Study on the Influence of Sn58Bi Alloy on Rock Perforation Plugging Performance

Abstract

1. Introduction

2. Alloy Properties and the Principle of Perforation Plugging in Rock

2.1. Alloy Characteristics

- (1)

- Low melting point: The energy demand for the melting process is relatively low.

- (2)

- Fluidity: It is capable of flowing into the minute gaps and irregular geometries within the perforation.

- (3)

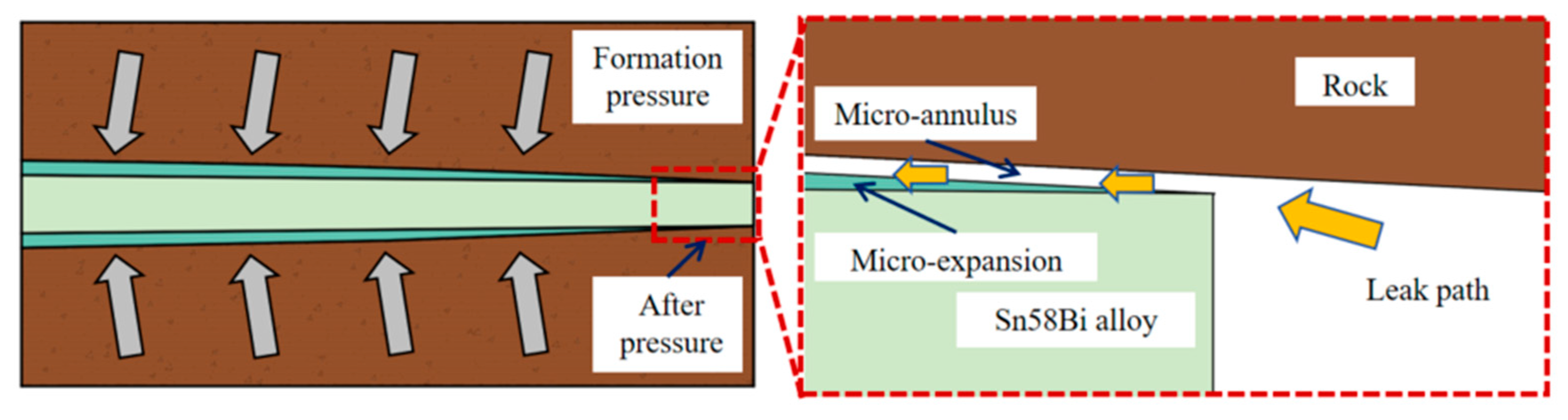

- Expansion: Upon solidification from the liquid state to the solid state, the alloy undergoes volume expansion, which is beneficial for perforation plugging.

- (4)

- High density: Owing to its high density, when the alloy flows into the perforation, low-density substances such as impurities or gases can be buoyed to the upper end. They become attached to the upper surface of the rock and are displaced. This phenomenon facilitates the formation of a pure alloy plug and enables the achievement of plug integrity.

- (5)

- Corrosion resistance: The alloy exhibits resistance to corrosion, particularly in the presence of gases such as H2S and CO2.

