Carbon Fiber-Reinforced Polyamide 6 Composites: Impact of Fiber Type and Concentration on the Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

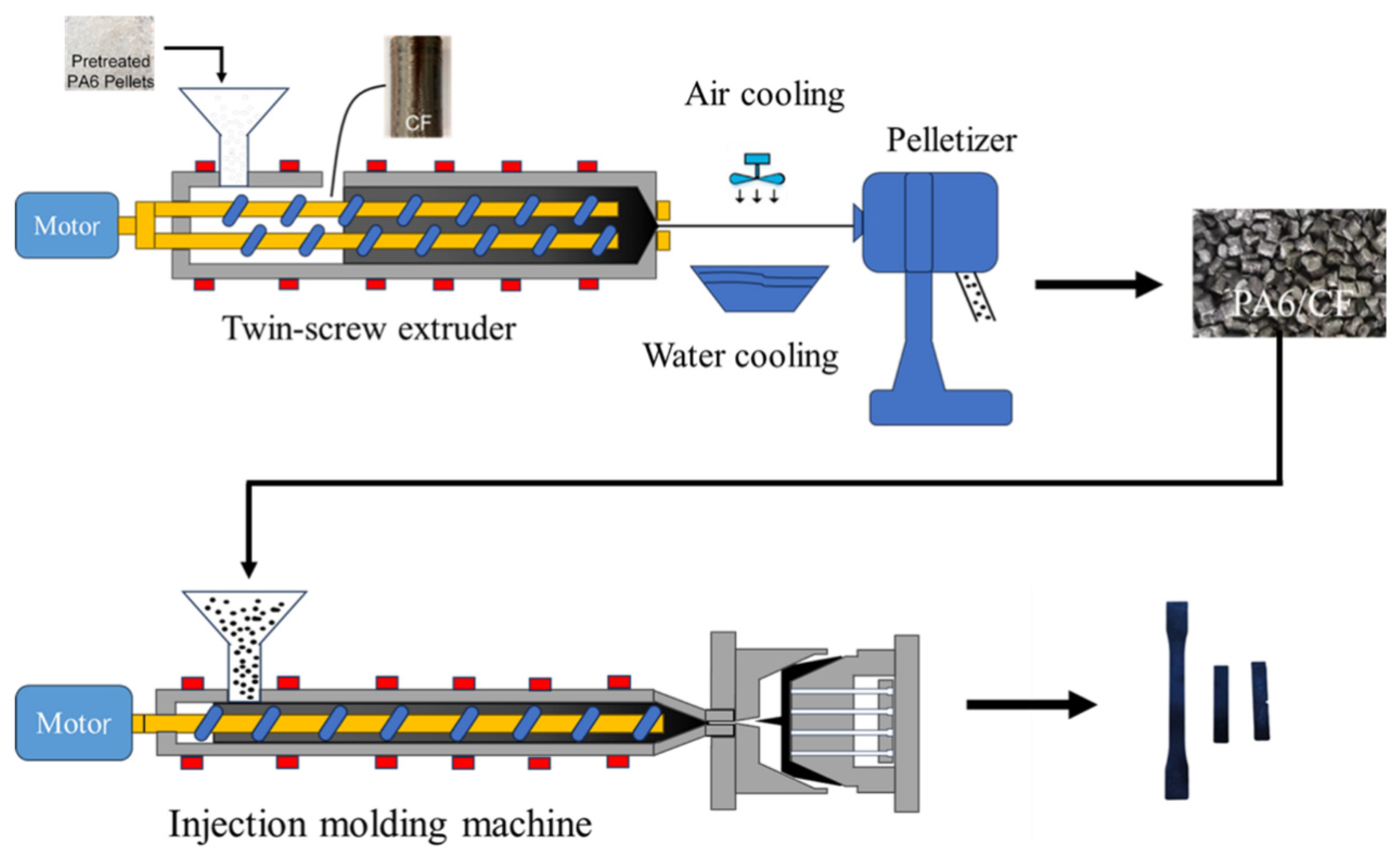

2.2. Preparation of PA6/CF Composites with Different Types and Contents of CF

2.3. Characterization

3. Results and Discussion

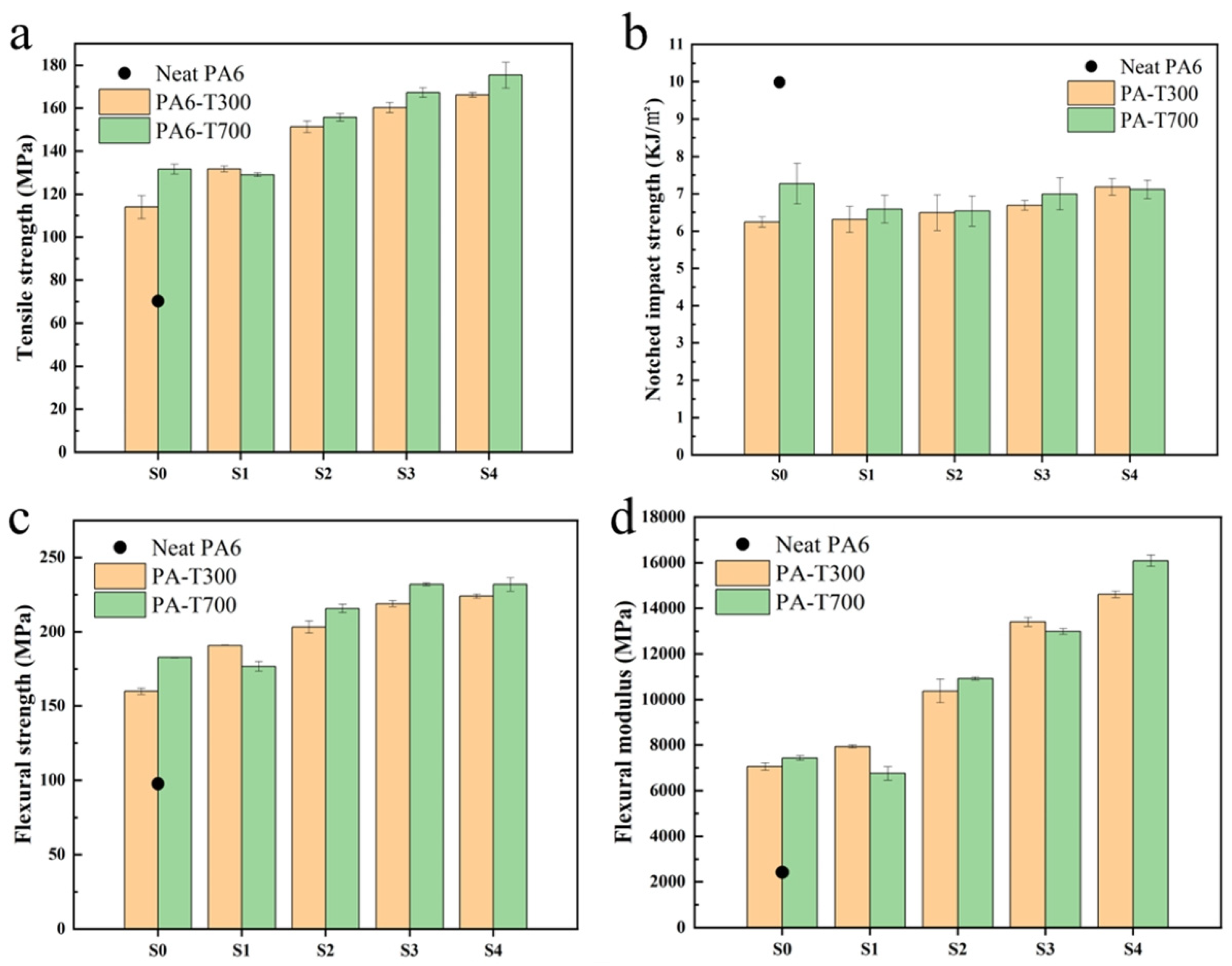

3.1. Mechanical Properties of PA6/CF Composites

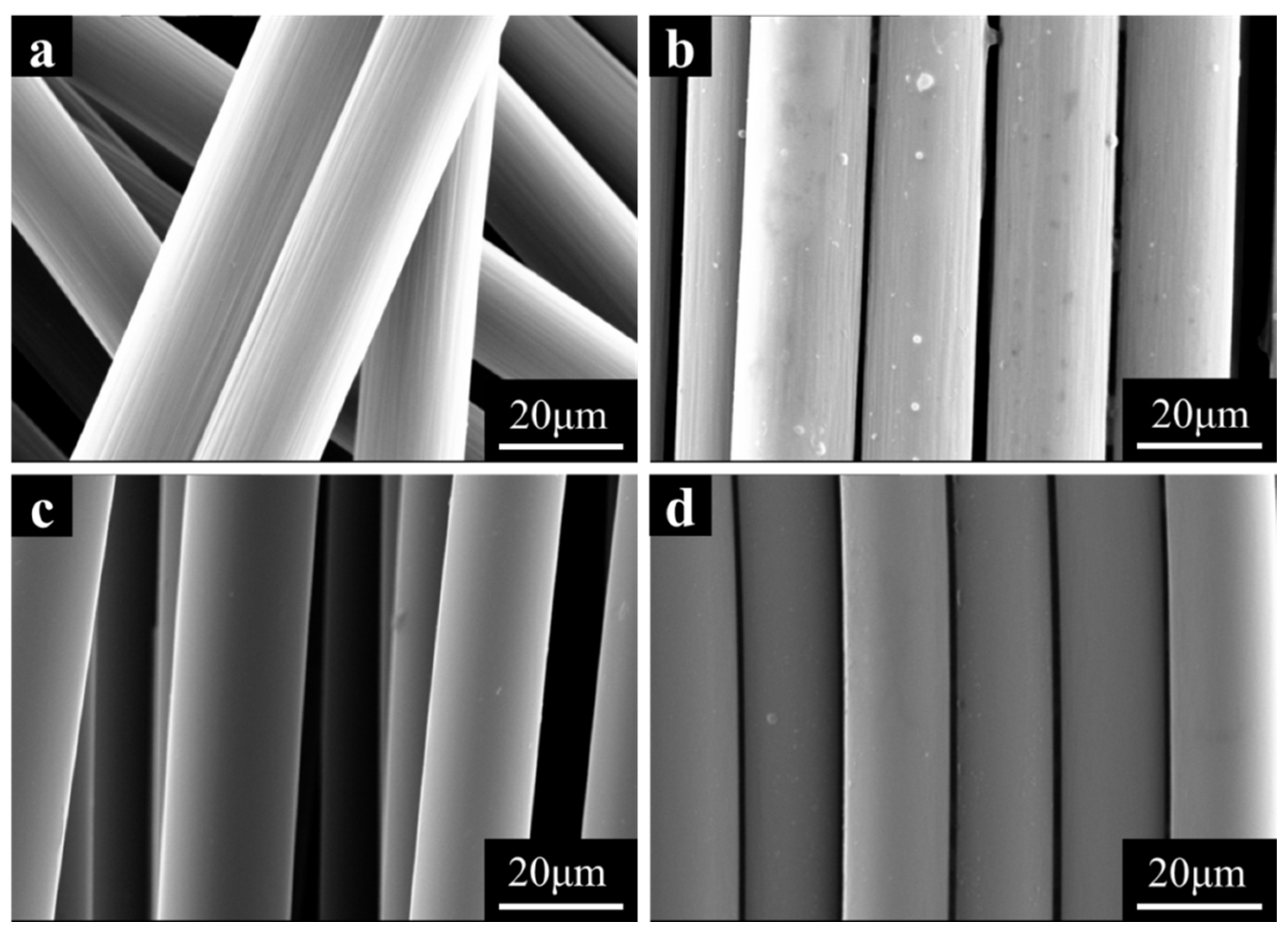

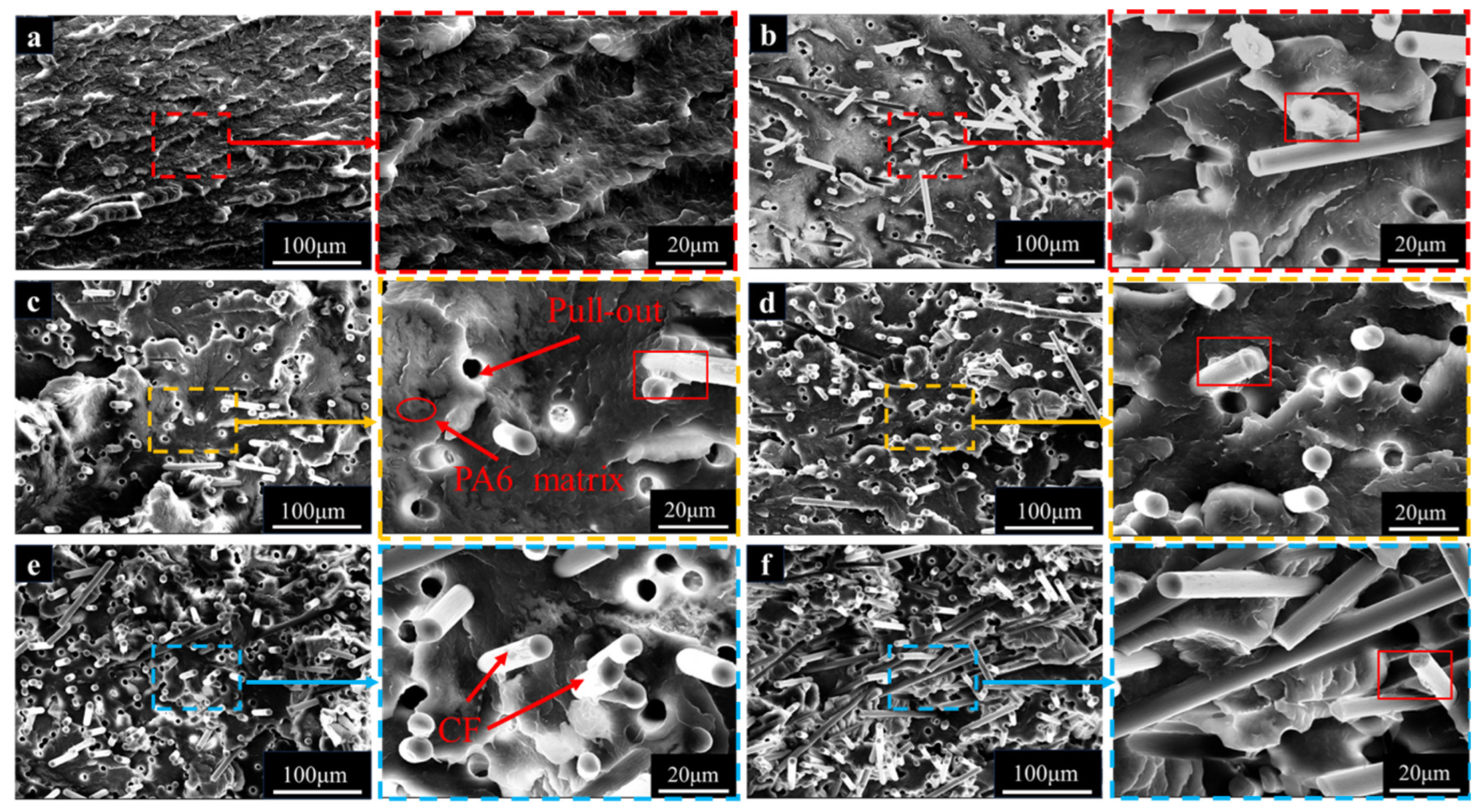

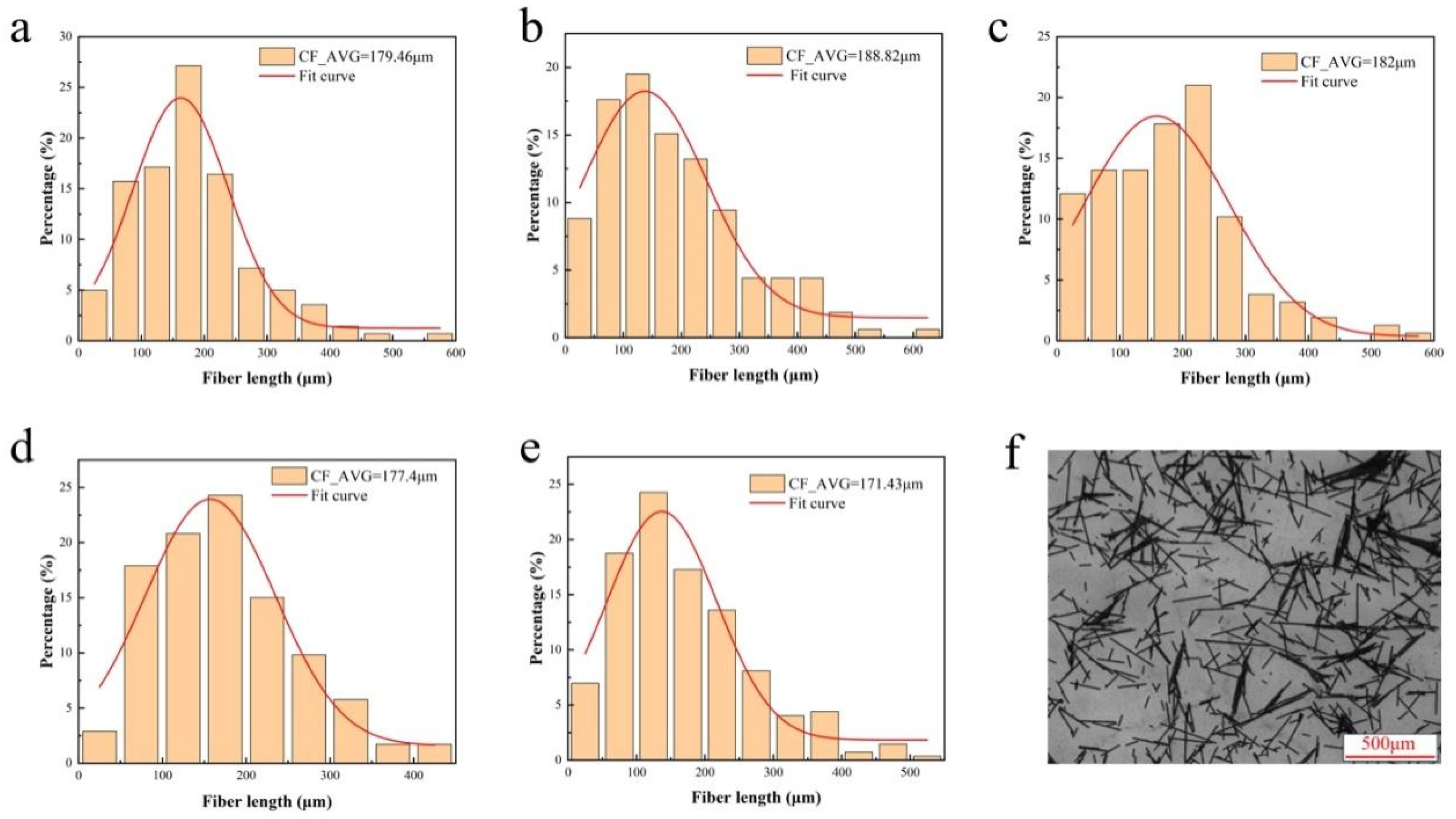

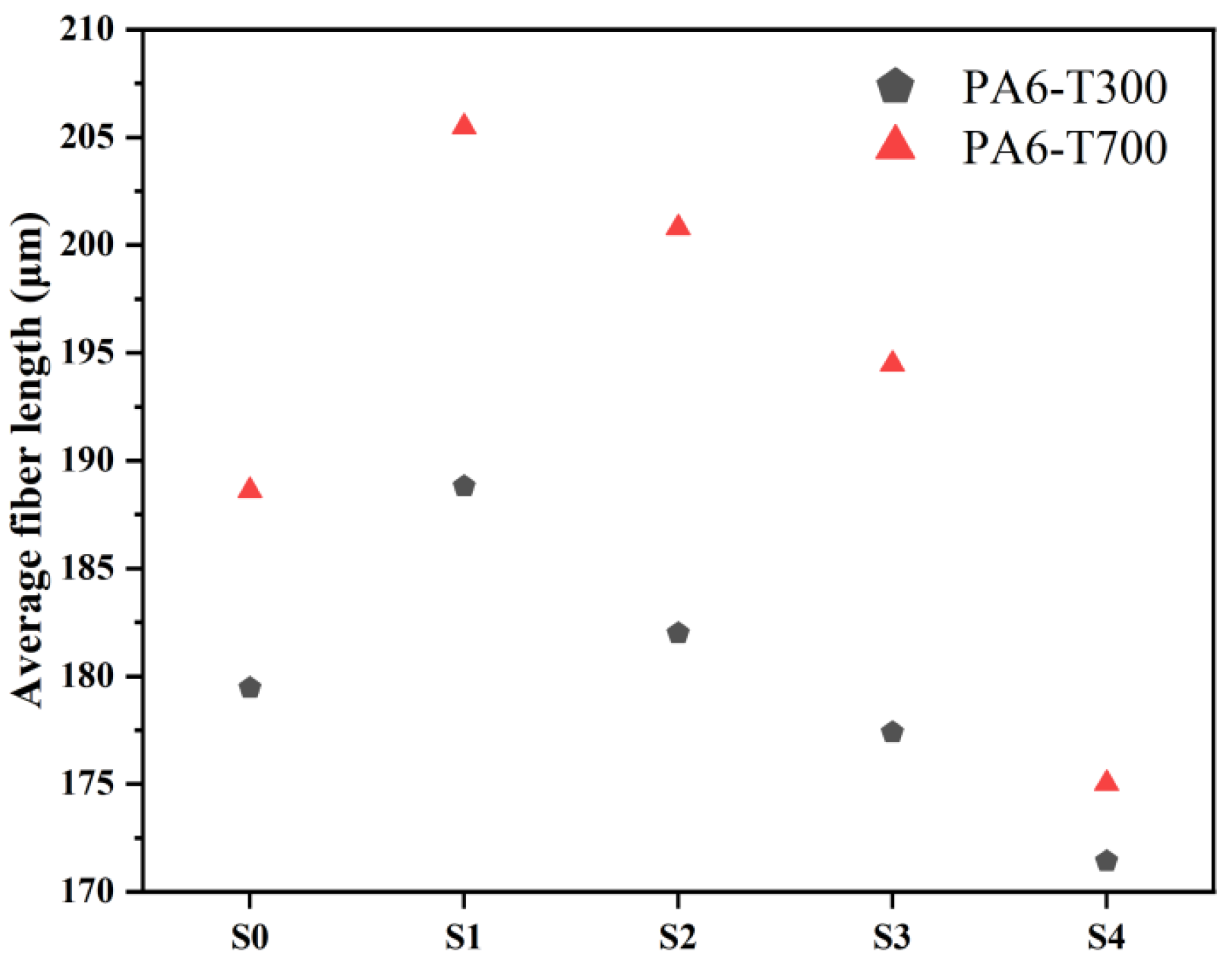

3.2. Microstructure of PA6/CF Composites

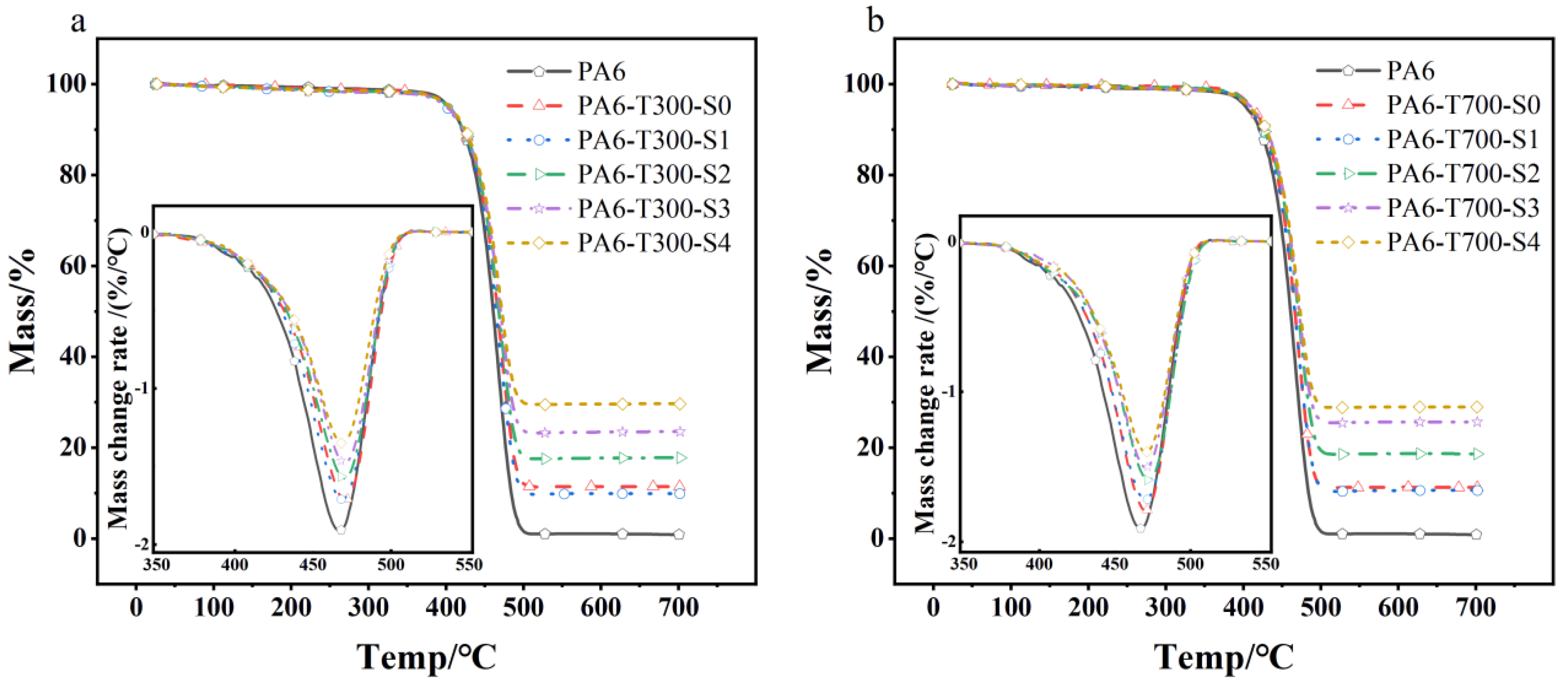

3.3. Thermogravimetric Analysis of PA6/CF Composites

