Reinforced Fill Structure with Alternative Fill Materials: An Application of Geogrid Creep Strain Analysis Using Numerical Modeling

Abstract

1. Introduction

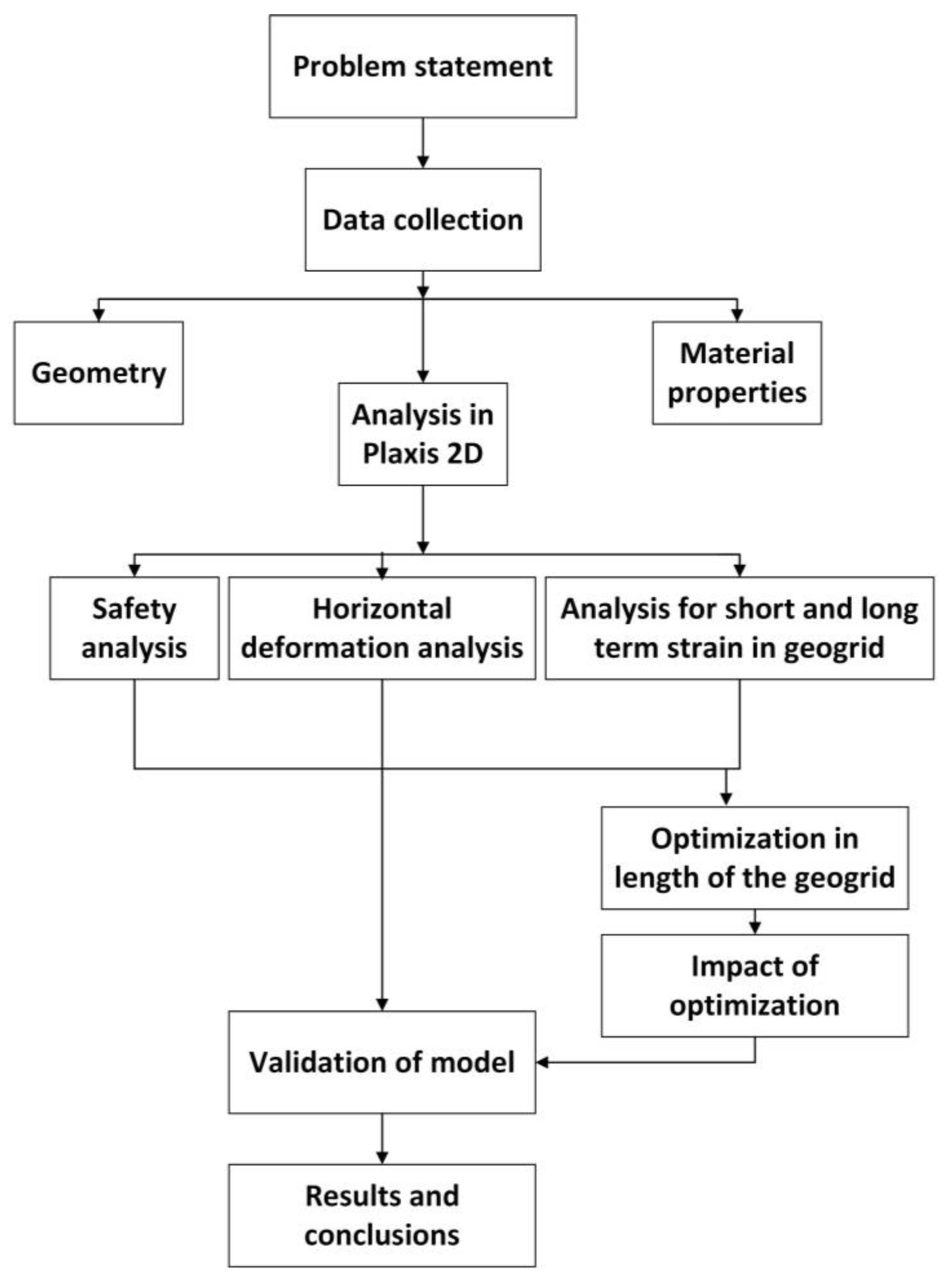

2. Materials and Methods

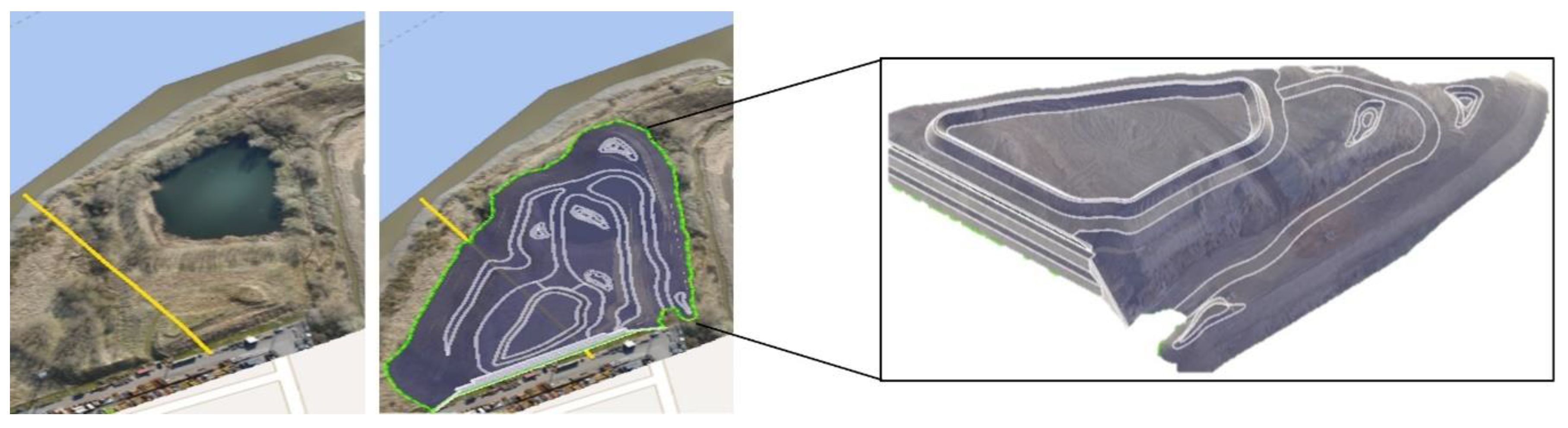

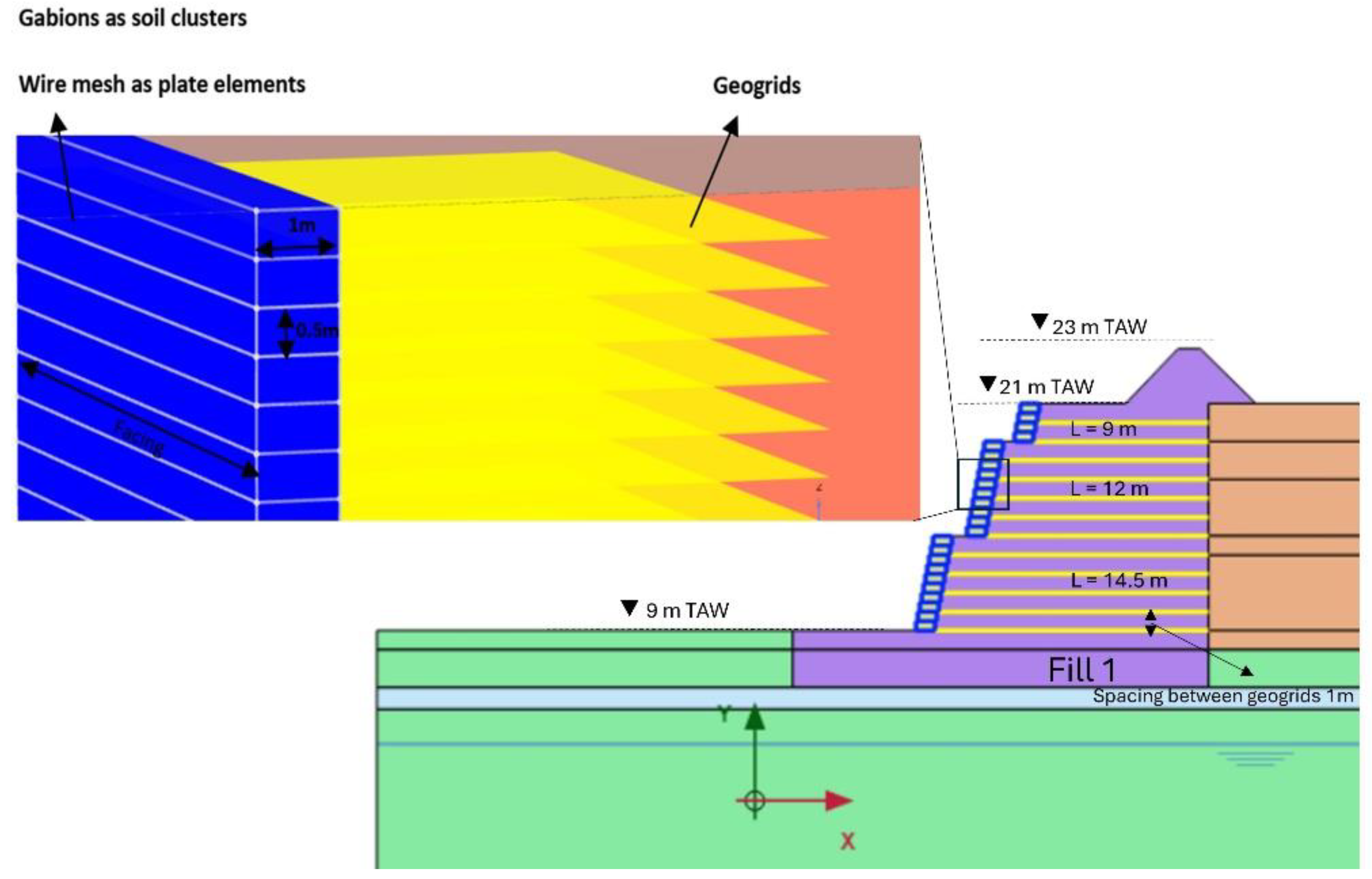

2.1. Numerical Modeling of Reinforced Fill Structure

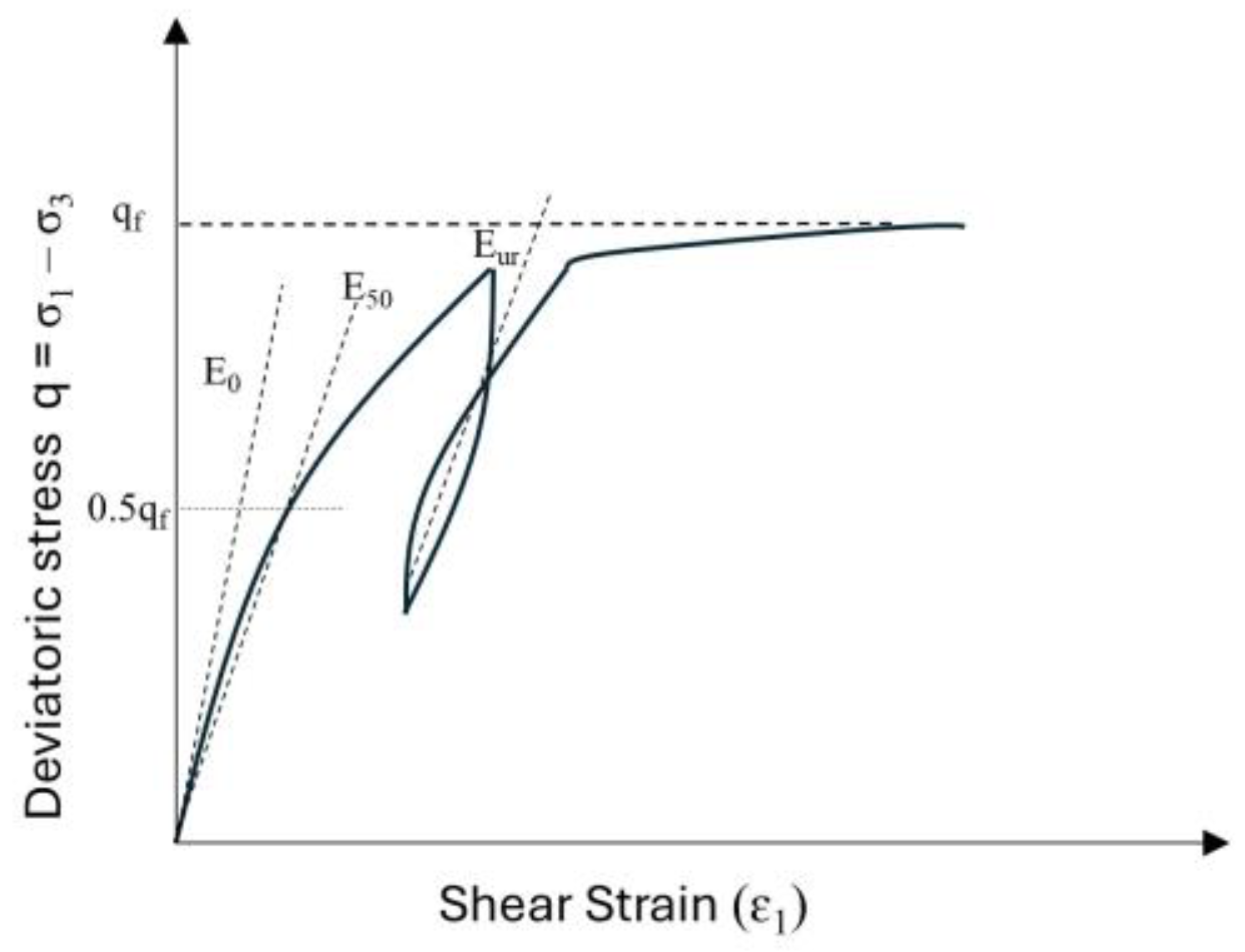

