A Micro-Nodal Tungsten-Rhenium Thin-Film Thermocouple Based on Electrohydrodynamic Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Electrohydrodynamic Printing System

2.3. Structure and Production

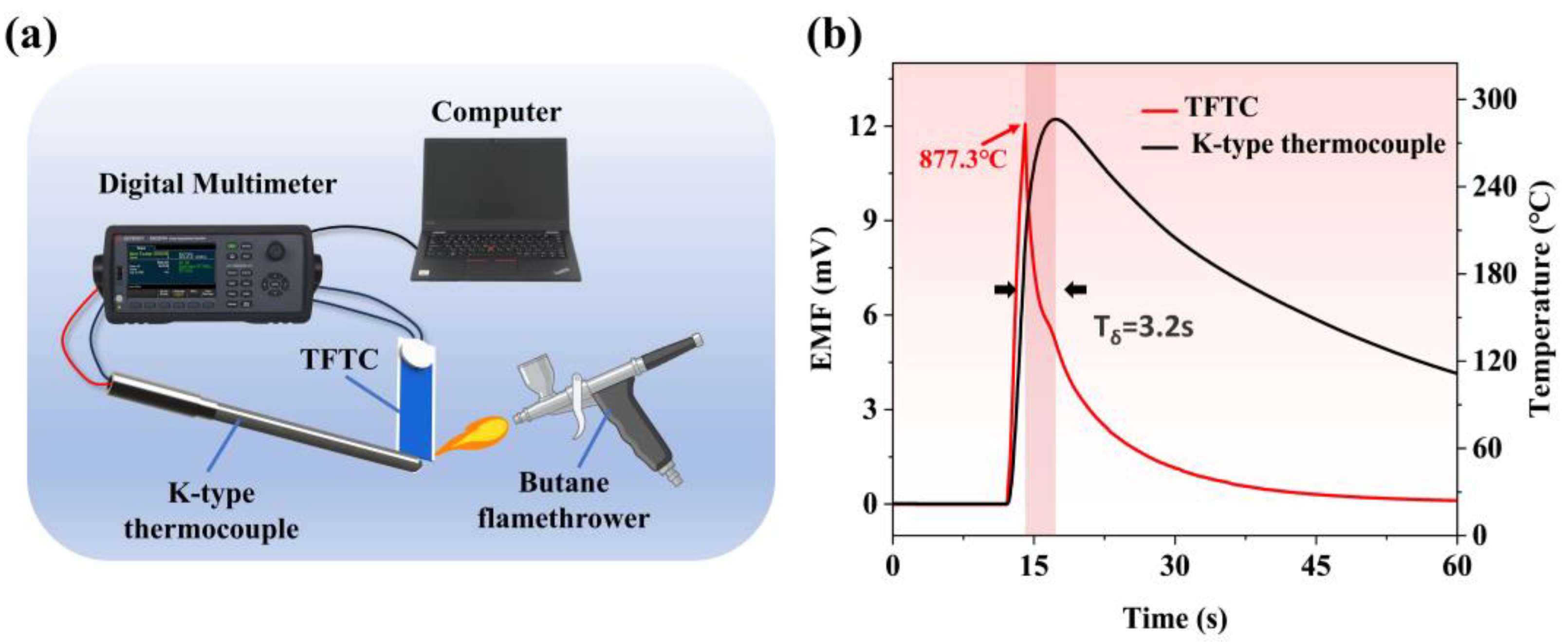

3. Results and Discussion

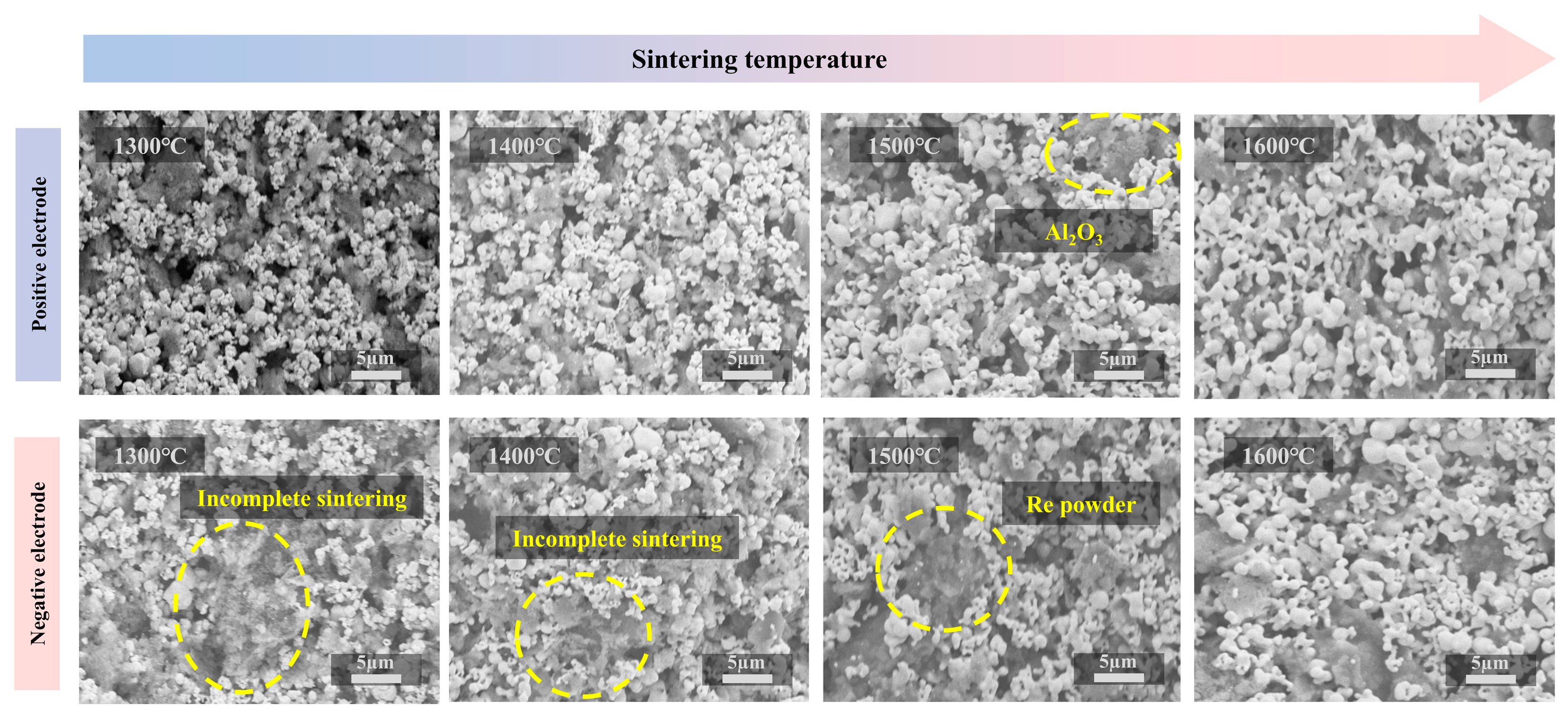

3.1. Effect of Sintering Temperature on TFTC

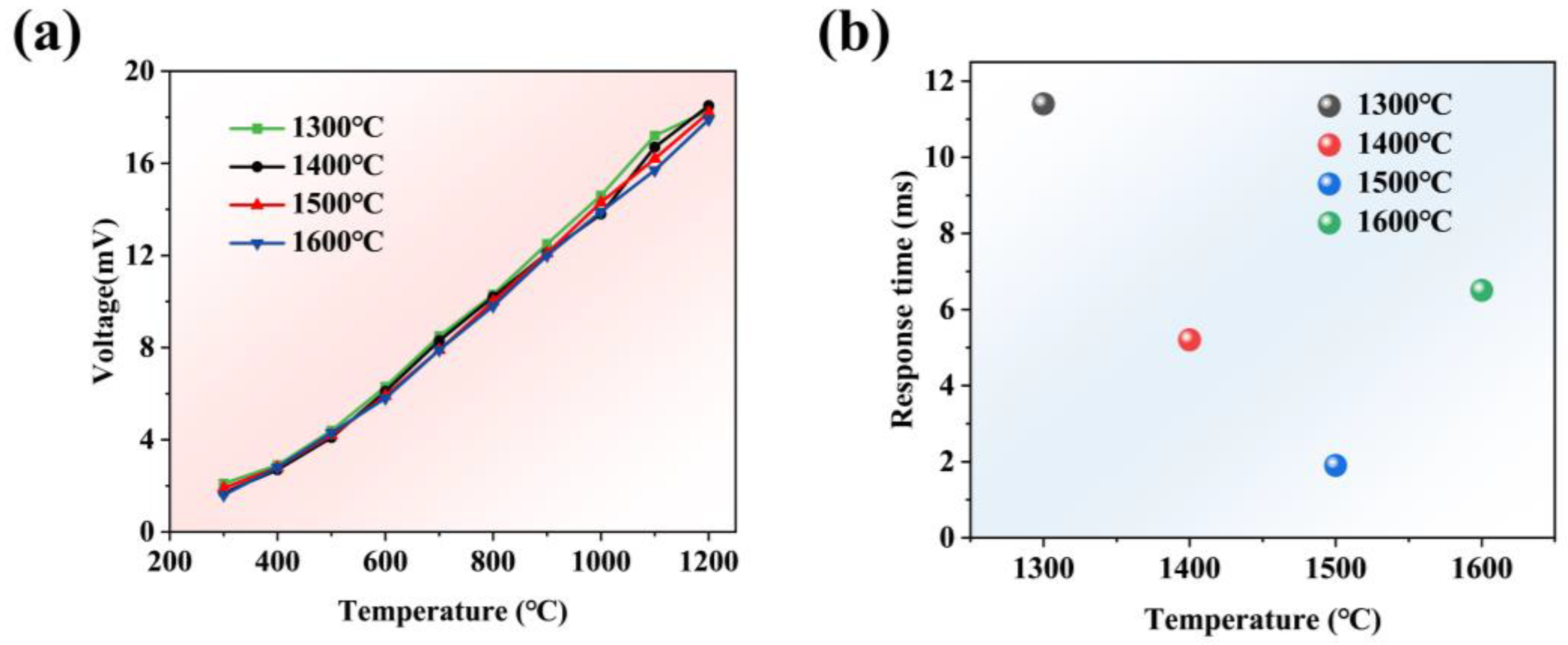

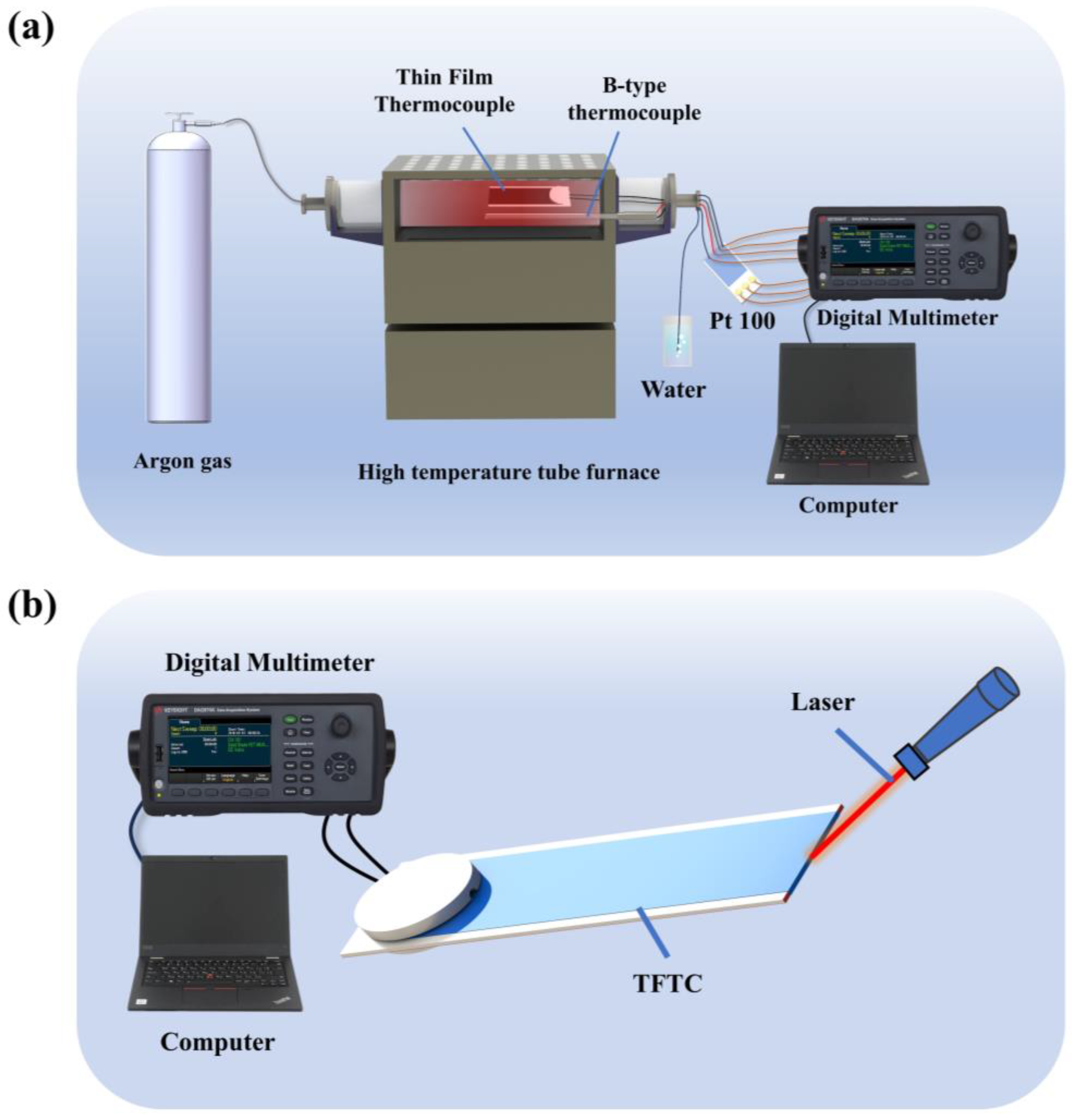

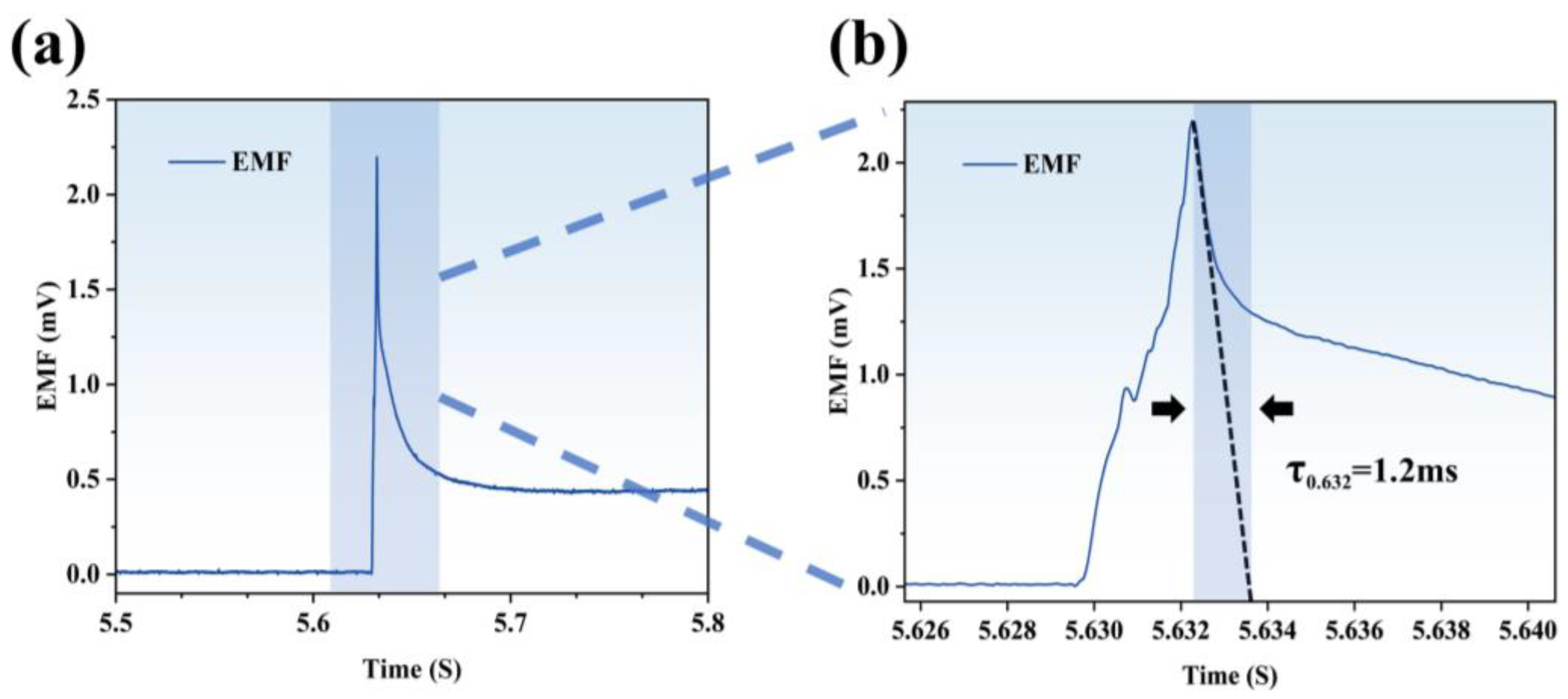

3.2. Sensor Performance Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviation

