Characterization of Morphological, Thermal, and Mechanical Performances and UV Ageing Degradation of Post-Consumer Recycled Polypropylene for Automotive Industries

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. UV Ageing Test

2.3. FE-SEM Analysis

2.4. Thermal Analysis

2.5. Fourier Transform Infrared (FT-IR) Analysis

2.6. Impact Behavior Test

2.7. Mechanical Characterization

3. Results

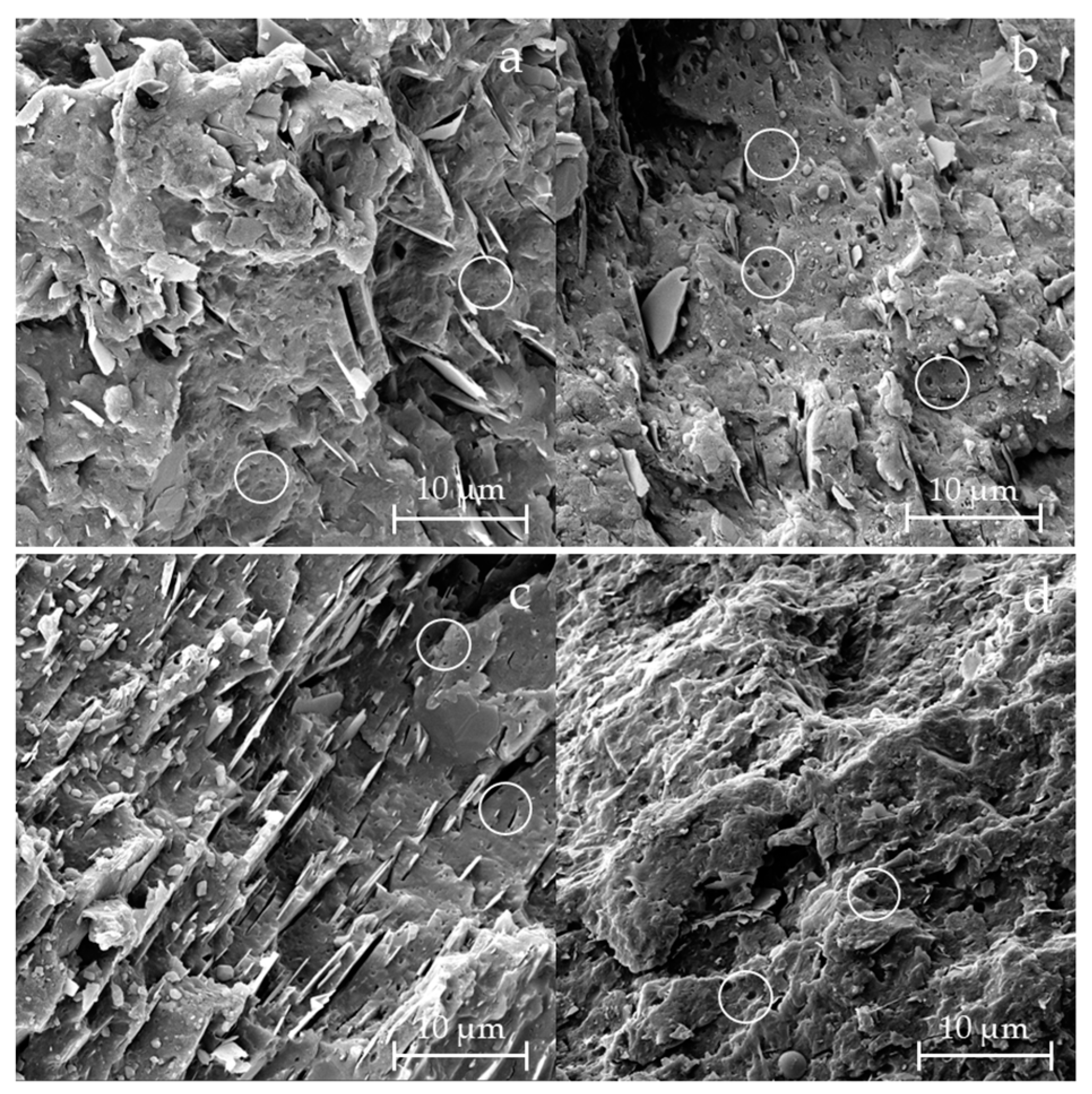

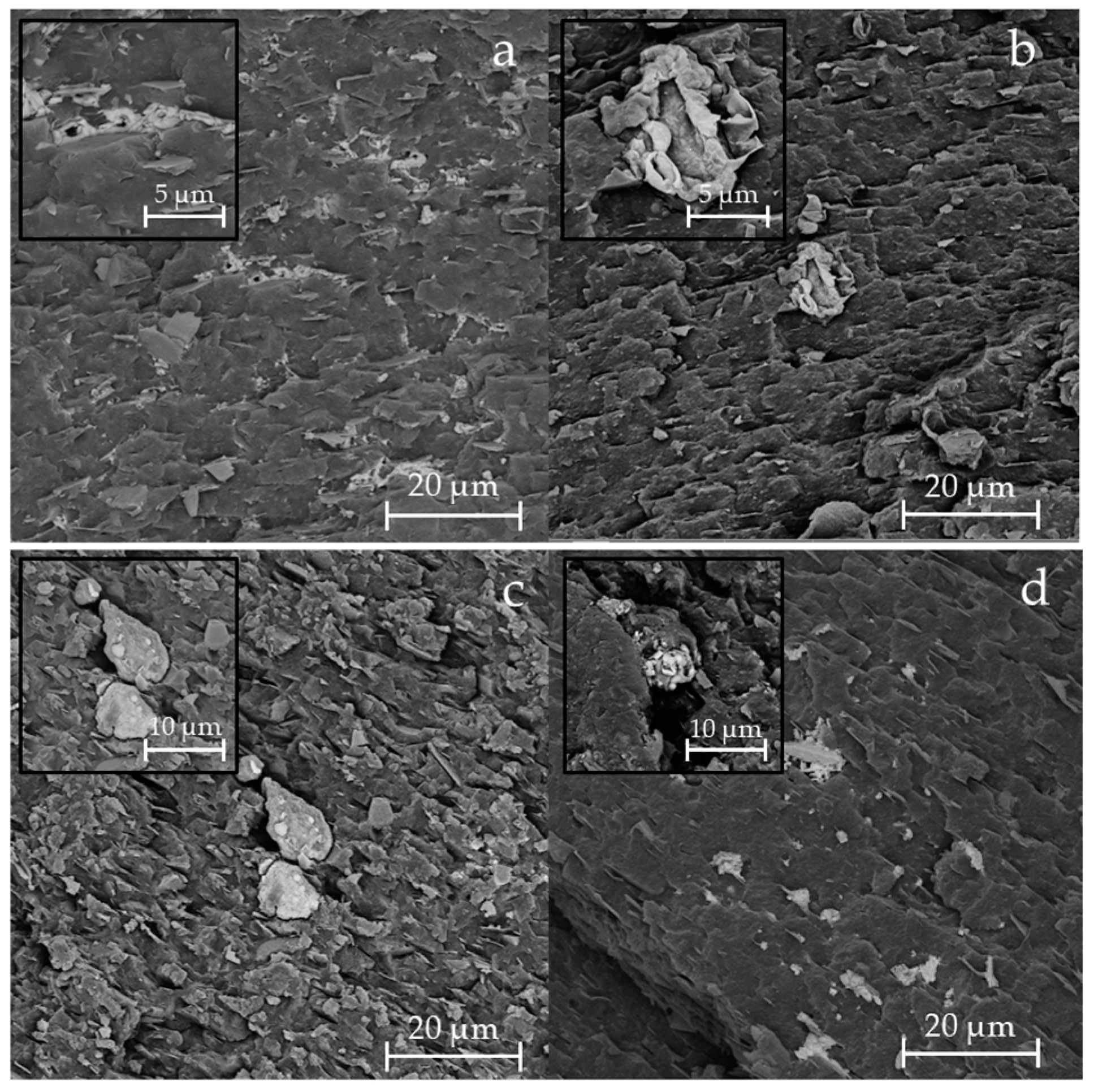

3.1. FE-SEM

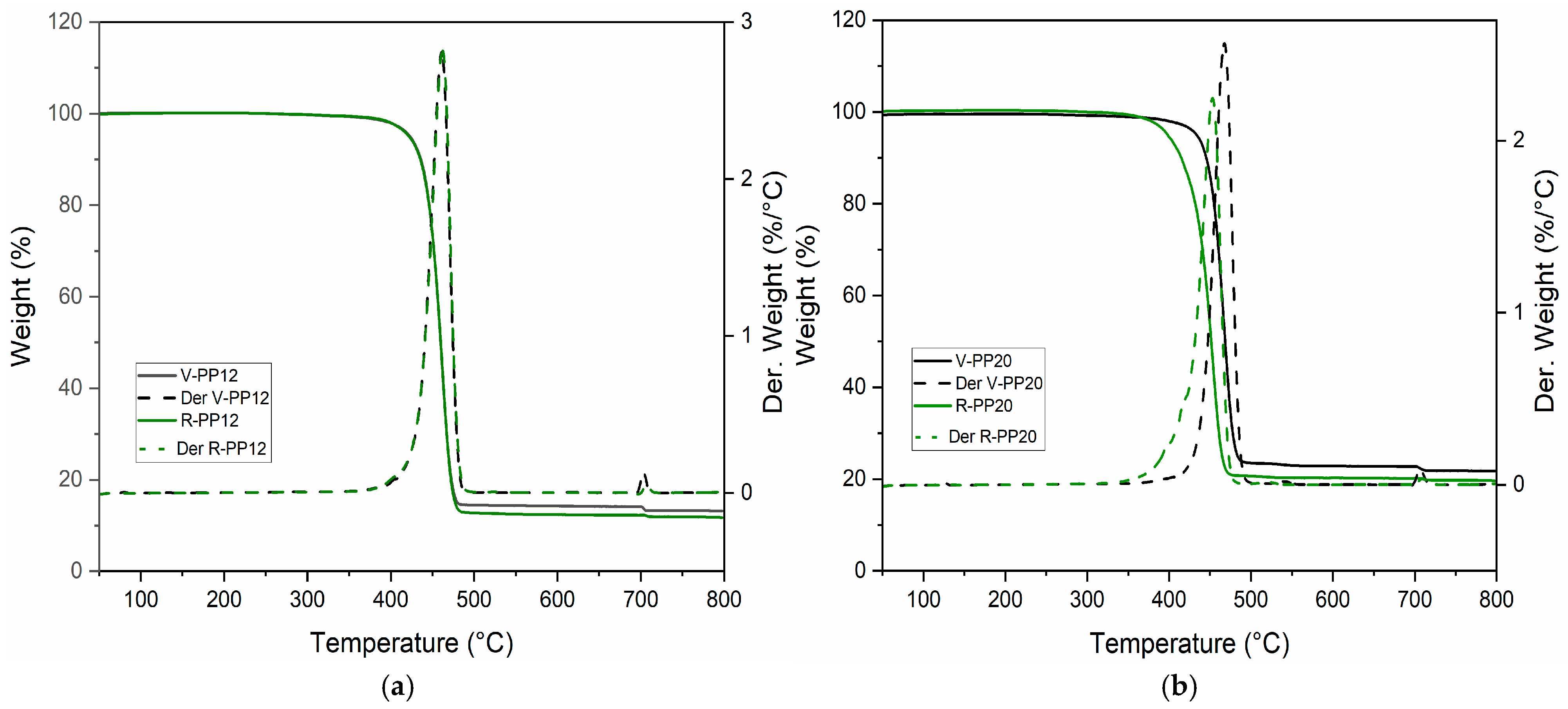

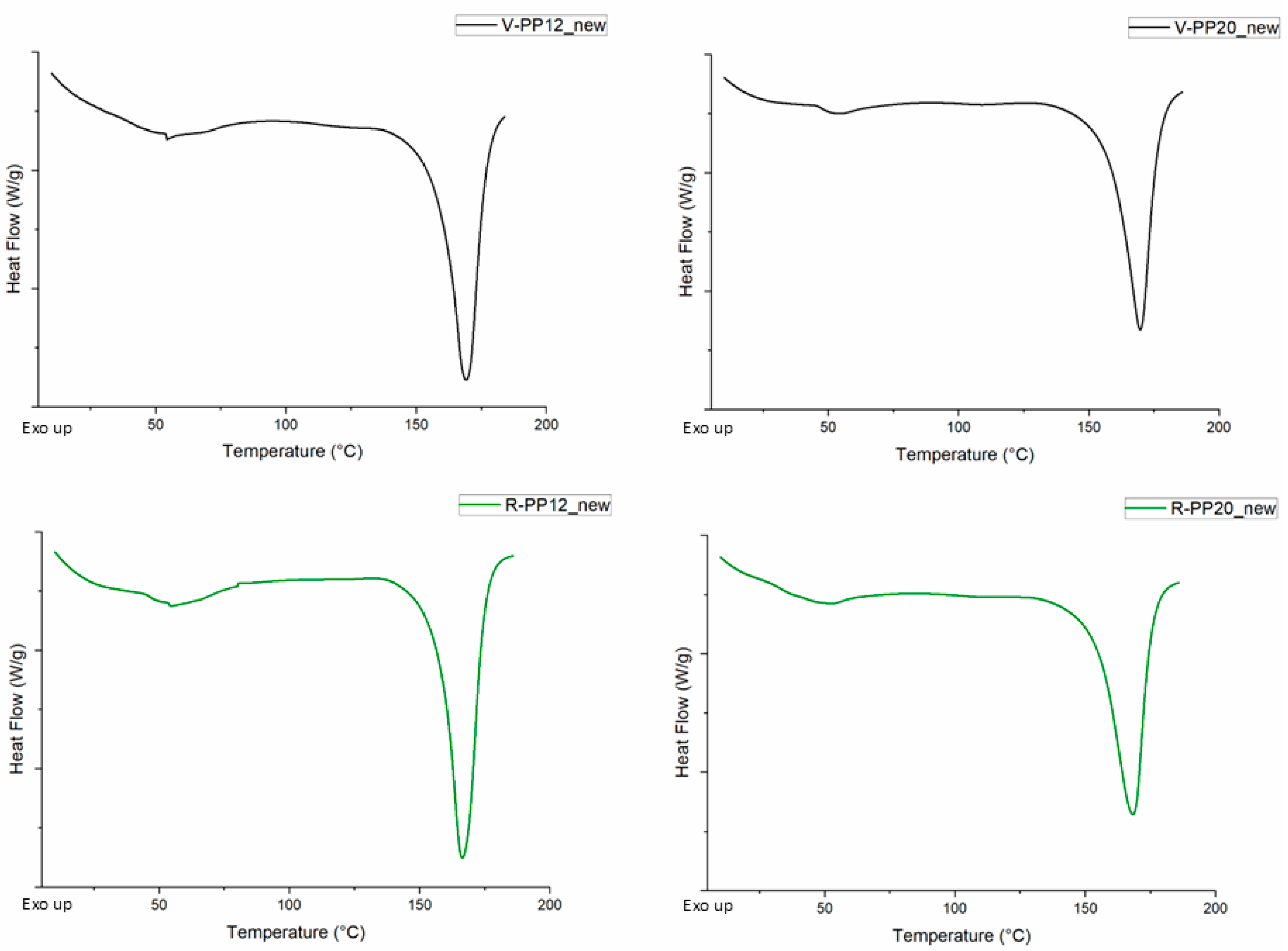

3.2. Thermal Analysis

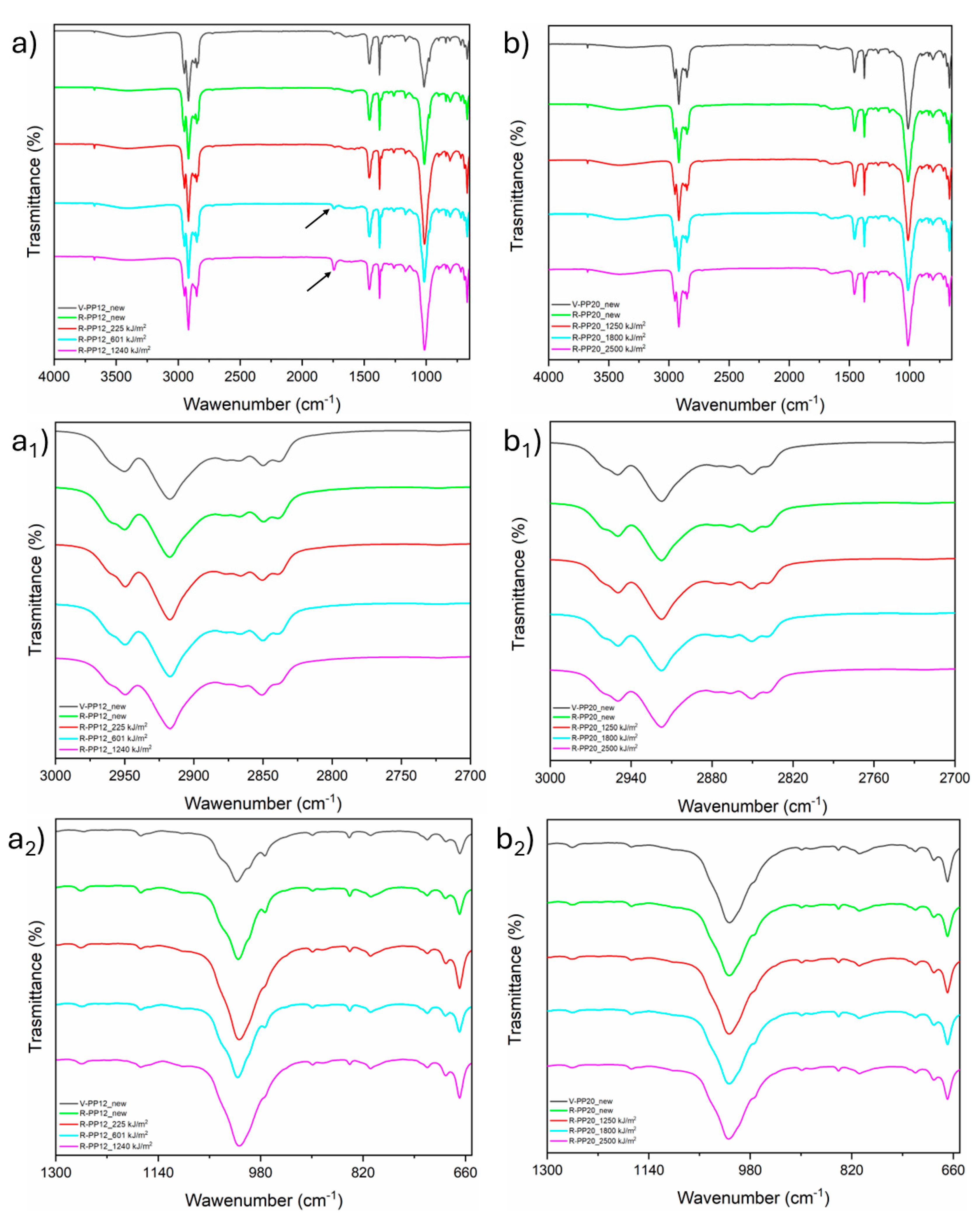

3.3. FT-IR

