The Effects of Heat Treatment on the Impact Toughness and Fracture of Selective Laser-Melted Corrax Maraging Stainless Steel

Abstract

1. Introduction

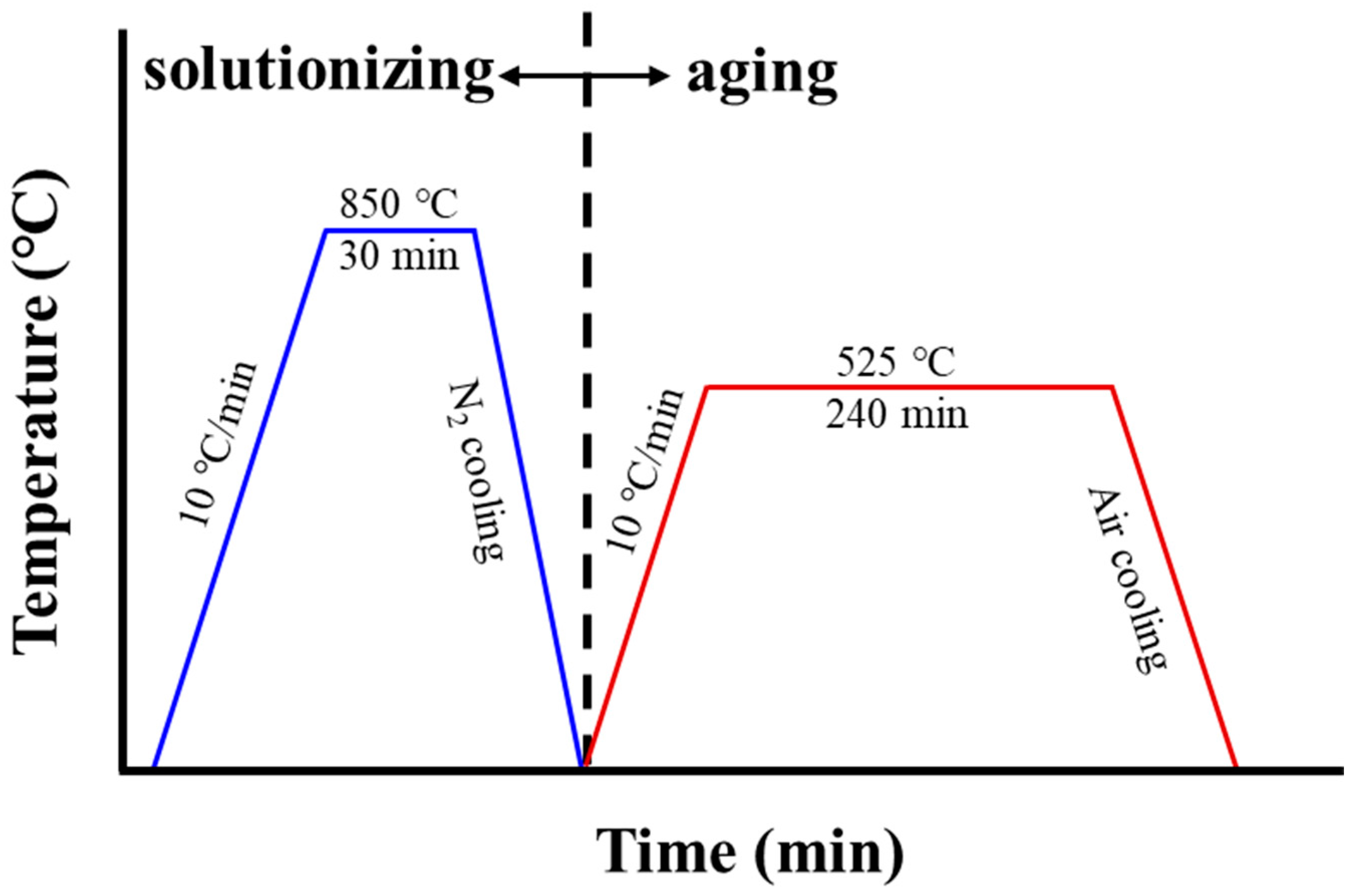

2. Experimental Procedures

3. Results and Discussion

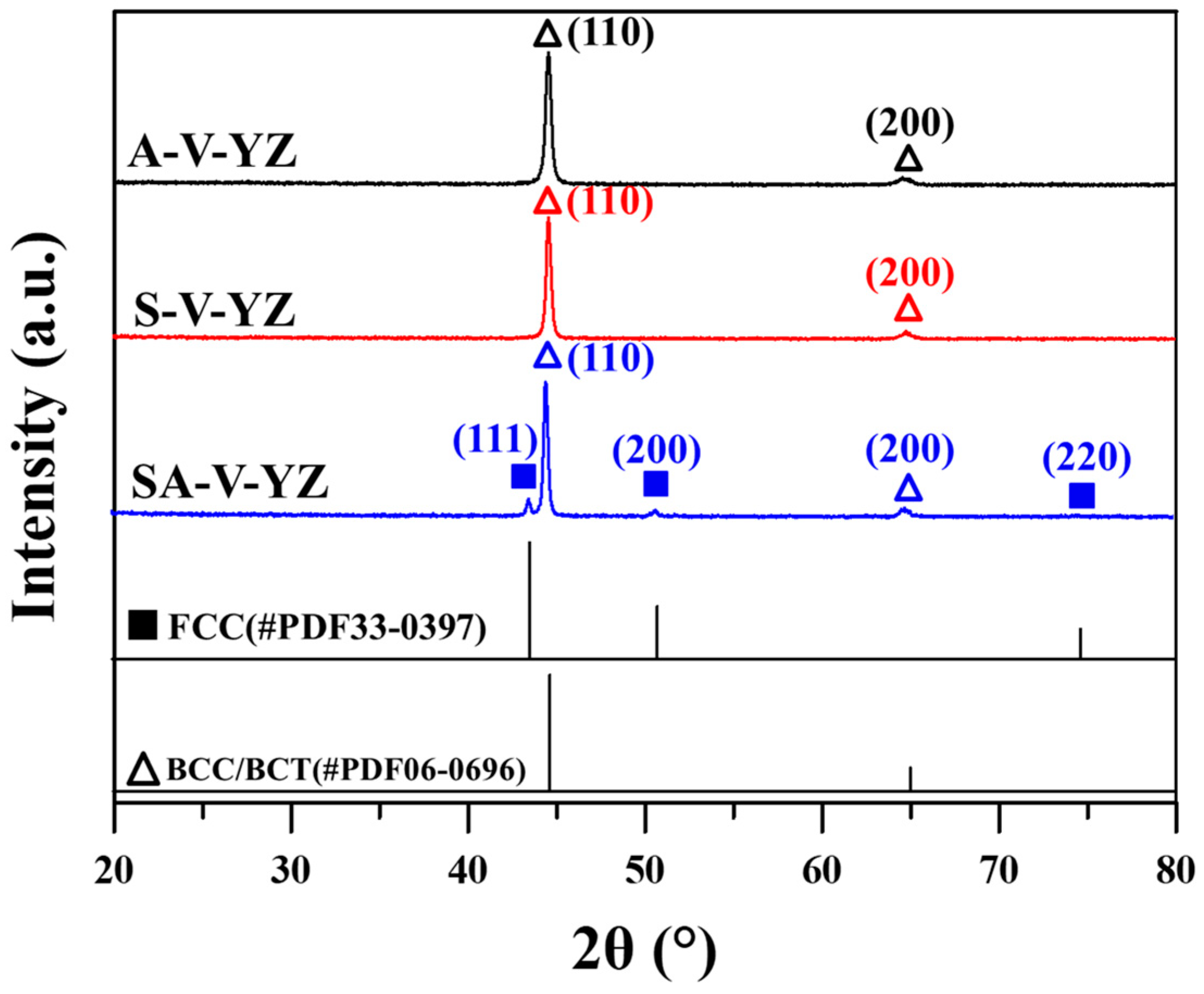

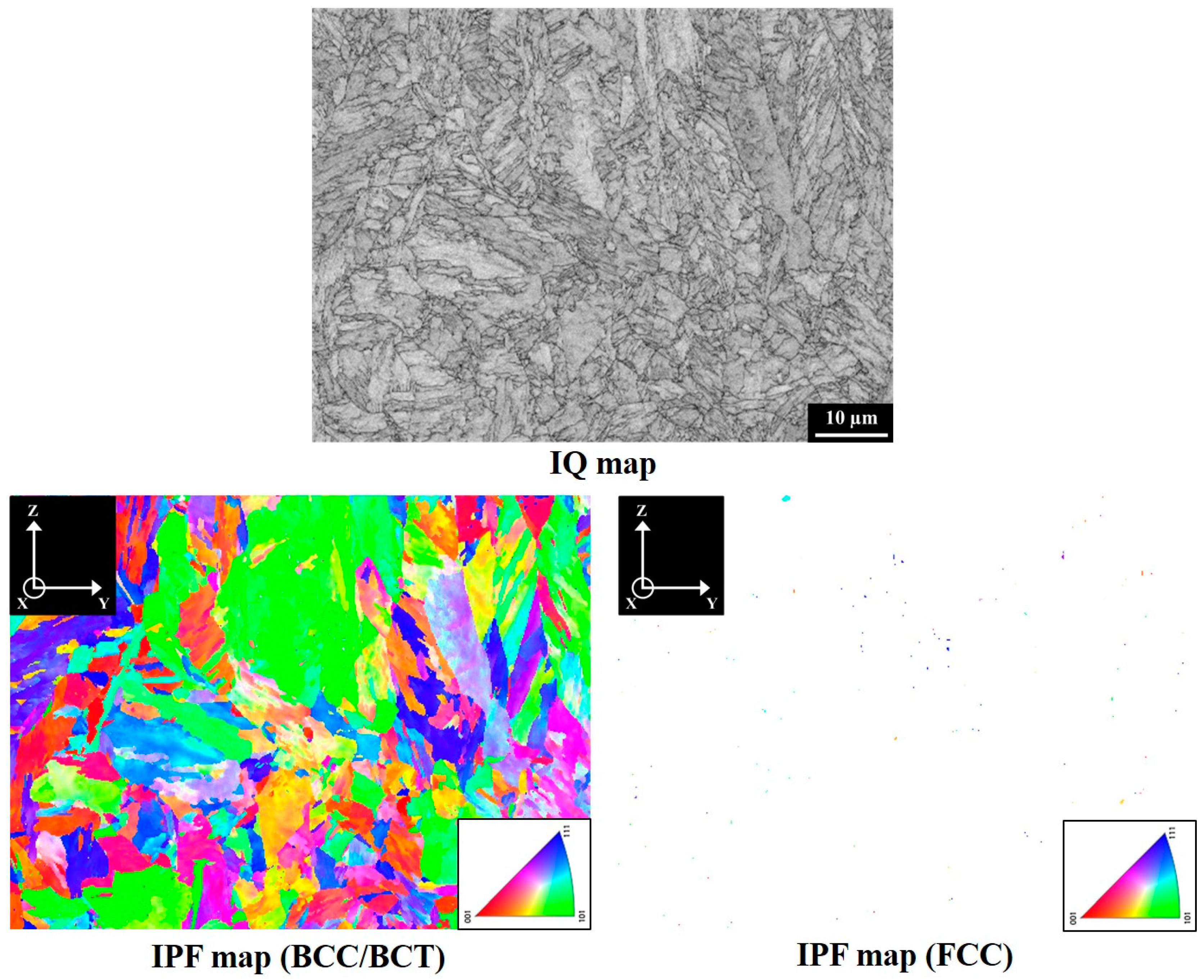

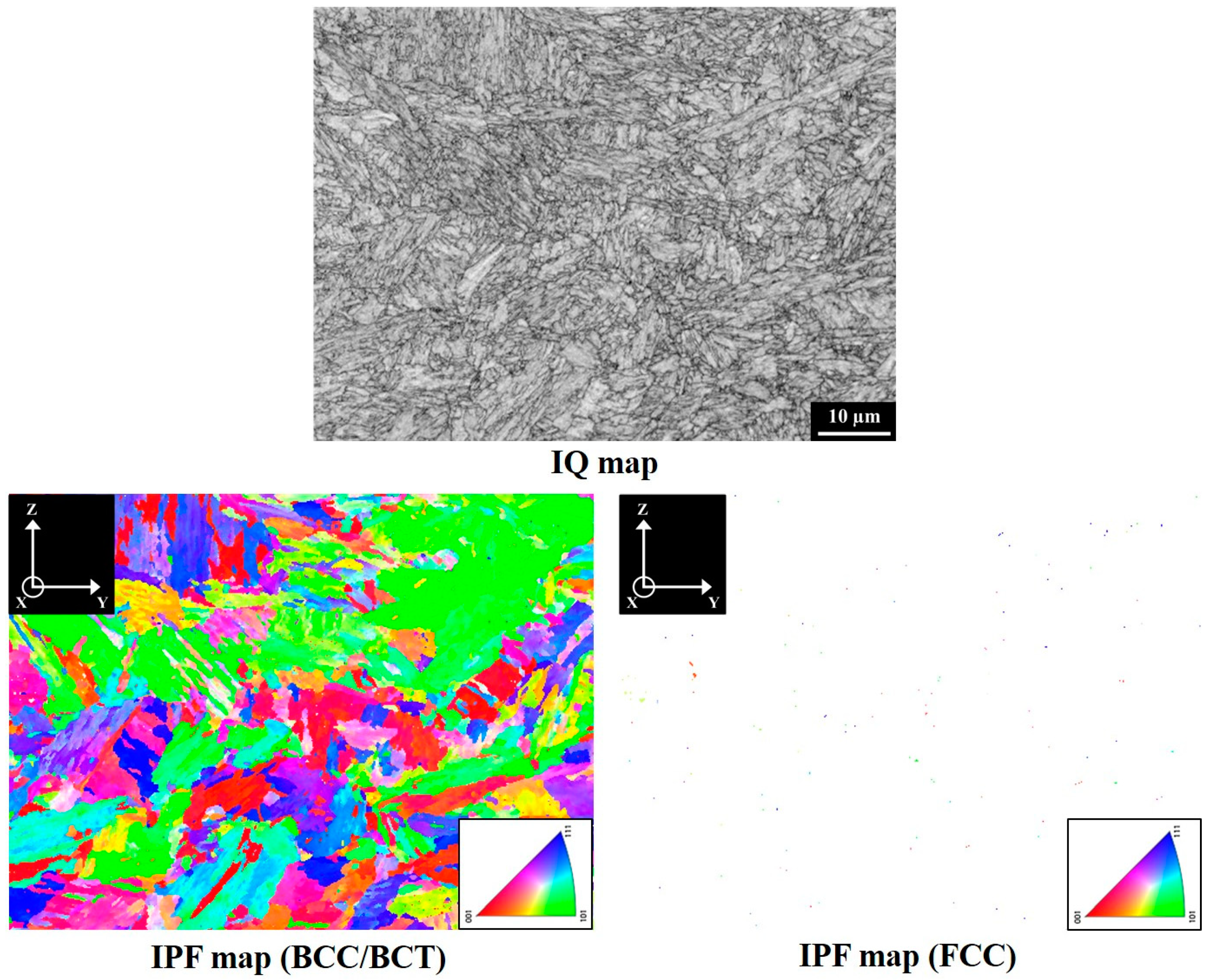

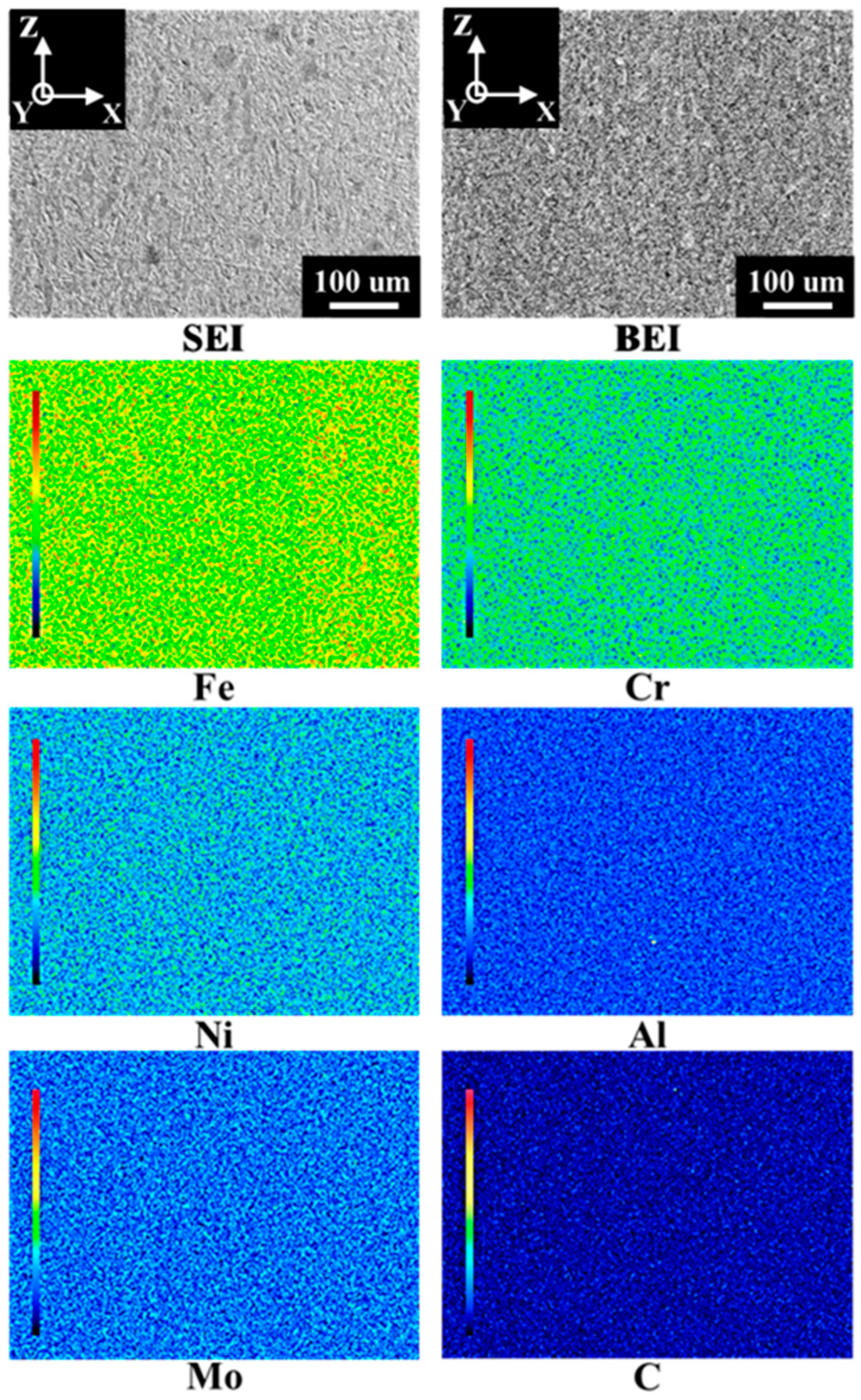

3.1. Microstructure and Elemental Distribution

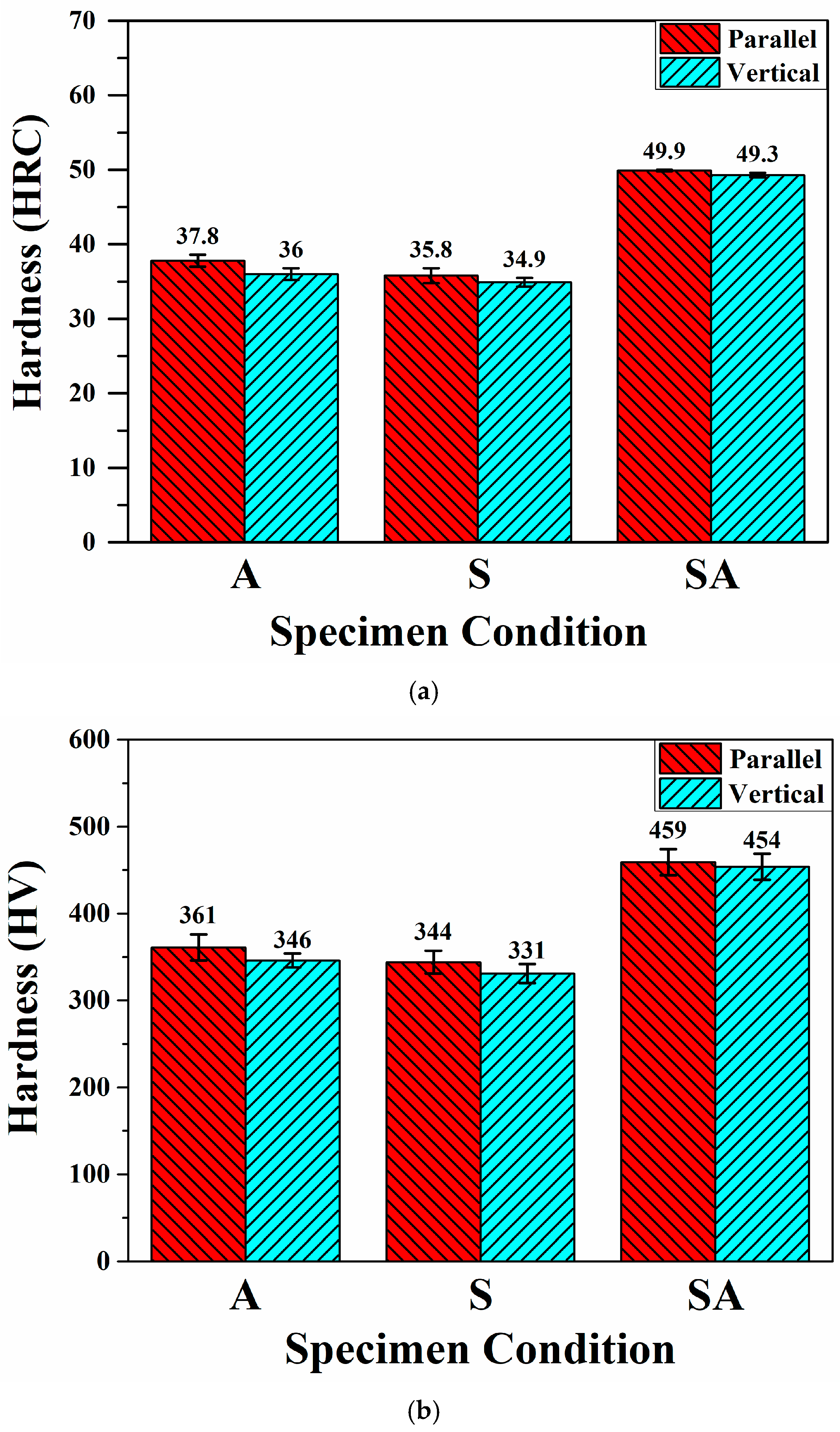

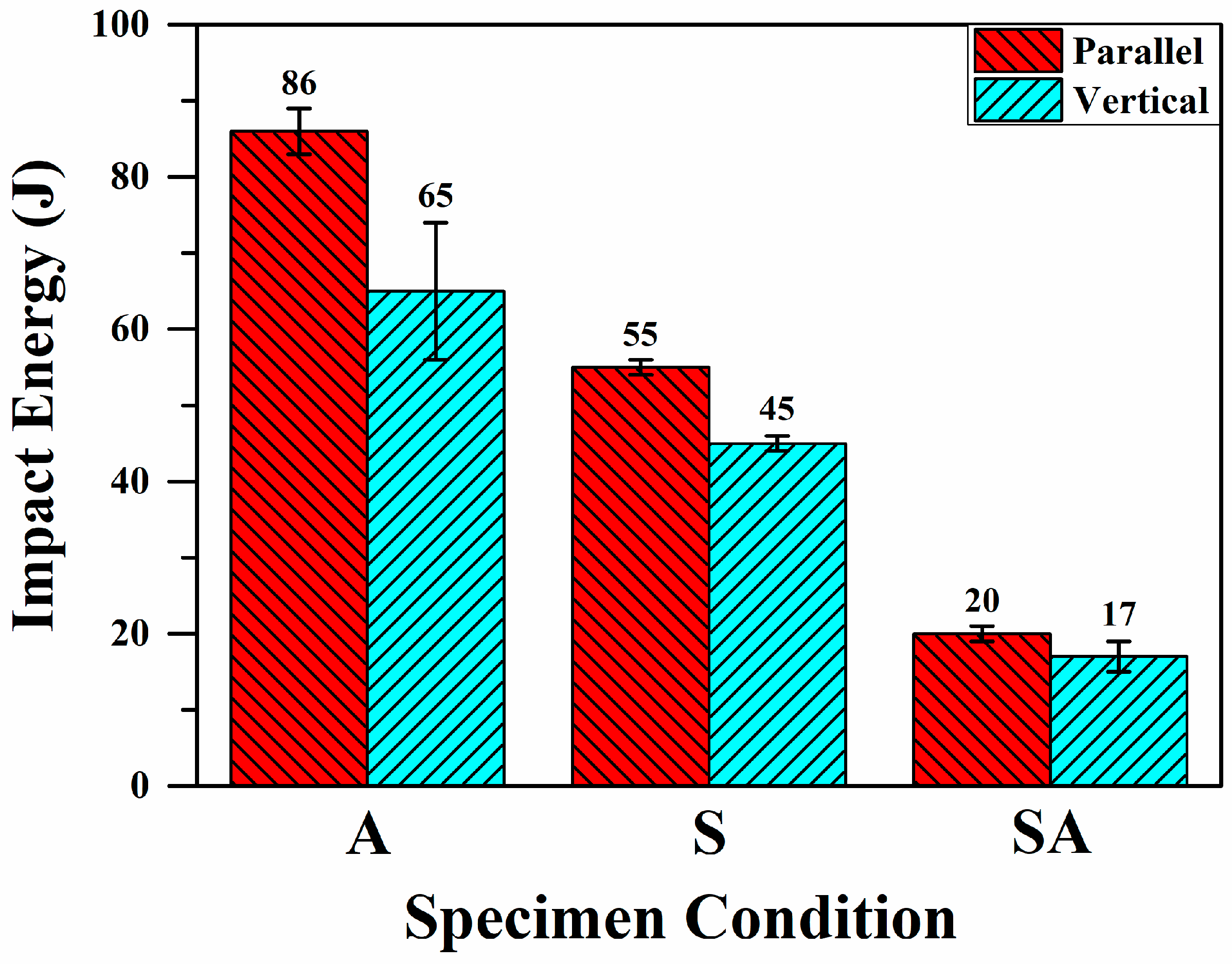