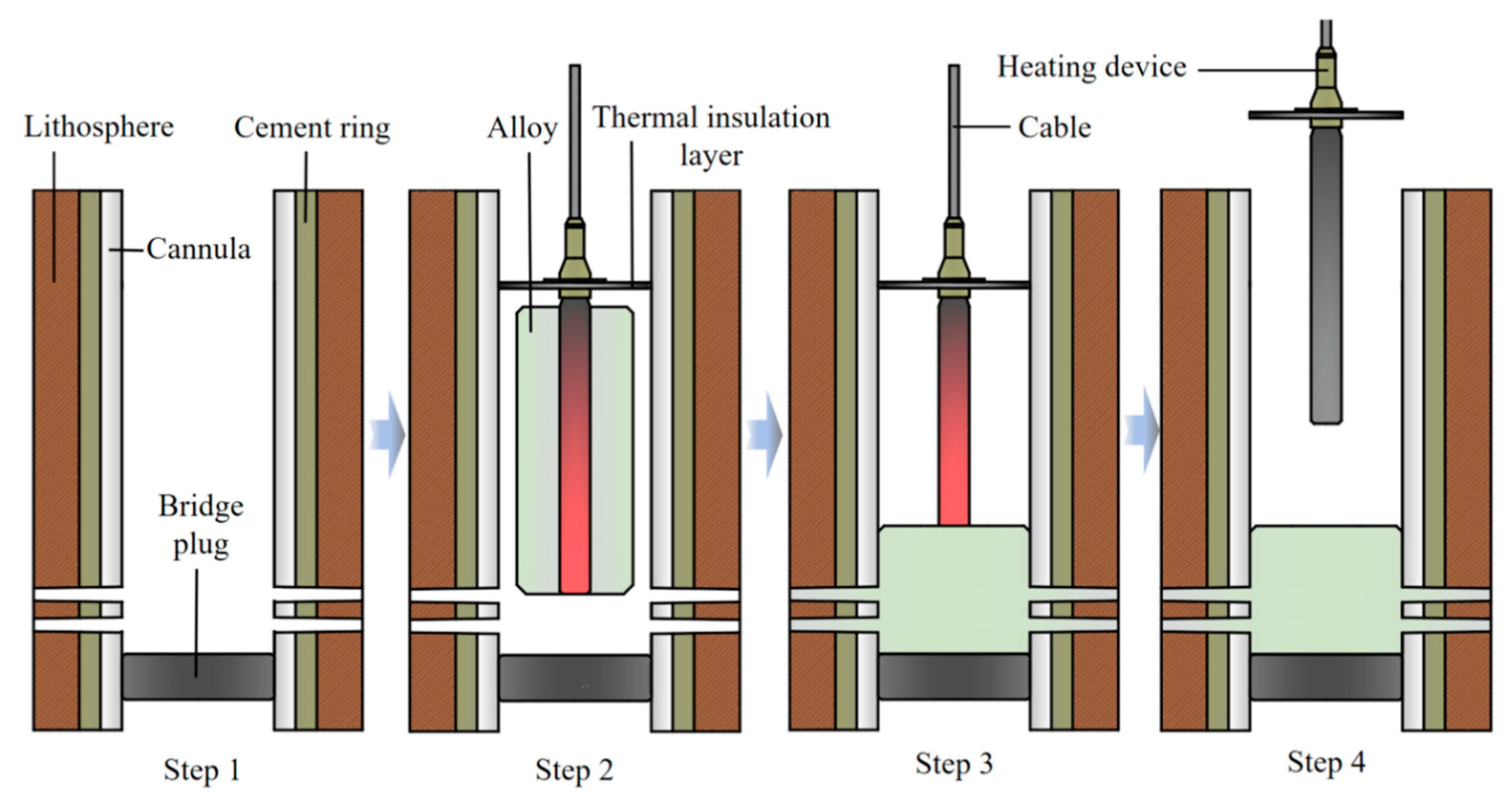

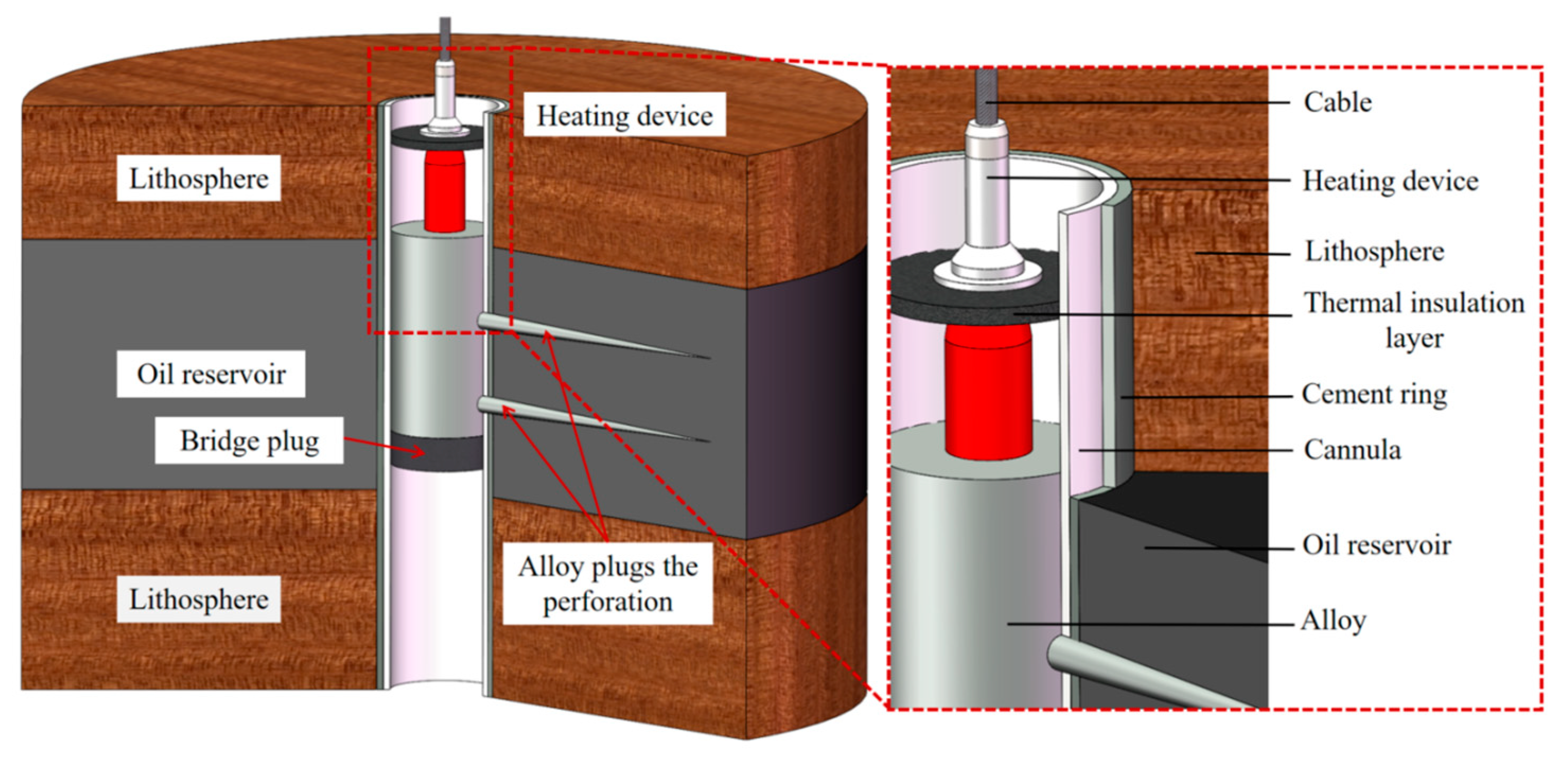

2.2. Alloy Plugging Method of Perforation

3. Experimental Device

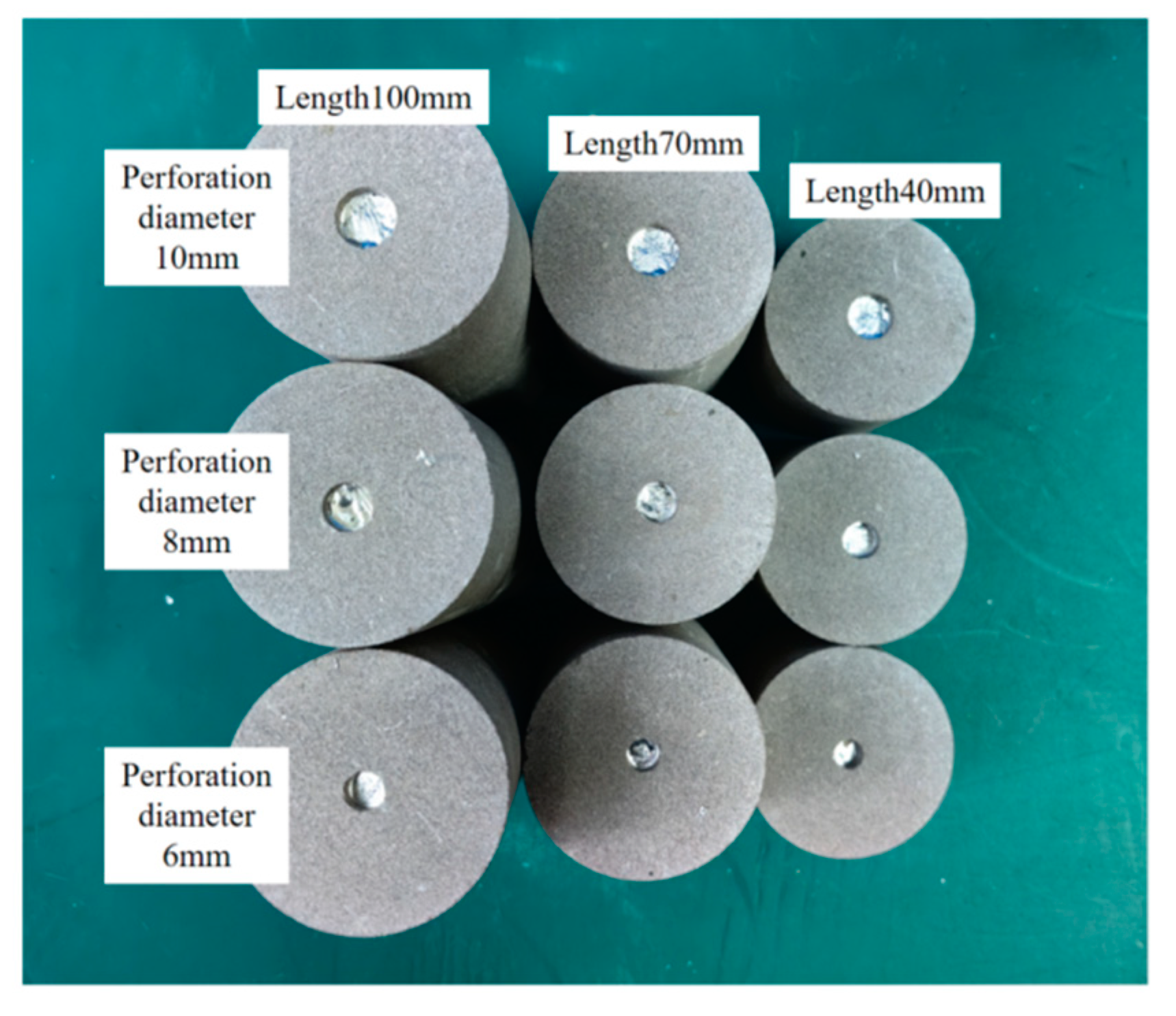

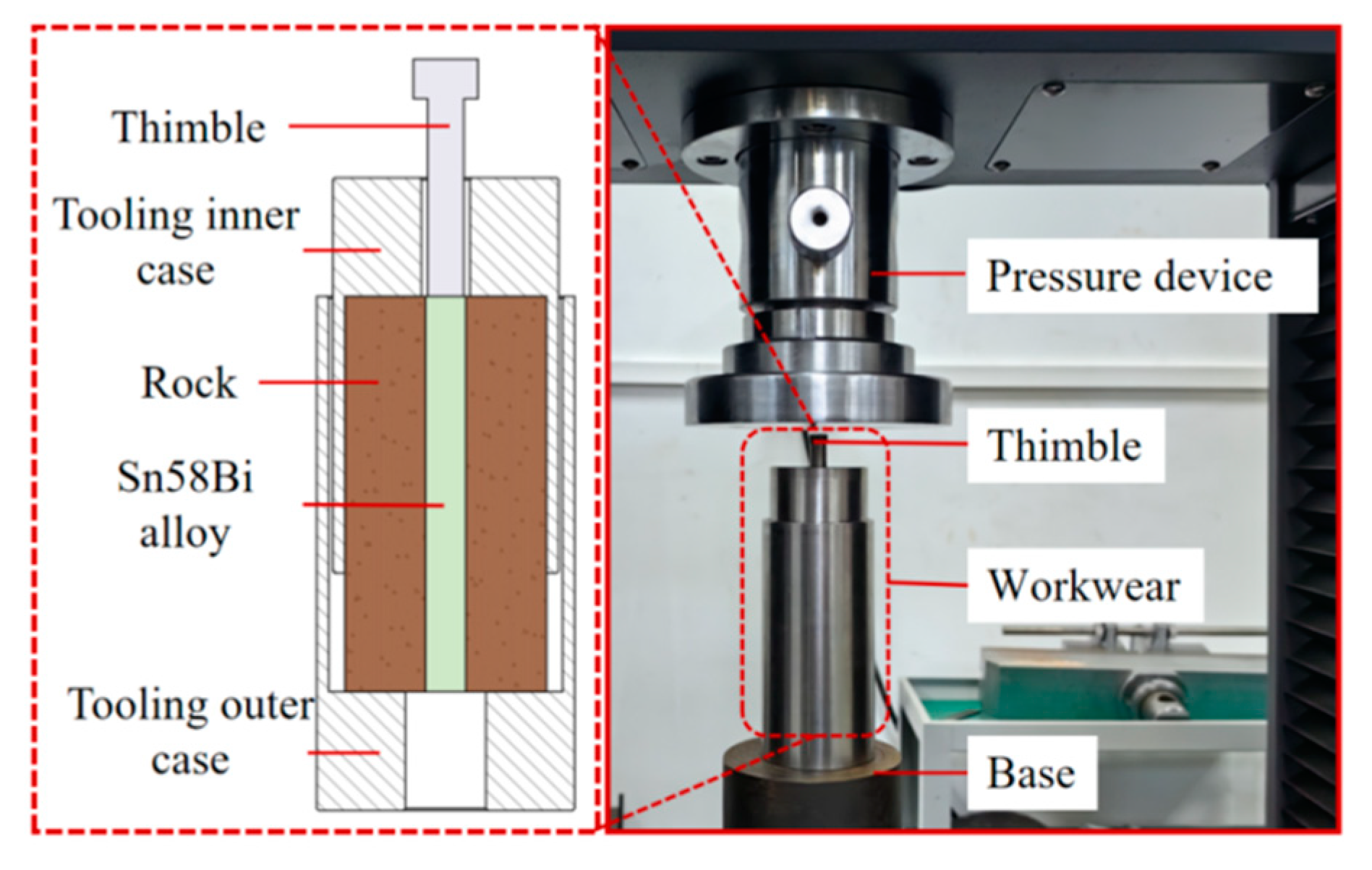

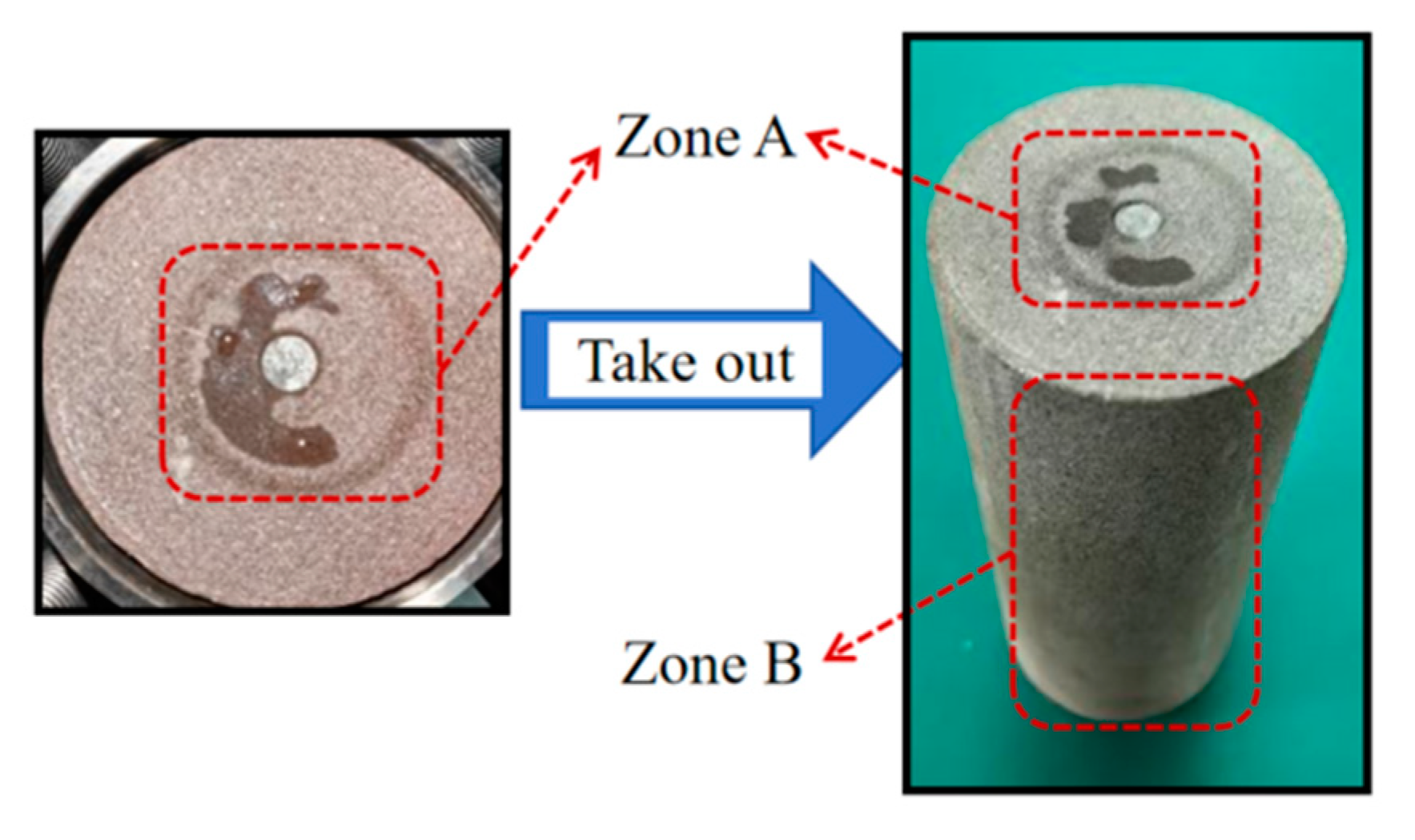

3.1. Preparation of Alloy in Rock Perforation

