Effect of Annealing in Air on the Structural and Optical Properties and Efficiency Improvement of TiO2/CuxO Solar Cells Obtained via Direct-Current Reactive Magnetron Sputtering

Abstract

1. Introduction

2. Materials and Methods

3. Results

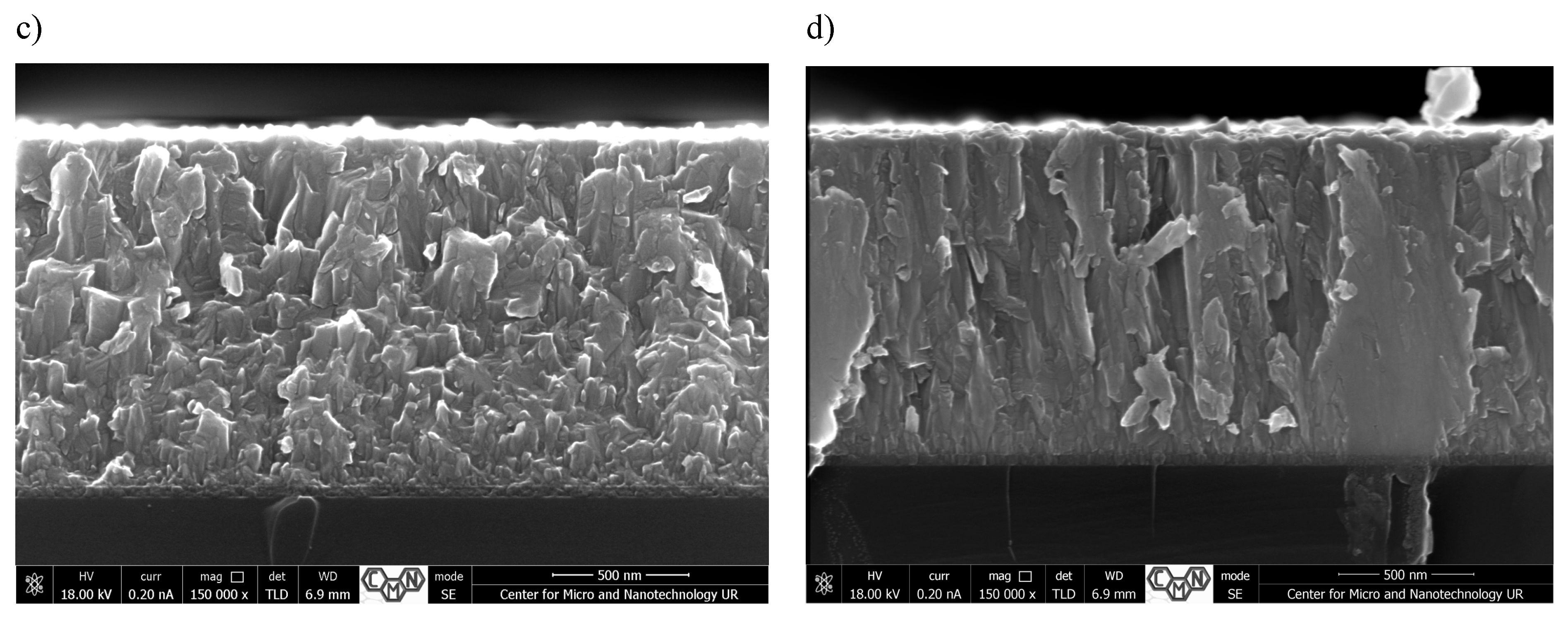

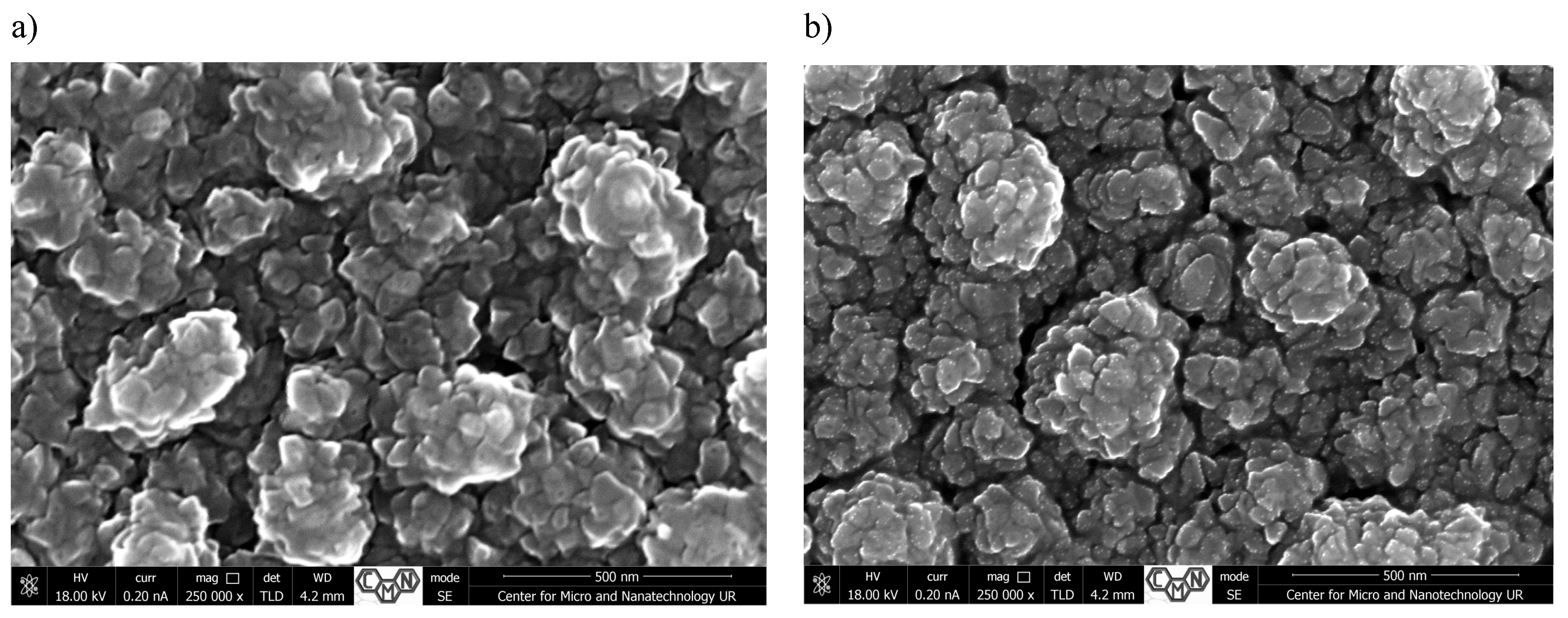

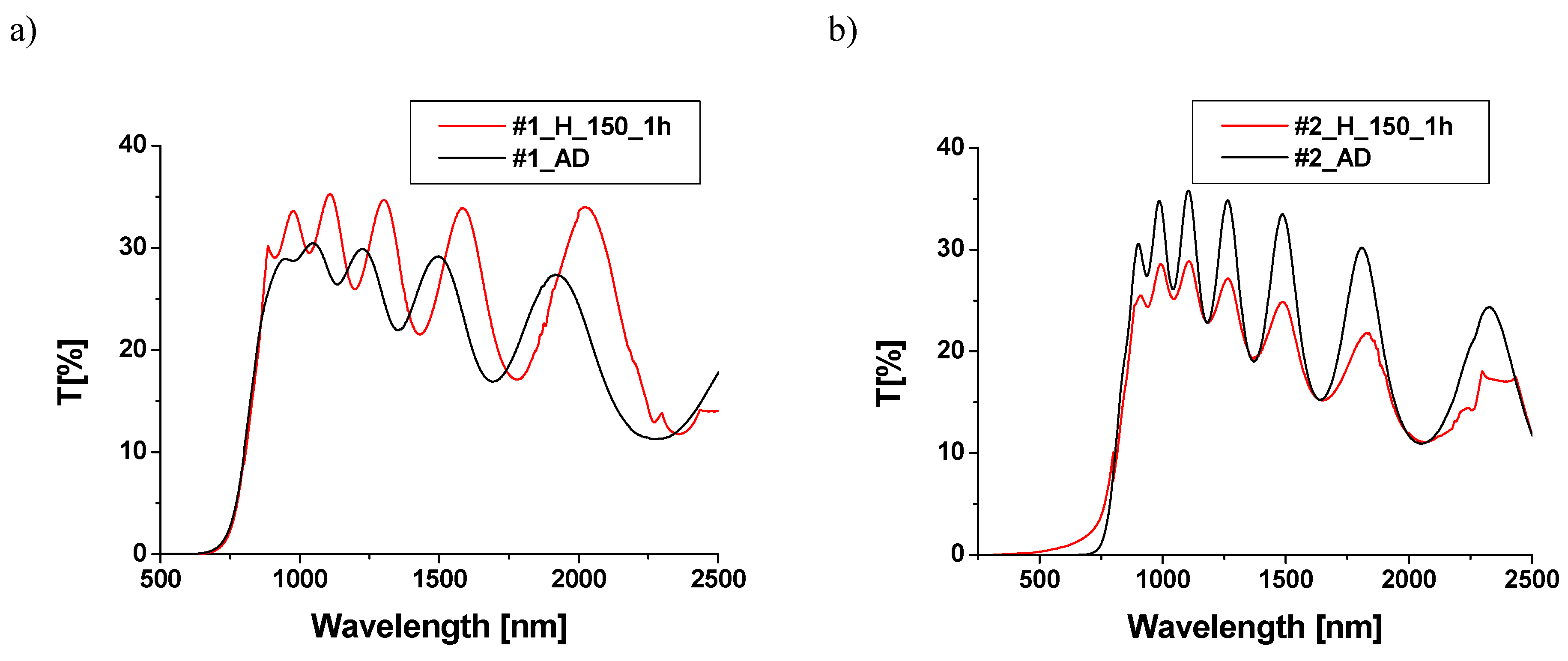

3.1. Structural Characterization

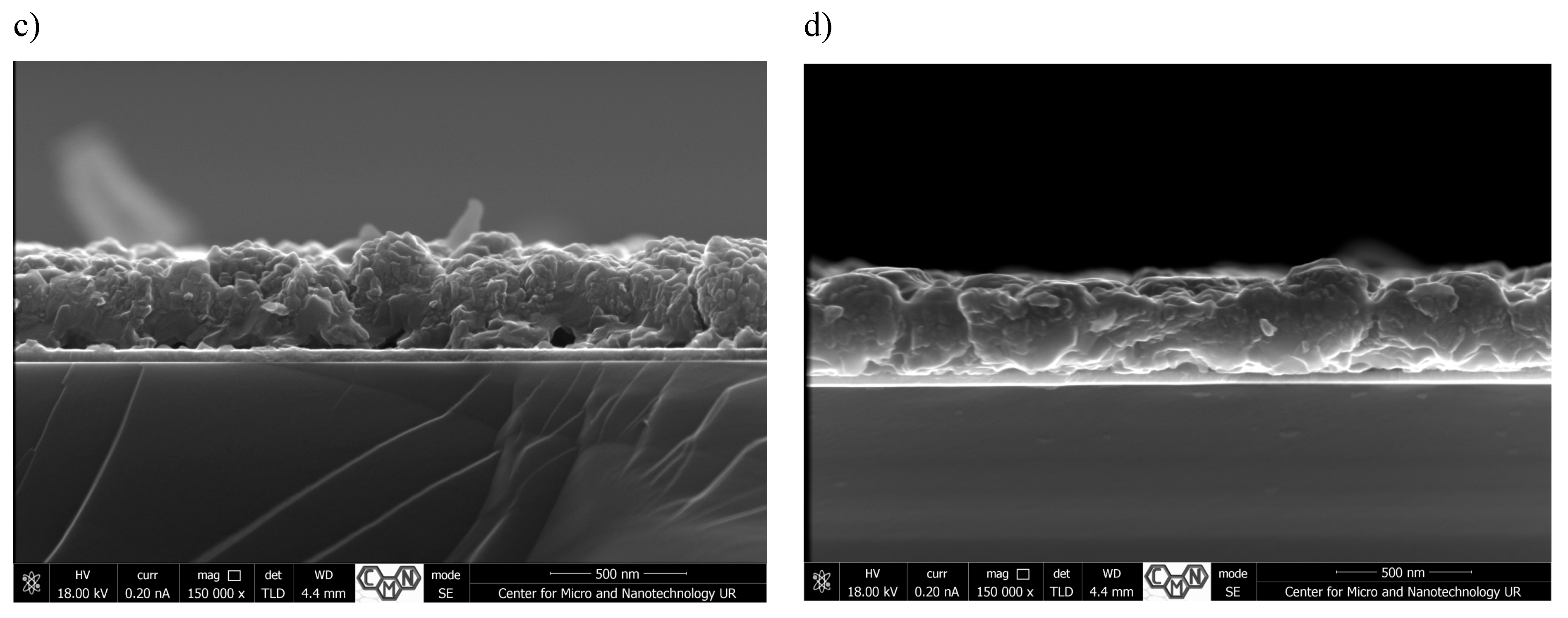

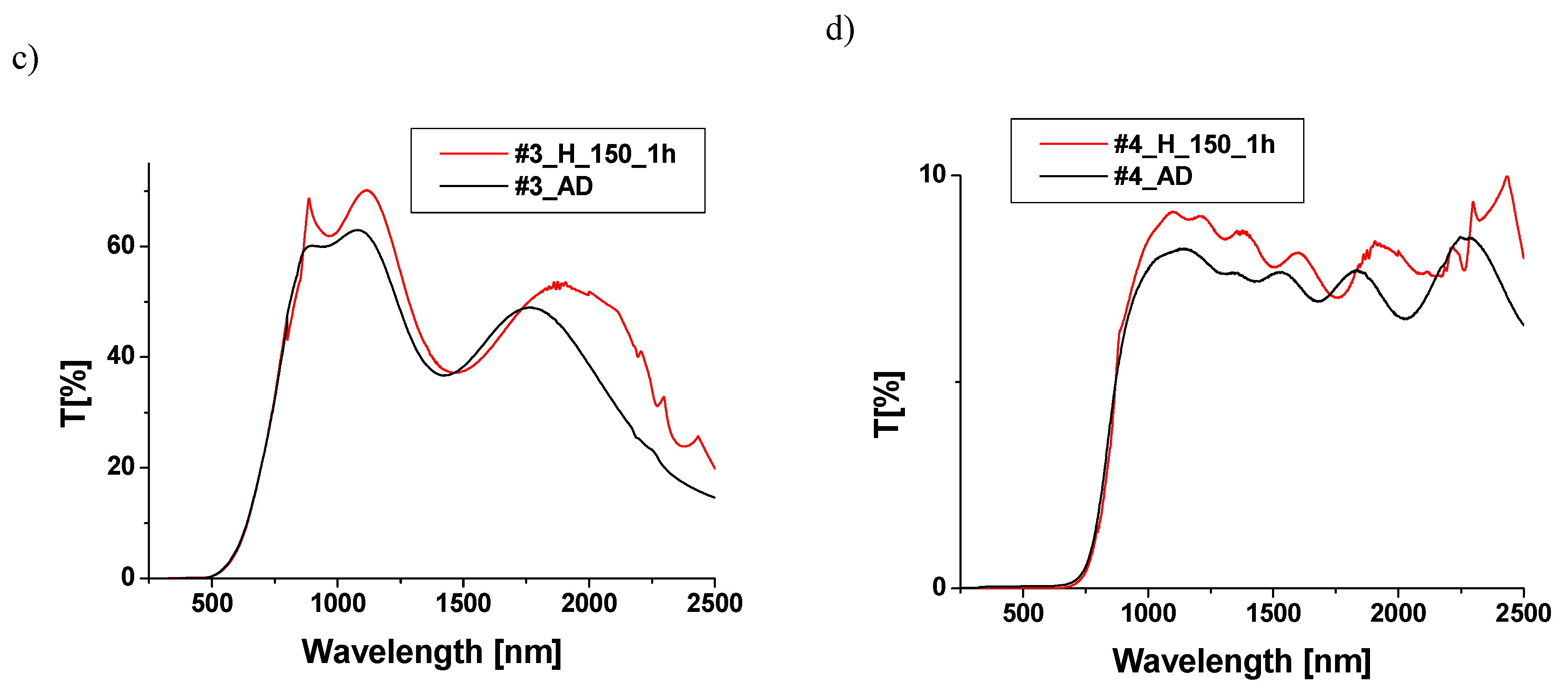

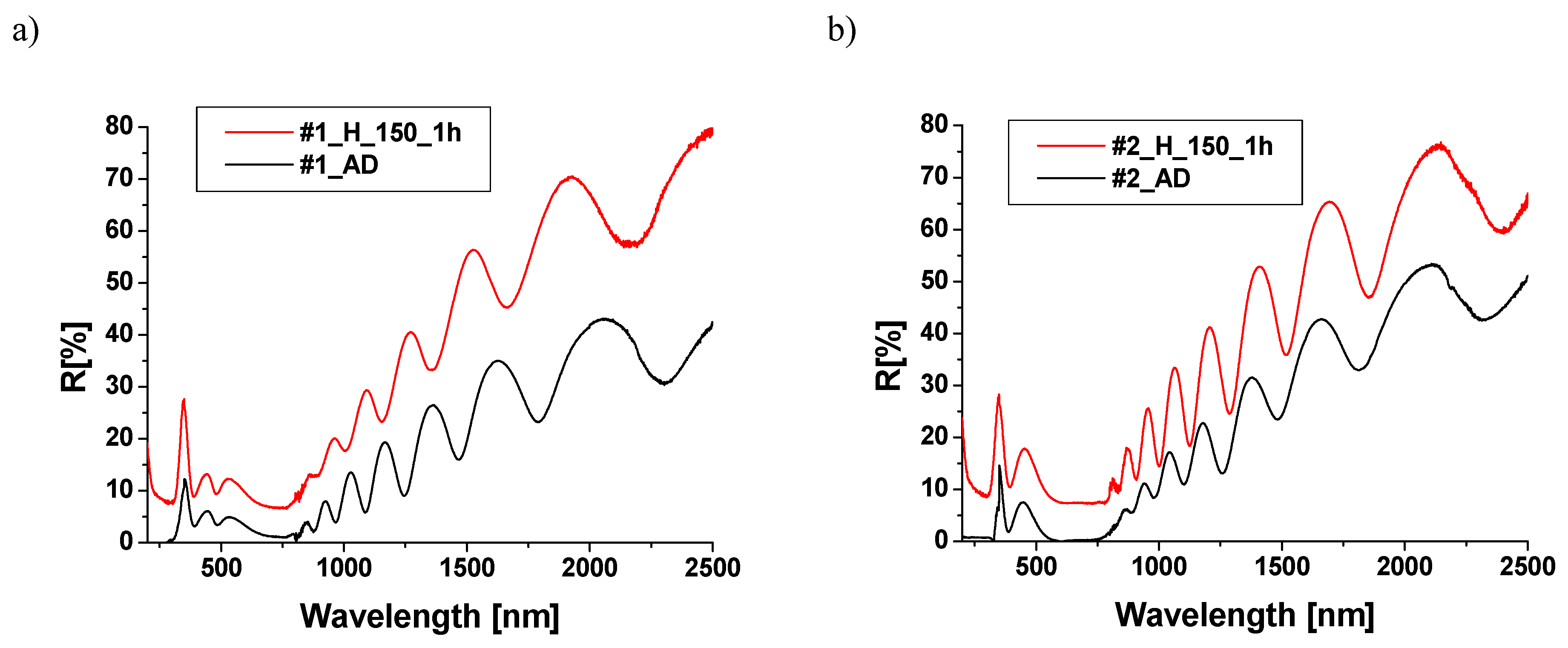

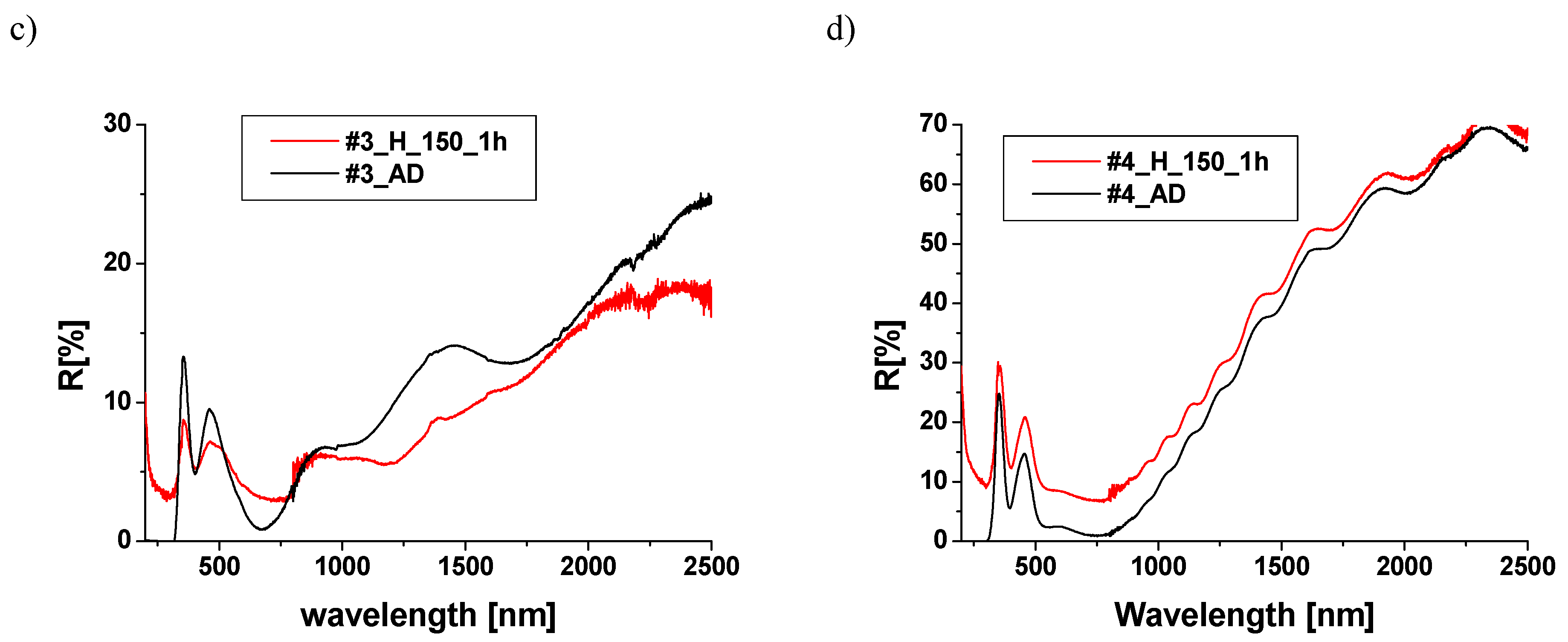

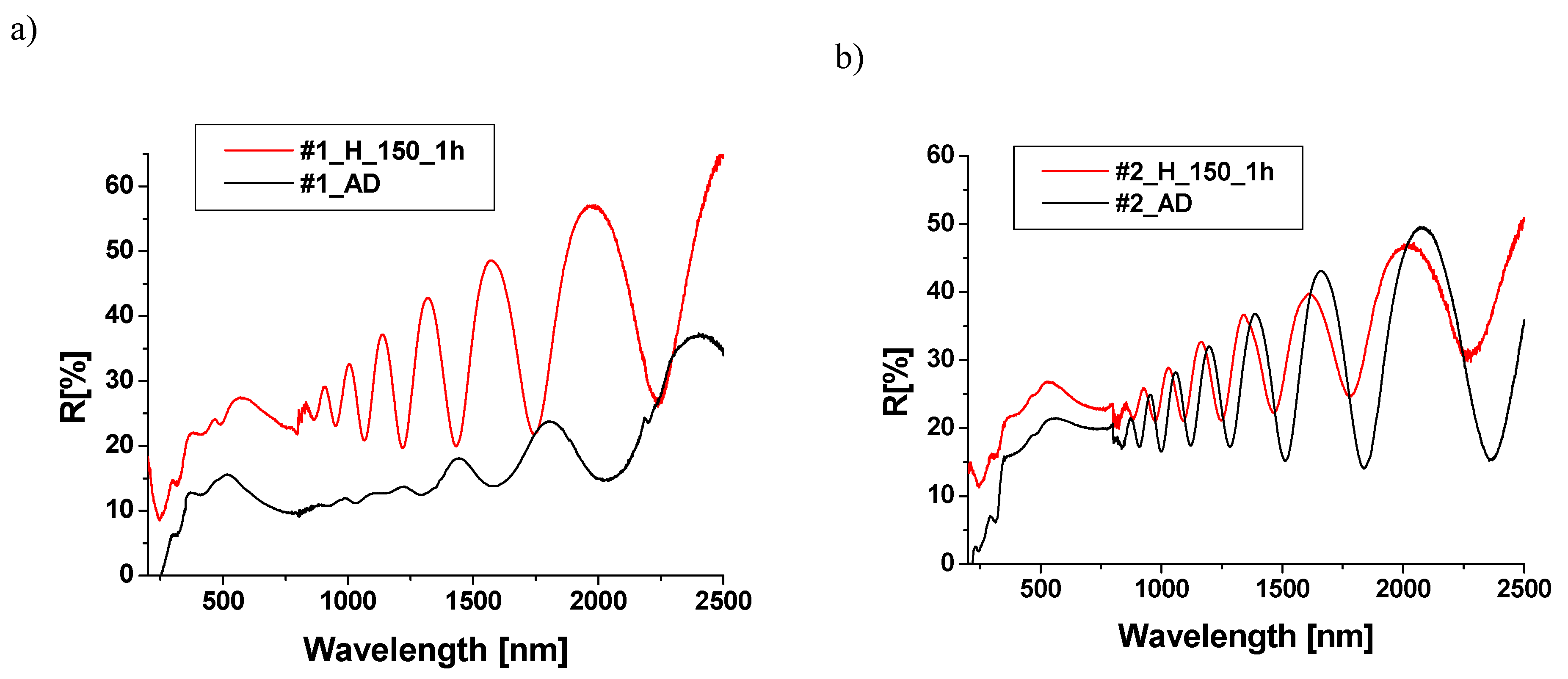

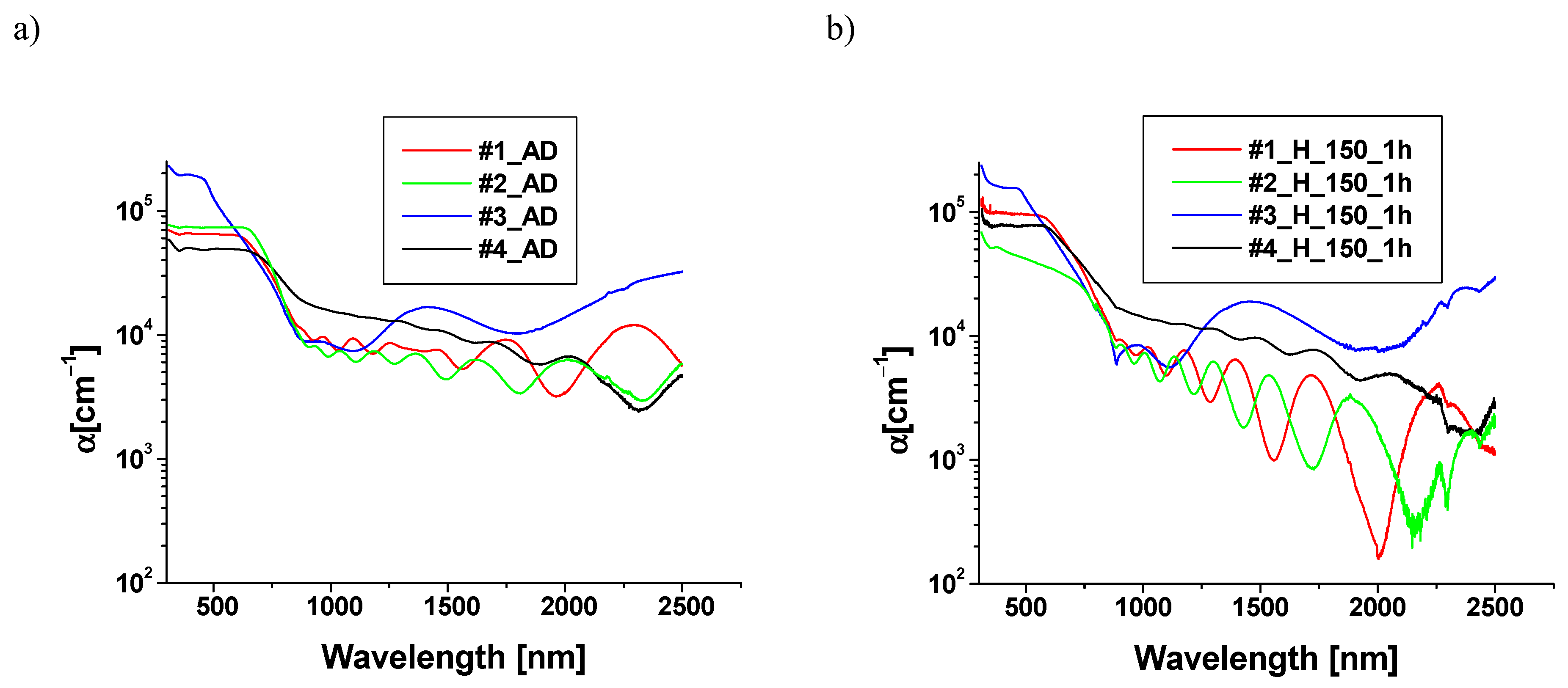

3.2. Optical Characterization

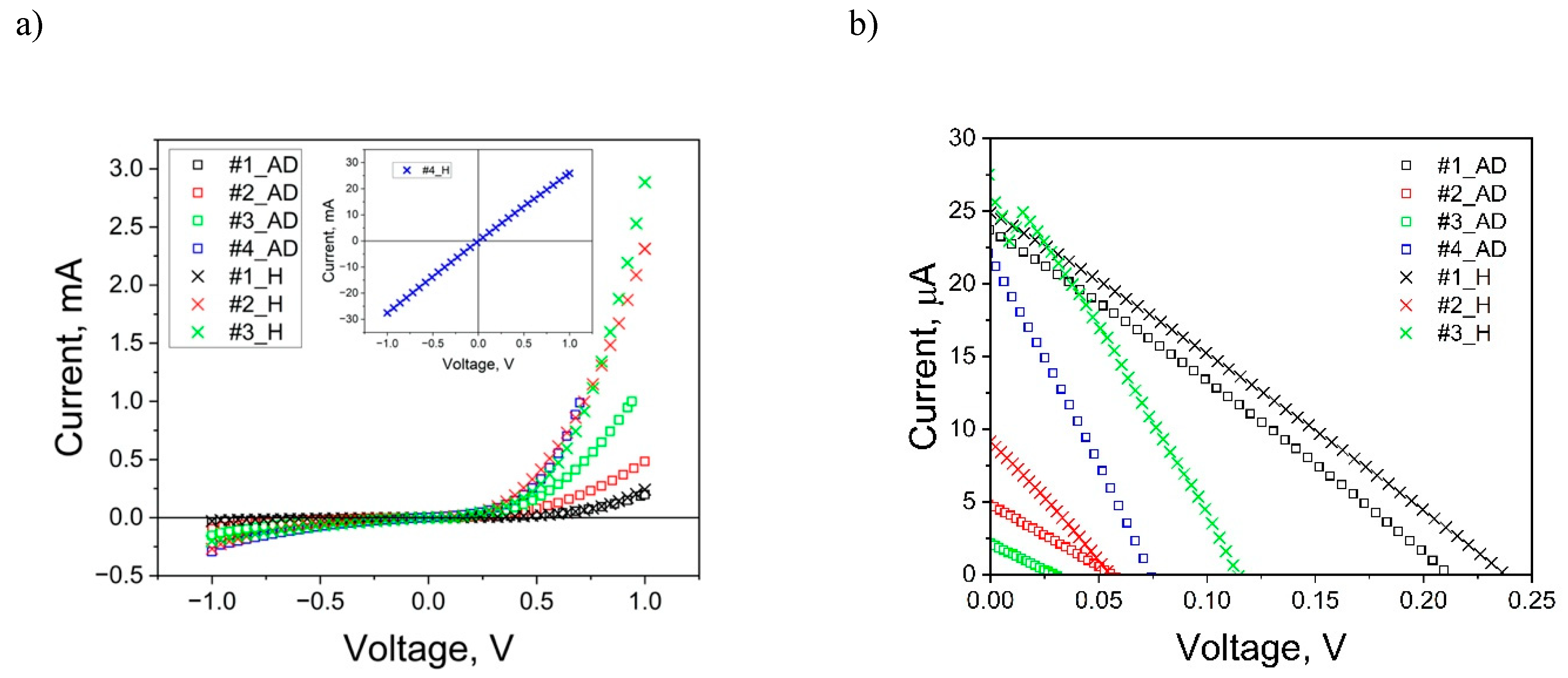

3.3. I-V Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shioki, T.; Tsuji, R.; Oishi, K.; Fukumuro, N.; Ito, S. Designed Mesoporous Architecture by 10–100 nm TiO2 as