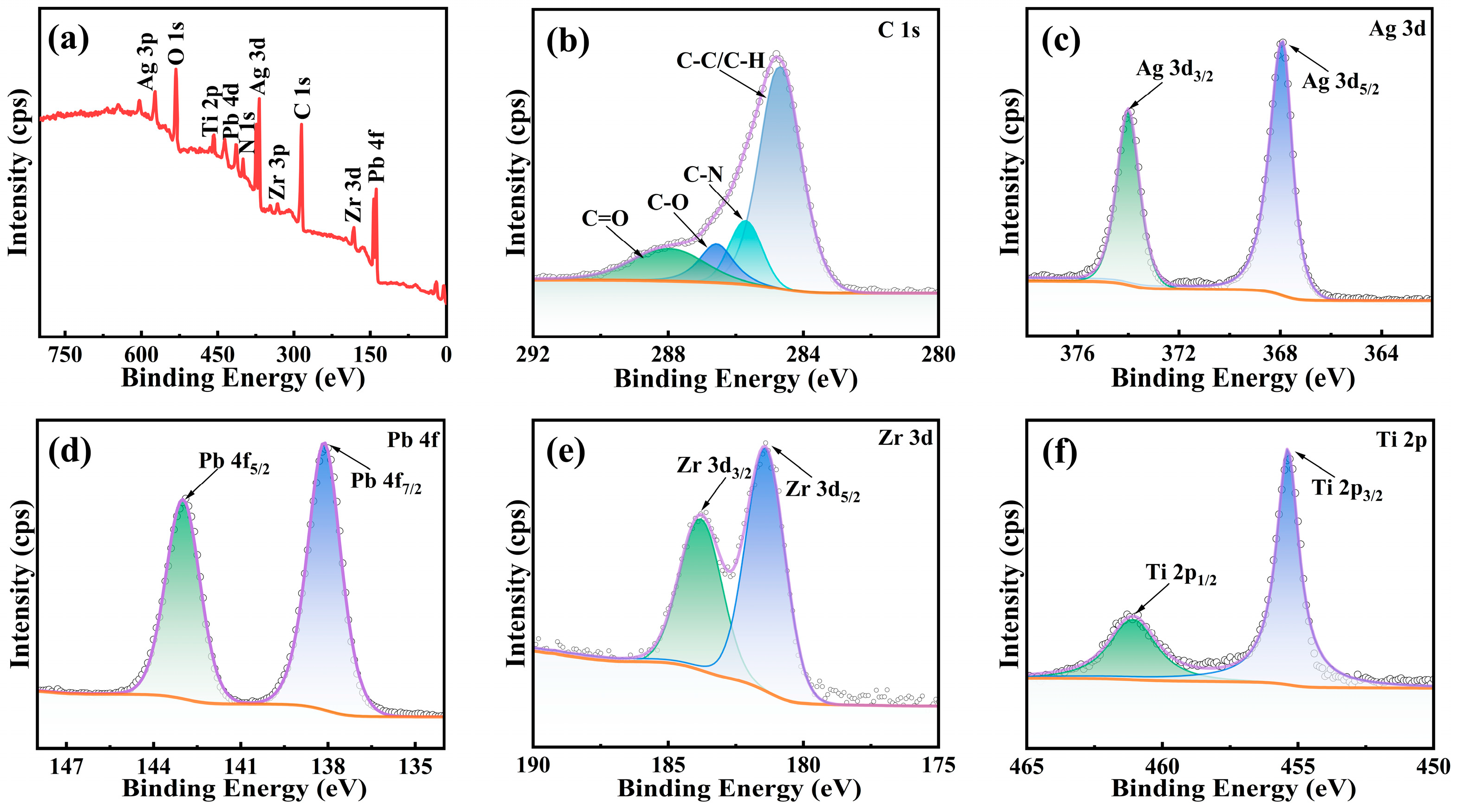

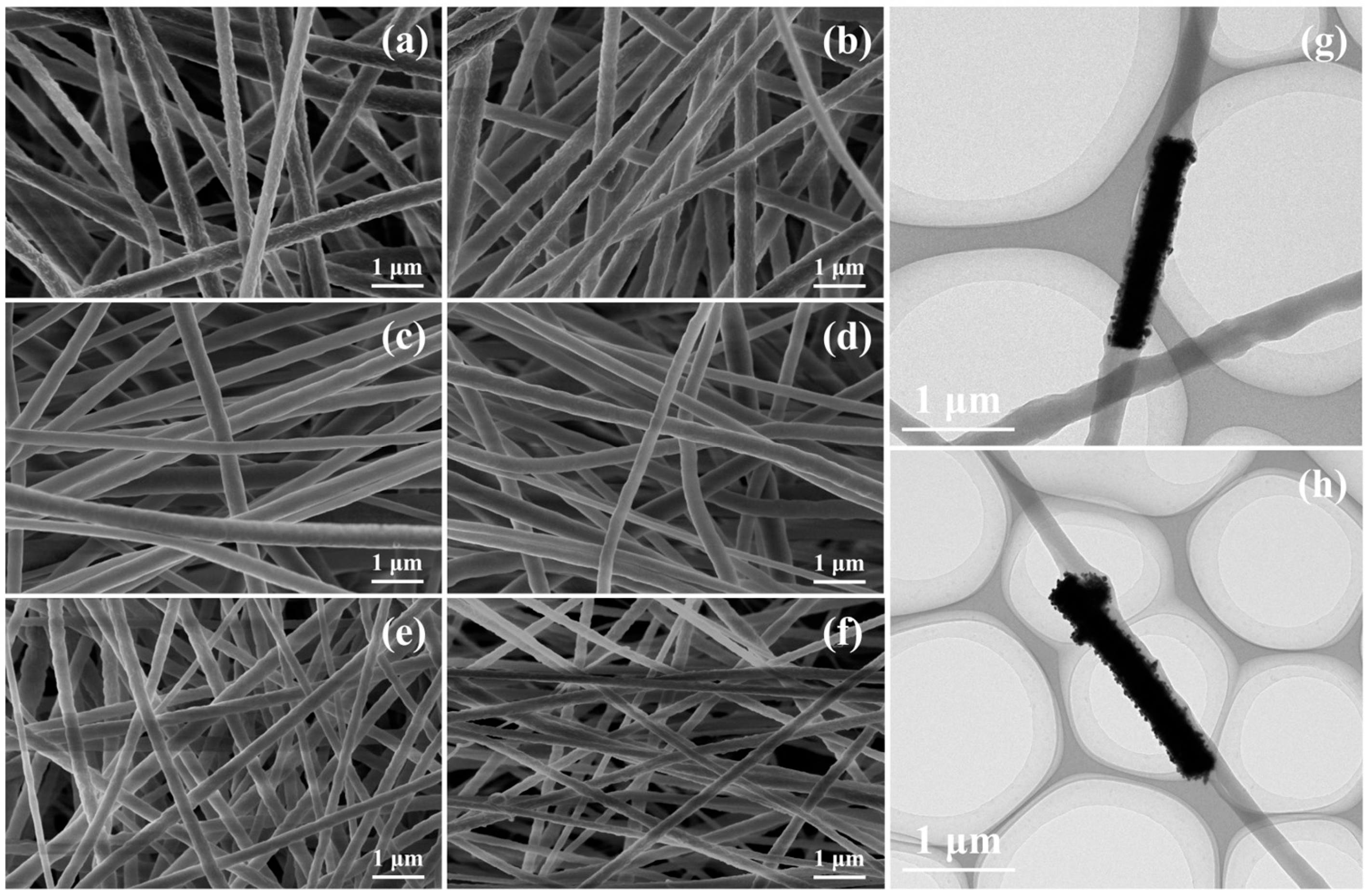

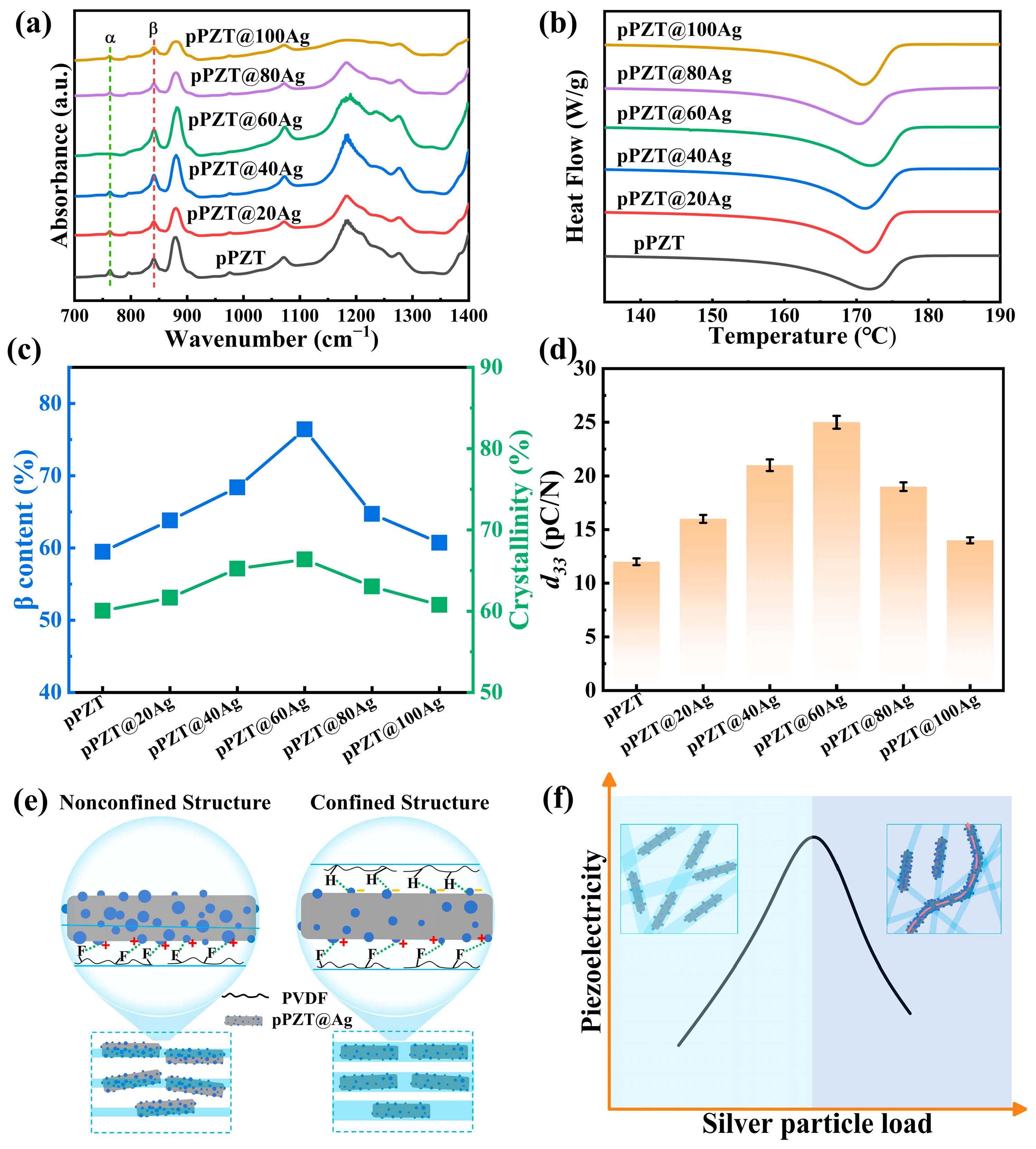

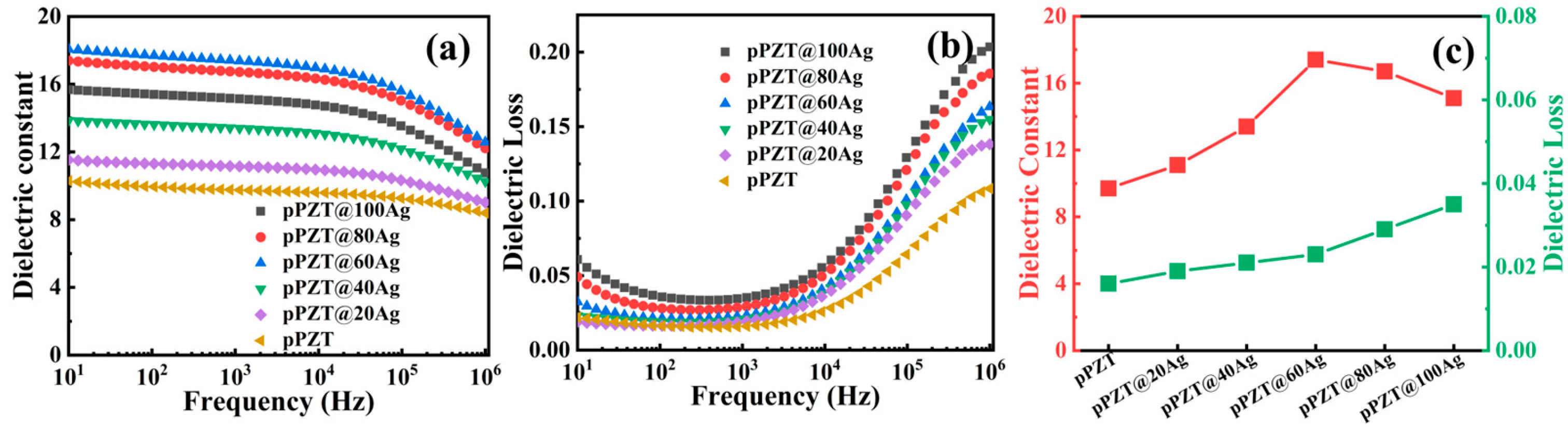

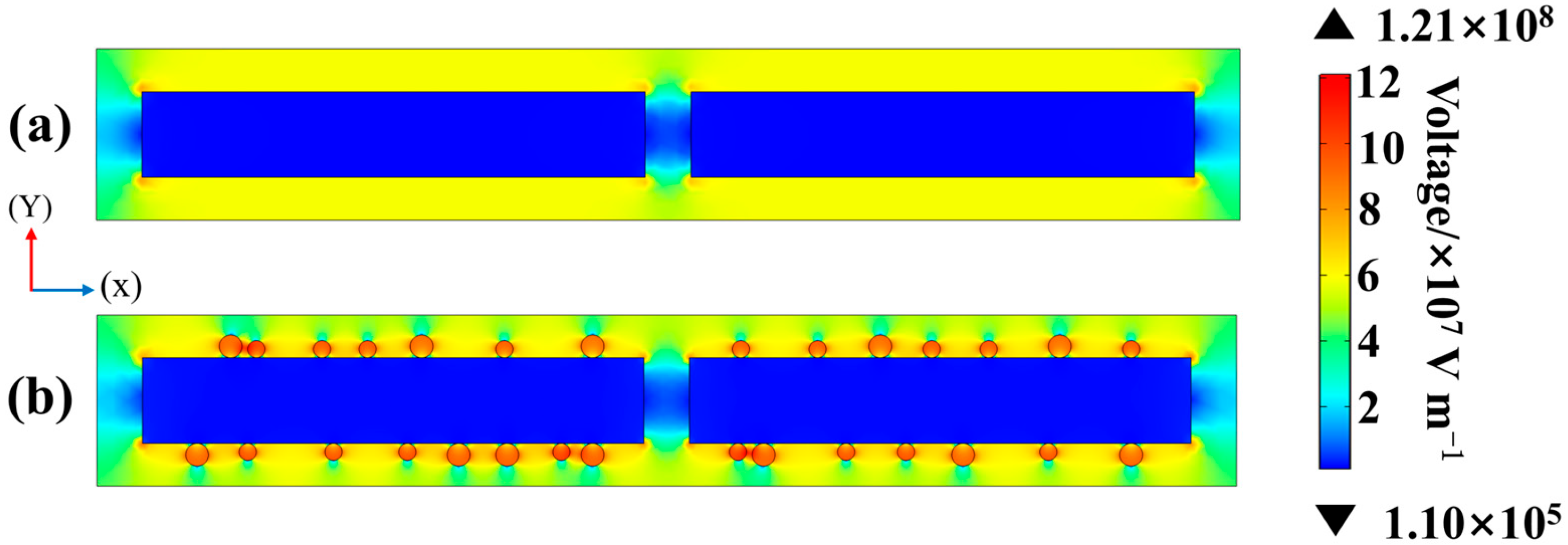

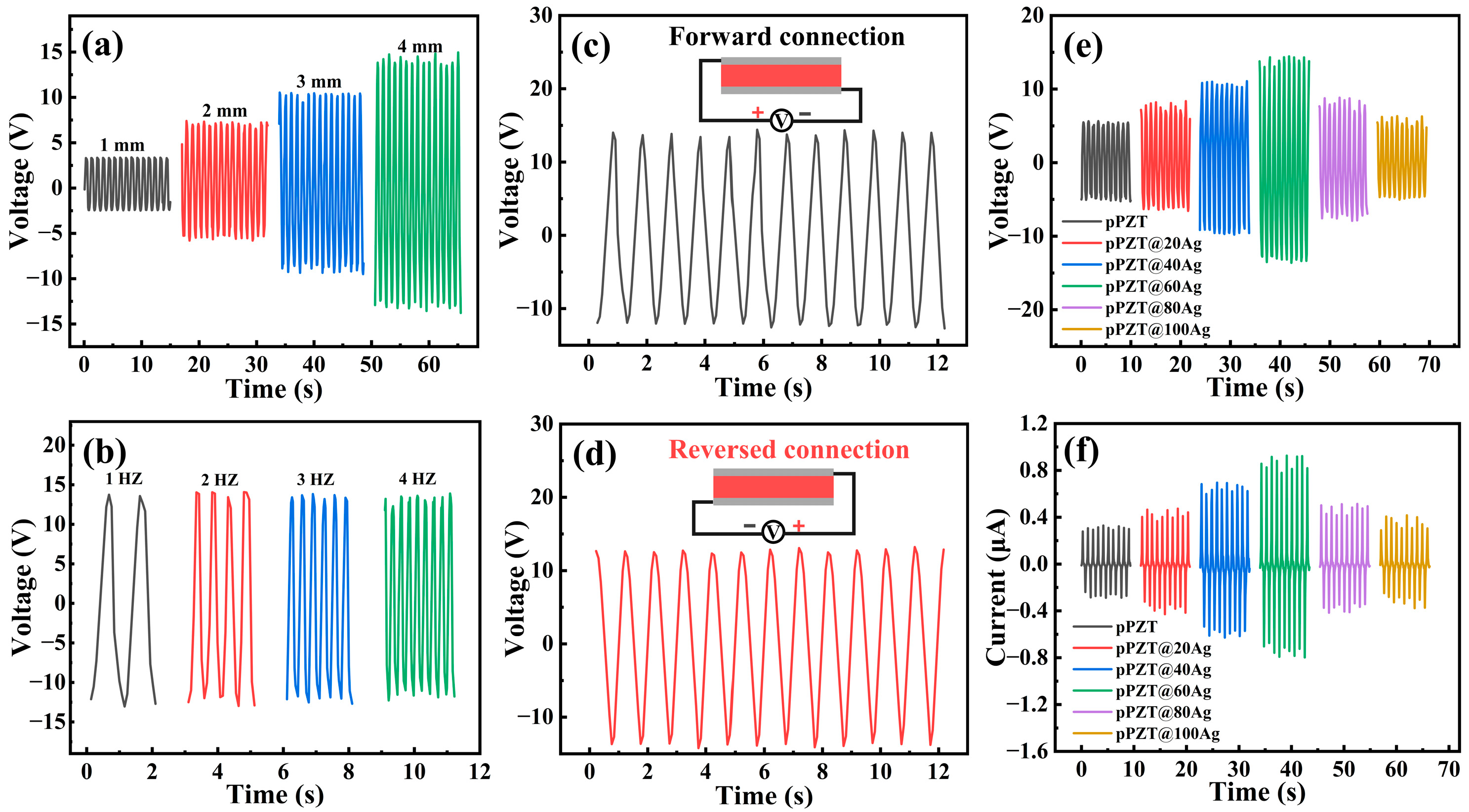

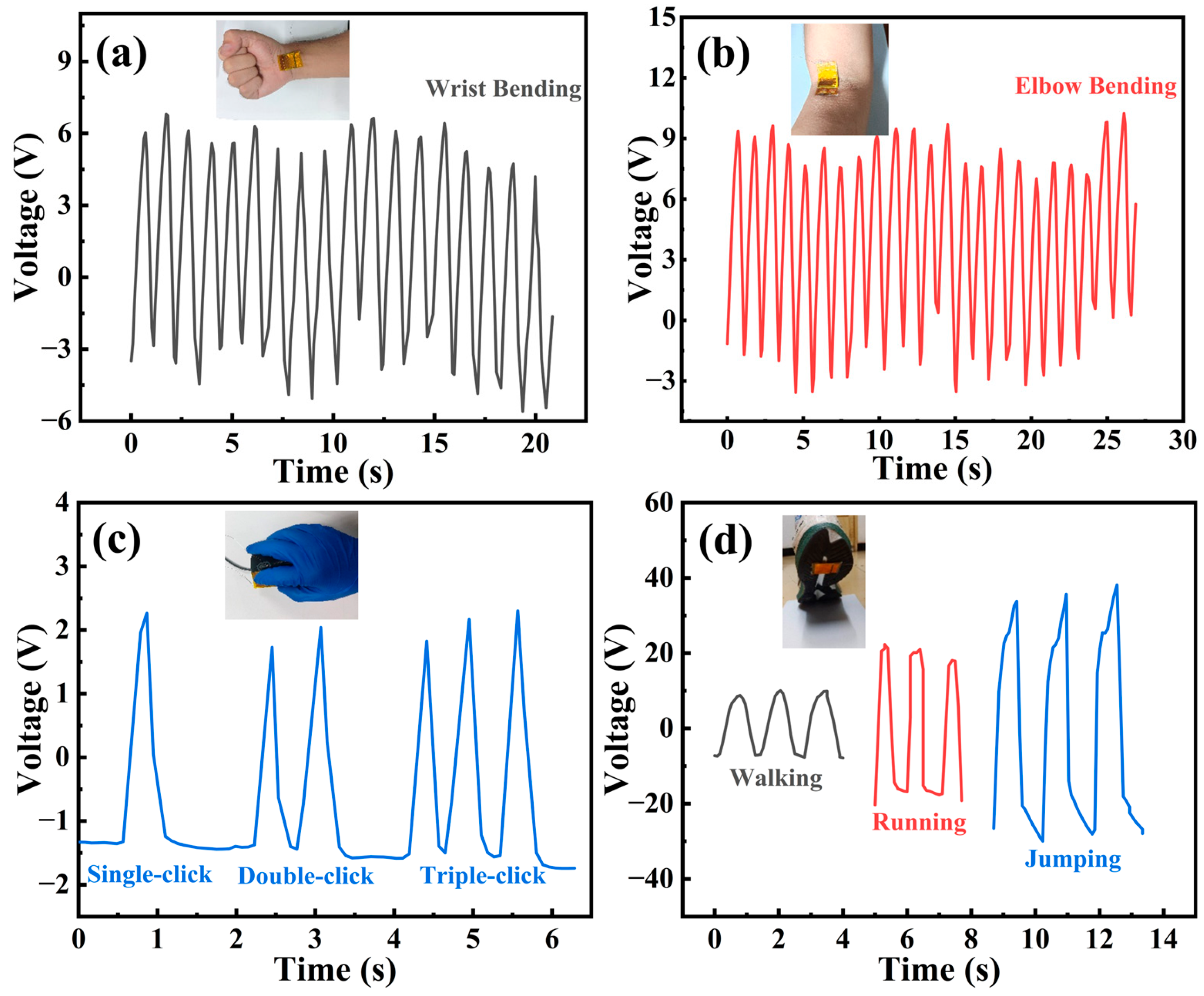

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chai, B.; Shi, K.; Wang, Y.; Liu, Y.; Liu, F.; Jiang, P.; Sheng, G.; Wang, S.; Xu, P.; Xu, X.; et