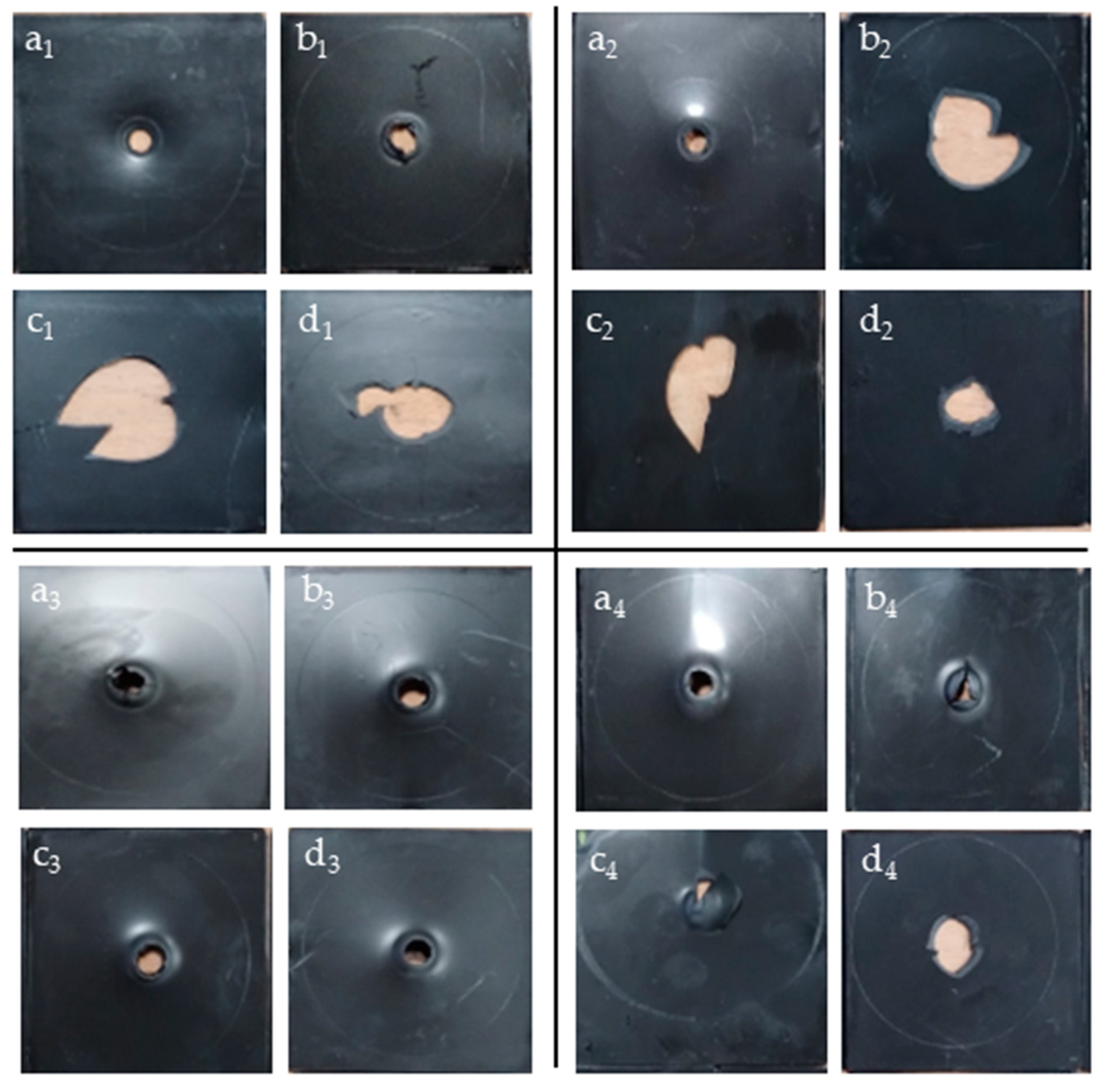

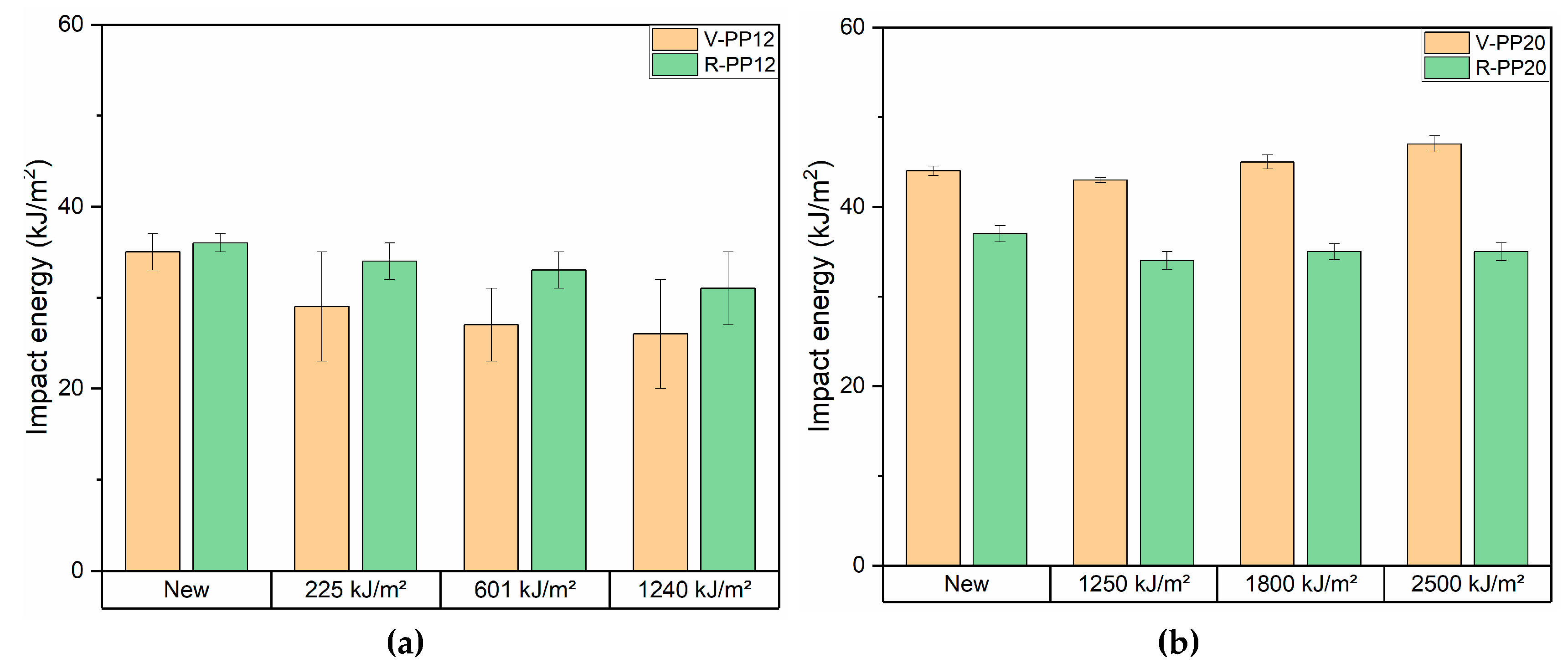

3.4. Impact Test Analysis

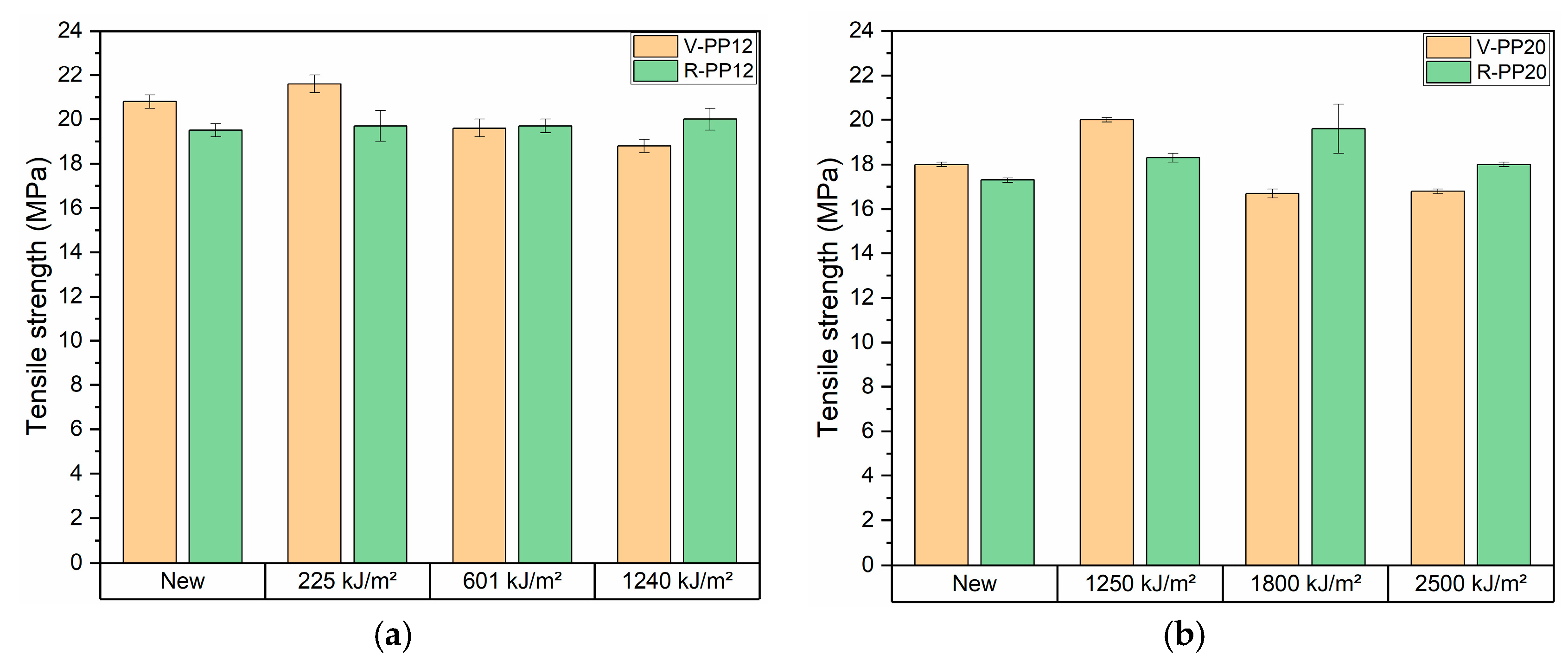

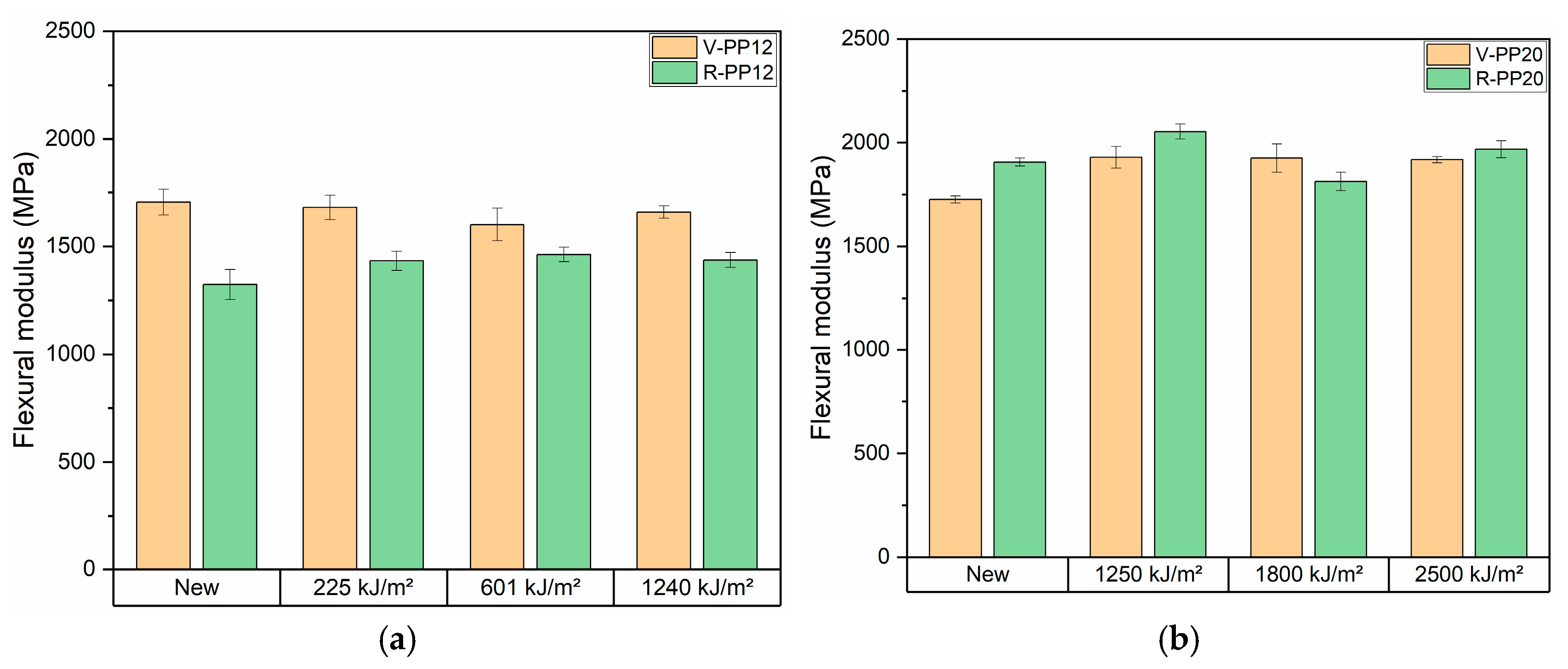

3.5. Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Patil, A.; Patel, A.; Purohit, R. An Overview of Polymeric Materials for Automotive Applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Ladhari, A.; Kucukpinar, E.; Stoll, H.; Sängerlaub, S. Comparison of Properties with Relevance for the Automotive Sector in Mechanically Recycled and Virgin Polypropylene. Recycling 2021, 6, 76. [Google Scholar] [CrossRef]

- Panaitescu, D.; Iorga, M.; Ciucu, A.; Serban, S.; Crucean, A.; Bercu, C. New Methods for Recycling Plastic Materials from End-of-Life Vehicles. WSEAS Trans. Environ. Dev. 2008, 4, 1009–1108. [Google Scholar]

- Szeteiová, K. Automotive Materials Plastics in Automotive Markets Today. 2010. Available online: https://www.mtf.stuba.sk/buxus/docs/internetovy_casopis/2010/3/szeteiova.pdf (accessed on 9 February 2025).

