Cavitation Erosion of Protective Coating Based on Cordierite Filler and Epoxy Matrix

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Synthesis of the Cordierite Filler

- (1)

- Kaolin—SiO2 = 53.87%, Al2O3 = 28.24%, Fe2O3 = 1.48%, CaO = 0.64%, Na2O = 0.03%, and K2O = 0.05%;

- (2)

- Alumina—SiO2 = 0.15%, Al2O3 = 95.12%, MgO = 0.01%, Fe2O3 = 0.1%, CaO = 0.17%, Na2O = 0.04%, and K2O = 0.02%;

- (3)

- Talc—SiO2 = 60.97%, Al2O3 = 1.68%, MgO = 28.91%, Fe2O3 = 2.23%, CaO = 2.95%, Na2O = 0.87%, and K2O = 0.91%.

2.2. Instrumental Methods for Characterization of the Synthetized Cordierite Filler

2.3. Preparation and Mix-Design of the Protective Coating

2.4. Instrumental Methods for Characterization of the Protective Coating

3. Results and Discussion

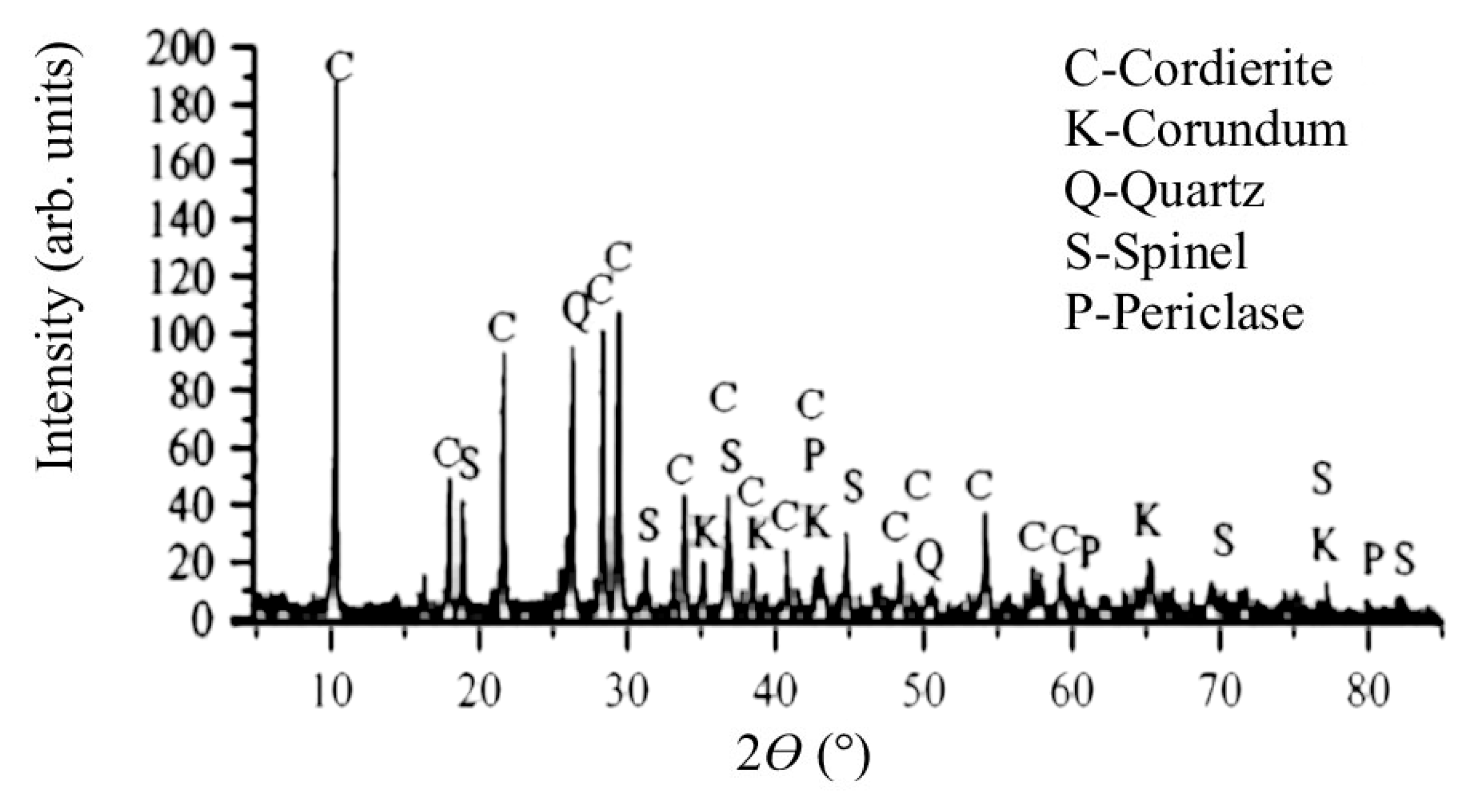