3.2. Hardness and Impact Energy

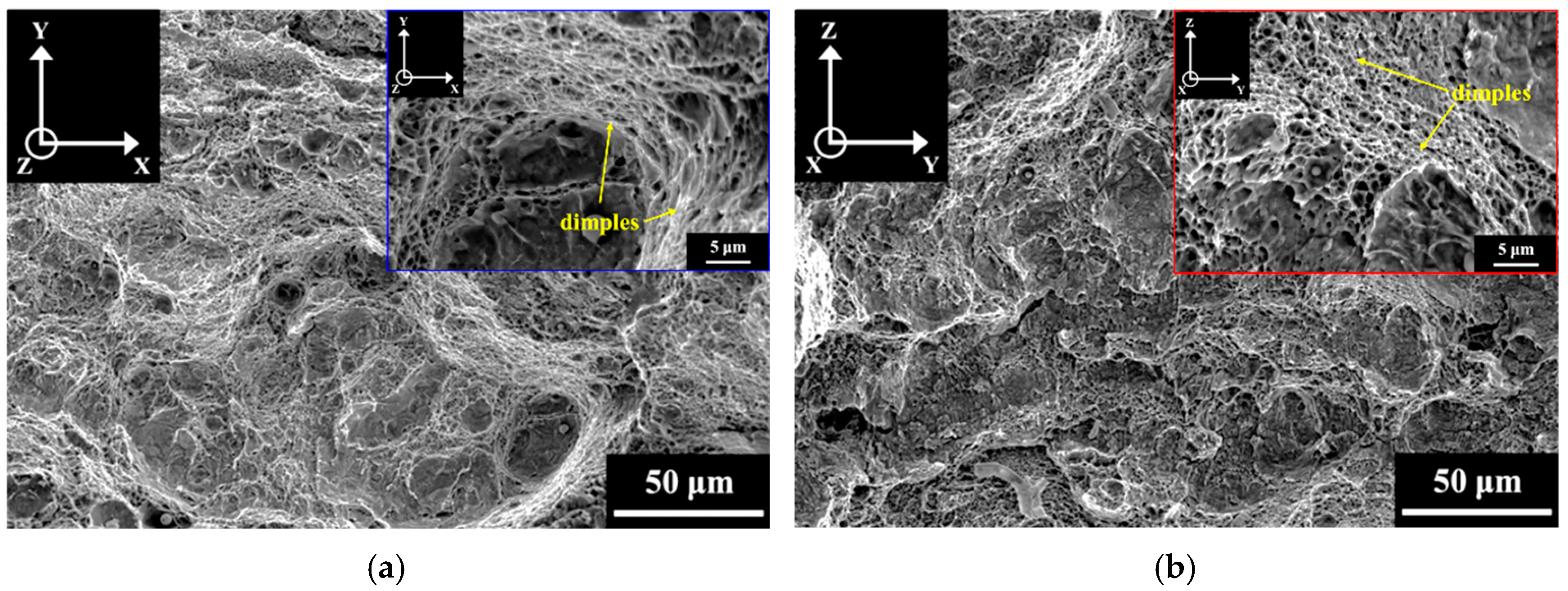

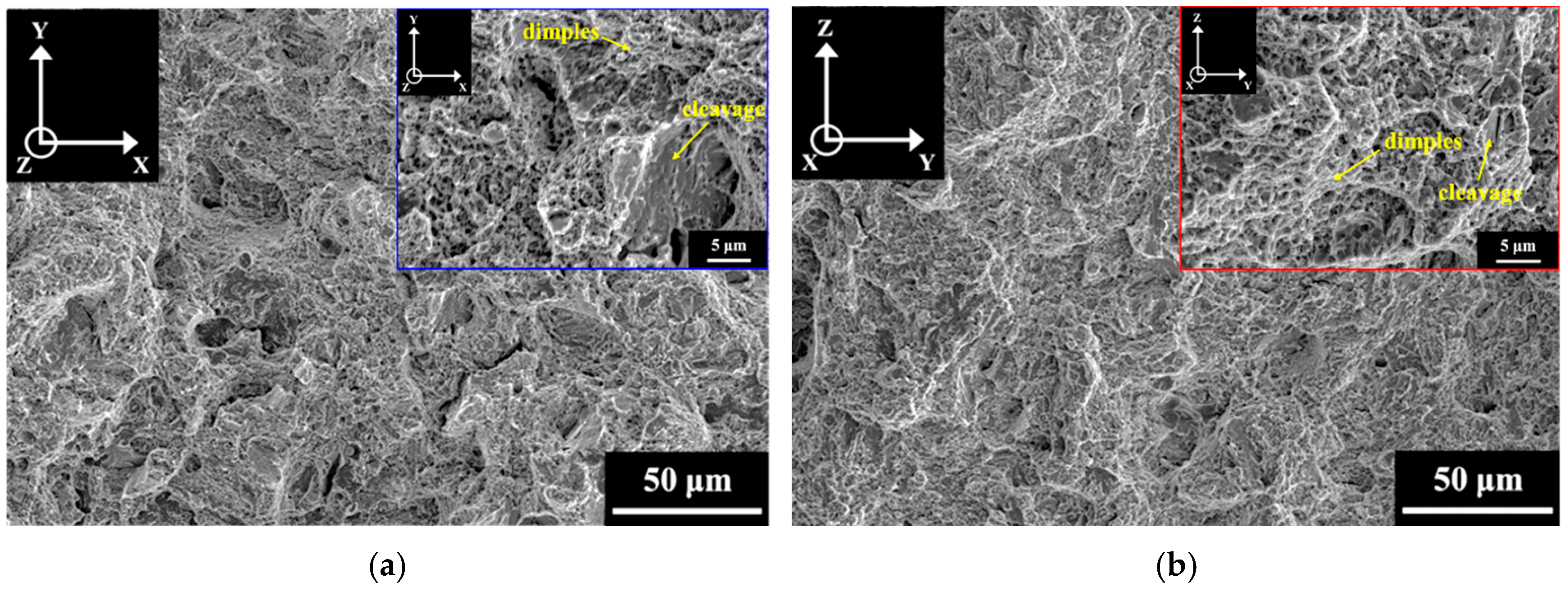

3.3. Fracture Surface

3.4. The Effects of HT and BD on Impact Toughness

4. Conclusions

- According to the EBSD analyses, the matrices of the A-V, S-V, and SA-V specimens were all composed of lath martensite. After S treatment, the austenite content was slightly reduced. However, after SA treatment, the fraction of austenite was obviously increased. The EPMA results indicated that the metallic elements were