Electron Transport Materials in Carbon-Based Multiporous-Layered-Electrode Perovskite Solar Cells. Photonics 2024, 11, 236. [Google Scholar] [CrossRef]

- Chen, Y.C.; Yang, Z.-L.; Hsu, Y.-K. Unassisted solar water splitting by dual Cu2O-based tandem device with complementary wavelength-dependent quantum efficiency and antipodal conductivity. Renew. Energy 2023, 212, 166–174. [Google Scholar] [CrossRef]

- Sibiński, M.; Sawicka-Chudy, P.; Wisz, G.; Gnida, P.; Schab-Balcerzak, E.; Wal, A.; Yavorskyi, R.; Cholewa, M. Impact of blocking layers based on TiO2 and ZnO prepared via direct current reactive magnetron sputtering on DSSC solar cells. Sci. Rep. 2024, 14, 10676. [Google Scholar] [CrossRef] [PubMed]

- Bencherif, H.; Dehimi, L.; Mahsar, N.; Kouriche, E.; Pezzimenti, F. Modeling and optimization of CZTS kesterite solar cells using TiO2 as efficient electron transport layer. Mat. Sci. Eng. B 2022, 276, 115574. [Google Scholar] [CrossRef]

- Du, Y.; Gao, X.; Meng, X. Preparation and characterization of single-phased n-type CuO film by DC magnetron sputtering. Phys. B 2019, 560, 37–40. [Google Scholar] [CrossRef]

- Kim, J.-A.; Park, J.-H.; Park, S.-G.; Son, C.-S.; Son, Y.-K.; Hwang, D.-H. Effect of Substrate Temperature on Variations in the Structural and Optical Properties of Cu2O Thin Films Deposited via RF Magnetron Sputtering. Crystals 2023, 13, 643. [Google Scholar] [CrossRef]

- Graillot-Vuillecot, R.; Thomann, A.-L.; Lecas, T.; Cachoncinlle, C.; Millon, E.; Caillard, A. Properties of Ti-oxide thin films grown in reactive magnetron sputtering with self-heating target. Vacuum 2022, 197, 110813. [Google Scholar] [CrossRef]

- Rosales Medina, P.Y.; Avelar Muñoz, F.; Flores Sigala, E.; Rosales, R.G.; Berumen Torres, J.A.; Araiza Ibarra, J.d.J.; Tototzintle Huitle, H.; Méndez