Electromagnetic Interference (EMI) Shielding Performance and Photoelectric Characteristics of ZnS Infrared Window

Abstract

1. Introduction

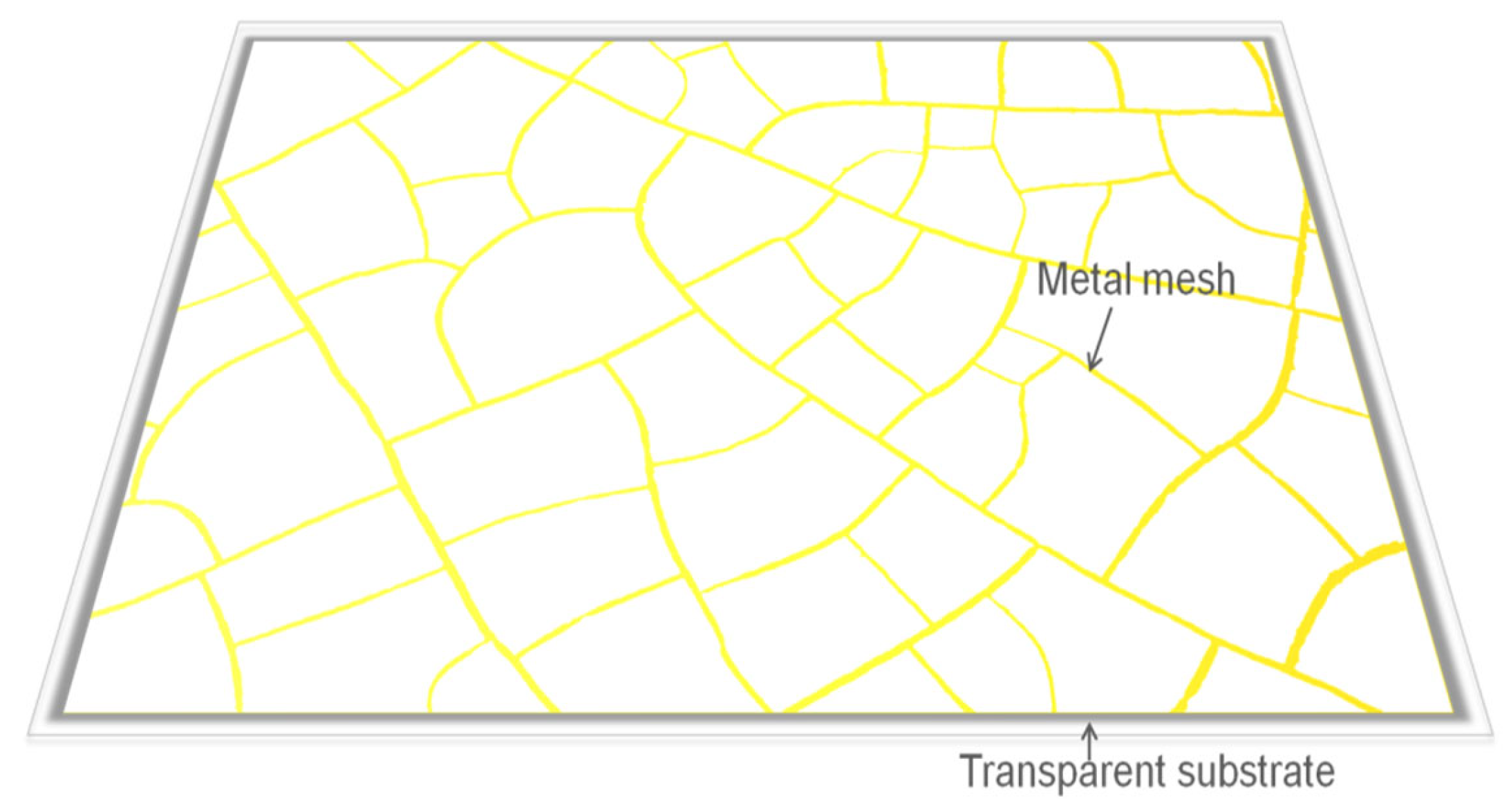

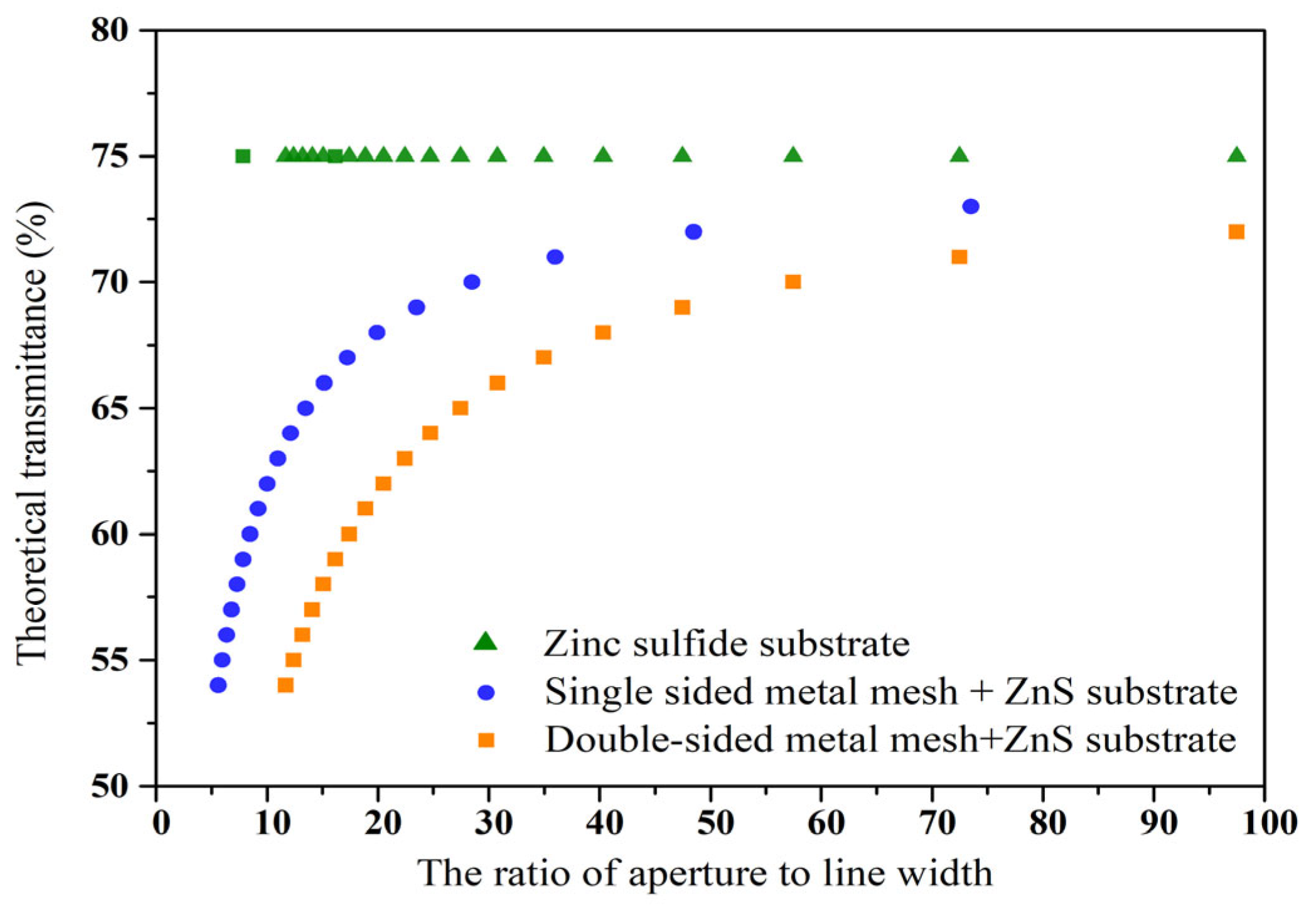

2. Structure Design and Simulation

3. Materials and Methods

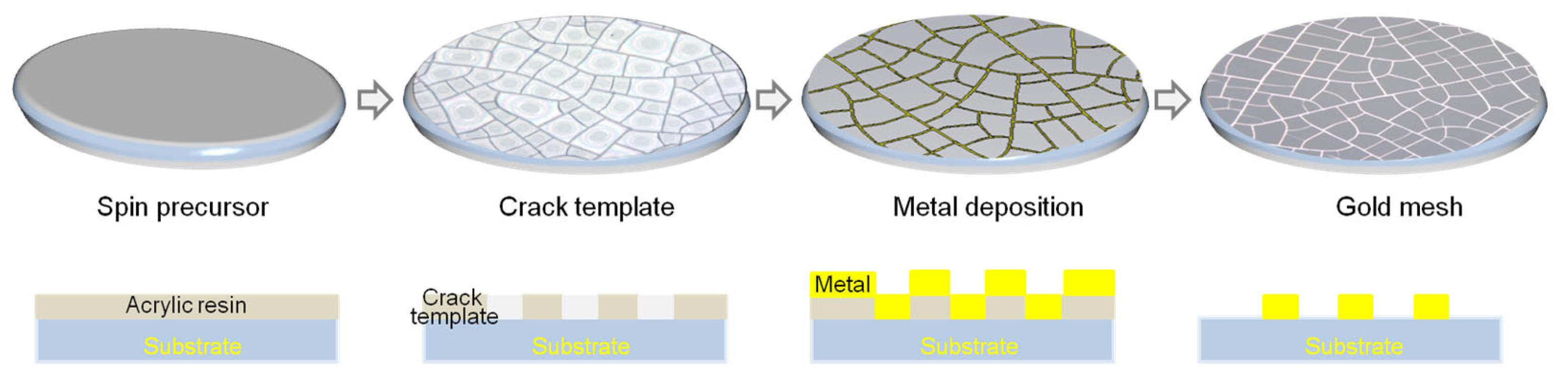

