Mechanical and Microstructural Performance of UHPC with Recycled Aggregates Modified by Basalt Fiber and Nanoalumina at High Temperatures

Abstract

1. Introduction

2. Methodology

2.1. Material Selection

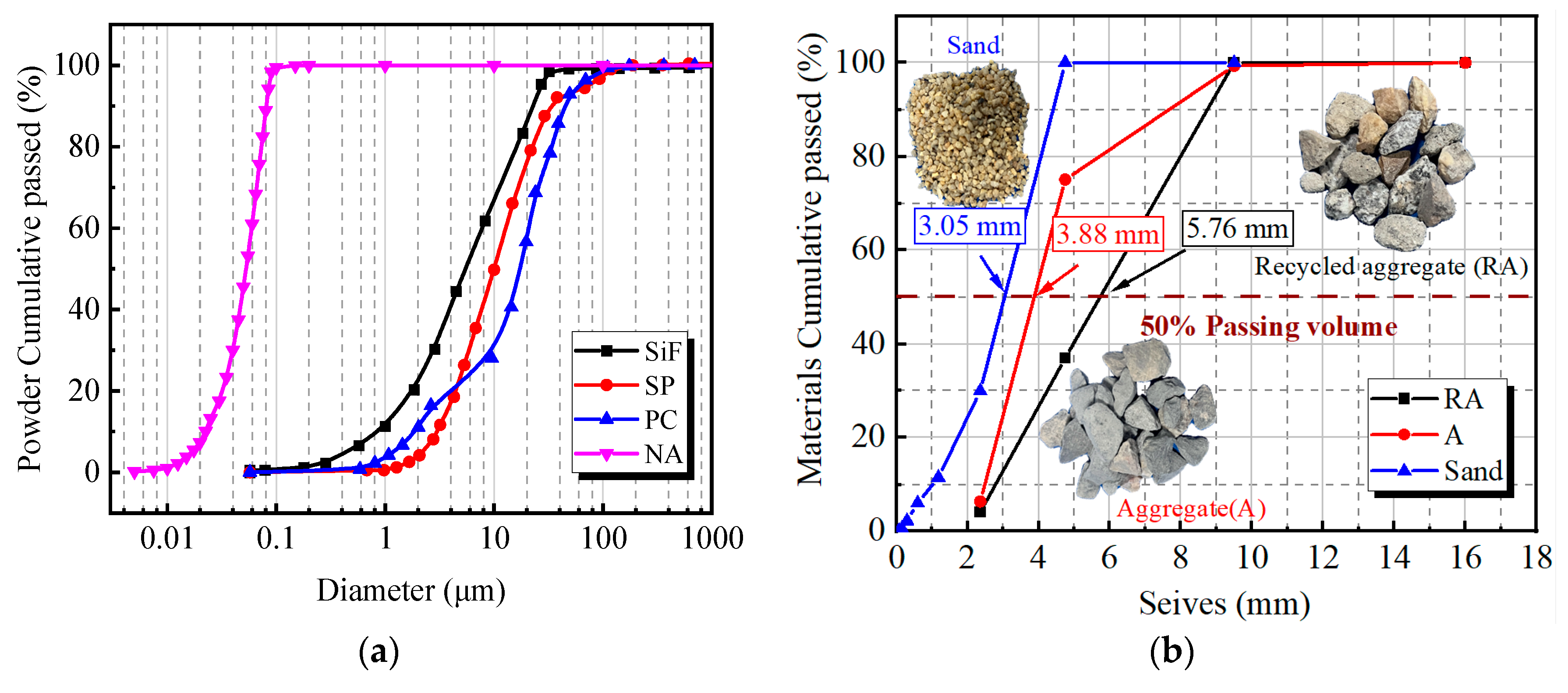

- Powder binders: These include silica fume (SiF), slag powder (SP), Portland cement (PC), and nanoalumina (NA). PC serves as the primary binder, filling millimeter-scale gaps between aggregates. Micron-scale particles (SiF and SP) fill the gaps between micro-level particles, and nano-scale particles (NA) further enhance the packing density. This combination of materials optimizes the packing density of the concrete mix.

- Aggregate fillers: These consist of fine aggregates (natural river sand), coarse aggregates (natural aggregates, A), and recycled aggregates (RAs).

- Fiber reinforcement: Basalt fiber (BF) is used to enhance the mechanical performance of the concrete.

- (1)

- Cement and Additives

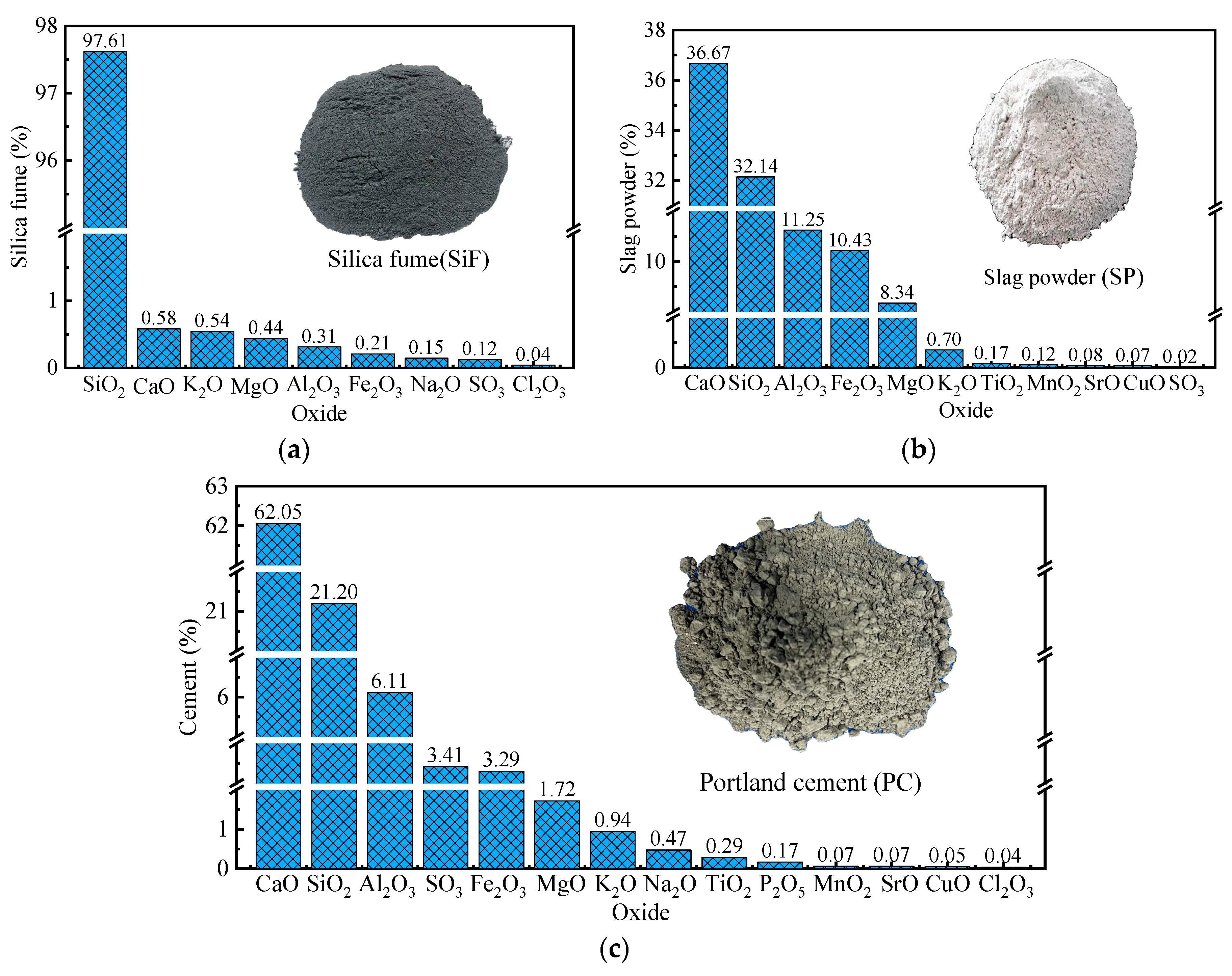

- Silica Fume (SiF): Silica fume is sourced from Changsha, Hunan Province, and serves as a supplementary material for pozzolanic reactions. It fills voids between cement particles, enhancing early strength and durability. The SiO2 content is 98% by mass, and the chemical composition is shown in Figure 1a.

- Slag Powder (SP): SP is finely ground blast furnace slag with a specific surface area of 4360 cm2/g and a 28-day activity index of 95%. It improves the workability of concrete. Its primary chemical composition is depicted in Figure 1b.

- Cement (PC): The cement used in this study is a Type II 52.5-grade Portland cement with chemical compositions as shown in Figure 1c. It contains 62.05% CaO and 21.2% SiO2, with a Blaine specific surface area of 3580 cm2/g and an average particle size of 15.3 μm.

- (2)

- Aggregates

- Fine Aggregate: The fine aggregate used is natural river sand, with a particle size range of 0–3.6 mm.

