Machine Learning-Assisted Multi-Property Prediction and Sintering Mechanism Exploration of Mullite–Corundum Ceramics

Highlights

- Machine learning (ML) models predict four properties of mullite-corundum ceramics.

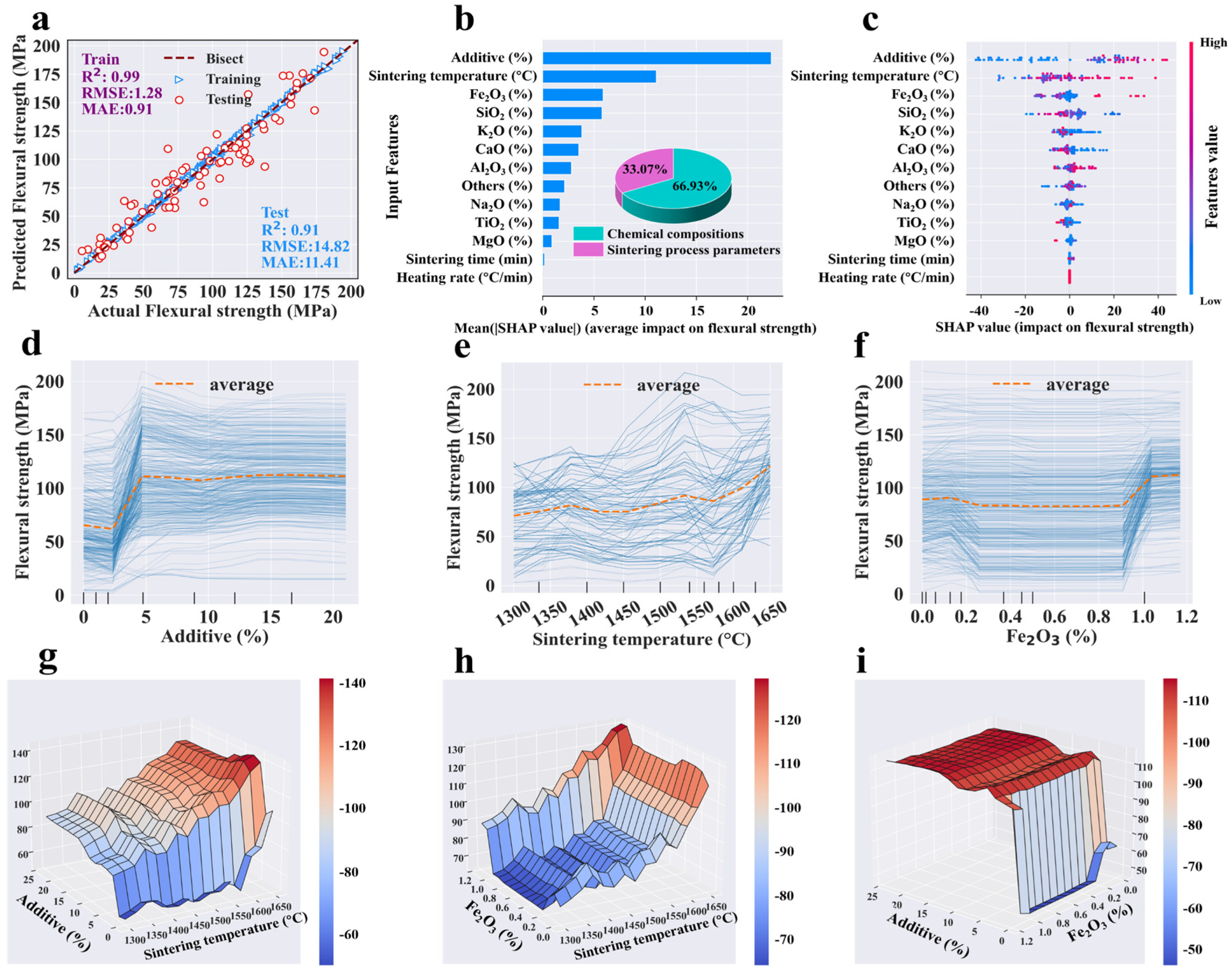

- Gradient boosting regression achieved optimal performance with test R2 of 0.91–0.95.

- Sintering temperature, K₂O, and additive were key features for ceramic properties.

