Abstract

In this work, measurements of the thermal diffusivity and thermal expansion of hot-working tool steel WLV (1.2365) were carried out in the temperature range from (−)50 °C to 500 °C. The results of these measurements were compared with those published earlier by the authors for other selected hot-working tool steels, i.e., 38HMJ (1.8509) and WCL (1.2342), in the temperature range from (−)50 °C to 500 °C and from room temperature (RT) to 1100 °C. This paper describes the procedures used to relate the thermal characteristics of the thermal diffusivity and thermal expansion obtained at low temperatures to those obtained at high temperatures. Thermal diffusivity and thermal expansion of WLV, 38HMJ and WCL steels in the temperature range from (−)50 °C to 1100 °C were used as input data for numerical simulations of heat transfer in devices made of these steels and operating in a wide temperature range. Thermophysical properties were tested using specialized NETZSCH test stands. Thermal diffusivity was studied using a LFA 467 light flash apparatus in the temperature range from (−)50 °C to 500 °C and a LFA 427 laser flash apparatus in the temperature range from RT to 1100 °C. Thermal expansion was tested using a DIL 402 Expedis dilatometer in the range from (−)50 °C to 500 °C and a DIL 402 C dilatometer in the temperature range from RT to 1100 °C. Finally, the results of tests on thermophysical properties of selected steels in the temperature range from (−)50 °C to 1100 °C were summarized.

1. Introduction

Numerical simulations are currently used in every field of technology, enabling the design of efficient and safe devices and structures. The knowledge of thermophysical properties, and in particular the thermal characteristics of the thermal diffusivity and thermal expansion of construction materials, plays a key role in obtaining accurate results of numerical simulations of heat transfer in a wide temperature range. This applies in particular to various types of steel, which are among the most common building materials in the world [1,2]. Steels are used where an appropriate strength and safety of a structure are required. An example of numerical analysis for safety reasons is the study of the influence of reinforced concrete structure architecture on the distribution of temperature fields in structural elements [3,4]. This type of analysis requires testing the steel mechanically in fire conditions as well. It is necessary to understand the mechanical damage to steel in fire. Other examples of devices that operate at high temperatures are hot extrusion dies and molds [5]. These types of components operate under very high mechanical and thermal loads. They are made of hot-work tool steels. These steels are also used to build pipes loaded with intense heat pulses, in which gas flows at a high pressure (in the order of hundreds of MPa) and high temperature (in the order of thousands of Kelvin) [6]. The thermal characteristics of thermal diffusivity and thermal expansion of three steels of this type, i.e., 38HMJ, WLV and WCL, are presented in this paper [7]. Obtaining these characteristics from sub-zero to high temperatures with a single device is often difficult because the measuring equipment is optimized for either high or low temperature operation [8,9].

The laser flash method, and the Laser Flash Apparatus (LFA) and the rod dilatometer (DIL) based on it are widely recognized as effective tools for measuring the thermal diffusivity and thermal expansion of a solid specimen in a wide temperature range [10,11,12,13,14,15]. The literature lacks descriptions of methods for combining the thermal characteristics obtained from measurements with different devices in a wide temperature range. It should be emphasized that these characteristics often do not overlap in common temperature ranges. This effect is actually due to the different accuracy of measuring a given parameter and the different aging rates of devices. This applies especially to the thermal characteristics of thermal diffusivity and, in special cases, thermal expansion [7].

Thermophysical property measurements in a wide temperature range are usually performed with at least two devices, one in the low temperature range and one in the high temperature range. This applies to measurements of thermal diffusivity and thermal expansion on Netzsch devices, e.g., for thermal diffusivity on the LFA427 and LFA467, and for thermal expansion on the DIL 402 Expedis and DIL 402C [16,17,18,19,20]. Despite the fact that the manufacturer declares the same measurement accuracy, and despite using the same measurement methods and even the same heat transfer models, there is a problem of stitching the results obtained at low temperatures with those obtained at high temperatures [17,21]. This is particularly evident in the case of thermal diffusivity, but problems also arise in the case of thermal expansion when we heat the sample several times without removing it from the dilatometer.

1.1. Thermal Diffusivity

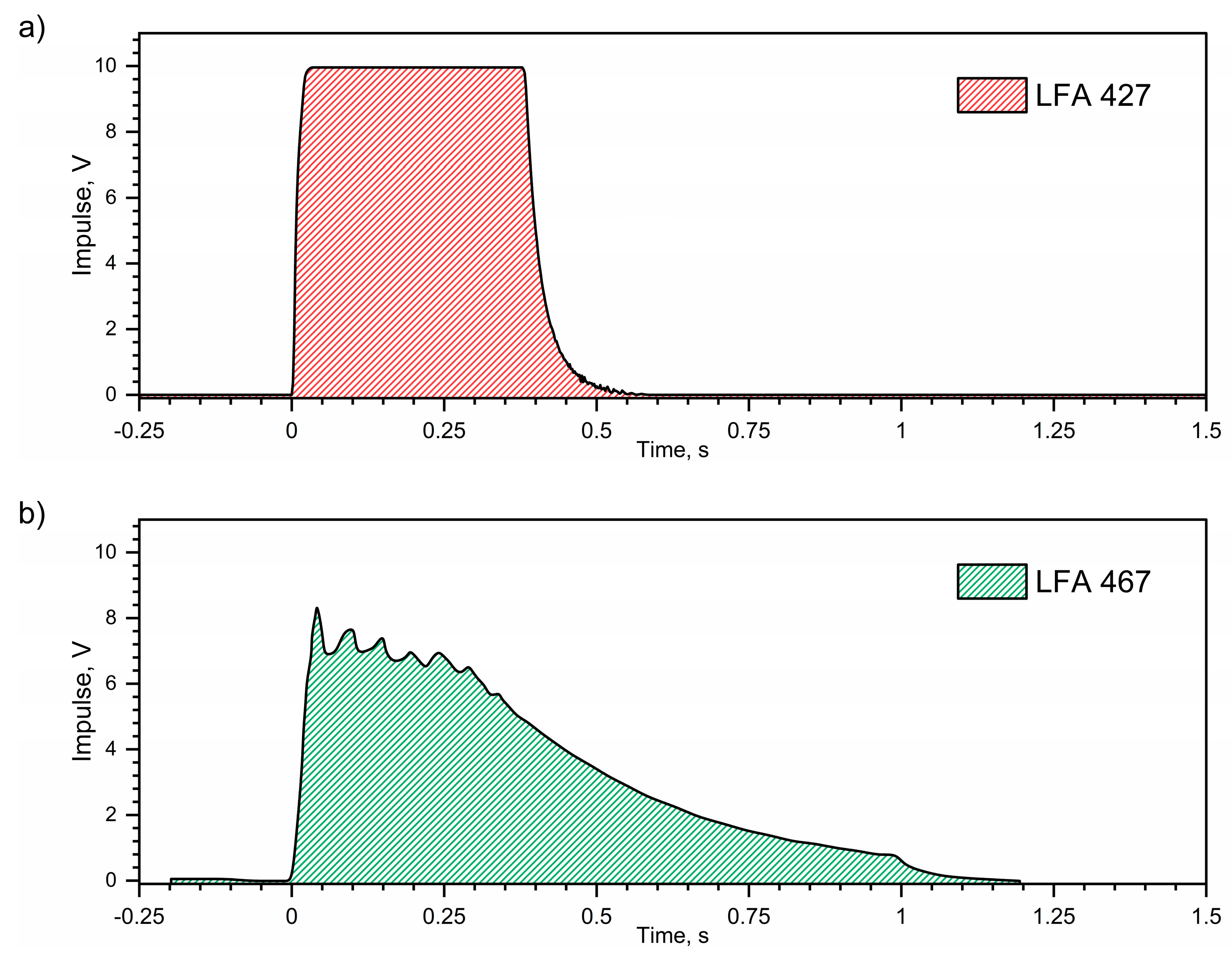

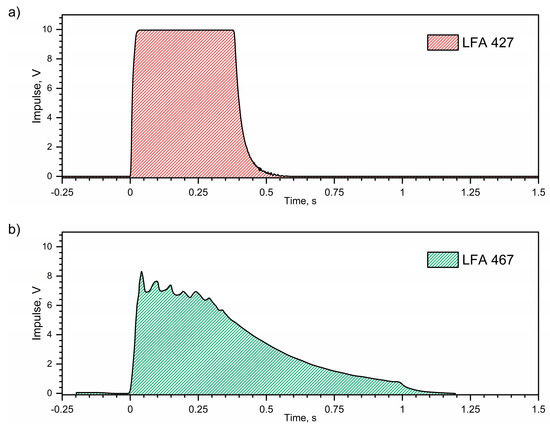

Despite the use of the same heat transfer model in the measuring specimen and the same method for determining the thermal diffusivity of the tested steels in both devices, i.e., LFA427 and LFA467, the obtained thermal characteristics of thermal diffusivity differ slightly, i.e., they do not overlap in the range from RT to approx. 500 °C. This is probably related to the impossible assumption of the heat transfer model in the specimen, which assumes that the front surface of the specimen is heated by a Dirac pulse at time t = 0 [17,19,20]. In the case of a high-temperature device, the adopted model of heat transfer in the specimen is closer to reality, because the laser pulse is, for example, 0.6 ms wide, i.e., it is short and has a shape close to a rectangle (Figure 1a). In the case of a low-temperature device, the pulse is obtained from a xenon lamp, but the shape of the pulse significantly differs from the Dirac pulse, and additionally the pulse is wide and extended in time, for example 1.2 ms (Figure 1b). It therefore seems that the results of the thermal diffusivity measurement of steel obtained using the LFA 427 device are more reliable, i.e., they are burdened with a smaller error compared to the results obtained using the LFA 467 device. The thermal diffusivity measurements of the tested steels were performed using both devices, i.e., LFA 427 and LFA 467 with the NETZSCH Proteus v.8.0.2 software and the Cape–Lehman plus pulse correction heat transfer model in the specimen, which takes into account the pulse width [22,23,24,25]. According to NETZSCH, the accuracy of the thermal diffusivity determination in both devices is the same and is +/− 3% [16]. According to the authors of this paper, in the case of a pulse extended in time, the results of thermal diffusivity calculations will be overestimated [26,27,28].