García, V.H.; Ortega Sigala, J.J. Growth of Nanocolumnar TiO2 Bilayer by Direct Current Reactive Magnetron Sputtering in Glancing-Angle Deposition Configuration for High-Quality Electron Transport Layer. Micromachines 2023, 14, 1483. [Google Scholar] [CrossRef]

- Wojcieszak, D.; Obstarczyk, A.; Domaradzki, J.; Kaczmarek, D.; Zakrzewska, K.; Pastuszek, R. Investigations of structure and electrical properties of TiO2/CuO thin film heterostructures. Thin Solid. Film. 2019, 290, 137538. [Google Scholar] [CrossRef]

- Patel, D.B.; Chauhan, K.R. 50% transparent solar cells of CuOx/TiO2: Device aspects. J. Alloys Compd. 2020, 842, 155594. [Google Scholar] [CrossRef]

- Sawicka-Chudy, P.; Sibiński, M.; Rybak-Wilusz, E.; Cholewa, M.; Wisz, G.; Yavorskyi, R. Review of the development of copper oxides with titanium dioxide thin film solar cells. AIP Adv. 2020, 10, 10701. [Google Scholar] [CrossRef]

- Wisz, G.; Sawicka-Chudy, P.; Wal, A.; Sibiński, M.; Potera, P.; Yavorskyi, R.; Nykyruy, L.; Płoch, D.; Bester, M.; Cholewa, M.; et al. Structure defects and photovoltaic properties of TiO2:ZnO/CuO solar cells prepared by reactive DC magnetron sputtering. Appl. Sci. 2023, 13, 3613. [Google Scholar] [CrossRef]

- Wisz, G.; Sawicka-Chudy, P.; Sibiński, M.; Yavorskyi, R.; Łabuz, M.; Płoch, D.; Bester, M. Formation and Characterization of Stable TiO2/CuxO-Based Solar Cells. Materials 2023, 16, 5683. [Google Scholar] [CrossRef]

- Ciria-Ramos, I.; Juarez-Perez, E.J.; Haro, M. Solar Energy Storage Using a Cu2O-TiO2 Photocathode in a Lithium Battery. Small 2023, 19, 2301244. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tareja, R.K.; Wilker, U.; Schade, W. Phase transformation in room temperature pulsed laser deposited TiO2 thin films. Appl. Surf. Sci. 2003, 206, 137–148. [Google Scholar] [CrossRef]

- Hussain, S.; Cao, C.; Usman, Z.; Chen, Z.; Nabi, G.; Khan, W.S.; Ali, Z.; Butt, F.K.; Mahmood, T. Fabrication and photovoltaic characteristics of Cu2O/TiO2 thin film heterojunction solar cell. Thin Solid. Films 2012, 522, 430–434. [Google Scholar] [CrossRef]

- Dette, C.; Pérez-Osorio, M.A.; Kley, C.S.; Punke, P.; Patrick, C.E.; Jacobson, P.; Giustino, F.; Jung, S.J.; Kern, K. TiO2 anatase with a bandgap in the visible region. Nano Lett. 2014, 14, 6533–6538. [Google Scholar] [CrossRef]

- Tahir, D.; Tougaard, S. Electronic and optical properties of Cu, CuO and Cu2O studied by electron spectroscopy. J. Phys. Condens. Matter 2012, 24, 175002. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, T.S.; Terasaki, I.; Karppinen, M. Anomalous thickness-dependent optical energy gap of ALD-grown ultra-thin CuO films. J. Phys. Condens. Matter 2016, 28, 475801. [Google Scholar] [CrossRef]