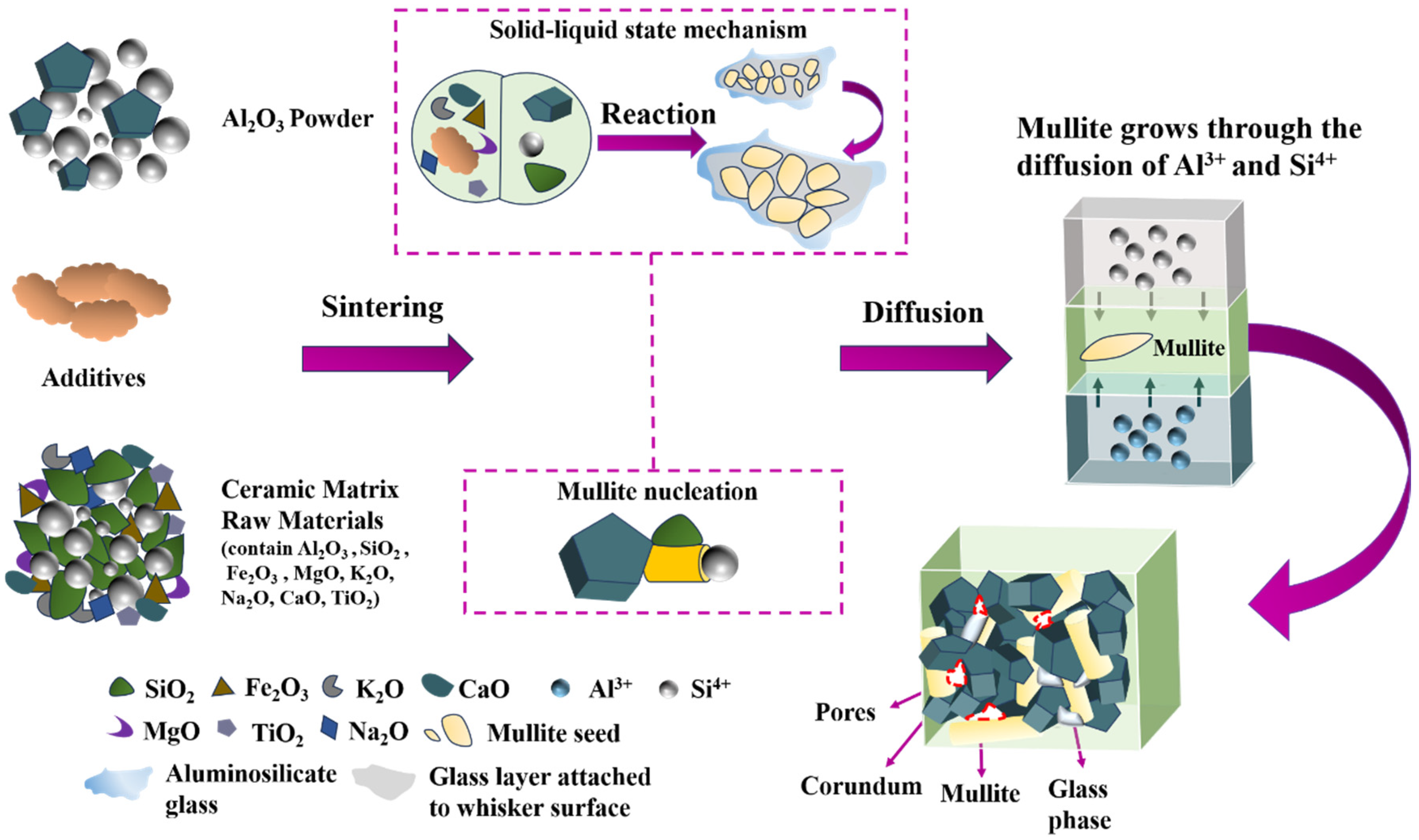

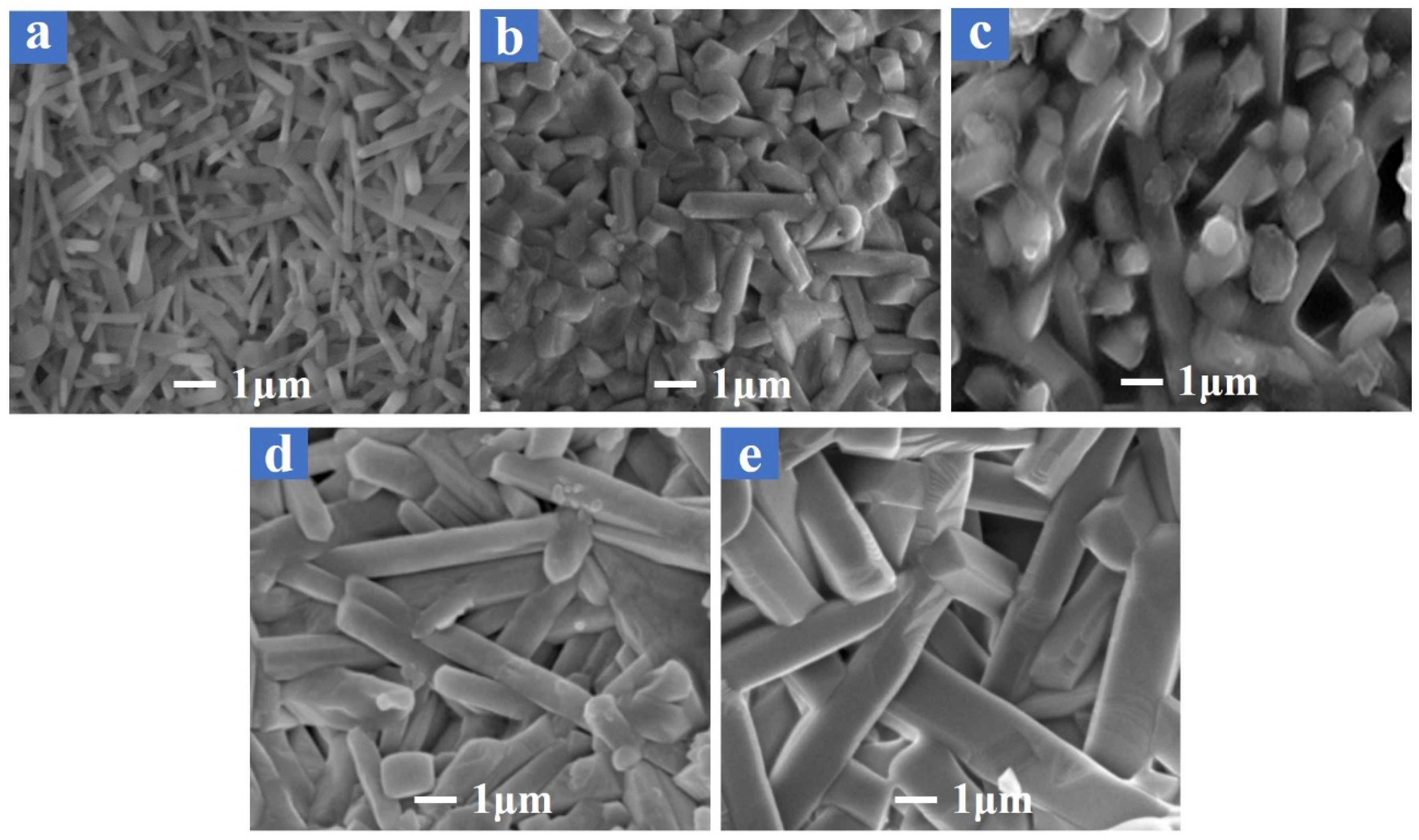

- A possible sintering mechanism of mullite-corundum ceramics was proposed.

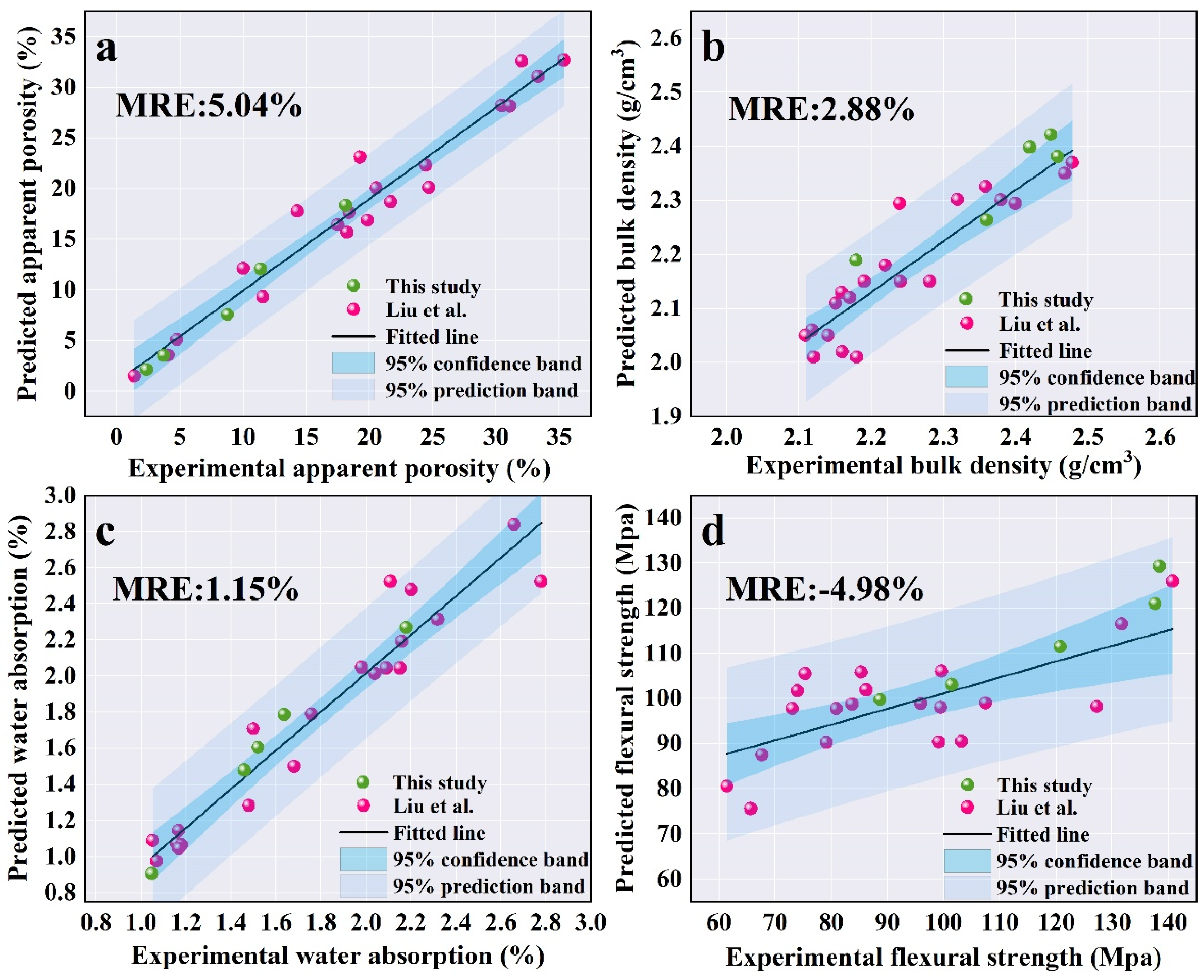

- An ML model's accuracy and generalization ability were validated by experiment.