al. Modulus-Modulated All-Organic Core-Shell Nanofiber with Remarkable Piezoelectricity for Energy Harvesting and Condition Monitoring. Nano Lett. 2023, 23, 1810–1819. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.; Han, Y.; Zhang, W.; Zhong, T.; Guan, H.; Song, Y.; Zhang, Y.; Xing, L.; Xue, X.; Li, G.; et al. A self-powered wearable body-detecting/brain-stimulating system for improving sports endurance performance. Nano Energy 2022, 93, 106851–106860. [Google Scholar] [CrossRef]

- Wu, T.; Lv, D.; Shen, W.; Song, W.; Tan, R. Trace-level ammonia detection at room temperature based on porous flexible polyaniline/polyvinylidene fluoride sensing film with carbon nanotube additives. Sens. Actuators B-Chem. 2020, 316, 128198–128206. [Google Scholar] [CrossRef]

- Liu, H.; Lin, X.; Zhang, S.; Huan, Y.; Huang, S.; Cheng, X. Enhanced performance of piezoelectric composite nanogenerator based on gradient porous PZT ceramic structure for energy harvesting. J. Mater. Chem. A 2020, 8, 19631–19640. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, R.; Zhang, C.; Zhou, Z.; Li, Y.; Liu, Z.; Dong, X. High-performance and high-thermally stable PSN-PZT piezoelectric ceramics achieved by high-temperature poling. J. Mater. Sci. Technol. 2022, 116, 238–245. [Google Scholar] [CrossRef]

- Zhao, C.; Wu, H.; Li, F.; Cai, Y.; Zhang, Y.; Song, D.; Wu, J.; Lyu, X.; Yin, J.; Xiao, D.; et al. Practical High Piezoelectricity in Barium Titanate Ceramics Utilizing Multiphase Convergence with Broad Structural Flexibility. J. Am. Chem. Soc. 2018, 140, 15252–15260. [Google Scholar] [CrossRef]

- Kimura, T.; Dong, Q.; Yin, S.; Hashimoto, T.; Sasaki, A.; Sato, T. Synthesis and piezoelectric properties of Li-doped BaTiO3 by a solvothemial approach. J. Eur. Ceram. Soc. 2013, 33, 1009–1015. [Google Scholar] [CrossRef]