3.2. A Device for Mechanical Push-Out Experiment

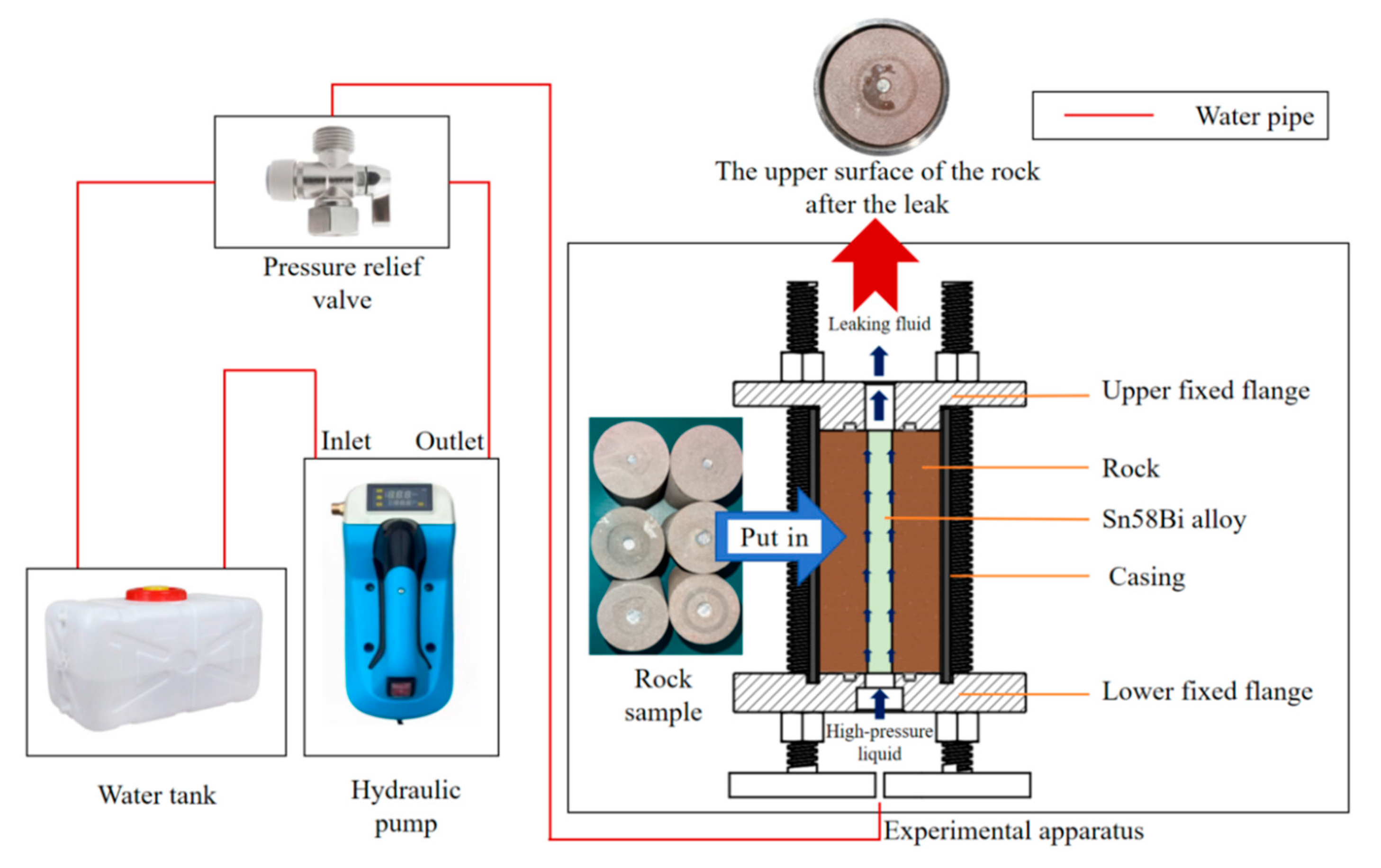

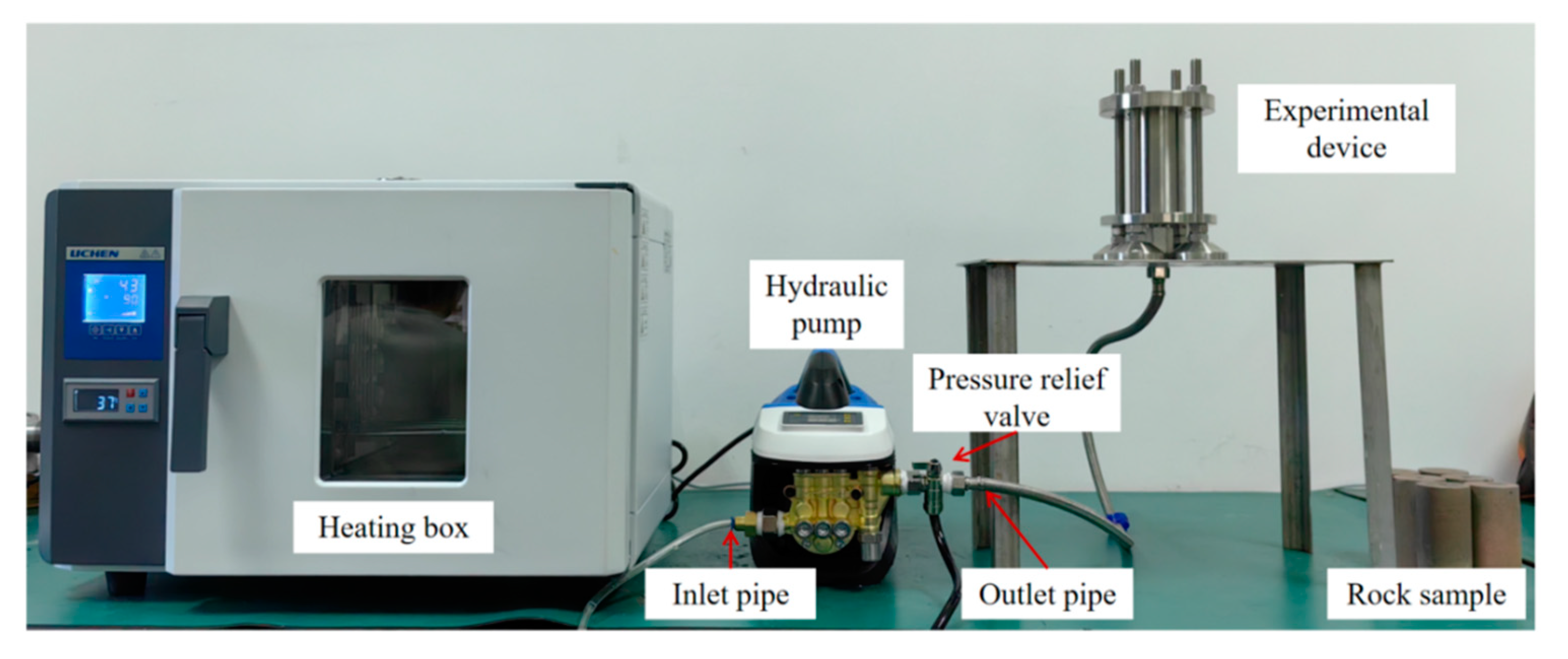

3.3. A Device for the Hydraulic Plugging Pressure Experiment

4. Study on the Properties of Alloy Plugging Rock Perforation

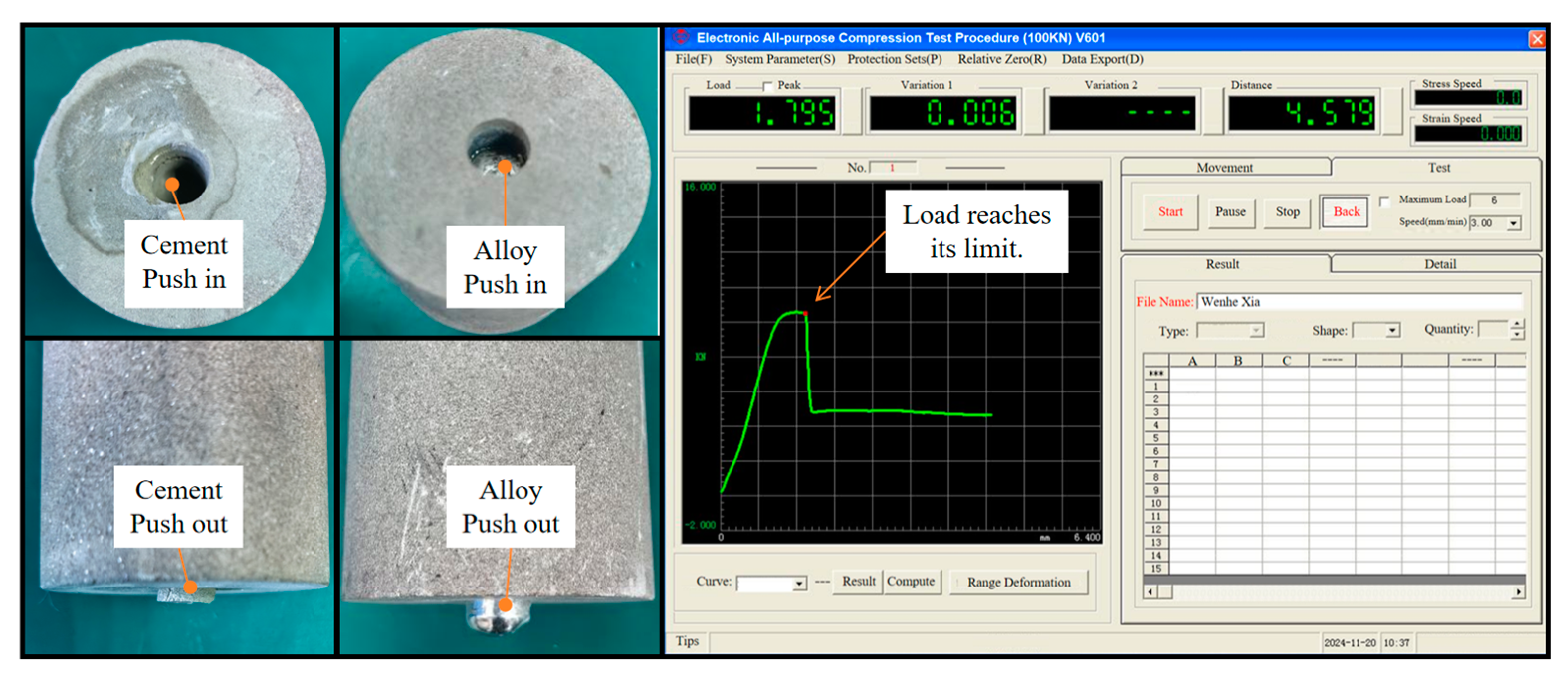