Abstract

:1. Introduction

2. Methods

2.1. Dataset Acquisition and Pre-Processing

2.2. Machine Learning Algorithms and Model Optimization

2.3. Modeling and Evaluation

2.4. Evaluation of Input Feature Influence on Target Variables

2.5. Model Application and Experimental Validation

3. Results and Discussions

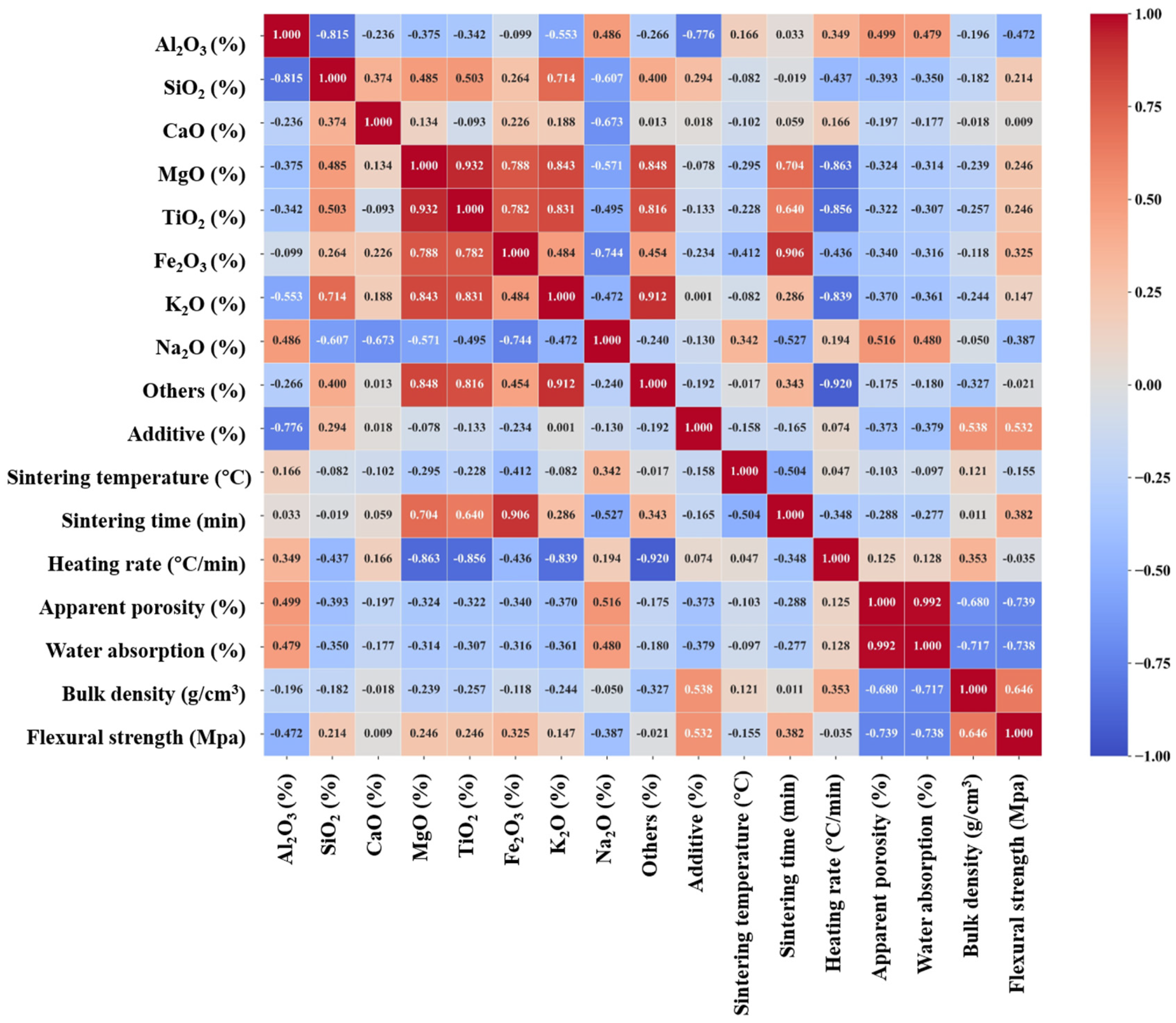

3.1. Statistical Analysis of the Pre-Processed Dataset

3.2. Hyper-Parameter Adjusting and Optimization

3.3. Multi-Property Prediction of Mullite–Corundum Ceramics

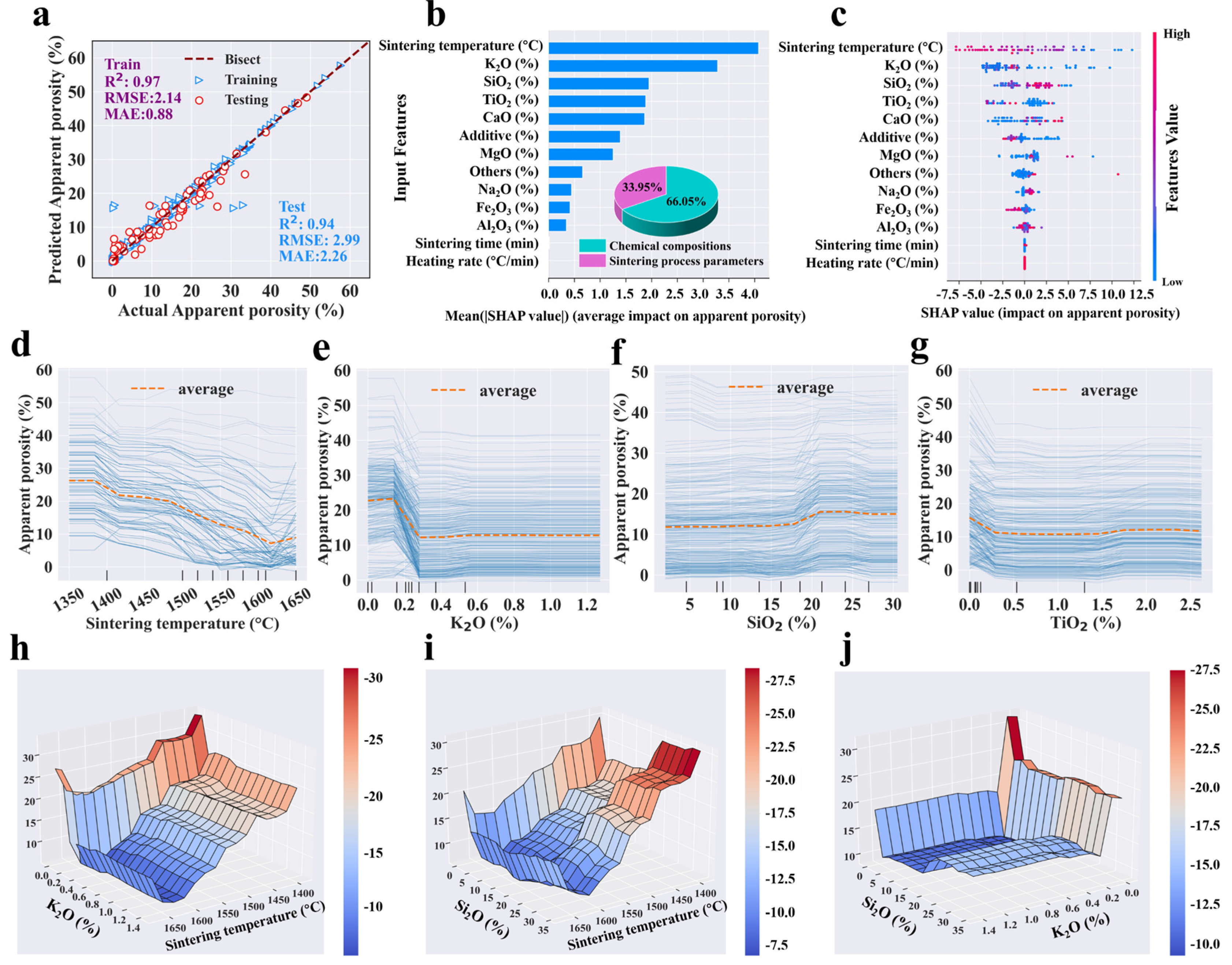

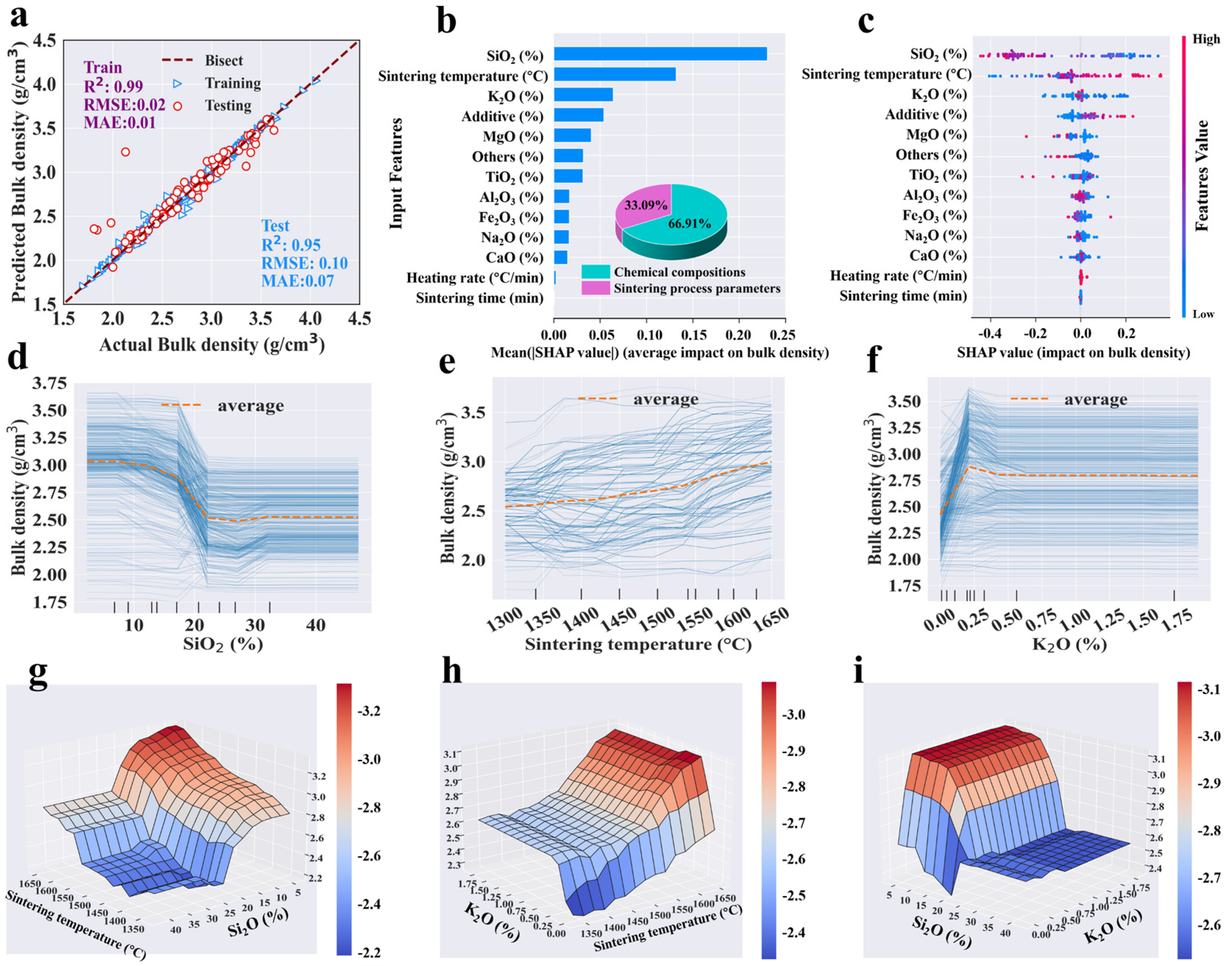

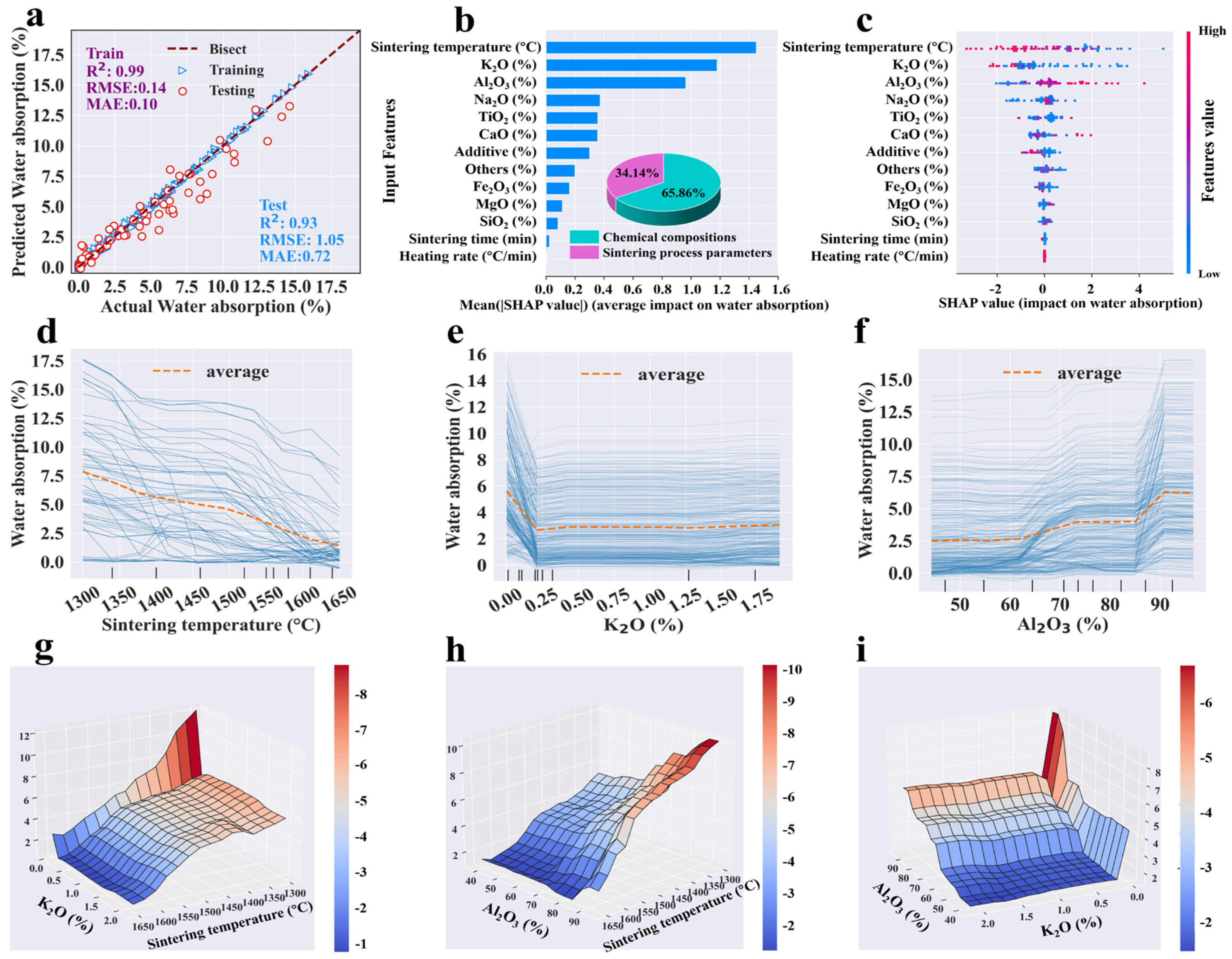

3.3.1. Model Evaluation and Performance Analysis

3.3.2. Feature Analysis for Each Target (Sensitivity Analysis)

3.4. Experimental Validation for Predictive Models

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schneider, H.; Schreuer, J.; Hildmann, B. Structure and Properties of Mullite—A Review. J. Eur. Ceram. Soc. 2008, 28, 329–344. [Google Scholar] [CrossRef]

- Xu, J.; Shao, Y.; Feng, X.; Zhang, X.; Li, H.; Yang, J.; Gao, F. Low Sintering Shrinkage Porous Ceramics: Principles, Progress, and Perspectives. J. Adv. Ceram. 2025, 14, 9221015. [Google Scholar] [CrossRef]

- Zhao, D.; Wu, D.; Shi, J.; Niu, F.; Ma, G. Microstructure and Mechanical Properties of Melt-Grown Alumina-Mullite/Glass Composites Fabricated by Directed Laser Deposition. J. Adv. Ceram. 2022, 11, 75–93. [Google Scholar] [CrossRef]

- Shen, Y.; Xu, X.; Wu, J.; Yu, J.; Qiu, S.; Zhang, D. Effect of ZrO2-MoO3 on the Properties of in Situ Synthesized Corundum-Mullite Composite Thermal Storage Ceramics. Ceram. Int. 2025, 51, 6110–6124. [Google Scholar] [CrossRef]