Figure 1.

(a) Example of a laser pulse from the LFA 427, (b) example of a xenon lamp pulse from the LFA 467.

1.2. Thermal Expansivity

In heat transfer calculations, an important role is played by the thermal characteristics of steel density, calculated by the relationship [25]:

where stands for density of steel at RT; is the thermal expansion, i.e., the relative change in the length of the specimen compared to the length of the specimen at RT.

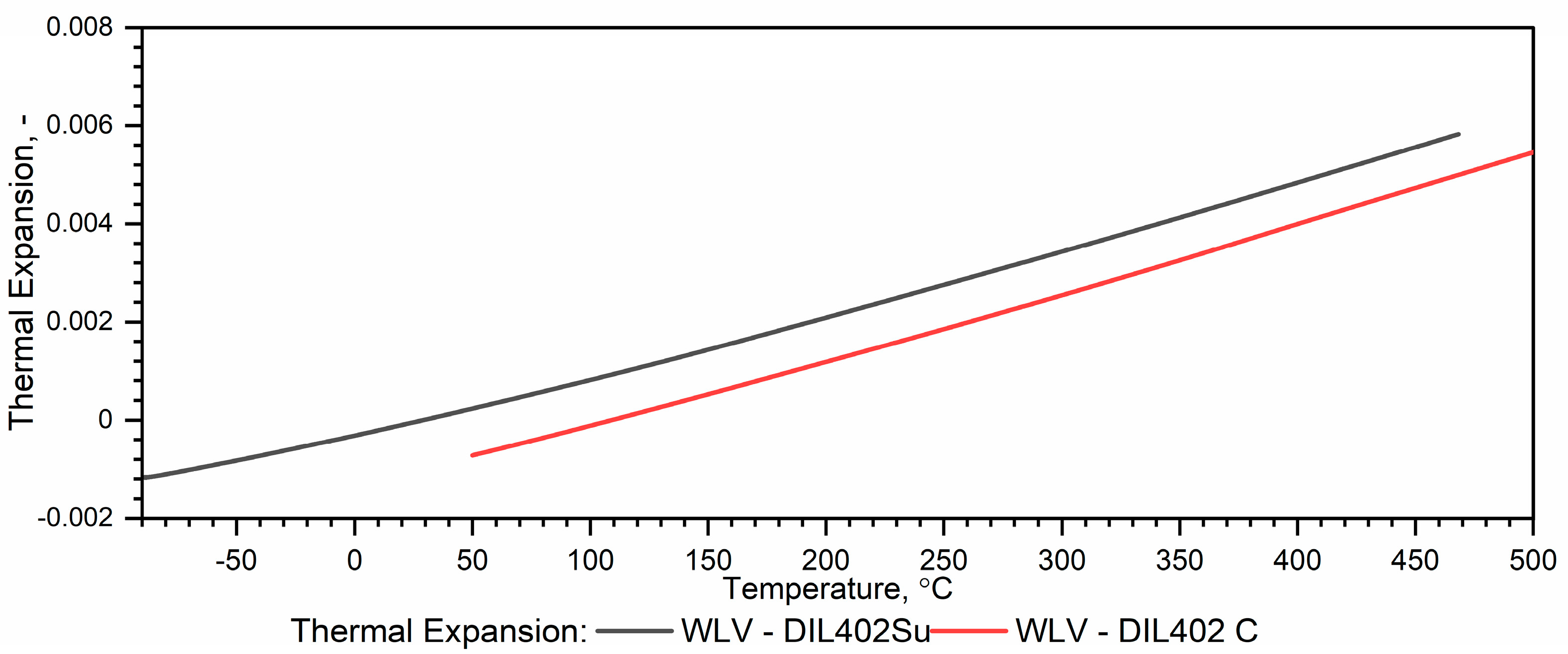

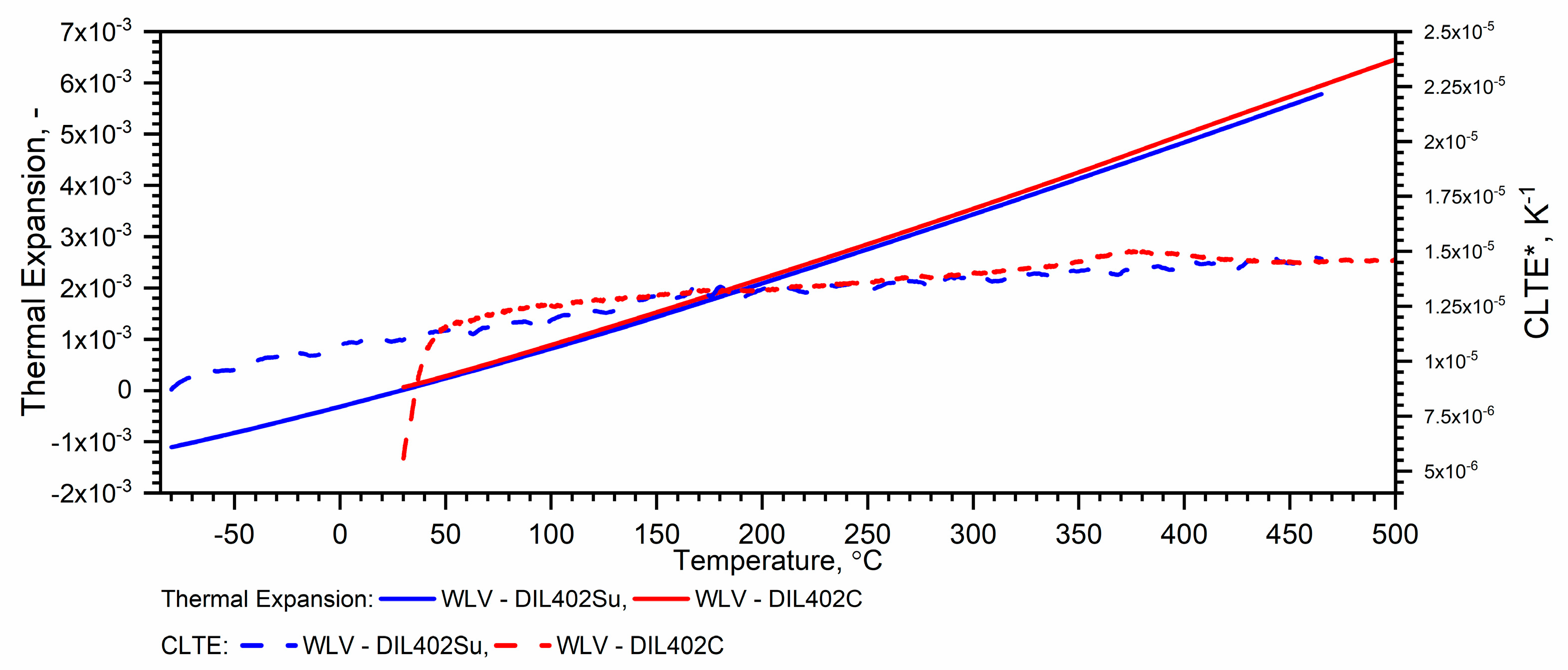

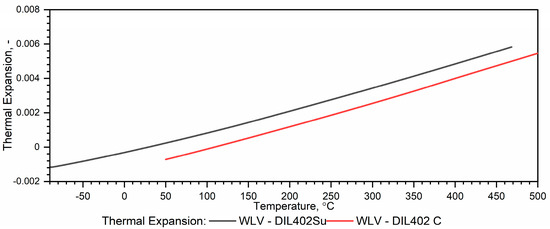

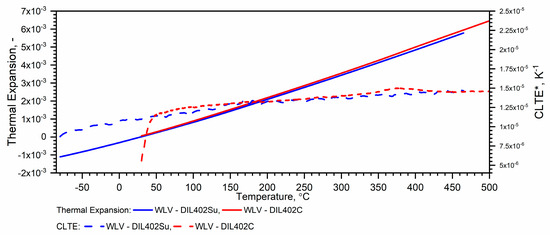

In contrast to the thermal diffusivity measurements, the thermal expansion characteristics obtained with the DIL 402 Expedis (DIL 402 Su) generally agree with the results of measurements taken with the DIL 402 C in the temperature range from RT to 500 °C [26,27]. Therefore, calculations can be performed over a wide temperature range, i.e., from (−)50 °C to 1100 °C, without additional procedures related to combining both characteristics. A problem occurs when the specimen has shrunk during the first run and the calculations are performed for the second heating run—Figure 2.

Figure 2.

