1. Introduction

Single-material topology optimization (TO) seeks the best distribution of a given material within the design domain so that the resulting structure, among other goals, minimizes compliance, minimizes von Mises stress growth, or maximizes the first natural frequency, subject to a volume constraint to maximize its performance. There are several approaches to defining design variables, such as those based on elements used by the Solid Isotropic Material with Penalization (SIMP) method by [

1,

2]. The Evolutionary Structural Optimization (ESO) methods by [

3,

4] and their variants: the Bi-directional Evolutionary Structural Optimization (BESO) method [

5,

6,

7] and the Smooth Evolutionary Structural Optimization (SESO) method by [

8,

9]. Or even, limit-based approaches, such as the Level Set Method (LSM) by [

10,

11,

12], are also considered.

In the last decade, Multi-Material Topology Optimization (MMTO) has attracted a lot of attention from researchers due to the advent of multi-material additive manufacturing. Bandyopadhyay and [

13,

14] highlight that multi-material manufacturing can be easily printed from a computer point-by-point and layer-by-layer.

The Level Set Method is widely used in multi-material optimization due to its ability to represent complex geometries implicitly, handle topology changes, and allow for easy incorporation of multiple materials. The classical LSM was extended to MMTO by [

15]. For

m materials, log(2

m) was used for the level set, and the structure was updated using a set of Hamilton–Jacobi equations. The multi-level set modeling method was extended for stress-constrained multi-material topology optimization by [

16,

17]. A level-based multi-material topology optimization method using a reaction–diffusion equation was proposed by [

18]. The modified multi-material description of the Multi-Material Level Set (MM-LS) was introduced by [

19], which also has the advantage that each phase is represented by a combined formulation of different level set functions. A new MMTO strategy based on the Material-Field Series-Expansion (MFSE) model was proposed for a structure composed of

m different solid material phases [

20]. In this approach,

m individual material fields are introduced to describe the topology distribution in the model’s multi-material representation.

Using the element approach, a SIMP-type multi-material interpolation model was proposed in [

21], first interpolating between two non-zero phases and then between ’solid’ (material) and ’void’ (absence of material). An MMTO approach was introduced by dividing the problem into a series of 0–1 TO subproblems [

22]. The SIMP model was employed between two adjacent materials, and the multi-material BESO method was proposed in [

23]. MMTO was extended under multiple volume and/or mass constraints using the Discrete Material Optimization (DMO) technique [

24,

25], while material nonlinearity was considered in [

26,

27]. Multi-material topology optimization, addressing multi-material volumes, has also been applied to diverse problems, including cable-suspended membrane structures, combined structural and thermal analyses, thermal buckling criteria, and lattice structures, as explored in [

28,

29,

30,

31], respectively.

One of the bottlenecks of MMTO is the interpolation functions, with the selection of the initial values of the design variables being crucial, as it can significantly influence the optimization result. If the initial values are not well chosen, the optimizer can get stuck in local optima. A mapping-based interpolation function for MMTO is proposed in [

32] as an alternative to polynomial interpolation functions or SIMP-based interpolation functions. The proposed function combines the p-norm of the design variables assigned to each finite element and the 1-norm of the design variable. In this sense, this article also contributes a new projection function for the design variables filtered for each material in the domain, implemented through the sigmoid function, which is smoother than the hyperbolic tangent function used by [

32]. This results in a clearer transition between the boundaries of each material in the optimized structure.

Despite recent advancements, current multi-material topology optimization (MMTO) methods still face significant challenges, particularly concerning interpolation functions and intermediate-density regions. MMTO formulations often rely on interpolation schemes, such as polynomial or SIMP-based methods, to transition between materials. However, these approaches frequently result in intermediate-density regions, which complicate manufacturability. While some studies have attempted to address this issue using projection functions, many still suffer from abrupt transitions or numerical instabilities. To mitigate these problems, this article introduces a new projection function based on the sigmoid function, which ensures smoother transitions and improved numerical stability.