2.2. Material Properties for the Finite Element Method

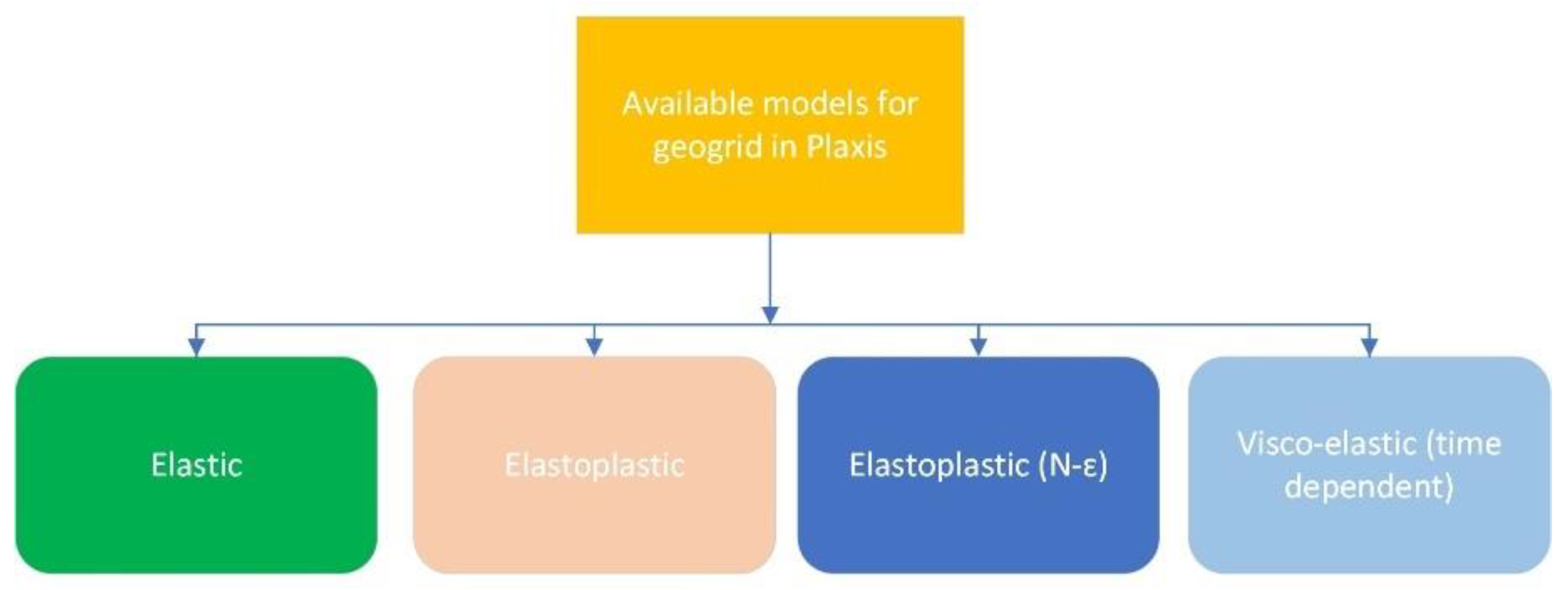

2.3. Modeling of Geogrids

- EA1: normal elastic stiffness (in plane);

- EA2: normal elastic stiffness (out of plane).

- Np,1: maximum force (in plane);

- Np,2: maximum force (out of plane).

- N1 − ε1: the strain-dependent strength diagram (in plane);

- N2 − ε2: the strain-dependent strength diagram (out of plane).