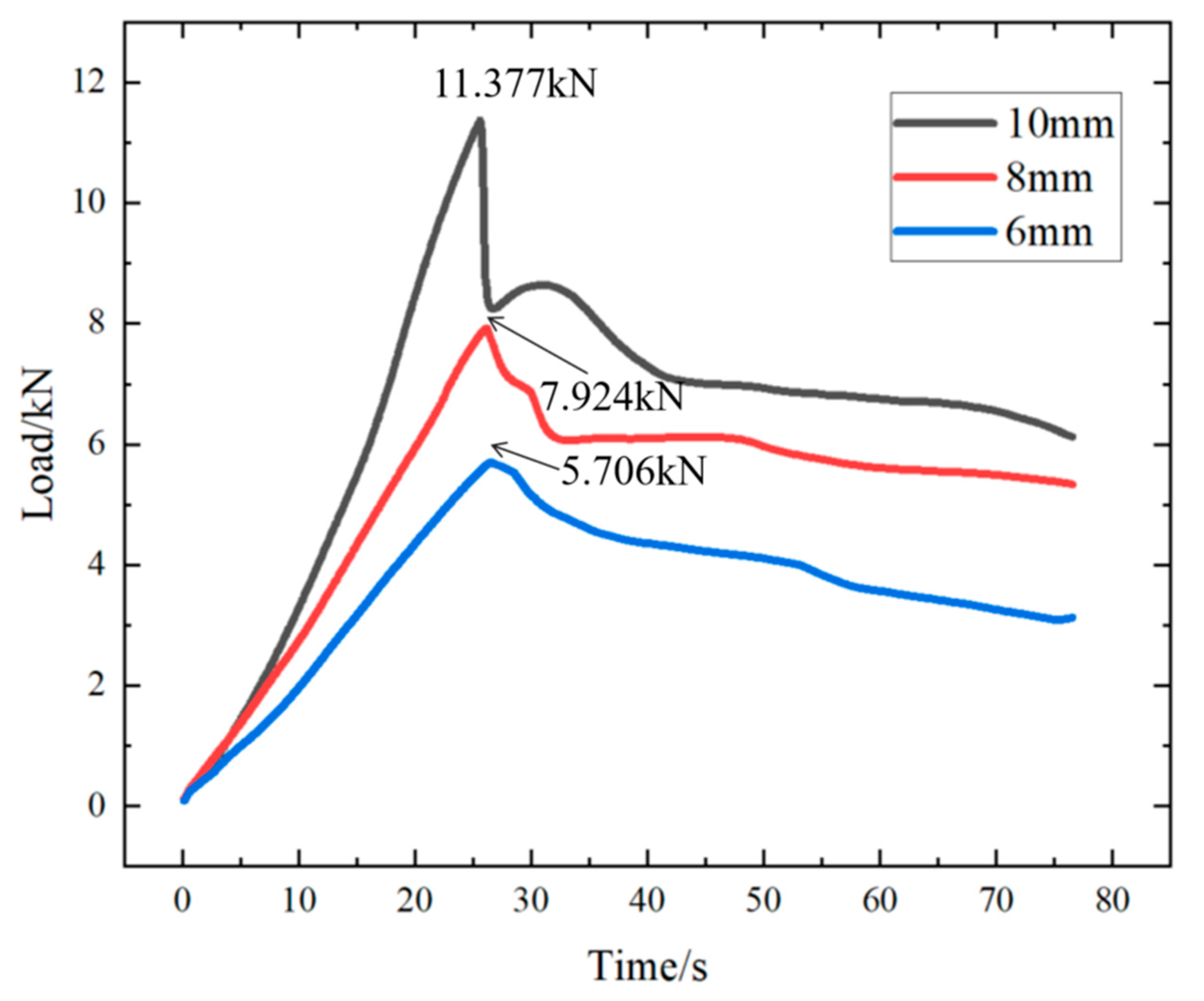

4.1. Mechanical Push-Out Experiment

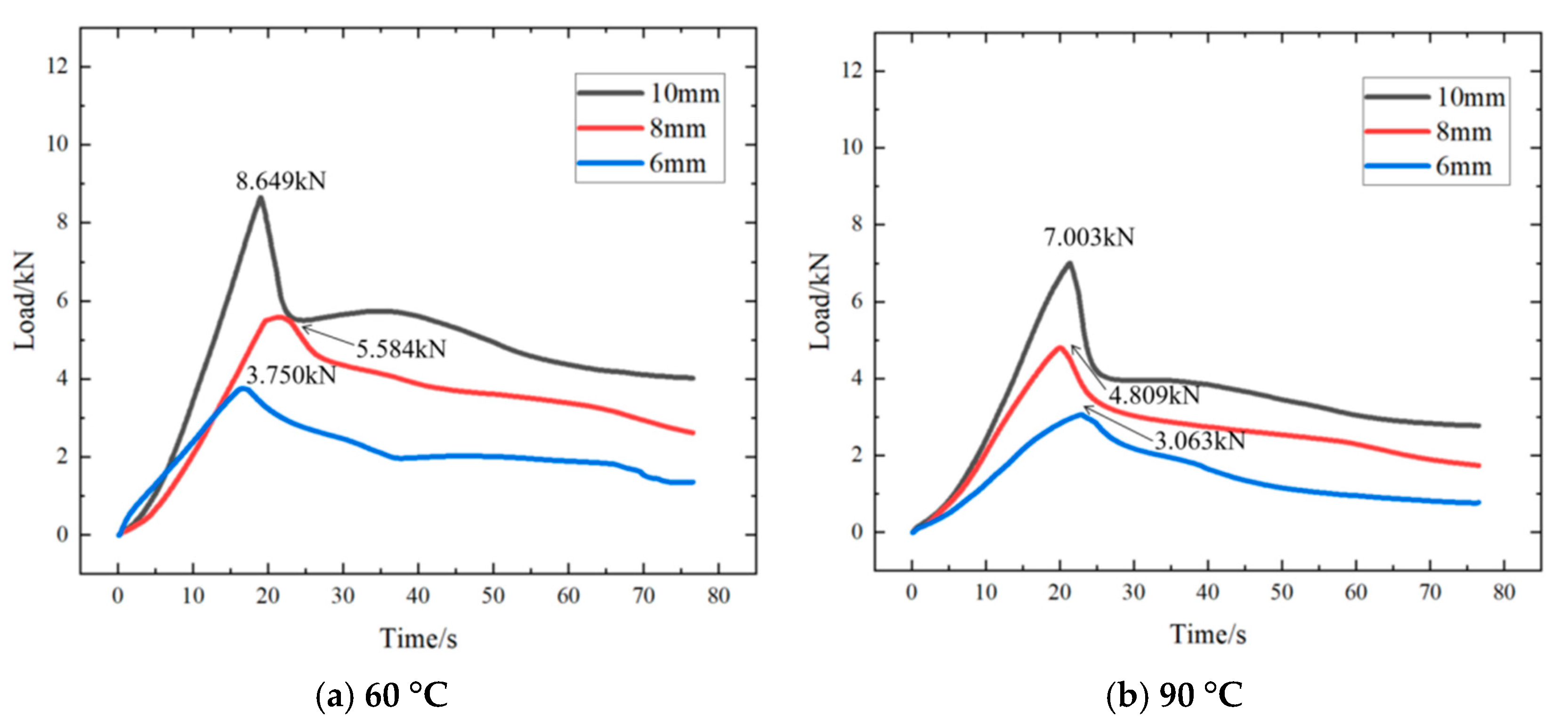

4.2. Hydraulic Plugging Pressure Experiment

5. Experimental Analysis

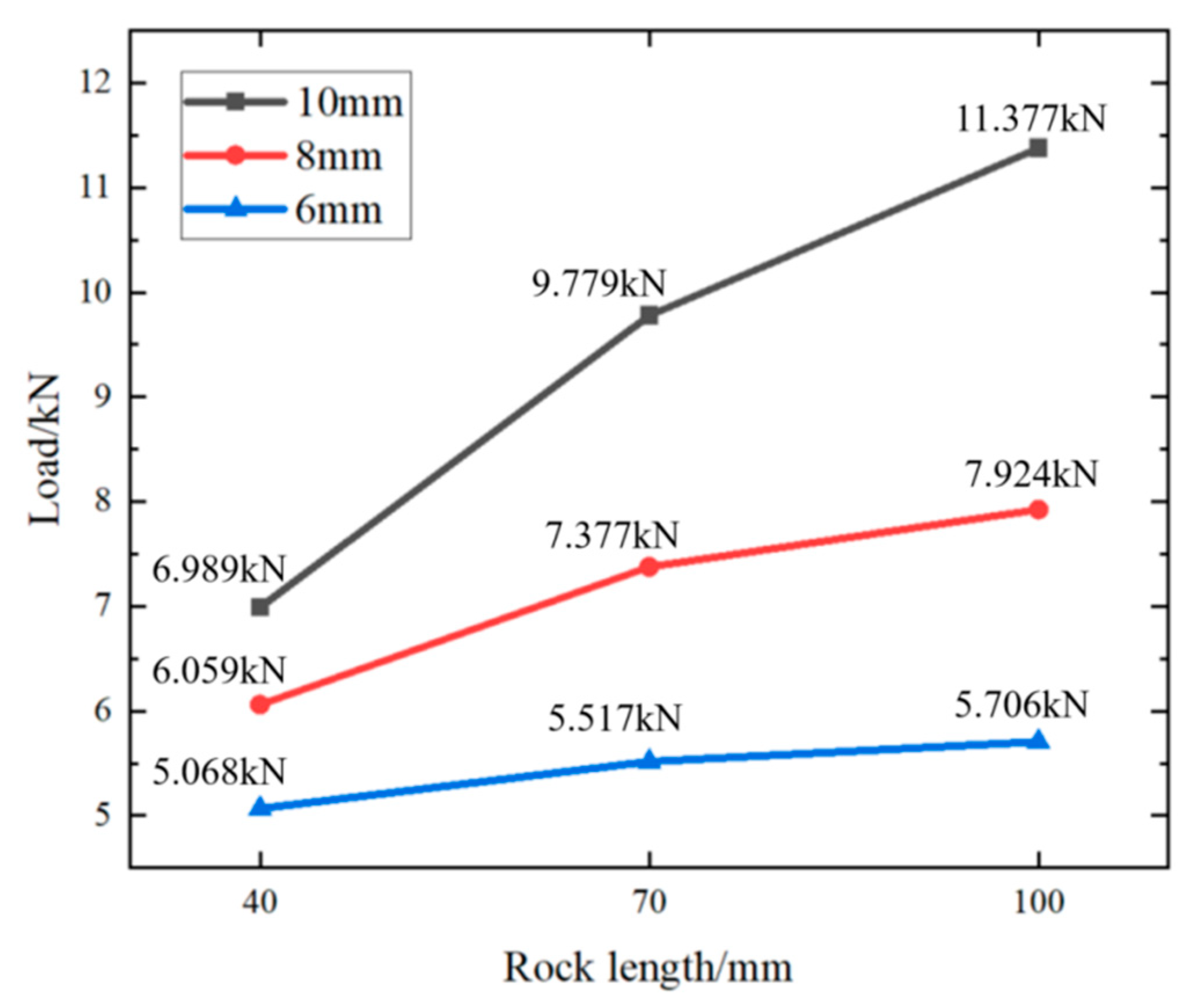

5.1. The Influence Factors of Mechanical Pressure of Alloy

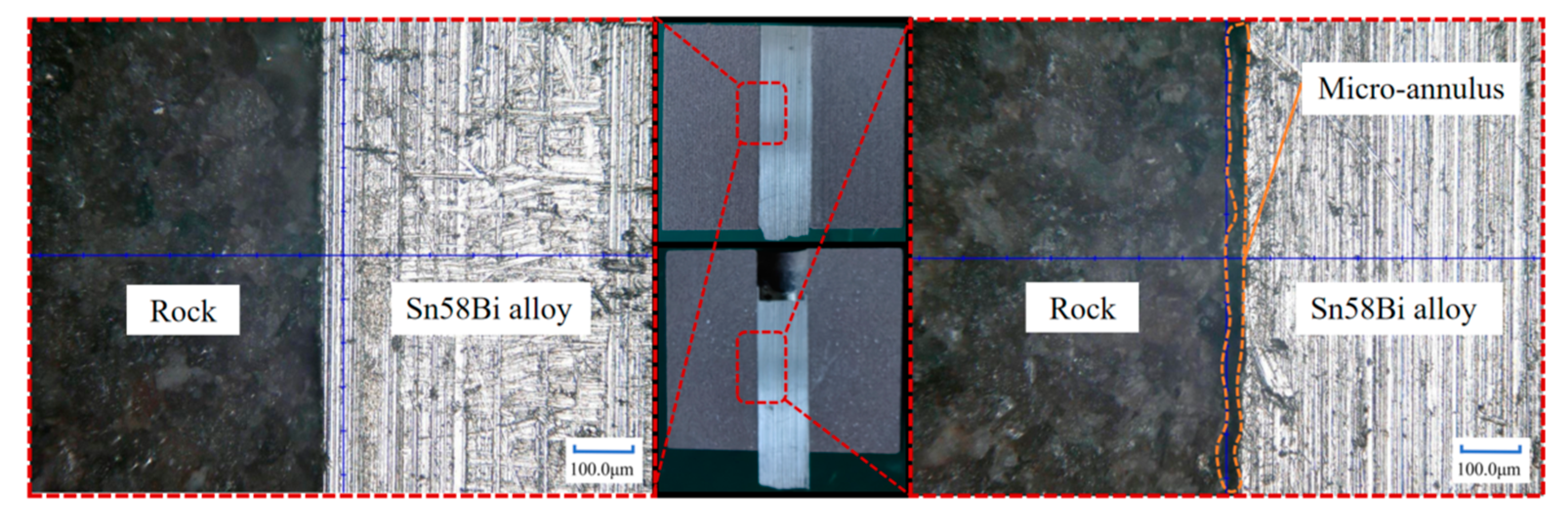