- Li, J.; Yang, F.; Long, Y.; Dong, Y.; Wang, Y.; Wang, X. Bulk Ferroelectric Metamaterial with Enhanced Piezoelectric and Biomimetic Mechanical Properties from Additive Manufacturing. ACS Nano 2021, 15, 14903–14914. [Google Scholar] [CrossRef]

- Huan, Y.; Zhang, X.; Song, J.; Zhao, Y.; Wei, T.; Zhang, G.; Wang, X. High-performance piezoelectric composite nanogenerator based on Ag/(K, Na)NbO3 heterostructure. Nano Energy 2018, 50, 62–69. [Google Scholar] [CrossRef]

- Shi, S.; Zhai, Y.; Zhang, Y.; Wang, H.; Li, Z.; Fan, X.; Zhang, Y.; Liu, J.; Li, P.; Zhai, J.; et al. Ultra-sensitive flexible piezoelectric energy harvesters inspired by pine branches for detection. Nano Energy 2022, 99, 107422–107430. [Google Scholar] [CrossRef]

- Burnham-Fay, E.D.; Le, T.; Tarbutton, J.A.; Ellis, J.D. Strain characteristics of additive manufactured polyvinylidene fluoride (PVDF) actuators. Sens. Actuators A-Phys. 2017, 266, 85–92. [Google Scholar] [CrossRef]

- Yuan, X.; Yan, A.; Lai, Z.; Liu, Z.; Yu, Z.; Li, Z.; Cao, Y.; Dong, S. A poling-free PVDF nanocomposite via mechanically directional stress field for self-powered pressure sensor application. Nano Energy 2022, 98, 107340–107351. [Google Scholar] [CrossRef]

- Liang, J.; Zeng, H.; Qiao, L.; Jiang, H.; Ye, Q.; Wang, Z.; Liu, B.; Fan, Z. 3D Printed Piezoelectric Wound Dressing with Dual Piezoelectric Response Models for Scar-Prevention Wound Healing. ACS Appl. Mater. Interfaces 2022, 14, 30507–30522. [Google Scholar] [CrossRef] [PubMed]

- Tian, G.; Deng, W.; Gao, Y.; Xiong, D.; Yan, C.; He, X.; Yang, T.; Jin, L.; Chu, X.; Zhang, H.; et al. Rich lamellar crystal baklava-structured PZT/PVDF piezoelectric sensor toward individual table tennis training. Nano Energy 2019, 59, 574–581. [Google Scholar] [CrossRef]

- Wu, Q.; Guo, H.; Sun, H.; Liu, X.; Sui, H.; Wang, F. Flexible piezoelectric energy harvesters with graphene oxide nanosheets and PZT-incorporated P(VDF-TrFE) matrix for mechanical energy harvesting. Ceram. Int. 2021, 47, 19614–19621. [Google Scholar] [CrossRef]

- Park, K.-I.; Lee, M.; Liu, Y.; Moon, S.; Hwang, G.-T.; Zhu, G.; Kim, J.E.; Kim, S.O.; Kim, D.K.; Wang, Z.L.; et al. Flexible Nanocomposite Generator Made of BaTiO3 Nanoparticles and Graphitic Carbons. Adv. Mater. 2012, 24, 2999–3004. [Google Scholar] [CrossRef]

- Koc, M.; Tatardar, F.; Musayeva, N.N.; Guluzade, S.; Sari, A.; Parali, L. The piezoelectric properties of three-phase electrospun PVDF/PZT/Multiwalled Carbone Nanotube composites for energy harvesting applications. J. Alloys Compd. 2024, 1003, 175578–175591. [Google Scholar] [CrossRef]

- Das, S.; Biswal, A.K.; Parida, K.; Choudhary, R.N.P.; Roy, A. Electrical and mechanical behavior of PMN-PT/CNT based polymer composite film for energy harvesting. Appl. Surf. Sci. 2018, 428, 356–363. [Google Scholar] [CrossRef]

- Wang, F.; Sun, H.; Guo, H.; Sui, H.; Wu, Q.; Liu, X.; Huang, D. High performance piezoelectric nanogenerator with silver nanowires embedded in polymer matrix for mechanical energy harvesting. Ceram. Int. 2021, 47, 35096–35104. [Google Scholar] [CrossRef]

- Yan, M.; Liu, S.; Liu, Y.; Xiao, Z.; Yuan, X.; Zhai, D.; Zhou, K.; Wang, Q.; Zhang, D.; Bowen, C.; et al. Flexible PVDF-TrFE Nanocomposites with Ag-Decorated BCZT Heterostructures for Piezoelectric Nanogenerator Applications. ACS Appl. Mater. Interfaces 2022, 14, 53261–53273. [Google Scholar] [CrossRef]

- Zeng, S.; Zhang, M.; Jiang, L.; Wang, Z.; Gu, H.; Xiong, J.; Du, Y.; Ren, L. Wearable Piezoelectric Nanogenerators Based on Core-Shell Ga-PZT@Ga-Ox Nanorod-Enabled P(VDF-TrFE) Composites. ACS Appl. Mater. Interfaces 2022, 14, 7990–8000. [Google Scholar] [CrossRef]