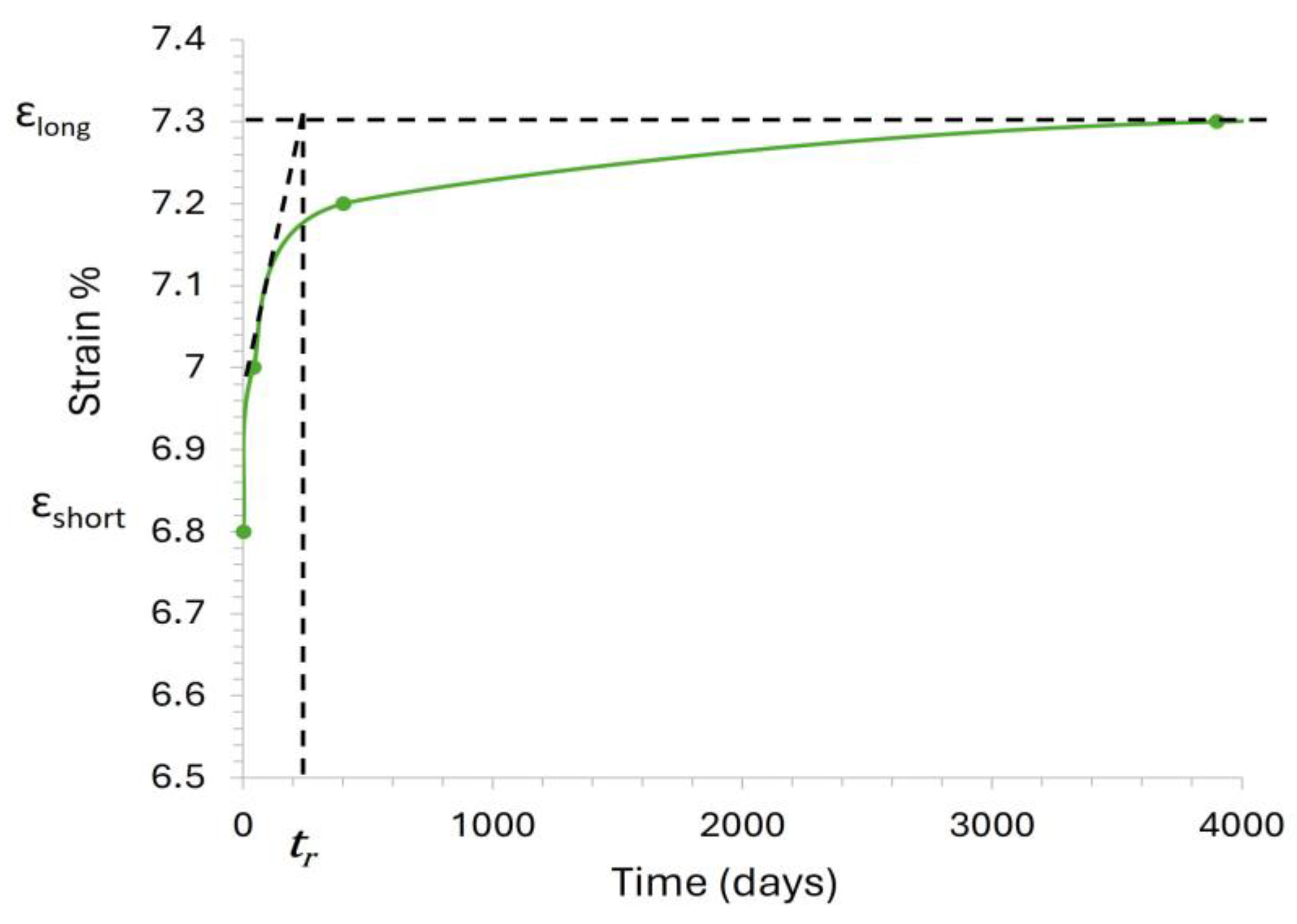

- EA1, short: normal elastic stiffness during an instantaneous (initial) strain increment (in plane);

- EA2, short: normal elastic stiffness during an instantaneous (initial) strain increment (out of plane);

- EA1, long: normal elastic stiffness during a long-term (infinite) strain increment (in plane);

- EA2, long: normal elastic stiffness during a long-term (infinite) strain increment (out of plane);

- Np,1: maximum force in one direction (in plane);

- Np,2: maximum force in two directions (out of plane);

- tr: retardation time.