- Coarse Aggregate: The coarse aggregates consist of natural basalt gravel (A) with a size range of 5–16 mm and recycled aggregate (RA) with the same particle size range, sourced from crushed original C50 concrete specimens. The basic properties of A and RA are shown in Table 2. Figure 2b illustrates the irregular edges, minute pores, and old cement mortar on the RA, indicating inherent damage and defects. The particle size distribution of fine and coarse aggregates is shown in Figure 2b, where the materials’ average particle size is comparable at the 50% passing rate, suggesting that the mixture will achieve dense packing. Before mixing, the RA undergoes a series of pre-treatment measures to ensure it reaches an optimal condition. Firstly, the RA is cleaned using high-pressure water to remove surface-attached cement paste and impurities, followed by mechanical screening to eliminate any oversized or non-compliant particles. Next, the RA is soaked in water for 24 h to reduce its water absorption rate, preventing any negative impact on the water-to-cement ratio of the concrete. Finally, the soaked RA is air-dried to achieve a Saturated-Surface-Dry (SSD) condition, ensuring no excess surface moisture while maintaining internal water saturation. This pre-treatment process effectively reduces water absorption and residual cement paste issues in RA, thereby preventing any adverse effects on the strength and durability of the concrete.

| Parameter | Specific Gravity (kg/m3) | Elongation Particle (%) | Flatness Particle (%) | Water Absorption (%) | Aggregate Impact Value (AIV) | Abrasion Loss (%) (LA) |

|---|---|---|---|---|---|---|

| Standard methods | BS812, Part 2 [34] | ASTM D4791 [35] | ASTM D4791 [35] | BS812, Part 2 [34] | BS812, Part 112 [36] | ASTM C131 [37] |

| A | 2650 | 10 | 25 | 0.7 | 12 | 20 |

| RA | 2380 | 16 | 17 | 1.90 | 20 | 45 |

- (3)

- Basalt Fiber

- (4)

- Nanoalumina

2.2. Experimental Design and Grouping

2.3. Sample Preparation

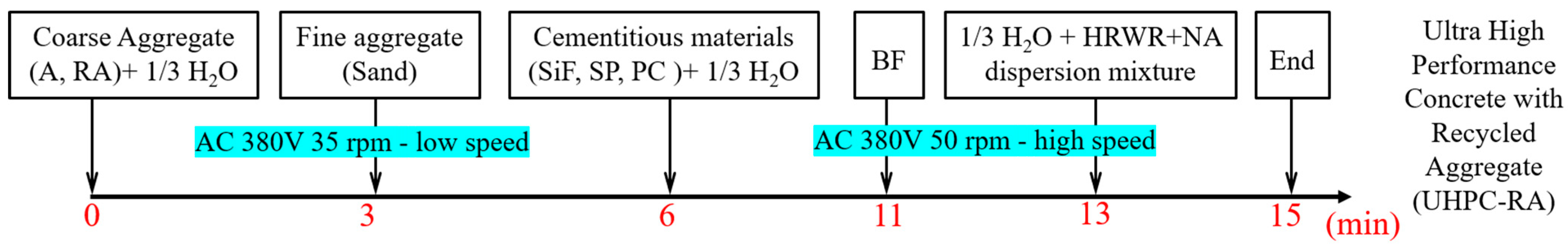

- At low speed, coarse aggregates and one-third of the water are added (0–3 min). Sand is then added, and mixing continues (3–6 min).

- The remaining powder binders and the other third of the water are added (6–11 min).

- The mixer is adjusted to high speed (50 rpm), and BF is gradually added (11–13 min), followed by the high-performance water reducer and the last third of the water (13–15 min). The mixing continues until the mixture is homogeneous.

- The fresh mixture is poured into molds and compacted on a vibration table to eliminate air bubbles. After 24 h, the specimens are demolded and cured in a curing chamber at 20 ± 2 °C and 90–95% relative humidity for 28 days.

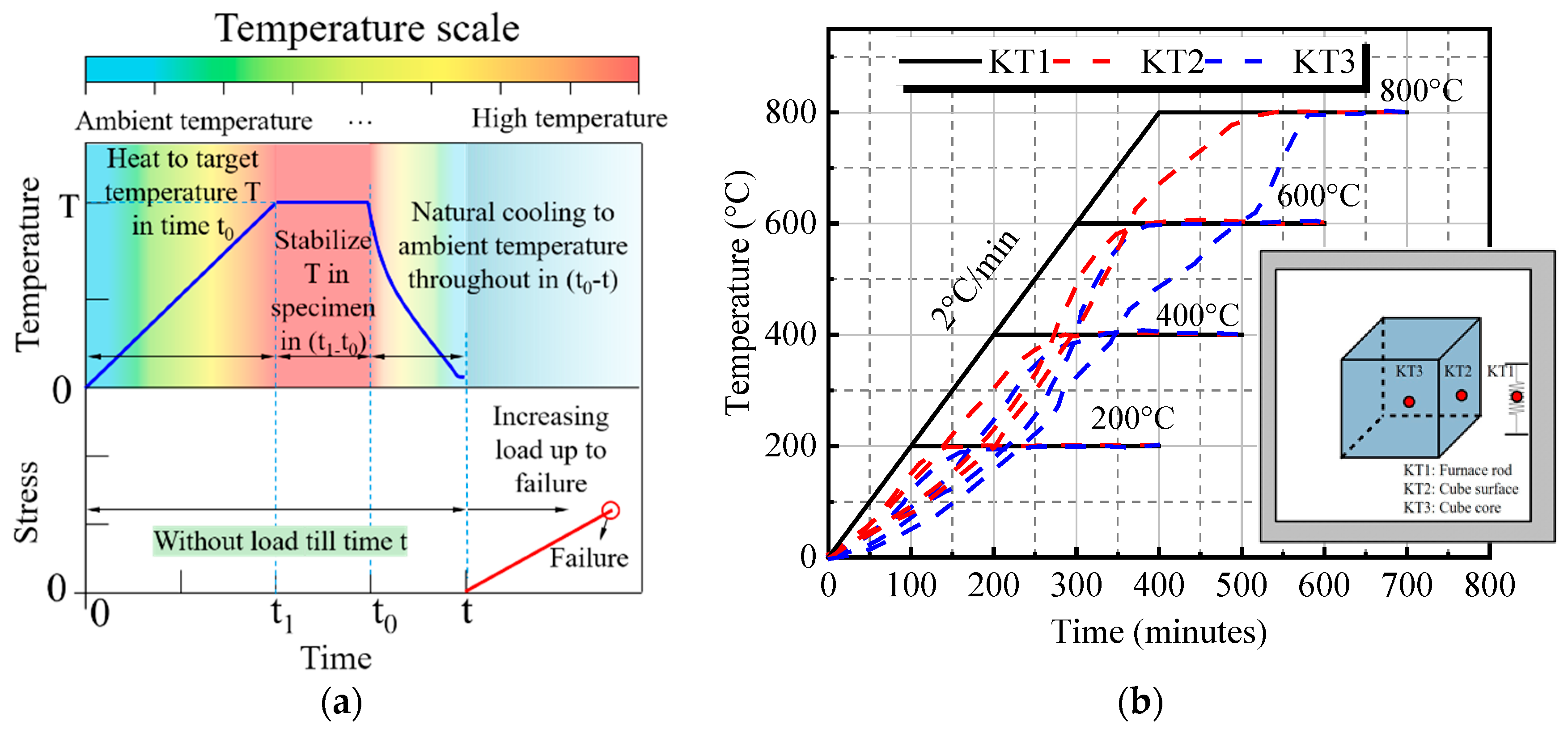

2.4. High-Temperature Exposure Test

2.5. Mechanical Property Testing Methods

- (1)

- Compressive Strength and Splitting Tensile Strength

- (2)

- Elastic Modulus

2.6. Microstructure Analysis: Scanning Electron Microscope (SEM)

2.7. Application of DIC Technology

- (1)

- Principle of DIC Technology

- (2)