| TFTC | Thin-Film Thermocouple |

References

- Le, V.T.; San Ha, N.; Goo, N.S. Advanced sandwich structures for thermal protection systems in hypersonic vehicles: A review. Compos. Part B-Eng. 2021, 226, 109301. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Xu, B.; Zhang, J.; Sun, M.; Li, D. Research progress on preparation technology of oxide dispersion strengthened steel for nuclear energy. Int. J. Extrem. Manuf. 2021, 3, 032001. [Google Scholar] [CrossRef]

- Li, W.; Chen, S.; Peng, X.; Xiao, M.; Gao, L.; Garg, A.; Bao, N. A Comprehensive Approach for the Clustering of Similar-Performance Cells for the Design of a Lithium-Ion Battery Module for Electric Vehicles. Engineering 2019, 5, 795–802. [Google Scholar] [CrossRef]

- Ognjanovic, O.V.; Maksimovic, S.M.; Vidanovic, N.D.; Segan, S.D.; Kastratovic, G.M. Numerical aerodynamic-thermal-structural analyses of missile fin configuration during supersonic flight conditions. Therm. Sci. 2017, 21, 3037–3049. [Google Scholar] [CrossRef]

- Daniel, K.; Feng, C.; Gao, S. Single wavelength and ratio pyrometry reflection errors in temperature measurement of gas turbine blade. Measurement 2016, 86, 133–140. [Google Scholar]