uniformly distributed in the A-V specimens, and no elemental segregation was observed at the analyzed magnification.

- The impact energies and apparent hardnesses of SLM Corrax steels were dominated by the HT. The S treatment simultaneously decreased the impact energies and apparent hardnesses. The SA treatment increased the apparent hardnesses but decreased the impact energies. BD played a minor role in both the impact energies and apparent hardnesses.

- In the A and S specimens, the impact fracture surfaces consisted of only ductile fracture features. After the SA treatment, the impact fracture surfaces exhibited a mixture of ductile and brittle fracture modes. The lower impact energies of the SA specimens can be mainly attributed to the less ductile martensitic matrix. The amount of austenite did not greatly influence the impact energy.

- The impact energies of SA-P and SA-V specimens were, respectively, 20 J and 17 J. The anisotropy in impact toughness of SA specimens was low due to its weak texture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Ann. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Gu, D.D.; Shi, X.Y.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J.H. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372, eabg1487. [Google Scholar] [CrossRef] [PubMed]

- Jeyaprakash, N.; Saravana Kumar, M.; Yang, C.H.; Cheng, Y.; Radhika, N.; Sivasankaran, S. Effect of microstructural evolution during melt pool formation on nano-mechanical properties in LPBF based SS316L parts. J. Mater. Res. Technol. 2024, 972, 172745. [Google Scholar] [CrossRef]

- Ragunath, S.; Radhika, N.; Saleh, B. Advancements and future prospects of additive manufacturing in high-entropy alloy applications. J. Alloys Compd. 2024, 997, 174859. [Google Scholar] [CrossRef]

- Buhair, M.A.; Foudz, F.M.; Jamhari, F.I.; Sulong, A.B.; Radzuan, N.A.M.; Muhamad, N.; Mohamed, I.F.; Azman, A.H.; Harun, W.S.W.; Al-Furjan, M.S.H. Review on volumetric energy density influence on morphology and mechanical properties of Ti6Al4V manufactured via laser powder bed fusion. Prog. Addit. Manuf. 2022, 8, 265–283. [Google Scholar] [CrossRef]