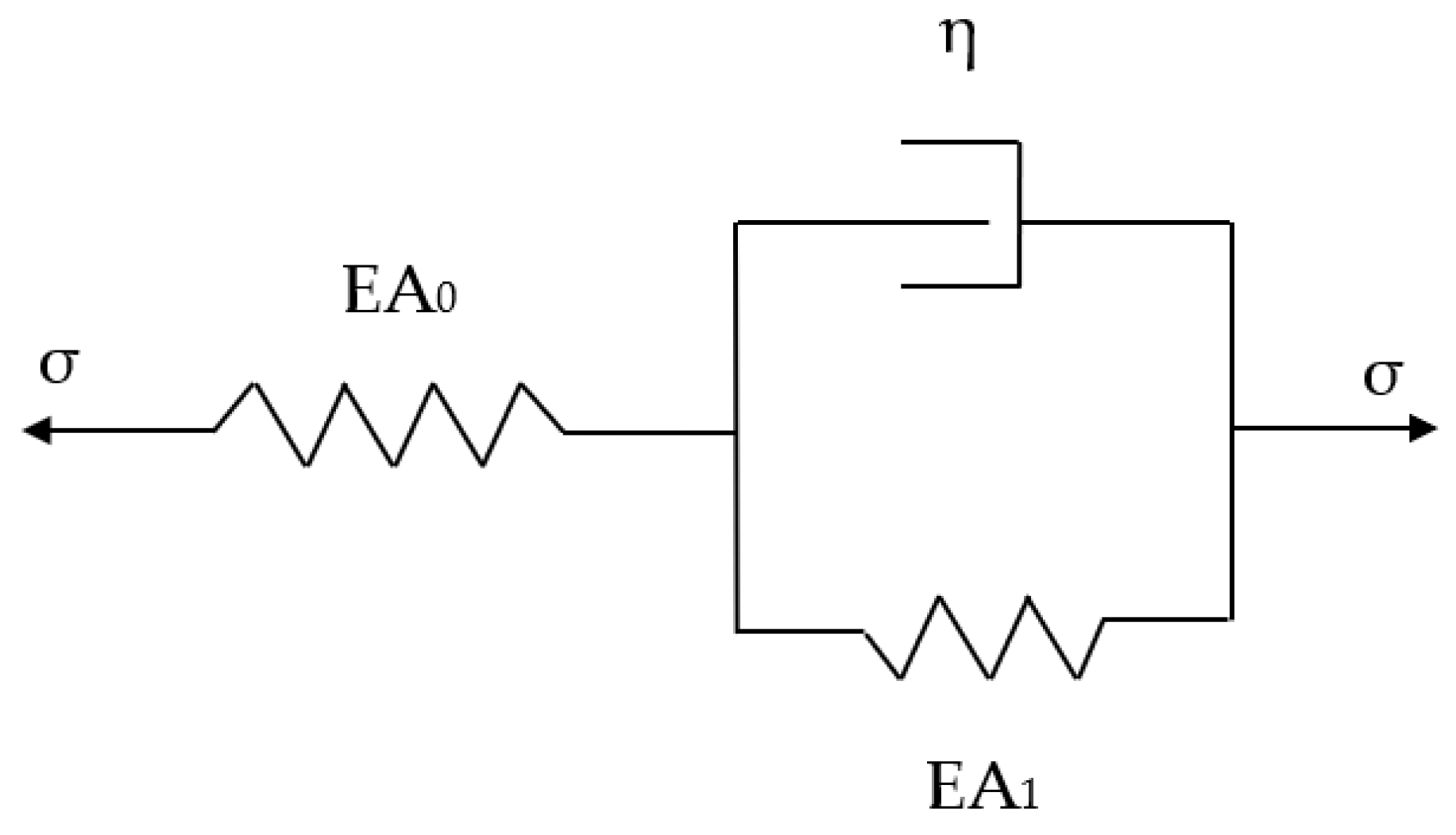

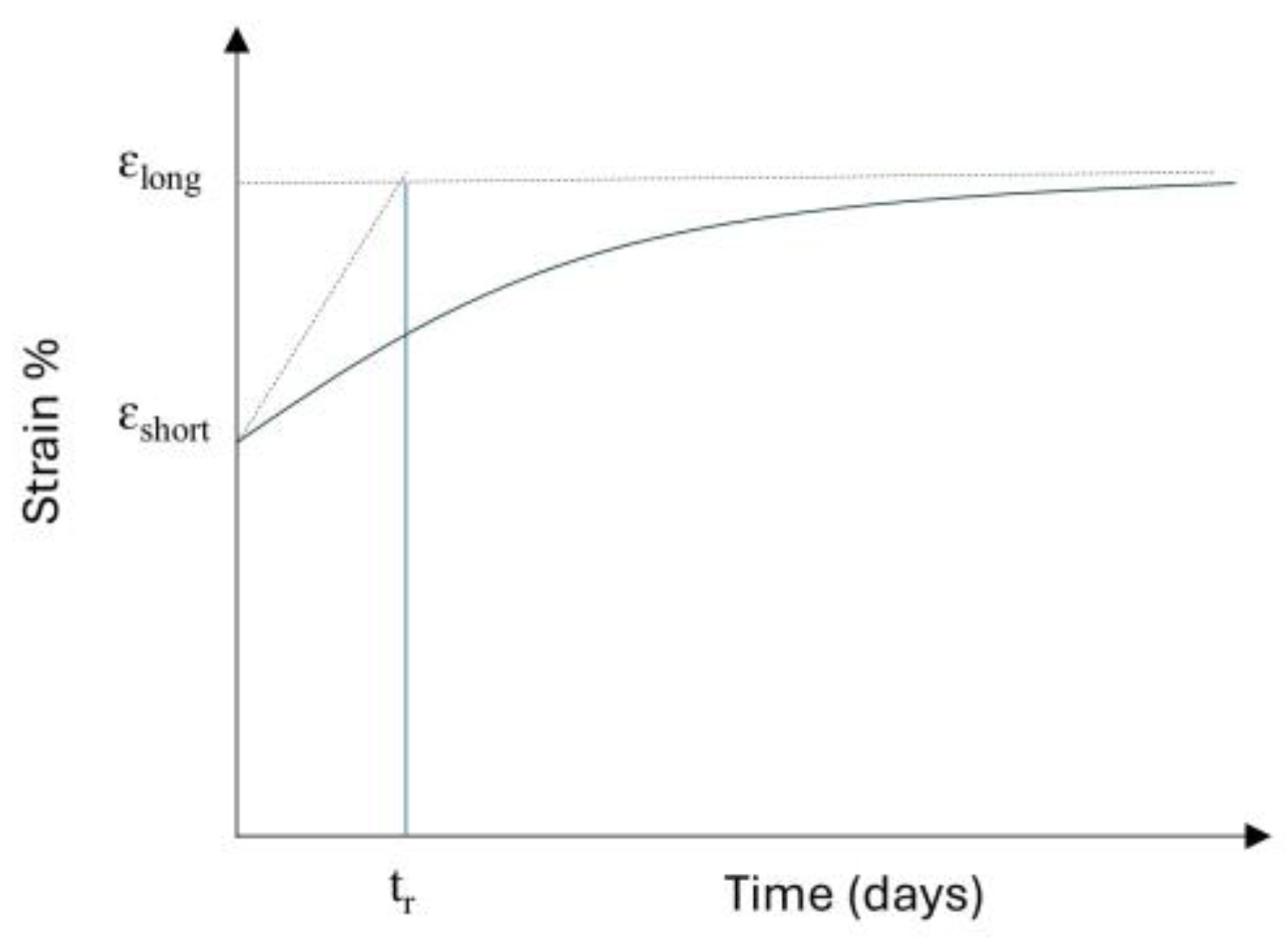

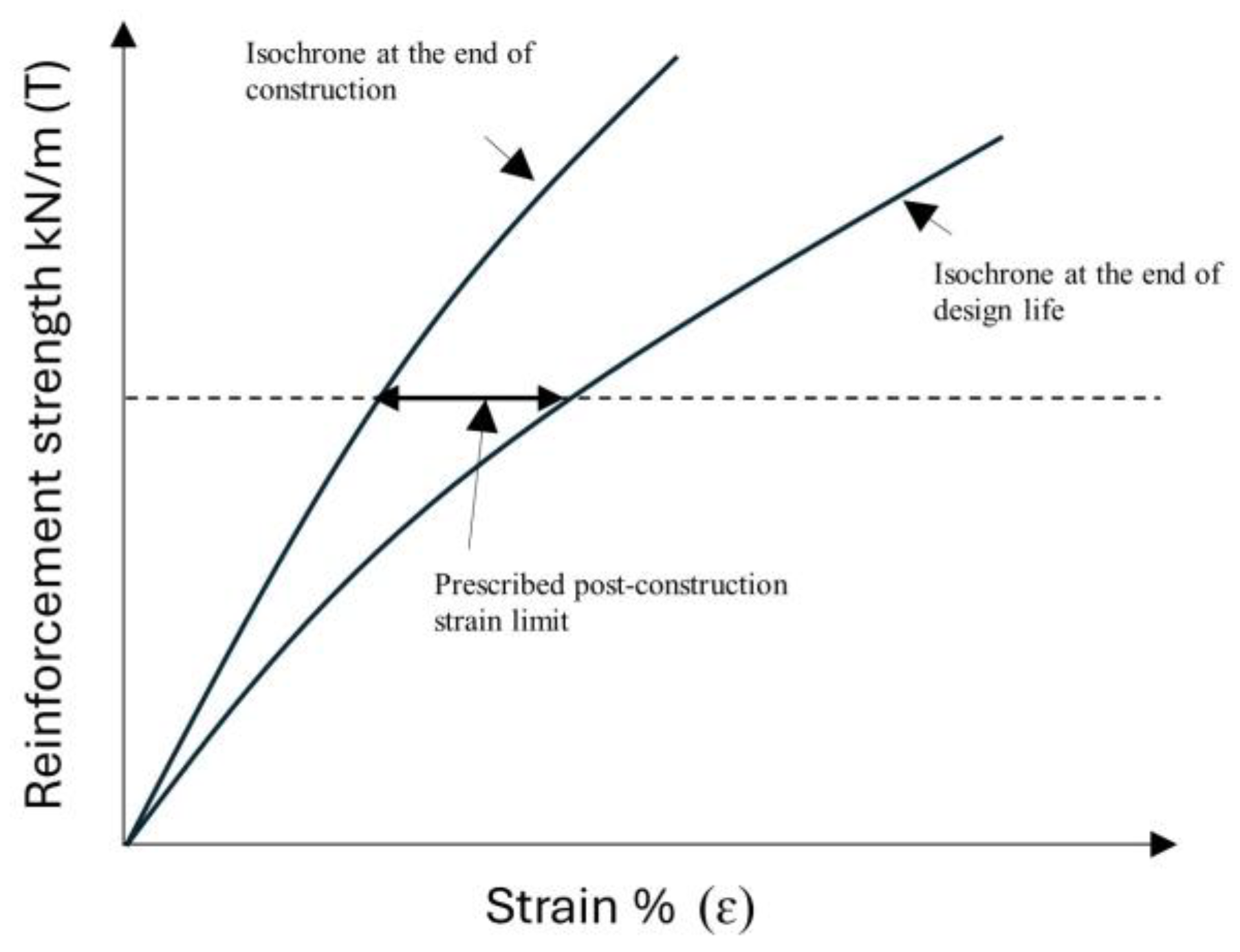

2.4. Modeling of Geogrid for Long-Term Creep Deformation

- RFCR = reduction factor due to creep;

- RFID = reduction factor for installation damage;

- RFW = reduction factor due to weathering;

- RFCH = reduction factor to allow for reductions in strength due to chemical and biological effects at the design temperature;

- fs = factor of safety for accounting the statistical variation in the reduction factors calculated.

- σ0 = applied stress (constant);

- E = elastic modulus of the spring;

- = retardation time;

- t = time.

