Effects of PPA Reinforcement and Sintering Parameters on the Densification and Hardness Properties of Al/Mg/PPA Composites

Abstract

1. Introduction

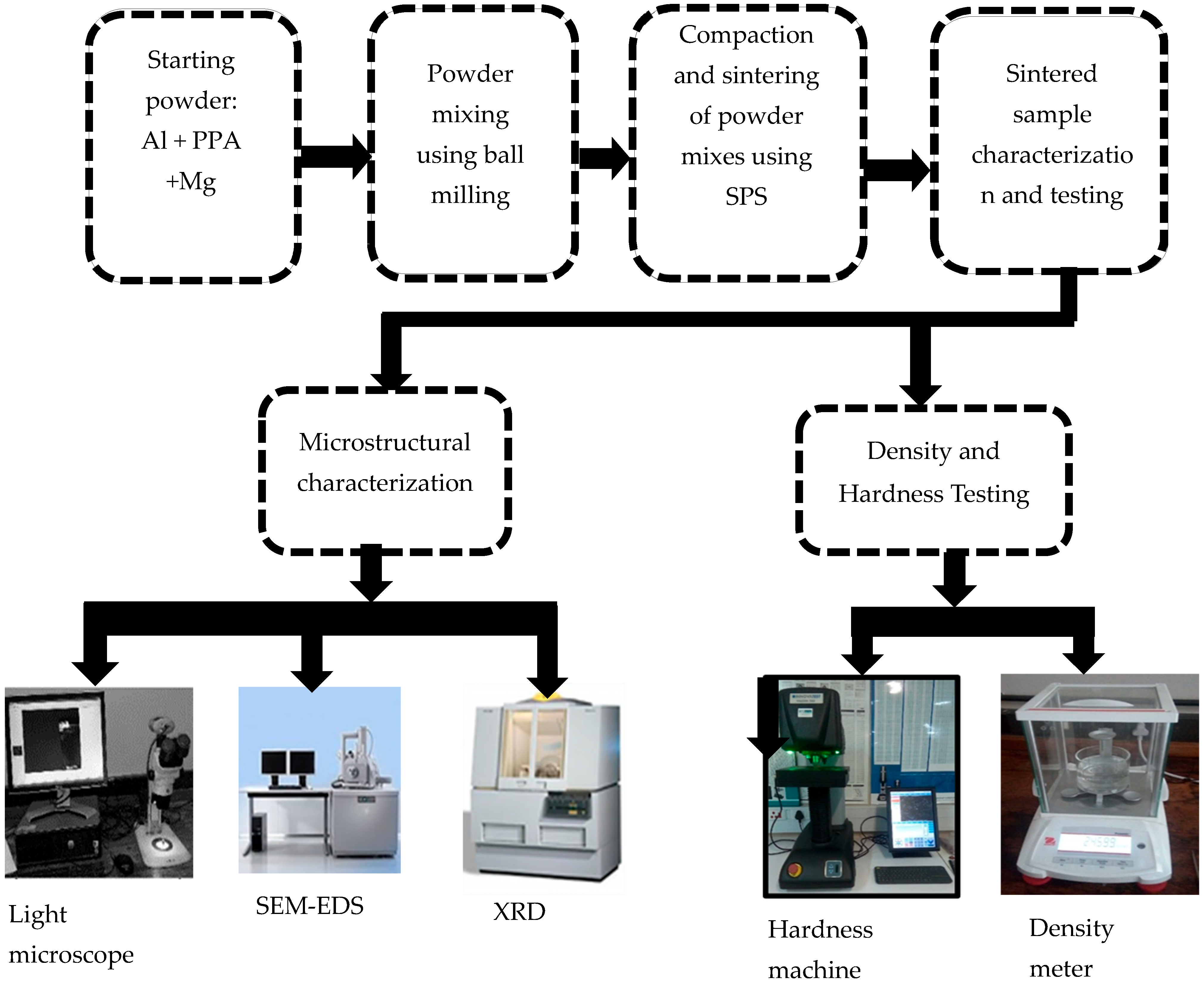

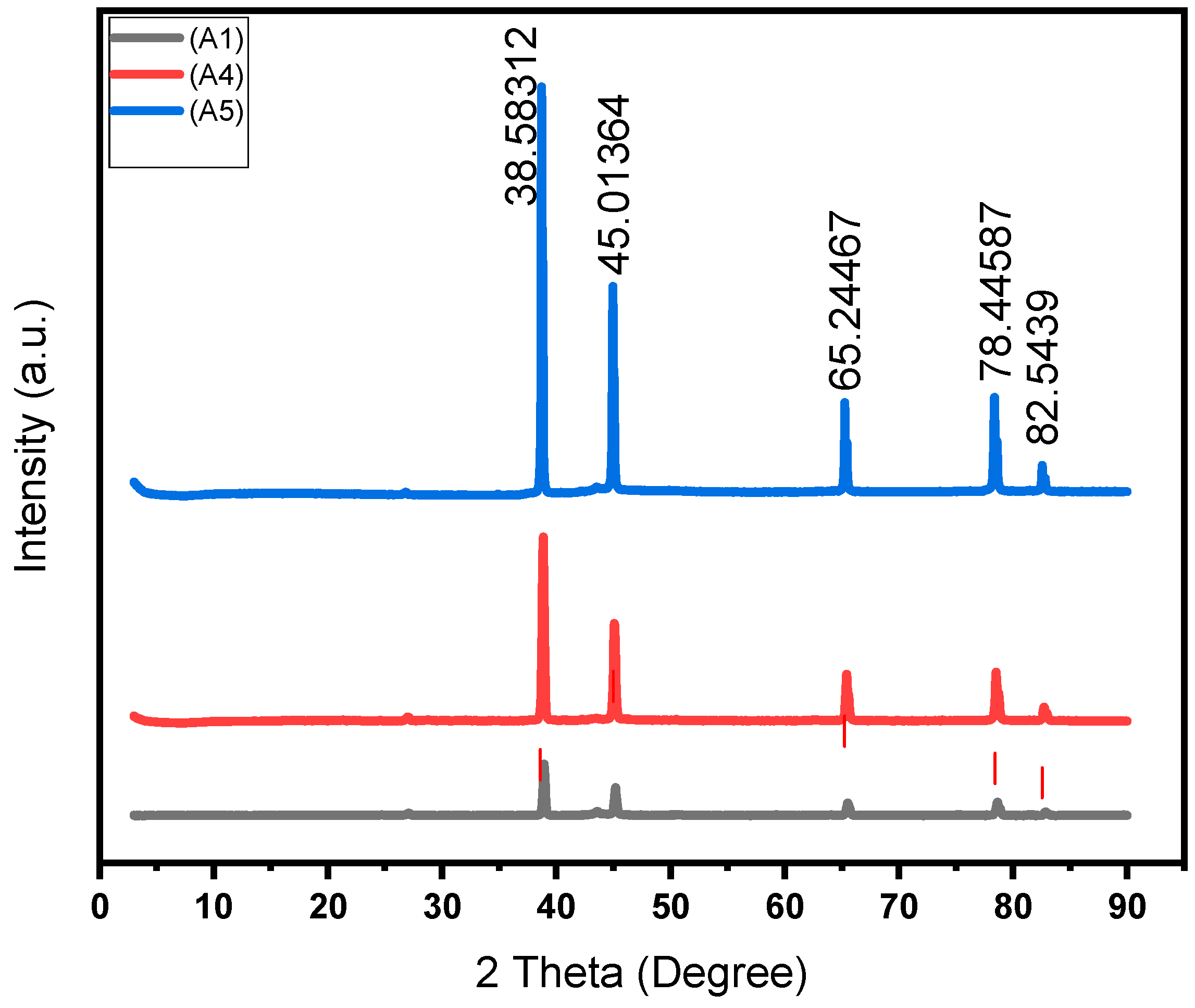

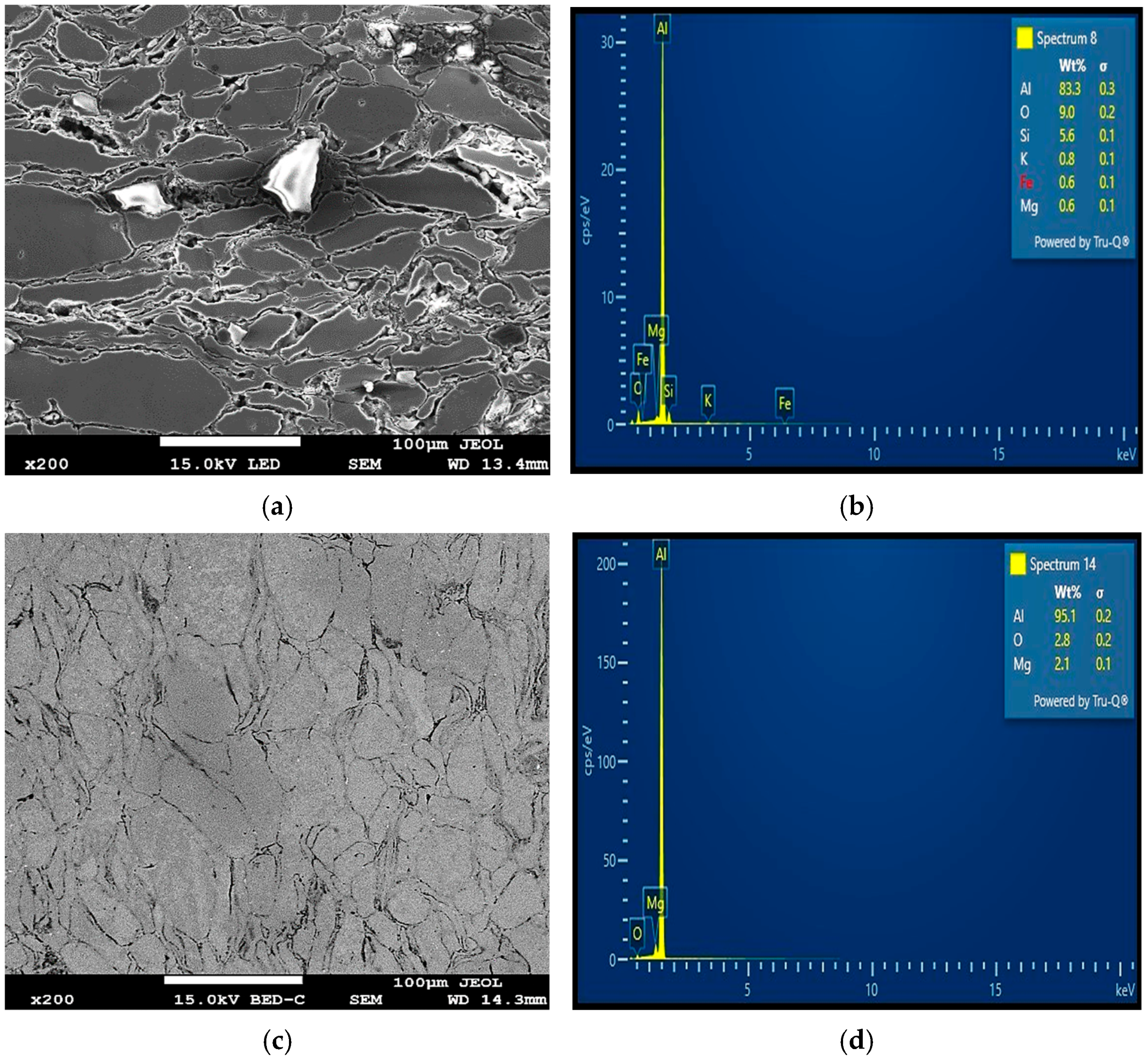

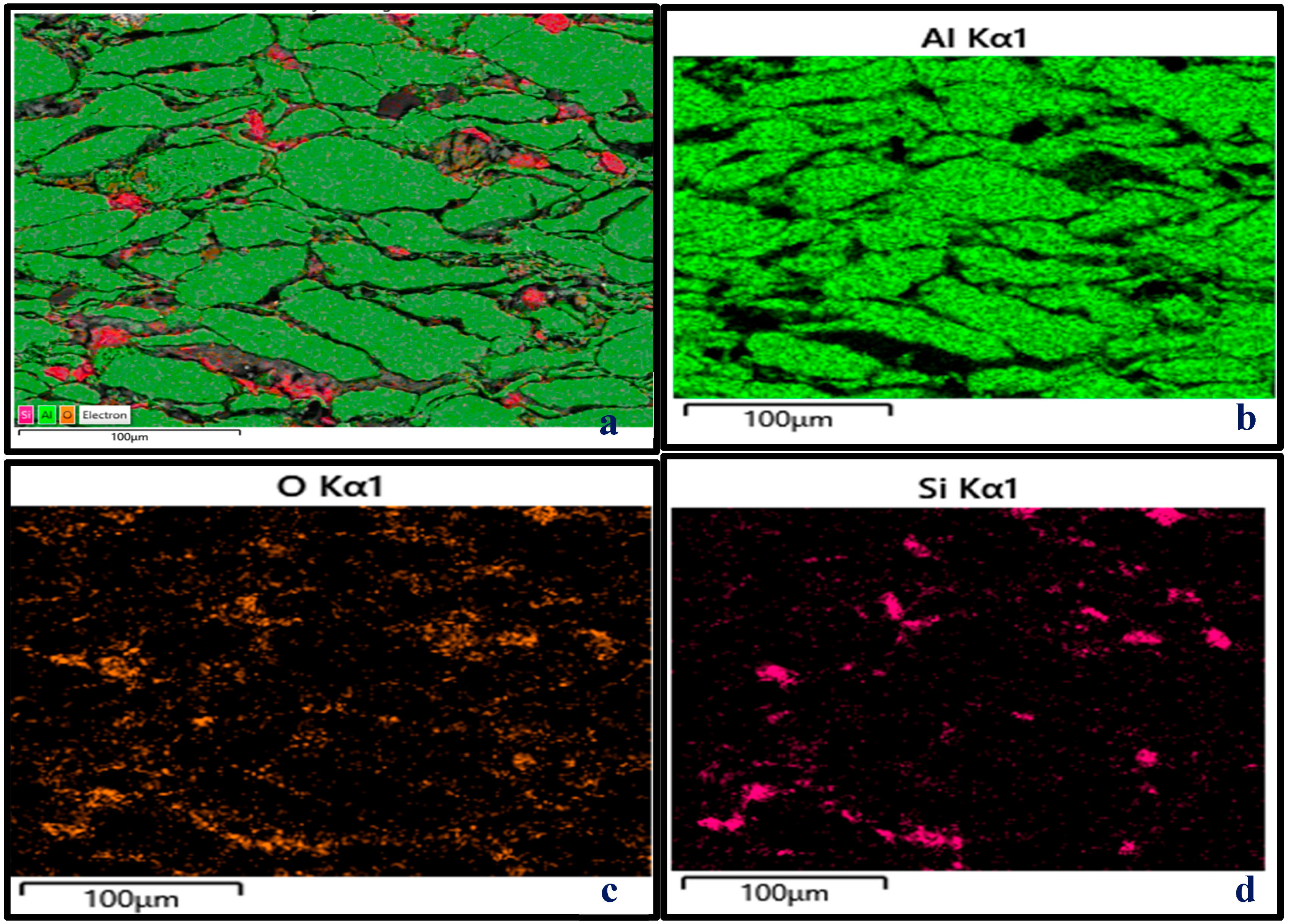

2. Materials and Methods

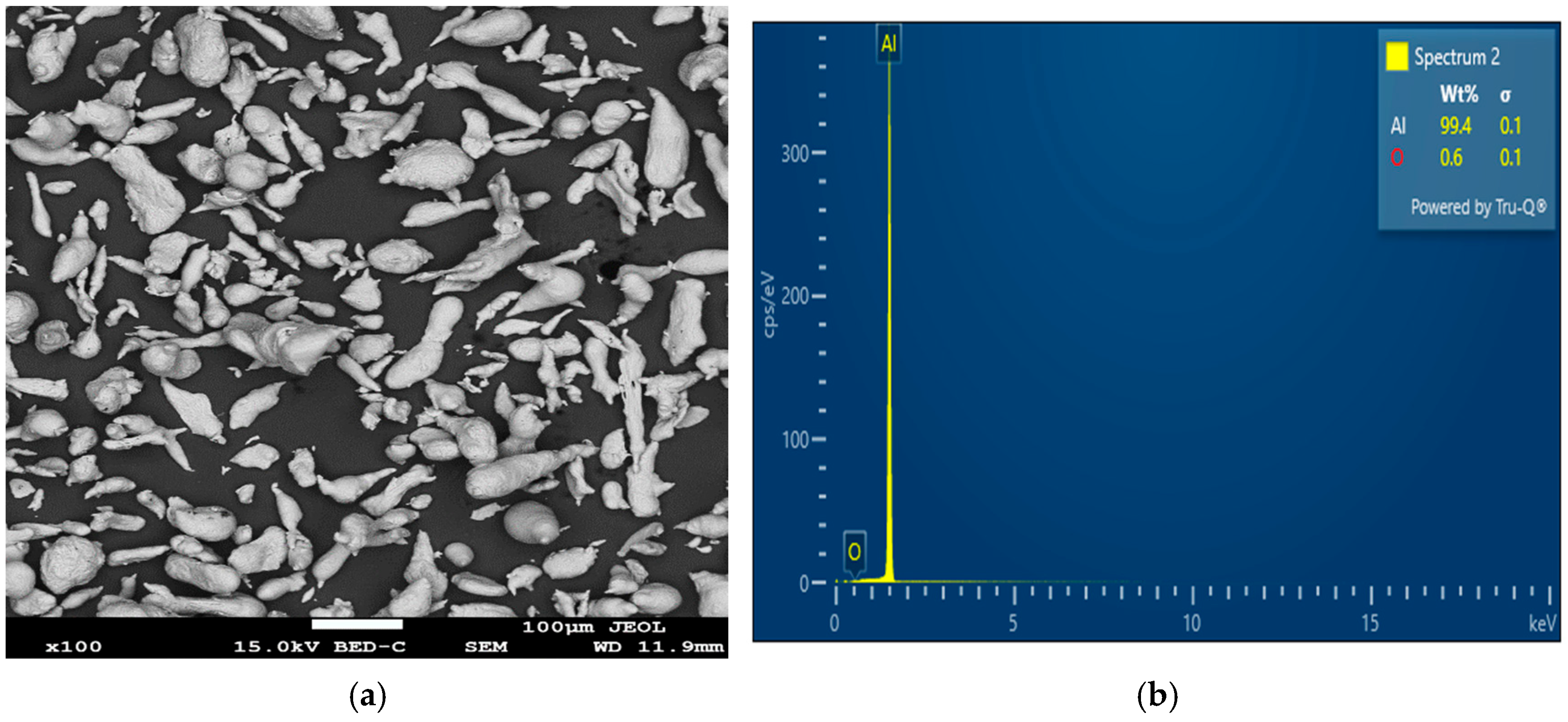

2.1. Starting Materials

2.2. Preparation of Plantain Peel Ash Reinforcement

2.3. Design of Experiment Using the Taguchi Method

2.4. Al/Mg/PPA Composite Sample Production