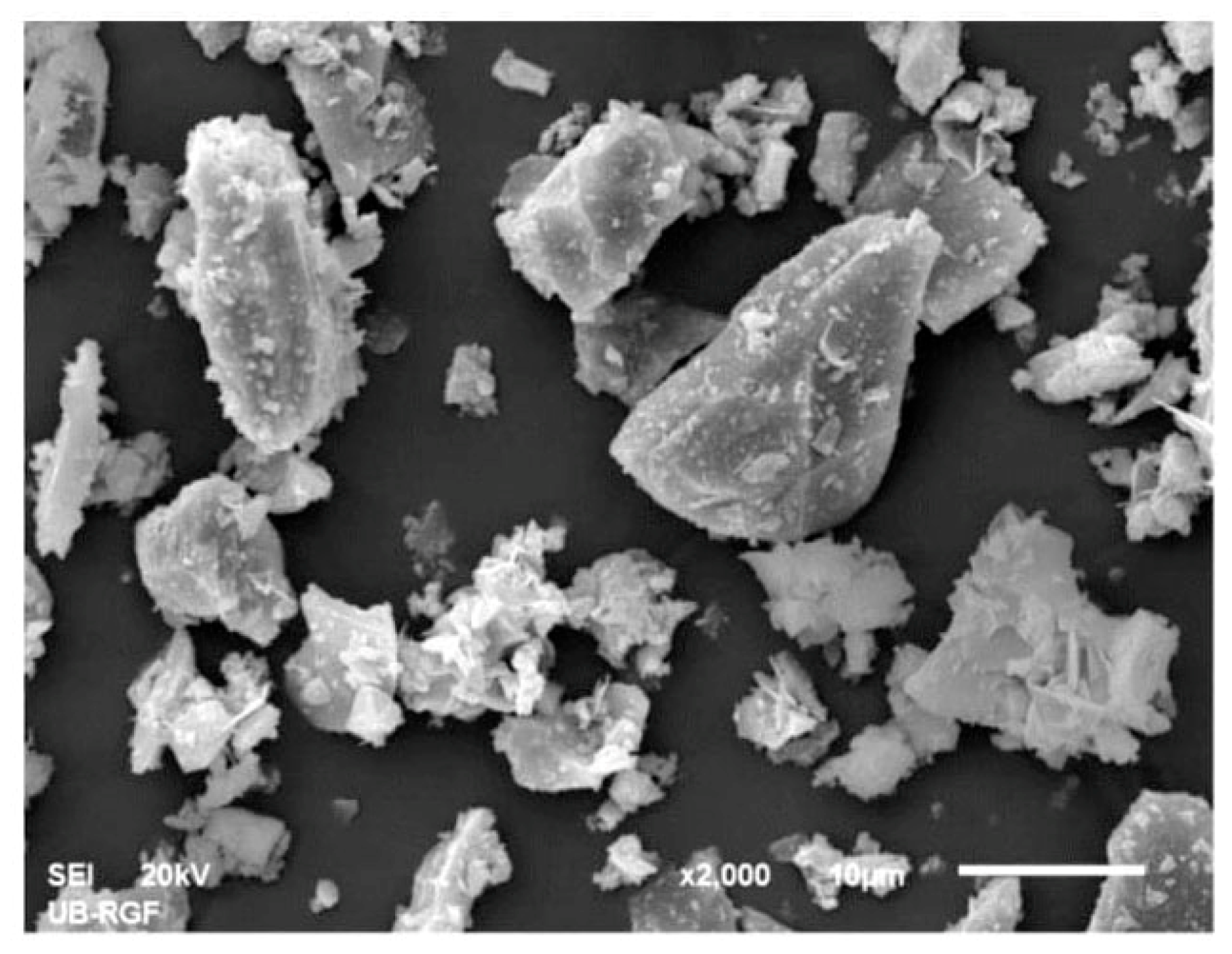

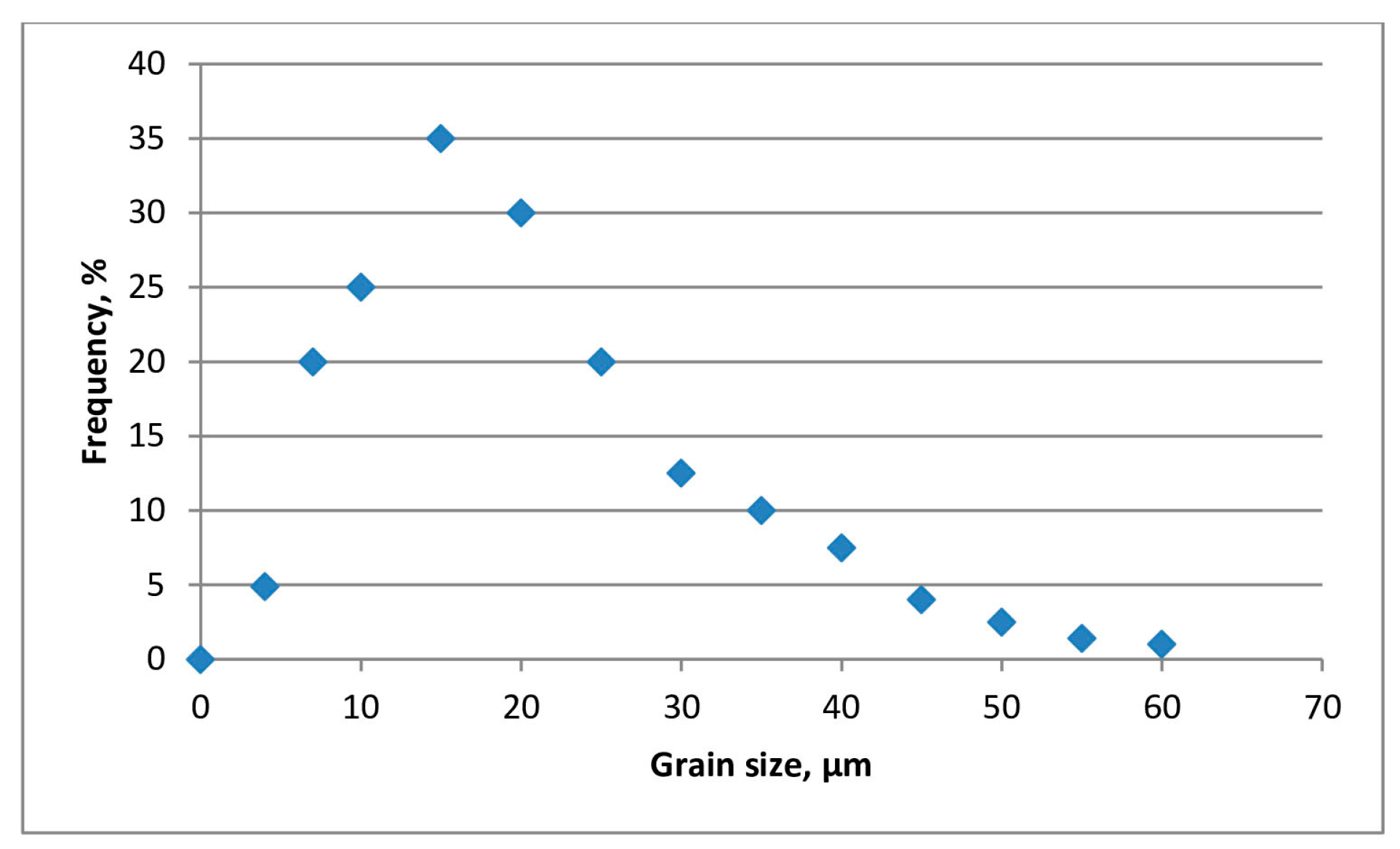

3.1. Properties of the Synthetized Cordierite Filler

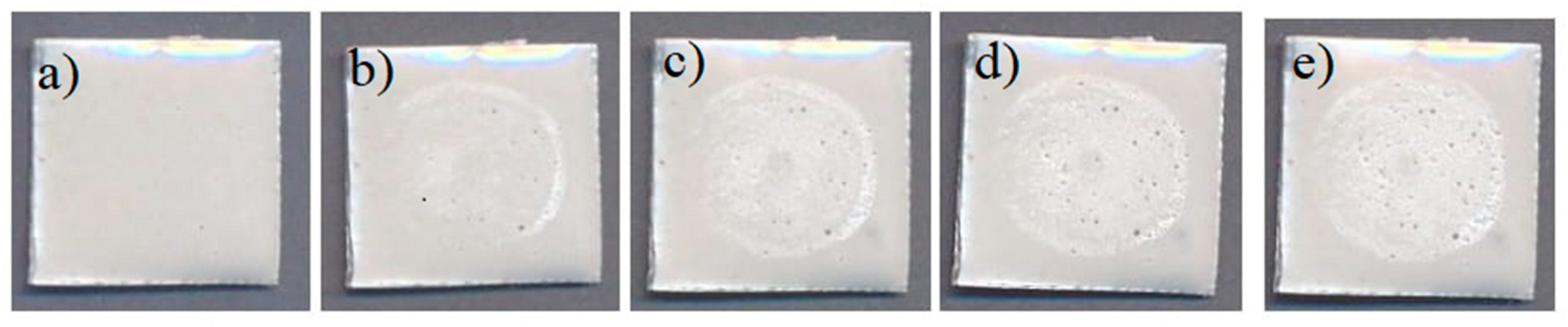

3.2. Properties of Protective Coating: Superficial Damage Formation and Development

4. Conclusions

- To acquire protective coatings with pre-designed properties, extra attention should be devoted to component selection from the coating composition, as well as to studies of coating production techniques. Grinding and mechanical activation processes are used to produce refractory fillers with certain grain sizes and shapes. For the synthesis of coatings with good rheological properties, the protection of metal and non-metal surfaces, and the application in harsh exploitation conditions (effect of wear, corrosion, and cavitation), to which parts of equipment in the process industry are exposed, the choice of binders, organic solvents, and additives to maintain the suspension is crucial. A high-strength, corrosion-resistant filler with high hardness and strength is chosen beforehand to guarantee the substrate’s surface protection over time. To minimize the rate at which damage to the coated surface forms and progresses, extra care is taken in filler preparation.

- The average grain in the filler mixture is sub-angular to sub-rounded, making it suitable for homogeneous coating solutions.

- The protective coating adhered properly to the aluminum substrate, completely covering the surface and leaving no bumps or bubbles. The coating dries quickly in the air and exhibits no delamination.