2.5. Interface Coefficient

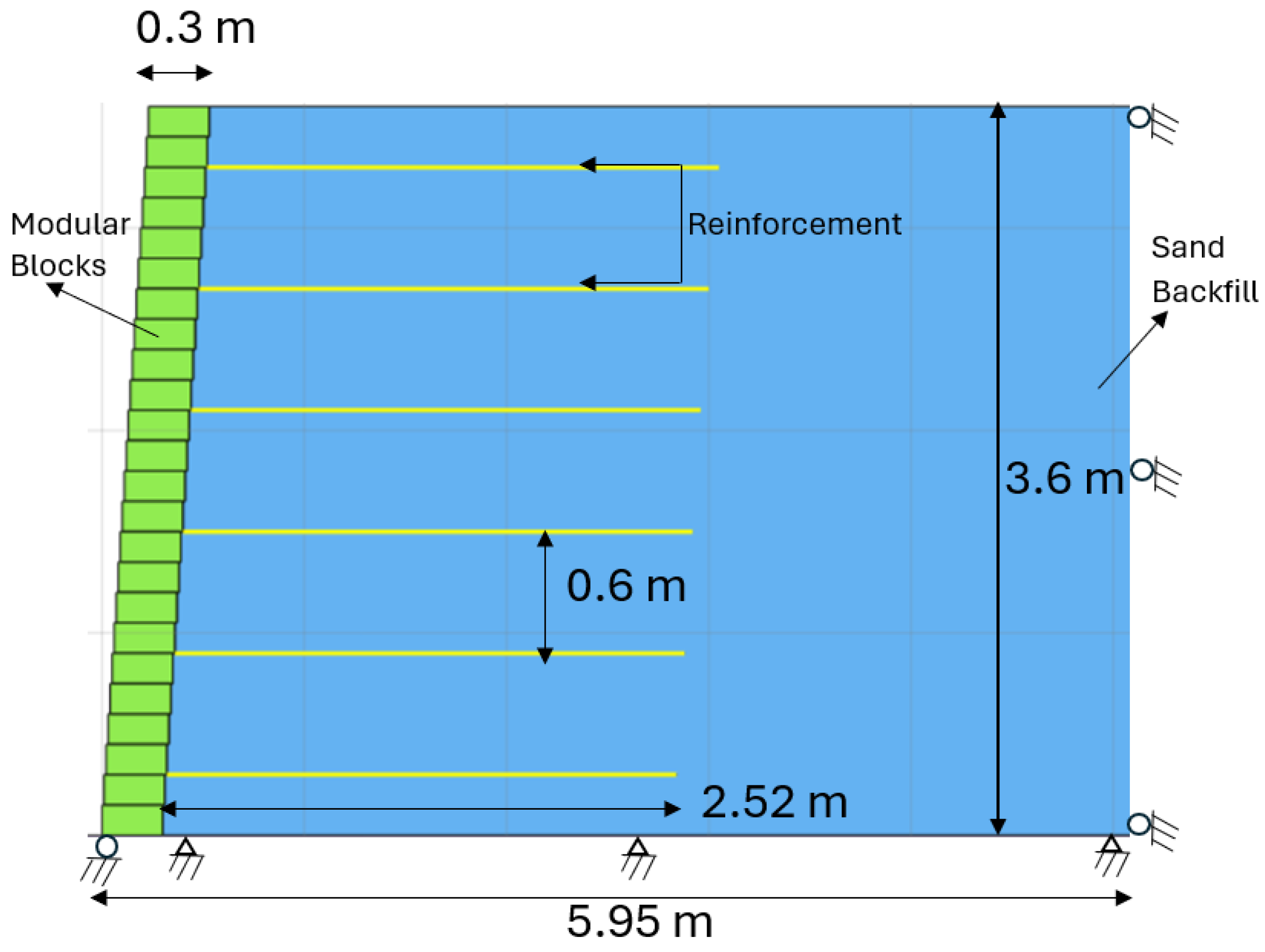

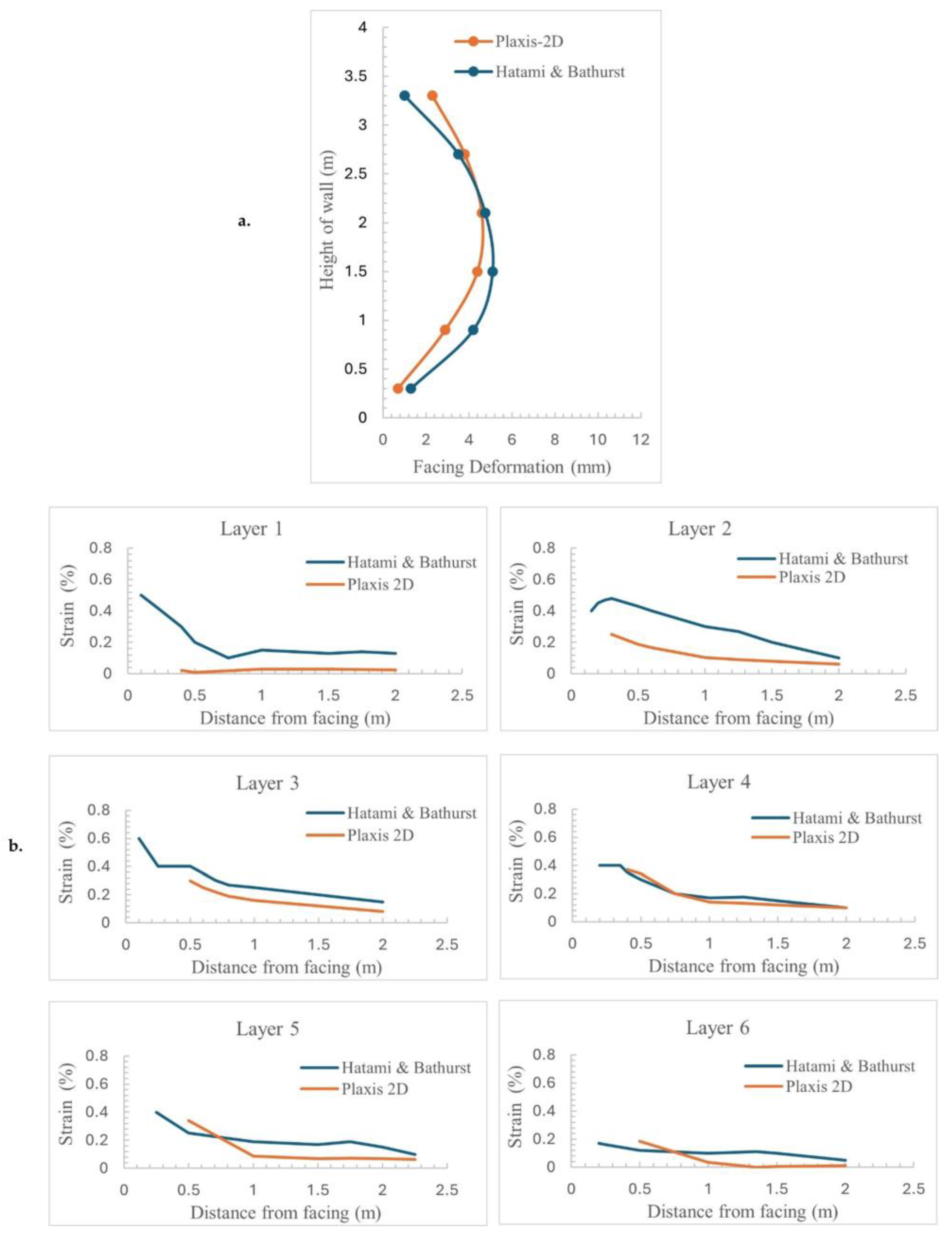

3. Validation of Model

4. Results and Discussion

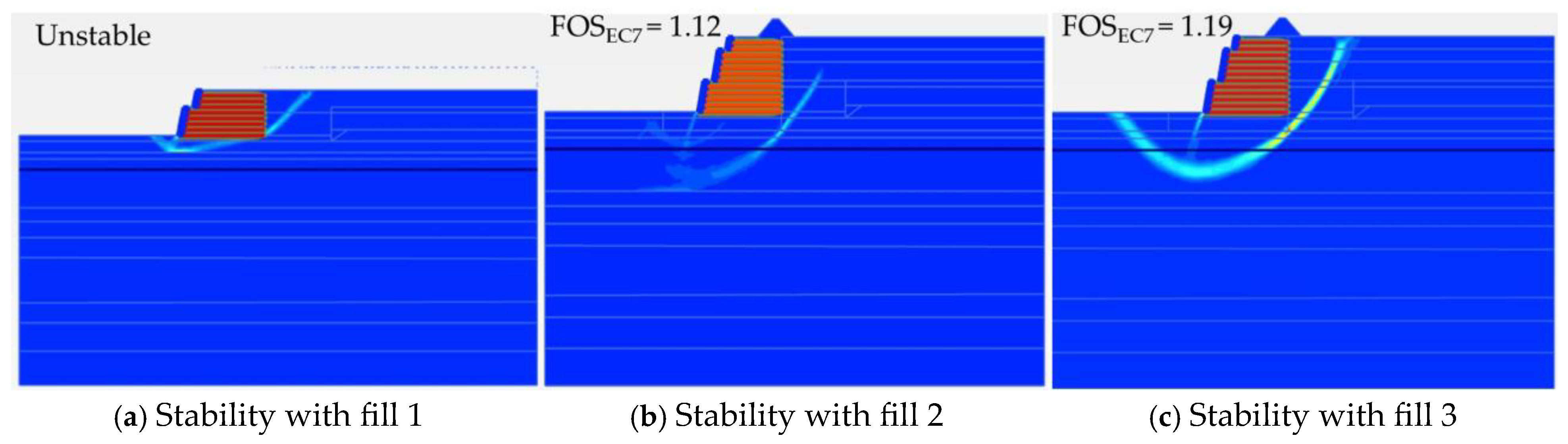

4.1. Stability Analysis

4.2. Horizontal Displacement

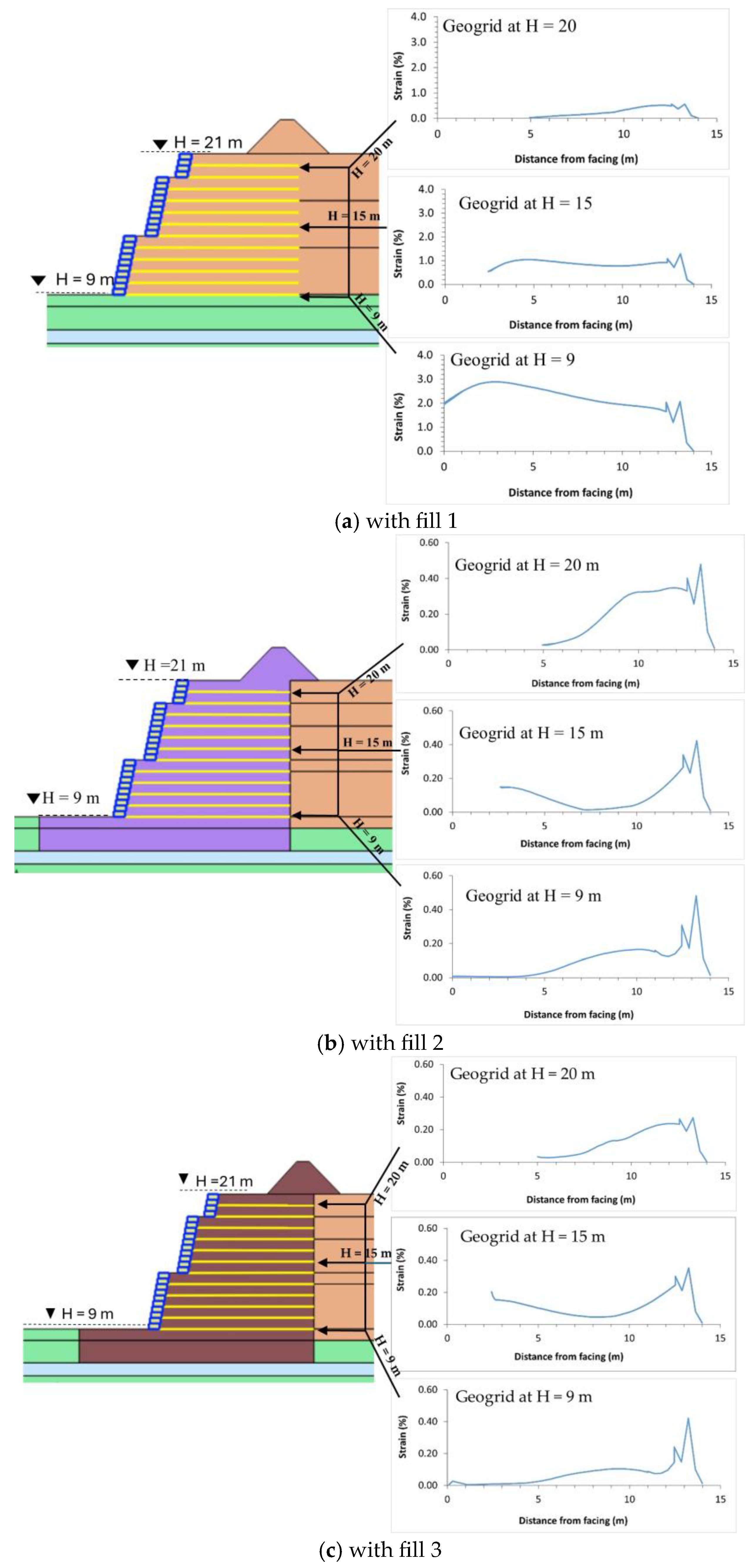

4.3. Strain in the Geogrid

4.3.1. Short-Term Strain

4.3.2. Long-Term Strain

4.4. Optimization of Geogrid Length in the Selected Model Among Different Solutions

5. Conclusions

- The results show that fill 1, with its low shear strength, stiffness, and poor fill–geogrid interaction, leads to an excessive lateral displacement of 85 cm, failing to meet the required stability criteria and making it unsuitable for RFS applications. Additionally, geogrid strain analysis reveals that fill 1 exceeds the prescribed serviceability strain limit (>1%) due to inadequate soil–geogrid interaction and high compressibility;

- With fill 2, the structure remained stable, achieving a Eurocode-based safety factor of 1.12, thereby satisfying stability requirements. The enhanced shear strength and stiffness of fill 2 effectively limited horizontal displacement to 23 cm, while the prescribed serviceability strain limit was within the threshold, thus confirming adequate performance;

- The results for fill 3 demonstrate that the structure remained stable, attaining a Eurocode-based safety factor of 1.19, thereby meeting stability requirements. The higher shear strength and stiffness of fill 3 contributed to a significantly reduced horizontal displacement of 20 cm. Additionally, the geogrid strain remained within the prescribed serviceability threshold, which ensures the effective mobilization of tensile resistance without excessive elongation;

- Finally, an optimization analysis was conducted on the geogrid length using fill 2 to assess its impact on horizontal displacement and cost efficiency. The initial design configuration recorded a displacement of 23 cm. Sequential optimization analysis revealed minimal variation in displacement while demonstrating a clear trend of cost reduction. The cost savings progressively increased, with reductions of 4%, 8%, 13%, 18%, 20%, 24%, and 29% from the first to the seventh stage, respectively. These findings highlight the effectiveness of iterative optimization in reducing costs while maintaining structural performance, reinforcing the importance of systematic design refinement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Tan, L.; Xiao, N.; Liu, K.; Jia, P.; Zhang, W. The hydro-mechanical characteristics and micro-structure of loess enhanced by microbially induced carbonate precipitation. Geomech. Energy Environ. 2023, 34, 100469. [Google Scholar] [CrossRef]