Another critical challenge is the computational cost and convergence difficulties associated with MMTO. The inclusion of multiple materials increases the number of design variables and constraints, leading to higher computational demands and slower convergence rates. This issue is especially pronounced in large-scale 3D problems, where traditional MMTO methods often struggle to deliver efficient solutions. Although iterative solvers like the Preconditioned Conjugate Gradient (PCG) method are effective for single-objective optimization due to their simplicity and low computational cost, they may not be suitable for more complex problems involving multiple conflicting objectives. In practical applications, multi-objective optimization is often necessary to address real-world engineering constraints. In such cases, alternative strategies, such as Pareto Front Methods (e.g., NSGA-II and MOEA/D) and scalarization techniques (e.g., the ε-constraint method and the weighted sum method), are more appropriate. These methods enable trade-offs between objectives like stiffness, weight, and cost, with the weighted sum method being particularly popular due to its ease of implementation and straightforward formulation.

To address these challenges, this work proposes a sigmoid-based projection function for MMTO, which enhances the transition between material and void regions while significantly reducing computational costs. Unlike the hyperbolic tangent function, the sigmoid function provides a more gradual and stable transition, effectively eliminating intermediate-density elements without introducing abrupt changes that could compromise structural integrity. Numerical results demonstrate that the proposed approach achieves up to a 36.7% reduction in computational cost and a 19.1% improvement in the objective function compared to traditional projection methods, making it a promising alternative for large-scale 3D MMTO problems.

This paper focuses on enhancing projection functions in MMTO to achieve smoother and more efficient transitions between material and void regions within the design domain. While hyperbolic tangent functions have been widely used, they exhibit drawbacks such as abrupt transitions that can lead to undesirable stress concentrations and less refined solutions. The proposed sigmoid function addresses these issues by improving problem discretization, optimizing material distribution, and reducing computational costs. Additionally, it aligns with the requirements of multi-material additive manufacturing, delivering optimized designs with clearly defined features and eliminating intermediate-density elements.