- Kouprianoff, D.; Preez, W.D. Reducing time and cost of the heat treatment post-processing of additively manufactured Ti6Al4V. Mater. Today Commun. 2023, 35, 106186. [Google Scholar] [CrossRef]

- Paul, M.J.; Kruzic, J.J.; Ramamurty, U.; Gludovatz, B. The importance of fracture toughness evaluation for additively manufactured metals. Acta Mater. 2024, 276, 120061. [Google Scholar] [CrossRef]

- Wang, L.; Wei, Q.S.; Xue, P.J.; Shi, Y.S. Fabricate mould insert with conformal cooling channel using selective laser melting. Adv. Mater. Res. 2012, 502, 67–71. [Google Scholar] [CrossRef]

- Bai, Y.C.; Yang, Y.Q.; Wang, D.; Zhang, M.K. Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melting. Mater. Sci. Eng. A 2017, 703, 116–123. [Google Scholar] [CrossRef]

- Zeng, G.H.; Song, T.; Dai, Y.H.; Tang, H.P.; Yan, M. 3D printed breathable mould steel: Small micrometer-sized, interconnected pores by creatively introducing foaming agent to additive manufacturing. Mater. Des. 2019, 169, 107693. [Google Scholar] [CrossRef]

- Han, S.; Salvatore, F.; Rech, J.; Bajolet, J. Abrasive fow machining (AFM) fnishing of conformal cooling channels created by selective laser melting (SLM). Precis. Eng. 2020, 64, 20–33. [Google Scholar] [CrossRef]

- Dong, D.; Chang, C.; Wang, H.; Yan, X.; Ma, W.; Liu, M.; Deng, S.; Gardan, J.; Bolot, R.; Liao, H. Selective laser melting (SLM) of CX stainless steel process: Theoretical calculation optimization and strengthening mechanism. J. Mater. Sci. Technol. 2021, 73, 151–164. [Google Scholar] [CrossRef]

- Afkhami, S.; Javaheri, V.; Dabiri, E.; Piili, H.; Bjork, T. Effects of manufacturing parameters, heat treatment, and machining on the physical and mechanical properties of 13Cr10Ni1⋅7Mo2Al0⋅4Mn0⋅4Si steel processed by laser powder bed fusion. Mater. Sci. Eng. A 2022, 832, 142402. [Google Scholar] [CrossRef]

- Wu, M.W.; Ku, S.W.; Yen, H.W.; Ku, M.H.; Chang, S.H.; Ni, K.; Shih, Z.S.; Tsai, C.; Hsu, T.W.; Li, C.L.; et al. The synergic effects of heat treatment and building direction on the microstructure and anisotropic mechanical properties of laser powder bed fusion Corrax maraging stainless steel. Mater. Sci. Eng. A 2023, 887, 145744. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Shahriari, A.; Amirkhiz, B.S.; Li, J.; Mohammadi, M. Additive manufacturing of an Fe–Cr–Ni–Al maraging stainless steel: Microstructure evolution, heat treatment, and strengthening mechanisms. Mater. Sci. Eng. A 2020, 787, 139470. [Google Scholar] [CrossRef]

- Aydin, G.; Andersson, J.; Valiente Bermejo, M.A. Additive Manufacturing of PH 13-8 Mo Family: A Review. Appl. Sci. 2024, 14, 7572. [Google Scholar] [CrossRef]

- Ku, M.H.; Ni, K.; Lin, Q.E.; Chang, S.H.; Hsu, T.W.; Li, C.L.; Wang, C.K.; Wu, M.W. Novel laser powder bed fusion Corrax maraging stainless steel lattice with superior specifc strength and energy absorption. J. Mater. Res. Technol. 2023, 25, 5240–5248. [Google Scholar] [CrossRef]

- Prakash, P.; Abdelbaset Midawi, A.; Muhammad, W.; Wells, M.; Hadadzadeh, A. Role of heat treatment conditions in the high-temperature deformation behavior of laser-powder bed fused Fe–Cr–Ni–Al maraging stainless steel. Mater. Sci. Eng. A 2024, 909, 146837. [Google Scholar] [CrossRef]

- Andersen, O.Z.; Henriksen, N.G.; Somers, M.; Christiansen, T.; Jellesen, M.S. Laser marking on microstructure and corrosion performance of martensitic stainless steel surfaces for biomedical applications. J. Heat. Treat. Mater. 2022, 77, 177–196. [Google Scholar]

- Zhao, X.; Jia, D.; Wei, S.; Gao, Y.; Liu, H. Investigation of tribo-corrosion behaviors of SLM-printed CX stainless steel under different loads. J. Mater. Res. Technol. 2024, 30, 5266–5277. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Niu, L.; Liu, J.; Wang, J.; Liu, Y.; Shi, Z. Effect of process parameters and heat treatment on the properties of stainless steel CX fabricated by selective laser melting. J. Alloys Compd. 2021, 877, 160062. [Google Scholar] [CrossRef]

- Chang, C.; Yan, X.; Bolot, R.; Gardan, J.; Gao, S.; Liu, M.; Liao, H.; Chemkhi, M.; Deng, S. Influence of post-heat treatments on the mechanical properties of CX stainless steel fabricated by selective laser melting. J. Mater. Sci. 2020, 55, 8303–8316. [Google Scholar] [CrossRef]

- Afkhami, S.; Javaheri, V.; Dabiri, E.; Piili, H.; Bjork, T. Data related to the microstructural identification and analyzing the mechanical properties of maraging stainless steel 13Cr10Ni1.7Mo2Al0.4Mn0.4Si (commercially known as CX) processed by laser powder bed fusion method. Data Brief 2022, 41, 107856. [Google Scholar] [CrossRef]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Marattukalama, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Hjorvarssona, B.; Sahlberg, M. The effect of laser scanning strategies on texture, mechanical properties, and site-specifc grain orientation in selective laser melted 316L SS. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Reijonen, J.; Bjorkstrand, R.; Riipinen, T.; Que, Z.; Metsa-Kortelainen, S.; Salmi, M. Cross-testing laser powder bed fusion production machines and powders: Variability in mechanical properties of heat-treated 316L stainless steel. Mater. Des. 2021, 204, 109684. [Google Scholar] [CrossRef]