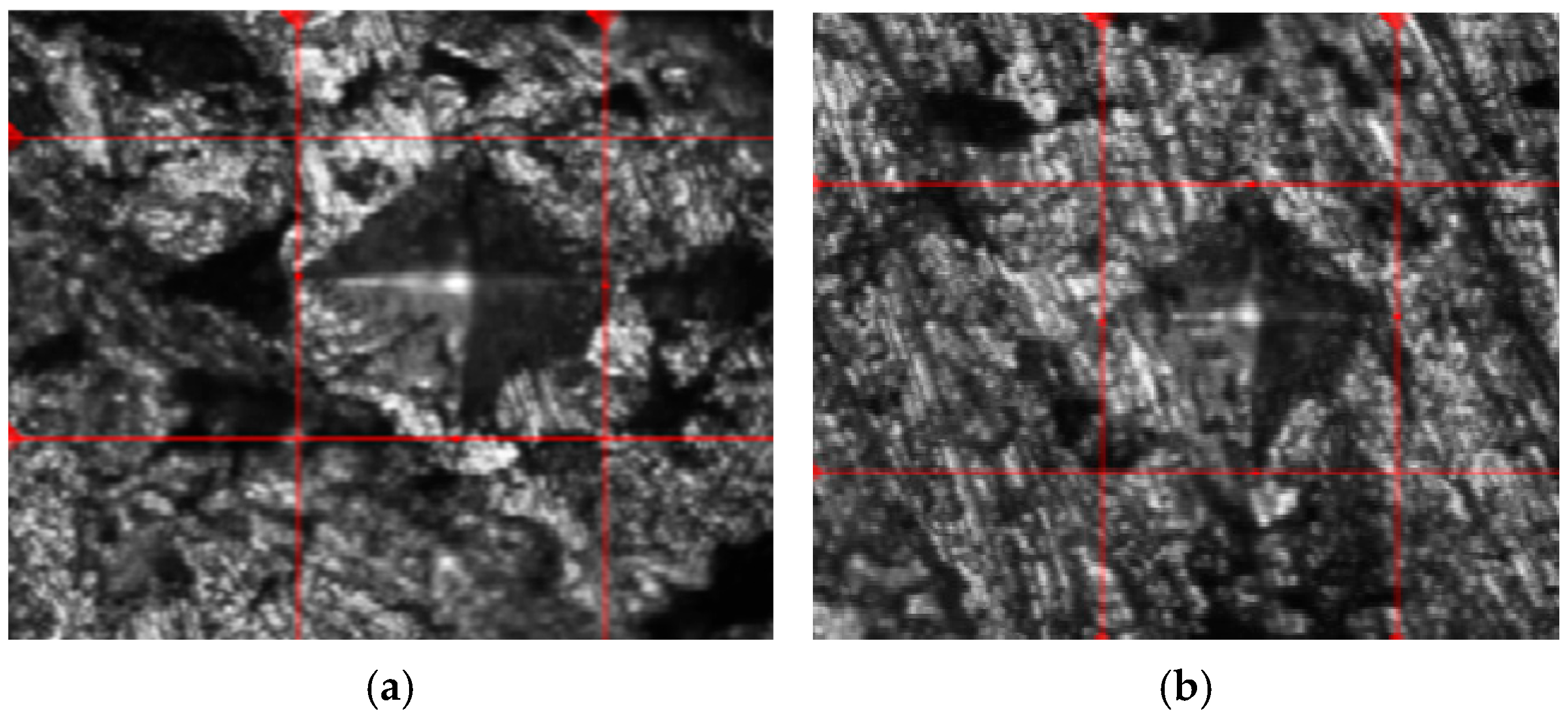

2.5. Characterization of Samples

2.6. Density Measurement

2.7. Hardness Testing

3. Results and Discussion

3.1. Optimal Input Parameters for RD

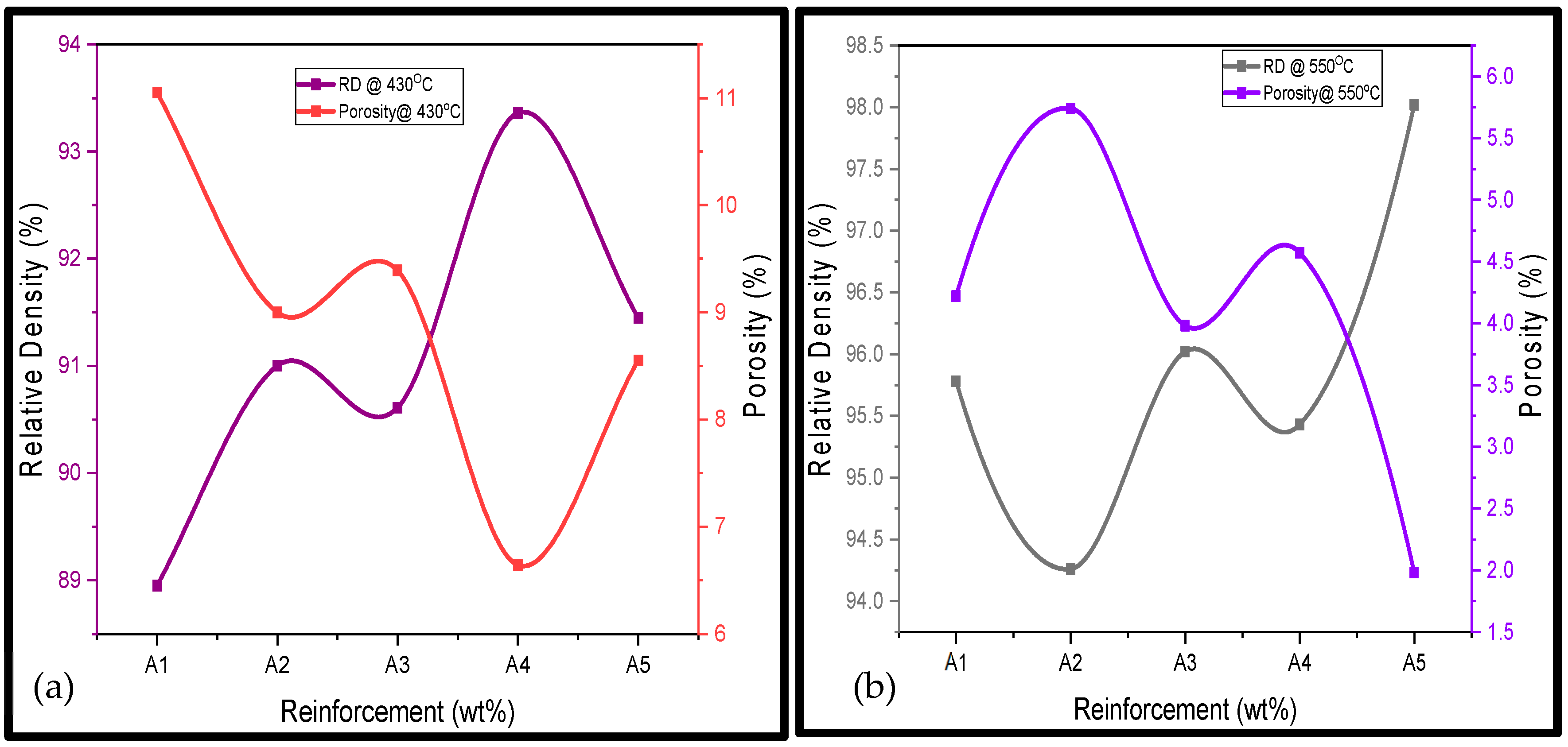

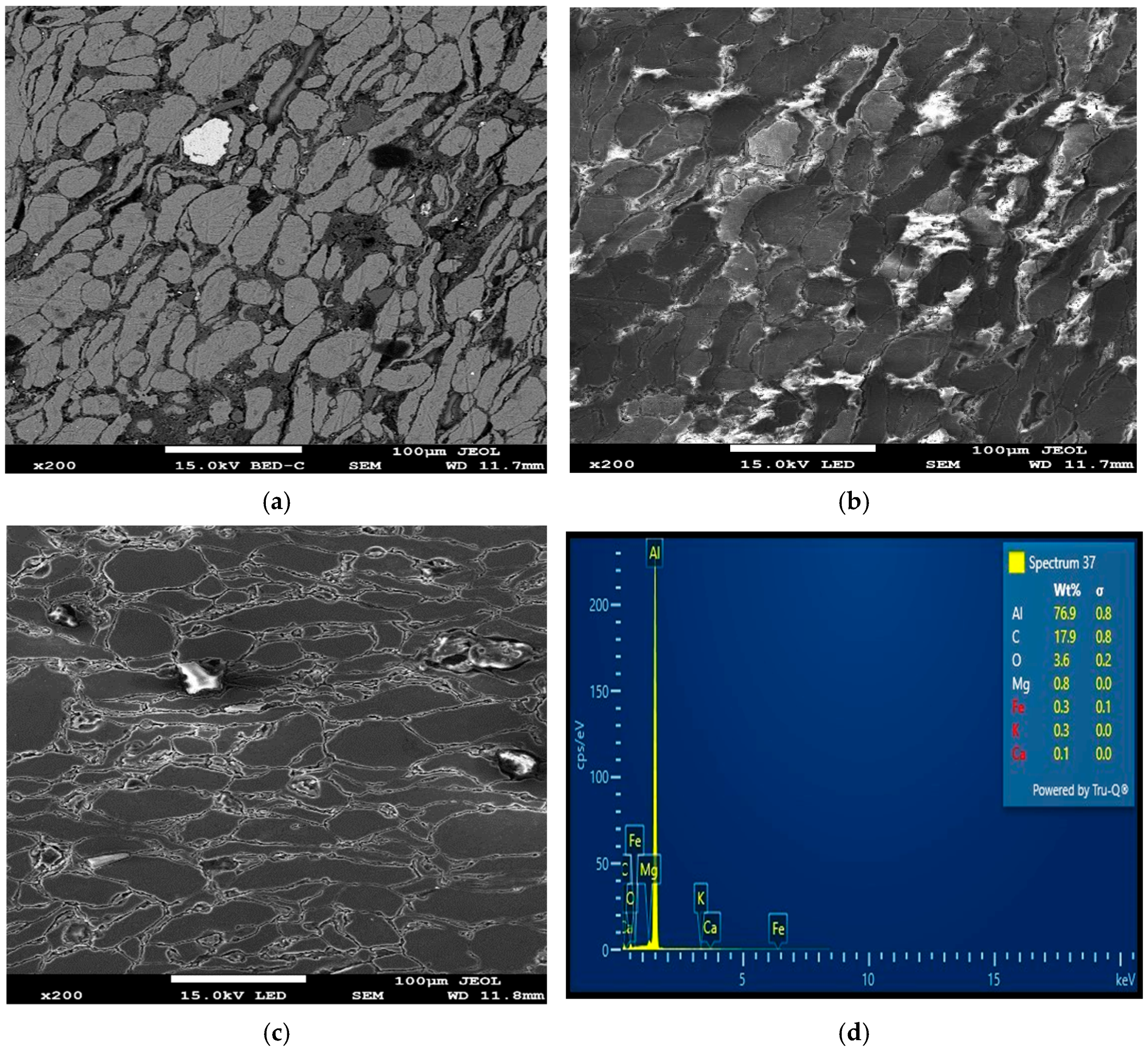

3.2. Influence of Input Parameters and Microstructure on Relative Density (RD) and Porosity

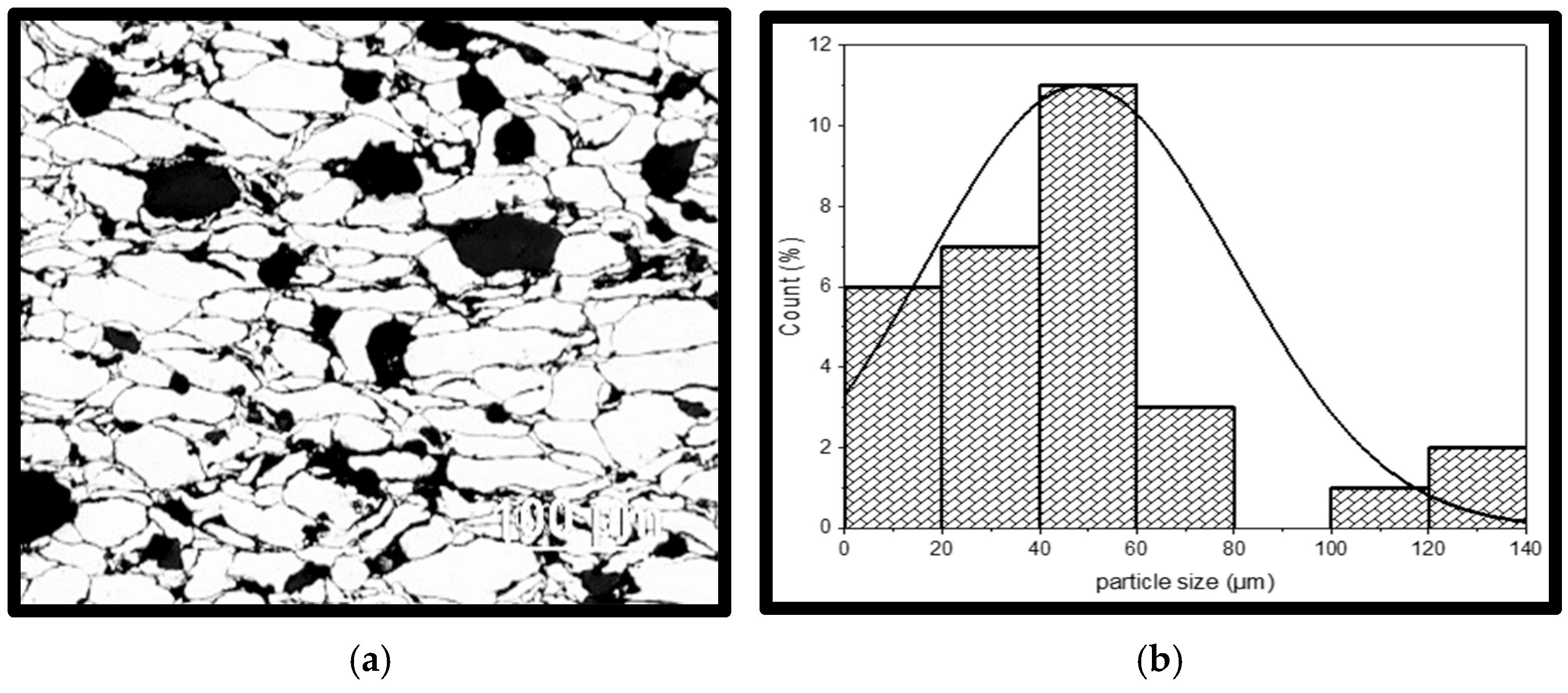

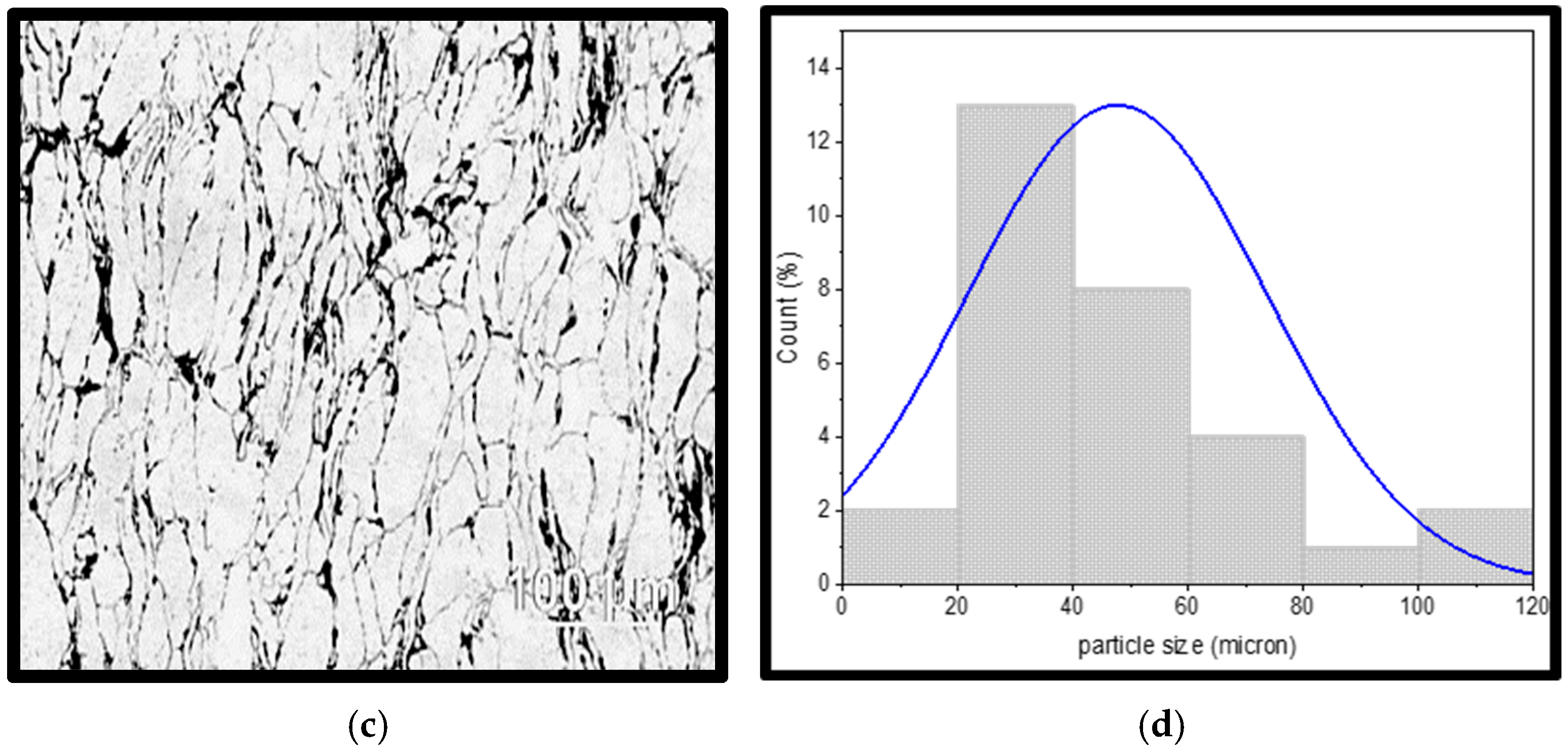

3.3. Influence of Matrix Reinforcement Characteristics and Microstructure on RD

3.4. Micro-Hardness of Sintered Al-Mg-PPA Samples