- Sarotto, E.; Brunella, V.; Cesano, F. Graphene-Loaded Recycled PET: Exploring and Enhancing Electrical Conductivity through Processing and Laser Treatments near the Electrical Percolation Threshold. Sustain. Mater. Technol. 2024, 40, e00986. [Google Scholar] [CrossRef]

- Finnveden, G.; Johansson, J.; Lind, P.; Moberg, Å. Life Cycle Assessment of Energy from Solid Waste—Part 1: General Methodology and Results. J. Clean. Prod. 2005, 13, 213–229. [Google Scholar] [CrossRef]

- Jones, H.; McClements, J.; Ray, D.; Hindle, C.S.; Kalloudis, M.; Koutsos, V. Thermomechanical Properties of Virgin and Recycled Polypropylene—High-Density Polyethylene Blends. Polymers 2023, 15, 4200. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Aumnate, C.; Rudolph, N.; Sarmadi, M. Recycling of Polypropylene/Polyethylene Blends: Effect of Chain Structure on the Crystallization Behaviors. Polymers 2019, 11, 1456. [Google Scholar] [CrossRef]

- Huang, P.-W.; Peng, H.-S. Number of Times Recycled and Its Effect on the Recyclability, Fluidity and Tensile Properties of Polypropylene Injection Molded Parts. Sustainability 2021, 13, 11085. [Google Scholar] [CrossRef]

- Brunella, V.; Aresti, V.; Romagnolli, U.; Muscato, B.; Girotto, M.; Rizzi, P.; Luda, M.P. Recycling of EPDM via Continuous Thermo-Mechanical Devulcanization with Co-Rotating Twin-Screw Extruder. Polymers 2022, 14, 4853. [Google Scholar] [CrossRef] [PubMed]

- Brachet, P.; Høydal, L.T.; Hinrichsen, E.L.; Melum, F. Modification of Mechanical Properties of Recycled Polypropylene from Post-Consumer Containers. Waste Manag. 2008, 28, 2456–2464. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Bahlouli, N.; Addiego, F.; Ahzi, S. Elastic and Yield Behaviors of Recycled Polypropylene-Based Composites: Experimental and Modeling Study. Compos. Part B Eng. 2016, 99, 132–153. [Google Scholar] [CrossRef]

- Ammar, O.; Bouaziz, Y.; Haddar, N.; Mnif, N. Talc as Reinforcing Filler in Polypropylene Compounds: Effect on Morphology and Mechanical Properties. Polym. Sci. 2017, 3. [Google Scholar] [CrossRef]

- Kausar, A. Contemporary Applications of Carbon Black-Filled Polymer Composites: An Overview of Essential Aspects. J. Plast. Film Sheeting 2018, 34, 256–299. [Google Scholar] [CrossRef]

- Lapcik, L.; Jindrova, P.; Lapcikova, B.; Tamblyn, R.; Greenwood, R.; Rowson, N. Effect of the Talc Filler Content on the Mechanical Properties of Polypropylene Composites. J. Appl. Polym. Sci. 2008, 110, 2742–2747. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability 2020, 13, 159. [Google Scholar] [CrossRef]

- Borrelle, S.B.; Ringma, J.; Law, K.L.; Monnahan, C.C.; Lebreton, L.; McGivern, A.; Murphy, E.; Jambeck, J.; Leonard, G.H.; Hilleary, M.A.; et al. Predicted Growth in Plastic Waste Exceeds Efforts to Mitigate Plastic Pollution. Science 2020, 369, 1515–1518. [Google Scholar] [CrossRef] [PubMed]

- Bunjes, A.; Arndt, J.-H.; Geertz, G.; Barton, B. Characterization and Chemometric Modelling of Mechanically Recycled Polypropylene for Automotive Manufacturing. Polymer 2022, 249, 124823. [Google Scholar] [CrossRef]

- Jamnongkan, T.; Intraramongkol, N.; Samoechip, W.; Potiyaraj, P.; Mongkholrattanasit, R.; Jamnongkan, P.; Wongwachirakorn, P.; Sugimoto, M.; Ito, H.; Huang, C.-F. Towards a Circular Economy: Study of the Mechanical, Thermal, and Electrical Properties of Recycled Polypropylene and Their Composite Materials. Polymers 2022, 14, 5482. [Google Scholar] [CrossRef]

- Hubo, S.; Ragaert, K.; Leite, L.; Martins, C. Evaluation of Post-Industrial and Post-Consumer Polyolefin-Based Polymer Waste Streams for Injection Moulding. In Proceedings of the 6th Polymers & Mould Innovations International Conference, Guimaraes, Portugal, 10–12 September 2014; pp. 201–206. [Google Scholar]

- Curtzwiler, G.W.; Schweitzer, M.; Li, Y.; Jiang, S.; Vorst, K.L. Mixed Post-Consumer Recycled Polyolefins as a Property Tuning Material for Virgin Polypropylene. J. Clean. Prod. 2019, 239, 117978. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Da Silva, W.A.; Araújo, E.M.; Da Silva, L.J.M.D.; De Melo, J.B.D.C.A.; Wellen, R.M.R. From Waste to Potential Reuse: Mixtures of Polypropylene/Recycled Copolymer Polypropylene from Industrial Containers: Seeking Sustainable Materials. Sustainability 2022, 14, 6509. [Google Scholar] [CrossRef]

- Schulte, A.; Kampmann, B.; Galafton, C. Measuring the Circularity and Impact Reduction Potential of Post-Industrial and Post-Consumer Recycled Plastics. Sustainability 2023, 15, 12242. [Google Scholar] [CrossRef]

- Juan, R.; Expósito, M.T.; Paredes, B.; Lechuga, D.; Martínez, C.; Cardil, A.; Aguilera-Villegas, L.; Ramos, J.; Domínguez, C.; Vega, J.F.; et al. Enhancing the Recyclability of ELV Plastic Bumpers: Characterization of Molecular, Morphological, Rheological, Mechanical Properties and Ageing Degradation. Polym. Degrad. Stab. 2024, 230, 111024. [Google Scholar] [CrossRef]

- Da Costa, H.M.; Ramos, V.D.; De Oliveira, M.G. Degradation of Polypropylene (PP) during Multiple Extrusions: Thermal Analysis, Mechanical Properties and Analysis of Variance. Polym. Test. 2007, 26, 676–684. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of Recycling on the Microstructure and the Mechanical Properties of Isotactic Polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Bahlouli, N.; Pessey, D.; Raveyre, C.; Guillet, J.; Ahzi, S.; Dahoun, A.; Hiver, J.M. Recycling Effects on the Rheological and Thermomechanical Properties of Polypropylene-Based Composites. Mater. Des. 2012, 33, 451–458. [Google Scholar] [CrossRef]

- Tocháček, J.; Vrátníčková, Z. Polymer Life-Time Prediction: The Role of Temperature in UV Accelerated Ageing of Polypropylene and Its Copolymers. Polym. Test. 2014, 36, 82–87. [Google Scholar] [CrossRef]