- Application to Concrete Mechanical Performance Testing

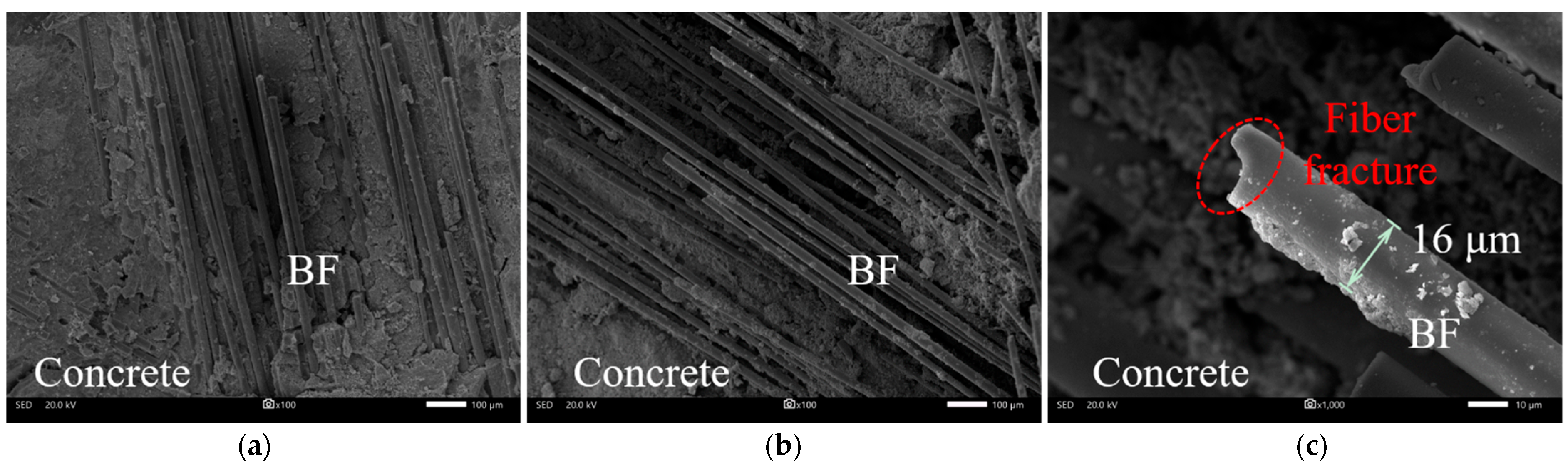

3. Results and Discussion

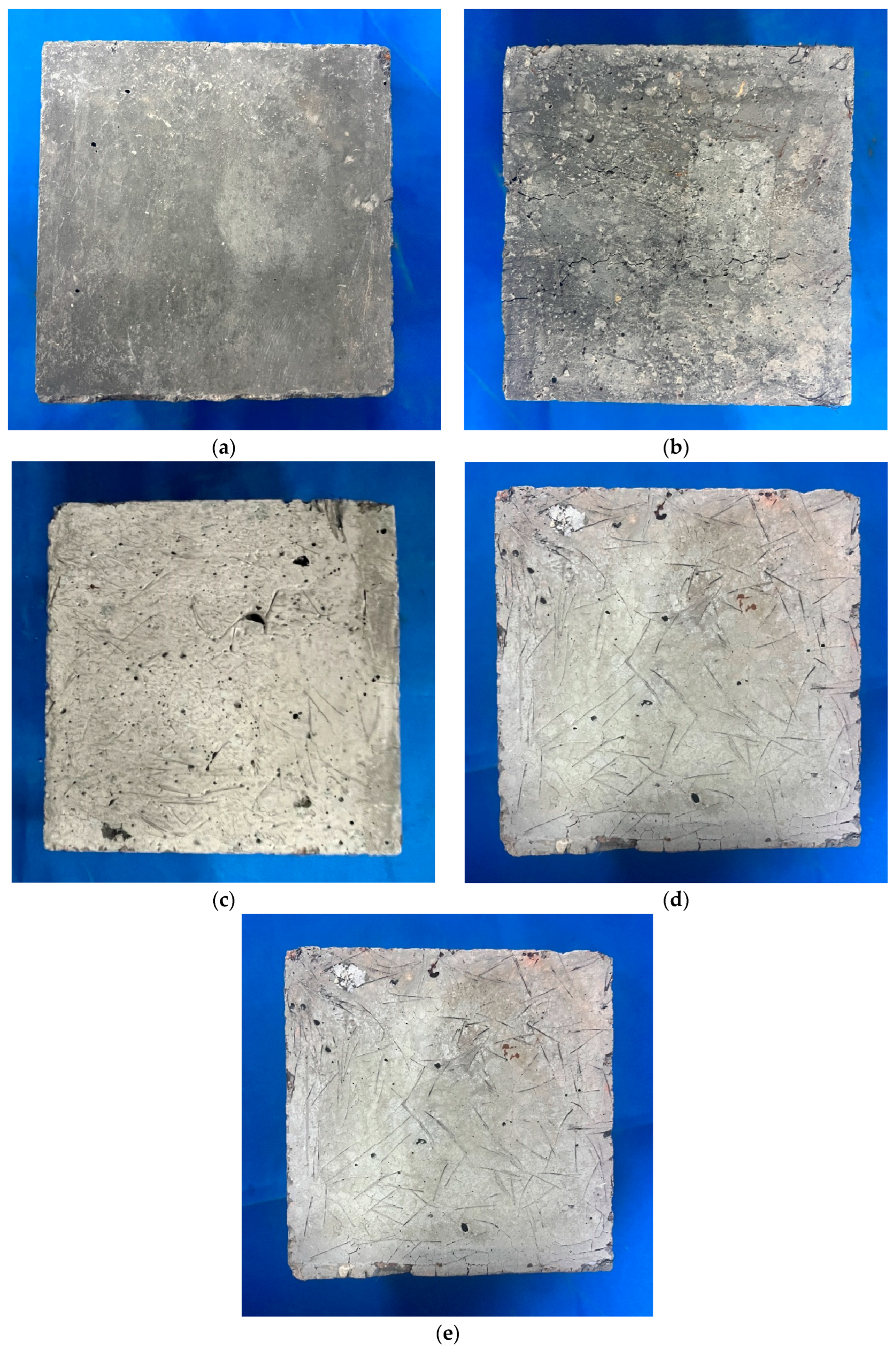

3.1. Visual Inspection and Mass Loss

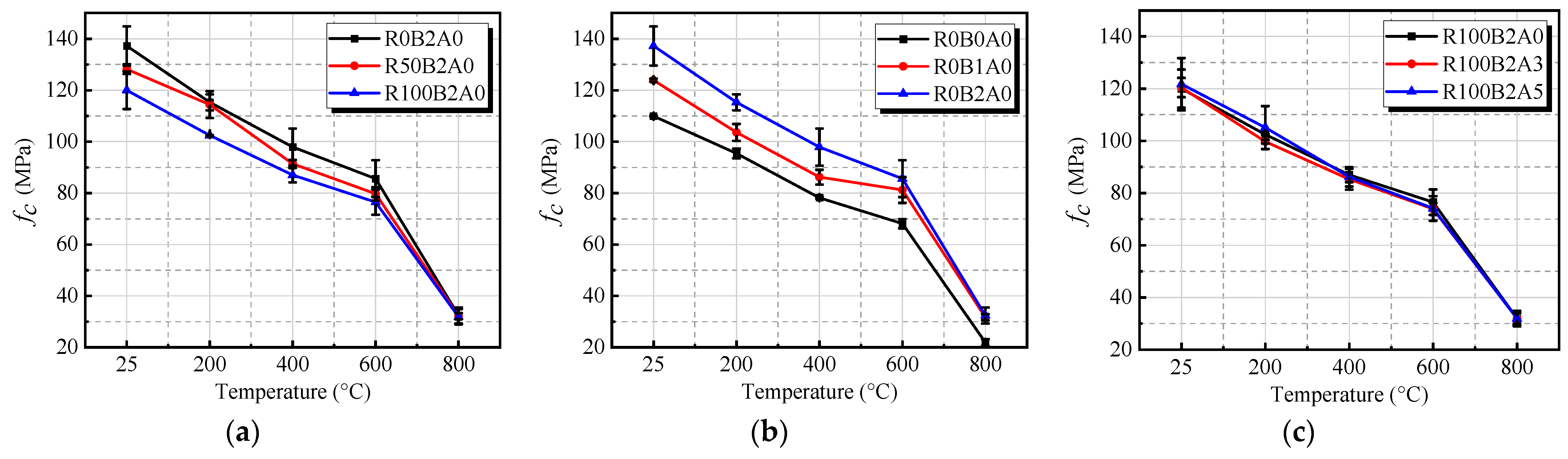

3.2. Compressive Strength at High Temperatures

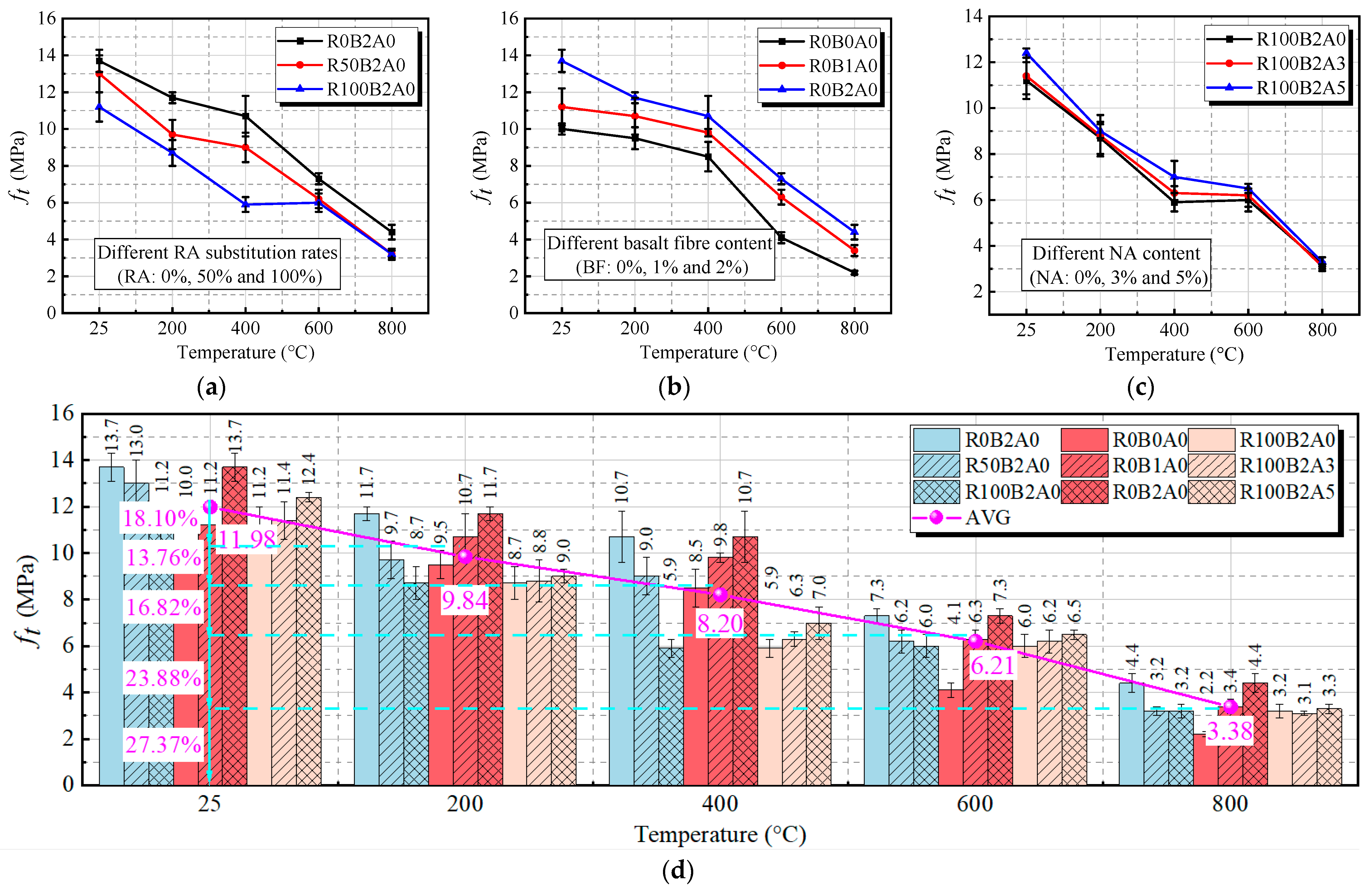

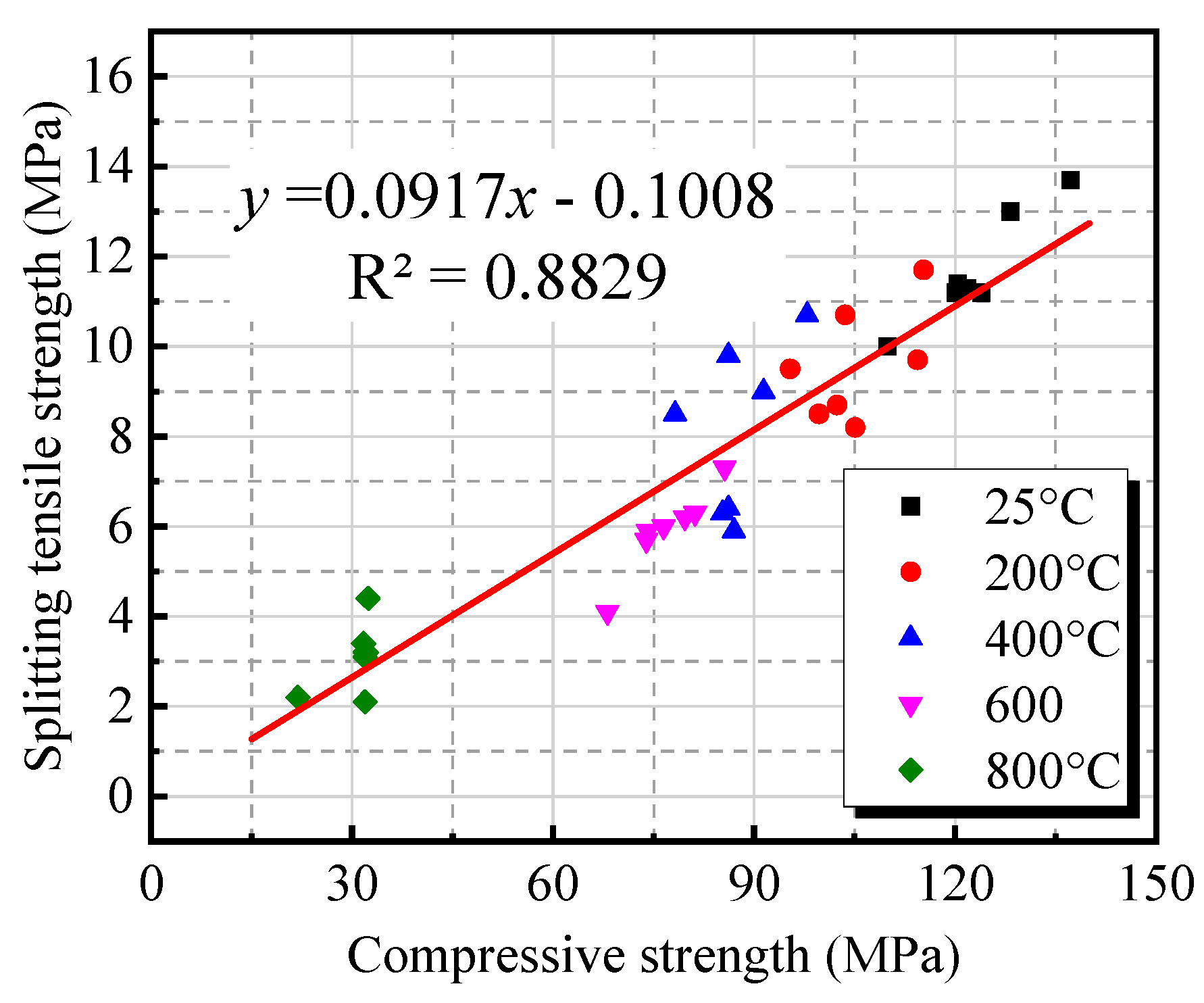

3.3. Splitting Tensile Strength at High Temperatures

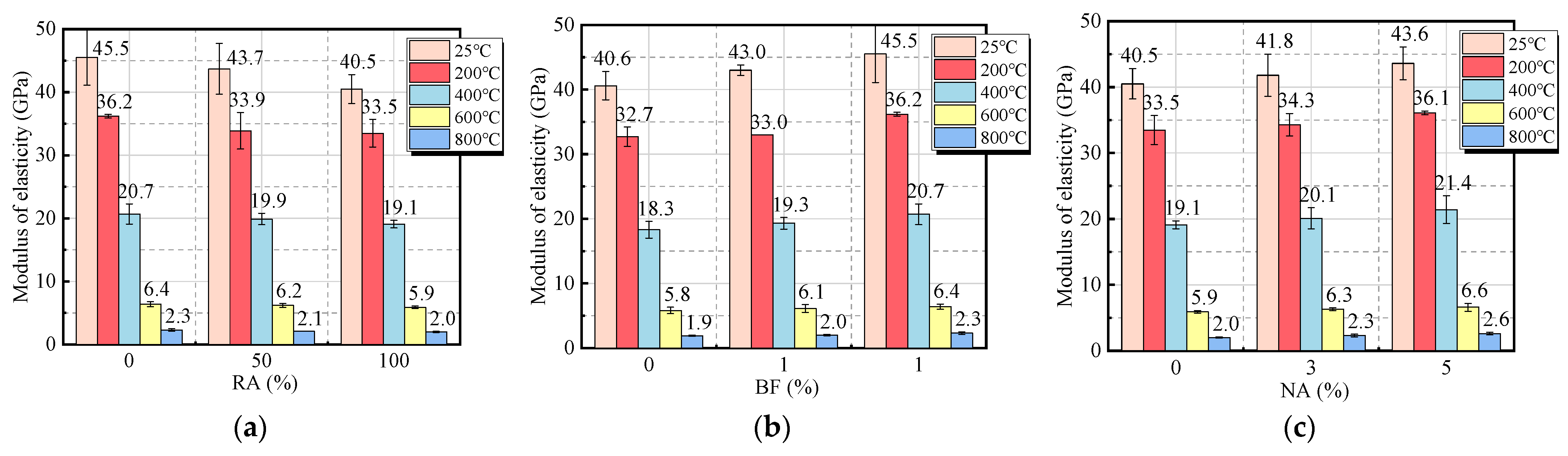

3.4. Elastic Modulus

3.5. Comprehensive Evaluation of Mechanical Performance

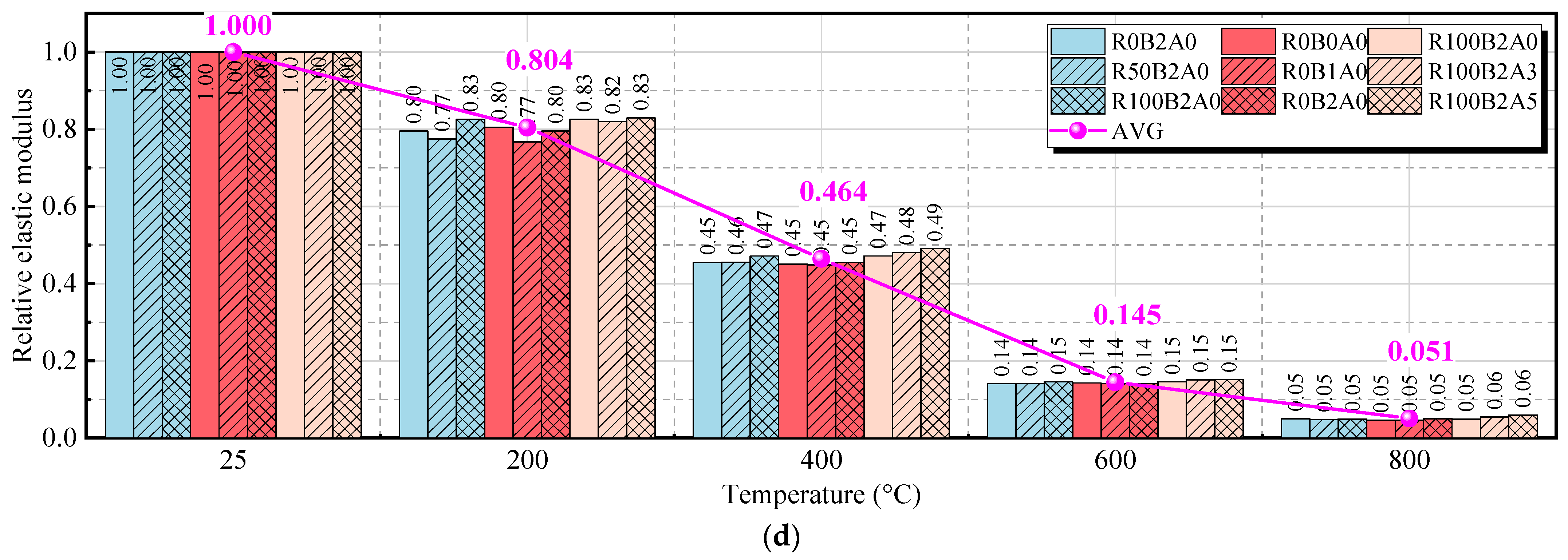

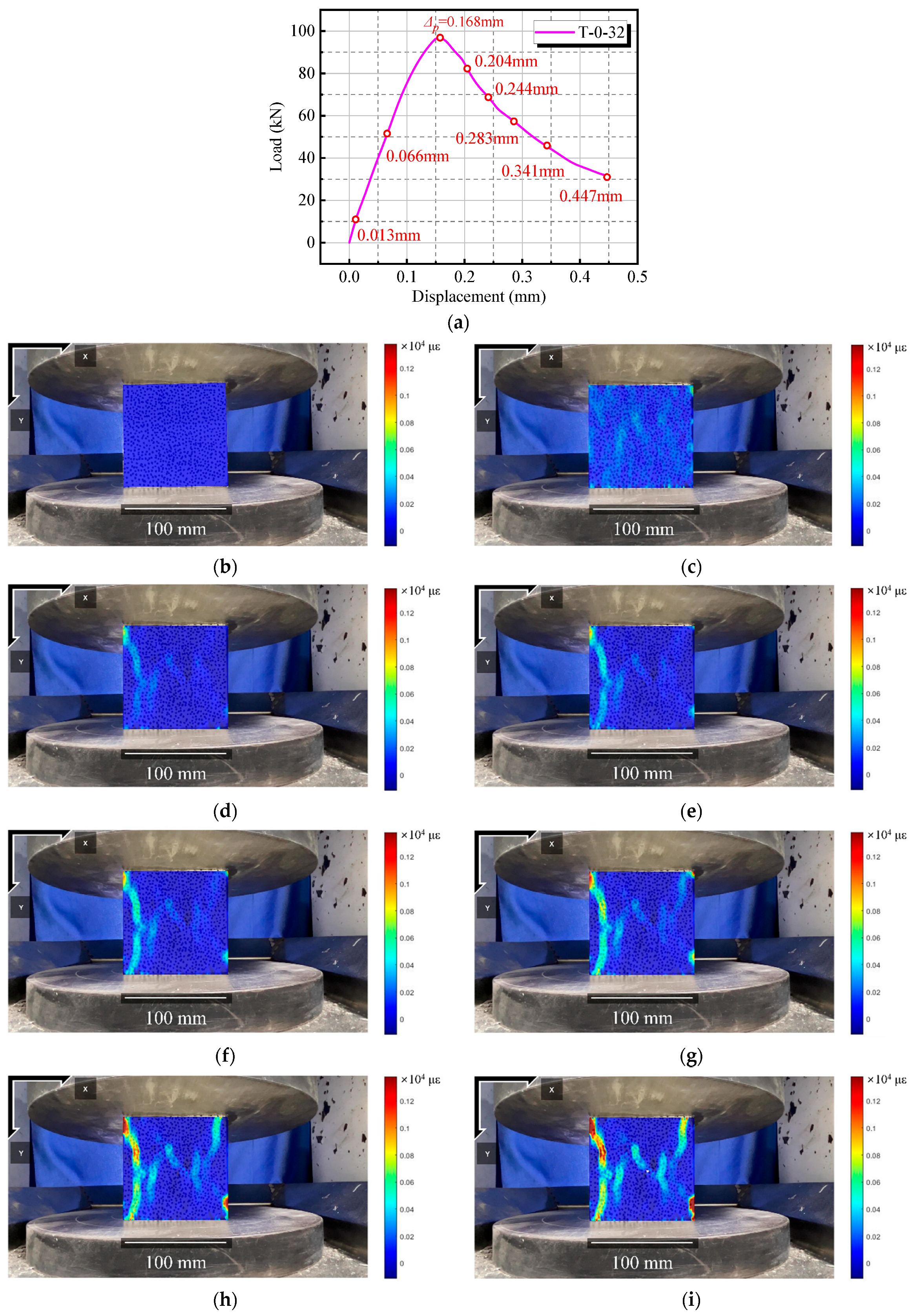

3.6. DIC Measurement Results

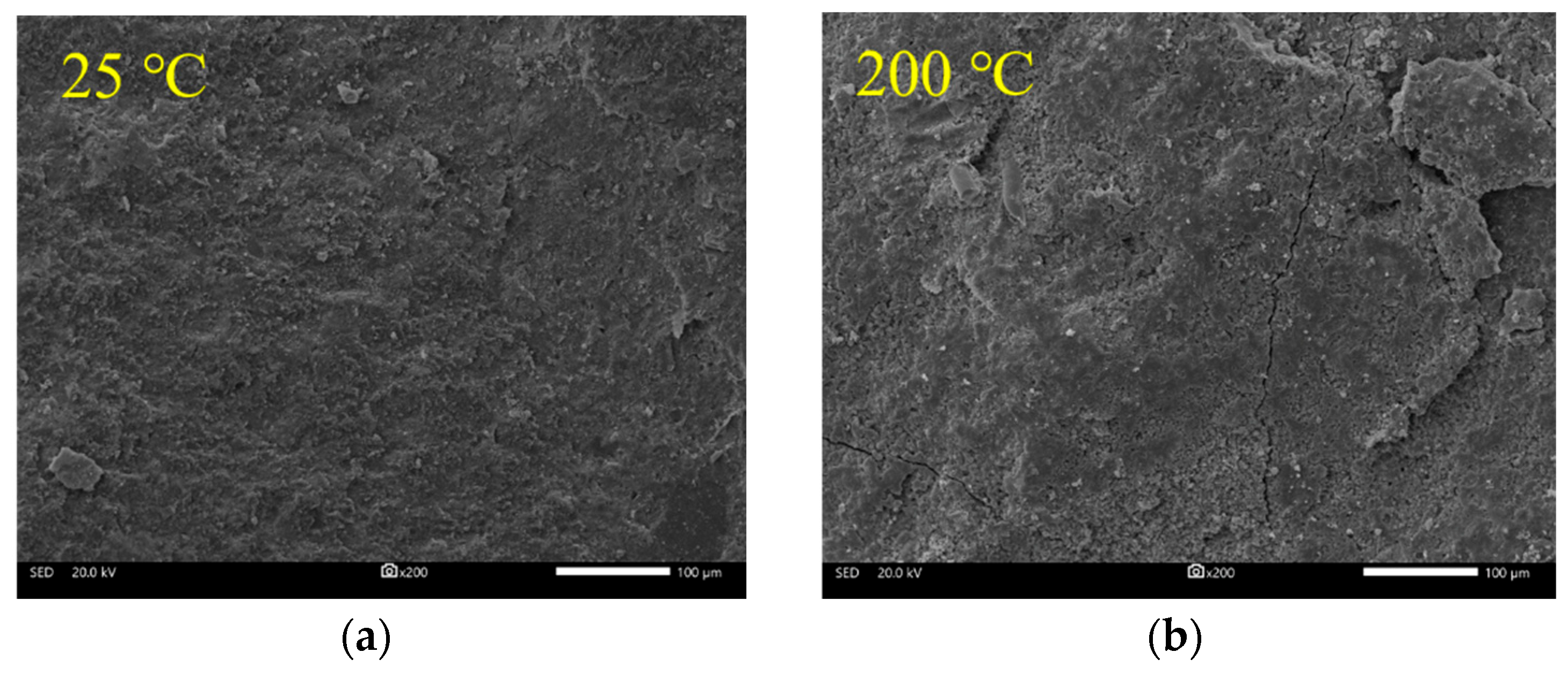

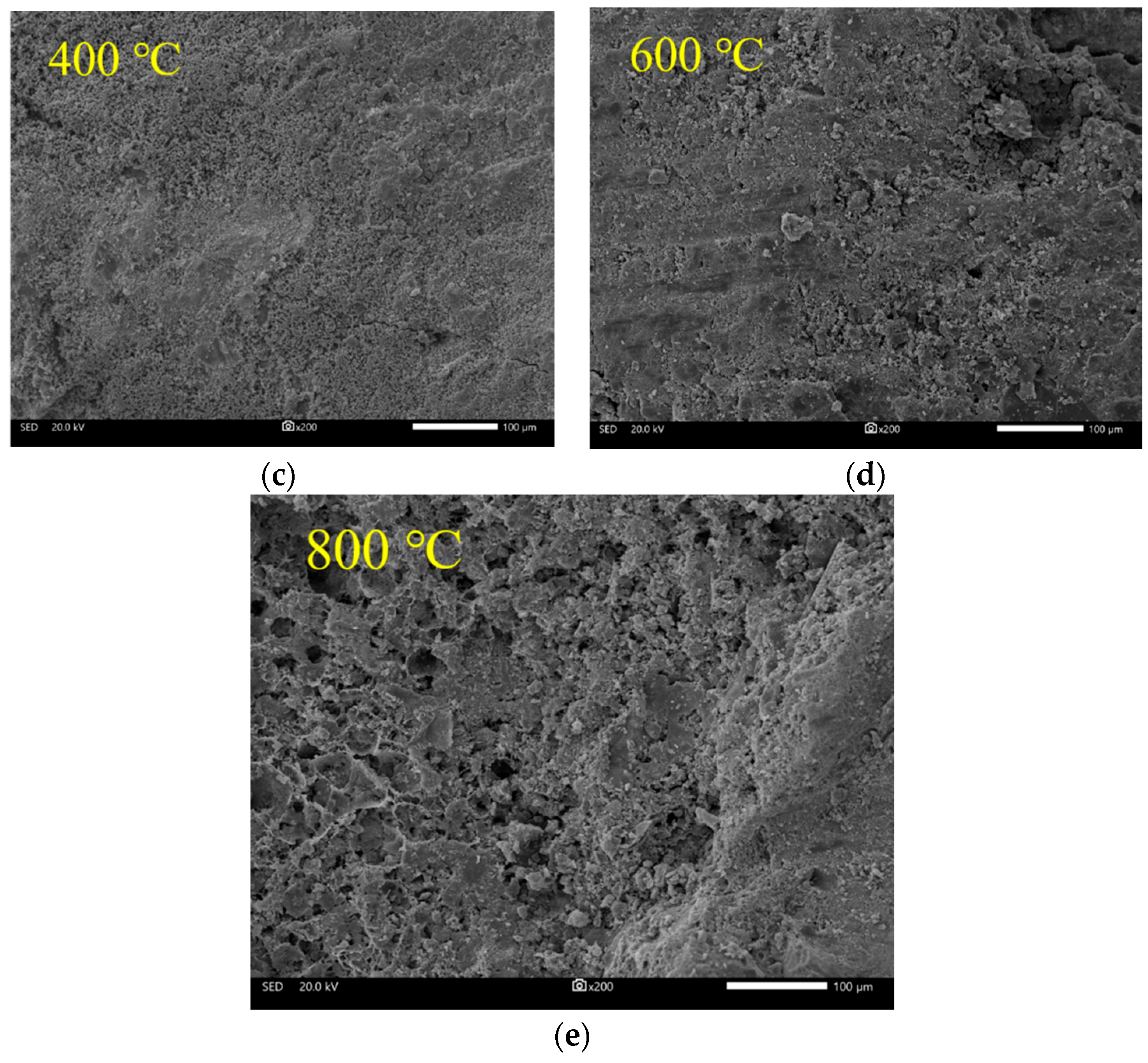

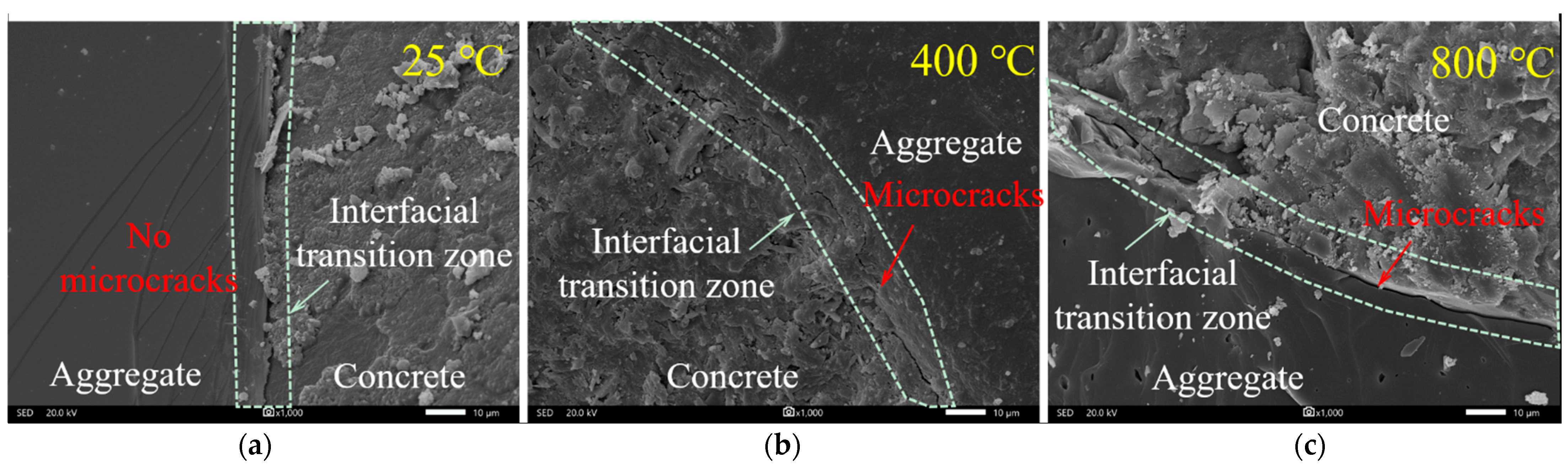

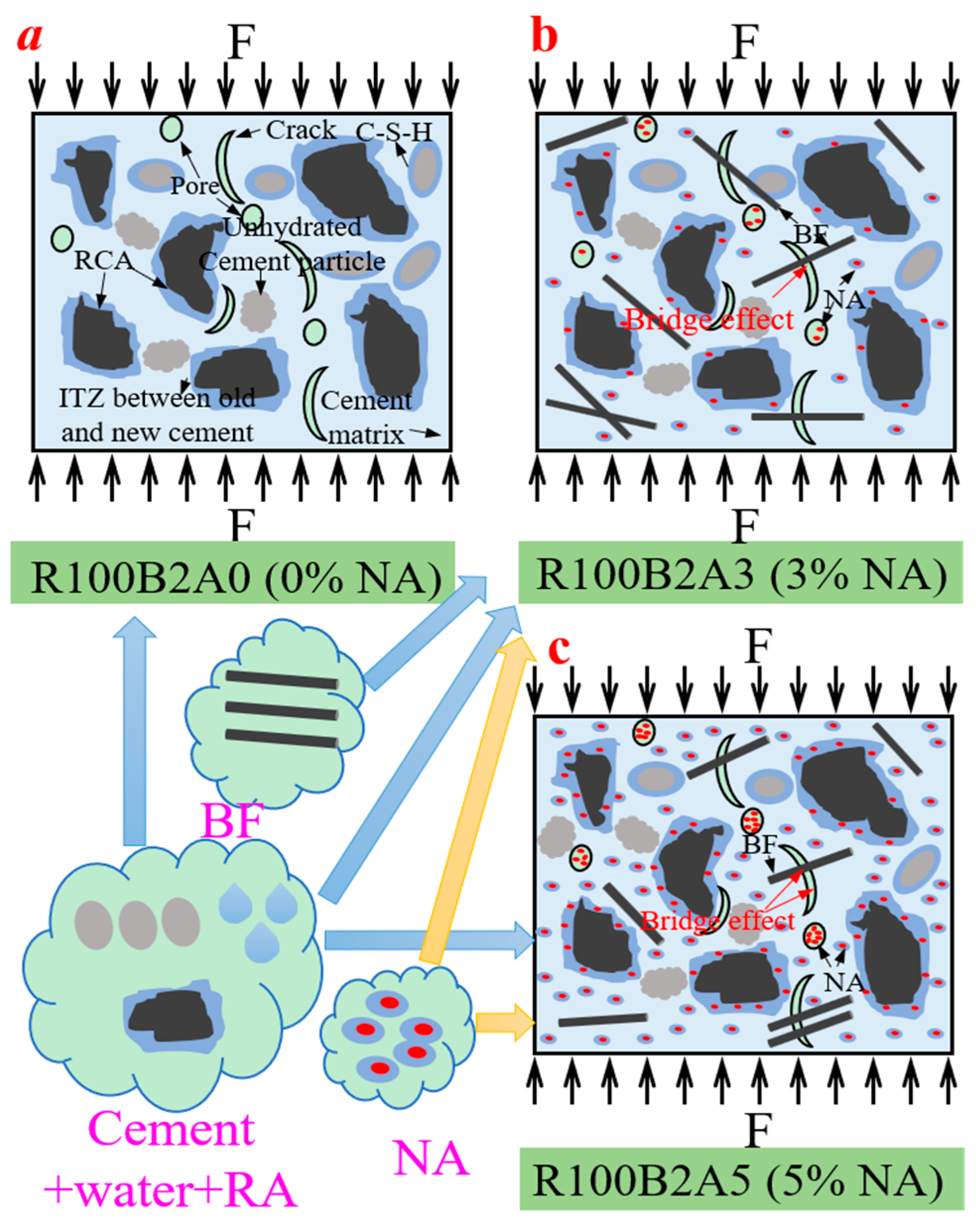

3.7. SEM Analysis

- (1)

- Microstructure of the Cement Matrix

- (2)

- Cement and Additives

- (3)

- Cement and Additives

3.8. Mechanism Analysis

4. Conclusions

4.1. Research Conclusions

