Developing Eco-Friendly, High-Performance Soy Protein Plywood Adhesive via Core–Shell Hybridization and Borate Chemistry

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extraction of Urushiol (U) from Raw Lacquer

2.3. Synthesis of the POSS-U Core–Shell Hybrid

2.4. Preparation of SPI/POSS-U/SB Adhesives

2.5. Plywood Preparation and Evaluation

2.6. Characterization

2.6.1. Fourier-Transform Infrared (FTIR) Spectroscopy

2.6.2. Flame Retardancy Testing

2.6.3. Thermogravimetric (TG) Measurement

2.6.4. Scanning Electron Microscopy (SEM)

2.6.5. Toughness Evaluation

2.6.6. Residual Rate Test

2.6.7. Mildew Resistance Testing

2.7. Statistical Analysis

3. Results and Discussion

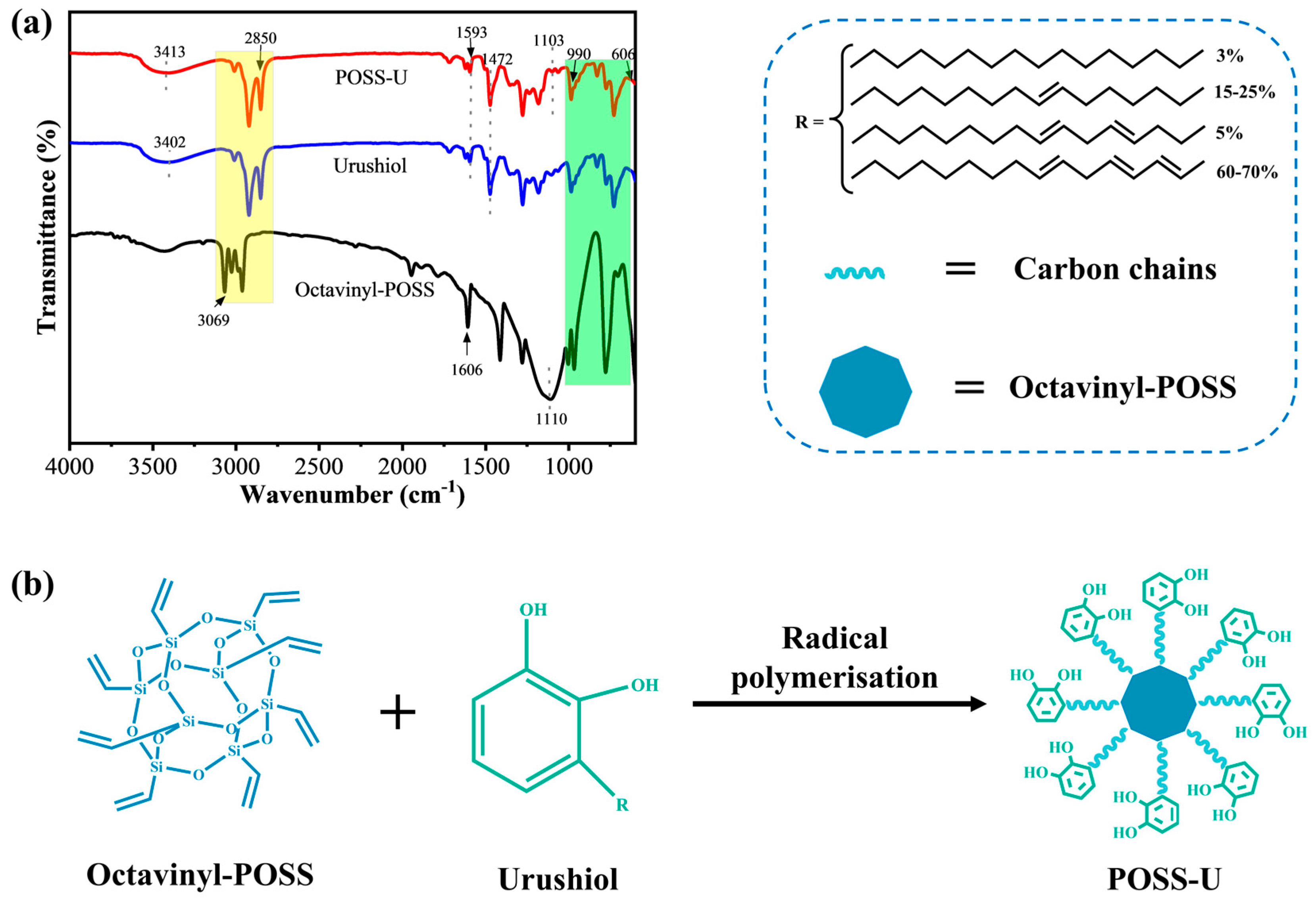

3.1. Synthesis Mechanism of Core–Shell POSS-U

3.2. Chemical and Microstructural Analysis of the Adhesives

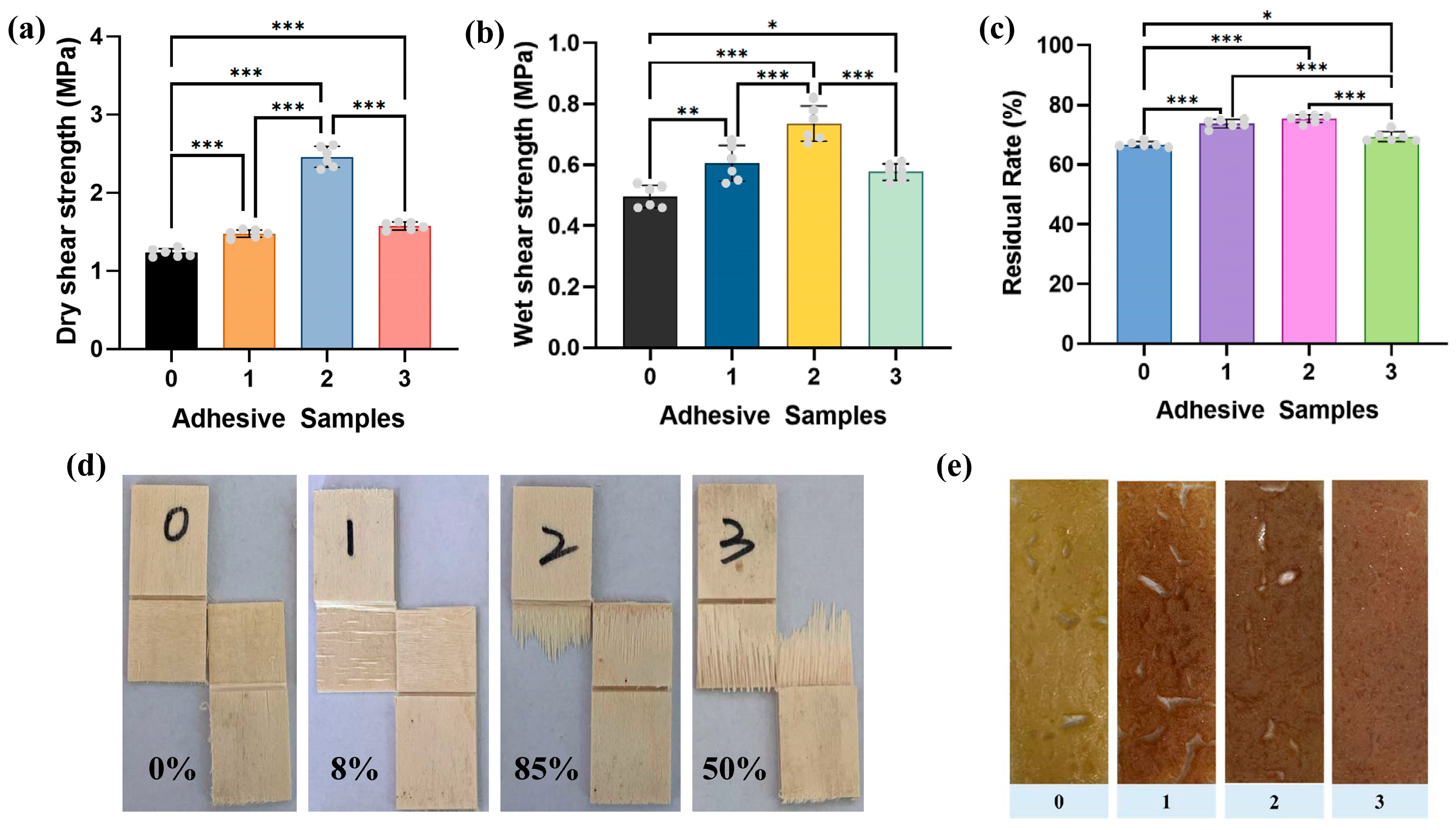

3.3. Mechanical Properties of Adhesives

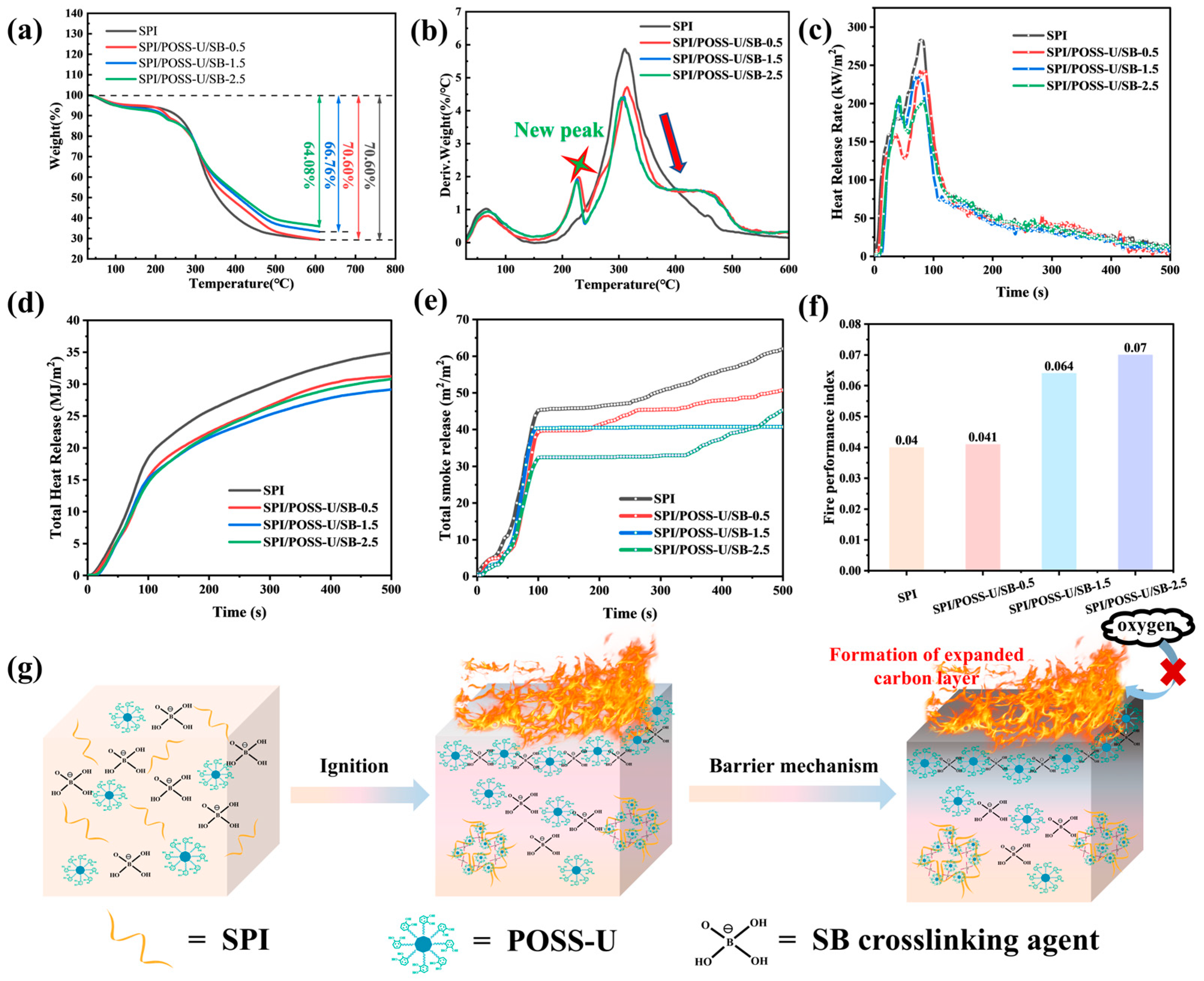

3.4. Flame-Retardant Properties of Adhesives