5.1.1. Optical Microscope Observation of Alloy and Rock Interface

5.1.2. Effect of the Diameter of Plugging Rock Perforation on the Mechanical Bearing Capacity of Alloy

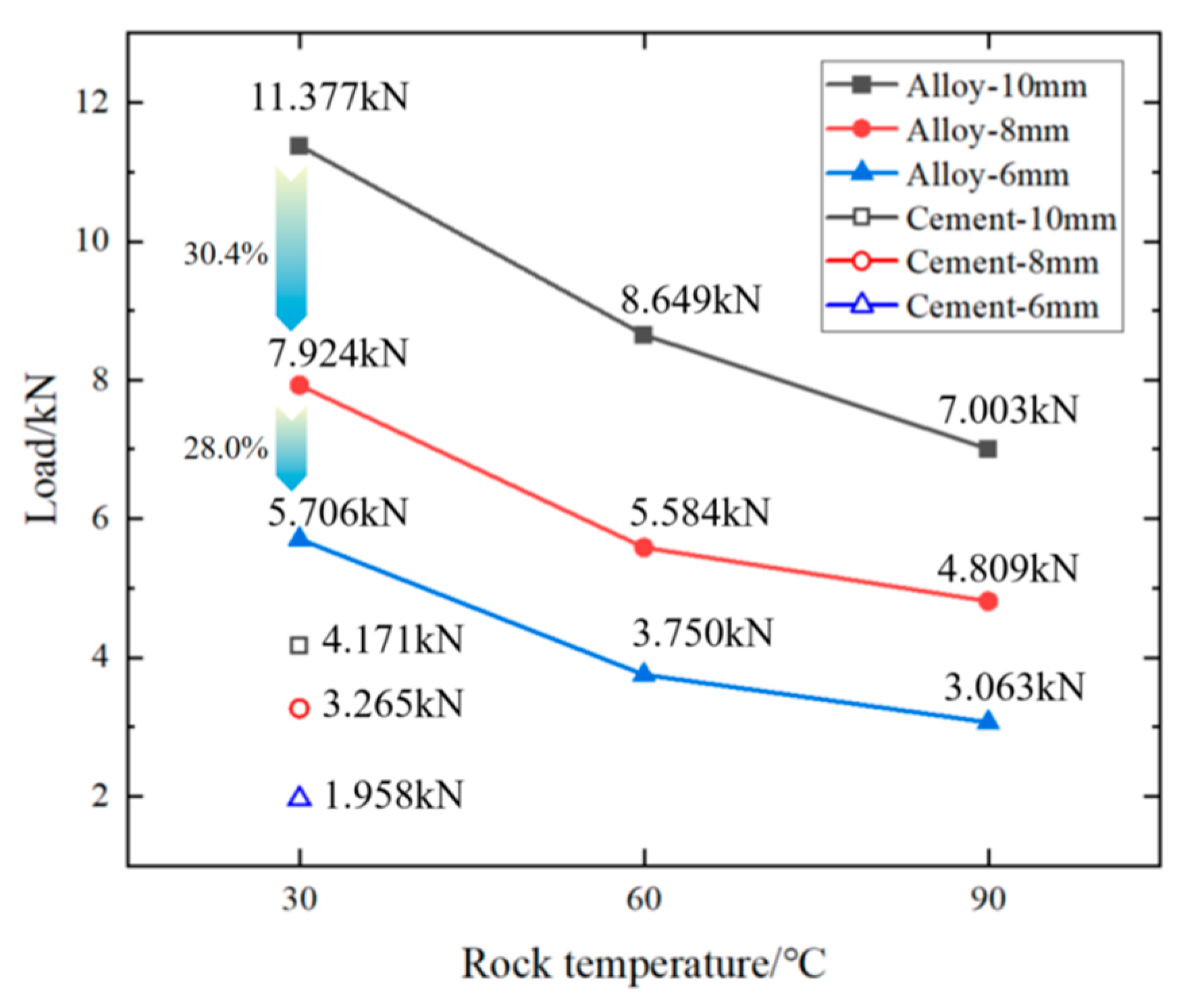

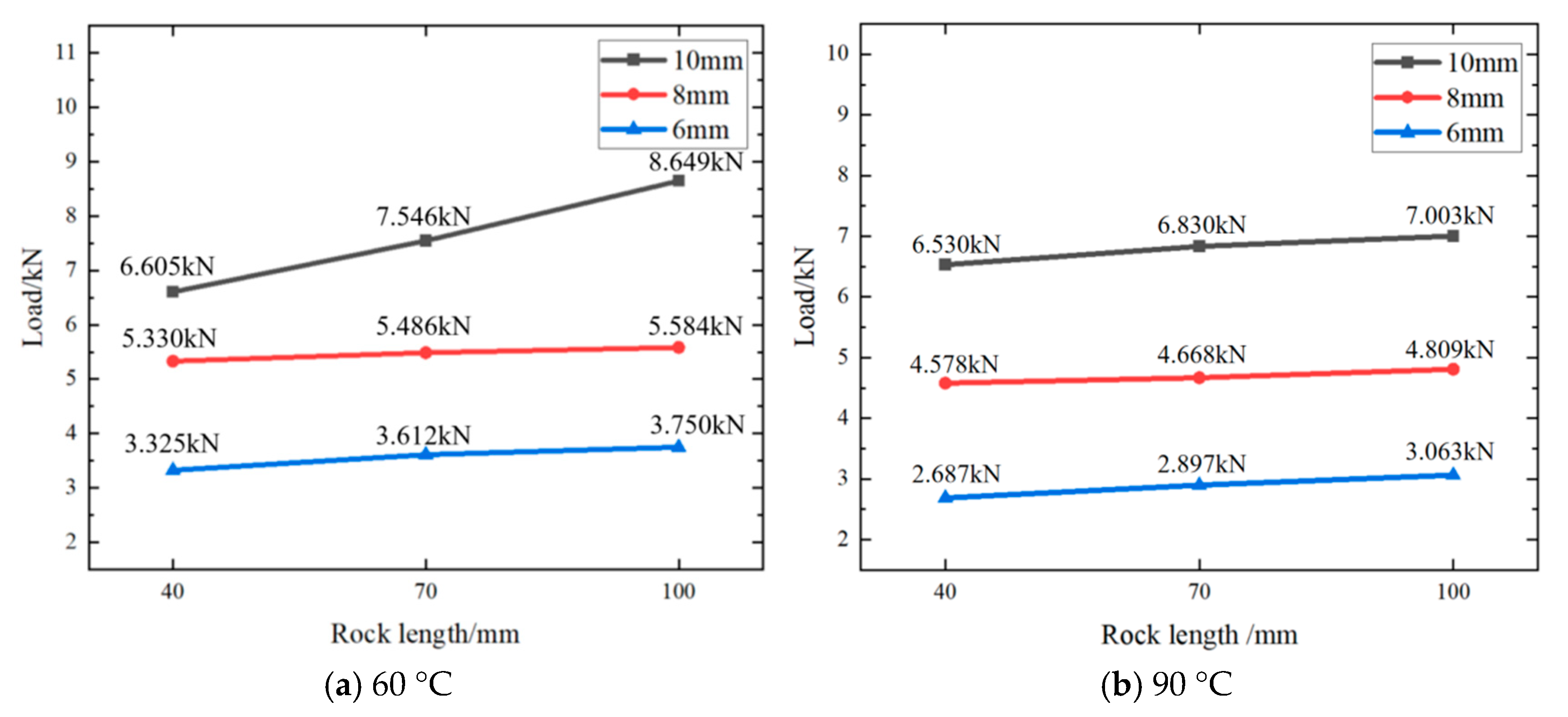

5.1.3. Effect of Ambient Temperature on Mechanical Pressure of Alloy Plug