Example measurement results for the WLV hot-work tool steel obtained from DIL 402 Expedis (own results) and DIL 402 C (based on data [7,29]).

The aims of this work are as follows:

- -

- Measure the thermal diffusivity and thermal expansion of hot-working tool steel WLV (1.2365) in the temperature range from (−)50 °C to 500 °C;

- -

- Investigate the methods of combining the thermal diffusivity characteristics a(T) of WLV, 38HMJ and WCL steels obtained with both devices, i.e., low-temperature LFA 467 and high-temperature LFA 427, into thermal diffusivity characteristics in the full temperature range, i.e., from (−)50 °C to 1100 °C;

- -

- Show the a(T) dependencies of selected steels as input data for calculations in the range from (−)50 °C to 1100 °C;

- -

- Propose conversion procedures in the range from (−)50 °C to 500 °C, which shift the characteristics to point 0 for RT;

- -

- Show the dependencies of selected steels as input data for calculations in the range from (−)50 °C to 1100 °C.

The main objective of this paper is to develop methods for combining the thermal characteristics of thermal diffusivity and thermal expansion obtained from measurements with different devices in the full temperature range, i.e., from (−)50 °C to 1100 °C, because there is no description of such methods in the literature.

2. Materials and Methods

2.1. Materials

WLV steel has been the subject of research on the thermal characteristics of thermal diffusivity and thermal expansion at low temperatures, i.e., in the range from (−)50 °C to 500 °C. Previously, the authors tested the same parameters of the same steel in the range from RT to 1100 °C [7,29]. The same 500.0 mm long and 71.0 mm diameter WLV steel bars, manufactured by Akrostal from Rogozno, Poland, were used to make the specimens. The nominal composition (wt.%) of WLV test steel is given in Table 1. The composition was obtained using a Foundry Master Spectrophotometer 01D0058 (Optic 01D0059) [30].

Table 1.

Chemical composition of the hot-work tool (WLV) steel [5,7,29,30,31].

As shown earlier, WLV steel is characterized by a ferrite–to–austenite transformation temperature of about 835.8 °C, which is related to the shrinkage of the steel [7].

2.2. Specimen Preparation

Specimens for testing the thermophysical properties of WLV steel were prepared in the same way as previously mentioned for measurements in a high temperature range, i.e., [7,29]:

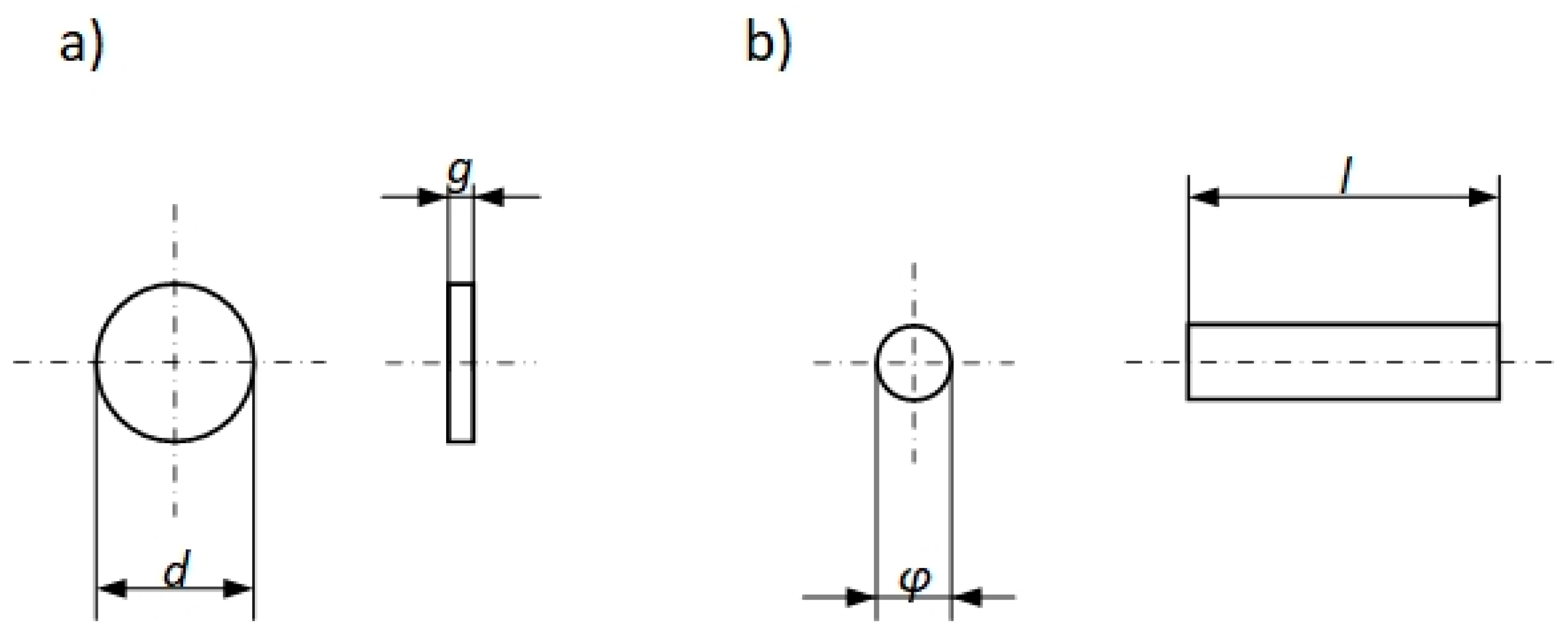

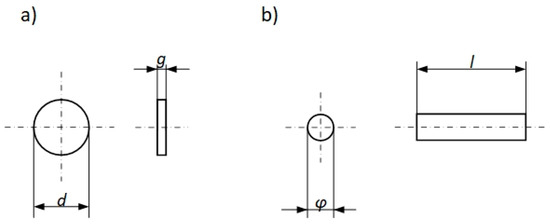

- -

- Specimens for testing thermal diffusivity had the shape of a cylinder with a diameter of d = 12.70 mm and a thickness of g = 1.63 mm, cut from a 71.0 mm diameter bar using a water-cooled cutting disc (Figure 3a);

Figure 3. Specimens for the testing of the WLV steel: (a)—thermal diffusivity; (b)—thermal expansion.

Figure 3. Specimens for the testing of the WLV steel: (a)—thermal diffusivity; (b)—thermal expansion. - -

- Specimens for testing thermal expansion had the shape of a cylinder with a diameter of = 6.0 mm and a length of l = 24.35 mm (Figure 3b); the specimens for the DIL tests were cut from the bar using a water-cooled cutting disc.

The density of the steel at room temperature was determined by double weighing (in air and water) using the SARTORIUS MSA125P-1CE-DA analytical balance (readability [d]: 0.01 mg). The density of the WLV steel was 7.80 g/cm3.

2.3. Thermal Diffusivity and Thermal Expansion Measurements

All measurements of the thermal diffusivity and thermal expansion of WLV steel and other steels, i.e., 38HMJ and WCL, presented in this paper were performed in the laboratory of the Military University of Technology (Warsaw, Poland), which was equipped with thermal analysis devices from NETZSCH (Selb, Germany)—a world-renowned manufacturer of thermal analysis instruments.

Thermal diffusivity measurements at low temperatures, i.e., from (−)50 °C to 500 °C, were performed with a NETZSCH Light Flesh LFA 467 (Selb, Germany) using the standard Cape–Lehman model with pulse correction [25]. The front surface of the plane-parallel specimen was heated by a short energy pulse generated by a xenon lamp. From the resulting excess temperature on the rear surface measured by an IR detector, the thermal diffusivity was calculated. Argon at a flow rate of 50 was used as an inert gas. The surface of the specimens were coated with a thin layer (2–3 ) of graphite (GRAPHIT 33 Kontakt Chemie, Zele, Belgium) to ensure the high absorption of the pulse generated by a xenon lamp.

Thermal expansion measurements at low temperatures, i.e., from (−)50 °C to 500 °C, were performed using a NETZSCH pushrod DIL 402 Expedis dilatometer (Selb, Germany). Liquid nitrogen was used to obtain low temperatures [25]. Helium was used as an inert gas at a flow rate of 60 . Thermal expansion of the sample during heating or under isothermal conditions was detected by a displacement system to which the pusher was connected.