- Xue, Y.; Ranjith, P.G.; Gao, F.; Zhang, Z.; Wang, S. Experimental investigations on effects of gas pressure on mechanical behaviors and failure characteristic of coals. J. Rock Mech. Geotech. Eng. 2023, 15, 412–428. [Google Scholar] [CrossRef]

- Kiersnowska, A.; Zi, Z. Sustainability of Geosynthetics-Based Solutions. Environments 2023, 10, 64. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, S.; Chai, J.; Liu, J.; Ranjith, P.G.; Cai, C.; Gao, F.; Bai, X. Effect of water-cooling shock on fracture initiation and morphology of high-temperature granite: Application of hydraulic fracturing to enhanced geothermal systems. Appl. Energy 2023, 337, 120858. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Naftchali, F.M. Geosynthetic reinforcement stiffness for analytical and numerical modelling of reinforced soil structures. Geotext. Geomembr. 2021, 49, 921–940. [Google Scholar] [CrossRef]

- Jelušič, P.; Žlender, B. Numerical Validation of Strains in Geogrids Embedded in Bridge Abutments. In Challenges and Innovations in Geomechanics. IACMAG 2022; Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2023; Volume 288, pp. 500–506. [Google Scholar] [CrossRef]

- Al-Barqawi, M.; Aqel, R.; Wayne, M.; Titi, H.; Elhajjar, R. Polymer geogrids: A review of material, design and structure relationships. Materials 2021, 14, 4745. [Google Scholar] [CrossRef]

- Rimoldi, P.; Shamrock, J.; Kawalec, J.; Touze, N. Sustainable use of geosynthetics in dykes. Sustainability 2021, 13, 4445. [Google Scholar] [CrossRef]

- Wu, H.; Yao, C.; Li, C.; Miao, M.; Zhong, Y.; Lu, Y.; Liu, T. Review of application and innovation of geotextiles in geotechnical engineering. Materials 2020, 13, 1774. [Google Scholar] [CrossRef]

- Yoo, C. Geosynthetic Solutions for Sustainable Transportation Infrastructure Development. Sustainability 2023, 15, 15772. [Google Scholar] [CrossRef]

- Sulovska, M.; Stacho, J. Analysis of Geogrid Reinforced Structures with a Passive Facing System Using Different Computational Methods. Civ. Environ. Eng. 2021, 17, 500–512. [Google Scholar] [CrossRef]

- Lelli, M.; Laneri, R.; Rimoldi, P. Innovative reinforced soil structures for high walls and slopes combining polymeric and metallic reinforcements. Procedia Eng. 2015, 125, 397–405. [Google Scholar] [CrossRef]

- Khan, A.R.; Di Emidio, G. Numerical analysis using FEM on the behavior of reinforced fill structure having geogrid and steel wire mesh as a reinforcing element. In Geosynthetics: Leading the Way to a Resilient Planet; CRC Press: Boca Raton, FL, USA, 2023; pp. 991–996. [Google Scholar] [CrossRef]

