Influence of C2H2 Flow Rates on Optical Properties, Surface Roughness, and Residual Stress of Ti/WC Thin Films Deposited on Glass Substrates

Highlights

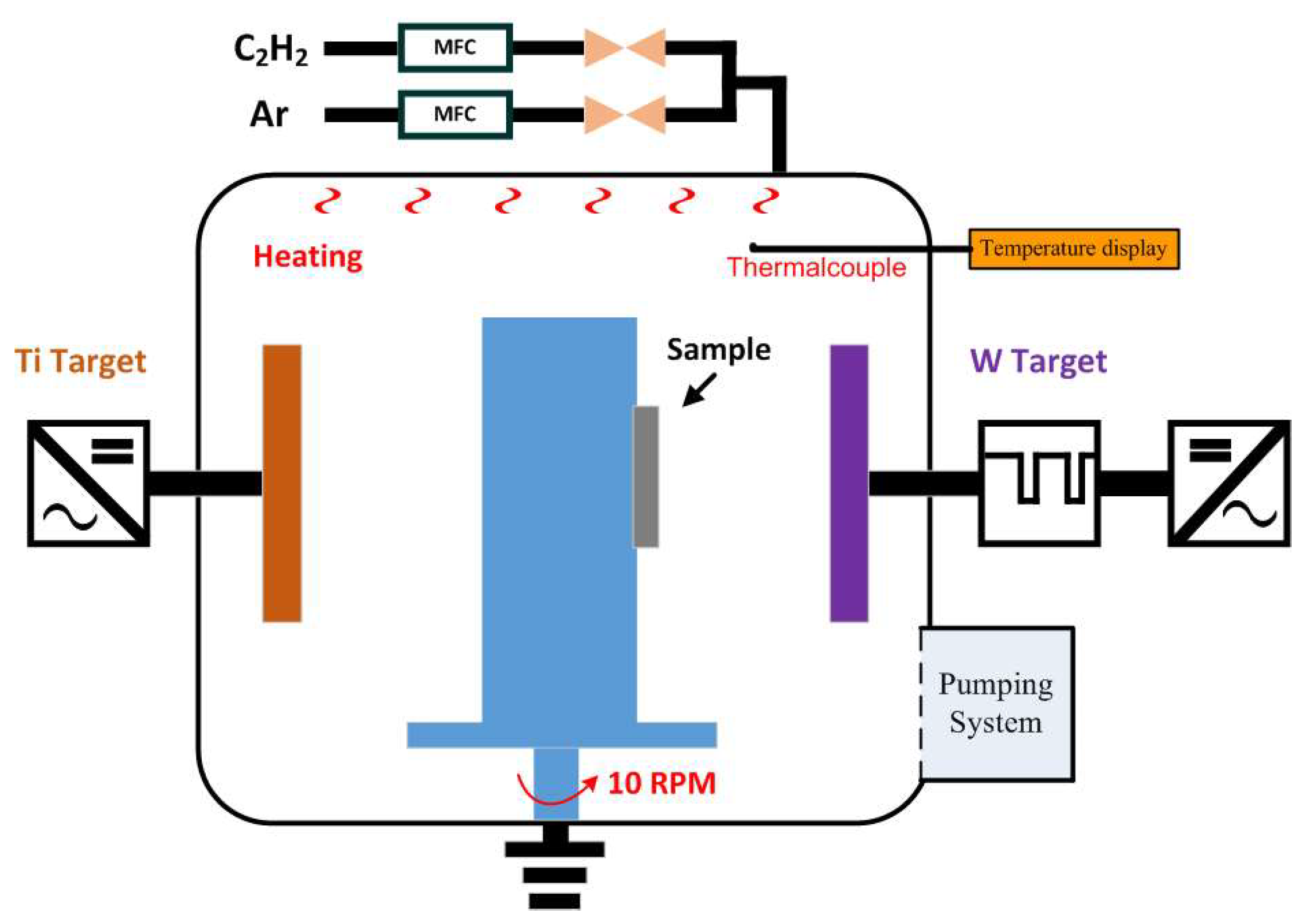

- Ti/WC thin films with different carbon contents were deposited on glass substrates using reactive pulsed DC magnetron sputtering technique.