- Xu, L.; Zheng, G.; Pei, S.; Wang, J. Investigation of optical bandgap variation and photoluminescence behavior in nanocrystalline CuO thin films. Optik 2018, 158, 382–390. [Google Scholar] [CrossRef]

- Zheng, W.; Chen, Y.; Peng, X.; Zhong, K.; Lin, Y.; Huang, Z. The phase evolution and physical properties of binary copper oxide thin films prepared by reactive magnetron sputtering. Materials 2018, 11, 1253. [Google Scholar] [CrossRef]

- Diachenko, O.; Kováč, J., Jr.; Dobrozhan, O.; Novák, P.; Kováč, J.; Skriniarova, J.; Opanasyuk, A. Structural and optical properties of CuO thin films, synthesized using spray pyrolysis method. Coatings 2021, 11, 1392. [Google Scholar] [CrossRef]

- Tariq, M.; Afzal, N.; Rafique, M. Enhanced photodetection performance of sputtered cupric oxide thin film through annealing process. Opt. Quant. Electron. 2021, 53, 685. [Google Scholar] [CrossRef]

- Onah, D.U.; Agbo, P.E.; Nwodo, M.O.; Ijeh, R.O.; Uguru, E.H.; Omeje, C.U. Thermal annealing on the EDS and optical properties of TiO2/CuO core-shell thin films. Eur. J. Mater. Sci. 2021, 8, 1–9. [Google Scholar]

- Yavorskyi, R.S. Features of optical properties of high stable CdTe photovoltaic absorber layer. Phys. Chem. Sol. State 2020, 21, 243–253. [Google Scholar] [CrossRef]

- Mathews, N.R.; Morales, E.R.; Cortés-Jacome, M.A.; Antonio, J.T. TiO2 thin films—Influence of annealing temperature on structural, optical and photocatalytic properties. Sol. Energy 2009, 83, 1499–1508. [Google Scholar] [CrossRef]

- Wisz, G.; Bester, M.; Łabuz, M.; Ruszała, M.; Potera, P.; Płoch, D.; Smertenko, P.; Yavorskyi, R.; Nykyruy, N. Impact of titanium and copper buffer layers on the structure and I-V characteristics of TiO2/CuxO thin film solar cells. Appl. Surf. Sci. 2025, 682, 161650. [Google Scholar] [CrossRef]

- Saliy, Y.P.; Nykyruy, L.I.; Yavorskyi, R.S.; Adamiak, S. The surface morphology of CdTe thin films obtained by open evaporation in vacuum. J. Nano Electron. Phys. 2017, 9, 05016. [Google Scholar] [CrossRef] [PubMed]

- Nykyrui, L.; Saliy, Y.; Yavorskyi, R.; Yavorskyi, Y.; Schenderovsky, V.; Wisz, G.; Górny, S. CdTe vapor phase condensates on (100) Si and glass for solar cells. In Proceedings of the 2017 IEEE 7th International Conference Nanomaterials: Application & Properties (NAP), Zatoka, Ukraine, 10–15 September 2017; p. 01PCSI26-1. [Google Scholar] [CrossRef]

- Punitha, K.; Sivakumar, R.; Sanjeeviraja, C.; Sathe, V.; Ganesan, V. Physical properties of electron beam evaporated CdTe and CdTe:Cu thin films. J. Appl. Phys. 2014, 116, 213502. [Google Scholar] [CrossRef]

- Kumi-Barimah, E.; Penhale-Jones, R.; Salimian, A.; Upadhyaya, H.; Hasnath, A.; Jose, G. Phase evolution, morphological, optical and electrical properties of femtosecond pulsed laser deposited TiO2 thin films. Sci. Rep. 2020, 10, 10144. [Google Scholar] [CrossRef]

- Santos, H.L.S.; Corradini, P.G.; Andrade, M.A.S., Jr.; Mascaro, L.H. CuO/NiOx thin film-based photocathodes for photoelectrochemical water splitting. J. Solid. State Electrochem. 2020, 24, 1899–1908. [Google Scholar] [CrossRef]

- Sawicka-Chudy, P.; Wisz, G.; Głowa, Ł.; Sibiński, M.; Potera, P.; Cholewa, M.; Wielgosz, M.; Górny, S. Optical and structural properties of TiO2 as intermediate buffer layer prepared by DC reactive magnetron sputtering for solar cells. Optik 2019, 181, 1122–1129. [Google Scholar] [CrossRef]

- Ravichandiran, C.; Sakthivelu, A.; Davidprabu, R.; Valanarasu, S.; Kathalingam, A.; Ganesh, V.; Mohd Shkir Sreelatha, C.J.; AlFaify, S. Effect of deposition temperature on key optoelectronic properties of electrodeposited cuprous oxide thin films. Opt. Quant. Electron. 2018, 50, 281. [Google Scholar] [CrossRef]

- Akaltun, Y. Effect of thickness on the structural and optical properties of CuO thin films grown by successive ionic layer adsorption and reaction. Thin Solid. Films 2015, 594A, 30–34. [Google Scholar] [CrossRef]

- Heinemann, M.; Eifert, B.; Heiliger, C. Band structure and phase stability of the copper oxides Cu2O, CuO, and Cu4O3. Phys. Rev. B 2013, 87, 115111. [Google Scholar] [CrossRef]

- Murali, D.S.; Kumar, S.; Choudhary, R.J.; Wadikar, A.D.; Jain, M.K.; Subrahmanyam, A. Synthesis of Cu2O from CuO thin films: Optical and electrical properties. Aip Adv. 2015, 5, 047143. [Google Scholar] [CrossRef]

- Viezbicke, B.D.; Patel, S.; Davis, B.E.; Birnie, D.P. Evaluation of the Tauc method for optical absorption edge determination: ZnO thin films as a model system. Phys. Status Solidi B 2015, 252, 1700–1710. [Google Scholar] [CrossRef]

- Wisz, G.; Potera, P.; Sawicka-Chudy, P.; Gwóźdź, K. Optical Properties of ITO/Glass Substrates Modified by Silver Nanoparticles for PV Applications. Coatings 2023, 13, 61. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, T.; Meng, D.; Yang, J.; Li, Y.; Ma, Q.; Han, J. Fabrication of nanostructured CuO films by electrodeposition and their photocatalytic properties. Appl. Surf. Sci. 2014, 317, 414. [Google Scholar] [CrossRef]