- Bajzek, T.J. Thermocouples: A sensor for measuring temperature. IEEE Instrum. Meas. Mag. 2005, 8, 35–40. [Google Scholar] [CrossRef]

- Arulprakasajothi, M.; Rupesh, P.L. Surface temperature measurement of gas turbine combustor using temperature-indicating paint. Int. J. Ambient Energy 2020, 43, 2324–2327. [Google Scholar] [CrossRef]

- Chen, Z.; Yi, C.; Li, C.; Liang, A.; Wen, G.; Jiang, Z. A new RRS method for measurement of temperature with magnetic-liquid crystal nanosurface molecularly imprinted polymer probe. Spectrochim. Acta Part A—Mol. Biomol. Spectrosc. 2025, 329, 125597. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Z.; Lei, J.; Chen, L.; Li, L.; Zhao, N.; Fang, X.; Ruan, Y.; Tian, B.; Zhao, L. Flexible thin film thermocouples: From structure, material, fabrication to application. iScience 2023, 26, 107303. [Google Scholar] [CrossRef]

- Gong, X.; Huang, K.; Wu, Y.-H.; Zhang, X.-S. Recent progress on screen-printed flexible sensors for human health monitoring. Sens. Actuators A—Phys. 2022, 345, 113821. [Google Scholar] [CrossRef]