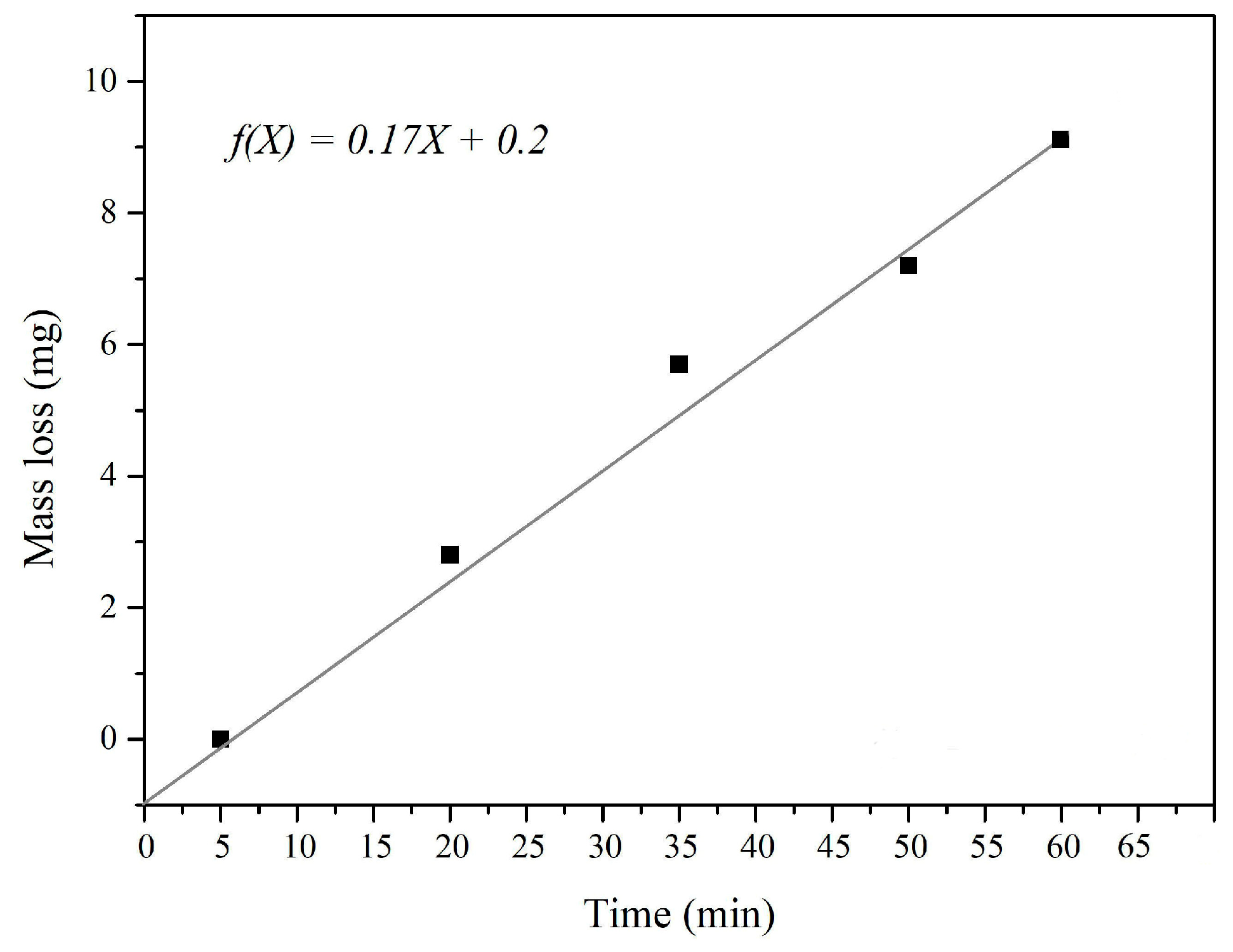

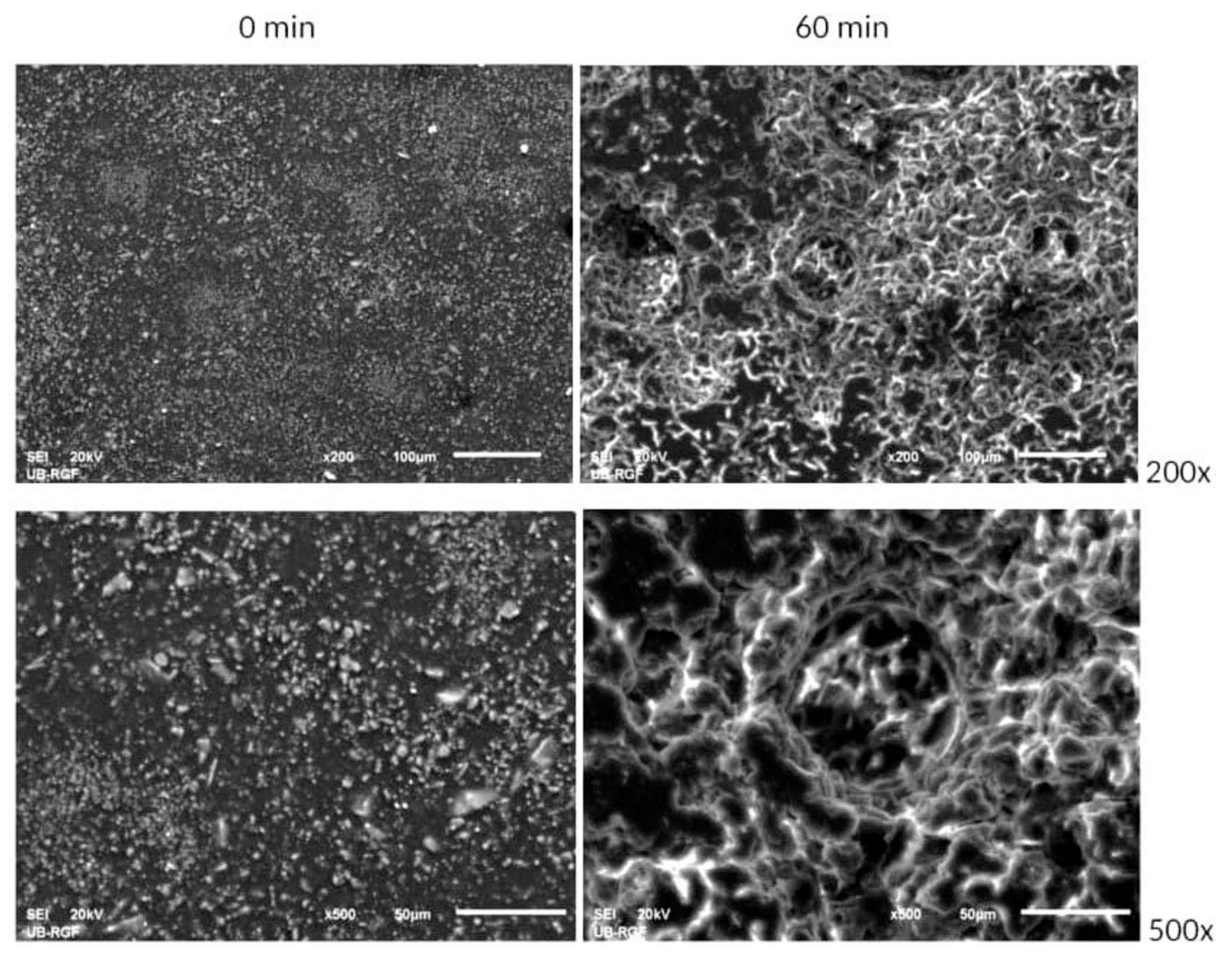

- The cavitation rate of 0.16 mg/min suggests a slow deterioration of the coating. The morphology of the protective coating samples from the last cavitation erosion phase of 60 min revealed the predominantly superficial pits. There are no empty clusters of deeper channels beginning with the surface cavitation pits. Extensive observation has revealed that whole-grain tearing, without the plastic deformation of the coating layer, is the primary damage mechanism. The presence of the protective layer prevented the metal substrate from being harmed by water stream action. This study shows that the proposed protective coating may be used in environments with cavitation loads and provides protection for the substrate material, which will be tested on a semi-industrial scale in the next step of the study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Almusallam, A.A.; Khan, F.M.; Dulaijan, S.U.; Al-Amoudi, O.S.B. Effectiveness of surface coatings in inproving concrete durability. Cem. Concr. Compos. 2003, 25, 473–481. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.; Li, N. A review on concrete surface treatment Part I: Types and mechanisms. Constr. Build. Mater. 2017, 132, 578–590. [Google Scholar] [CrossRef]

- Korjakins, A.; Kara, P.; Toropovs, N. Improving quality of high performance concrete by cavitation treatment of the raw materials. Procedia Eng. 2013, 57, 597–604. [Google Scholar] [CrossRef]