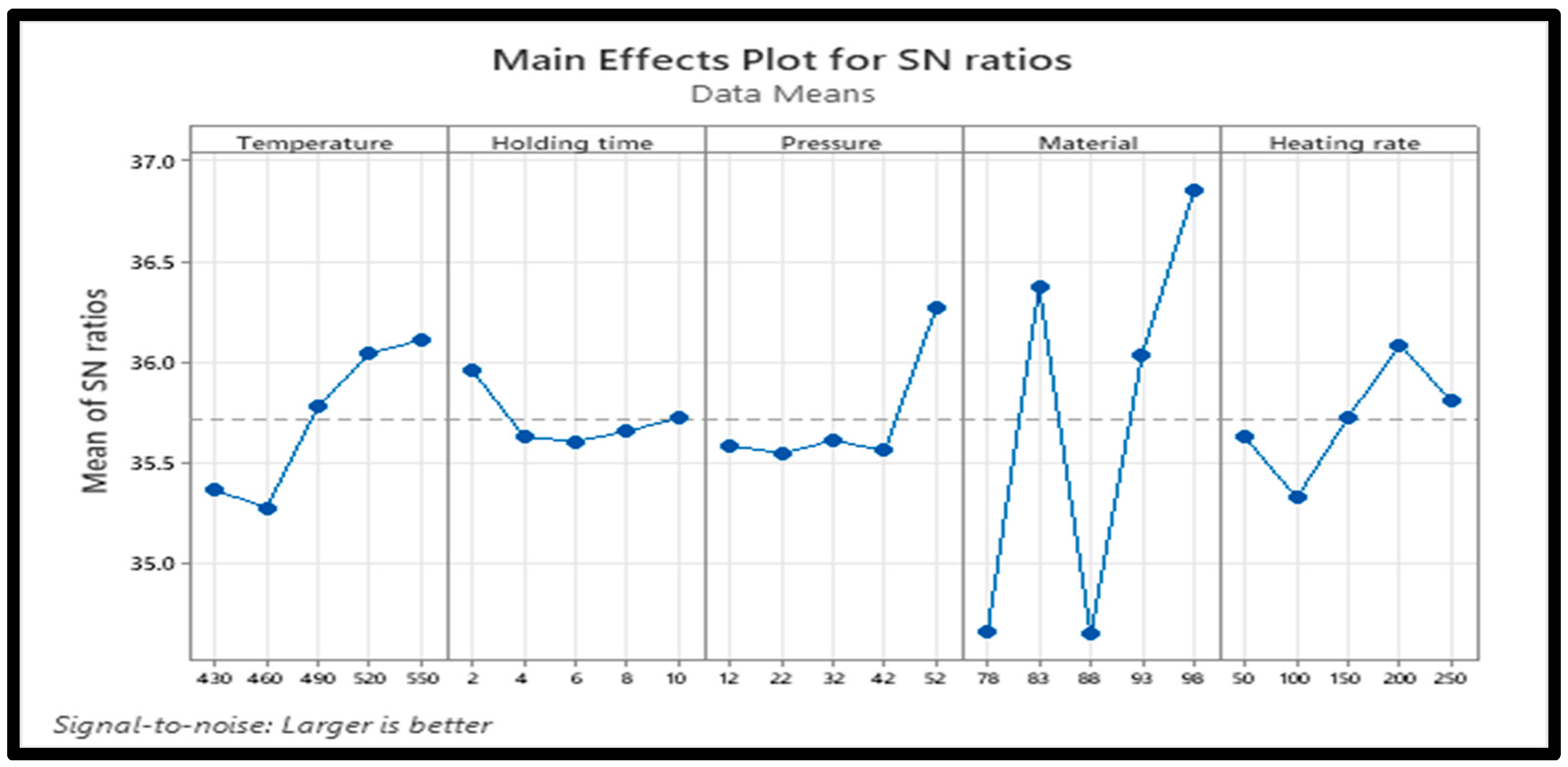

3.5. Optimal Input Parameters for Micro-Hardness

3.6. Influence of Sintering Parameters and Microstructure on Micro-Hardness

3.7. Influence of Reinforcement Characteristics and Microstructure on Micro-Hardness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kulkarni, P.P.; Siddeswarappa, B. A study on microstructure and mechanical behavior of AA6063 metal matrix composite reinforced with areca sheath ash (ASA) and rice husk ash (RHA). Mater. Today Proc. 2022, 52, 445–451. [Google Scholar] [CrossRef]