- Niu, S.; Xu, X.; Li, X.; Chen, X.; Luo, Y. Microstructure Evolution and Properties of Silica-Based Ceramic Cores Reinforced by Mullite Fibers. J. Alloys Compd. 2020, 829, 154494. [Google Scholar] [CrossRef]

- Shen, Y.; Xu, X.; Wu, J.; Qiu, S.; Zhang, D.; Shi, X. Fabrication and Characterization of Corundum-Mullite Composite Solar Thermal Storage Ceramics with Enhanced Thermophysical Properties. Ceram. Int. 2025, in press. [CrossRef]

- Fu, L.; Gu, H.; Huang, A.; Or, S.W.; Zou, Y.; Zou, Y.; Zhang, M. Design, Fabrication and Properties of Lightweight Wear Lining Refractories: A Review. J. Eur. Ceram. Soc. 2022, 42, 744–763. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, G.; Gu, Q.; Li, S.; Fan, B.; Zhang, R.; Li, H. Preparation of Corundum-Mullite Refractories with Lightweight, High Strength and High Thermal Shock Resistance. Materialia 2019, 8, 100517. [Google Scholar] [CrossRef]

- Liu, D.; Gui, K.; Long, J.; Zhao, Y.; Han, W.; Wang, G. Low-Temperature Densification and Mechanical Properties of Monolithic Mullite Ceramic. Ceram. Int. 2020, 46, 12329–12334. [Google Scholar] [CrossRef]

- Lima, L.K.S.; Silva, K.R.; Menezes, R.R.; Santana, L.N.L.; Lira, H.L. Microstructural Characteristics, Properties, Synthesis and Applications of Mullite: A Review. Ceramica 2022, 68, 126–142. [Google Scholar] [CrossRef]

- Xu, X.; Li, J.; Wu, J.; Tang, Z.; Chen, L.; Li, Y.; Lu, C. Preparation and Thermal Shock Resistance of Corundum-Mullite Composite Ceramics from Andalusite. Ceram. Int. 2017, 43, 1762–1767. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, W.; Li, N.; Schafföner, S.; Zhou, W.; Chen, Z.; Wei, J. Mullite-Corundum Gas-Permeable Refractories Reinforced by in-Situ Formed SiC Whiskers. Ceram. Int. 2020, 46, 25155–25163. [Google Scholar] [CrossRef]