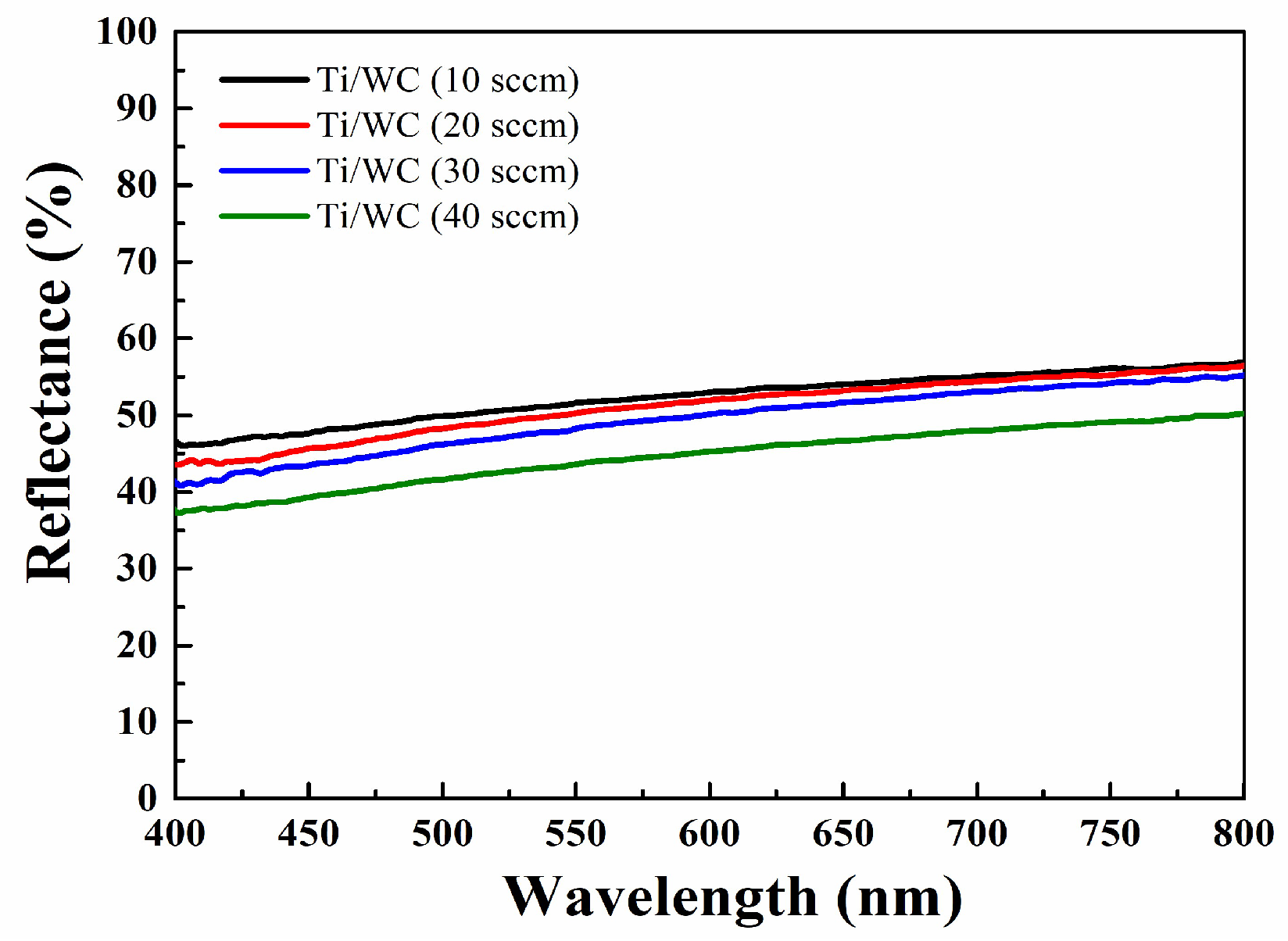

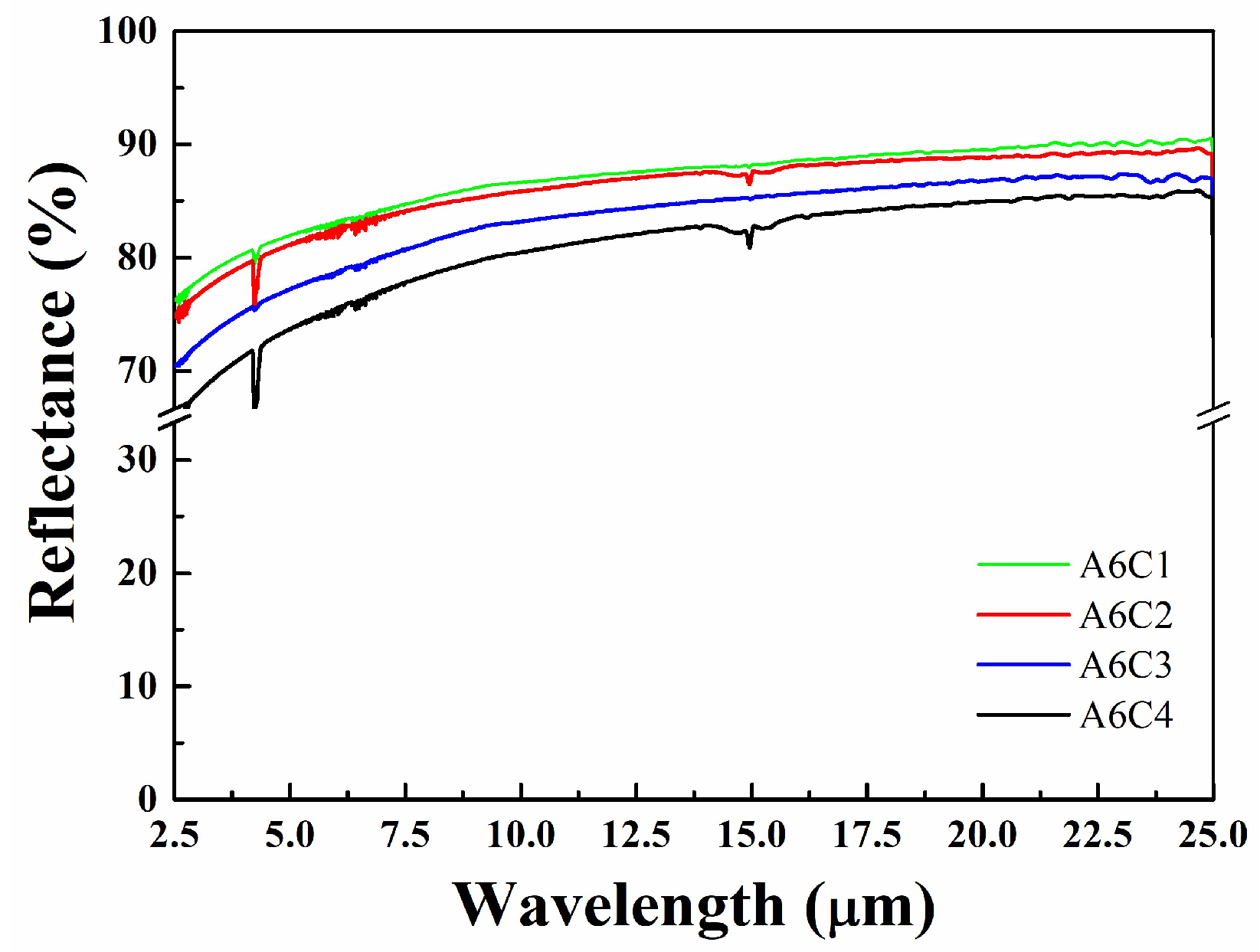

- As the C2H2 flow rate increases, the average reflectance in the visible light spectrum (400~800 nm) decreases, and the infrared reflectance (2.5~25 μm) also shows a downward trend.