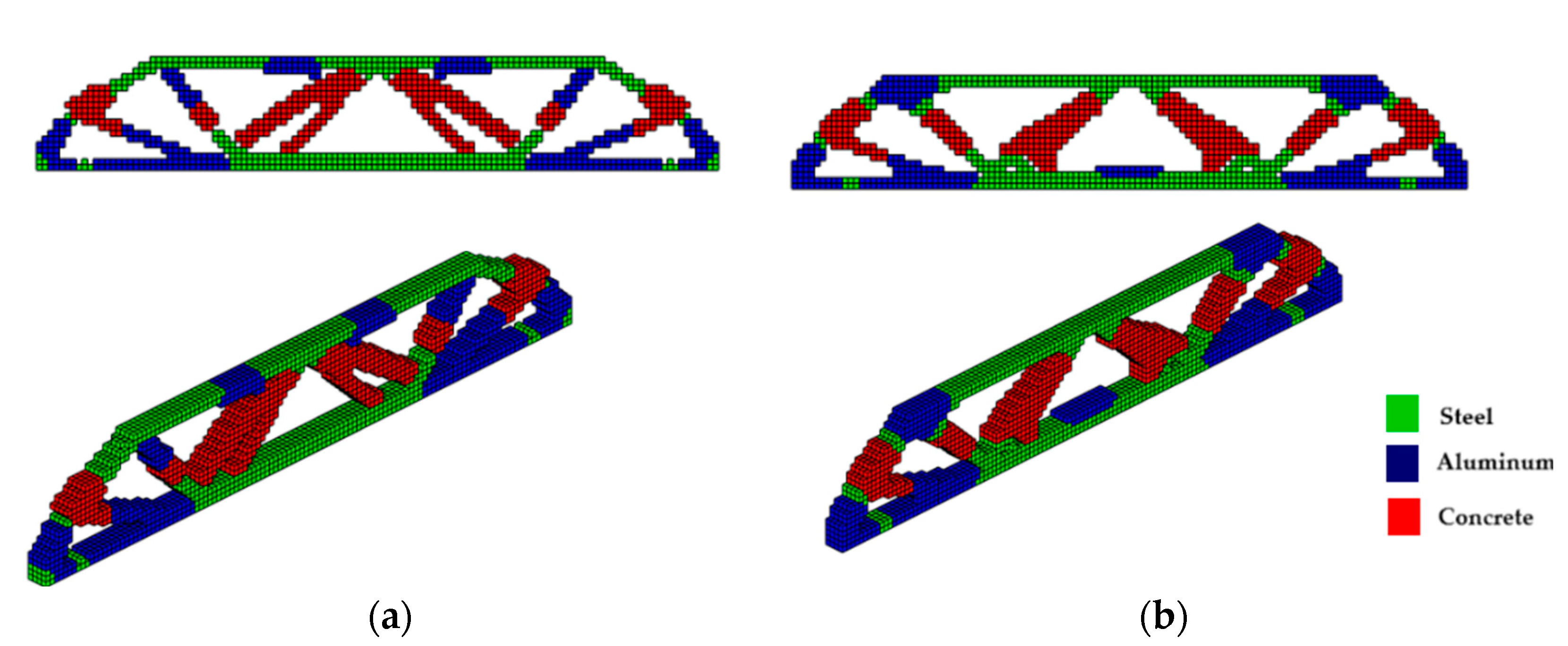

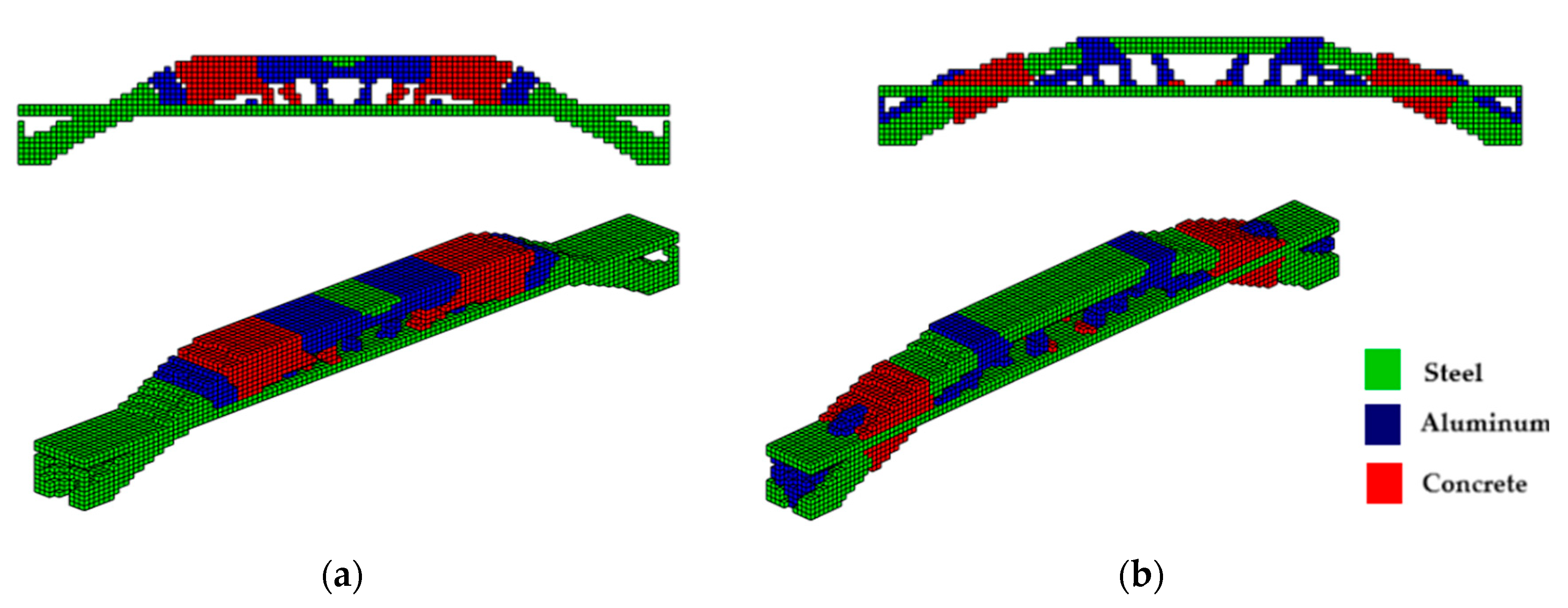

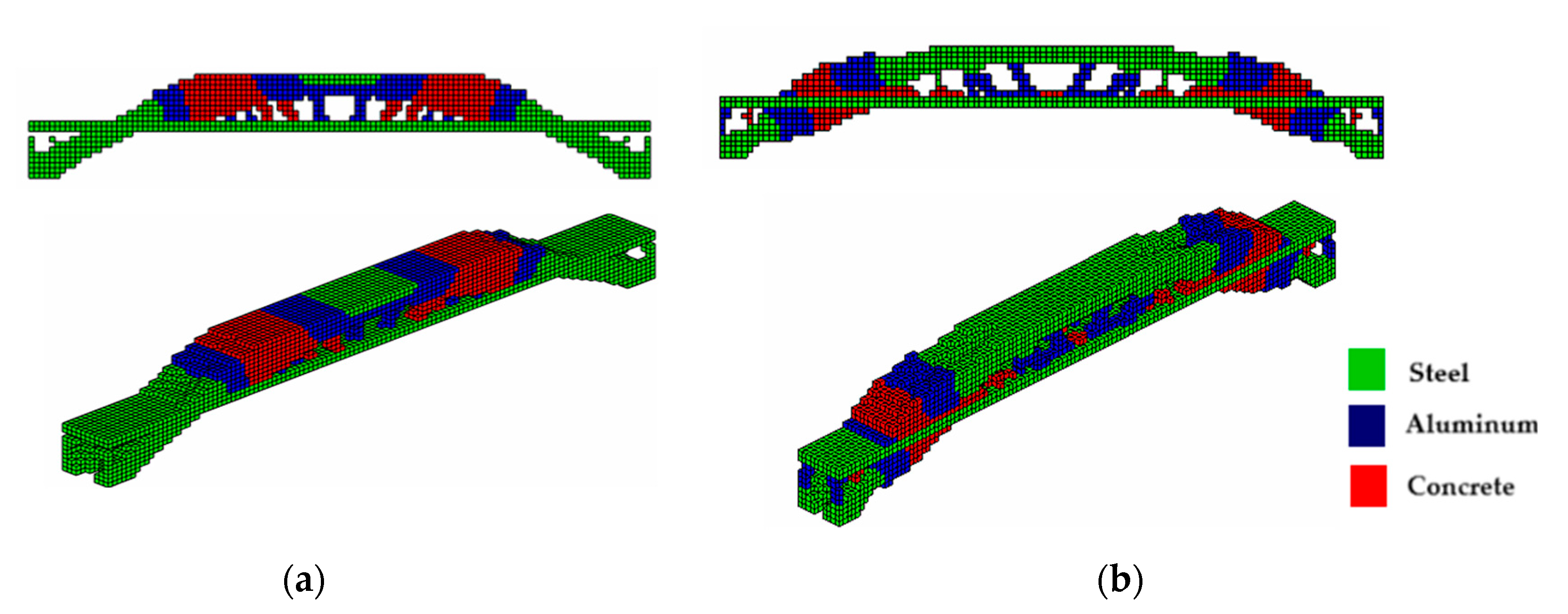

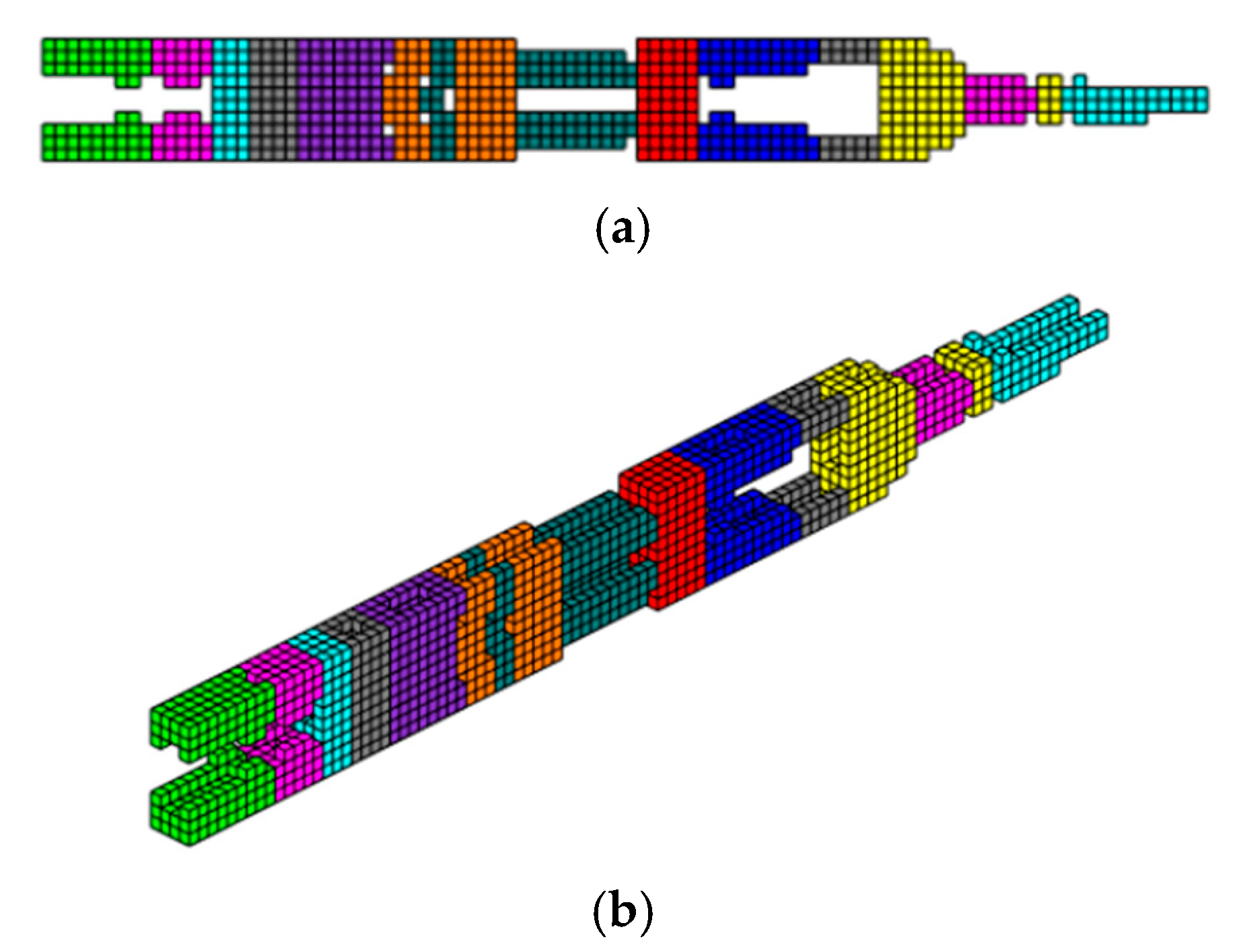

To demonstrate the effectiveness of the proposed approach, the authors apply MMTO using three materials—concrete (red), aluminum (blue), and steel (green)—to a cantilever beam, an MBB beam, and a bridge structure with two types of supports. These examples highlight the influence of boundary conditions and the advantages of the sigmoid projection function. Furthermore, a cantilever beam under axial load is analyzed to showcase the algorithm’s capability to handle up to 10 different materials, achieving an intelligent and optimized design solution.

This article is organized as follows.

Section 2 describes the formulation of the MMTO problem, including the design variable matrix and the sigmoid projection function, while discussing the limitations of existing projection functions.

Section 3 presents the numerical implementation and the iterative solution using Preconditioned Conjugate Gradients (PCG) and Incomplete Cholesky algorithms.