- Zhong, X.; Gallagher, B.; Liu, S.; Kailkhura, B.; Hiszpanski, A.; Han, T.Y.J. Explainable Machine Learning in Materials Science. npj Comput. Mater. 2022, 8, 204. [Google Scholar] [CrossRef]

- Rajendra, P.; Girisha, A.; Gunavardhana Naidu, T. Advancement of Machine Learning in Materials Science. Mater. Today Proc. 2022, 62, 5503–5507. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, T.; Huang, G. State-of-the-Art Research Progress and Challenge of the Printing Techniques, Potential Applications for Advanced Ceramic Materials 3D Printing. Mater. Today Commun. 2024, 40, 110001. [Google Scholar] [CrossRef]

- Bourgès, C.; Lambard, G.; Sato, N.; Tachibana, M.; Ishii, S.; Mori, T. Process Optimization on Kesterite-Based Ceramics for Enhancing Their Thermoelectric Performances Assisted by Active Machine Learning Approach: A Tool for Metal-Sulfide Ceramics Development. Acta Mater. 2024, 281, 120342. [Google Scholar] [CrossRef]

- Zong, X.; Wu, S.; Lin, K.; Zhang, J.; Li, Y.; Lu, D.; Deng, X.; Lu, S.; Qiu, J.; Shao, Y.; et al. Advanced Ceramics with Integrated Structures and Functions: Machine Learning Prediction and Experimental Verification. Ceram. Int. 2024, 50, 24126–24138. [Google Scholar] [CrossRef]

- Furushima, R.; Nakashima, Y.; Zhou, Y.; Hirao, K.; Ohji, T.; Fukushima, M. Thermal Conductivity Prediction of Sintered Reaction Bonded Silicon Nitride Ceramics Using a Machine Learning Approach Based on Process Conditions. Ceram. Int. 2024, 50, 8520–8526. [Google Scholar] [CrossRef]

- Garg, P.; Broderick, S.; Mazumder, B. Machine Learning-Based Accelerated Design of Fluorphlogopite Glass Ceramic Chemistries with Targeted Hardness. J. Am. Ceram. Soc. 2023, 106, 4654–4663. [Google Scholar] [CrossRef]