- Dwivedi, S.P.; Srivastava, A.K.; Maurya, N.K.; Sahu, R. Microstructure and mechanical behavior of Al/SiC/agro-waste RhA hybrid metal matrix composite. Rev. Des. Compos. Mater. Av. 2020, 30, 43–47. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminum matrix hybrid composites: A review of reinforcement philosophies; Mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Bahrami, A.; Soltani, N.; Pech-Canul, M.I.; Gutiérrez, C.A. Development of metal-matrix composites from industrial/agricultural waste materials and their derivatives. Crit. Rev. Environ. Sci. Technol. 2016, 46, 143–207. [Google Scholar] [CrossRef]

- Sonker, P.K.; Jackson Singh, T.; Kumar Verma, Y. Effect of reinforced diverse synthetic and agricultural-industrial waste materials on the microstructural and mechanical performance of hybrid metal matrix composite. Mater. Today Proc. 2023, 106, 94–98. [Google Scholar] [CrossRef]

- Olusesi, O.S.; Udoye, N.E. Development and characterization of AA6061 aluminum alloy/clay and rice husk ash composite. Manuf. Lett. 2021, 29, 34–41. [Google Scholar] [CrossRef]

- Phiri, R.; Rangappa, S.M.; Siengchin, S.; Marinkovic, D. Agro-waste natural fiber sample preparation techniques for bio-composites development: Methodological insights. Facta Univ. Ser. Mech. Eng. 2023, 21, 631. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Sanusi, K.O. Microstructural characteristics, mechanical and wear behavior of aluminum matrix hybrid composites reinforced with alumina, rice husk ash, and graphite. Eng. Sci. Technol. Int. J. 2015, 18, 416–422. [Google Scholar] [CrossRef]

- Haigh, L.; de Wit, M.; von Daniels, C.; Colloricchio, A.; Hoogzaad, J. The Circularity Gap Report 2021; Circle Economy: Amsterdam, The Netherlands, 2021; pp. 1–71. [Google Scholar]