Section 4 provides numerical examples comparing the sigmoid projection function with the hyperbolic tangent function, emphasizing the advantages of the proposed approach. Finally,

Section 5 concludes the paper.

2. The Formulation of the Multi-Material Topology Optimization Problem

2.1. Matrix of Design Variables

The formulation of the Multi-Material Topology Optimization (MMTO) problem using a mapping-based interpolation function consists of finding the optimal distribution of the different materials within the design domain, considering volume or mass constraints. For optimization of a single material, a density is assigned, and modeling the interpolation function of the problem is easier. In this case, the design variables can be expressed by the vector , where N is the number of elements used in the discretization.

In the case of MMTO, the existence of multiple materials in the design domain makes the problem more complex. The design variables are now obtained by multiplying the vector that contains the types of materials by the vector of design variables, that is, a number of elements of discretization, see [

32]. Thus, the MMTO design variable matrix

, has the rows,

M, representing the material properties and the columns,

N, representing the index of the finite elements of the discretization of the design domain; that is, the number of design variables and can be expressed as:

2.2. Formulation of the MMTO

In the search for the maximum stiffness topology via MMTO, it is common to employ the minimization of the average compliance or the maximum von Mises stress as an objective function, while the restriction is imposed on the structural weight, limiting the maximum volume of material allowed. As compliance represents the work performed by applied loads in the structure’s equilibrium state, an alternative approach to maximum stiffness design is to use elastic strain energy as a measure of structural stiffness. Thus, the compliance minimization problem can be reformulated as a problem of minimizing the total elastic strain energy. The formulation of the MMTO problem with multiple design variables assigned to each finite element can be defined as:

where

K,

, and

F represent the stiffness matrix, the displacement vector, and the force vector, respectively.