3.1. Metal Mesh Preparation

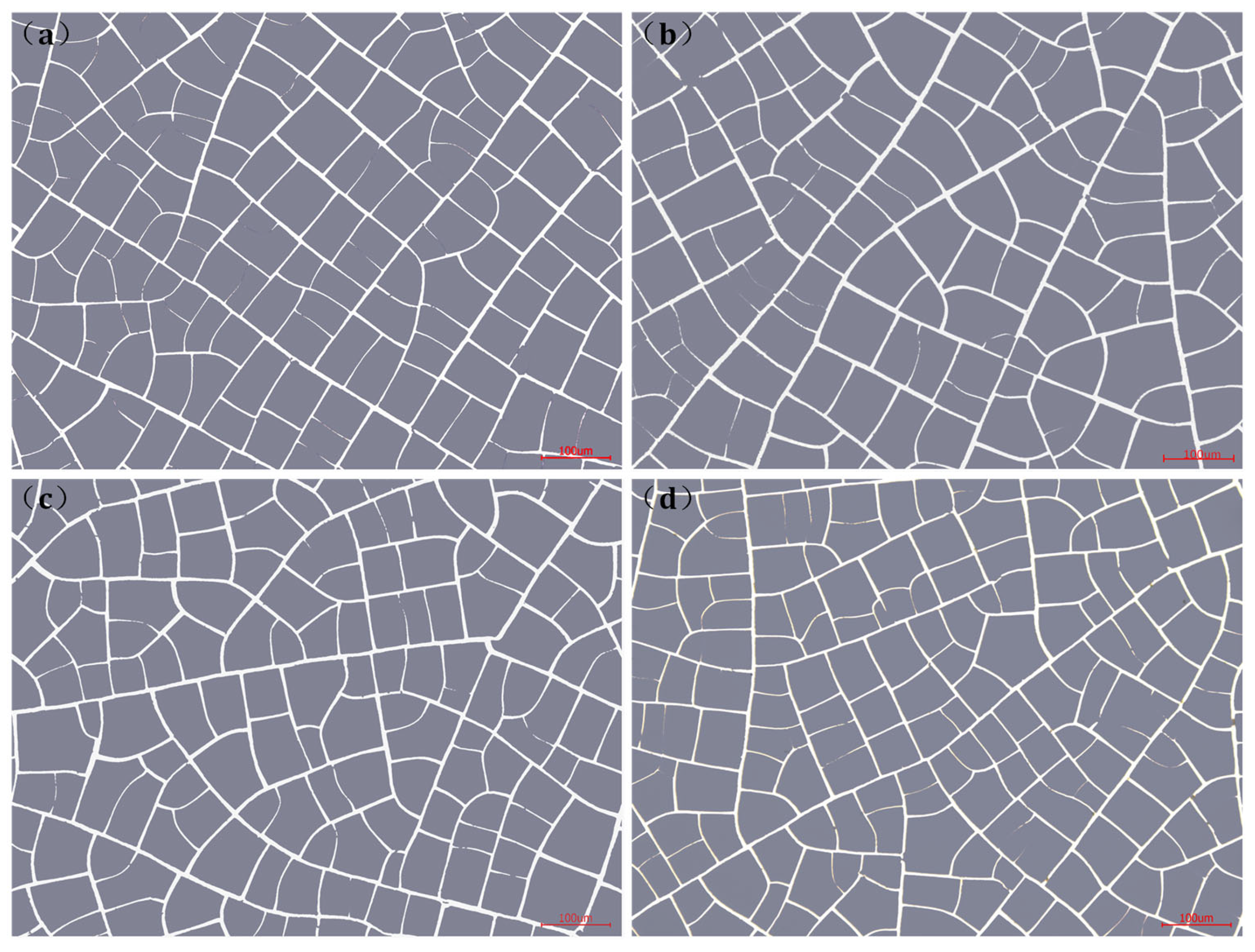

3.2. Microscopic Study

3.3. Optoelectric Study

3.4. EMI Shielding Measurements

4. Results

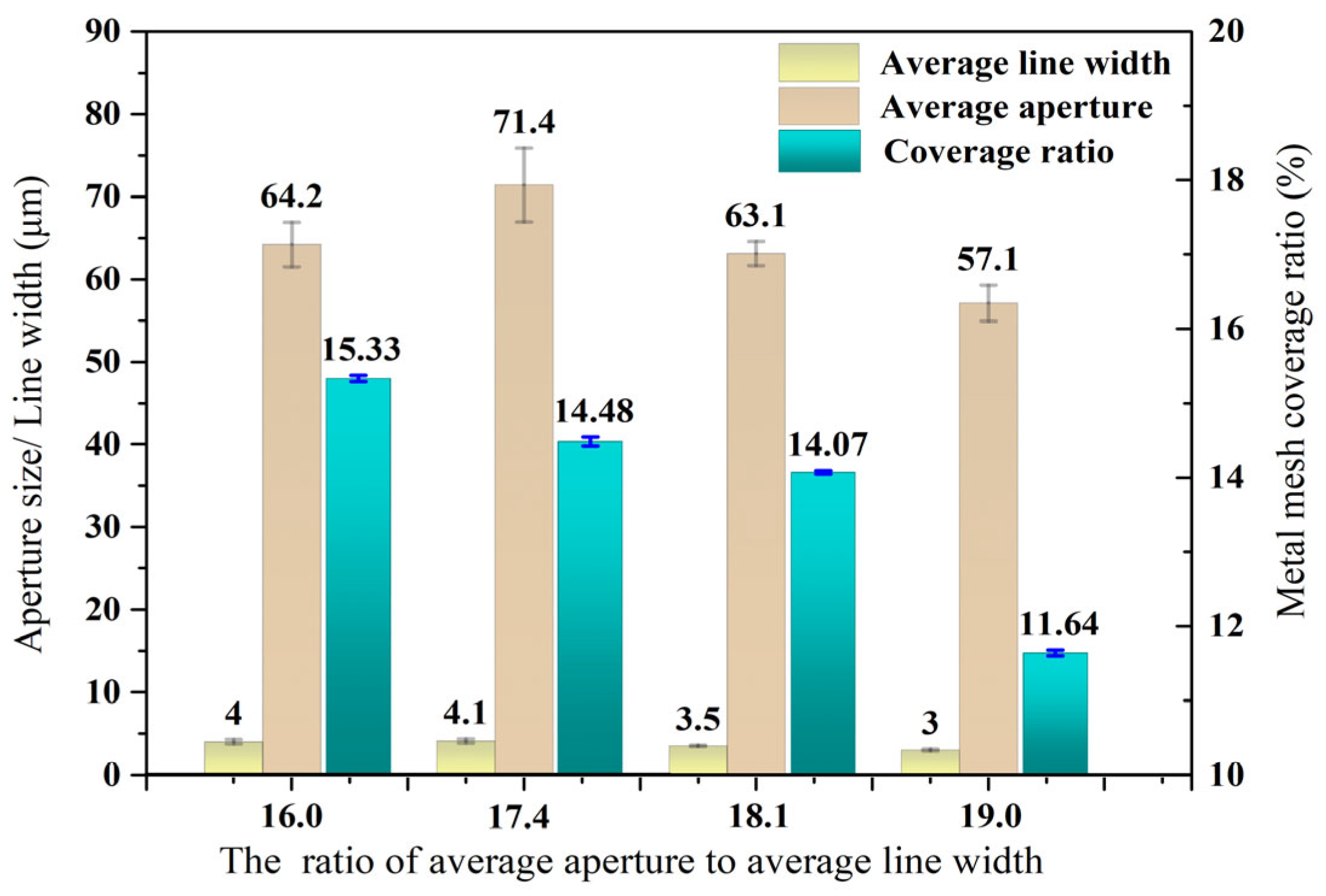

4.1. Morphology and Structure of Metal Mesh

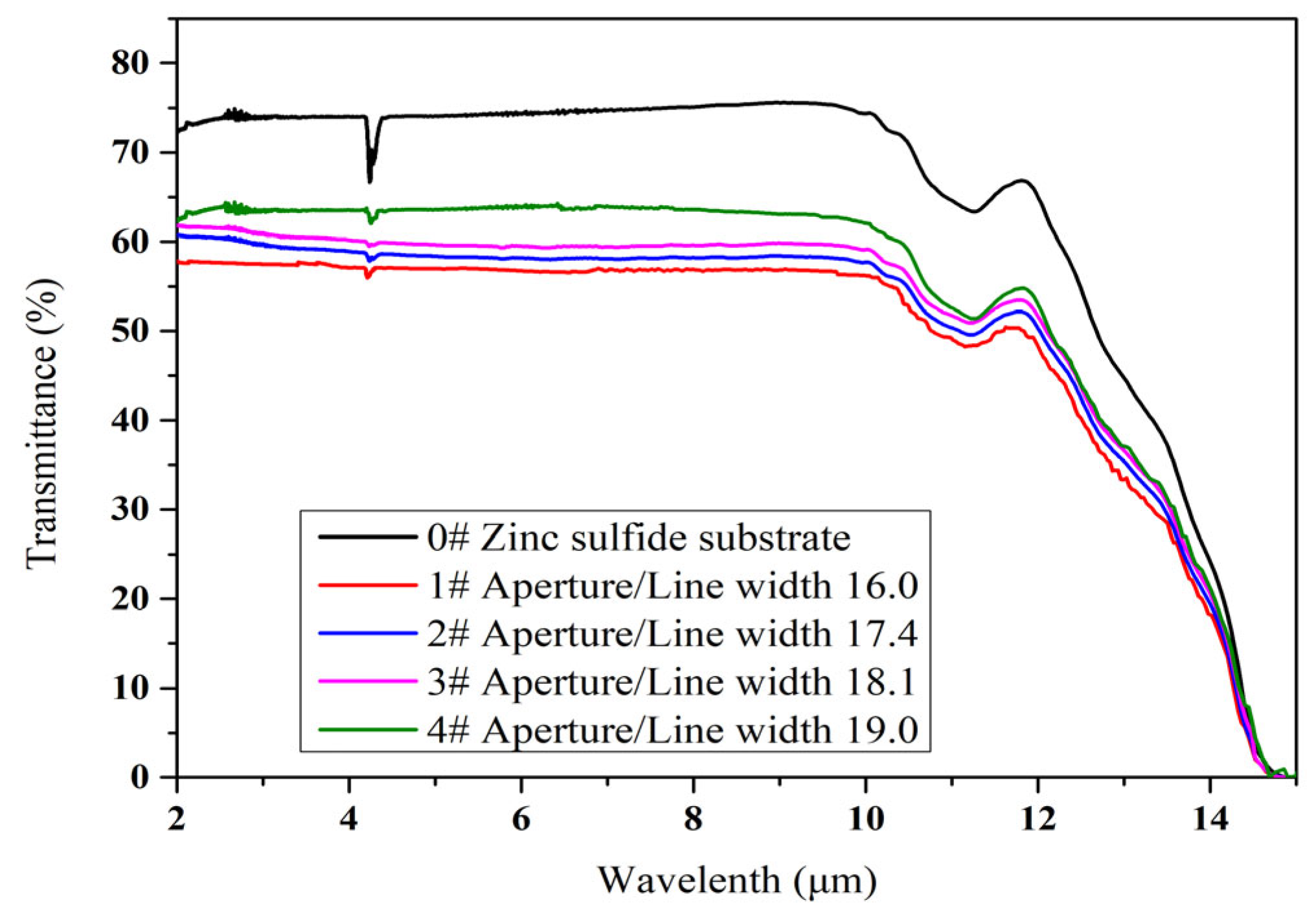