- Lu, X.; Wang, L.; Chen, C.; Chen, J.; Zhou, J.; Deng, J. Study on the influence mechanism of material damage on the cavitation erosion properties of hydraulic concrete. Constr. Build. Mater. 2023, 400, 132849. [Google Scholar] [CrossRef]

- Park, D.C. Carbonation of concrete in relation to CO2 permeability and degradation of coatings. Constr. Build. Mater. 2008, 22, 2260–2268. [Google Scholar] [CrossRef]

- Aguiar, J.B.; Júnior, C. Carbonation of surface protected concrete. Constr. Build. Mater. 2013, 49, 478–483. [Google Scholar] [CrossRef]

- Shariatmadar, M.; Gholamhosseini, P.; Abdorrezaee, Z.; Ghorbanzadeh, S.; Feizollahi, S.; Hosseini, F.S.; Shahraki, F.A.; Mahdavian, M. Leveraging polyaniline grafted micaceous iron oxide as a dual active-barrier pigment for anti-corrosion polymer coatings. Surf. Coat. Technol. 2024, 479, 130501. [Google Scholar] [CrossRef]

- Liu, X. A comparative study on UV degradation of organic coatings for concrete: Structure, adhesion, and protection performance. Prog. Org. Coat. 2020, 149, 105892. [Google Scholar] [CrossRef]

- Selvaraj, R.; Selvaraj, M.; Iyer, S.V.K. Studies on the evaluation of the performance of organic coatings used for the prevention of corrosion of steel rebars in concrete structures. Prog. Org. Coat. 2009, 64, 454–459. [Google Scholar] [CrossRef]