C is the compliance,

is the volume of each material and

is the maximum volume fraction allowed for each material,

is the designed density and

is the intermediate density. Then, the stiffness matrix designed for the MMTO must be assembled as:

Here,

represents the total stiffness matrix of the system, which is obtained by summing the individual stiffness matrices of all elements

e in the domain, weighted by the material interpolation functions

. For the SIMP method, the material interpolation functions based on those proposed by [

33,

34] are described as follows:

In this paper,

is the penalization factor, which is used to guide the convergence of the design variable to 0 or 1.

is the mapping-based interpolation function proposed by [

32] and expressed as:

The term is a very small value used to avoid the mathematical indeterminacy operation . Therefore, the higher the value of δ, the lower the precision in the approximation; this strategy is used to balance precision and robustness. Furthermore, is the Young’s modulus for the i-th material and represents the Young’s modulus of the void regions.

Furthermore,

and

are the p-norm and 1-norm of the projected design variables given by:

The interpolation function computes the effective Young’s modulus of each element by combining the moduli of different materials weighted by the function . This enables the optimized structure to exhibit desired mechanical properties, adapting to performance requirements. Additionally, the use of p-norm and 1-norm in the interpolation functions allows to accurately represent the relative contribution of each material within an element, helping to avoid indeterminacies and ensuring that the sum of contributions from different materials does not exceed the material’s capacity. To ensure robustness in the calculation of the interpolation function, the parameter δ is introduced, preventing indeterminacies and contributing to the stability of the optimization algorithm, especially in regions where design variables approach zero.

2.3. Projection of the Filtered Element

To solve mesh dependency and checkerboard problems, a density filter is used, which is already provided in the 88-line MATLAB code (v.R2021b) of [

35] and in this extended article for MMTO. Then, the filtered element is calculated using the expression:

where

is the neighborhood of an element

defined as

with

R being the filter radius, and

being the weighting factor defined as

.

In the SIMP method, it is common to find intermediate densities during the TO procedure. However, to avoid the presence of elements with intermediate densities in the MMTO optimized structures and guarantee a binary (0–1) solution, the projection function originally proposed by [

32,

36,

37], which is a hyperbolic tangent, has been replaced in this article by a sigmoid function. The sigmoid function is a suitable choice for forcing densities to approach 0 or 1 smoothly, ensuring that only binary values are considered in optimization. This helps to simplify the resulting structures and makes their fabrication more feasible. Thus, the projected density is given by Expression (9):

and the projection function is given by Expression (10):

The parameter

β is used to control the slope of the function, that is, the sharpness of the projected filtered variable

; the parameter η defines the center of the smooth transition part of the function and is selected as 0.5 as proposed in [

32]. The parameter

is used to customize the sigmoid function and aims to approximate the sigmoid values with the hyperbolic tangent values.

Note that in the two graphs in

Figure 1, the behaviors are similar. However, the sigmoid function is a little smoother than the hyperbolic tangent. It can also be observed that for

β = 0, the filtered density

is equal to the projected density (

that is, the density is filtered linearly; for

β → ∞ the function acts as a step function. For all other cases of

β, the function acts as a penalty, forcing the intermediate density to move in the 0 –1 direction.

The use of the sigmoid projection function in multi-material topology optimization leads to better optimal configurations due to its ability to promote smooth transitions between material and void regions, delivering a better distribution of the materials. The hyperbolic tangent, while also providing continuous transitions, tends to exhibit more abrupt changes and discontinuities in the distribution, which can result in less refined solutions and undesirable structural behavior. These discontinuities can lead to unwanted stress concentrations, compromising structural integrity. The sigmoid function, with its mapping restricted between 0 and 1, allows for more delicate control over material configuration, which is essential in problems involving multiple materials. This smoothness in transition is important for avoiding stress concentrations and ensuring a more homogeneous structural response, resulting in configurations that maximize stiffness while minimizing the weight of the structure. Therefore, the sigmoid function proves to be more suitable for seeking efficient solutions in multi-material topology optimization. However, the sigmoid projection function, while effective in smoothing transitions and eliminating intermediate densities, can face challenges in complex geometries where more careful tuning of the β and η parameters is required to balance convergence and accuracy; as smoothing transitions can lead to loss of fine details, potentially impacting structural performance. To address the influence of β in the optimization process, we implemented a dynamic update procedure for β using a linearly increasing function. This procedure allows β to gradually increase every 20 iterations, until reaching the limit of 5.85, which yielded the best topology results. The progressive growth of β ensures a smooth transition at the beginning of the optimization, preventing premature convergence to suboptimal solutions. As β increases, it enforces sharper boundaries between materials, effectively eliminating intermediate densities without compromising numerical stability. The upper limit of 5.85 was empirically determined as the best balance between accuracy, computational efficiency, and convergence behavior across different structural configurations.