- Wu, M.W.; Lai, P.H.; Chen, J.K. Anisotropy in the impact toughness of selective laser melted Ti–6Al–4V alloy. Mater. Sci. Eng. A 2016, 650, 295–299. [Google Scholar] [CrossRef]

- Wu, M.W.; Lai, P.H. The positive effect of hot isostatic pressing on improving the anisotropies of bending and impact properties in selective laser melted Ti-6Al-4V alloy. Mater. Sci. Eng. A 2016, 658, 429–438. [Google Scholar] [CrossRef]

- Tian, Y.; Palad, R.; Aranas, C., Jr. Microstructural evolution and mechanical properties of a newly designed steel fabricated by laser powder bed fusion. Addit. Manuf. 2020, 36, 101495. [Google Scholar] [CrossRef]

- ASTM E23-12c; Standard Test Methods for Notch Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2013; pp. 1–24.

- Fang, R.; Deng, N.; Zhang, H.; Wang, G.; Su, Y.; Zhou, H.; Gao, K.; Gu, L. Effect of selective laser melting process parameters on the microstructure and properties of a precipitation hardening stainless steel. Mater. Des. 2021, 212, 110265. [Google Scholar] [CrossRef]

- Yan, X.; Chen, C.; Chang, C.; Dong, D.; Zhao, R.; Jenkins, R.; Wang, J.; Ren, Z.; Liu, M.; Liao, H.; et al. Study of the microstructure and mechanical performance of C-X stainless steel processed by selective laser melting (SLM). Mater. Sci. Eng. A 2020, 781, 139227. [Google Scholar] [CrossRef]

- Trottier, W.T.; Kreitcberg, A.; Brailovski, V. Structure and mechanical properties of laser powder bed-fused and wrought PH13-8Mo-type precipitation hardening stainless steels: Comparative study. J. Manuf. Mater. Process. 2021, 5, 67. [Google Scholar] [CrossRef]

- Chang, C.; Yan, X.; Deng, Z.; Lu, B.; Bolot, R.; Gardan, J.; Deng, S.; Chemkhi, M.; Liu, M.; Liao, H. Heat treatment induced microstructural evolution, oxidation behavior and tribological properties of Fe-12Cr-9Ni-2Al steel (CX steel) prepared using selective laser melting. Surf. Coat. Technol. 2022, 429, 127982. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, K.; Gao, Y.; Wang, D. Influence of microdefect on mechanical behaviors of CX stainless steel produced by selective laser melting. Met. Mater. Int. 2024, 31, 70–83. [Google Scholar] [CrossRef]

- Sanjari, M.; Mahmoudiniya, M.; Pirgazi, H.; Tamimi, S.; Ghoncheh, M.H.; Shahriairi, A.; Hadadzadeh, A.; Amirkhiz, B.S.; Purdy, M.; de Araujo, E.G.; et al. Microstructure, texture, and anisotropic mechanical behavior of selective laser melted maraging stainless steels. Mater. Charact. 2022, 192, 112185. [Google Scholar] [CrossRef]

| Material Condition | Building Direction | Plane Analyzed | Grain Size of Martensite Phase (µm) | Percentage of Austenite (%) |

|---|---|---|---|---|

| A | P | XY | 1.5 | 2.3 |

| YZ | 1.7 | 1.5 | ||

| A | V | XY | 2.1 | 0.1 |

| YZ | 1.9 | 0.1 | ||

| S | P | XY | 1.5 | 0.4 |

| YZ | 1.6 | 0.2 | ||

| S | V | XY | 1.8 | 0 |

| YZ | 1.7 | 0.1 | ||

| SA | P | XY | 1.6 | 4.5 |

| YZ | 1.3 | 3.7 | ||

| SA | V | XY | 1.6 | 7.5 |

| YZ | 1.5 | 7.5 |

| No. | Weight Percentage (wt.%) | |||||

|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Al | Mo | Total | |

| 1 | 75.9 | 12.5 | 8.73 | 1.45 | 1.42 | 100 |

| 2 | 75.4 | 12.6 | 9.21 | 1.45 | 1.33 | 100 |

| 3 | 75.6 | 12.6 | 8.84 | 1.55 | 1.37 | 100 |

| 4 | 76.2 | 12.5 | 8.46 | 1.46 | 1.33 | 100 |

| 5 | 75.4 | 12.7 | 8.97 | 1.5 | 1.42 | 100 |

| 6 | 75.3 | 12.6 | 9.1 | 1.55 | 1.41 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ku, M.-H.; Ku, S.-W.; Li, C.-L.; Chang, S.-H.; Wu, M.-W. The Effects of Heat Treatment on the Impact Toughness and Fracture of Selective Laser-Melted Corrax Maraging Stainless Steel. Materials 2025, 18, 1150. https://doi.org/10.3390/ma18051150

Ku M-H, Ku S-W, Li C-L, Chang S-H, Wu M-W. The Effects of Heat Treatment on the Impact Toughness and Fracture of Selective Laser-Melted Corrax Maraging Stainless Steel. Materials. 2025; 18(5):1150. https://doi.org/10.3390/ma18051150

Chicago/Turabian StyleKu, Ming-Hsiang, Shu-Wei Ku, Chien-Lun Li, Shih-Hsien Chang, and Ming-Wei Wu. 2025. "The Effects of Heat Treatment on the Impact Toughness and Fracture of Selective Laser-Melted Corrax Maraging Stainless Steel" Materials 18, no. 5: 1150. https://doi.org/10.3390/ma18051150

APA StyleKu, M.-H., Ku, S.-W., Li, C.-L., Chang, S.-H., & Wu, M.-W. (2025). The Effects of Heat Treatment on the Impact Toughness and Fracture of Selective Laser-Melted Corrax Maraging Stainless Steel. Materials, 18(5), 1150. https://doi.org/10.3390/ma18051150