- Qu, H.; Feng, M.; Li, M.; Tian, D.; Zhang, Y.; Chen, X.; Li, G. Enhancing the carbonation and chloride resistance of concrete by nano-modified eco-friendly water-based organic coatings. Mater. Today Commun. 2023, 37, 107284. [Google Scholar] [CrossRef]

- Gu, S.; Shi, H.; Li, J.; Xu, H.; Udoh, I.I.; Liu, F.; Han, E. Self-diagnosing and active protective dual-functional water-borne polyurethane coating based on smart mesoporous containers. Prog. Org. Coat. 2023, 183, 107789. [Google Scholar] [CrossRef]

- Sun, F.; Fu, J.; Peng, Y.; Jiao, X.; Liu, H.; Du, F.; Zhang, Y. Dual-functional intumescent fire-retardant/self-healing water-based plywood coatings. Prog. Org. Coat. 2021, 154, 106187. [Google Scholar] [CrossRef]

- Nejad, S.A.T.; Amanian, S.; Alibakhshi, E.; Hajisoltani, M.; Haddadi, S.A.; Arjmand, M.; Ramezanzadeh, B.; Mahdavian, M. Enhancing epoxy-silicone coating’s protection performance: Harnessing the power of sulfur-doped graphene oxide. Prog. Org. Coat. 2024, 188, 108195. [Google Scholar] [CrossRef]

- Bobzin, K.; Zhao, L.; Heinemann, H.; Burbaum, E.; Li, S. Effect of heat treatment on the structure, fracture toughness and oxidation behavior of a silicon coating by atmospheric plasma spraying. Surf. Coat. Technol. 2023, 472, 129965. [Google Scholar] [CrossRef]

- Qi, C.; Dam-Johansen, K.; Weinell, C.E.; Wu, H. Synthesis of micro-structured zinc particles by thermal evaporation and their application in zinc containing coatings for steel corrosion protection. Prog. Org. Coat. 2024, 187, 108143. [Google Scholar] [CrossRef]