2.4. Sensitivity Analysis

Sensitivity in structural optimization measures how changes in design variables impact the objective function and constraints. It is critical to understand the effect of these small changes in design variables on the overall performance of the structure. This sensitivity of the objective function C about the design variables

can be obtained by the chain rule, and can be calculated as follows:

Mathematically manipulating Equation (11) and writing the projected variables as a function, we have

The Young’s moduli of each material interpolated by the mapping-based interpolation function can be expressed as follows:

Using the quotient rule to derive the interpolation function, Equation (5), about the projected variable and mathematically manipulating Equations (6) and (7) we obtain:

3. Numerical Implementation

To solve systems of linear equations as defined in the equality constraint, in Equation (2), two types of methods are used: direct and iterative. Since the system is defined by the equation

KU =

F, the stiffness matrix

K is positive definite. Direct solvers generally use Cholesky factorization, which is a variant of Gaussian elimination that takes advantage of the symmetric and positive definite properties to reduce storage, arithmetic, and guarantee stability without pivoting. For positive definite and symmetric linear systems, the Conjugate Gradient (CG) method is one of the most popular approaches in the family of Krylov subspace methods [

38]. The convergence of the CG method depends on the condition number of the matrix. The CG method converges faster for well-conditioned matrices.

Typically, the CG method is combined with a preconditioner to accelerate its convergence. The preconditioner is symbolically represented by a matrix; in this article, is used, and the original linear system is replaced by . A good preconditioner should be a good approximation of and solving systems of the type should be relatively cheap. Another requirement is that K must be symmetric and positive definite. The CG method minimizes the K-norm of the error in each iteration.

There is extensive literature on preconditioner generation for the CG scheme. Some of the popular preconditioners include incomplete Cholesky factorization, domain decomposition, and block Jacobi. The approximate factorization preconditioners of the CG method are called incomplete Cholesky preconditioners. Early versions of this method limited the preconditioner to having the same sparsity structure as the matrix

K. Subsequent improvements defined padding levels to allow for more non-zero elements in

K [

39]. This was followed by the notion of incomplete Cholesky preconditioners based on elimination tolerance, where filling is allowed at arbitrary locations as long as the elements exceed a specified tolerance. In

Section 3.1, the Preconditioned Conjugate Gradient (PCG) methods employed in our MMTO program are present. Two types of preconditioners, available as MATLAB routines, were implemented to enhance the efficiency and convergence of the PCG method: one based on the diagonal matrix and the other utilizing the Incomplete Cholesky Decomposition.

The diagonal preconditioner is straightforward and computationally inexpensive, providing a basic level of improvement in convergence rates. On the other hand, the Incomplete Cholesky Decomposition preconditioner offers a more sophisticated approach by approximating the Cholesky decomposition of the system matrix.

3.1. Iterative Solution: Preconditioned Conjugated Gradients

In the multi-material OT program, the PCG algorithm from MATLAB code is used to solve the systems defined by the equilibrium equation.

%ITERATIVE SOLVER—PRECONDITIONED CONJUGATED GRADIENT %

tolit = 10^(-8);

maxit = 8000;

M = diag(diag(K(freedofs,freedofs)));

U(freedofs,:) = pcg(K(freedofs,freedofs),F(freedofs,:),tolit,maxit,M); |

This MATLAB code pcg function is used to solve the KU = F system. The function arguments are described as follows: K is the stiffness matrix; U is the displacement vector found when solving the system; F is the vector of external forces applied to the structure; tol is the tolerance that determines when the iterative method should stop. The algorithm continues with the iterative process until the residue is less than or equal to tol; maxit is the maximum number of iterations allowed for the method; M creates a diagonal matrix M from the diagonal elements of the matrix K, restricted to the rows and columns specified by freedofs.