- Abshalomu, Y.; Jyothi, Y.; Balamurugan, K.; Selvaraj, R. Effect of Varied Cashew Nut Ash Reinforcement in Aluminum Matrix Composite. Adv. Mater. Sci. Eng. 2023, 2023, 3383777. [Google Scholar] [CrossRef]

- Prasad, D.S.; Shoba, C.; Ramanaiah, N. Investigations on mechanical properties of aluminum hybrid composites. J. Mater. Res. Technol. 2014, 3, 79–85. [Google Scholar] [CrossRef]

- Ikele, U.S.; Alaneme, K.K.; Oyetunji, A. Mechanical behavior of stir cast aluminum matrix composites reinforced with silicon carbide and palm kernel shell ash. Manuf. Rev. 2022, 9, 12. [Google Scholar] [CrossRef]

- Surappa, M.K. Aluminium matrix composites: Challenges and opportunities. Sadhana Acad. Proc. Eng. Sci. 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Saad, M.H.; Nazzal, M.A.; Darras, B.M. A general framework for sustainability assessment of manufacturing processes. Ecol. Indic. 2019, 97, 211–224. [Google Scholar] [CrossRef]

- Ayodele, O.O.; Babalola, B.J.; Olubambi, P.A. Characterization, nanomechanical, and wear attributes of sintered Al–TiB2 composites. J. Mater. Res. Technol. 2023, 24, 4153–4167. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K.; Salem, K.H.; Mohammed, K.A.; Singh, R.; Prakash, C. Effects of various fabrication techniques on the mechanical characteristics of metal matrix composites: A review. Adv. Mater. Process. Technol. 2024, 10, 277–294. [Google Scholar] [CrossRef]

- Soares, E.; Bouchonneau, N.; Alves, E.; Alves, K.; Araújo Filho, O.; Mesguich, D.; Chevallier, G.; Laurent, C.; Estournès, C. Microstructure and mechanical properties of AA7075 aluminum alloy fabricated by spark plasma sintering (SPS). Materials 2021, 14, 430. [Google Scholar] [CrossRef] [PubMed]

- Lade, J.; Mohammed, K.A.; Singh, D.; Verma, R.P.; Math, P.; Saraswat, M.; Gupta, L.R. A critical review of fabrication routes and their effects on mechanical properties of AMMCs. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Edosa, O.O.; Tekweme, F.K.; Olubambi, P.A.; Gupta, K. Microstructural Analysis, Compressive Strength, and Wear Properties of Spark-Plasma-Sintered Al–Mg–PPA Composites. Quantum Beam Sci. 2024, 8, 32. [Google Scholar] [CrossRef]

- Guan, H.D.; Li, C.J.; Gao, P.; Yi, J.H.; Bao, R.; Tao, J.M.; Fang, D.; Feng, Z.X. Fe-based metallic glass particles reinforced Al-7075 matrix composites prepared by spark plasma sintering. Adv. Powder Technol. 2020, 31, 3500–3506. [Google Scholar] [CrossRef]

- Anand Sekhar, R.; Rakesh Pillai, R.; Mubarak Ali, M.; Shyam Kumar, C.N. Enhanced mechanical and wear properties of aluminium-based composites reinforced with a unique blend of granite particles and boron carbide for sustainable material recycling. J. Alloys Compd. 2023, 963, 171165. [Google Scholar] [CrossRef]

- Rominiyi, A.L.; Shongwe, M.B.; Tshabalala, L.C.; Ogunmuyiwa, E.N.; Jeje, S.O.; Babalola, B.J.; Olubambi, P.A. Spark plasma sintering of Ti–Ni–TiCN composites: Microstructural characterization, densification and mechanical properties. J. Alloys Compd. 2020, 848, 156559. [Google Scholar] [CrossRef]

- Akbarpour, M.R. Microstructure, Densification, and Compressive Properties of Al-CNT Metal Matrix Composites Fabricated by Flake Powder Metallurgy and Conventional Sintering Process. Adv. Ceram. Prog. 2022, 8, 27–33. [Google Scholar]

- Rahimian, M.; Ehsani, N.; Parvin, N.; Baharvandi, H. The effect of particle size, sintering temperature and sintering time on the properties of Al-Al2O3 composites, made by powder metallurgy. J. Mater. Process. Technol. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

- Ponhan, K.; Tassenberg, K.; Weston, D.; Nicholls, K.G.M.; Thornton, R. Effect of SiC nanoparticle content and milling time on the microstructural characteristics and properties of Mg-SiC nanocomposites synthesized with powder metallurgy incorporating high-energy ball milling. Ceram. Int. 2020, 46, 26956–26969. [Google Scholar] [CrossRef]

- Surya, M.S.; Gugulothu, S.K. Fabrication, Mechanical and Wear Characterization of Silicon Carbide Reinforced Aluminium 7075 Metal Matrix Composite. Silicon 2022, 14, 2023–2032. [Google Scholar] [CrossRef]

- Xiong, B.; Liu, K.; Yan, Q.; Xiong, W.; Wu, X. Microstructure and mechanical properties of graphene nanoplatelets reinforced Al matrix composites fabricated by spark plasma sintering. J. Alloys Compd. 2020, 837, 155495. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, W. A review on aluminum matrix composites’ characteristics and applications for automotive sector. Heliyon 2024, 10, 38576. [Google Scholar] [CrossRef] [PubMed]

- Seyed Pourmand, N.; Asgharzadeh, H. Aluminum Matrix Composites Reinforced with Graphene: A Review on Production, Microstructure, and Properties. Crit. Rev. Solid State Mater. Sci. 2020, 45, 289–337. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K.; Olevsky, E.A. Progress in aluminium and magnesium matrix composites obtained by spark plasma, microwave and induction sintering. Int. Mater. Rev. 2023, 68, 225–246. [Google Scholar] [CrossRef]

- Tosun, G.; Kurt, M. The porosity, microstructure, and hardness of Al-Mg composites reinforced with micro particle SiC/Al2O3 produced using powder metallurgy. Compos. Part B Eng. 2019, 174, 106965. [Google Scholar] [CrossRef]

- Manohar, G.; Pandey, K.M.; Maity, S.R. Effect of spark plasma sintering on microstructure and mechanical properties of AA7075/B4C/ZrC hybrid nanocomposite fabricated by powder metallurgy techniques. Mater. Chem. Phys. 2022, 282, 126000. [Google Scholar] [CrossRef]

- Delavari, M.; Salarvand, A.; Rahi, A.; Shahri, F. The effect of powder metallurgy process parameters on mechanical properties of micro and nano-iron powder. Int. J. Eng. Sci. Technol. 2012, 3, 86–94. [Google Scholar] [CrossRef]

| Sample Designation | Composition | Theoretical Density (g/cm3) |

|---|---|---|

| A1 | 98Al:2Mg | 2.6816 |

| A2 | 93Al:2Mg:5PPA | 2.6636 |

| A3 | 88Al:2Mg:10PPA | 2.6476 |

| A4 | 83Al:2Mg:15PPA | 2.6276 |

| A5 | 78Al:2Mg:20PPA | 2.6096 |

| Parameters | Levels | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Sintering temperature (ST) °C | 430 | 460 | 490 | 520 | 550 |

| Holding (sintering) time (HT) min | 2 | 4 | 6 | 8 | 10 |

| Sintering pressure (SP) MPa | 12 | 22 | 32 | 42 | 52 |

| Heating rate (HR) °C/min | 50 | 100 | 150 | 200 | 250 |

| Exp. Runs | Input Processing Parameters | Results | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ST (°C) | HT (min) | ‘SP’ (MPa) | PPA wt% | HR (°C/min) | Av. Exp. Density (g) | RD (%) | Average Hardness (HV) | Standard Dev. for Hardness | |