3. Results and Discussion

3.1. Thermal Diffusivity Results

3.1.1. WLV Thermal Diffusivity Results

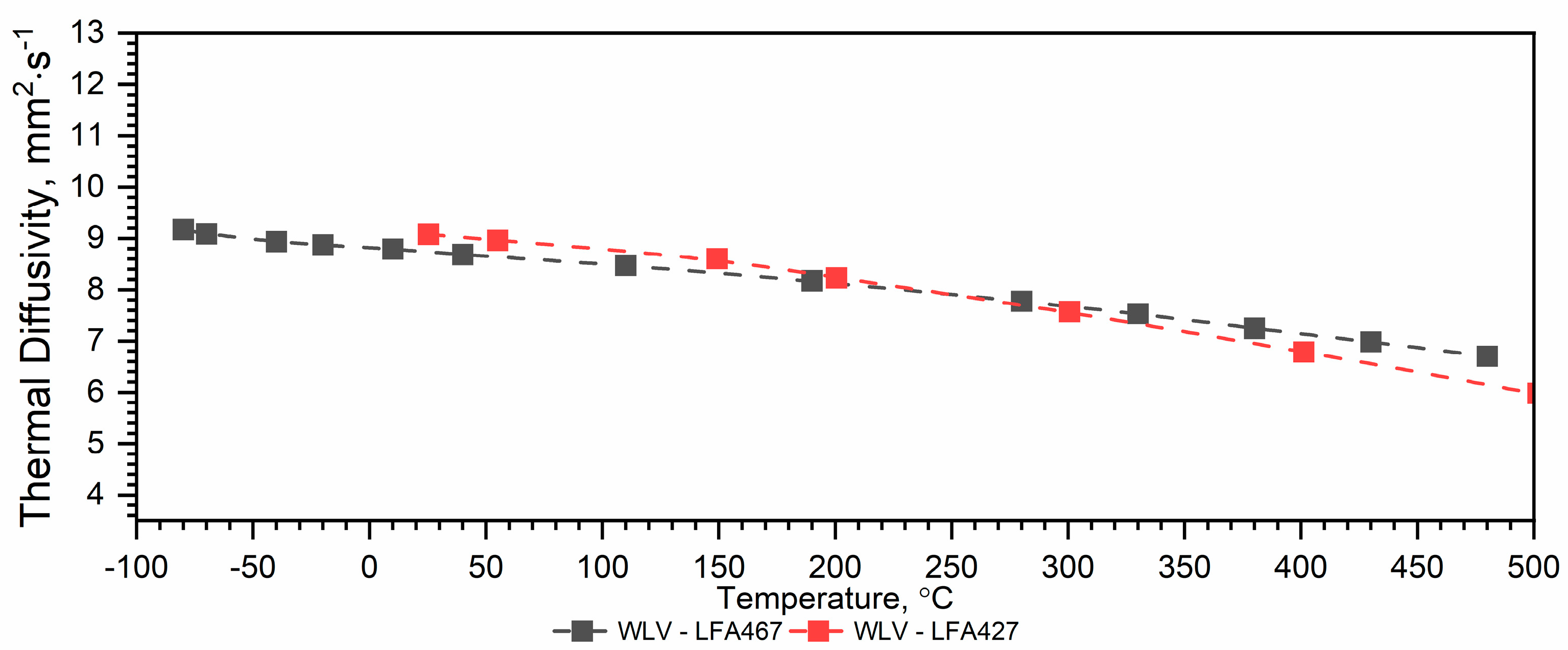

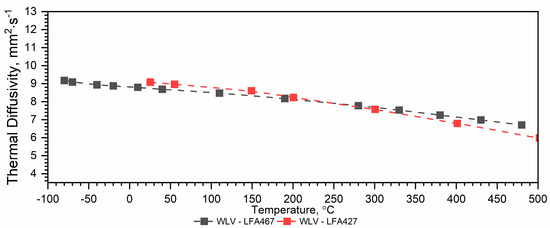

The results of the thermal diffusivity measurements of WLV steel as a function of temperature a(T) in the temperature range from (−)50 °C to approximately 500 °C, performed using LFA 467, were compared with the results of such measurements carried out using LFA 427 in the same temperature range—Figure 4. The maximum relative error ∆a/a between the results from LFA 467 and LFA 427 related to the thermal diffusivity value from LFA 467 occurs at 500 °C and is 7%. Below 500 °C, i.e., in the range from RT to approximately 500 °C, the results from both devices are within 3%.

Figure 4.

Thermal diffusivity as a function of temperature for the WLV hot-work tool steel obtained from LFA 467 (own results) and LFA 427 (based on data [7,29]).