- Yang, A.; Romanyk, D.; Hogan, J.D. High-Velocity Impact Study of an Advanced Ceramic Using Finite Element Model Coupling with a Machine Learning Approach. Ceram. Int. 2023, 49, 10481–10498. [Google Scholar] [CrossRef]

- Qu, N.; Liu, Y.; Liao, M.; Lai, Z.; Zhou, F.; Cui, P.; Han, T.; Yang, D.; Zhu, J. Ultra-High Temperature Ceramics Melting Temperature Prediction via Machine Learning. Ceram. Int. 2019, 45, 18551–18555. [Google Scholar] [CrossRef]

- Wang, A.; He, H.; Xiong, W.; Wang, S.; Liu, J.; Xie, H.; Dai, Y. Intelligent Prediction of Si3N4 Ceramic Strength Considering Inherent Defect Characteristics. J. Eur. Ceram. Soc. 2025, 45, 116900. [Google Scholar] [CrossRef]

- Zhou, Q.; Xu, F.; Gao, C.; Zhang, D.; Shi, X.; Yuen, M.F.; Zuo, D. Machine Learning-Assisted Mechanical Property Prediction and Descriptor-Property Correlation Analysis of High-Entropy Ceramics. Ceram. Int. 2023, 49, 5760–5769. [Google Scholar] [CrossRef]

- Zhou, Q.; Xu, F.; Gao, C.; Zhao, W.; Shu, L.; Shi, X.; Yuen, M.F.; Zuo, D. Design of High-Performance High-Entropy Nitride Ceramics via Machine Learning-Driven Strategy. Ceram. Int. 2023, 49, 25964–25979. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, N.; Ke, L.; Lv, Y.; Liu, Y.; Bai, Y.; Ou, Z.; Li, J. Machine Learning-Assisted Design of Al2O3–SiO2 Porous Ceramics Based on Few-Shot Datasets. Ceram. Int. 2023, 49, 29400–29408. [Google Scholar] [CrossRef]

- Kumaraswamy, J.; Thirumalesh; Ashok, A.S.; Shankar, N.B.; Praveen, S.R. Sukhateertha Research Article on Thermal Evaluation of Al-Si3N4 Composites Using Machine Learning. Mater. Today Commun. 2024, 41, 110859. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, N.; Ye, Y.; Chen, D.; Gui, L.; Tang, R. A Novel Deep Learning Strategy to Optimize Al2O3–SiO2 Porous Ceramics with Phosphate Tailings as Raw Material. Ceram. Int. 2024, 50, 35079–35088. [Google Scholar] [CrossRef]

- Guo, W.; Wang, L.; Zhu, L.; Ye, Y.; Zhang, Z.; Yang, B.; Zhang, S.; Bai, S. Accelerated Discovery and Formation Mechanism of High-Entropy Carbide Ceramics Using Machine Learning Based on Low-Cost Descriptors. J. Alloys Compd. 2024, 1004, 175929. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Q.; Chen, J.; Xu, D.; Zhan, H.; Peng, H.; Pan, J.; Vlaskin, M.; Leng, L.; Li, H. Machine Learning for Hydrothermal Treatment of Biomass: A Review. Bioresour. Technol. 2023, 370, 128547. [Google Scholar] [CrossRef]

- Zhang, W.; Li, J.; Liu, T.; Leng, S.; Yang, L.; Peng, H.; Jiang, S.; Zhou, W.; Leng, L.; Li, H. Machine Learning Prediction and Optimization of Bio-Oil Production from Hydrothermal Liquefaction of Algae. Bioresour. Technol. 2021, 342, 126011. [Google Scholar] [CrossRef]

- Feltrin, A.C.; Hedman, D.; Akhtar, F. Thermal Properties and High-Temperature Ablation of High-Entropy (Ti0.25V0.25Zr0.25Hf0.25)B2 Coating on Graphite Substrate. J. Adv. Ceram. 2024, 13, 1268–1281. [Google Scholar] [CrossRef]

- Chen, Z.; Ji, W.; Huang, Y.; Wei, Y.; Lu, J.; Liu, L.; Poon, C.S. Upcycling Municipal Solid Wastes to Self-Foaming Glass-Ceramics by Chemical Additive-Free and Rapid Low-Temperature Sintering. J. Clean. Prod. 2024, 444, 141261. [Google Scholar] [CrossRef]

- Yadav, U.; Pathrudkar, S.; Ghosh, S. Interpretable Machine Learning Model for the Deformation of Multiwalled Carbon Nanotubes. Phys. Rev. B 2021, 103, 035407. [Google Scholar] [CrossRef]

- Karathanasopoulos, N.; Singh, A.; Hadjidoukas, P. Machine Learning-Based Modelling, Feature Importance and Shapley Additive Explanations Analysis of Variable-Stiffness Composite Beam Structures. Structures 2024, 62, 106206. [Google Scholar] [CrossRef]

- Saarela, M.; Jauhiainen, S. Comparison of Feature Importance Measures as Explanations for Classification Models. SN Appl. Sci. 2021, 3, 272. [Google Scholar] [CrossRef]

- Mwakipunda, G.C.; Nafouanti, M.B.; Ibrahim, A.W.; Yu, L. Estimating the Hydrogen Adsorption in Depleted Shale Gas Reservoirs for Kerogens in Underground Hydrogen Storage Using Machine Learning Algorithms. Fuel 2025, 388, 134534. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y.; Zhang, C.L.; Hong, W.; Yang, C.X.; Wang, J.W.; Sun, J.; Li, W.; Yan, C. Length-Scale Effect on the Hardness of Metallic/Ceramic Multilayered Composites: A Machine Learning Prediction. Scr. Mater. 2024, 242, 115921. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, W.; Ai, H.; Zhou, H.; Feng, L.; Cheng, L.; Guo, R.; Song, X. Application of Machine Learning in Predicting the Thermal Conductivity of Single-Filler Polymer Composites. Mater. Today Commun. 2024, 39, 109116. [Google Scholar] [CrossRef]

- Zhang, W.; Ai, Z.; Chen, Q.; Chen, J.; Xu, D.; Cao, J.; Kapusta, K.; Peng, H.; Leng, L.; Li, H. Automated Machine Learning-Aided Prediction and Interpretation of Gaseous by-Products from the Hydrothermal Liquefaction of Biomass. Sci. Total Environ. 2024, 945, 173939. [Google Scholar] [CrossRef]

- Nakajima, H.; Matsumoto, N.; Ogura, T.; Kondo, N.; Mimura, K.I.; Tanaka, S.; Tsuruta, A.; Watanabe, R.; Oishi, A.; Usukawa, R.; et al. Hidden Correlation between Rheological Dynamics and Crack Formation in Water-Based Slurry. J. Eur. Ceram. Soc. 2024, 44, 4141–4149. [Google Scholar] [CrossRef]

- Mo, L.; Qin, J.; Ma, M.; Liu, Z. Machine Learning Assisted Q×f Value Prediction of ABO4-Type Microwave Dielectric Ceramics. J. Mater. 2024, 11, 100926. [Google Scholar] [CrossRef]

- Ai, Z.; Zhang, W.; Yang, L.; Chen, H.; Xu, Z.; Leng, L.; Li, H. Journal of Analytical and Applied Pyrolysis Investigation and Prediction of Co-Pyrolysis between Oily Sludge and High-Density Polyethylene via in-Situ DRIFTS, TGA, and Artificial Neural Network. J. Anal. Appl. Pyrolysis 2022, 166, 105610. [Google Scholar] [CrossRef]