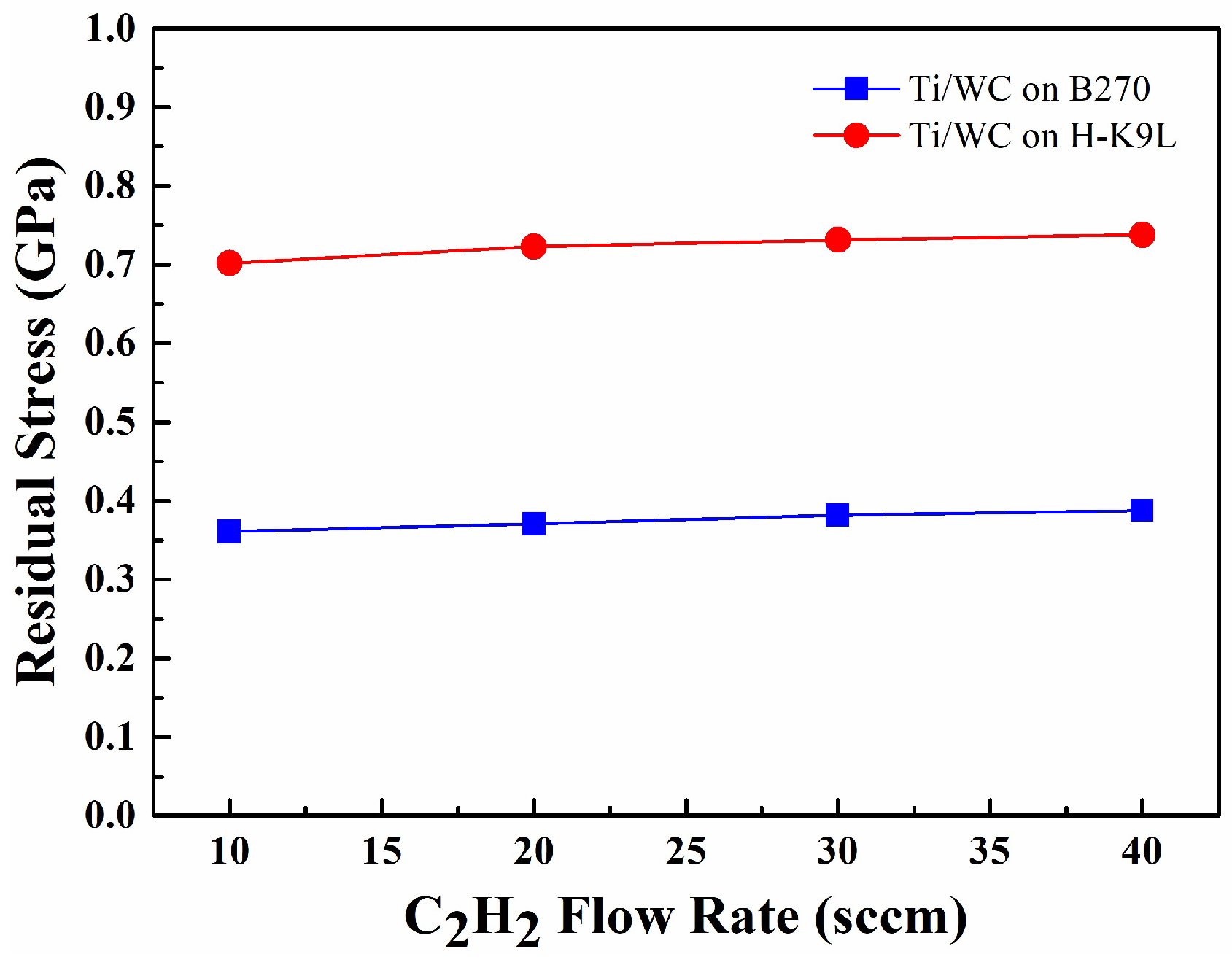

- The tensile stress in Ti/WC films increases with the increase in C2H2 flow rate.