3.1.2. Thermal Diffusivity of WLV, 38HMJ and WCL Steels in the Temperature Range from −50 °C to 1100 °C

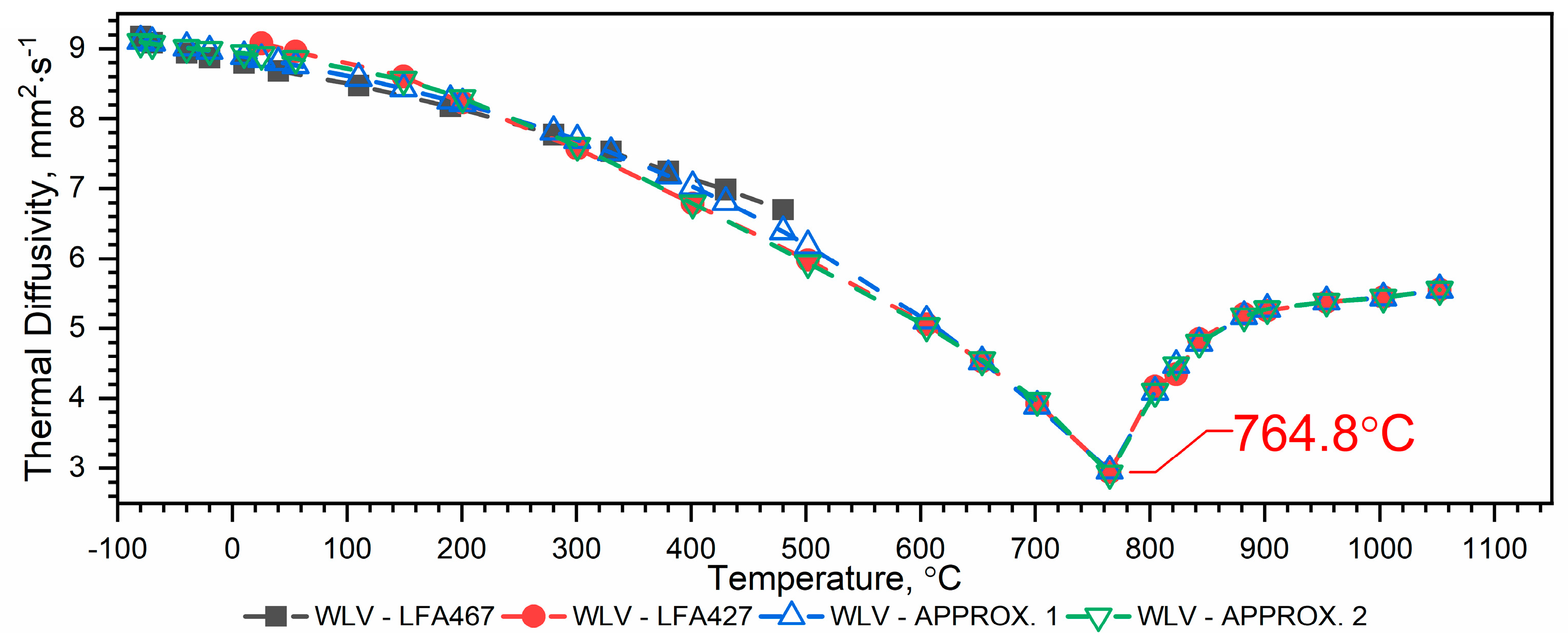

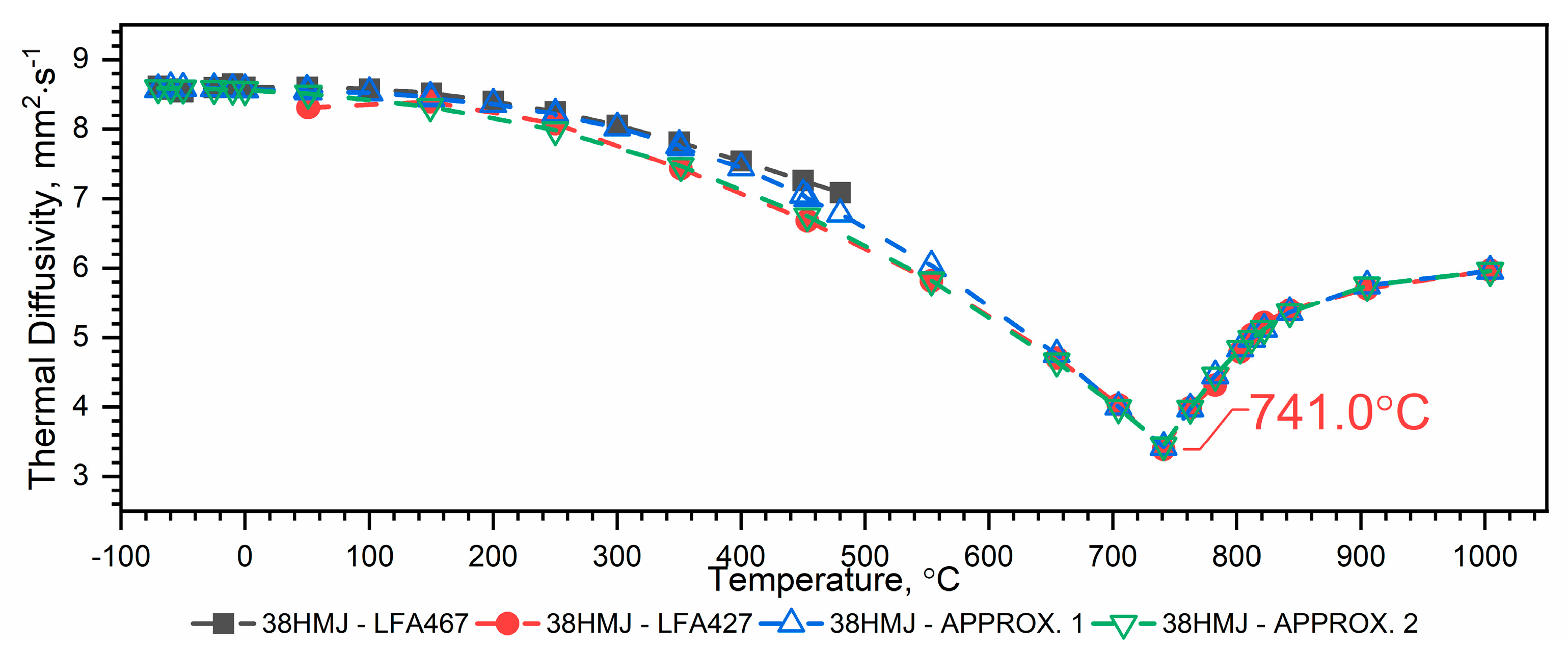

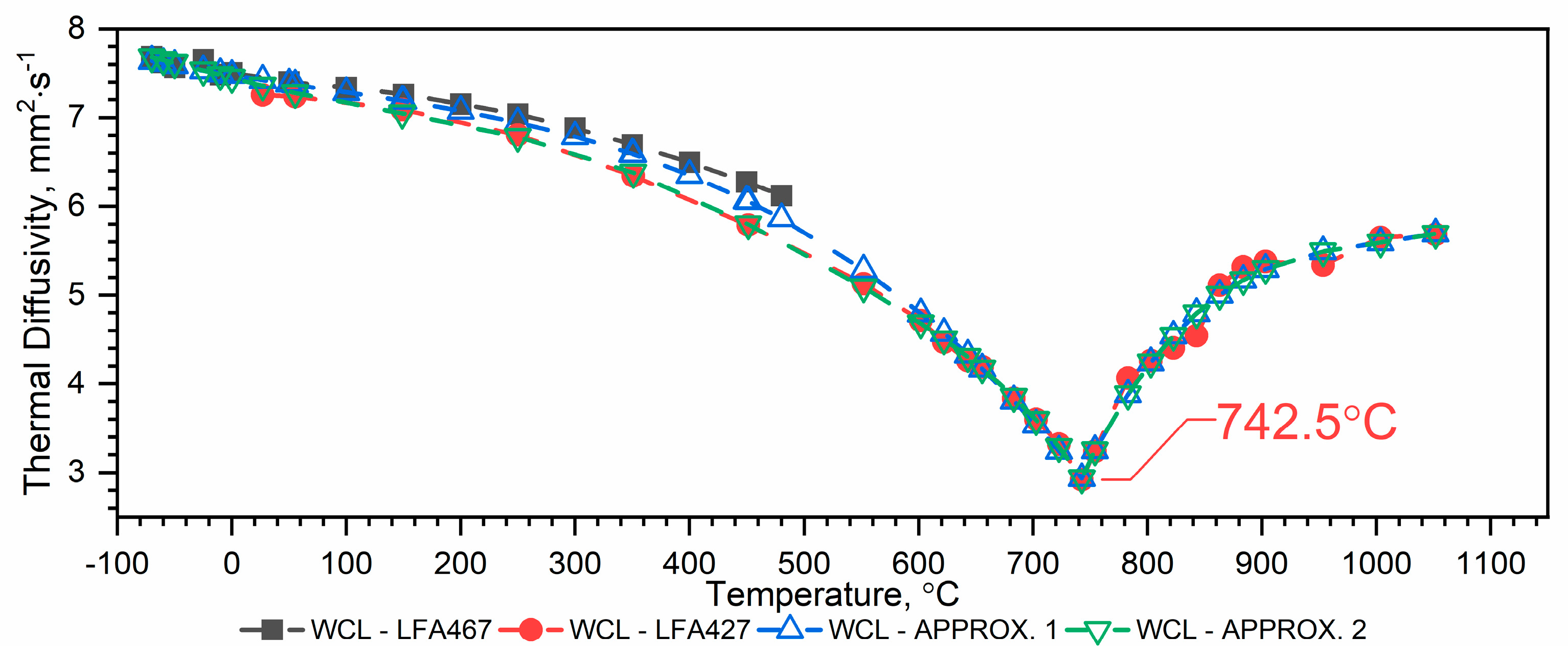

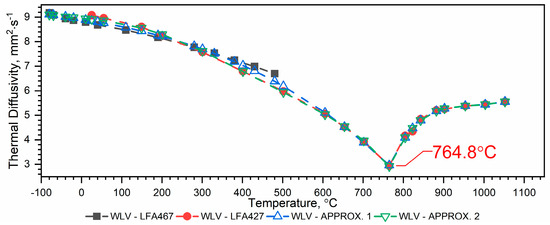

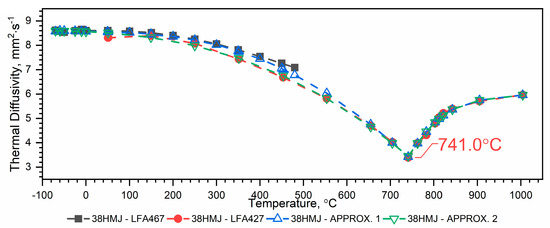

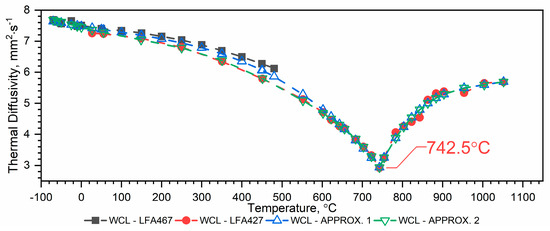

The results of the thermal diffusivity measurements a(T) of WLV, 38HMJ and WCL steels in the temperature range from (−)50 °C to about 1100 °C obtained using LFA 467 and LFA 427 devices are shown in Figure 5, Figure 6 and Figure 7. The combination of thermal diffusivity characteristics of WLV, 38HMJ and WCL steels obtained from both devices, i.e., low-temperature LFA 467 and high-temperature LFA 427, with thermal diffusivity characteristics in the full temperature range, i.e., from (−)50 °C to 1100 °C, can be achieved through two ways, i.e.:

Figure 5.

Thermal diffusivity as a function of temperature for the WLV hot-work tool steel in the range of (−)50 °C to 1100 °C ((−)50 °C–500 °C—own results, RT—1100 °C—based on [7,29]).

Figure 6.

Thermal diffusivity as a function of temperature for the 38HMJ hot-work tool steel in the range of (−)50 °C to 1100 °C ((−)50 °C–500 °C—own results, RT—1100 °C—based on [26,27]).

Figure 7.

Thermal diffusivity as a function of temperature for the WCL hot-work tool steel in the range of (−)50 °C to 1100 °C ((−)50 °C–500 °C—own results, RT—1100 °C—based on [26,27]).

The correlation formulas of thermal diffusivity as a function of temperature for WLV, 38HMJ and WCL steels in the form of polynomials are as follows:

- For WLV steel—Figure 5:

Approx. 1—combining the data of both runs and making an approximation based on it (blue color):

The values of coefficients ai are given in Table 2.

Table 2.

Coefficients for calculating thermal diffusivity of WLV specimens in Equation (2).

Approx. 2—combining the sub-zero temperature range results from the LFA 467 with all measurement points from the LFA 427 (green color):

The values of coefficients ai are given in Table 3.

Table 3.

Coefficients for calculating thermal diffusivity of WLV specimens in Equation (3).

- For 38HMJ steel—Figure 6:

Approx. 1—combining the data of both runs and making an approximation based on it (blue color):

The values of coefficients ai are given in Table 4.

Table 4.

Coefficients for calculating thermal diffusivity of 38HMJ specimens in Equation (4).

Approx. 2—combining the sub-zero temperature range results from the LFA 467 with all measurement points from the LFA 427 (green color):

The values of coefficients ai are given in Table 5.

Table 5.

Coefficients for calculating thermal diffusivity of 38HMJ specimens in Equation (5).

- For WCL steel—Figure 7:

Approx. 1—combining the data of both runs and making an approximation based on it (blue color):

The values of coefficients ai are given in Table 6.

Table 6.

Coefficients for calculating thermal diffusivity of WLV specimens in Equation (6).

Approx. 2—combining the sub-zero temperature range results from the LFA 467 with all measurement points from the LFA 427 (green color):

The values of coefficients ai are given in Table 7.

Table 7.

Coefficients for calculating thermal diffusivity of 38HMJ specimens in Equation (7).

3.1.3. Discussion

Both methods of determining the thermal characteristics of the thermal diffusivity of WLV, 38HMJ and WCL steels in the temperature range from (−)50 °C to 1100 °C can be used because:

- Approx. 1—takes into account all measurement data, determined in the full temperature ranges of the thermal diffusivity measurements of both devices, i.e., from (−)50 °C to about 500 °C and from RT to about 1100 °C;

- Approx. 2—takes into account measurement data determined in the temperature range from (−)50 °C to RT and from RT to about 1100 °C.

Although both methods of combining the thermal diffusivity characteristics of WLV, 38HMJ and WCL steels can be used, the authors recommend Approx. 1. The dependence of a(T) obtained in this way is within the measurement error for both LFA 467 and LFA 427, i.e., +/− 3%. Table 8 summarizes the relative errors of thermal diffusivity calculations and in the temperature range from (−)50 °C to approximately 500 °C, using both approximation methods, i.e., Approx. 1 and Approx. 2.

Table 8.