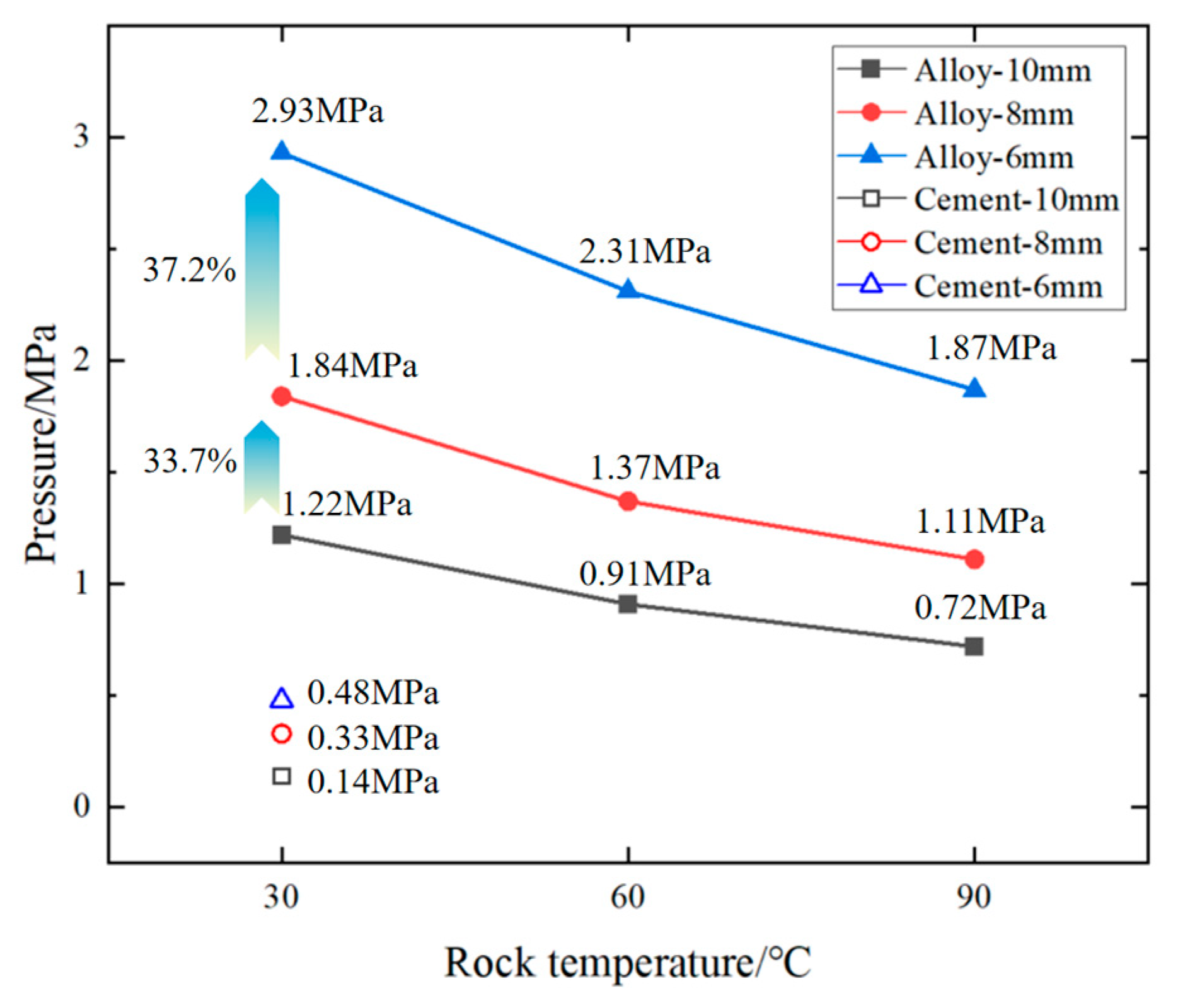

5.2. Effect of Ambient Temperature on Alloy Plugging Hydraulic Plug

6. Conclusions

- (1)

- Under identical conditions and when the ambient temperature (30 °C, 60 °C, 90 °C) is lower than the melting point of the Sn58Bi alloy (138 °C), both the mechanical and hydraulic plugging performances of the alloy are superior to those of cement. The primary reason lies in the fact that the alloy undergoes a certain slight expansion upon solidification. This expansion contributes to a more effective plugging effect between the alloy and the rock perforation.