4.2. Optical and Electrical Properties of ZnS EMI Shielding Windows

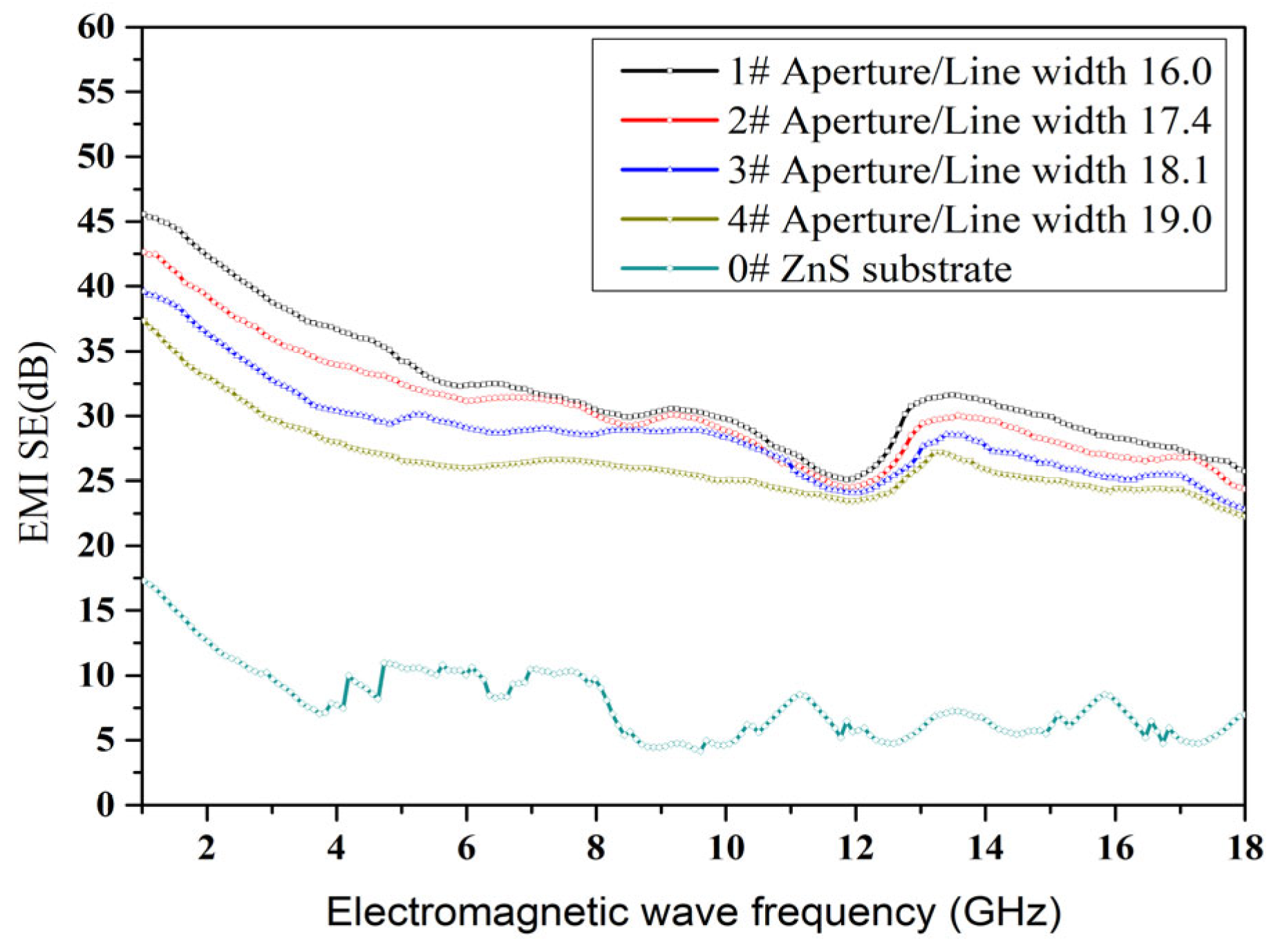

4.3. EMI Shielding Properties of Au Meshes

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, Y.L.; Liu, L.P.; Wang, C.; Li, C.; Lin, N.; Niu, S.C.; Han, Z.W.; Duan, J.A. Bioinspired near-full transmittance MgF2 window for infrared detection in extremely complex environments. ACS Appl. Mater. Interfaces 2023, 15, 30985–30997. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.Y.; Oh, Y.; Yu, J.; Jang, S.G.; Yeo, H.; Park, J.J.; You, N.H. Long-wave infrared transparent sulfur polymers enabled by symmetric thiol cross-linker. Nat. Commun. 2023, 14, 2866. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.C.; Zhang, Z.B.; Han, J.C.; Yang, L.; Li, J.J.; Song, Z.C.; Wang, T.Y.; Zhu, J.Q. Advanced liquid crystal-based switchable optical devices for light protection applications: Principles and strategies. Sci. Appl. 2023, 12, 11. [Google Scholar] [CrossRef]