The relative errors of thermal diffusivity calculations and of selected steels in the temperature range from about (−)50 °C to about 500 °C: —thermal diffusivity with LFA 467; —thermal diffusivity with LFA 427; ; Approx. 1—app1; Approx. 2—app2; ; .

The thermal diffusivity characteristics of the tested steels, i.e., WLV, 38HMJ and WCL—Figure 5, Figure 6 and Figure 7, show that at temperatures of approx. 764.8 °C for WLV steel, 741.0 °C for 38HMJ steel and 742.5 °C for WCL steel, a phase transition from the ferromagnetic to the paramagnetic state occurs—the so-called Curie point. This was discussed in the authors’ papers [7,26,27,29]. This work describes the procedures used to relate the thermal diffusivity characteristics obtained at low temperatures to those obtained at high temperatures.

3.2. Thermal Expansion Results

3.2.1. WLV Thermal Expansion Results

Using the NETZSCH Proteus v.8.0.2 software supporting the DIL 402 C dilatometer, we can obtain delta specimen length increments, i.e., , over the entire measured temperature range. Therefore, at each point we can write the expression for as follows [25]:

because in addition we have

from here we obtain the expression for

If in the thermal expansion characteristics in the temperature range from RT to 1100 °C starts below zero—Figure 2, we can recalculate its values using the expression (11)—Figure 8. The data prepared in this way can be used to calculate over the entire temperature range, i.e., from (−)50 °C to 1100 °C—Figure 12.

Figure 8.

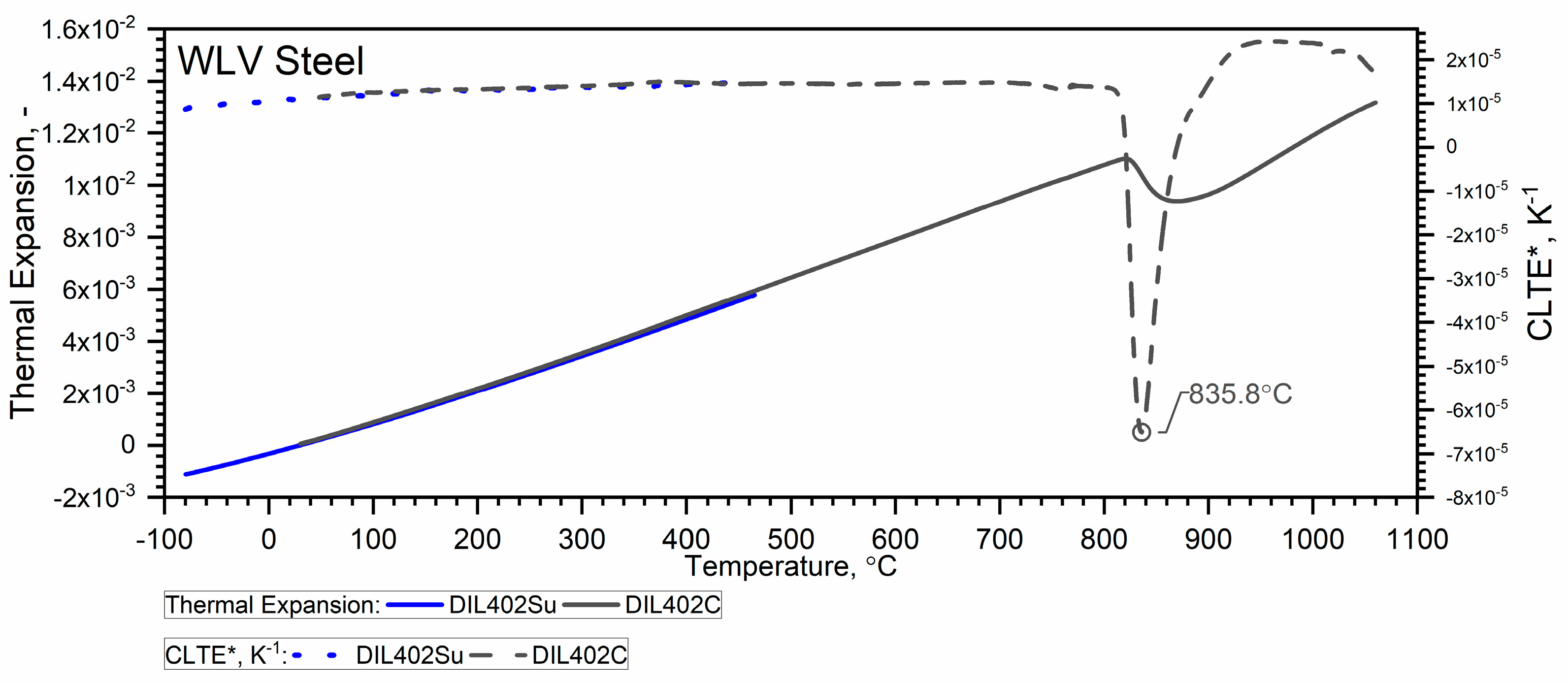

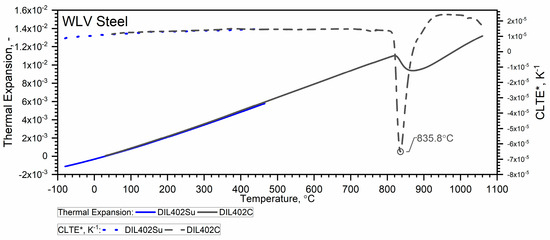

Example measurement results and CLTE* with DIL 402 Expedis and DIL 402 C ((−)50 °C–500 °C—own results, RT—1100 °C—based on [7,29]).