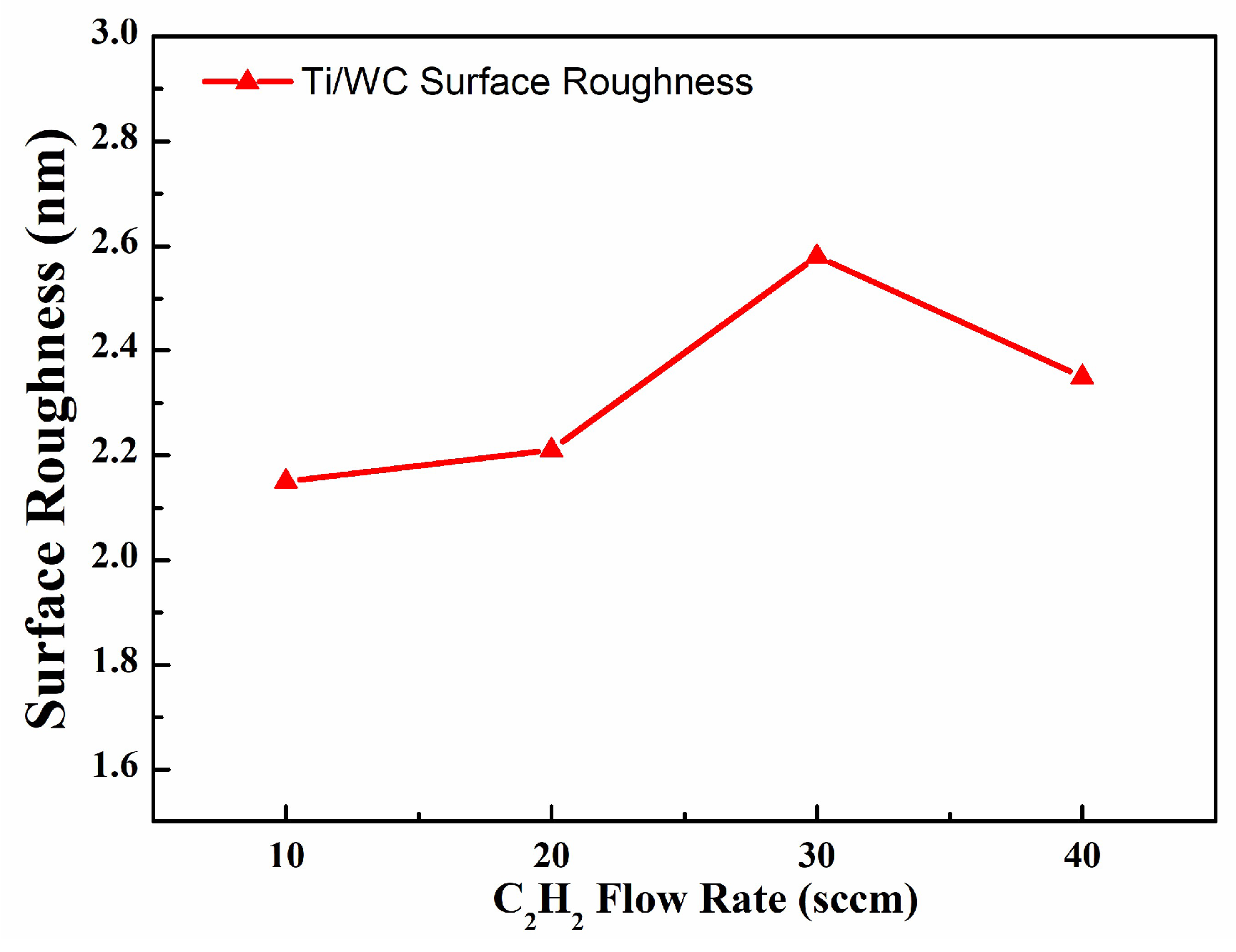

- The C2H2 flow ratio, in addition to the reflectivity, also significantly affects the surface roughness and residual stress of Ti/WC films.