- Wen, K.; Huang, X.J.; Tian, T.; Huang, W.T.; Liu, P.G. Design and demonstration of high-power density infrared nonlinear filtering window with EM shielding. Opt. Express 2024, 32, 5956–5968. [Google Scholar] [CrossRef]

- Li, X.H.; Huang, X.W.; Hu, X.C.; Guo, X.X.; Han, Y.H. Recent progress on mid-infrared pulsed fiber lasers and the applications. Opt. Laser Technol. 2023, 158, 108898. [Google Scholar] [CrossRef]

- Palik, E.D.; Addamiano, A. Zinc Sulfide (ZnS). In Handbook of Optical Constants of Solids; 1997; Volume I, pp. 597–691. [Google Scholar] [CrossRef]

- Firoozifar, S.A.R.; Behjat, A.; Kadivar, E.; Ghorashi, S.M.B.; Zarandi, M.B. A study of the optical properties and adhesion of zinc sulfide anti-reflection thin film coated on a germanium substrate. Appl. Surf. Sci. 2011, 258, 818–882. [Google Scholar] [CrossRef]

- John, S.M.; Ralph, K.; Brian, Z. Effects of Temperature, Pressure, and Metal Promoter on the Recrystallized Structure and Optical Transmission of Chemical Vapor Deposited Zinc Sulfide. J. Am. Ceram. Soc. 2009, 92, 1725–1731. [Google Scholar] [CrossRef]

- Zhou, T.F.; Zhu, Z.C.; Liu, X.H.; Liang, Z.Q.; Wang, X.B. A Review of the precision glass molding of chalcogenide glass (ChG) for infrared optic. Micromachines 2018, 9, 337. [Google Scholar] [CrossRef]

- Lee, D.K.; Yoo, J.; Kim, H.; Park, S.H. Investigation of electromagnetic interference shielding effectiveness and electrical percolation of carbon nanotube polymer composites with various aspect ratios. Carbon. Lett. 2023, 34, 133–140. [Google Scholar] [CrossRef]

- Yang, P.A.; Qu, Z.; Ruan, H.; Huang, Y.; Huang, X.; Li, W.; Li, R. Nanostructured films of ordered Fe nanowires for high-performance transparent electromagnetic interference shielding. ACS Appl. Nano Mater. 2023, 6, 8540–8549. [Google Scholar] [CrossRef]

- Li, M.; Zarei, M.; Mohammadi, K.; Walker, S.; LeMieux, M.; Leu, P. Silver meshes for record-performance transparent electromagnetic interference shielding. ACS Appl. Mater. Interfaces 2023, 15, 30591–30599. [Google Scholar] [CrossRef]

- Chen, Q.; Huang, L.; Wang, X.; Yuan, Y. Transparent and flexible composite films with excellent electromagnetic interference shielding and thermal insulating performance. ACS Appl. Mater. Interfaces 2023, 15, 24901–24912. [Google Scholar] [CrossRef] [PubMed]

- Liao, D.; Zheng, Y.; Ma, X.; Fu, Y. Honeycomb-ring hybrid random mesh design with electromagnetic interference (EMI) shielding for low stray light. Opt. Express 2023, 31, 32200–32213. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, Y.; Zhao, W.; Feng, Y.; Zhou, B.; Liu, C. Flexible, hierarchical MXene@ SWNTs transparent conductive film with multi-source thermal response for electromagnetic interference shielding. Compos. Sci. Technol. 2024, 12, 110484. [Google Scholar] [CrossRef]

- Erdogan, N.; Erden, F.; Astarlioglu, A.T.; Ozdemir, M.; Ozbay, S.; Aygun, G.; Ozyuzer, L. ITO/Au/ITO multilayer thin films on transparent polycarbonate with enhanced EMI shielding properties. Curr. Appl. Phys. 2020, 20, 489–497. [Google Scholar] [CrossRef]

- Wang, X.; Zou, F.; Zhao, Y.; Li, G.; Liao, X. Electromagnetic interference shielding composites and the foams with gradient structure obtained by selective distribution of MWCNTs into hard domains of thermoplastic polyurethane. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107861. [Google Scholar] [CrossRef]

- Feng, Y.; Song, J.; Han, G.; Zhou, B.; Liu, C.; Shen, C. Transparent and stretchable electromagnetic interference shielding film with fence-like aligned silver nanowire conductive network. Small Methods 2023, 7, 2201490. [Google Scholar] [CrossRef]

- Zhao, W.; Dong, J.; Li, Z.; Zhou, B.; Liu, C.; Feng, Y. Centrifugal inertia-induced directional alignment of AgNW network for preparing transparent electromagnetic interference shielding films with joule heating ability. Adv. Sci. 2024, 8, 2406758. [Google Scholar] [CrossRef]

- Bai, X.L.; Mei, Z.L.; Zhang, J.W.; Xu, W.B.; Lin, W.J.; Niu, T.M. An Ultrawideband, wide-angle, and transparent microwave absorber using indium tin oxide conductive films. IEEE Antennas Wirel. Propag. Lett. 2024, 23, 1543–1547. [Google Scholar] [CrossRef]