- (2)

- As the ambient temperature rises, the internal structure of the Sn58Bi alloy undergoes alterations, and the bonding interface between the alloy and the rock perforation is also affected. This ultimately results in the degradation of the mechanical plugging performance of the alloy plug. Moreover, this performance degradation is associated with the diameter of the alloy plug. As the diameter of the alloy plug decreases, the micro-expansion effect induced by the alloy weakens. Consequently, the radial force between the alloy and the rock diminishes, which in turn leads to a further decline in the mechanical plugging performance of the alloy plug.

- (3)

- At a constant alloy-plugging length, as the ambient temperature of the Sn58Bi alloy-plugged rock increases, the hydraulic plugging effect weakens. Conversely, as the diameter of the alloy-plugged pores decreases (from 10 mm to 8 mm and then to 6 mm), the hydraulic plugging performance of the alloy improves. Furthermore, with a reduction in the alloy-plugging diameter, the disparity in plugging performance becomes more pronounced.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, H.; Sun, X. A Summary of Perforating Technology Development inside and outside of China. Explos. Mater. 2006, 35, 33–36. [Google Scholar]

- Chen, C.; Dai, Y.; Zhang, H. Research on sealing technology of oil and water well. China’s New Technol. New Prod. 2014, 21, 34. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Wang, Y. Oil well perforation technology: Status and prospects. Pet. Explor. Dev. 2014, 41, 731–737. [Google Scholar] [CrossRef]

- Reddy, B.R.; Xu, Y.; Ravi, K.; Gray, D.W.; Pattillo, P. Cement-Shrinkage Measurement in Oilwell Cementing—A Comparative Study of Laboratory Methods and Procedures. SPE Drill. Complet. 2009, 24, 104–114. [Google Scholar] [CrossRef]

- Liu, Z.-X.; Gao, M.; Zhang, X.-M.; Liang, Y.; Guo, Y.-J.; Liu, W.-L.; Bao, J.-W. CCUS and CO2 injection field application in abroad and China: Status and progress. Geoenergy Sci. Eng. 2023, 229, 212011. [Google Scholar] [CrossRef]

- Saasen, A.; Wold, S.; Ribesen, B.T.; Tran, T.N.; Huse, A.; Rygg, V.; Grannes, I.; Svindland, A. Permanent abandonment of a North sea well using unconsolidated well plugging material. SPE Drill. Complet. 2011, 26, 371–375. [Google Scholar] [CrossRef]

- Jia, Z.; Shi, B.; Zhou, H.; Chen, F.; Meng, X. Well Path Optimization Technique for Horizontal Wells in Reservoirs with Ultra—Low Permeability and Horizontal Fractures. Spec. Oil Gas Reserv. 2017, 24, 150–154. [Google Scholar] [CrossRef]

- Carragher, P.; Fulks, J. Well Abandonment Solutions Utilizing Bismuth and Thermite. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar]

- Manataki, A.; Kontis, P.; Sangesland, S. Investigation of the microstructure of bismuth alloy and its interaction with cement and steel casing. In Proceedings of the ASME 2023 42nd International Conference on Ocean, Offshore and Arctic Engineering, Melbourne, Australia, 11–16 June 2023. [Google Scholar] [CrossRef]

- Zhang, H.; Ramakrishnan, T.S.; Elias, Q.K.; Perez, A. Evaluation of bismuth-tin alloy for well plug and abandonment. SPE Prod. Oper. 2020, 35, 111–124. [Google Scholar] [CrossRef]

- Hmadeh, L.; Elahifar, B.; Sangesland, S.; Abrahamsen, A.E. A Full Laboratory Study on the Physical and Mechanical Properties of a Bismuth Plug. In Proceedings of the SPE/IADC International Drilling Conference and Exhibition, Stavanger, Norway, 7–9 March 2023. [Google Scholar] [CrossRef]

- Hmadeh, L.; Jaculli, M.A.; Elahifar, B.; Sangesland, S. Development of bismuth-based solutions for well plugging and abandonment: A review. Pet. Res. 2024, 9, 250–264. [Google Scholar] [CrossRef]

- Zhang, H.; Ramakrishnan, T.S.; Elkady, Y.M.; Feng, Y.; Elias, Q.K. Comparative Evaluation of Bismuth-Silver and Bismuth-Tin Alloys for Plug and Abandonment. SPE Drill. Complet. 2020, 36, 368–382. [Google Scholar] [CrossRef]

- Liang, B.; Hu, P.; Ni, Y.; Feng, G.; Zhou, J.; Bai, Y.; Niu, G.; Niu, W.; Zhou, Y. Experimental of mechanical properties and mechanism for theeutectic Sn-Bi alloys under different temperatures and strain rates loading. Funct. Mater. 2021, 52, 1145–1155. [Google Scholar] [CrossRef]

- Carragher, P.; Fulks, J. A New Look at Sealing with Bismuth and Thermite. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar]

- Abdelal, G.F.; Robotham, A.; Carragher, P. Numerical simulation of a patent technology for sealing of deep-sea oil wells using nonlinear finite element method. J. Pet. Sci. Eng. 2015, 133, 192–200. [Google Scholar] [CrossRef]

| Melting Point (°C) | Surface Tension (MPa·s) | Volume Change (Liquid to Solid) | Density /g × cm−3 | Elastic Modulus /GPa | Tensile Strength /MPa | Elongation /25 °C |

|---|---|---|---|---|---|---|

| 138 | 438 | +0.77% | 8.72 | 47.2 | 71.7 | 20.1% |

| Rock Perforation Length | Ambient Temperature | Perforation Diameter 10 mm | Perforation Diameter 8 mm | Perforation Diameter 6 mm |

|---|---|---|---|---|

| 100 mm | 30 °C | 11.377 | 7.924 | 5.706 |

| 60 °C | 8.649 | 5.584 | 3.750 | |

| 90 °C | 7.003 | 4.809 | 3.063 | |

| 70 mm | 30 °C | 9.779 | 7.377 | 5.517 |

| 60 °C | 7.546 | 5.486 | 3.612 | |

| 90 °C | 6.830 | 4.668 | 2.897 | |

| 40 mm | 30 °C | 6.989 | 6.059 | 5.068 |

| 60 °C | 6.605 | 5.330 | 3.325 | |

| 90 °C | 6.530 | 4.578 | 2.687 |

| Ambient Temperature | Perforation Diameter 10 mm | Perforation Diameter 8 mm | Perforation Diameter 6 mm |

|---|---|---|---|

| 30 °C | 1.22 | 1.84 | 2.93 |

| 60 °C | 0.91 | 1.37 | 2.31 |

| 90 °C | 0.72 | 1.11 | 1.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zha, C.; Xia, W.; Wang, W.; Liu, G.; Li, J.; Liu, W. Study on the Influence of Sn58Bi Alloy on Rock Perforation Plugging Performance. Materials 2025, 18, 1195. https://doi.org/10.3390/ma18061195

Zha C, Xia W, Wang W, Liu G, Li J, Liu W. Study on the Influence of Sn58Bi Alloy on Rock Perforation Plugging Performance. Materials. 2025; 18(6):1195. https://doi.org/10.3390/ma18061195

Chicago/Turabian StyleZha, Chunqing, Wenhe Xia, Wei Wang, Gonghui Liu, Jun Li, and Wei Liu. 2025. "Study on the Influence of Sn58Bi Alloy on Rock Perforation Plugging Performance" Materials 18, no. 6: 1195. https://doi.org/10.3390/ma18061195

APA StyleZha, C., Xia, W., Wang, W., Liu, G., Li, J., & Liu, W. (2025). Study on the Influence of Sn58Bi Alloy on Rock Perforation Plugging Performance. Materials, 18(6), 1195. https://doi.org/10.3390/ma18061195