- Lin, D.; Huang, B.; Lin, S. Deformation Analyses of Gabion Structures. In Proceedings of the INTERPRAEVENT Conference, Taipei, Taiwan, 26–30 April 2010; pp. 512–526. [Google Scholar]

- Uray, E. Gabion structures and retaining walls design criteria. Adv. Eng. Sci. 2022, 2, 127–134. [Google Scholar]

- Rimoldi, P.; Scotto, M. Hybrid reinforced soil structures for high walls and slopes. In Proceedings of the Second Pan American Geosynthetics Conference & Exhibition, GeoAmericas, Lima, Peru, 6–9 May 2012. [Google Scholar]

- Moropoulou, A.; Biscontin, G.; Bakolas, A.; Bisbikou, K. Technology and behavior of rubble masonry mortars. Constr. Build. Mater. 1997, 11, 119–129. [Google Scholar] [CrossRef]

- Cardile, G.; Pisano, M.; Recalcati, P.; Moraci, N. A new apparatus for the study of pullout behaviour of soil-geosynthetic interfaces under sustained load over time. Geotext. Geomembr. 2021, 49, 1519–1528. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Mendonça, G.; de Lopes, M.L. Effect of Sustained Loading on the Direct Shear Behaviour of Recycled C&D Material–Geosynthetic Interfaces. Materials 2023, 16, 1722. [Google Scholar] [CrossRef]

- Vibha, S.; Divya, P.V. Geosynthetic-Reinforced Soil Walls with Sustainable Backfills. Indian Geotech. J. 2021, 51, 1135–1144. [Google Scholar] [CrossRef]

- Mandloi, P.; Hegde, A. Performance evaluation of reinforced earth walls with sustainable backfills subjected to railway loading. Front. Built Environ. 2022, 8, 1048079. [Google Scholar] [CrossRef]

- Koerner, R.M.; Koerner, G.R. An extended data base and recommendations regarding 320 failed geosynthetic reinforced mechanically stabilized earth (MSE) walls. Geotext. Geomembr. 2018, 46, 904–912. [Google Scholar] [CrossRef]

- Koerner, R.M.; Koerner, G.R. A data base, statistics and recommendations regarding 171 failed geosynthetic reinforced mechanically stabilized earth (MSE) walls. Geotext. Geomembr. 2013, 40, 20–27. [Google Scholar] [CrossRef]

- Gofar, N. Hanafiah Contribution of Suction on the Stability of Reinforced-Soil Retaining Wall. MATEC Web Conf. 2018, 195, 03004. [Google Scholar] [CrossRef]

- Jia, X.; Xu, J.; Sun, Y. Deformation Analysis of Reinforced Retaining Wall Using Separate Finite Element. Discret. Dyn. Nat. Soc. 2018, 2018, 6946492. [Google Scholar] [CrossRef]

- Guler, E.; Cicek, E.; Demirkan, M.M.; Hamderi, M. Numerical analysis of reinforced soil walls with granular and cohesive backfills under cyclic loads. Bull. Earthq. Eng. 2012, 10, 793–811. [Google Scholar] [CrossRef]

- Hatami, K.; Bathurst, R.J. Development and verification of a numerical model for the analysis of geosynthethic-reinforced soil segmental walls under working stress conditions. Can. Geotech. J. 2005, 42, 1066–1085. [Google Scholar] [CrossRef]

- Takano, A.; Hughes, M.; Winter, S. A multidisciplinary approach to sustainable building material selection: A case study in a Finnish context. Build. Environ. 2014, 82, 526–535. [Google Scholar] [CrossRef]

- Belardi, P.; Gusella, V.; Liberotti, R.; Sorignani, C. Built Environment’s Sustainability: The Design of the Gypso|TechA of the University of Perugia. Sustainability 2022, 14, 6857. [Google Scholar] [CrossRef]

- Liberotti, R.; Cluni, F.; Faralli, F.; Gusella, V. Natural FRCM and Heritage Buildings: Experimental Approach to Innovative Interventions on “Wall Beams”. Buildings 2022, 12, 1076. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Makul, N.; Siripattarapravat, C. Utilization of ground waste seashells in cement mortars for masonry and plastering. J. Environ. Manag. 2012, 111, 133–141. [Google Scholar] [CrossRef]

- Pourkhorshidi, S.; Sangiorgi, C.; Torreggiani, D.; Tassinari, P. Using Recycled Aggregates from Construction and Demolition Waste in Unbound Layers of Pavements. Sustainability 2020, 12, 9386. [Google Scholar] [CrossRef]

- Koerner, R.M.; Koerner, G.R. The importance of drainage control for geosynthetic reinforced mechanically stabilized earth walls. J. Geoengin. 2011, 6, 3–13. [Google Scholar] [CrossRef]

- Elias, V.; Barry, R.C.; Berg, R.R. Mechanically Stabilized Earth Walls and Reinforced Soil Slopes: Design and Construction Guidelines (Updated Version); Federal Highway Administration: Washington, DC, USA, 2001. [Google Scholar]

- Collin, J.G. Design Manual for Segmental Retaining Walls; National Concrete Masonry Association: Herndon, VA, USA, 1997. [Google Scholar]

- Vahedifard, F.; Mortezaei, K.; Leshchinsky, B.A.; Leshchinsky, D.; Lu, N. Role of suction stress on service state behavior of geosynthetic-reinforced soil structures. Transp. Geotech. 2016, 8, 45–56. [Google Scholar] [CrossRef]

- Divya, P.V. Geosynthetic Reinforced Soil Structures: Forensic Investigation on Failures and Remedial Measures. Indian Geotech. J. 2024, 54, 258–265. [Google Scholar] [CrossRef]

- Dhanya, K.A.; Venkatesh, T.S.D.; Divya, P.V. Influence of Suction on the Interface Characteristics of Unsaturated Marginal Lateritic Soil Backfills with Composite Geosynthetics. Int. J. Geosynth. Gr. Eng. 2023, 9, 73. [Google Scholar] [CrossRef]

- Hardianto, F.S.; Lugli, G.; Ruel, S. Geosynthetic Strip-Reinforced MSE Walls Using Local Sustainable Backfill. In Proceedings of the Geoenvironmental Engineering, Louisville, KY, USA, 2–5 March 2025; pp. 199–211. [Google Scholar]

- Khan, A.R.; Di Emidio, G. Prediction of creep behaviour of Geogrid reinforced fill structure using numerical analysis: A Finite Element Method. In Proceedings of the 9th International Congress on Environmental Geotechnics, Chania, Greece, 25–28 June 2023; International Society for Soil Mechanics and Geotechnical Engineering: London, UK, 2023; Volume 3. [Google Scholar]

- Cristelo, N.; Vieira, C.S.; De Lurdes Lopes, M. Geotechnical and Geoenvironmental Assessment of Recycled Construction and Demolition Waste for Road Embankments. Procedia Eng. 2016, 143, 51–58. [Google Scholar] [CrossRef]

- Mohsan, M. Data Assimilation and Machine Learning for Slope Stability Assessment. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2024. [Google Scholar]

- Bentley. PLAXIS 2D 2024.1: 2—Reference Manual; Bentley: Crewe, UK, 2023; pp. 1–670. Available online: https://bentleysystems.service-now.com/community?id=kb_article&sys_kb_id=082fe67a97668a1081d373b0f053afbc (accessed on 23 February 2024).

- Mortimore, S.; Horgan, G.; Woods, D.; Manceau, S.; Macdiarmid, C. Design of soil reinforced slopes and structures. In ICE Manual of Geotechnical Engineering, Second Edition, Volume II: Geotechnical Design, Construction and Verification; Emerald Publishing Limited: Bingley, UK, 2023; pp. 1189–1214. ISBN 978-0-7277-6683-0. [Google Scholar]

- Ferreira, F.B.; Vieira, C.S.; Pereira, P.; de Lurdes Lopes, M. Recycled construction and demolition waste as backfill material for geosynthetic-reinforced structures. In Sustainable Civil Engineering; CRC Press: Boca Raton, FL, USA, 2023; pp. 1–27. [Google Scholar]

- Report, T. Technical Report Iso/Tr. Measurement 2004, 2004, 14345. [Google Scholar]

- Hajikarimi, P.; Moghadas Nejad, F. Mechanical Models of Viscoelasticity; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 9780128212103. [Google Scholar]

- BS 8006-1:2010+A1:2016; Code of Practice for Strengthened/Reinforced Soils and Other Fills. BSI Standards Publication: London, UK, 2016.