- Kim, M.J. A study on optimal indium tin oxide thickness as transparent conductive electrodes for near-ultraviolet light-emitting diodes. Materials 2023, 16, 4718. [Google Scholar] [CrossRef]

- Kürschner, D.; Hallumb, G.; Vogel, S.; Huber, H.P.; Schulz, W.F. Static and transient optical properties of thin film indium tin oxide during laser excitation. Int. J. Heat Mass Transf. 2023, 209, 124119. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Dong, H.X.; Li, Q.S.; Mou, N.L.; Chen, L.L.; Zhang, L. Double-layer metal mesh etched by femtosecond laser for high-performance electromagnetic interference shielding window. RSC Adv. 2019, 9, 22282–22287. [Google Scholar] [CrossRef] [PubMed]

- Li, H.K.; Zhang, Y.X.; Tai, Y.P.; Zhu, X.Y.; Qi, X.M.; Zhou, L.J.; Li, Z.H.; Lan, H.B. Flexible transparent electromagnetic interference shielding films with silver mesh fabricated using electric-field-driven microscale 3D printing. Opt. Laser Technol. 2022, 148, 107717. [Google Scholar] [CrossRef]

- Chung, S.I.; Kang, T.W.; Kim, P.K.; Ha, T.G.; Hong, Y.P. Highly transparent Ka-/W-Band electromagnetic shielding films based on double-layered metal meshes. ACS Appl. Mater. Interfaces 2023, 15, 56612–56622. [Google Scholar] [CrossRef]

- Lu, Z.G.; Zhang, Y.L.; Lu, X.; Wang, H.Y.; Tan, J.B. Two-step randomized design of multi-rings metallic mesh for ultra-uniform diffraction distribution. Opt. Laser Technol. 2021, 144, 107396. [Google Scholar] [CrossRef]

- Voronin, A.S.; Simunin, M.M.; Fadeev, Y.V.; Ivanchenko, F.S.; Karpova, D.V.; Tambasov, I.A.; Khartov, S.V. Technological basis of the formation of micromesh transparent electrodes by means of a self-organized template and the study of their properties. Tech. Phys. Lett. 2019, 45, 366–369. [Google Scholar] [CrossRef]

- Han, B.; Pei, K.; Huang, Y.L.; Zhang, X.J.; Rong, Q.K.; Lin, Q.G.; Guo, Y.F.; Sun, T.Y.; Guo, C.F.; Carnahan, D.; et al. Uniform self-forming metallic network as a high-performance transparent conductive electrode. Adv. Mater. 2014, 26, 873–877. [Google Scholar] [CrossRef]

- Voronin, A.S.; Fadeev, Y.V.; Govorun, I.V.; Podshivalov, I.V.; Simunin, M.M.; Tambasov, I.A.; Karpova, D.V.; Smolyarova, T.E.; Lukyanenko, A.V.; Karacharov, A.A.; et al. Cu–Ag and Ni–Ag meshes based on cracked template as efficient transparent electromagnetic shielding coating with excellent mechanical performance. J. Mater. Sci. 2021, 56, 14741–14762. [Google Scholar] [CrossRef]

- Voronin, A.S.; Fadeev, Y.V.; Ivanchenko, F.S.; Dobrosmyslov, S.S.; Makeev, M.O.; Mikhalev, P.A.; Osipkov, A.S.; Damaratsky, I.A.; Ryzhenko, D.S.; Yurkov, G.Y.; et al. Original concept of cracked template with controlled peeling of the cells perimeter for high-performance transparent EMI shielding films. Surf. Interfaces 2023, 38, 102793. [Google Scholar] [CrossRef]

- Jo, S.W.; Akin, S.; Park, M.S.; Martin, B.G. Selective metallization on glass surface by laser direct writing combined with supersonic particle deposition. Manuf. Lett. 2022, 31, 64–68. [Google Scholar] [CrossRef]

- Liang, Z.; Zhao, Z.; Pu, M.; Luo, J.; Xie, X.; Wang, Y.; Guo, Y.; Ma, X.; Luo, X. Metallic nanomesh for high-performance transparent electromagnetic shielding. Opt. Mater. Express 2020, 10, 796–806. [Google Scholar] [CrossRef]

- Li, H.; Zi, D.; Zhu, X.; Zhang, H.; Tai, Y.; Wang, R.; Sun, L.; Zhang, Y.; Ge, W.; Huang, Y.; et al. Electric field driven printing of repeatable random metal meshes for flexible transparent electrodes. Opt. Laser Technol. 2023, 157, 108730. [Google Scholar] [CrossRef]

- Anna, C.; Mehrnaz, B.M.; Peeranuch, P.; Clémence, B.; Beniamino, S. Nanoparticle imprint lithography: From nanoscale metrology to printable metallic grids. ACS Nano 2023, 17, 9361–9373. [Google Scholar] [CrossRef]

- Cui, M.Q.; Zhang, X.H.; Rong, Q.K.; Nian, L.; Shui, L.L.; Zhou, G.F.; Li, N. High conductivity and transparency metal network fabricated by acrylic colloidal self-cracking template for flexible thermochromic device. Org. Electron. 2020, 83, 105763. [Google Scholar] [CrossRef]

- Amralah, N. Metal mesh selection guide for shielding effectiveness and optical visibility. In Proceedings of the 2022 Antenna Measurement Techniques Association Symposium (AMTA), Denver, CO, USA, 9–14 October 2022. [Google Scholar] [CrossRef]