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Ti/WC Thin Films

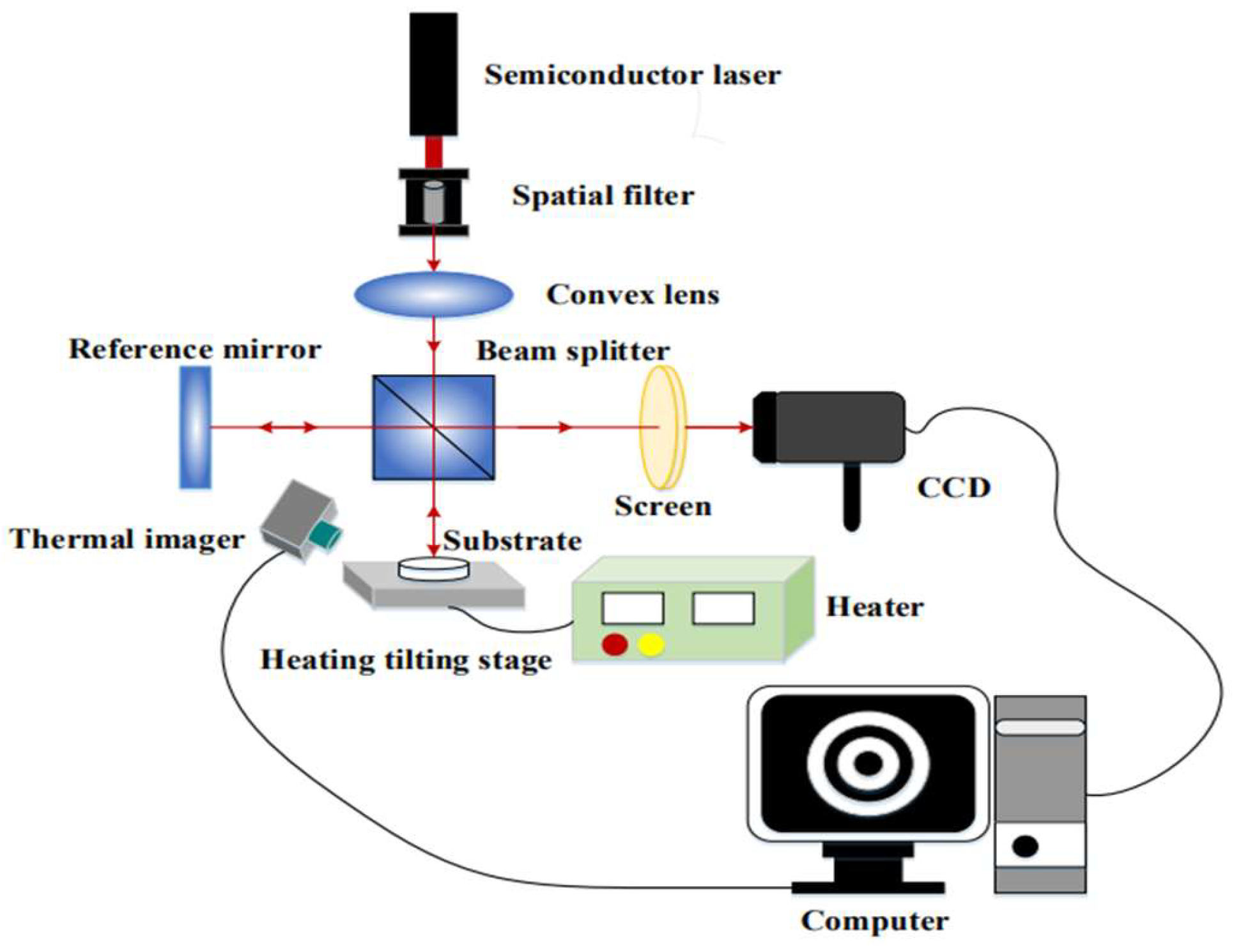

2.2. Residual Stress Measurement

3. Results and Discussion

3.1. Optical Properties of Ti/WC Thin Film in Visible Light and Infrared Spectra

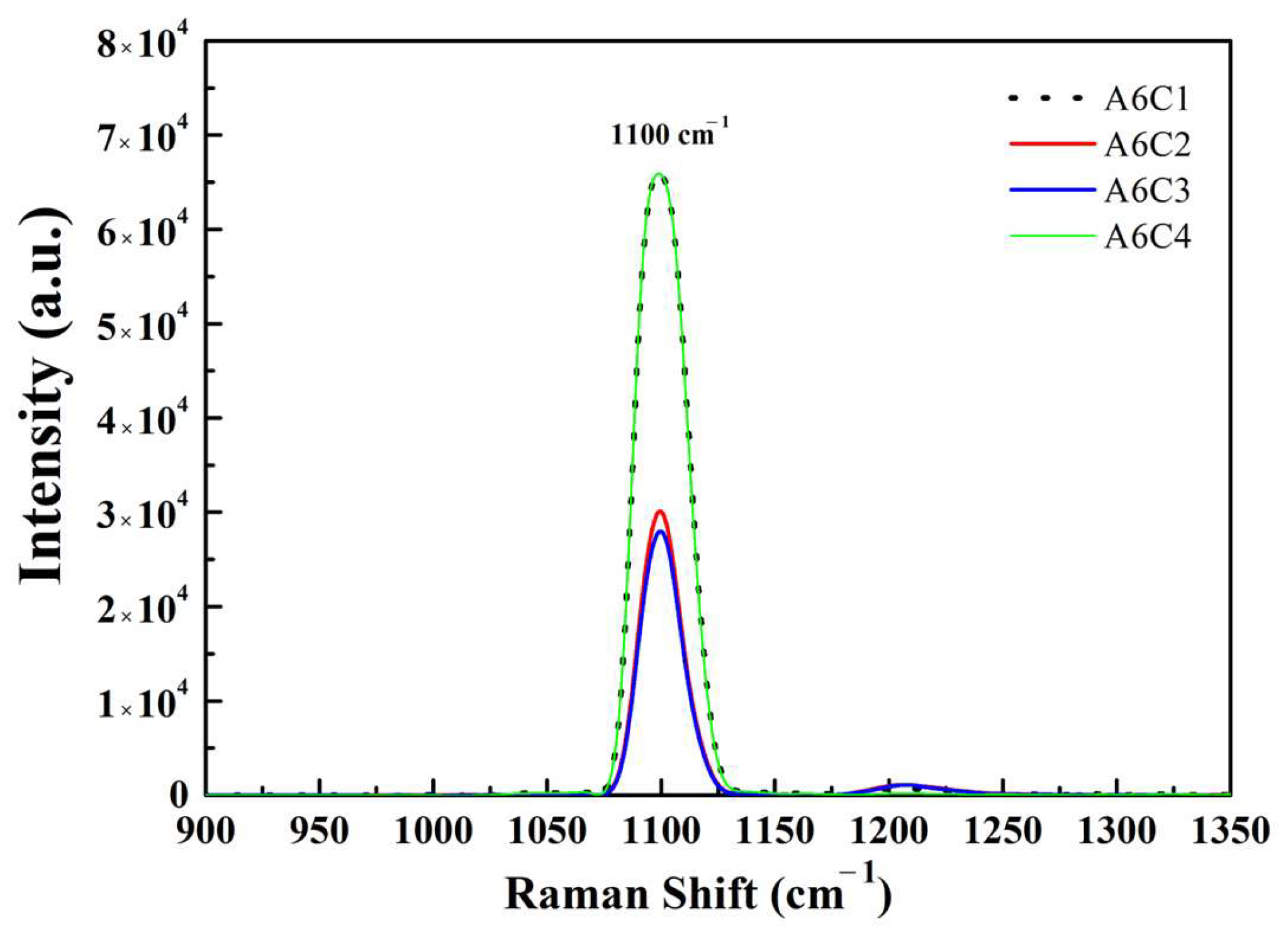

3.2. Raman Spectra of Ti/WC Thin Films

3.3. Residual Stress in Ti/WC Thin Films

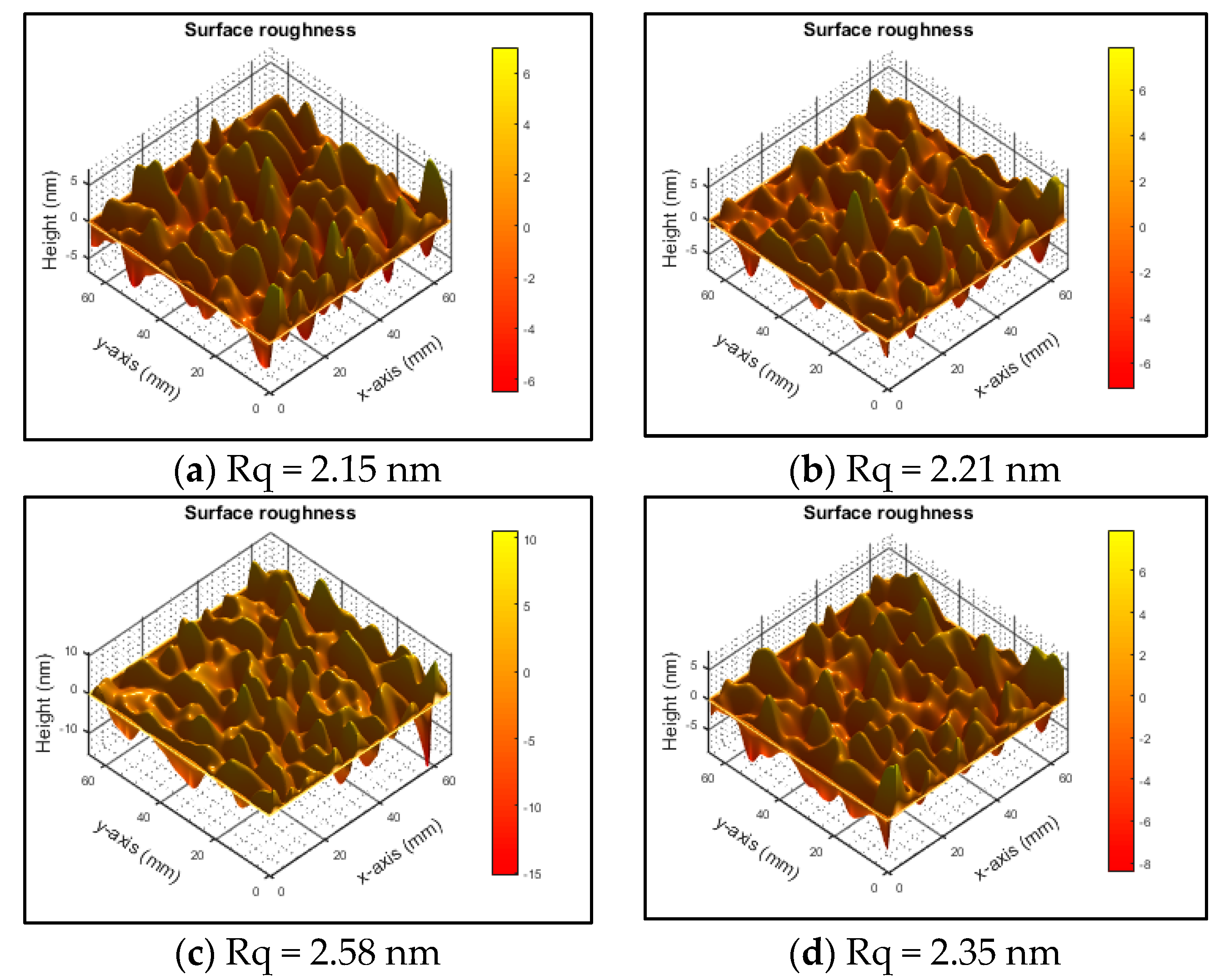