| Experimental Values | |||||||||

| 1 | 430 | 2 | 12 | 20 | 50 | 2.3864 | 91.45 | 55.1 | 7.1 |

| 2 | 430 | 4 | 22 | 15 | 100 | 2.4531 | 93.36 | 56.9 | 3.8 |

| 3 | 430 | 6 | 32 | 10 | 150 | 2.3989 | 90.61 | 61.9 | 7.6 |

| 4 | 430 | 8 | 42 | 5 | 200 | 2.4250 | 91.00 | 68.9 | 4.6 |

| 5 | 430 | 10 | 52 | 0 | 250 | 2.3853 | 88.95 | 72.6 | 7.3 |

| 6 | 460 | 2 | 22 | 10 | 200 | 2.4660 | 93.14 | 54.5 | 7.0 |

| 7 | 460 | 4 | 32 | 5 | 250 | 2.5380 | 95.30 | 63.0 | 7.9 |

| 8 | 460 | 6 | 42 | 0 | 50 | 2.5021 | 93.31 | 61.5 | 1.6 |

| 9 | 460 | 8 | 52 | 20 | 100 | 2.4323 | 93.21 | 53.3 | 2.5 |

| 10 | 460 | 10 | 12 | 15 | 150 | 2.5280 | 96.21 | 58.8 | 5.3 |

| 11 | 490 | 2 | 32 | 0 | 100 | 2.4644 | 91.90 | 64.7 | 4.4 |

| 12 | 490 | 4 | 42 | 20 | 150 | 2.4592 | 94.24 | 53.5 | 4.5 |

| 13 | 490 | 6 | 52 | 15 | 200 | 2.4759 | 94.23 | 77.0 | 6.2 |

| 14 | 490 | 8 | 12 | 10 | 250 | 2.4750 | 93.48 | 52.1 | 7.3 |

| 15 | 490 | 10 | 22 | 5 | 50 | 2.4938 | 93.63 | 63.5 | 5.9 |

| 16 | 520 | 2 | 42 | 15 | 250 | 2.6026 | 99.05 | 71.5 | 7.0 |

| 17 | 520 | 4 | 52 | 10 | 50 | 2.5243 | 95.34 | 55.7 | 5.5 |

| 18 | 520 | 6 | 12 | 5 | 100 | 2.5159 | 94.45 | 61.7 | 5.4 |

| 19 | 520 | 8 | 22 | 0 | 150 | 2.5059 | 93.45 | 74.5 | 3.2 |

| 20 | 520 | 10 | 32 | 20 | 200 | 2.5168 | 96.44 | 56.1 | 6.2 |

| 21 | 550 | 2 | 52 | 5 | 150 | 2.5107 | 94.26 | 70.4 | 8.7 |

| 22 | 550 | 4 | 12 | 0 | 200 | 2.5685 | 95.78 | 75.8 | 4.9 |

| 23 | 550 | 6 | 22 | 20 | 250 | 2.5580 | 98.02 | 52.7 | 3.1 |

| 24 | 550 | 8 | 32 | 15 | 50 | 2.5074 | 95.43 | 67.5 | 4.8 |

| 25 | 550 | 10 | 42 | 10 | 100 | 2.5421 | 96.02 | 56.2 | 4.5 |

| Al | 550 | 4 | 12 | 100 | 200 | 2.6901 | 99.63 | 41.2 | 3.3 |

| Level | Temperature | Holding Time | Pressure | Material | Heating Rate |

|---|---|---|---|---|---|

| 1 | 39.19 | 39.46 | 39.49 | 39.52 | 39.45 |

| 2 | 39.48 | 39.54 | 39.49 | 39.61 | 39.44 |

| 3 | 39.42 | 39.47 | 39.45 | 39.43 | 39.44 |

| 4 | 39.62 | 39.40 | 39.53 | 39.44 | 39.47 |

| 5 | 39.64 | 39.48 | 39.39 | 39.34 | 39.54 |

| Delta | 0.45 | 0.14 | 0.14 | 0.28 | 0.11 |

| Rank | 1 | 4 | 3 | 2 | 5 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Regression | 5 | 85.147 | 17.029 | 8.05 | 0.000 |

| Temperature | 1 | 62.362 | 62.362 | 29.49 | 0.000 |

| Holding time | 1 | 0.414 | 0.414 | 0.20 | 0.663 |

| Pressure | 1 | 1.528 | 1.528 | 0.72 | 0.406 |

| Material | 1 | 17.500 | 17.500 | 8.28 | 0.010 |

| Heating rate | 1 | 3.344 | 3.344 | 1.58 | 0.224 |

| Error | 19 | 40.175 | 2.115 | ||

| Total | 24 | 125.322 |

| Level | Temperature | Holding Time | Pressure | Material | Heating Rate |

|---|---|---|---|---|---|

| 1 | 35.37 | 35.96 | 35.59 | 34.67 | 35.63 |

| 2 | 35.28 | 35.63 | 35.55 | 36.38 | 35.33 |

| 3 | 35.78 | 35.61 | 35.61 | 34.66 | 35.73 |

| 4 | 36.05 | 35.66 | 35.57 | 36.04 | 36.09 |

| 5 | 36.11 | 35.73 | 36.27 | 36.85 | 35.81 |

| Delta | 0.83 | 0.35 | 0.72 | 2.19 | 0.76 |

| Rank | 2 | 5 | 4 | 1 | 3 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Regression | 5 | 643.95 | 128.789 | 2.63 | 0.057 |

| Temperature | 1 | 137.12 | 137.117 | 2.80 | 0.111 |

| Holding time | 1 | 5.51 | 5.511 | 0.11 | 0.741 |

| Pressure | 1 | 51.01 | 51.005 | 1.04 | 0.320 |

| Material | 1 | 406.70 | 406.695 | 8.31 | 0.010 |

| Heating rate | 1 | 43.62 | 43.618 | 0.89 | 0.357 |

| Error | 19 | 929.86 | 48.940 | ||

| Total | 24 | 1573.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Edosa, O.O.; Tekweme, F.K.; Olubambi, P.A.; Gupta, K. Effects of PPA Reinforcement and Sintering Parameters on the Densification and Hardness Properties of Al/Mg/PPA Composites. Materials 2025, 18, 1246. https://doi.org/10.3390/ma18061246

Edosa OO, Tekweme FK, Olubambi PA, Gupta K. Effects of PPA Reinforcement and Sintering Parameters on the Densification and Hardness Properties of Al/Mg/PPA Composites. Materials. 2025; 18(6):1246. https://doi.org/10.3390/ma18061246

Chicago/Turabian StyleEdosa, Osarue Osaruene, Francis Kunzi Tekweme, Peter A. Olubambi, and Kapil Gupta. 2025. "Effects of PPA Reinforcement and Sintering Parameters on the Densification and Hardness Properties of Al/Mg/PPA Composites" Materials 18, no. 6: 1246. https://doi.org/10.3390/ma18061246

APA StyleEdosa, O. O., Tekweme, F. K., Olubambi, P. A., & Gupta, K. (2025). Effects of PPA Reinforcement and Sintering Parameters on the Densification and Hardness Properties of Al/Mg/PPA Composites. Materials, 18(6), 1246. https://doi.org/10.3390/ma18061246