- Harris, D.C.; Baronowski, M.; Henneman, L.; LaCroix, L.; Wilson, C.; Kurzius, S.; Burns, B.; Kitagawa, K.; Gembarovic, J.; Goodrich, S.M.; et al. Thermal, structural, and optical properties of Cleartran® multispectral zinc sulfide. Opt. Eng. 2008, 47, 114001. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, J. Frequency dependent model of sheet resistance and effect analysis on shielding effectiveness of transparent conductive mesh coatings. Prog. Electromage. Res. 2013, 140, 353–368. [Google Scholar] [CrossRef]

- Yang, L.Q.; Guan, Y.M.; Gao, F.; Wan, R.; Wang, P.F. Effect of crack template structure morphology on electromagnetic shielding efficiency and visual performance of metal mesh optical window. Results Eng. 2025, 25, 103888. [Google Scholar] [CrossRef]

- Kuzhir, P.P.; Paddubskaya, A.G.; Maksimenko, S.A.; Kaplas, T.; Svirko, Y. Microwave absorption properties of pyrolytic carbon nanofilm. Nanoscale Res. Lett. 2013, 8, 60. [Google Scholar] [CrossRef]

- Yang, Z.H.; Hao, Q.; Zhang, S.H.; Sun, X.J.; Tian, W.M.; Liu, F.L. Multispectral transparent electromagnetic-wave-absorbing optical window technology based on a random grid. Opt. Express 2023, 31, 26355. [Google Scholar] [CrossRef]

- Clark, I.B. Grid and mesh patterned electrically conductive coatings in IR systems. In Proceedings Volume 1050, Infrared Systems and Components III; SPIE: Bellingham, WA, USA, 1989; pp. 212–217. [Google Scholar]

- Savrun, E. Electrically conductive tungsten silicide coatings for EMI/RFI shielding of optically transparent windows. J. Mater. Sci. 1998, 33, 2893–2897. [Google Scholar] [CrossRef]

- Li, T.F.; Chen, X.L.; Xu, Z.H.; Nie, S.; Xu, W.Y. High-performance visible-infrared broadband transparent copper mesh conductor and applications for electromagnetic shielding and heating. Sci. China Mater. 2025, 68, 421–443. [Google Scholar] [CrossRef]

- Fu, K.H.; Jin, Y.L.; Xu, B.; Han, B.; Chen, W. Graphene Infrared Electromagnetic Interference Shielding Filter on ZnS and As40Se60 substrates. Proc. SPIE 2018, 10846, 637–649. [Google Scholar] [CrossRef]

| Subtrate | Films Material and Morphology | Grid Structure | Transmittance | Sheet Resistances | EMI SE | Refs. |

|---|---|---|---|---|---|---|

| ZnS (thickness 4.5 mm) | Double layer films: Cu radom grid | line width: 1.75–1.96 μm, average period: 50–106 μm | 460–800 nm and 8–12 μm: >89.8% | 85 Ω/sq | 2–18 GHz: >31 dB | [41] |

| ZnS | Ag period grid | period: 7.62 mm, line width: 0.635 mm | 8–12 μm: >80% | — | 1 GHz: 23.3 | [42] |

| ZnS | WSi2 single layer | Thickness 0.75 μm | — | — | 0.4–18 GHz: >30 dB | [43] |

| ZnS | Cu radom grid | period: 80–100 μm, line width: 2.3 μm thickness: 6.4 μm | 550 nm: 71%, 3–10 μm: 65–72% | 0.06–0.15 Ω/sq | — | [44] |

| ZnS | graphene layer, 13 layers | — | 8–12 μm: 94.7% | 68 Ω/sq | 30 MHz~1.5 GHz: 15.6 dB | [45] |

| ZnS | single layer films: Au radom grid | The ratios of the aperture to line width were 16.1, 17.4, 18.0, and 19.0 | 2–10 μm: 57.1–63.2% | 9.5–16.7 Ω/sq | 1–18 GHz: >22.5 dB | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Guo, R.; Gao, F.; Guan, Y.; Zhang, M.; Wang, P. Electromagnetic Interference (EMI) Shielding Performance and Photoelectric Characteristics of ZnS Infrared Window. Materials 2025, 18, 1067. https://doi.org/10.3390/ma18051067

Yang L, Guo R, Gao F, Guan Y, Zhang M, Wang P. Electromagnetic Interference (EMI) Shielding Performance and Photoelectric Characteristics of ZnS Infrared Window. Materials. 2025; 18(5):1067. https://doi.org/10.3390/ma18051067

Chicago/Turabian StyleYang, Liqing, Rongxing Guo, Fei Gao, Yongmao Guan, Mengwen Zhang, and Pengfei Wang. 2025. "Electromagnetic Interference (EMI) Shielding Performance and Photoelectric Characteristics of ZnS Infrared Window" Materials 18, no. 5: 1067. https://doi.org/10.3390/ma18051067

APA StyleYang, L., Guo, R., Gao, F., Guan, Y., Zhang, M., & Wang, P. (2025). Electromagnetic Interference (EMI) Shielding Performance and Photoelectric Characteristics of ZnS Infrared Window. Materials, 18(5), 1067. https://doi.org/10.3390/ma18051067