3.4. Surface Roughness of Ti/WC Thin Films

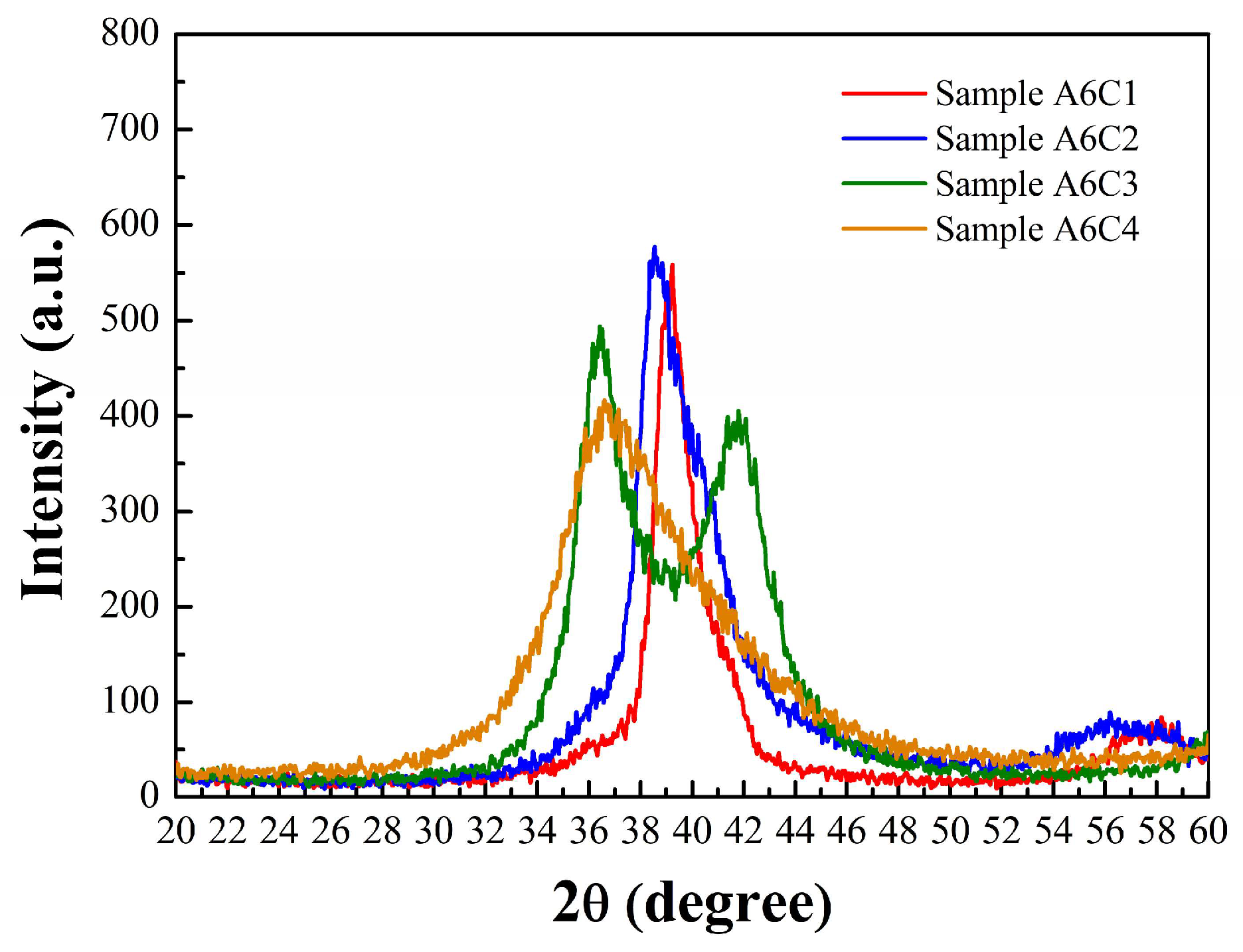

3.5. X-Ray Diffraction (XRD) Pattern Analysis of Ti/WC Thin Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bewilogua, K.; Hofmann, D. History of diamond-like carbon films- from first experiments to worldwide applications. Surf. Coat. Technol. 2014, 242, 214–225. [Google Scholar] [CrossRef]