3.4. DSC Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Salas, A.; Berrio, M.E.; Martel, S.; Díaz-Gómez, A.; Palacio, D.A.; Tuninetti, V.; Medina, C.; Meléndrez, M.F. Towards recycling of waste carbon fiber: Strength, morphology and structural features of recovered carbon fibers. Waste Manag. 2023, 165, 59–69. [Google Scholar] [CrossRef]

- Li, C.; Qian, X.; Hao, M.; Wang, X.; Zhu, S.; Guo, M.; Gong, H.; Zhang, Y. Outstanding electromagnetic wave absorption performance of polyacrylonitrile-based ultrahigh modulus carbon fibers decorated with CoZn-bimetallic ZIFs. J. Alloys Compd. 2023, 950, 169912. [Google Scholar]

- Zhang, Y.; Tao, W.; Zhang, Y.; Tang, L.; Gu, J.; Jiang, Z. Continuous carbon fiber/crosslinkable poly(ether ether ketone) laminated composites with outstanding mechanical properties, robust solvent resistance and excellent thermal stability. Compos. Sci. Technol. 2018, 165, 148–153. [Google Scholar] [CrossRef]

- Yudhanto, A.; Wafai, H.; Lubineau, G.; Yaldiz, R.; Verghese, N. Characterizing the influence of matrix ductility on damage phenomenology in continuous fiber-reinforced thermoplastic laminates undergoing quasi-static indentation. Compos. Struct. 2018, 186, 324–334. [Google Scholar] [CrossRef]

- Subhash, W.; Sagar, S.; Kapil, A.; Pravin, K. A mini review on fibre reinforced polymer composites. Mater. Today Proc. 2022, 54 Pt 3, 682–689. [Google Scholar]

- Hui, S.X.; Lin, L.X.; Ming, L.Y.; Zhi, L.; Yi, W.D. Flame-retardant strategy and mechanism of fiber reinforced polymeric com-posite: A review. Compos. Part B Eng. 2022, 233, 109663. [Google Scholar]