- Arese, M.; Mania, I.; Brunella, V.; Lambertini, V.G.; Gorra, R. Evaluation of Aging Effect on the Durability of Antibacterial Treatments Applied on Textile Materials for the Automotive Industry. ACS Omega 2024, 9, 27169–27176. [Google Scholar] [CrossRef] [PubMed]

- François-Heude, A.; Richaud, E.; Desnoux, E.; Colin, X. A General Kinetic Model for the Photothermal Oxidation of Polypropylene. J. Photochem. Photobiol. A Chem. 2015, 296, 48–65. [Google Scholar] [CrossRef]

- Alam, L.; Piezel, B.; Sicot, O.; Aivazzadeh, S.; Moscardelli, S.; Van-Schoors, L. UV Accelerated Aging of Unidirectional Flax Composites: Comparative Study between Recycled and Virgin Polypropylene Matrix. Polym. Degrad. Stab. 2023, 208, 110268. [Google Scholar] [CrossRef]

- Hernández-Fernández, J.; Rayón, E.; López, J.; Arrieta, M.P. Enhancing the Thermal Stability of Polypropylene by Blending with Low Amounts of Natural Antioxidants. Macro Mater. Eng. 2019, 304, 1900379. [Google Scholar] [CrossRef]

- Huang, J. Carbon Black Filled Conducting Polymers and Polymer Blends. Adv. Polym. Technol. 2002, 21, 299–313. [Google Scholar] [CrossRef]

- Attwood, J.; Philip, M.; Hulme, A.; Williams, G.; Shipton, P. The Effects of Ageing by Ultraviolet Degradation of Recycled Polyolefin Blends. Polym. Degrad. Stab. 2006, 91, 3407–3415. [Google Scholar] [CrossRef]

- Ulutan, S. Influence of Additional Thermal Stabilizers on the Reprocessing of Postconsumer Poly(Vinyl Chloride) Bottles. J. Appl. Polym. Sci. 2003, 90, 3994–3999. [Google Scholar] [CrossRef]

- ISO 180:2023; Plastics—Determination of Izod Impact Strength. ISO: Geneva, Switzerland, 2023.

- ASTM D3763-18; Standard Test Method for High Speed Puncture Properties of Plastics Using Load and Displacement Sensors. ASTM: West Conshohocken, PA, USA, 2023.

- ISO 527:2019; Plastics—Determination of Tensile Properties. ISO: Geneva, Switzerland, 2019.

- ISO 178:2019; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- Shao, W.; Liu, L.-Z.; Wang, Y.; Wang, Y.; Shi, Y.; Song, L. Investigation of Crystallization, Morphology, and Mechanical Properties of Polypropylene/Polypropylene-Polyethylene Block Copolymer Blends. Polymers 2023, 15, 4680. [Google Scholar] [CrossRef] [PubMed]

- Qiu, F.; Wang, M.; Hao, Y.; Guo, S. The Effect of Talc Orientation and Transcrystallization on Mechanical Properties and Thermal Stability of the Polypropylene/Talc Composites. Compos. Part. A Appl. Sci. Manuf. 2014, 58, 7–15. [Google Scholar] [CrossRef]

- Bedia, E.L.; Astrini, N.; Sudarisman, A.; Sumera, F.; Kashiro, Y. Characterization of Polypropylene and Ethylene-Propylene Copolymer Blends for Industrial Applications. J. Appl. Polym. Sci. 2000, 78, 1200–1208. [Google Scholar] [CrossRef]

- Tang, L.; Qu, B.; Shen, X. Mechanical Properties, Morphological Structure, and Thermal Behavior of Dynamically Photocrosslinked PP/EPDM Blends. J. Appl. Polym. Sci. 2004, 92, 3371–3380. [Google Scholar] [CrossRef]

- l’Abee, R.M.A.; Vissers, A.M.J.T.; Goossens, J.G.P.; Spoelstra, A.B.; Van Duin, M. Characterization of the Morphology of Co-Extruded, Thermoplastic/Rubber Multi-Layer Tapes. Anal. Chim. Acta 2009, 654, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Antunes, C.F.; Machado, A.V.; Van Duin, M. Morphology Development and Phase Inversion during Dynamic Vulcanisation of EPDM/PP Blends. Eur. Polym. J. 2011, 47, 1447–1459. [Google Scholar] [CrossRef]

- Uthaipan, N.; Jarnthong, M.; Peng, Z.; Junhasavasdikul, B.; Nakason, C.; Thitithammawong, A. Micro-Scale Morphologies of EPDM/EOC/PP Ternary Blends: Relating Experiments to Predictive Theories of Dispersion in Melt Mixing. Mater. Des. 2016, 100, 19–29. [Google Scholar] [CrossRef]

- Antunes, C.F.; Van Duin, M.; Machado, A.V. Effect of Crosslinking on Morphology and Phase Inversion of EPDM/PP Blends. Mater. Chem. Phys. 2012, 133, 410–418. [Google Scholar] [CrossRef]

- Douiri, L.; Jdidi, H.; Kordoghli, S.; El Hajj Sleiman, G.; Béreaux, Y. Degradation Indicators in Multiple Recycling Processing Loops of Impact Polypropylene and High Density Polyethylene. Polym. Degrad. Stab. 2024, 219, 110617. [Google Scholar] [CrossRef]

- Gaxiola-Cockburn, R.; Martínez-Romero, O.; Elías-Zúñiga, A.; Olvera-Trejo, D.; Reséndiz-Hernández, J.; Soria-Hernández, C. Investigation of the Mechanical Properties of Parts Fabricated with Ultrasonic Micro Injection Molding Process Using Polypropylene Recycled Material. Polymers 2020, 12, 2033. [Google Scholar] [CrossRef]

- Shang-Guan, Y.; Chen, F.; Zheng, Q. Microstructure, Morphology, Crystallization and Rheological Behavior of Impact Polypropylene Copolymer. Sci. China Chem. 2012, 55, 698–712. [Google Scholar] [CrossRef]

- Fernández, A.; Expósito, M.T.; Peña, B.; Berger, R.; Shu, J.; Graf, R.; Spiess, H.W.; García-Muñoz, R.A. Molecular Structure and Local Dynamic in Impact Polypropylene Copolymers Studied by Preparative TREF, Solid State NMR Spectroscopy, and SFM Microscopy. Polymer 2015, 61, 87–98. [Google Scholar] [CrossRef]

- Austermann, J.; Kuscera, R.; Wipperfürth, J.; Hopmann, C.; Dahlmann, R. Influence of Material Modification and Fillers on the Dimensional Stability and Warpage of Polypropylene in Screw-extrusion-based Large Area Additive Manufacturing. Polym. Eng. Sci. 2023, 63, 1598–1612. [Google Scholar] [CrossRef]