- Under high-temperature exposure, UHPC-RA concrete-containing BF and RA exhibited significant changes in appearance. As the temperature increased, the surface color of the specimens gradually lightened, cracks increased, and peeling occurred, especially at 800 °C, where cracks became more prominent. The incorporation of BF effectively suppressed crack propagation, particularly at higher temperatures. Specimens with a higher BF content demonstrated better crack resistance, with the initial cracking temperature being lower, thereby enhancing the high-temperature integrity of the concrete. Additionally, the mass loss rate significantly increased under high temperatures, but the incorporation of BF and NA effectively slowed mass loss, showing better thermal stability.

- The compressive strength, splitting tensile strength, and elastic modulus of the specimens all showed a decreasing trend as the temperature increased. Notably, compressive strength decreased significantly above 600 °C. However, the inclusion of BF effectively enhanced the compressive strength at high temperatures. At 800 °C, the compressive strength increased by 44.8% to 47.9% compared to specimens without BF. While NA particles had a limited effect on compressive strength improvement, they contributed to the enhancement of splitting tensile strength, particularly at 400 °C, where they significantly increased the splitting tensile strength of the concrete.

- The relative comprehensive performance (RCP) parameter was used to quantify the effect of different mix ratios on the overall performance of UHPC-RA and the temperature-induced decline in mechanical properties. The results indicated that as the temperature increased, the comprehensive mechanical performance of the specimens gradually decreased, with the RCP value reaching its lowest at 800 °C, indicating that high temperature had a significant impact on the mechanical properties of the concrete. Proper amounts of BF and NA could effectively improve the material’s overall performance, with the synergistic effect of BF and NA significantly improving the mechanical properties of concrete under high-temperature conditions.

- DIC technology was used to monitor strain and crack development in concrete during loading. The results showed that at room temperature, strain distribution was uniform, and crack propagation was slow. However, at high temperatures, crack propagation accelerated, and strain concentration areas became significantly larger, indicating that high temperature aggravated concrete damage. At 800 °C, cracks penetrated the entire specimen, with severe damage.

- SEM analysis revealed that with increasing temperature, the cementitious matrix transitioned from a dense structure to a porous one, with an increase in porosity and decomposition of hydration products, leading to a decline in mechanical properties. The bridging effect of BFs significantly enhanced the crack resistance of concrete, particularly at high temperatures, where BFs effectively limited crack propagation and reduced high-temperature damage. NA particles improved the high-temperature resistance of concrete by filling voids and enhancing the densification of the interfacial transition zone (ITZ), with the synergistic effect of NA and BF significantly improving the mechanical properties and thermal stability of the material.