- Zhao, J.; Zheng, M.; Gao, X.; Zhu, M.; Hou, Y. High-performance flexible piezocomposites based on an enhanced interfacial polarization effect via BCZT@Ag heterostructure design. J. Alloys Compd. 2024, 970, 172702–172708. [Google Scholar] [CrossRef]

- Li, X.; Yuan, C.; Zhou, H.; Gao, G.; He, J.; Liu, X.; Li, Y.; Sun, H.; Liu, X. A novel PZT hollow structure utilized in high-performance piezoelectric nanogenerator. Ceram. Int. 2024, 50, 34756–34767. [Google Scholar] [CrossRef]

- Shuai, C.; Liu, G.; Yang, Y.; Qi, F.; Peng, S.; Yang, W.; He, C.; Wang, G.; Qian, G. A strawberry-like Ag-decorated barium titanate enhances piezoelectric and antibacterial activities of polymer scaffold. Nano Energy 2020, 74, 104825. [Google Scholar] [CrossRef]

- Wang, S.; Shao, H.-Q.; Liu, Y.; Tang, C.-Y.; Zhao, X.; Ke, K.; Bao, R.-Y.; Yang, M.-B.; Yang, W. Boosting piezoelectric response of PVDF-TrFE via MXene for self-powered linear pressure sensor. Compos. Sci. Technol. 2021, 202, 108600. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, T.; Tian, G.; Lan, B.; Deng, W.; Tang, L.; Ao, Y.; Sun, Y.; Zeng, W.; Ren, X.; et al. Spatially Confined MXene/PVDF Nanofiber Piezoelectric Electronics. Adv. Fiber Mater. 2024, 6, 133–144. [Google Scholar] [CrossRef]

- Ting, Y.; Suprapto; Chiu, C.-W.; Gunawan, H. Characteristic analysis of biaxially stretched PVDF thin films. J. Appl. Polym. Sci. 2018, 135, 46677. [Google Scholar] [CrossRef]

- Mohammadi, B.; Yousefi, A.A.; Bellah, S.M. Effect of tensile strain rate and elongation on crystalline structure and piezoelectric properties of PVDF thin films. Polym. Test. 2007, 26, 42–50. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef]

- Ince-Gunduz, B.S.; Alpern, R.; Amare, D.; Crawford, J.; Dolan, B.; Jones, S.; Kobylarz, R.; Reveley, M.; Cebe, P. Impact of nanosilicates on poly(vinylidene fluoride) crystal polymorphism: Part 1. Melt-crystallization at high supercooling. Polymer 2010, 51, 1485–1493. [Google Scholar] [CrossRef]

- Maity, K.; Garain, S.; Henkel, K.; Schmeißer, D.; Mandal, D. Natural Sugar-Assisted, Chemically Reinforced, Highly Durable Piezoorganic Nanogenerator with Superior Power Density for Self-Powered Wearable Electronics. ACS Appl. Mater. Interfaces 2018, 10, 44018–44032. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Liu, M.; Feng, Y.; Zheng, H.; Wu, Y. ZnO@Ag modified piezoelectric fibers for higher sensitivity and enhanced energy harvesting. J. Mater. Res. Technol. 2022, 20, 2689–2704. [Google Scholar] [CrossRef]

- Shi, K.; Sun, B.; Huang, X.; Jiang, P. Synergistic effect of graphene nanosheet and BaTiO3 nanoparticles on performance enhancement of electrospun PVDF nanofiber mat for flexible piezoelectric nanogenerators. Nano Energy 2018, 52, 153–162. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, S.; Zhang, M.; Xiong, J.; Gu, H.; Wang, Z.; Hu, Y.; Zhang, X.; Du, Y.; Ren, L. Giant Piezoelectric Output and Stability Enhancement in Piezopolymer Composites with Liquid Metal Nanofillers. Adv. Sci. 2023, 10, 2304096. [Google Scholar] [CrossRef] [PubMed]

- Jia, Q.-Q.; Luo, J.-Q.; Xue, Z.-Y.; Tang, J.-S.; Qiu, W.-Q.; Wang, C.-F.; Zhang, Z.-X.; Lu, H.-F.; Zhang, Y.; Fu, D.-W. Enhanced output power density of PVDF/LM composite for piezoelectric sensor. Chin. Chem. Lett. 2024, 110471. [Google Scholar] [CrossRef]

- Pickford, T.; Gu, X.; Heeley, E.L.; Wan, C. Effects of an ionic liquid and processing conditions on the β-polymorph crystal formation in poly(vinylidene fluoride). Crystengcomm 2019, 21, 5418–5428. [Google Scholar] [CrossRef]

- Gregorio, R., Jr.; Borges, D.S. Effect of crystallization rate on the formation of the polymorphs of solution cast poly(vinylidene fluoride). Polymer 2008, 49, 4009–4016. [Google Scholar] [CrossRef]

- Zhang, C.; Wei, W.; Sun, H.; Zhu, Q. Performance enhancements in poly(vinylidene fluoride)-based piezoelectric films prepared by the extrusion-casting process. J. Mater. Sci.-Mater. Electron. 2021, 32, 21837–21847. [Google Scholar] [CrossRef]