- Corea, J.R.; Flynn, A.M.; Lechene, B.; Scott, G.; Reed, G.D.; Shin, P.J.; Lustig, M.; Arias, A.C. Screen-printed flexible MRI receive coils. Nat. Commun. 2016, 7, 10839. [Google Scholar] [CrossRef] [PubMed]

- Gafurov, A.N.; Phung, T.H.; Ryu, B.H.; Kim, I.; Lee, T.M. AI-Aided Printed Line Smearing Analysis of the Roll-to-Roll Screen Printing Process for Printed Electronics. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 339–352. [Google Scholar] [CrossRef]

- Hai, Z.; Su, Z.; Guo, M.; Chen, J.; Lin, R.; Chen, Y.; Zhang, Y.; Zhu, H.; Liang, R.; Gong, S.; et al. Utilizing screen printing technology to fabricate tungsten-rhenium thick film thermocouples with a maximum temperature limit of 1600 °C. Measurement 2025, 239, 115454. [Google Scholar] [CrossRef]

- Fan, X.; Tian, B.; Shi, M.; Zhang, Z.; Liu, Z.; Zhou, G.; Liu, J.; Le, L.; Lin, Q.; Jiang, Z. Sandwich probe temperature sensor based on In2O3-IZO thin film for ultra-high temperatures. Int. J. Extrem. Manuf. 2024, 6, 055504. [Google Scholar] [CrossRef]

- Yu, X.; Wang, C.; Liu, Y.; Yu, D.; Xing, T. Recent developments in magnetron sputtering. Plasma Sci. Technol. 2006, 8, 337–343. [Google Scholar]

- Ruan, Y.; Xue, M.; Teng, J.; Wu, Y.; Shi, M. Horizontal Oxidation Diffusion Behavior of MEMS-Based Tungsten-Rhenium Thin Film Thermocouples. Materials 2022, 15, 5071. [Google Scholar] [CrossRef]

- Liu, Y.T.; Shi, P.; Ren, W.; Huang, R. Thermoelectrical Properties of ITO/Pt, In2O3/Pt and ITO/In2O3 Thermocouples Prepared with Magnetron Sputtering. Crystals 2023, 13, 533. [Google Scholar] [CrossRef]

- Jayasinghe, S.N.; Edirisinghe, M.J.; De Wilde, T. A novel ceramic printing technique based on electrostatic atomization of a suspension. Mater. Res. Innov. 2002, 6, 92–95. [Google Scholar] [CrossRef]

- Jayasinghe, S.N.; Edirisinghe, M.J. A novel process for simulataneous printing of multiple tracks from concentrated suspensions. Mater. Res. Innov. 2003, 7, 62–64. [Google Scholar] [CrossRef]

- Song, J.H.; Edirisinghe, M.J.; Evans, J.R.G. Formulation and multilayer jet printing of ceramic inks. J. Am. Ceram. Soc. 1999, 82, 3374–3380. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Shin, Y.-S.; Park, S.-E.; Yu, T.-U.; Hwang, J. Electrohydrodynamic printing of silver nanoparticles by using a focused nanocolloid jet. Appl. Phys. Lett. 2007, 90, 081905. [Google Scholar] [CrossRef]

- Wang, D.Z.; Edirisinghe, M.J.; Jayasinghe, S.N. Solid freeform fabrication of thin-walled ceramic structures using an electrohydrodynamic jet. J. Am. Ceram. Soc. 2006, 89, 1727–1729. [Google Scholar] [CrossRef]

- Jaworek, A.; Krupa, A. Classification of the modes of EHD spraying. J. Aerosol Sci. 1999, 30, 873–893. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, J.; Su, S.; Zhang, C.; Li, J.; Yang, M.; Cao, S.; Zhou, H.; Zhao, K.; Wang, D. Preparation of defect-free alumina insulation film using layer-by-layer electrohydrodynamic jet deposition for high temperature applications. Ceram. Int. 2021, 47, 14498–14505. [Google Scholar] [CrossRef]

- Su, S.; Liang, J.; Wang, Z.; Xin, W.; Li, X.; Wang, D. Microtip focused electrohydrodynamic jet printing with nanoscale resolution. Nanoscale 2020, 12, 24450–24462. [Google Scholar] [CrossRef]