- Iga, K.; Oda, A.; Kousaka, H.; Ohta, T. Formation of diamond-like carbon film using high-power impulse magnetron sputtering. Thin Solid Film. 2019, 672, 104–108. [Google Scholar] [CrossRef]

- Moriguchi, H.; Ohara, H.; Tsujioka, M. History and applications of diamond-like carbon manufacturing processes. Sumitomo Electr. Ind. Tech. Rev. 2016, 82, 52–58. [Google Scholar]

- Ferreira, F.; Aijaz, A.; Kubart, T.; Cavaleiro, A.; Oliveira, J. Hard and dense diamond like carbon coatings deposited by deep oscillations magnetron sputtering. Surf. Coat. Technol. 2018, 336, 92–98. [Google Scholar] [CrossRef]

- Nakao, S.; Yukimura, K.; Nakano, S.; Ogiso, H. DLC coating by HiPIMS: The influence of substrate bias voltage. IEEE Trans. Plasma Sci. 2013, 41, 1819–1829. [Google Scholar] [CrossRef]

- Rajak, D.K.; Kumar, A.; Behera, A.; Menezes, P.L. Diamond-Like Carbon (DLC) Coatings: Classification, Properties, and Applications. Appl. Sci. 2021, 11, 4445. [Google Scholar] [CrossRef]

- Choi, S.S.; Kim, D.W.; Joe, J.W.; Moon, J.H.; Park, K.C.; Jang, J. Deposition of diamondlike carbon films by plasma enhanced chemical vapour deposition. Mater. Sci. Eng. B 1997, 46, 133–136. [Google Scholar] [CrossRef]

- Meškinis, Š.; Vasiliauskas, A.; Andrulevičius, M.; Peckus, D.; Tamulevičius, S.; Viskontas, K. Diamond Like C Films Containing Si. Structure and Non-linear Optical Properties. Materials 2020, 13 , 1003. [Google Scholar]

- Vitelaru, C.; Parau, A.C.; Constantin, L.R.; Kiss, A.E.; Vladescu, A.; Sobetkii, A.; Kubart, T. A Strategy for Alleviating Micro Arcing During HiPMS Deposition of DLC Coatings. Materials 2020, 13, 1038. [Google Scholar] [CrossRef]

- Shao, W.; Zhou, Y.; Shi, Z.; Rao, L.; Hu, T.; Xing, X.; Yang, Q. Effects of carbide forming elements Me on residual stress and mechanical properties of DLC films by molecular dynamics simulation. Mater. Today Commun. 2020, 23, 100946. [Google Scholar] [CrossRef]

- Li, X.; Liu, J.; Wu, H.; Miao, K.; Wu, H.; Li, R.; Liu, C.; Fang, W.; Fan, G. Research progress of residual stress measurement methods. Heliyon 2024, 10, e28348. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-Like Amorphous Carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Song, R.; Chen, S.; Liu, Z.; Huo, C.; Chen, Q. Effect of W-doping on the structure and properties of DLC films prepared by combining physical and chemical vapor deposition. Diam. Relat. Mater. 2023, 132, 109687. [Google Scholar] [CrossRef]

- Ouchabane, M.; Hassani, S.; Dublanche-Tixier, C.; Peter, S.; Kechouane, M.; Djerraf, S.; Lahmar, H. Effect of DLC films thickness on residual stress and mechanical properties. Sci. Adv. Mater. 2015, 7, 157–162. [Google Scholar] [CrossRef]

- Zambrano, G.; Prieto, P.; Perez, F.; Rincon, C.; Galindo, H.; Cota-Araiza, L.; Esteve, J.; Martinez, E. Hardness and morphological characterization of tungsten carbide thin films. Surf. Coat. Technol. 1998, 108–109, 323–327. [Google Scholar] [CrossRef]

- Tavsanoglu, T.; Begum, C.; Alkan, M.; Yucel, O. Deposition and characterization of Tungsten carbide thin films by DC magnetron sputtering for wear-resistant applications. J. Miner. Met. Mater. Soc. 2013, 65, 562–566. [Google Scholar] [CrossRef]

- Raekelboom, E.; Abdelouahdi, K.; Legrand-Buscema, C. Structural investigation by the Rietveld method of sputtered tungsten carbide thin films. Thin Solid Film. 2009, 517, 1555–1558. [Google Scholar] [CrossRef]

- Sivkov, A.; Nassyrbayev, A.; Nikitin, D.; Tsimmerman, A.; Vympina, Y.; Rahmatullin, I. Obtaining Superhard Coatings of Cubic Tungsten Carbide under High-speed Plasma Spraying. In Proceedings of the 7th International Congress on Energy Fluxes and Radiation Effects (EFRE) 2020, Tomsk, Russia, 14–26 September 2020. [Google Scholar]

- Beadle, K.A.; Gupta, R.; Mathew, A.; Chen, J.G.; Willis, B.G. Chemical vapor deposition of phase-rich WC thin films on silicon and carbon substrates. Thin Solid Film. 2008, 516, 3847–3854. [Google Scholar] [CrossRef]

- Ji, H.X.; Amato-Wierda, C.C. Chemical vapor deposition of Ti-W-C thin films. Surf. Coat. Technol. 2001, 148, 262–267. [Google Scholar] [CrossRef]

- Hsu, T.W.; Greczynski, G.; Boyd, R.; Kolozsvari, S.; Polcik, P.; Od´en, M. Dense and hard TiWC protective coatings grown with tungsten ion irradiation using WC-HiPIMS/TiC-DCMS co-sputtering technique without external heating. Appl. Surf. Sci. 2023, 618, 156639. [Google Scholar] [CrossRef]

- Kubart, T.; Andersson, J.; Ferreira, F.; Oliveira, J.C.; Sobetkii, A.; Parau, A.C.; Vitelaru, C. High power impulse magnetron sputtering of diamond-like carbon coatings. J. Vac. Sci. Technol. A 2020, 38, 043408. [Google Scholar] [CrossRef]