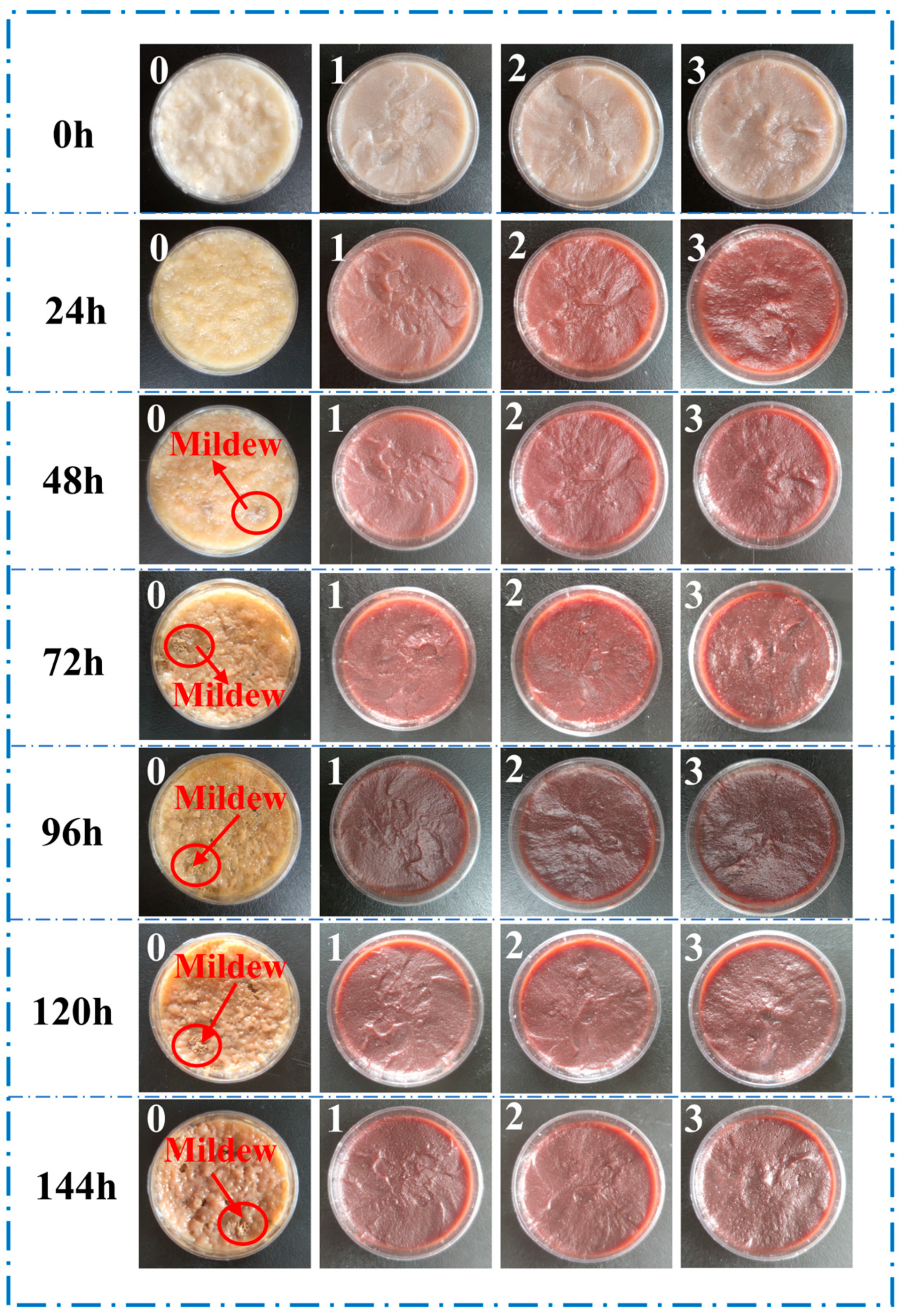

3.5. Mildew Resistance of Adhesives

3.6. Comprehensive Performance of the SPI/POSS-U/SB Adhesive

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Sun, Q.; Dong, X.; Chen, J. Automotive adhesive defect detection based on improved YOLOv8. Signal Image Video Process. 2024, 18, 2583–2595. [Google Scholar] [CrossRef]