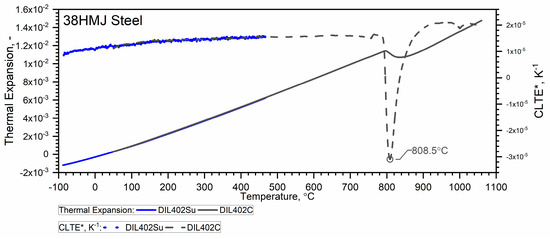

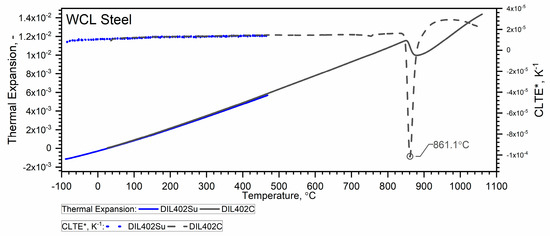

3.2.2. Thermal Expansion of WLV, 38HMJ and WCL Steels in the Temperature Range from −50 °C to 1100 °C

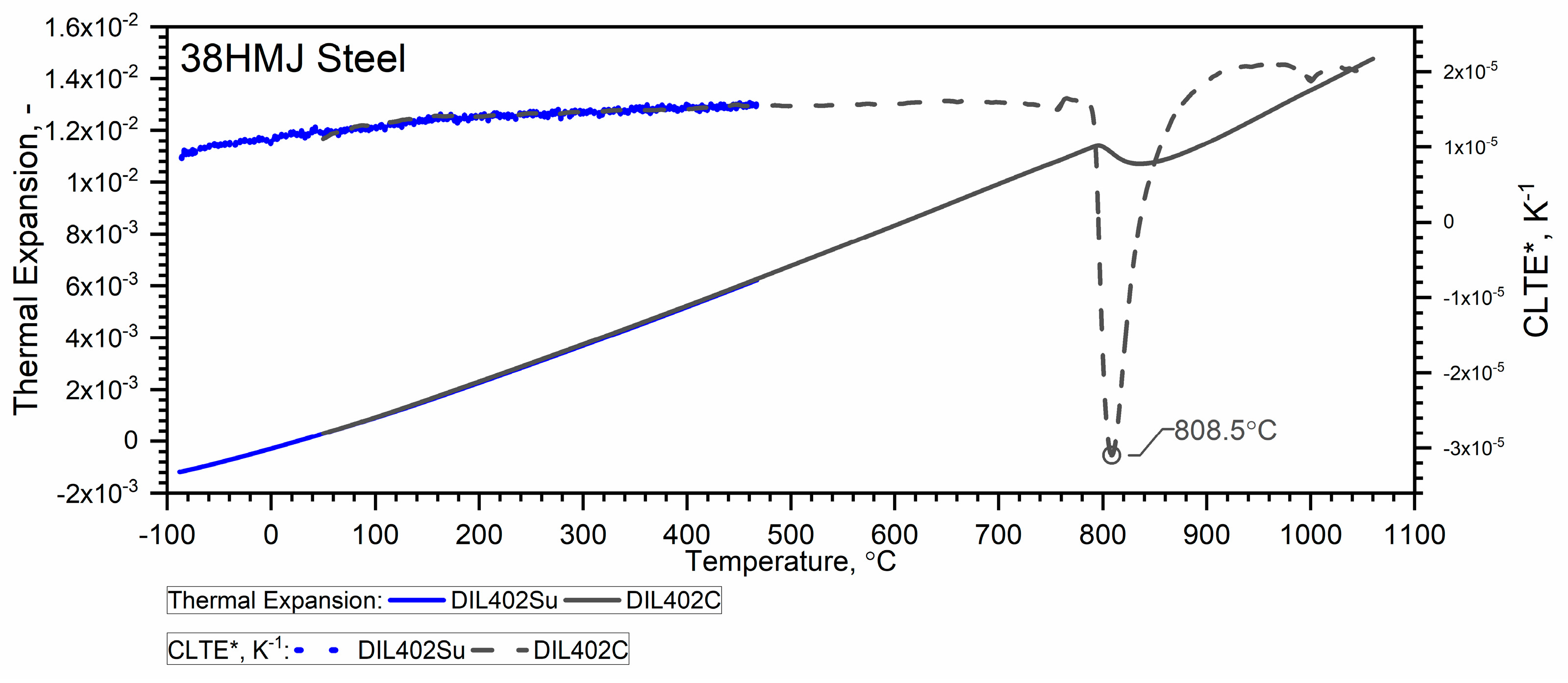

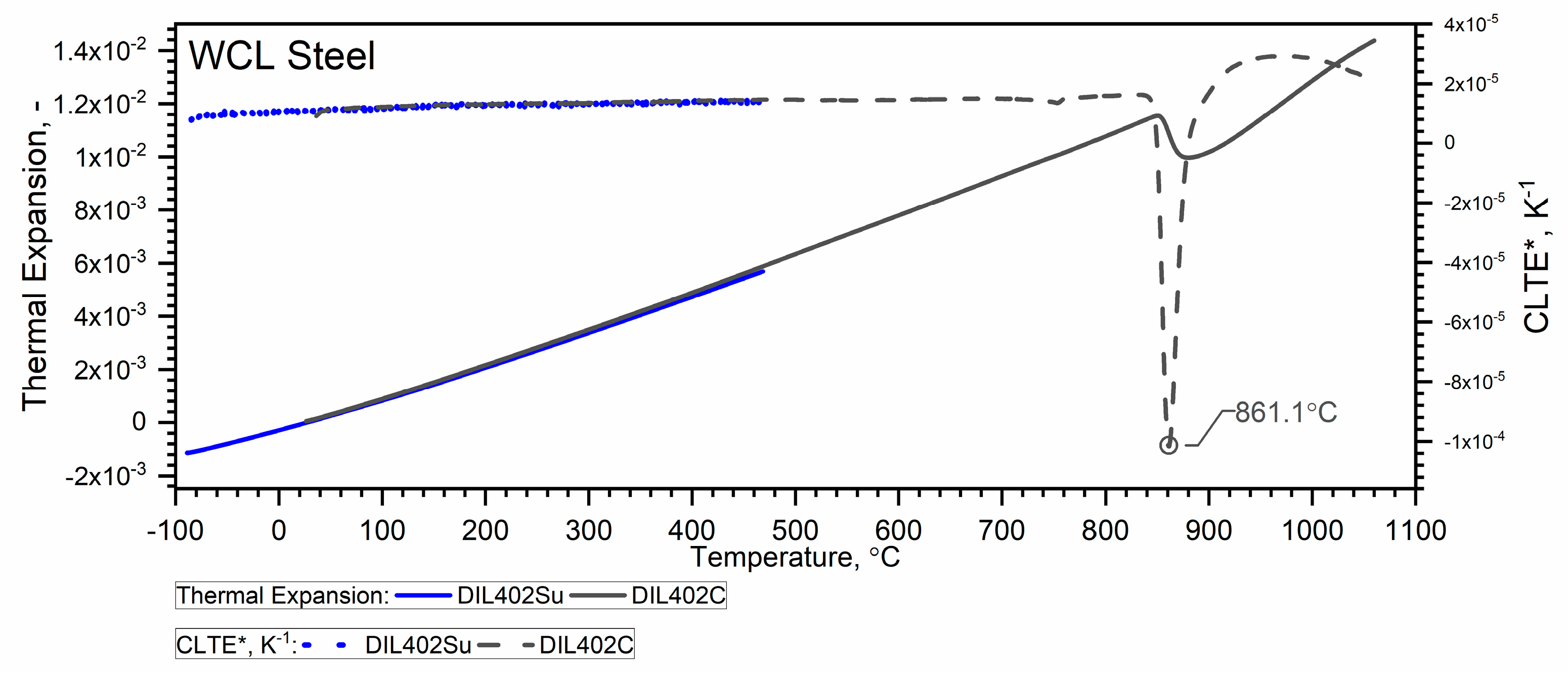

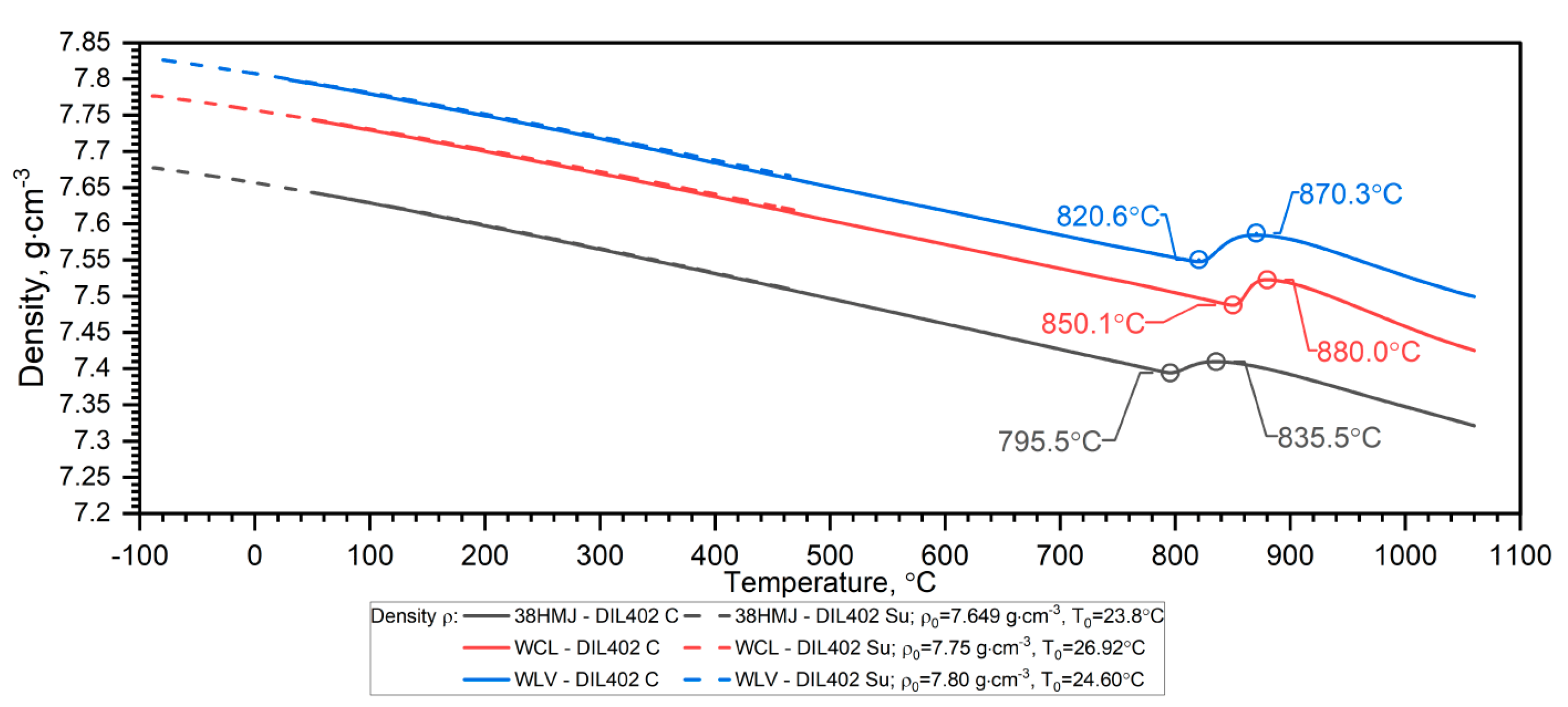

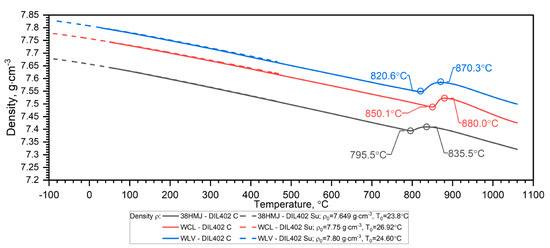

Due to the material shrinkage that occurs in the tested steels, and which is characterized by a rapid increase in density—Figure 12, it is more convenient to present the characteristics in the form of data densification at the shrinkage temperature. The results of the thermal expansion measurements and the coefficient of linear thermal expansion (CLTE) regarding the initial specimen length —denoted as of WLV, 38HMJ and WCL steels in the temperature range from (−)50 °C to about 1100 °C obtained using DIL 402 Expedis (DIL 402 Su) and DIL 402C devices are shown in Figure 9, Figure 10, Figure 11 and Figure 12 and summarized in Table 9.

Figure 9.

Thermal expansion and linear thermal expansion CLTE*(T) for the WLV steel ((−)50 °C–500 °C—own results, RT—1100 °C—based on [7,29]).

Figure 10.

Thermal expansion and CLTE*(T) for the 38HMJ steel ((−)50 °C–500 °C—own results, RT—1100 °C—based on [26,27]).

Figure 11.

Thermal expansion and CLTE*(T) for the WCL steel ((−)50 °C–500 °C—own results, RT—1100 °C—based on [26,27]).

Figure 12.

Density for the WLV, 38HMJ and WCL steels ((−)50 °C–500 °C—own results, RT—1100 °C—based on [7,26,27,29]).