3.2. Incomplete Cholesky

Another precondition used for multi-material TO solve the linear system defined by the equilibrium equation was the incomplete Cholesky from the MATLAB code. The

‘ichol’ method in MATLAB is used to calculate an incomplete Cholesky decomposition of a symmetric, positive definite matrix, in this case, the stiffness matrix

K. The Cholesky decomposition is a form of matrix factorization that writes the matrix

K as the product of a lower triangular matrix

L and its conjugate transpose,

L’.

%%%%%%%%ITERATIVE SOLVE—INCOMPLETE CHOLESKY %%%%%%%%

L = ichol(K(freedofs,freedofs));

U(freedofs,:) = pcg(K(freedofs,freedofs),F(freedofs,:),10^(-8),1000,L,L’); |

In MATLAB, ichol computes an incomplete approximation of the matrix L. This means that some off-diagonal elements of L can be approximated as zero to save time and space. This approach is useful in problems where the matrix A is sparse, which is common in many engineering applications. The PCG call arguments in this routine are described as follows: L is the lower triangular matrix of the incomplete Cholesky decomposition. L’ is the upper triangular matrix, which is the conjugate transpose of L.

5. Discussion

This article addresses one of the key challenges in multi-material topology optimization (MMTO): the formulation of projection functions that ensure smoother and more efficient material distributions, particularly in complex three-dimensional structures. The gap in the literature that this study seeks to fill relates to the need for projection techniques that balance computational efficiency with optimized solutions that eliminate intermediate-density elements. While projection functions such as the hyperbolic tangent have been widely employed, their implementation can result in abrupt discontinuities, leading to undesirable stress concentrations and suboptimal structural performance.

The results highlight the strengths of the proposed sigmoid function. In addition to reducing computational costs by up to 36.7% compared to the hyperbolic tangent, the method achieves a better distribution of materials within the domain, especially in applications involving multiple materials. The sigmoid function was observed to promote smoother transitions between material (solid) and void regions, which not only improves structural homogeneity but also meets the growing demands of multi-material additive manufacturing. This advancement is particularly relevant given the increasing interest in applying combined materials to optimize structural performance.

However, some limitations of the study warrant attention. Firstly, the approach was tested on a limited set of representative examples, such as cantilever beams and bridge configurations. While the results are promising, it would be beneficial to extend the analysis to industrial-scale problems or more complex topologies, such as structures with geometric nonlinearity. Furthermore, the influence of different model parameters, such as the values of β in the sigmoid projection function, could be more comprehensively explored, including sensitivity analyses to better understand the impact of these choices on the final results.

Finally, this article demonstrates the effectiveness of combining innovative projection functions with efficient iterative methods, such as the Preconditioned Conjugate Gradient (PCG) and Incomplete Cholesky Decomposition, to address multi-material optimization problems robustly and computationally feasibly. In this aspect, the work shows in the examples presented that the two preconditioners applied allow the sigmoid function to produce a more regular distribution of elements and slenderer structures, even a lower computational cost than using the hyperbolic tangent function.

Future research could explore the application of this approach to other optimization criteria, such as controlling maximum displacements or minimizing localized stresses, as well as evaluate the impact of emerging manufacturing technologies on its practical implementation.

The results of the sensitivity analysis showed that lower values of η (e.g., 0.25) result in less smoothing of the transition between materials, reducing the computational cost to 442 s, while higher values (0.50 and 0.75) promote a better distribution of materials, but with an increase in the computational cost, respectively, to 595 and 772 s. Among these, η = 0.50 presented the highest computational cost, as it balances the smoothing of the transition and the definition of the material boundaries, resulting in a more uniform and structured distribution. With η = 0.75, it was observed that the concrete tends to concentrate more densely in a single region, reducing the dispersion of materials in the domain, see

Table 2.

Figure 14 shows the graph of the objective function (compliance), volume and beta by the number of iterations. It is noted that the variation in β in the interval [2.85, 5.85] showed that higher values effectively eliminate intermediate densities, making the boundaries between materials more defined and demonstrating how these parameters influence the convergence and distribution of materials, validating the choice of η = 0.50 as the best alternative between topology quality and computational efficiency.