- Yang, G.; Gong, Z.; Luo, X.; Chen, L.; Shuai, L. Bonding wood with uncondensed lignins as adhesives. Nature 2023, 621, 511–515. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Meng, Y.; Lu, J.; Tao, Y.; Cheng, Y.; Wang, H. A Review on Lignin-Based Phenolic Resin Adhesive. Macromol. Chem. Phys. 2022, 223, 2100434. [Google Scholar] [CrossRef]

- Heinrich, L.A. Future opportunities for bio-based adhesives—advantages beyond renewability. Green Chem. 2019, 21, 1866–1888. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnan, S.; Samal, S.K.; Mohanty, S.; Nayak, S.K. Toughening of Petroleum Based (DGEBA) Epoxy Resins with Various Renewable Resources Based Flexible Chains for High Performance Applications: A Review. Ind. Eng. Chem. Res. 2018, 57, 2711–2726. [Google Scholar] [CrossRef]

- Tian, W.; Wang, X.; Ye, Y.; Wu, W.; Wang, Y.; Jiang, S.; Wang, J.; Han, X. Recent progress of biomass in conventional wood adhesives: A review. Green Chem. 2023, 25, 10304–10337. [Google Scholar] [CrossRef]

- Chen, S.; Shi, S.Q.; Zhou, W.; Li, J. Developments in Bio-Based Soy Protein Adhesives: A Review. Macromol. Mater. Eng. 2022, 307, 2200277. [Google Scholar] [CrossRef]

- Cheng, H.N.; Ford, C.; Dowd, M.K.; He, Z. Soy and cottonseed protein blends as wood adhesives. Ind. Crops Prod. 2016, 85, 324–330. [Google Scholar] [CrossRef]

- Cai, L.; Li, Y.; Lin, X.; Chen, H.; Gao, Q.; Li, J. High-performance adhesives formulated from soy protein isolate and bio-based material hybrid for plywood production. J. Clean. Prod. 2022, 353, 131587. [Google Scholar] [CrossRef]

- Lamaming, S.Z.; Lamaming, J.; Rawi, N.F.M.; Hashim, R.; Kassim, M.H.M.; Hussin, M.H.; Bustami, Y.; Sulaiman, O.; Amini, M.H.M.; Hiziroglu, S. Improvements and limitation of soy protein-based adhesive: A review. Polym. Eng. Sci. 2021, 61, 2393–2405. [Google Scholar] [CrossRef]

- Li, Z.; Niu, W.; Cai, L.; Li, J.; Chen, H.; Gao, Q. Performance of eco-friendly soy protein adhesive reinforced by aldehyde sodium alginate. Int. J. Adhes. Adhes. 2024, 131, 103649. [Google Scholar] [CrossRef]

- Zhao, S.; Kong, D.; Lian, X.; Zhang, Y.; Xiang, S.; Fu, F.; Liu, X. A review of recent developments for applicational performances in soybean protein-bonded wood composites. Int. J. Adhes. Adhes. 2024, 132, 103676. [Google Scholar] [CrossRef]

- Jin, S.; Li, K.; Li, J.; Chen, H. A Low-Cost, Formaldehyde-Free and High Flame Retardancy Wood Adhesive from Inorganic Adhesives: Properties and Performance. Polymers 2017, 9, 513. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Han, Y.; Li, J.; Luo, J.; Shi, S.Q.; Li, J.; Gao, Q.; Mao, A. Research Progress of Soybean Protein Adhesive: A Review. J. Renew. Mater. 2022, 10, 2519–2541. [Google Scholar] [CrossRef]