- Tripathi, A.; Dixit, T.; Agrawal, J.; Singh, V. Bandgap engineering in CuO nanostructures: Dual-band, broadband, and UV-C photodetectors. Appl. Phys. Lett. 2020, 116, 111102. [Google Scholar] [CrossRef]

- Erdogan, I.Y.; Güllü, Ö. Optical and structural properties of CuO nanofilm: Its diode application. J. Alloy. Compd. 2010, 492, 378–383. [Google Scholar] [CrossRef]

- Khan, M.A.; Nayan, N.; Shadiullah, A.; Ahmad, M.K.; Soon, C.F. Surface study of CuO nanopetals by advanced nanocharacterization techniques with enhanced optical and catalytic properties. Nanomaterials 2020, 10, 1298. [Google Scholar] [CrossRef]

- Dhanasekaran, V.; Mahalingam, T.; Chandramohan, R. Post Heat Treatment Effect on Electrochemically Synthesized CuO Thin Films. ECS Transactions 2013, 45, 73–78. [Google Scholar] [CrossRef]

- Tran, T.H.; Nguyen, V.T. Phase transition of Cu2O to CuO nanocrystals by selective laser heating. Mat. Sci. Semicon. Proc. 2016, 46, 6–9. [Google Scholar] [CrossRef]

- Diantoro, M.; Suprayogi, T.; Hidayat, A.; Taufiq, A.; Fuad, A.; Suryana, R. Shockley’s Equation Fit Analyses for Solar Cell Parameters from I–V Curves. Int. J. Photoenergy 2018, 2018, 9214820. [Google Scholar] [CrossRef]

- Peng, L.; Sun, Y.; Meng, Z.; Wang, Y.; Xu, Y. A new method for determining the characteristics of solar cells. J. Power Sources 2013, 227, 131–136. [Google Scholar] [CrossRef]

- Znajdek, K.; Sibiński, M.; Kubiak, A.; Ruta, Ł.; Lisik, Z.; Janczak, D. Analysis of back contact layers for flexible CdTe/CdS photovoltaic structures. Opto-Electron. Rev. 2019, 27, 32–38. [Google Scholar] [CrossRef]

- Yang, Y.; Han, J.; Ning, X.; Cao, W.; Xu, W.; Guo, L. Controllable Morphology and Conductivity of Electrodeposited Cu2O Thin Film: Effect of Surfactants. ACS Appl. Mater. Interfaces 2014, 6, 22534–22543. [Google Scholar] [CrossRef]

| Samples | Unheated (_AD) | Heated (_H) | ||

|---|---|---|---|---|

| Sa, nm | Sq, nm | Sa, nm | Sq, nm | |

| #1 | 130.3 | 177.6 | 148.1 | 201.5 |

| #2 | 126.1 | 172.7 | 149.1 | 200.6 |

| #3 | 171.9 | 222.5 | 145.6 | 193.2 |

| #4 | 135.0 | 185.6 | 133.6 | 186.0 |

| #1 | #2 | #3 | #4 | |

|---|---|---|---|---|

| Eg [eV] before annealing | 2.08 | 2.01 | 2.87 | 1.84 |

| Eg [eV] after annealing | 2.00 | 3.52 | 2.55 | 1.81 |

| Parameter | #1 [27] | #1_H | #2 [27] | #2_H | #3 [27] | #3_H | #4 [27] | #4_H |

|---|---|---|---|---|---|---|---|---|

| Voc [mV] | 213 | 238 | 54 | 55 | 29 | 114 | 74 | - |

| Isc [mA] | 24 | 25 | 4.5 | 9 | 2.0 | 26 | 22 | - |

| η [%] | 5 × 10−3 | 1 × 10−2 | 2 × 10−4 | 1 × 10−3 | 6 × 10−5 | 8 × 10−3 | 4 × 10−3 | - |

| Contact area [mm2] | 35 | 35 | 45 | 45 | 40 | 40 | 35 | 35 |

| Voc/CuO thickness [mV/nm] | 0.19 | 0.20 | 0.04 | 0.04 | 0.02 | 0.35 | 0.05 | - |

| Voc/TiO2 thickness [mV/nm] | 4.38 | 5.87 | 1.15 | 1.01 | 0.70 | 2.59 | 1.71 | - |

| FF [%] | 27 | 26.6 | 26 | 26.7 | 25 | 29.1 | 26.5 | - |

| Rsh [Ω] | 36,000 | 50,000 | 11,000 | 5900 | 8700 | 6000 | 4200 | 1 |

| Rs [Ω] | 968 | 576 | 1216 | 151 | 315 | 72 | 253 | 35 |

| Parameter | #1_H [%] | #2_H [%] | #3_H [%] | #4_H [%] |

|---|---|---|---|---|

| Voc | +12 i | +2 i | +294 i | −d |

| Isc | +4 i | +100 i | +1200 i | −d |

| FF | −1 d | +3 i | +16 i | −d |

| Rsh | +39 i | −46 d | −31 d | −99 d |

| Rs | −40 i | −88 i | −77 i | −86 i |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wisz, G.; Sibiński, M.; Łabuz, M.; Potera, P.; Płoch, D.; Bester, M.; Yavorskyi, R. Effect of Annealing in Air on the Structural and Optical Properties and Efficiency Improvement of TiO2/CuxO Solar Cells Obtained via Direct-Current Reactive Magnetron Sputtering. Materials 2025, 18, 888. https://doi.org/10.3390/ma18040888

Wisz G, Sibiński M, Łabuz M, Potera P, Płoch D, Bester M, Yavorskyi R. Effect of Annealing in Air on the Structural and Optical Properties and Efficiency Improvement of TiO2/CuxO Solar Cells Obtained via Direct-Current Reactive Magnetron Sputtering. Materials. 2025; 18(4):888. https://doi.org/10.3390/ma18040888

Chicago/Turabian StyleWisz, Grzegorz, Maciej Sibiński, Mirosław Łabuz, Piotr Potera, Dariusz Płoch, Mariusz Bester, and Rostyslav Yavorskyi. 2025. "Effect of Annealing in Air on the Structural and Optical Properties and Efficiency Improvement of TiO2/CuxO Solar Cells Obtained via Direct-Current Reactive Magnetron Sputtering" Materials 18, no. 4: 888. https://doi.org/10.3390/ma18040888

APA StyleWisz, G., Sibiński, M., Łabuz, M., Potera, P., Płoch, D., Bester, M., & Yavorskyi, R. (2025). Effect of Annealing in Air on the Structural and Optical Properties and Efficiency Improvement of TiO2/CuxO Solar Cells Obtained via Direct-Current Reactive Magnetron Sputtering. Materials, 18(4), 888. https://doi.org/10.3390/ma18040888