- Sun, D.; Gu, Q.; Wen, H.; Xu, J.; Zhang, Y.; Shi, S.; Xue, M.; Zhou, X. Assessment of Landslide Susceptibility along Mountain Highways Based on Different Machine Learning Algorithms and Mapping Units by Hybrid Factors Screening and Sample Optimization. Gondwana Res. 2023, 123, 89–106. [Google Scholar] [CrossRef]

- Yap, B.W.; Sim, C.H. Comparisons of Various Types of Normality Tests. J. Stat. Comput. Simul. 2011, 81, 2141–2155. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, C.; Xie, N.; Zhu, J.; Liu, Y.; Huang, S.; Shen, X.; Yang, Z.; Lin, X.; Kong, L. Mechanical Properties of in Situ Synthesized Mullite-Based Composite Ceramics with Three-Dimensional Network Structure. Int. J. Appl. Ceram. Technol. 2022, 19, 1659–1668. [Google Scholar] [CrossRef]

- Li, Y.; Zhong, C.; Qin, T.; Wang, M. Preparation and Performance of CaO-MgO-SiO2-Al2O3-CaF2 Glass/Al2O3 Ceramic with High Flexural Strength. J. Non. Cryst. Solids 2023, 602, 122088. [Google Scholar] [CrossRef]

- Qin, T.; Zhong, C.; Tang, B.; Zhan, S. A Novel Type of Composite LTCC Material for High Flexural Strength Application. J. Eur. Ceram. Soc. 2021, 41, 1342–1351. [Google Scholar] [CrossRef]

- KDong, W.; Bao, Q.; Zhou, J.; Zhao, T.; Liu, K.; Li, S.; Liu, S.; Ma, K. Comparison and Low-Temperature Sintering Mechanism of “K2O-Na2O” and “Li2O-K2O-Na2O” Fluxes on the Porcelain Building Tiles. J. Ceram. Soc. Japan 2020, 128, 821–831. [Google Scholar] [CrossRef]

- Zhang, K.; He, R.; Ding, G.; Bai, X.; Fang, D. Effects of Fine Grains and Sintering Additives on Stereolithography Additive Manufactured Al2O3 Ceramic. Ceram. Int. 2021, 47, 2303–2310. [Google Scholar] [CrossRef]

- Mendes, A.; Pereira, F.; De Melo, J.; Lucena, D.; Rodrigues, R.; Cam, C.A.D. The Harnessing of the Waste Arising from Y-TZP Dental Ceramics Manufactured by CAD/CAM to Be Used as Alternative Dental Materials. Ceram. Int. 2022, 48, 36149–36155. [Google Scholar] [CrossRef]

- Yu, J.; Wang, Y.; Zhou, F.; Wang, L.; Pan, Z. Laser Remelting of Plasma-Sprayed Nanostructured Al2O3–20 Wt.% ZrO2 Coatings onto 316L Stainless Steel. Appl. Surf. Sci. 2018, 431, 112–121. [Google Scholar] [CrossRef]

- Yu, T.; Zhao, Z.; Li, J. Effect of Sintering Temperature and Sintering Additives on the Properties of Alumina Ceramics Fabricated by Binder Jetting. Ceram. Int. 2023, 49, 9948–9955. [Google Scholar] [CrossRef]

- Gao, C.H.; Jiang, P.; Li, Y.; Sun, J.L.; Zhang, J.J.; Yang, H.Y. One Step Sintering of Homogenized Bauxite Raw Material and Kinetic Study. Int. J. Miner. Metall. Mater. 2016, 23, 1231–1238. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, N.; Zhang, H.; Huang, S.; Wu, C.; He, S.; Zhu, J.; Liu, Y. Effect of Al(OH)3 Addition on Densification Mechanism and Properties of Reaction-Sintered Mullite-Corundum Composite Ceramics. J. Asian Ceram. Soc. 2022, 10, 703–712. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, N.; Huang, S.; Zhang, H.; Wu, C.; Cui, K.; Liu, Y.; Zhu, H.; Zhu, J.; Xue, C. Influence of Zirconia on the Sintering Behaviour and Mechanical Properties of Reaction-Sintered Mullite-Based Composite Ceramics. Clay Miner. 2022, 57, 97–104. [Google Scholar] [CrossRef]

- Schiiller, K.H. Structure Development in Porcelain. Ber. Deut. Keram. Ges. 1965, 42, 299–307. [Google Scholar]

- Salem, A.; Aghahosseini, S. Determination of Fluxing Agents Mixing Ratio for Enhancing Thermal Shock Resistance of Ceramic Raschig Ring via a Systematic Approach. Thermochim. Acta 2012, 545, 57–66. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, W.; Schafföner, S.; Zhi, J.; Li, N. High-Strength Microporous Corundum-Mullite Refractory Aggregates with Sub-Micron Pores Using Vacuum Impregnation Treatment. J. Mater. Res. Technol. 2022, 19, 3433–3442. [Google Scholar] [CrossRef]

- Liu, W.; Xie, Z.; Cheng, L. Sintering Kinetics Window: An Approach to the Densification Process during the Preparation of Transparent Alumina. Adv. Appl. Ceram. 2015, 114, 33–38. [Google Scholar] [CrossRef]

- Xu, X.; Lao, X.; Wu, J.; Zhang, Y.; Xu, X.; Li, K. Microstructural Evolution, Phase Transformation, and Variations in Physical Properties of Coal Series Kaolin Powder Compact during Firing. Appl. Clay Sci. 2015, 115, 76–86. [Google Scholar] [CrossRef]

- Lee, W.E.; Souza, G.P.; McConville, C.J.; Tarvornpanich, T.; Iqbal, Y. Mullite Formation in Clays and Clay-Derived Vitreous Ceramics. J. Eur. Ceram. Soc. 2008, 28, 465–471. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, C.; Liu, S.; Zong, Y.; Zhou, Q.; Qin, S. Preparation of Steel Slag Ceramics with Different MgO/Al2O3 Ratios. Appl. Sci. 2019, 9, 4741. [Google Scholar] [CrossRef]

- Wu, J.; Wei, P.; Xie, G.; Xu, X.; Yu, J.; Shen, Y. Microstructure and Thermal Shock Resistance of ZrO2–Al2O3–A3S2 Composites for Casting Filter Materials. Ceram. Int. 2024, 50, 5140–5149. [Google Scholar] [CrossRef]

- Djangang, C.N.; Tchamba, A.B.; Kamseu, E.; Melo, U.C.; Elimbi, A.; Ferrari, A.M.; Leonelli, C. Reaction Sintering and Microstructural Evolution in Metakaolin-Metastable Alumina Composites. J. Therm. Anal. Calorim. 2014, 117, 1035–1045. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Q.; Wu, J.; Zhou, S.; Tian, K.; Wu, C. Preparation and Characterization of Corundum Ceramics Doped with Fe2O3 and TiO2 for High Temperature Thermal Storage. Ceram. Int. 2022, 48, 1820–1826. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, N.; Zhang, H.; Huang, S.; Wang, K.; Wang, Q.; Xue, C.; Zhu, H.; Li, J.; Liu, Y.; et al. Effect of Tm2O3 on the Properties of Corundum-Mullite Composite Ceramics for Solar Heat Transmission Pipelines. Int. J. Appl. Ceram. Technol. 2024, 21, 2069–2080. [Google Scholar] [CrossRef]