- Xiao, X.Q.; Wang, D.M.; Li, Y.X.; Jackson, E.; Fang, Y.; Zhang, Y.; Xie, N.; Shi, X. Investigation into the Synergistic Effect of Nano-sized Materials on the Anti-corrosion Properties of a Waterborne Epoxy Coating. Int. J. Electrochem. Sci. 2016, 11, 6023–6042. [Google Scholar] [CrossRef]

- Soleimani, M.; Bagheri, E.; Mosaddegh, P.; Rabiee, T.; Fakhar, A.; Sadeghi, M. Stable waterborne epoxy emulsions and the effect of silica nanoparticles on their coatings properties. Prog. Org. Coat. 2021, 156, 106250. [Google Scholar] [CrossRef]

- Yao, H.R.; Li, L.J.; Li, W.S.; Qi, D.; Fu, W.; Wang, N. Application of nanomaterials in waterborne coatings: A review. Resour. Chem. Mater. 2022, 1, 184–200. [Google Scholar] [CrossRef]

- Semmler, C.; Gyoktepeliler-Akin, E.; Killinger, A. Plasma sprayed ceramic coatings for the thermal protection of carbon fiber reinforced plastics (CFRP): Thermal and mechanical properties of YSZ, aluminum titanate, cordierite and mullite coatings. Surf. Coat. Technol. 2023, 462, 129509. [Google Scholar] [CrossRef]

- Ferraris, M.; Salvo, M.; Smeacetto, F. Cordierite-mullite coating for SiCf/SiC composites. J. Eur. Ceram. Soc. 2002, 22, 2343–2347. [Google Scholar] [CrossRef]

- Wei, Z.; Shi, X.; Cui, D.; Wei, Z.; Hong, S. Effect of 3.5% NaCl solution with different Na2S concentrations on ultrasonic cavitation erosion behaviors of HVOF sprayed WC-Ni coatings. Ultrason. Sonochem. 2023, 101, 106707. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Zhao, L.; Si, C.; Tian, Y.; Xu, S. Microstructure development and cavitation erosion resistance enhancement of additive manufactured Hastelloy C276 alloy coating on martensitic stainless–steel via directed energy deposition. Optics Laser Technol. 2024, 171, 110395. [Google Scholar] [CrossRef]

- Kumar, P.; Singal, S.K.; Gohil, P.P. A technical review on combined effect of cavitation and silt erosion on Francis turbine. Renew. Sustain. Energy Rev. Part B 2024, 190, 114096. [Google Scholar] [CrossRef]

- Dojčinović, M.; Cvetković, R.P.; Sedmak, A.; Popović, O.; Cvetković, I.; Radu, D. Effect of Shielding Gas Arc Welding Process on Cavitation Resistance of Welded Joints of AlMg4.5Mn Alloy. Materials 2023, 16, 4781. [Google Scholar] [CrossRef] [PubMed]

- Aćimović, Z.; Terzić, A.; Andrić, L.; Pavlović, M. Comparison of refractory coatings based on talc, cordierite, zircon and mullite fillers for lost-foam casting. Mater. Technol. 2015, 49, 157–164. [Google Scholar]

- Pavlović, M.; Nikolić, J.; Andrić, L.; Todorović, D.; Božić, K.; Drmanić, S. Synthesis of the new lost foam refractory coatings based on talc. J. Serb. Chem. Soc. 2022, 87, 491–503. [Google Scholar] [CrossRef]

- Pavlović, M.; Cvetković, A.; Trumbulović, M.; Milovanović, A. Cavitation resistance of basalt-based protective coatings and epoxy system. Struct. Integr. Life 2021, 21, 185–189. [Google Scholar]

- Pavlović, M.; Dojčinović, M.; Harbinja, M.; Hođić, A.; Stojanović, M.; Čeganjac, Z.; Aćimović, Z. New types of protective coatings and development of test methods. Struct. Integr. Life 2023, 23, 257–260. [Google Scholar]

- Pavlović, M.; Dojčinović, M.; Nikolić, J.; Terzić, A.; Pavićević, V.; Drmanić, S.; Kurtanović, E.E. Application of waste raw materials as a reinforcement for protective coatings based on pyrophyllite: Original scientific paper. Chem. Ind. Chem. Eng. Q. 2024. [Google Scholar] [CrossRef]

- Kljajević, B. Software Program OZARIA 2.5 for Determining the Size and Shape of Grains of Refractory Fillers; VAGA Lab: Belgrade, Serbia, 2000. [Google Scholar]

- ASTM D-2393; Test Method for Viscosity of Epoxy Resins and Related Components. ASTM: West Conshohocken, PA, USA, 1986.