4.2. Limitations and Suggestions for Future Research

- The coupling mechanism between microstructure and mechanical properties could be further explored using advanced micro-characterization techniques such as X-ray micro-CT and SEM. This would allow for a deeper understanding of the interactions and synergistic effects of RA, BF, and NA particles at the micro-scale, and their collaborative repair mechanisms. Special attention should be given to the impact of these materials on the cement matrix, ITZ, and fiber–matrix interface transition zones under high-temperature conditions, revealing their specific mechanisms in improving mechanical properties.

- Long-term performance evaluation under high-temperature exposure should be conducted. Future research should investigate the performance changes in UHPC-RA under prolonged high-temperature exposure, particularly the effects of long-term exposure on mechanical properties, durability, fatigue performance, and crack propagation behavior.

- Research on the repair and modification of RAs should be undertaken to explore methods such as surface treatment, chemical modification, or the addition of functional fillers to improve the bond strength between RA and the cement matrix, and overall performance. In particular, modifying RA to improve its thermal stability and crack resistance under high-temperature conditions could enhance its performance in high-temperature environments.

- Future studies could focus on the sustainability of UHPC-RA, assessing its environmental impact throughout the life cycle. Research should also investigate the balance between material cost and performance to achieve cost-effective mix designs, leading to more sustainable and economically viable building material solutions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbols | Content |

| AE | Acoustic emission |

| BF | Basalt fiber |

| CP | Comprehensive mechanical performance |

| DIC | Digital image correlation |

| E | Elastic modulus |

| fc | Compressive strength |

| FRC | Fiber-reinforced concrete |

| ft | Splitting tensile strength |

| HPWR | High-performance water reducer |

| ITZ | Interfacial transition zone |

| NA | Nano alumina |

| NDE | Non-destructive evaluation |

| PC | Portland cement |

| RA | Recycled aggregates |

| RAC | Recycled aggregate concrete |

| RCP | Relative comprehensive performance |

| SCHSC | Self-compacting high-strength concrete |

| SCHSFRC | Self-compacting high-strength fiber-reinforced concrete |

| SEM | Scanning electron microscopy |

| SFRC | Steel fiber-reinforced concrete |

| SiF | Silica fume |

| SP | Slag powder |

| SSD | Saturated-surface-dry |

| UHPC | Ultra-high-performance concrete |

| UHPC-RA | Ultra-high-performance concrete with recycled aggregates |

| UPV | Ultrasonic pulse velocity |

| UTM | Universal testing machine |

| wc | Weight coefficient for compressive strength |

| wE | Weight coefficient for elastic modulus |

| wt | Weight coefficient for splitting tensile strength |

| XRD | X-ray diffraction |

References

- Feng, C.; Cui, B.; Huang, Y.; Guo, H.; Zhang, W.; Zhu, J. Enhancement technologies of recycled aggregate–Enhancement mechanism, influencing factors, improvement effects, technical difficulties, life cycle assessment. Constr. Build. Mater. 2022, 317, 126168. [Google Scholar] [CrossRef]

- Liang, C.; Pan, B.; Ma, Z.; He, Z.; Duan, Z. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Sollero, M.; Junior, A.M.; Costa, C. Residual mechanical strength of concrete exposed to high temperatures–international standardization and influence of coarse aggregates. Constr. Build. Mater. 2021, 287, 122843. [Google Scholar] [CrossRef]

- Sun, H.; Luo, L.; Li, X.; Yuan, H. The treated recycled aggregates effects on workability, mechanical properties and microstructure of ultra-high performance concrete Co-reinforced with nano-silica and steel fibers. J. Build. Eng. 2024, 86, 108804. [Google Scholar] [CrossRef]

- Sun, H.; Luo, L.; Yuan, H.; Li, X. Experimental evaluation of mechanical properties and microstructure for recycled aggregate concrete collaboratively modified with nano-silica and mixed fibers. Constr. Build. Mater. 2023, 403, 133125. [Google Scholar] [CrossRef]

- Alaskar, A.; Albidah, A.; Alqarni, A.S.; Alyousef, R.; Mohammadhosseini, H. Performance evaluation of high-strength concrete reinforced with basalt fibers exposed to elevated temperatures. J. Build. Eng. 2021, 35, 102108. [Google Scholar] [CrossRef]

- Luo, L.; Shi, J.; Wang, J.; Qu, Y.; Dai, B. Experimental study on flexural performance of ultra-high-performance concrete with recycled aggregate co-modified by nano-silica and steel fiber. Constr. Build. Mater. 2024, 411, 134417. [Google Scholar] [CrossRef]

- Luo, L.; Jia, M.; Cheng, X. Experimental study and analytical modeling of tensile performance of ultra-high-performance concrete incorporating modified recycled aggregates. J. Clean. Prod. 2024, 468, 143123. [Google Scholar] [CrossRef]

- Luo, L.; Sun, H.; Jia, M.; Peng, B.; Li, X.; Yuan, H.; Liu, G. Experimental study and theoretical prediction of axial compression behavior in PMC-reinforced CFST columns with void defects. Eng. Struct. 2024, 313, 118258. [Google Scholar] [CrossRef]

- Dong, E.; Fu, S.; Wu, C.; Lv, W.; Zhang, L.; Feng, Y.; Shui, Z.; Yu, R. Value-added utilization of phosphogypsum industrial by-products in producing green Ultra-High performance Concrete: Detailed reaction kinetics and microstructure evolution mechanism. Constr. Build. Mater. 2023, 389, 131726. [Google Scholar] [CrossRef]

- Tang, Y.; Feng, W.; Feng, W.; Chen, J.; Bao, D.; Li, L. Compressive properties of rubber-modified recycled aggregate concrete subjected to elevated temperatures. Constr. Build. Mater. 2021, 268, 121181. [Google Scholar] [CrossRef]

- He, Z.-H.; Shen, M.-L.; Shi, J.-Y.; Yalçınkaya, Ç.; Du, S.-G.; Yuan, Q. Recycling coral waste into eco-friendly UHPC: Mechanical strength, microstructure, and environmental benefits. Sci. Total Environ. 2022, 836, 155424. [Google Scholar] [CrossRef]

- Zaid, O.; Althoey, F.; Abuhussain, M.A.; Alashker, Y. Spalling behavior and performance of ultra-high-performance concrete subjected to elevated temperature: A review. Constr. Build. Mater. 2024, 411, 134489. [Google Scholar]

- Yuan, J.; Luo, L.; Zheng, Y.; Yu, S.; Shi, J.; Wang, J.; Shen, J. Analysis of the working performance of large curvature prestressed concrete box girder bridges. Materials 2022, 15, 5414. [Google Scholar] [CrossRef]

- Xargay, H.; Folino, P.; Nuñez, N.; Gómez, M.; Caggiano, A.; Martinelli, E. Acoustic emission behavior of thermally damaged self-compacting high strength fiber reinforced concrete. Constr. Build. Mater. 2018, 187, 519–530. [Google Scholar] [CrossRef]

- Mpalaskas, A.C.; Kytinou, V.K.; Zapris, A.G.; Matikas, T.E. Optimizing building rehabilitation through nondestructive evaluation of fire-damaged steel-fiber-reinforced concrete. Sensors 2024, 24, 5668. [Google Scholar] [CrossRef]

- Huang, K.; Xie, J.; Feng, Y.; Wang, R.; Ji, J. Axial impact behaviors of UHPC: The roles of nanomaterials and steel fibres. Constr. Build. Mater. 2023, 384, 131396. [Google Scholar] [CrossRef]

- Mostafa, S.A.; Faried, A.S.; Farghali, A.A.; El-Deeb, M.M.; Tawfik, T.A.; Majer, S.; Abd Elrahman, M. Influence of nanoparticles from waste materials on mechanical properties, durability and microstructure of UHPC. Materials 2020, 13, 4530. [Google Scholar] [CrossRef]

- Alvi, I.H.; Li, Q.; Hou, Y.; Onyekwena, C.C.; Zhang, M.; Ghaffar, A. A critical review of cement composites containing recycled aggregates with graphene oxide nanomaterials. J. Build. Eng. 2023, 69, 105989. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Y.; Zhuo, J.; Zhang, Y.; Wan, C. A review of the mechanical properties and durability of basalt fiber-reinforced concrete. Constr. Build. Mater. 2022, 359, 129360. [Google Scholar] [CrossRef]

- Iskra-Kozak, W.; Konkol, J. The impact of nano-Al2O3 on the physical and strength properties as well as on the morphology of cement composite crack surfaces in the early and later maturation age. Materials 2021, 14, 4441. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.; Jia, M.; Wang, H.; Cheng, X. Experimental evaluation and microscopic analysis of the sustainable ultra-high-performance concrete after exposure to high temperatures. Struct. Concr. 2025, 26, 1–29. [Google Scholar] [CrossRef]

- Liu, H.; Yang, J.; Wang, X. Bond behavior between BFRP bar and recycled aggregate concrete reinforced with basalt fiber. Constr. Build. Mater. 2017, 135, 477–483. [Google Scholar] [CrossRef]

- Bastami, M.; Baghbadrani, M.; Aslani, F. Performance of nano-Silica modified high strength concrete at elevated temperatures. Constr. Build. Mater. 2014, 68, 402–408. [Google Scholar] [CrossRef]

- Muzenski, S.; Flores-Vivian, I.; Sobolev, K. Ultra-high strength cement-based composites designed with aluminum oxide nano-fibers. Constr. Build. Mater. 2019, 220, 177–186. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Thermal and residual mechanical profile of recycled aggregate concrete prepared with carbonated concrete aggregates after exposure to elevated temperatures. Fire Mater. 2018, 42, 134–142. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Zhao, X.-Y. Residual mechanical properties of compound concrete containing demolished concrete lumps after exposure to high temperatures. Fire Saf. J. 2019, 105, 62–78. [Google Scholar] [CrossRef]