- Chang, Z.; Shen, Y.; Xue, J.; Sun, Y.; Zhang, S. Products. Multifunctional soy protein gels with excellent initial adhesion and bonding strength based on a mussel-inspired redox self-catalytic and oyster-inspired organic-inorganic hybrid dual-bionic strategy. Ind. Crops Prod. 2023, 195, 116430. [Google Scholar] [CrossRef]

- Qi, G.; Li, N.; Wang, D.; Sun, X.S. Adhesion and Physicochemical Properties of Soy Protein Modified by Sodium Bisulfite. J. Am. Oil Chem. Soc. 2013, 90, 1917–1926. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, H.; Zhu, C.; Wan, K.; Zhang, Y.; Fang, Z.; Ai, Z. Mechanical and water-resistant properties of rice straw fiberboard bonded with chemically-modified soy protein adhesive. RSC Adv. 2018, 8, 15188–15195. [Google Scholar] [CrossRef]

- Kan, Y.; Li, J.; Zhang, S.; Gao, Z. Novel bridge assistance strategy for tailoring crosslinking networks within soybean-meal-based biocomposites to balance mechanical and biodegradation properties. Chem. Eng. J. 2023, 472, 144858. [Google Scholar] [CrossRef]

- Yan, Q.; Sun, Y.; Li, Z.; Zhu, Y.; Zhang, S. Products. Excellent strength and toughness and multifunctional protein-based adhesive produced by polyether block sulfuretted polyamidoamine-epichlorohydrin via a dual-crosslinking strategy. Ind. Crops Prod. 2023, 203, 117083. [Google Scholar] [CrossRef]

- Sun, Y.; Pang, H.; Li, Z.; Kang, H.; Zhang, S. Polyphenols induced in situ organic-inorganic crosslinking/mineralization strategy for constructing eco-friendly soy adhesive with high waterproof bonding strength. Compos. Part B Eng. 2022, 242, 110027. [Google Scholar] [CrossRef]

- Hu, Y.; Qu, L.; Bao, Z.; Li, Z.; Wei, R.; Huang, Q.; Qing, Y.; Li, X.; Wu, Y. An environmentally friendly multifunctional soy protein adhesive composed of rosin acid derivative inspired from organic-inorganic hybrid structure. J. Clean. Prod. 2024, 449, 141847. [Google Scholar] [CrossRef]

- Gu, W.; Li, F.; Liu, X.; Gao, Q.; Gong, S.; Li, J.; Shi, S.Q. Borate chemistry inspired by cell walls converts soy protein into high-strength, antibacterial, flame-retardant adhesive. Green Chem. 2020, 22, 1319–1328. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, X.; Liu, Z.; Zhang, X.; Luo, J.; Li, J.; Shi, S.Q.; Li, J.; Gao, Q. Constructing SiO2 nanohybrid to develop a strong soy protein adhesive with excellent flame-retardant and coating ability. Chem. Eng. J. 2022, 446, 137065. [Google Scholar] [CrossRef]

- He, D.; Wang, S.; Lei, L.; Hou, Z.; Shang, P.; He, X.; Nie, H. Core–shell particles for controllable release of drug. Chem. Eng. Sci. 2015, 125, 108–120. [Google Scholar] [CrossRef]

- Singh, R.; Bhateria, R. Core–shell nanostructures: A simplest two-component system with enhanced properties and multiple applications. Environ. Geochem. Health 2020, 43, 2459–2482. [Google Scholar] [CrossRef]

- Choi, H.; Zhang, W.; Kim, S.; Seo, Y. Core-Shell Structured Electro- and Magneto-Responsive Materials: Fabrication and Characteristics. Materials 2014, 7, 7460–7471. [Google Scholar] [CrossRef]

- Li, S.P.; Wu, Q.S.; Zhu, H.J.; Lin, Q.; Wang, C.S. Impact Resistance Enhancement by Adding Core-Shell Particle to Epoxy Resin Modified with Hyperbranched Polymer. Polymers 2017, 9, 684. [Google Scholar] [CrossRef]