- Pavlović, M.; Andrić, L.; Radulović, D.; Drmanić, S.; Đorđević, N.; Petrov, M. Influence of Mechanical Activation of a Cordierite–Based Filler on Sedimentation Stability of Lost Foam Refractory Coatings. Sci. Sinter. 2019, 51, 15. [Google Scholar] [CrossRef]

- Pavlović, M.; Dojčinović, M. Kavitaciona Oštećenja Refrakcionih Materijala; Akademska Misao: Belgrade, Serbia, 2020; p. 165. ISBN 978-86-7466-823-8. [Google Scholar]

- ASTM G32-16; Standard Test Method for Cavitation Erosion Using Vibratory Apparatus. ASTM International: West Conshohocken, PA, USA, 2016. Available online: https://webstore.ansi.org/standards/astm/astmg3216red (accessed on 15 January 2024).

- Hauer, M.; Gärtner, F.; Krebs, S.; Klassen, T.; Watanabe, M.; Kuroda, S.; Krömmer, W.; Henkel, K.J. Process selection for the fabrication of cavitation erosion-resistant bronze coatings by thermal and kinetic spraying in maritime applications. Therm. Spray Technol. 2021, 30, 1310–1328. [Google Scholar] [CrossRef]

- Geiger, C.; Rager, H.; Czank, M. Cordierite III: The site occupation and concentration of Fe3+. Contrib. Mineral. Petrol. 2000, 140, 344–352. [Google Scholar] [CrossRef]

- Götze, J.; Pan, Y.; Müller, A. Mineralogy and mineral chemistry of quartz: A review. Mineral. Mag. 2021, 85, 639–664. [Google Scholar] [CrossRef]

- Petrović, R.; Janaćković, Đ.; Zec, S.; Drmanić, S.; Kostić-Gvozdenović, L. Phase-transformation kinetics in triphasic cordierite gel. J. Mater. Res. 2001, 16, 451–458. [Google Scholar] [CrossRef]

- American Gem Society and the International Gem Society. Available online: https://www.gemsociety.org/article/select-gems-ordered-mohs-hardness/ (accessed on 23 January 2025).

- Glasser, F.P. Cordierite. In Concise Encyclopedia of Advanced Ceramic Materials; Brook, R.J., Ed.; Pergamon Press: Oxford, UK, 1991; pp. 91–92. ISBN 9780080347202. [Google Scholar] [CrossRef]

- Kasper-Zubillaga, J.J. Roundness in quartz grains from inland and coastal dune sands, Altar Desert, Sonora, Mexico. Bol. Soc. Geol. Mex. 2009, 61, 1–12. [Google Scholar] [CrossRef]

- del Carmen Gutiérrez-Castorena, M.; Effland, W.R. 21—Pedogenic and Biogenic Siliceous Features. In Interpretation of Micromorphological Features of Soils and Regoliths; Stoops, G., Marcelino, V., Mees, F., Eds.; Elsevier: Amsterdam, the Netherlands, 2010; pp. 471–496. ISBN 9780444531568. [Google Scholar] [CrossRef]

- Arai, S.; Tamura, A.; Miura, M.; Morishita, T. Origin of spinel-hosted mineral inclusions in mantle peridotite from Setogawa in the Circum-Izu Massif Serpentine Belt, central Japan: Implications for the chromitite genesis. Ore Geol. Rev. 2022, 140, 104422. [Google Scholar] [CrossRef]

- Hossain, Z.; Fabricius, I.L.; Christensen, H.F. Elastic and nonelastic deformation of greensand. Lead Edge 2009, 28, 86–88. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlović, M.; Dojčinović, M.; Nikolić, J.; Aleksić, S.; Tucović, N.; Čeganjac, Z.; Drmanić, S. Cavitation Erosion of Protective Coating Based on Cordierite Filler and Epoxy Matrix. Materials 2025, 18, 1034. https://doi.org/10.3390/ma18051034

Pavlović M, Dojčinović M, Nikolić J, Aleksić S, Tucović N, Čeganjac Z, Drmanić S. Cavitation Erosion of Protective Coating Based on Cordierite Filler and Epoxy Matrix. Materials. 2025; 18(5):1034. https://doi.org/10.3390/ma18051034

Chicago/Turabian StylePavlović, Marko, Marina Dojčinović, Jasmina Nikolić, Stanko Aleksić, Nedeljko Tucović, Zoran Čeganjac, and Saša Drmanić. 2025. "Cavitation Erosion of Protective Coating Based on Cordierite Filler and Epoxy Matrix" Materials 18, no. 5: 1034. https://doi.org/10.3390/ma18051034

APA StylePavlović, M., Dojčinović, M., Nikolić, J., Aleksić, S., Tucović, N., Čeganjac, Z., & Drmanić, S. (2025). Cavitation Erosion of Protective Coating Based on Cordierite Filler and Epoxy Matrix. Materials, 18(5), 1034. https://doi.org/10.3390/ma18051034