- Xu, X.; Xu, X.; Wu, J.; Lao, X.; Zhang, Y.; Li, K. Effect of Sm2O3 on Microstructure, Thermal Shock Resistance and Thermal Conductivity of Cordierite-Mullite-Corundum Composite Ceramics for Solar Heat Transmission Pipeline. Ceram. Int. 2016, 42, 13525–13534. [Google Scholar] [CrossRef]

- Xu, X.; Shen, Y.; Wu, J.; Qiu, S.; Yu, J.; Zhou, Y. Effect of Different Silicon Sources on the Properties of In-Situ Synthesized Corundum-Mullite Composite Thermal Storage Ceramics. Ceram. Int. 2024, 50, 17043–17053. [Google Scholar] [CrossRef]

- Ye, H.; Li, Y.; Sun, J. Kinetic Study on the Anisotropic Grain Growth of Elongated Iron-Containing Mullite. Ceram. Int. 2019, 45, 12934–12941. [Google Scholar] [CrossRef]

- Chen, P.; Gu, X.; Zhou, X.; He, Z.; Zhang, Q.; Chen, J.; Yu, J.; Song, H.; Xuan, W.; Ren, Z. Green Mullite Whiskers Prepared from Zeolite Waste at Low-Temperature. Ceram. Int. 2024, 50, 47051–47066. [Google Scholar] [CrossRef]

| Items | Schemes (wt %) | Chemical Compositions (%) | Ref. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mullite | Al2O3 Powder | Corundum | SiO2 | Al2O3 | CaO | MgO | Fe2O3 | TiO2 | K2O | Na2O | Others | ||

| B0 | 100 | 0 | 38.30 | 53.94 | – | 0.04 | 1.51 | 0.65 | 0.54 | – | 5.02 | [45] | |

| B1 | 95 | 5 | 36.39 | 56.19 | – | 0.04 | 1.43 | 0.62 | 0.51 | – | 4.82 | ||

| B2 | 90 | 10 | 34.47 | 58.45 | – | 0.04 | 1.36 | 0.59 | 0.49 | – | 4.60 | ||

| B3 | 85 | 15 | 32.56 | 60.70 | – | 0.03 | 1.28 | 0.55 | 0.46 | – | 4.42 | ||

| B4 | 80 | 20 | 25.09 | 71.43 | 0.64 | 0.08 | 0.63 | 0.22 | 0.74 | 0.05 | 1.12 | This study | |

| Minimum | Maximum | Average | Standard Deviation | |

|---|---|---|---|---|

| Al2O3 (%) | 20.13 | 99.20 | 71.11 | 16.15 |

| SiO2 (%) | 0 | 69.73 | 18.17 | 12.48 |

| MgO (%) | 0 | 0.59 | 0.06 | 0.13 |

| K2O (%) | 0 | 2.81 | 0.44 | 0.63 |

| CaO (%) | 0 | 1.88 | 0.17 | 0.24 |

| TiO2 (%) | 0 | 3.33 | 0.44 | 0.73 |

| Fe2O3 (%) | 0 | 4.49 | 0.50 | 0.68 |

| Na2O (%) | 0 | 1.80 | 0.28 | 0.40 |

| Others (%) | 0 | 33.72 | 3.35 | 5.96 |

| Additive (%) | 0 | 25.74 | 5.49 | 6.89 |

| Sintering temperature (°C) | 25 | 1670 | 1493.1 | 166.10 |

| Sintering time (min) | 120 | 240 | 141.41 | 36.73 |

| Heating rate (°C/min) | 3 | 5 | 4.88 | 0.48 |

| Apparent porosity (%) | 0.05 | 57.70 | 13.78 | 12.12 |

| Water absorption (%) | 0.01 | 15.92 | 3.49 | 3.83 |

| Bulk density (g/cm3) | 1.70 | 4.06 | 2.78 | 0.46 |

| Flexural strength (MPa) | 2.76 | 210.67 | 89.70 | 42.38 |

| Dataset a | Data Points | Target (Output) | ML Algorithms | Optimized Hyper-Parameters and 5-Fold Cross-Validation | |

|---|---|---|---|---|---|

| n_Estimators | Max_Depth | ||||

| #1 | 344 | apparent porosity | GBR | 81 | 5 |

| RF | 52 | 9 | |||

| #2 | 362 | water absorption | GBR | 75 | 5 |

| RF | 52 | 9 | |||

| #3 | 440 | bulk density | GBR | 101 | 5 |

| RF | 52 | 18 | |||

| #4 | 413 | flexural strength | GBR | 71 | 5 |

| RF | 52 | 9 | |||

| Dataset a | Target (Output) | Optimized Model | Train R2 | Train RMSE | Train MAE | Test R2 | Test RMSE | Test MAE |

|---|---|---|---|---|---|---|---|---|

| #1 | apparent porosity | GBR | 0.97 | 2.14 | 0.88 | 0.94 | 2.99 | 2.26 |

| (%) | RF | 0.96 | 2.46 | 1.29 | 0.89 | 3.87 | 2.81 | |

| ANN | 0.94 | 3.04 | 1.83 | 0.91 | 3.60 | 2.41 | ||

| #2 | water absorption | GBR | 0.99 | 0.14 | 0.10 | 0.93 | 1.05 | 0.72 |

| (%) | RF | 0.98 | 0.56 | 0.41 | 0.89 | 1.32 | 0.95 | |

| ANN | 0.93 | 1.01 | 0.64 | 0.88 | 1.39 | 1.00 | ||

| #3 | bulk density | GBR | 0.99 | 0.02 | 0.01 | 0.85 | 0.18 | 0.09 |

| (g/cm3) | RF | 0.99 | 0.55 | 0.03 | 0.83 | 0.19 | 0.10 | |

| ANN | 0.94 | 0.11 | 0.07 | 0.91 | 0.14 | 0.10 | ||

| #4 | flexural strength | GBR | 0.99 | 1.28 | 0.91 | 0.91 | 14.82 | 11.41 |

| (MPa) | RF | 0.95 | 9.13 | 6.68 | 0.86 | 18.33 | 13.10 | |

| ANN | 0.92 | 11.83 | 8.11 | 0.89 | 16.00 | 11.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Q.; Zhang, W.; Liang, X.; Feng, H.; Xu, W.; Wang, P.; Pan, J.; Cheng, B. Machine Learning-Assisted Multi-Property Prediction and Sintering Mechanism Exploration of Mullite–Corundum Ceramics. Materials 2025, 18, 1384. https://doi.org/10.3390/ma18061384

Chen Q, Zhang W, Liang X, Feng H, Xu W, Wang P, Pan J, Cheng B. Machine Learning-Assisted Multi-Property Prediction and Sintering Mechanism Exploration of Mullite–Corundum Ceramics. Materials. 2025; 18(6):1384. https://doi.org/10.3390/ma18061384

Chicago/Turabian StyleChen, Qingyue, Weijin Zhang, Xiaocheng Liang, Hao Feng, Weibin Xu, Pengrui Wang, Jian Pan, and Benjun Cheng. 2025. "Machine Learning-Assisted Multi-Property Prediction and Sintering Mechanism Exploration of Mullite–Corundum Ceramics" Materials 18, no. 6: 1384. https://doi.org/10.3390/ma18061384

APA StyleChen, Q., Zhang, W., Liang, X., Feng, H., Xu, W., Wang, P., Pan, J., & Cheng, B. (2025). Machine Learning-Assisted Multi-Property Prediction and Sintering Mechanism Exploration of Mullite–Corundum Ceramics. Materials, 18(6), 1384. https://doi.org/10.3390/ma18061384