- Hou, Z.; Tian, X.; Zheng, Z.; Zhang, J.; Zhe, L.; Li, D.; Malakhov, A.V.; Polilov, A.N. A constitutive model for 3D printed continuous fiber reinforced composite structures with variable fiber content. Compos. Part B Eng. 2020, 189. [Google Scholar] [CrossRef]

- Brown, K.R.; Harrell, T.M.; Skrzypczak, L.; Scherschel, A.; Wu, H.F.; Li, X. Carbon fibers derived from commodity polymers: A review. Carbon 2022, 196, 422–439. [Google Scholar]

- Gon, C.B.; Ram, J.S.; Hun, H.J.; Ho, K.G.; Bin, P.Y. Interphase strengthening of carbon fiber/polyamide 6 composites through mixture of sizing agent and reduced graphene oxide coating. Carbon 2021, 149, 106521. [Google Scholar]

- Li, B.; Song, G.; Peng, Z.; Zhang, W.; Zheng, H.; Zhu, J.; Wang, C.; Wang, J.; Ma, R.; Zhu, S.; et al. Improving mechanical and thermal properties of short carbon fiber/polyamide 6 composites through a polydopamine/nano-silica interface layer. J. Appl. Polym. Sci. 2022, 140, e53457. [Google Scholar] [CrossRef]

- García Hernández, Z.; Miranda Teran, Z.N.; González Morones, P.; Yañez Macías, R.; Solís Rosales, S.G.; Romero, G.Y.; Sifuentes-Nieves, I.; Hernández-Hernández, E. Performance of nylon 6 composites reinforced with modified agave fiber: Structural, morphological, and mechanical features. J. Appl. Polym. Sci. 2021, 138, 50857. [Google Scholar] [CrossRef]

- Chen, H.; Cai, Q.; Wu, J.; Xia, X.; Liu, H.; Luo, Z. Interfacial enhancement of carbon fiber/nylon 12 composites by grafting nylon 6 to the surface of carbon fiber. Appl. Surf. Sci. 2018, 441, 538–545. [Google Scholar] [CrossRef]

- Zhu, Y.; Ma, Y.; Yan, C.; Xu, H.; Liu, D.; Chen, G.; Shi, P.; Hu, J.; Gao, C. Improved interfacial shear strength of CF/PA6 and CF/epoxy composites by grafting graphene oxide onto carbon fiber surface with hyperbranched polyglycerol. Surf. Interface Anal. 2021, 53, 831–843. [Google Scholar] [CrossRef]

- Sun, N.; Zhu, B.; Gao, X.; Qiao, K.; Zhang, Y.; Wang, B.; Fan, J.; Yu, K.; Liu, C.; Li, C.; et al. Improved the interfacial characteristics of carbon fiber/polyamide 6 composites by synthesizing polydopamine rapidly on the carbon fiber surface with ultrasound-assisted. Compos. Sci. Technol. 2023, 234, 109950. [Google Scholar] [CrossRef]