- Zhou, L.; Du, Q.; Shan, T.; He, J.; Wang, C.; Zheng, K.; He, H.; Chen, S.; Wang, X.J.P.I. Synthesis, properties and applications of well-designed hybrid polymers based on polyhedral oligomeric silsesquioxane. Polym. Int. 2022, 71, 379–392. [Google Scholar]

- Kausar, A. Polymeric nanocomposite with polyhedral oligomeric silsesquioxane and nanocarbon (fullerene, graphene, carbon nanotube, nanodiamond)—Futuristic headways. Polym.-Plast. Technol. Mater. 2023, 62, 921–934. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Xu, Y.C.; Li, J.C.; Shi, S.Q.; Li, J.Z.; Gao, Q. High performance and multifunctional protein-based adhesive produced via phenol-amine chemistry and mineral reinforcement strategy inspired by arthropod cuticles. Chem. Eng. J. 2021, 426, 130852. [Google Scholar] [CrossRef]

- Burton, R.A.; Gidley, M.J.; Fincher, G.B.J.N.C.B. Heterogeneity in the chemistry, structure and function of plant cell walls. Nat. Chem. Biol. 2010, 6, 724–732. [Google Scholar] [CrossRef] [PubMed]

- Kinnaert, C.; Daugaard, M.; Nami, F.; Clausen, M.H.J.C.R. Chemical Synthesis of Oligosaccharides Related to the Cell Walls of Plants and Algae. Chem. Rev. 2017, 117, 11337–11405. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Wei, J.; Cao, P.S.; Han, Y.L.; Zhang, S.F.; Chen, Y.X.; Guo, Y. Barnacle and mussel-inspired of functional silk fibroin to prepare biomass adhesive with ultra-high cold-pressing adhesion. Cellulose 2025, 1–19. [Google Scholar] [CrossRef]

- Sun, Y.; Yan, Q.; Liang, Z.; Zhang, S. Facile synthesis of soy protein adhesives with high cold-pressing bonding ability through waterborne epoxy resin and bifunctional branched structure system. Ind. Crops Prod. 2024, 221, 119287. [Google Scholar] [CrossRef]

- GB/T 17657-2022; Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels. National Standards of the People’s Republic of China: Beijing, China, 2022.

- Pang, H.; Wang, Y.; Chang, Z.; Xia, C.; Han, C.; Liu, H.; Li, J.; Zhang, S.; Cai, L.; Huang, Z. Soy meal adhesive with high strength and water resistance via carboxymethylated wood fiber-induced crosslinking. Cellulose 2021, 28, 3569–3584. [Google Scholar] [CrossRef]

- GB/T 16172-2007; Test Method for Heat Release Rate of Building Materials. National Standards of the People’s Republic of China: Beijing, China, 2007.

- Ma, Z.; Liu, X.; Xu, X.; Liu, L.; Yu, B.; Maluk, C.; Huang, G.; Wang, H.; Song, P. Bioinspired, Highly Adhesive, Nanostructured Polymeric Coatings for Superhydrophobic Fire-Extinguishing Thermal Insulation Foam. ACS Nano 2021, 15, 11667–11680. [Google Scholar] [CrossRef]

- Luo, J.; Luo, J.; Li, X.; Li, K.; Gao, Q.; Li, J. Toughening improvement to a soybean meal-based bioadhesive using an interpenetrating acrylic emulsion network. J. Mater. Sci. 2016, 51, 9330–9341. [Google Scholar] [CrossRef]

- ASTM D5570/D5570M-10(2022); Standard Test Method for Water Resistance of Tape and Adhesives Used as Box Closure. ASTM International: West Conshohocken, PA, USA, 2022.

- GB/T 1741-2020; Test Method for Determining the Resistance of Paints Film to Mold. Standardization Administration of China (SAC): Beijing, China, 2020.

- Li, Y.; Huang, X.; Xu, Y.; Ma, C.; Cai, L.; Zhang, J.; Luo, J.; Li, J.; Li, J.; Shi, S.Q.; et al. A bio-inspired multifunctional soy protein-based material: From strong underwater adhesion to 3D printing—ScienceDirect. Chem. Eng. J. 2021, 430, 133017. [Google Scholar] [CrossRef]

- Je, H.; Won, J. Natural urushiol as a novel under-water adhesive. Chem. Eng. J. 2020, 404, 126424. [Google Scholar] [CrossRef]

- LY/T 2720-2016; Method for Determining the Breakage Rate of Glued Laminated Wood. Standards Press of China: Beijing, China, 2016.