- He, Y.; Chen, H.; Li, L.; Liu, J.; Guo, M.; Su, Z.; Duan, B.; Zhao, Y.; Sun, D.; Hai, Z. Electrohydrodynamic Printed Ultramicro AgNPs Thin-Film Temperature Sensor. IEEE Sens. J. 2023, 23, 21018–21028. [Google Scholar] [CrossRef]

- Shakeel, M.; Rehman, K.; Ahmad, S.; Choi, K.-H.; Khan, A. A Weldless Approach for Thermocouple Fabrication Through Direct Ink Writing Technique. IEEE Sens. J. 2021, 21, 1279–1286. [Google Scholar] [CrossRef]

- Webster, E. A critical review of the common thermocouple reference functions. Metrologia 2021, 58, 025004. [Google Scholar] [CrossRef]

- Yamamoto, T. Improvements in Flash Sintering for Practical Application. Mater. Trans. 2023, 64, 2059–2068. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, B.; Yu, Q.; Lin, Q.; Zhao, N.; Jing, W.; Jiang, Z. A Protected Tungsten-Rhenium Thin Film Thermocouples sensor. In Proceedings of the 12th IEEE Annual International Conference on Nano/Micro Engineered and Molecular Systems (IEEE-NEMS), Los Angeles, CA, USA, 9–12 April 2017; pp. 796–799. [Google Scholar]

- Chen, J.; Su, Z.; Lin, R.; Yang, K.; Hu, S.; Liu, S.; Chen, Y.; Zhang, Y.; Xue, C.; Hai, Z.; et al. A Dual-Parametric G-Type Coaxial Thermocouple With Superior Thermal Measurement Capabilities. IEEE Sens. J. 2024, 24, 36403–36411. [Google Scholar] [CrossRef]

- Zeng, Y.; Chen, G.; Zhao, F.; Wu, C.; Xu, L.; Zhang, Y.; Wu, W.; Lin, Y.; He, G.; Chen, Q.; et al. Metal-based sandwich type thick-film platinum resistance temperature detector for in-situ temperature monitoring of hot-end components. Appl. Surf. Sci. 2023, 637, 157979. [Google Scholar] [CrossRef]

- Papaioannou, N.; Leach, F.; Davy, M. Effect of Thermocouple Size on the Measurement of Exhaust Gas Temperature in Internal Combustion Engines; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Citroni, R.; Mangini, F.; Frezza, F. Efficient Integration of Ultra-low Power Techniques and Energy Harvesting in Self-Sufficient Devices: A Comprehensive Overview of Current Progress and Future Directions. Sensors 2024, 24, 4471. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Chen, J.; Gong, S.; Li, Y.; Liu, S.; Li, J.; Wang, S.; Hai, Z.; Liu, Z.; Li, J. A Micro-Nodal Tungsten-Rhenium Thin-Film Thermocouple Based on Electrohydrodynamic Printing. Materials 2025, 18, 1031. https://doi.org/10.3390/ma18051031

Hu S, Chen J, Gong S, Li Y, Liu S, Li J, Wang S, Hai Z, Liu Z, Li J. A Micro-Nodal Tungsten-Rhenium Thin-Film Thermocouple Based on Electrohydrodynamic Printing. Materials. 2025; 18(5):1031. https://doi.org/10.3390/ma18051031

Chicago/Turabian StyleHu, Shuntao, Jun Chen, Shigui Gong, Ying Li, Shilong Liu, Jihao Li, Shuaida Wang, Zhenyin Hai, Zhichun Liu, and Junyang Li. 2025. "A Micro-Nodal Tungsten-Rhenium Thin-Film Thermocouple Based on Electrohydrodynamic Printing" Materials 18, no. 5: 1031. https://doi.org/10.3390/ma18051031

APA StyleHu, S., Chen, J., Gong, S., Li, Y., Liu, S., Li, J., Wang, S., Hai, Z., Liu, Z., & Li, J. (2025). A Micro-Nodal Tungsten-Rhenium Thin-Film Thermocouple Based on Electrohydrodynamic Printing. Materials, 18(5), 1031. https://doi.org/10.3390/ma18051031