- Feng, N.; Wang, X.; Wu, D. Surface modification of recycled carbon fiber and its reinforcement effect on nylon 6 composites: Mechanical properties, morphology and crystallization behaviors. Curr. Appl. Phys. 2013, 13, 2038–2050. [Google Scholar] [CrossRef]

- Zhao, Y.; Dai, S.; Pei, W.; Guo, J.; Gao, L.; Ao, Y.; Du, W.; Xu, H.; Liu, Y.; Liu, L. Synergistic of UV resistant water-borne polyurethane sizing with metal chelation to enhance the interfacial properties of CF/PA6 composites. Compos. Sci. Technol. 2024, 248, 110449. [Google Scholar] [CrossRef]

- Gao, L.; Yan, F.; Dai, S.; Zhao, L.; Wang, J.; Liu, Y.; Ao, Y.; Liu, L. Synthesis of hyperbranched polyu-rethane sizing agent with high-solid content via self-catalytic method for improving interfacial adhesion of CF/PA6 composites. Compos. Sci. Technol. 2022, 228, 109664. [Google Scholar] [CrossRef]

- Karsli, N.G.; Ozkan, C.; Aytac, A.; Deniz, V. Effects of sizing materials on the properties of carbon fiber-reinforced polyamide 6,6 composites. Polym. Compos. 2013, 34, 1583–1590. [Google Scholar] [CrossRef]

- de Toro, E.V.; Sobrino, J.C.; Martínez, A.M.; Eguía, V.M.; Pérez, J.A. Investigation of a Short Carbon Fibre-Reinforced Polyamide and Comparison of Two Manufacturing Processes: Fused Deposition Modelling (FDM) and Polymer Injection Moulding (PIM). Materials 2020, 13, 672. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Cheng, H.; Tang, M.; Guo, L.; Feng, Z.; Qian, Z.; Wang, Q.; Zhai, H. A novel overflow extrusion-annealing process for preparing high performance recycled carbon fiber reinforced Nylon 6 composites. Polym. Compos. 2024, 45, 15046–15061. [Google Scholar] [CrossRef]

- Jin, J.D.; Hyung, L.J.; Jin, L.J.; Jieun, H.; Hun, K.S. Strengthening of polyamide 6 and isosorbide-containing copolyester immis-cible blends by in-situ reactive compatibilization. Polymer 2023, 265, 125597. [Google Scholar]

- Liu, L.; Wu, F.; Yao, H.; Shi, J.; Chen, L.; Xu, Z.; Deng, H. Investigation of surface properties of pristine and γ-irradiated PAN-based carbon fibers: Effects of fiber instinct structure and radiation medium. Appl. Surf. Sci. 2015, 337, 241–248. [Google Scholar] [CrossRef]

- Liao, G.; Li, Z.; Cheng, Y.; Xu, D.; Zhu, D.; Jiang, S.; Guo, J.; Chen, X.; Xu, G.; Zhu, Y. Properties of oriented carbon fiber/polyamide 12 composite parts fabricated by fused deposition modeling. Mater. Des. 2018, 139, 283–292. [Google Scholar] [CrossRef]

- Damacena, L.H.C.; Ferreira, E.H.C.; Ribeiro, H.; Fechine, G.J.M.; Souza, A.M.C. High-performance hierarchical composites based on polyamide 6, carbon fiber and graphene oxide. Polym. Compos. 2023, 44, 3387–3400. [Google Scholar] [CrossRef]

- An, H.J.; Kim, J.S.; Kim, K.-Y.; Lim, D.Y.; Kim, D.H. Mechanical and Thermal Properties of Long Carbon Fiber-reinforced Poly amide 6 Composites. Fibers Polym. 2014, 15, 2355–2359. [Google Scholar]

- Wang, R.; Kuan, H.-C.; Qiu, A.; Su, X.; Ma, J.; Santa, J. A facile approach to the scalable preparation of thermoplastic/carbon nanotube composites. Nanotechnology 2019, 31, 195706. [Google Scholar] [CrossRef]

- Thodsaratpreeyakul, W.; Uawongsuwan, P.; Kataoka, A.; Negoro, T.; Hamada, H. Mechanical properties and fiber characteristics of glass fiber/carbon fiber reinforced polyethylene terephthalate hybrid composites fabricated by direct fiber feeding injection molding. J. Polym. Eng. 2017, 38, 513–523. [Google Scholar] [CrossRef]

- Dong, W.; Bao, C.; Liu, R.; Li, S. Interfacial performance of phenolic-sized continuous carbon fiber-reinforced phenolic resin composites with different impregnation nozzle diameters via 3D printing. Polym. Compos. 2023, 44, 9063–9073. [Google Scholar] [CrossRef]

- Chen, X.; Xu, H.; Zhu, Y.; Yan, C.; Liu, D.; Zhang, Y. Polyphosphazene nanotubes/carbon fibers hierarchical hybrid reinforcement for improving interfacial adhesion of polyamide 6 composites. Iran. Polym. J. 2023, 32, 1033–1044. [Google Scholar] [CrossRef]

- SungEun, K.; JunGeol, A.; Seungjae, A.; DoHyung, P.; DaHee, C.; JaeChul, L.; HyunIk, Y.; KiYoung, K. Development of PA6/GF Long-Fiber-Reinforced Thermoplastic Composites Using Pultrusion and Direct Extrusion Manufacturing Processes. Appl. Sci. 2022, 12, 4838. [Google Scholar] [CrossRef]