- Xu, Y.; Zhang, X.; Wang, G.; Zhang, X.; Luo, J.; Li, J.; Shi, S.Q.; Li, J.; Gao, Q. Preparation of a strong soy protein adhesive with mildew proof, flame-retardant, and electromagnetic shielding properties via constructing nanophase-reinforced organic-inorganic hybrid structure. Chem. Eng. J. 2022, 447, 137536. [Google Scholar] [CrossRef]

- Peng, J.; Lei, J.; Feng, F.; Liu, F.; Ma, Y.; Bai, J.; Da, G.; Wei, C.; Huo, Z.; Cui, J. Eco-friendly and novel tannin-based wood adhesive enhanced with cellulose nanofibrils grafted by hyperbranched polyamides. Ind. Crops Prod. 2024, 222, 119576. [Google Scholar] [CrossRef]

- Chen, X.; Xi, X.; Pizzi, A.; Fredon, E.; Du, G.; Gerardin, C.; Amirou, S. Oxidized demethylated lignin as a bio-based adhesive for wood bonding. J. Adhes. 2021, 97, 873–890. [Google Scholar] [CrossRef]

- Yao, X.; Liu, H.; Li, C. Development of Eco-Friendly Soy Meal Adhesives Enhanced by Ethylene Glycol Diglycidyl Ether. Adv. Polym. Technol. 2019, 2019, 8697047. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliacik, J.; Noshchenko, G.; Kacík, F.; Bekhta, N. Characteristics of beech bark and its effect on properties of UF adhesive and on bonding strength and formaldehyde emission of plywood panels. Eur. J. Wood Wood Prod. 2021, 79, 423–433. [Google Scholar] [CrossRef]

- Feng, S.H.; Shui, T.; Wang, H.Y.; Ai, X.B.; Kuboki, T.; Xu, C.B.C. Properties of phenolic adhesives formulated with activated organosolv lignin derived from cornstalk. Ind. Crops Prod. 2021, 161, 113225. [Google Scholar] [CrossRef]

| Sample | SPI (g) | POSS-U (g) | SB (g) | Deionized Water (g) |

| 12 | 0 | 0 | 88 |

| 12 | 3 | 0.5 | 88 |

| 12 | 3 | 1.5 | 88 |

| 12 | 3 | 2.5 | 88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Sun, L.; Li, X.; Fu, Z.; Li, Y.; Sun, W.; Sun, Y.; Huang, R.; Guo, M. Developing Eco-Friendly, High-Performance Soy Protein Plywood Adhesive via Core–Shell Hybridization and Borate Chemistry. Materials 2025, 18, 1144. https://doi.org/10.3390/ma18051144

Zhang Y, Sun L, Li X, Fu Z, Li Y, Sun W, Sun Y, Huang R, Guo M. Developing Eco-Friendly, High-Performance Soy Protein Plywood Adhesive via Core–Shell Hybridization and Borate Chemistry. Materials. 2025; 18(5):1144. https://doi.org/10.3390/ma18051144

Chicago/Turabian StyleZhang, Yi, Longxiang Sun, Xinyu Li, Ziye Fu, Yang Li, Weisheng Sun, Yawei Sun, Rongfeng Huang, and Minghui Guo. 2025. "Developing Eco-Friendly, High-Performance Soy Protein Plywood Adhesive via Core–Shell Hybridization and Borate Chemistry" Materials 18, no. 5: 1144. https://doi.org/10.3390/ma18051144

APA StyleZhang, Y., Sun, L., Li, X., Fu, Z., Li, Y., Sun, W., Sun, Y., Huang, R., & Guo, M. (2025). Developing Eco-Friendly, High-Performance Soy Protein Plywood Adhesive via Core–Shell Hybridization and Borate Chemistry. Materials, 18(5), 1144. https://doi.org/10.3390/ma18051144