- Mohiuddin, A. Analysis of Laboratory and Field Pull-Out Tests of Geosynthetics in Clayey Soils; Louisiana State University and Agricultural & Mechanical College: Baton Rouge, LA, USA, 2003; ISBN 9798819301630. [Google Scholar]

- Palmeira, E.M. Soil-geosynthetic interaction: Modelling and analysis. Geotext. Geomembr. 2009, 27, 368–390. [Google Scholar] [CrossRef]

- Moraci, N.; Cardile, G.; Gioffrè, D.; Mandaglio, M.C.; Calvarano, L.S.; Carbone, L. Soil Geosynthetic Interaction: Design Parameters from Experimental and Theoretical Analysis. Transp. Infrastruct. Geotechnol. 2014, 1, 165–227. [Google Scholar] [CrossRef]

- Ardah, A.; Abu-Farsakh, M.; Voyiadjis, G. Numerical parametric study of geosynthetic reinforced soil integrated bridge system (GRS-IBS). Geotext. Geomembr. 2021, 49, 289–303. [Google Scholar] [CrossRef]

- Nunes, G.B.; Portelinha, F.H.M.; Futai, M.M.; Yoo, C. Numerical study of the impact of climate conditions on stability of geocomposite and geogrid reinforced soil walls. Geotext. Geomembr. 2022, 50, 807–824. [Google Scholar] [CrossRef]

- Bathurst, R.J.; Hatami, K. Parametric analysis of reinforced soil walls with different height and reinforcement stiffness. In Proceedings of the 8th International Conference on Geosynthetics, Yokohama, Japan, 18–22 September 2006; pp. 1343–1346. [Google Scholar]

- Zhao, C.; Xu, C.; Shen, P.; Li, G.; Wang, Q. Assessing Numerical Simulation Methods for Reinforcement–Soil/Block Interactions in Geosynthetic-Reinforced Soil Structures. Buildings 2024, 14, 422. [Google Scholar] [CrossRef]

- Hatami, K.; Bathurst, R.J. Parametric Analysis of Reinforced Soil Walls with Different Backfill Material Properties. In Proceedings of the 2006 NAGW National Conference, Las Vegas, NV, USA, 20–23 July 2006; pp. 1–15. [Google Scholar]

- Majumder, M.; Venkatraman, S.; Bheda, M.; Patil, M. Numerical Studies on the Performance of Geosynthetic Reinforced Soil Walls Filled with Marginal Soil. Indian Geotech. J. 2023, 53, 805–826. [Google Scholar] [CrossRef]

- Vadavadagi, S.S.; Chawla, S.; Kumar, P. Prediction and validation of geogrid tensile force distribution in back-to-back MSE walls under rail axle load: Finite-element and intelligent techniques. Environ. Earth Sci. 2024, 83, 149. [Google Scholar] [CrossRef]

| ϒdry kN/m3 | ϒwet kN/m3 | Model | C’ref kN/m2 | Φ’ [°] | |

|---|---|---|---|---|---|

| Fill 1 | 17 | 19 | HS | 5 | 25 |

| Fill 2 | 18 | 19 | HS | 20 | 40 |

| Fill 3 | 18 | 19 | HS | 23 | 36.8 |

| Clayey sand | 18 | 19 | HS | 14.7 | 32 |

| Sand 01 | 17 | 19 | HS | 02 | 30 |

| Clayey sand | 18 | 19 | HS | 12 | 30 |

| Sand 02 | 19 | 20 | HS | 02 | 32 |

| Clay 02 | 18 | 18 | HS | 08 | 20 |

| Sand 03 | 19 | 20 | HS | 02 | 32 |

| Clay 03 | 18 | 18 | HS | 08 | 22 |

| Property | Units | Geogrid |

|---|---|---|

| Axial stiffness | kN/m2 | 3000 |

| Axial force | kN/m2 | 300 |

| Material type | - | Elastoplastic |

| Property | Units | Gabion |

|---|---|---|

| Unit weight | kN/m3 | 18 |

| Angle of internal friction | Degree | 40 |

| Cohesion | kN/m2 | 27 |

| Poisson’s ratio | - | 0.3 |

| Elastic modulus | MPa | 40 |

| Material model | - | Mohr–Coulomb |

| Properties | Symbol | Units | Value |

|---|---|---|---|

| Axial stiffness | EA | kN/m | 62,832 |

| Flexural rigidity | EI | kNm2/m | 0.251 |

| Weight | W | kN/m/m | 0.023 |

| Poisson’s ratio | V | - | 0.3 |

| Maximum bending moment | Mp | kN/m/m | 0.23 |

| Maximum axial force | Np | kN/m | 135 |

| Cohesion | C | kN/m2 | 27 |

| Soil | tan δ/tan φ (Wire Mesh) | tan δ/tan φ (Geogrid) |

|---|---|---|

| Clay | 0.3 | 0.4 |

| Silt | 0.4 | 0.7 |

| Sand | 0.65 | 0.9 |

| Gravel | 0.9 | 0.9 |

| Property | Symbol | Value |

|---|---|---|

| Density | Ρ | 1680 kg/m3 |

| Angle of internal friction | Ø | 44° |

| Dilation angle | Ψ | 11° |

| Cohesion | C | 1 kPa |

| Poisson’s ratio | v | 0.3 |

| Youngs modulus | E | 48 MPa |

| Property | Symbol | Value |

|---|---|---|

| Young’s modulus | E | 20 Mpa |

| Poisson’s ratio | v | 0.2 |

| Density | ρ | 2500 kg/m3 |

| Property | Symbol | Value |

|---|---|---|

| Axial stiffness | EA | 119 Kn/m |

| Youngs modulus | E | 37.8 Mpa |

| Poisson’s ratio | v | 0.5 |

| Structures | Strain |

|---|---|

| Bridge abutments and retaining walls with permanent structural loading 0.5 | 0.5% |

| Retaining walls with no applied structural loading, i.e., transient live loadings only | 1% |

| Nmax @ End of Construction (kN/m) | EA Short (kN/m) | Retardation Time (days) | Strain (Short Term) (%) | Nmax @ End of Design Life (kN/m) | EA Long (kN/m) | Strain (Long Term) (%) | Prescribed Post- Construction Strain Limit (%) | |

|---|---|---|---|---|---|---|---|---|

| 77.42 | 3160 | 100 | 2.45 | 77.31 | 1992 | 3.88 | 1.43 | |

| Fill 1 | 76.90 | 3160 | 200 | 2.43 | 76.02 | 1992 | 3.82 | 1.39 |

| 80.55 | 3160 | 365 | 2.55 | 77.54 | 1992 | 3.89 | 1.34 | |

| 16.18 | 3160 | 100 | 0.51 | 16.31 | 1992 | 0.82 | 0.31 | |

| Fill 2 | 16.38 | 3160 | 200 | 0.52 | 16.56 | 1992 | 0.83 | 0.31 |

| 16.63 | 3160 | 365 | 0.53 | 16.09 | 1992 | 0.81 | 0.28 | |

| 16.54 | 3160 | 100 | 0.52 | 16.62 | 1992 | 0.83 | 0.31 | |

| Fill 3 | 16.57 | 3160 | 200 | 0.52 | 16.52 | 1992 | 0.83 | 0.31 |

| 16.87 | 3160 | 365 | 0.53 | 16.38 | 1992 | 0.82 | 0.29 |

| Horizontal Displacement at The Toe UX (cm) | |

|---|---|

| Basic design (First) | 23 |

| Geogrid length optimization (second) | 24 |

| Geogrid length optimization (third) | 24.5 |

| Geogrid length optimization (fourth) | 25 |

| Geogrid length optimization (fifth) | 25 |

| Geogrid length optimization (sixth) | 25 |

| Geogrid length optimization (seventh) | 25 |

| Geogrid length optimization (eighth) | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.R.; Di Emidio, G. Reinforced Fill Structure with Alternative Fill Materials: An Application of Geogrid Creep Strain Analysis Using Numerical Modeling. Materials 2025, 18, 1346. https://doi.org/10.3390/ma18061346

Khan AR, Di Emidio G. Reinforced Fill Structure with Alternative Fill Materials: An Application of Geogrid Creep Strain Analysis Using Numerical Modeling. Materials. 2025; 18(6):1346. https://doi.org/10.3390/ma18061346

Chicago/Turabian StyleKhan, Ahsan Rehman, and Gemmina Di Emidio. 2025. "Reinforced Fill Structure with Alternative Fill Materials: An Application of Geogrid Creep Strain Analysis Using Numerical Modeling" Materials 18, no. 6: 1346. https://doi.org/10.3390/ma18061346

APA StyleKhan, A. R., & Di Emidio, G. (2025). Reinforced Fill Structure with Alternative Fill Materials: An Application of Geogrid Creep Strain Analysis Using Numerical Modeling. Materials, 18(6), 1346. https://doi.org/10.3390/ma18061346