- Chen, Q.; Yu, R.B. Effect of Talc on High-Temperature ExothermicPeak and Properties of Polypropylene. IOP Conf. Ser. Mater. Sci. Eng. 2018, 359, 012031. [Google Scholar] [CrossRef]

- Prior, L.; Oliveira, M.S.A.; Zhiltsova, T. Assessment of the Impact of Superficial Contamination and Thermo-Oxidative Degradation on the Properties of Post-Consumer Recycled Polypropylene. Materials 2023, 16, 1198. [Google Scholar] [CrossRef] [PubMed]

- Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. [Google Scholar] [CrossRef] [PubMed]

- Garofalo, E.; Di Maio, L.; Scarfato, P.; Pietrosanto, A.; Protopapa, A.; Incarnato, L. Study on Improving the Processability and Properties of Mixed Polyolefin Post-Consumer Plastics for Piping Applications. Polymers 2020, 13, 71. [Google Scholar] [CrossRef]

- Caban, R. FTIR-ATR Spectroscopic, Thermal and Microstructural Studies on Polypropylene-Glass Fiber Composites. J. Mol. Struct. 2022, 1264, 133181. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, Y.; Zhang, L.; Zheng, G.; Yan, X.; Dai, K.; Liu, C.; Shen, C.; Guo, Z. Interfacial Interaction Enhancement by Shear-Induced β-Cylindrite in Isotactic Polypropylene/Glass Fiber Composites. Polymer 2016, 100, 111–118. [Google Scholar] [CrossRef]

- Zhu, X.; Yan, D.; Fang, Y. In Situ FTIR Spectroscopic Study of the Conformational Change of Isotactic Polypropylene during the Crystallization Process. J. Phys. Chem. B 2001, 105, 12461–12463. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhao, Y.; Zhang, C.; Yang, J.; Xu, Y.; Wang, D. In-Situ Investigation on the Structural Evolution of Mesomorphic Isotactic Polypropylene in a Continuous Heating Process. Polymer 2016, 105, 133–143. [Google Scholar] [CrossRef]

- Castillo, L.A.; Barbosa, S.E.; Capiati, N.J. Influence of Talc Morphology on the Mechanical Properties of Talc Filled Polypropylene. J. Polym. Res. 2013, 20, 152. [Google Scholar] [CrossRef]

- Castillo, L.A.; Barbosa, S.E. Influence of Processing and Particle Morphology on Final Properties of Polypropylene/Talc Nanocomposites. Polym. Compos. 2020, 41, 3170–3183. [Google Scholar] [CrossRef]

- Bouakkaz, A.; Albedah, A.; Bouiadjra, B.B.; Khan, S.M.; Benyahia, F.; Elmeguenni, M. Effect of Temperature on the Mechanical Properties of Polypropylene–Talc Composites. J. Thermoplast. Compos. Mater. 2018, 31, 896–912. [Google Scholar] [CrossRef]

- Fernandes, L.L.; Freitas, C.A.; Demarquette, N.R.; Fechine, G.J.M. Photodegradation of Thermodegraded Polypropylene/High-impact Polystyrene Blends: Mechanical Properties. J. Appl. Polym. Sci. 2011, 120, 770–779. [Google Scholar] [CrossRef]

| Sample | Material Code | Talc (%) | PIR (wt.%) | Density (g/cm3) | MFR (g/10 min) |

|---|---|---|---|---|---|

| 1 | V-PP12 | 12 | – | 0.97 | 30 |

| 2 | R-PP12 | 12 | 20 | 0.98 | 30 |

| 3 | V-PP20 | 20 | – | 1.04 | 22 |

| 4 | R-PP20 | 20 | 20 | 1.04 | 30 |

| Sample | T Onset | % Polymer [w/w] | % CB [w/w] | % Residue [w/w] |

|---|---|---|---|---|

| V-PP12 | 425 ± 2.2 | 86 ± 0.1 | 0.9 ± 0.04 | 13 ± 0.2 |

| R-PP12 | 411 ± 15.7 | 87 ± 0.71 | 0.5 ± 0.02 | 12 ± 0.6 |

| V-PP20 | 429 ± 9.5 | 78 ± 0.05 | 0.9 ± 0.41 | 22 ± 0.4 |

| R-PP20 | 417 ± 15.5 | 80 ± 3.9 | 0.5 ± 0.2 | 19 ± 3.9 |

| Sample | Tm (°C) | Tc (°C) | Δhm (J/g) |

|---|---|---|---|

| Before ageing | |||

| V-PP12 | 166 ± 0.5 | 128 ± 0.1 | 53 ± 1.9 |

| R-PP12 | 167 ± 0.5 | 127 ± 0.5 | 54 ± 1.9 |

| V-PP20 | 166 ± 0.6 | 129 ± 0.1 | 44 ± 2.2 |

| R-PP20 | 166 ± 0.1 | 129 ± 0.6 | 47 ± 1.6 |

| After III ageing step | |||

| V-PP12 | 166 ± 0.6 | 128 ± 0.6 | 56 ± 1.4 |

| R-PP12 | 166 ± 0.6 | 129 ± 0.1 | 49 ± 0.3 |

| V-PP20 | 167 ± 0.6 | 129 ± 0.1 | 43 ± 0.6 |

| R-PP20 | 166 ± 0.6 | 128 ± 0.5 | 47 ± 0.8 |

| Sample | Ductile Break | Ductile/Brittle Transition |

|---|---|---|

| V-PP12 | −10 °C | −10 °C/−20 °C |

| R-PP12 | 0 °C | 0 °C/−10 °C |

| V-PP20 | −30 °C | >−30 °C |

| R-PP20 | −10 °C | −10 °C/−20 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arese, M.; Cavallo, B.; Ciaccio, G.; Brunella, V. Characterization of Morphological, Thermal, and Mechanical Performances and UV Ageing Degradation of Post-Consumer Recycled Polypropylene for Automotive Industries. Materials 2025, 18, 1090. https://doi.org/10.3390/ma18051090

Arese M, Cavallo B, Ciaccio G, Brunella V. Characterization of Morphological, Thermal, and Mechanical Performances and UV Ageing Degradation of Post-Consumer Recycled Polypropylene for Automotive Industries. Materials. 2025; 18(5):1090. https://doi.org/10.3390/ma18051090

Chicago/Turabian StyleArese, Matilde, Beatrice Cavallo, Gabriele Ciaccio, and Valentina Brunella. 2025. "Characterization of Morphological, Thermal, and Mechanical Performances and UV Ageing Degradation of Post-Consumer Recycled Polypropylene for Automotive Industries" Materials 18, no. 5: 1090. https://doi.org/10.3390/ma18051090

APA StyleArese, M., Cavallo, B., Ciaccio, G., & Brunella, V. (2025). Characterization of Morphological, Thermal, and Mechanical Performances and UV Ageing Degradation of Post-Consumer Recycled Polypropylene for Automotive Industries. Materials, 18(5), 1090. https://doi.org/10.3390/ma18051090