- Yan, J.; Liu, M.; Jeong, Y.G.; Kang, W.; Li, L.; Zhao, Y.; Deng, N.; Cheng, B.; Yang, G. Performance enhancements in poly(vinylidene fluoride)-based piezoelectric nanogenerators for efficient energy harvesting. Nano Energy 2019, 56, 662–692. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, J.; Ni, Y. Dielectric relaxation processes in PVDF composite. Polym. Test. 2020, 91, 106801–106808. [Google Scholar] [CrossRef]

- Pei, J.-Y.; Yin, L.-J.; Zhong, S.-L.; Dang, Z.-M. Suppressing the Loss of Polymer-Based Dielectrics for High Power Energy Storage. Adv. Mater. 2023, 35, 2203623–2203640. [Google Scholar] [CrossRef]

- Deutz, D.B.; Pascoe, J.-A.; Schelen, B.; van der Zwaag, S.; de Leeuw, D.M.; Groen, P. Analysis and experimental validation of the figure of merit for piezoelectric energy harvesters. Mater. Horiz. 2018, 5, 444–453. [Google Scholar] [CrossRef]

- Yang, X.; Guo, H.; Yuan, C.; Li, Y.; Sun, H. Enhancing output current in degradable flexible piezoelectric nanogenerators through internal electrode construction. J. Colloid Interface Sci. 2024, 667, 640–649. [Google Scholar] [CrossRef]

- Yang, C.; Song, H.-s.; Liu, D.-b. Effect of coupling agents on the dielectric properties of CaCu3Ti4O12/PVDF composites. Compos. Part B-Eng. 2013, 50, 180–186. [Google Scholar] [CrossRef]

- Dudem, B.; Kim, D.H.; Bharat, L.K.; Yu, J.S. Highly-flexible piezoelectric nanogenerators with silver nanowires and barium titanate embedded composite films for mechanical energy harvesting. Appl. Energy 2018, 230, 865–874. [Google Scholar] [CrossRef]

- Yeo, H.G. Piezoelectric energy-harvesting devices for wearable self-powering system. JMST Adv. 2023, 5, 37–43. [Google Scholar] [CrossRef]

- Rosso, M. Intentional and Inherent Nonlinearities in Piezoelectric Energy Harvesting; SpringerBriefs in Applied Sciences and Technology Part F2361; Springer: Cham, Switzerland, 2024; pp. 1–134. [Google Scholar]

- Liang, M.; Wang, J.; Su, L.; Xin, X.; Chen, Z.; Zhang, Y.; Jiao, Y.; Luan, X.; Chen, L.; Yao, Z. Versatile Lamellar Wrap-Structured PVDF/PZT/CNTs Piezoelectric Sensor for Road Traffic Information Sensing, Monitoring, and Energy Harvesting. Chem. Eng. J. 2024, 497, 154554. [Google Scholar] [CrossRef]

- Badatya, S.; Bharti, D.K.; Sathish, N.; Srivastava, A.K.; Gupta, M.K. Humidity Sustainable Hydrophobic Poly(vinylidene fluoride)-Carbon Nanotubes Foam Based Piezoelectric Nanogenerator. ACS Appl. Mater. Interfaces 2021, 13, 27245–27254. [Google Scholar] [CrossRef]

- Panda, S.; Hajra, S.; Jeong, H.; Panigrahi, B.K.; Pakawanit, P.; Dubal, D.; Hong, S.; Kim, H.J. Biocompatible CaTiO3-PVDF composite-based piezoelectric nanogenerator for exercise evaluation and energy harvesting. Nano Energy 2022, 102, 107682. [Google Scholar] [CrossRef]

- Wang, S.; Yu, Z.; Wang, L.; Wang, Y.; Yu, D.; Wu, M. A core-shell structured barium titanate nanoparticles for the enhanced piezoelectric performance of wearable nanogenerator. Appl. Energy 2023, 351, 121835. [Google Scholar] [CrossRef]

- Jeder, K.; Bouhamed, A.; Nouri, H.; Abdelmoula, N.; Jöhrmann, N.; Wunderle, B.; Khemakhem, H.; Kanoun, O. Enhancement of the performance of flexible lead-free nanogenerators by doping in BaTiO3 nanoparticles. Energy 2022, 261, 125169. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Guo, H.; Yang, X.; Wu, F.; Li, Y.; Li, X.; Xu, Q.; Sun, H. Electrospun Silver-Modified PZT/PVDF Composites for High-Performance Piezoelectric Energy Harvester. Materials 2025, 18, 1425. https://doi.org/10.3390/ma18071425

Liu X, Guo H, Yang X, Wu F, Li Y, Li X, Xu Q, Sun H. Electrospun Silver-Modified PZT/PVDF Composites for High-Performance Piezoelectric Energy Harvester. Materials. 2025; 18(7):1425. https://doi.org/10.3390/ma18071425

Chicago/Turabian StyleLiu, Xiang, Huiling Guo, Xinyue Yang, Fuling Wu, Yuanhui Li, Xiao Li, Qing Xu, and Huajun Sun. 2025. "Electrospun Silver-Modified PZT/PVDF Composites for High-Performance Piezoelectric Energy Harvester" Materials 18, no. 7: 1425. https://doi.org/10.3390/ma18071425

APA StyleLiu, X., Guo, H., Yang, X., Wu, F., Li, Y., Li, X., Xu, Q., & Sun, H. (2025). Electrospun Silver-Modified PZT/PVDF Composites for High-Performance Piezoelectric Energy Harvester. Materials, 18(7), 1425. https://doi.org/10.3390/ma18071425