- Li, X.; He, J.; Hu, Z.; Ye, X.; Wang, S.; Zhao, Y.; Wang, B.; Ou, Y.; Zhang, J. High strength carbon-fiber rein-forced polyamide 6 composites additively manufactured by screw-based extrusion. Compos. Sci. Technol. 2022, 229, 109707. [Google Scholar]

| Model | Density (g/cm3) |

|---|---|

| T300-CF unsized | 1.57 |

| T300-CF sized | 1.56 |

| T700-CF unsized | 1.77 |

| T700-CF sized | 1.62 |

| Model | Name | CF Actual Content |

|---|---|---|

| PA6-T300-CF unsized | PA6-T300-S0 | 11.46 wt.% |

| PA6-T300-1 strand CF sized | PA6-T300-S1 | 9.94 wt.% |

| PA6-T300-2 strand CF sized | PA6-T300-S2 | 17.78 wt.% |

| PA6-T300-3 strand CF sized | PA6-T300-S3 | 23.54 wt.% |

| PA6-T300-4 strand CF sized | PA6-T300-S4 | 29.66 wt.% |

| PA6-T700-CF unsized | PA6-T700-S0 | 11.26 wt.% |

| PA6-T700-1 strand CF sized | PA6-T700-S1 | 10.62 wt.% |

| PA6-T700-2 strand CF sized | PA6-T700-S2 | 18.65 wt.% |

| PA6-T700-3 strand CF sized | PA6-T700-S3 | 25.64 wt.% |

| PA6-T700-4 strand CF sized | PA6-T700-S4 | 28.98 wt.% |

| Material Name | Temperature at 5% Decomposition (°C) | TG Residue (wt.%) | Maximum Weight Loss Rate Temperature (°C) | Density (g/cm3) |

|---|---|---|---|---|

| Neat PA6 | 403.11 | 0.88 | 465.04 | 1.13 |

| PA6-T300-S0 | 402.23 | 11.46 | 471.09 | 1.15 |

| PA6-T300-S1 | 400.34 | 9.94 | 468.32 | 1.17 |

| PA6-T300-S2 | 402.25 | 17.78 | 470.19 | 1.18 |

| PA6-T300-S3 | 400.17 | 23.54 | 470.22 | 1.23 |

| PA6-T300-S4 | 404.53 | 29.66 | 470.44 | 1.26 |

| PA6-T700-S0 | 410.37 | 11.26 | 470.35 | 1.16 |

| PA6-T700-S1 | 406.32 | 10.62 | 468.32 | 1.16 |

| PA6-T700-S2 | 408.57 | 18.65 | 472.45 | 1.19 |

| PA6-T700-S3 | 409.70 | 25.64 | 470.58 | 1.22 |

| PA6-T700-S4 | 407.14 | 28.98 | 473.14 | 1.26 |

| Sample Code | Tm (°C) | Tc (°C) | ∆Hm (J/g) | Xc (%) |

|---|---|---|---|---|

| Neat PA6 | 224.60 | 181.40 | 103.10 | 44.83 |

| PA6-T300-S0 | 224.90 | 185.60 | 61.85 | 30.37 |

| PA6-T300-S1 | 224.70 | 185.00 | 66.21 | 31.96 |

| PA6-T300-S2 | 224.20 | 185.00 | 55.78 | 29.50 |

| PA6-T300-S4 | 224.00 | 184.20 | 49.97 | 30.89 |

| PA6-T700-S0 | 226.30 | 183.90 | 53.89 | 26.40 |

| PA6-T700-S1 | 229.40 | 184.30 | 62.12 | 30.22 |

| PA6-T700-S2 | 229.00 | 184.90 | 53.71 | 28.71 |

| PA6-T700-S4 | 226.00 | 185.20 | 45.54 | 27.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, W.; Yu, Z.; Sun, X.; Hu, Z.; E, S.; Tong, F.; Wang, S.; Li, X. Carbon Fiber-Reinforced Polyamide 6 Composites: Impact of Fiber Type and Concentration on the Mechanical Properties. Materials 2025, 18, 1413. https://doi.org/10.3390/ma18071413

Dong W, Yu Z, Sun X, Hu Z, E S, Tong F, Wang S, Li X. Carbon Fiber-Reinforced Polyamide 6 Composites: Impact of Fiber Type and Concentration on the Mechanical Properties. Materials. 2025; 18(7):1413. https://doi.org/10.3390/ma18071413

Chicago/Turabian StyleDong, Weiping, Zhaozhu Yu, Xingxiang Sun, Zhonglue Hu, Shiju E, Fangqiang Tong, Sisi Wang, and Xiping Li. 2025. "Carbon Fiber-Reinforced Polyamide 6 Composites: Impact of Fiber Type and Concentration on the Mechanical Properties" Materials 18, no. 7: 1413. https://doi.org/10.3390/ma18071413

APA StyleDong, W., Yu, Z., Sun, X., Hu, Z., E, S., Tong, F., Wang, S., & Li, X. (2025). Carbon Fiber-Reinforced Polyamide 6 Composites: Impact of Fiber Type and Concentration on the Mechanical Properties. Materials, 18(7), 1413. https://doi.org/10.3390/ma18071413