- Tien, C.L.; Zeng, H.D. Measuring residual stress of anisotropic thin film by fast Fourier transform. Opt. Express 2010, 18, 16594–16600. [Google Scholar] [CrossRef] [PubMed]

- Tien, C.L.; Lin, T.W.; Yu, K.C.; Tsai, T.Y.; Shih, H.F. Evaluation of electrical, mechanical properties, and surface roughness of DC sputtering nickel-iron thin films. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Dong, X.; Su, Y.; Wu, Z.; Xu, X.; Xiang, Z.; Shi, Y.; Chen, W.; Dai, J.; Huang, Z.; Wang, T.; et al. Reactive pulsed DC magnetron sputtering deposition of vanadium oxide thin films: Role of pulse frequency on the film growth and properties. Appl. Surf. Sci. 2021, 562, 150138. [Google Scholar] [CrossRef]

- Evans, R.D.; Shiller, P.J.; Howe, J.Y. Adhesion of tungsten carbide reinforced amorphous hydrocarbon thin films (WC/a-C:H) to steel substrates for tribological applications. J. Appl. Phys. 2011, 109, 023518. [Google Scholar] [CrossRef]

- Stoney, G.G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. 1909, 32, 172. [Google Scholar]

- Kuzmany, H.; Pfeiffer, R.; Salk, N.; Günther, B. The mystery of the 1140 cm−1 Raman line in nanocrystalline diamond films. Carbon 2004, 42, 911–917. [Google Scholar] [CrossRef]

- Okada, K.; Kanda, H.; Komatsu, S.; Matsumoto, S. Effect of the excitation wavelength on Raman scattering of microcrystalline diamond prepared in a low pressure inductively coupled plasma. J. Appl. Phys. 2000, 88, 1674–1678. [Google Scholar] [CrossRef]

- Teii, K.; Yoshida, T. Lower pressure limit of diamond growth in inductively coupled plasma. J. Appl. Phys. 1999, 85, 1864–1870. [Google Scholar] [CrossRef]

- Bilek, M.M.; Mckenzie, D.R.; Moeller, W. Use of low energy and high frequency PBII during thin film deposition to achieve relief of intrinsic stress and microstructural changes. Surf. Coat. Technol. 2004, 186, 21. [Google Scholar] [CrossRef]

- Bilek, M.M.; Verdon, M.; Ryves, L.; Oates, T.W.; Ha, C.T.; McKenzie, D.R. A model for stress generation and stress relief mechanisms applied to as deposited filtered cathodic vacuum arc amorphous carbon films. Thin Solid Film. 2005, 482, 69. [Google Scholar] [CrossRef]

- Baba, K.; Hatada, R.; Flege, S.; Ensinger, W. Diamond-Like Carbon Films with Low Internal Stress by a Simple Bilayer Approach. Coatings 2020, 10, 696. [Google Scholar] [CrossRef]

- Saravanan, M.; Venkatesharan, N.; Devaraju, A.; Krishnakumari, A. Tribological Behavior of Thin Nano Tungsten Carbide Film Deposited on 316L Stainless Steel Surface. Surf. Rev. Lett. 2017, 25, 1950027. [Google Scholar] [CrossRef]

| Thin Film Samples | Ar Flow Rate (sccm) | C2H2 Flow Rate (sccm) | Processing Time (min) | Initial Pressure (Pa) | Working Pressure (Pa) | Substrate Temperature (°C) |

|---|---|---|---|---|---|---|

| A6C1 | 60 | 10 | Ti: 40; MF: 40 | 1.5 × 10−5 | 0.25 | 80 ± 5 |

| A6C2 | 60 | 20 | Ti: 40; MF: 40 | 1.5 × 10−5 | 0.25 | 80 ± 5 |

| A6C3 | 60 | 30 | Ti: 40; MF: 40 | 1.5 × 10−5 | 0.25 | 80 ± 5 |

| A6C4 | 60 | 40 | Ti: 40; MF: 40 | 1.5 × 10−5 | 0.25 | 80 ± 5 |

| Glass Substrates | B270 | H-K9L |

|---|---|---|

| Thermal expansion coefficient (°C−1) | 8.2 × 10−6 | 7.6 × 10−6 |

| Young’s modulus (GPa) | 71.5 | 79 |

| Poisson’s ratio | 0.219 | 0.214 |

| Thickness (mm) | 1.5 | 1.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tien, C.-L.; Wang, Y.-L.; Chang, Y.-M.; Lin, S.-C.; Wang, C.-C. Influence of C2H2 Flow Rates on Optical Properties, Surface Roughness, and Residual Stress of Ti/WC Thin Films Deposited on Glass Substrates. Materials 2025, 18, 1269. https://doi.org/10.3390/ma18061269

Tien C-L, Wang Y-L, Chang Y-M, Lin S-C, Wang C-C. Influence of C2H2 Flow Rates on Optical Properties, Surface Roughness, and Residual Stress of Ti/WC Thin Films Deposited on Glass Substrates. Materials. 2025; 18(6):1269. https://doi.org/10.3390/ma18061269

Chicago/Turabian StyleTien, Chuen-Lin, Yi-Lin Wang, Yuan-Ming Chang, Shih-Chin Lin, and Ching-Chiun Wang. 2025. "Influence of C2H2 Flow Rates on Optical Properties, Surface Roughness, and Residual Stress of Ti/WC Thin Films Deposited on Glass Substrates" Materials 18, no. 6: 1269. https://doi.org/10.3390/ma18061269

APA StyleTien, C.-L., Wang, Y.-L., Chang, Y.-M., Lin, S.-C., & Wang, C.-C. (2025). Influence of C2H2 Flow Rates on Optical Properties, Surface Roughness, and Residual Stress of Ti/WC Thin Films Deposited on Glass Substrates. Materials, 18(6), 1269. https://doi.org/10.3390/ma18061269