- Wu, B.; Yu, Y.; Chen, Z.; Zhao, X. Shape effect on compressive mechanical properties of compound concrete containing demolished concrete lumps. Constr. Build. Mater. 2018, 187, 50–64. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Y.; Liu, F. Stress–strain relationship of coarse RCA concrete exposed to elevated temperatures. Mag. Concr. Res. 2017, 69, 649–664. [Google Scholar] [CrossRef]

- Priyadharshini, P.; Ramamurthy, K.; Robinson, R. Influence of temperature and duration of thermal treatment on properties of excavated soil as fine aggregate in cement mortar. J. Mater. Civ. Eng. 2019, 31, 04019137. [Google Scholar] [CrossRef]

- Khan, A.-U.-R.; Aziz, T.; Fareed, S.; Xiao, J. Behaviour and residual strength prediction of recycled aggregates concrete exposed to elevated temperatures. Arab. J. Sci. Eng. 2020, 45, 8241–8253. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, C.; Li, Y.; Chen, J.; Wu, B. Study on the mechanical properties of recycled concrete after high temperature. J. Archit. Struct. 2017, 38, 9. [Google Scholar]

- Algourdin, N.; Pliya, P.; Beaucour, A.; Noumowé, A.; Di Coste, D. Effect of fine and coarse recycled aggregates on high-temperature behaviour and residual properties of concrete. Constr. Build. Mater. 2022, 341, 127847. [Google Scholar] [CrossRef]

- Woodward, D. Chapter 24: Aggregate properties and test methods. In ICE Manual of Construction Materials: Volume I: Fundamentals and Theory Concrete; Asphalts in Road Construction; Masonry; Thomas Telford Ltd.: London, UK, 2009; pp. 273–284. [Google Scholar]

- ASTM D4791; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. ASTM International West Conshohocken: West Concord, PA, USA, 2010.

- 812-105.2-1990; Testing Aggregates—Part 112, Methods for Determination of Aggregate Impact Value. British Standards Institution: London, UK, 1990.

- American Society for Testing and Materials. Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; American Society for Testing and Materials: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Mohammed, A.A.; Khodair, Z.T.; Khadom, A.A. Preparation and investigation of the structural properties of α-Al2O3 nanoparticles using the sol-gel method. Chem. Data Collect. 2020, 29, 100531. [Google Scholar] [CrossRef]

- Zhu, Y.; Hussein, H.; Kumar, A.; Chen, G. A review: Material and structural properties of UHPC at elevated temperatures or fire conditions. Cem. Concr. Compos. 2021, 123, 104212. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Ríos, J.D.; Martínez-De La Concha, A.; Cifuentes, H.; Jiménez, J.R.; Fernández, J.M. Effect of moderate temperatures on compressive strength of ultra-high-performance concrete: A microstructural analysis. Cem. Concr. Res. 2021, 140, 106303. [Google Scholar] [CrossRef]

- Zheng, W.; Li, H.; Wang, Y. Compressive behaviour of hybrid fiber-reinforced reactive powder concrete after high temperature. Mater. Des. 2012, 41, 403–409. [Google Scholar] [CrossRef]

- Wang, Y.; Li, S.; Hughes, P.; Fan, Y. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar]

- GB/T 50081-2019; Test Method for Physical and Mechanical Properties of Concrete. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- Pliya, P.; Hajiloo, H.; Romagnosi, S.; Cree, D.; Sarhat, S.; Green, M. The compressive behaviour of natural and recycled aggregate concrete during and after exposure to elevated temperatures. J. Build. Eng. 2021, 38, 102214. [Google Scholar] [CrossRef]

- Wei, S.; Yiqiang, C.; Yunsheng, Z.; Jones, M. Characterization and simulation of microstructure and thermal properties of foamed concrete. Constr. Build. Mater. 2013, 47, 1278–1291. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R. Tensile strength behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Dilbas, H.; Şimşek, M.; Çakır, Ö. An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Constr. Build. Mater. 2014, 61, 50–59. [Google Scholar] [CrossRef]

| Properties | Physical Properties | Fineness (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Loss on Ignition | Specific Surface Area (cm2/g) | Specific Gravity | Moisture Content (%) | Water Absorption (%) | Mean Particle Size Diameter (μm) | Retained on 38 μm Sieve | Retained on 45 μm Sieve | Retained on 90 μm Sieve | |

| Silica fume (SiF) | 0.8 | 2250 | 2.25 | 0.15 | 5.6 | 24.56 | 15.6 | 12.13 | 3.54 |

| Slag powder (SP) | 0.7 | 4360 | 2.9 | 0.1 | 4.32 | 11.6 | 11.35 | 8.17 | 2.31 |

| Portland cement (PC) | 1.3 | 3580 | 3.1 | 0.08 | 2.3 | 15.3 | 8.65 | 5.04 | 0.78 |

| Length (mm) | Diameter (μm) | Density (kg/m3) | Modulus of Elasticity (GPa) | Number of Fibers per kg | Fracture Elongation (%) | Thermal Conductivity (W/m·K) | Melting Point (°C) | Tensile Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 °C | 200 °C | 400 °C | 600 °C | 800 °C | ||||||||

| 12 | 16 | 2700 | 85–110 | ~250 million | 3 | 50.2 | 1450 | 3000–4800 | 2800–4500 | 2500–4000 | 2000–3500 | 1500–2500 |

| Product | Type | Crystal Form | Appearance | Particle Size D50 nm | Purity% | Specific Surface Area m2/g | Bulk Density g/cm3 | PH Value | Viscosity (25 °C) | Place of Origin |

|---|---|---|---|---|---|---|---|---|---|---|

| Nanoalumina | TAP-A21 | α-phase | White powder | 30–40 | >99.99 | 20 | 0.2 | 6~8 | 800cps | Nanjing |

| Mix No. | Tag | Water | SiF | SP | Sand | HPWR | Cement | NA | A | RA | BF |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | R0B2A0 | 220 | 224 | 206 | 550 | 6 | 430 | 0 | 1100 | 0 | 2 |

| 2 | R50B2A0 | 430 | 0 | 550 | 550 | 2 | |||||

| 3 | R100B2A0 | 430 | 0 | 0 | 1100 | 2 | |||||

| 4 | R0B0A0 | 430 | 0 | 1100 | 0 | 0 | |||||

| 5 | R0B1A0 | 430 | 0 | 1100 | 0 | 1 | |||||

| 6 | R100B2A3 | 417.1 | 12.9 | 0 | 1100 | 2 | |||||

| 7 | R100B2A5 | 408.5 | 21.5 | 0 | 1100 | 2 |

| Physical property | Style | PH | Density (g/mL) | Water secretion rate (%) | Water reduction rate (%) | Viscosity (mPa·s) | Picture |

| ZY-S type polycarboxylic acid | 5.9 | 1.02 | 30 | 26 | 50 |  | |

| Effect on concrete | Initial setting time difference (min) | Final setting time difference (min) | Shrinkage ratio (MPa) | Effect on BF corrosion | Compressive strength ratio (%) | ||

| 3 d | 28 d | ||||||

| 95 | 100 | 104 | None | 176 | 153 | ||

| Performance | Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Elastic Modulus (GPa) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 °C | 200 °C | 400 °C | 600 °C | 800 °C | 25 °C | 200 °C | 400 °C | 600 °C | 800 °C | 25 °C | 200 °C | 400 °C | 600 °C | 800 °C | |

| R0B2A0 | 137.2 | 115.3 | 97.9 | 85.6 | 32.4 | 13.7 | 11.7 | 10.7 | 7.3 | 4.4 | 45.5 | 36.2 | 20.7 | 6.4 | 2.3 |

| R50B2A0 | 128.2 | 114.4 | 91.4 | 79.7 | 32.1 | 13 | 9.7 | 9 | 6.2 | 3.2 | 43.7 | 33.9 | 19.9 | 6.2 | 2.1 |

| R100B2A0 | 120 | 102.4 | 87 | 76.5 | 31.9 | 11.2 | 8.7 | 5.9 | 6 | 3.2 | 40.5 | 33.5 | 19.1 | 5.9 | 2 |

| R0B0A0 | 109.9 | 95.4 | 78.2 | 68.1 | 21.9 | 10 | 9.5 | 8.5 | 4.1 | 2.2 | 40.6 | 32.7 | 18.3 | 5.8 | 1.9 |

| R0B1A0 | 123.9 | 103.6 | 86.2 | 81.2 | 31.7 | 11.2 | 10.7 | 9.8 | 6.3 | 3.4 | 43 | 33 | 19.3 | 6.1 | 2 |

| R100B2A3 | 120.4 | 99.7 | 85.3 | 73.9 | 31.9 | 11.4 | 8.8 | 6.3 | 6.2 | 3.1 | 41.8 | 34.3 | 20.1 | 6.3 | 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Luo, L.; Hou, Y.; Yang, Y. Mechanical and Microstructural Performance of UHPC with Recycled Aggregates Modified by Basalt Fiber and Nanoalumina at High Temperatures. Materials 2025, 18, 1072. https://doi.org/10.3390/ma18051072

Jiang H, Luo L, Hou Y, Yang Y. Mechanical and Microstructural Performance of UHPC with Recycled Aggregates Modified by Basalt Fiber and Nanoalumina at High Temperatures. Materials. 2025; 18(5):1072. https://doi.org/10.3390/ma18051072

Chicago/Turabian StyleJiang, Hong, Liang Luo, Yuan Hou, and Yifei Yang. 2025. "Mechanical and Microstructural Performance of UHPC with Recycled Aggregates Modified by Basalt Fiber and Nanoalumina at High Temperatures" Materials 18, no. 5: 1072. https://doi.org/10.3390/ma18051072

APA StyleJiang, H., Luo, L., Hou, Y., & Yang, Y. (2025). Mechanical and Microstructural Performance of UHPC with Recycled Aggregates Modified by Basalt Fiber and Nanoalumina at High Temperatures. Materials, 18(5), 1072. https://doi.org/10.3390/ma18051072