Table 9.

Density of WLV, 38HMJ and WCL steels in the temperature range from (−)50 °C to 1100 °C.

The thermal expansion characteristics of the tested steels, i.e., WLV, 38HMJ and WCL—Figure 9, Figure 10 and Figure 11, show that at a temperature of about 835.8 °C for WLV steel, 808.4 °C for 38HMJ steel and 760.9 °C for WCL steel, a ferrite–austenite phase transition occurs—the so-called shrinkage effect. This was discussed in the authors’ work [7,26,27,29]. This paper describes the procedures used to relate the thermal expansion characteristics obtained at low temperatures to those obtained at high temperatures.

4. Conclusions

The authors performed measurements of the thermal characteristics of thermal diffusivity and thermal expansion of WLV steel in the low temperature range, i.e., from (−)50 °C to 500 °C. The measurement data a(T) and ε(T) for WLV steel were supplemented with the low temperature range, because the authors had previously performed such measurements in the range from RT to 1100 °C. In the case of the remaining steels, i.e., 38HMJ and WCL, the authors performed such tests earlier in the full temperature range, i.e., from (−)50 °C to 1100 °C. However, the methods of combining the thermal characteristics of a(T) and ε(T) in the low temperature range with the same characteristics in the high temperature range were not analyzed. Finally, the thermal characteristics a(T) and ε(T) were presented as input data for numerical simulations of heat transfer in devices made of these steels and operating in a wide temperature range. Due to the relatively mild nature of the thermal diffusivity changes as a function of temperature, the characteristic a(T) of selected steels, i.e., WLV, 38HMJ and WCL, were presented in the form of polynomials. In the case of the thermal characteristics of thermal expansion, it is more convenient to present the ε(T) data in the form of tables due to the rapid nature of the ε(T) changes at the shrinkage temperature of these steels, i.e., at 835.8 °C for WLV steel, 808.4 °C for 38HMJ steel and 860.9 °C for WCL steel.

This paper presents two alternative methods of combining thermal characteristics a(T) obtained from measurements with LFA 467—in the low temperature range, with the same results a(T) obtained from measurements with LFA 427—in the high temperature range. Although both methods of combining the thermal diffusivity characteristics of WLV, 38HMJ and WCL steels can be used, i.e., Approx. 1 and Approx. 2, in the temperature range from (−)50 °C to 1100 °C the authors recommend Approx. 1. We consider the full range of measurement data from both devices, and furthermore the a(T) relationship obtained in this way is within the measurement error limits for both thermal diffusivity characteristics, i.e., those obtained using LFA 467 and LFA 427. In the case of Approx. 1, the relative errors of thermal diffusivity calculations in the temperature range from (−)50 °C to approx. 500 °C are smaller compared to .

In the case of the thermal expansion measurements of our selected steels, the thermal characteristics ε(T) obtained from measurements with the DIL 402 Expedis—in the low temperature range, generally coincide with the same ε(T) results obtained from measurements with the DIL 402 C—in the high temperature range from RT to 500 °C. A problem occurs when we analyze the ε(T) measurement results in the range from RT to 1100 °C from the second heating run without removing the specimen from the DIL 402 C dilatometer. Due to specimen shrinkage after the first heating, the thermal ε(T) characteristics start with negative values. In this case, the authors suggest calculating the ε(T) dependence according to the procedure proposed in this paper. It should be emphasized that material shrinkage is caused by cracks. Exceeding the shrinkage temperature multiple times results in material degradation. The described effect occurs in devices made of such steel, which operate in a wide temperature range.

The results of the thermal property studies are summarized as follows:

- (1)

- The analysis of combining thermal characteristics a(T) obtained from measurements with LFA 467—in the low temperature range, with the same results a(T) obtained from measurements with LFA 427—in the high temperature range allows us to conclude the following:

- (a)

- The thermal diffusivity characteristics of LFA 427 and LFA 467 in the range from RT to about 500 °C do not overlap. This is due to the different methods of generating a thermal pulse on the front surface of the specimen;

- (b)

- Although both methods of combining thermal diffusivity characteristics, i.e., Approx. 1 and Approx 2, can be used, the authors recommend Approx. 1 because the a(T) dependence obtained in this way is within the measurement errors for both LFA 467 and LFA 427.

- (2)

- The analysis of the DIL thermograms obtained from measurements with DIL 402 Expedis (DIL 402 Su)—in the low temperature range and DIL 402C—in the high temperature range shows the following:

- (a)

- The thermal expansion ε(T) obtained by DIL 402 Expedis is substantially consistent with the ε(T) results obtained by DIL 402 C in the range from RT to 500 °C;

- (b)

- Due to the sample shrinkage after the first heating, in the process of combining the characteristics from DIL 402 Expedis and DIL 402 C, the authors propose the calculation of the dependence ε(T) from DIL 402 C in accordance with the proposed procedure.

Author Contributions

Conceptualization, P.K. and M.Z; methodology, P.K., M.Z., and J.Z.; validation, J.Z.; formal analysis, P.K. and M.Z.; investigation, P.K. and M.Z.; writing—original draft preparation, P.K. and M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The methods and results presented in this paper were obtained thanks to funding from the university research project UGB-821 of the Military University of Technology in 2023 (Warsaw, PL).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Moynihan, M.C.; Allwood, J.M. The flow of steel into the construction sector. Resour. Conserv. Recycl. 2012, 68, 88–95. [Google Scholar] [CrossRef]

- Ajayebi, A.; Hopkinson, P.; Zhou, K.; Lam, D.; Chen, H.-M.; Wang, Y. Estimation of structural steel and concrete stocks and flows at urban scale–towards a prospective circular economy. Resour. Conserv. Recycl. 2021, 174, 105821. [Google Scholar] [CrossRef]

- Bolina, F.L.; Fachinelli, E.G.; Pachla, E.C.; Centeno, F.R. A critical analysis of the influence of architecture on the temperature field of RC structures subjected to fire using CFD and FEA models. Appl. Therm. Eng. 2024, 247, 123086. [Google Scholar] [CrossRef]

- Bolina, F.L.; Rodrigues, J.P.C. Finite element analysis criteria for composite steel decking concrete slabs subjected to fire. Fire Saf. J. 2023, 139, 103818. [Google Scholar] [CrossRef]

- Mesquita, R.A.; Michael, K.; Schneider, R. Tool Steels: Properties and Performance; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781439881729. [Google Scholar]

- Zieliński, M.; Koniorczyk, P.; Surma, Z. Influence of the Shrinkage of the Inner Layer of Steel Tubes on Permissible Thermal Load. Energies 2024, 17, 702. [Google Scholar] [CrossRef]

- Koniorczyk, P.; Zieliński, M.; Sienkiewicz, J.; Zmywaczyk, J. Thermophysical properties and microstructure of 32CrMoV12-28 hot-work tool steel. Arch. Thermodyn. 2024, 45, 269–277. [Google Scholar] [CrossRef]

- NETZSCH—Analyzing and Testing. Leading in Thermal Analysis, Rheology and Fire Testing. Light/Laser Flash Analyzer (LFA). Available online: https://analyzing-testing.netzsch.com/en/products/thermal-diffusivity-and-conductivity (accessed on 5 February 2025).

- NETZSCH—Analyzing and Testing. Leading in Thermal Analysis, Rheology and Fire Testing. The Most Advanced Instruments for Dilatometry by NETZSCH. Available online: https://analyzing-testing.netzsch.com/en/products/dilatometry-dil (accessed on 5 February 2025).

- Nishi, T.; Shibata, H.; Tsutsumi, K.; Ohta, H.; Waseda, Y. Measurement of Thermal Diffusivity of Steels at Elevated Temperature by a Laser Flash Method. ISIJ Int. 2002, 42, 498–503. [Google Scholar] [CrossRef]

- Terpiłowski, J. A Modified Flash Method for Determination of Thermal Diffusivity in Solids. Arch. Thermodyn. 2003, 24, 59–80. [Google Scholar]

- Terpiłowski, J.; Piotrowska-Woroniak, J.; Romanowska, J. A study of thermal diffusivity of carbon-epoxy and glass-epoxy composites using the modified pulse method. Arch. Thermodyn. 2014, 35, 117–128. [Google Scholar] [CrossRef]

- Terpiłowski, J.; Rudzki, R.; Szczepaniak, R.; Woroniak, G. Thermal diffusivity investigation of Fe61Ni39, Fe52Ni48 and Fe40Ni60 binary iron–nickel alloys using the modified pulse method. J. Alloys Compd. 2016, 657, 748–754. [Google Scholar] [CrossRef]

- Kaschnitz, E.; Hofer-Hauser, P.; Funk, W. Electrical resistivity measured by millisecond pulse-heating in comparison to thermal conductivity of the hot work tool steel AISI H11 (1.2343) at elevated temperature. HTHP High Temp.-High Press. 2020, 49, 75–87. [Google Scholar] [CrossRef]

- Xing, Y.; Wang, W.; Al-azzani, H. Assessment of thermal properties of various types of high-strength steels at elevated temperatures. Fire Saf. J. 2021, 122, 103348. [Google Scholar] [CrossRef]

- Technical Specifications. Available online: https://analyzing-testing.netzsch.com/en/products/thermal-diffusivity-and-conductivity/lfa-467-hyper-flash-light-flash-apparatus (accessed on 23 January 2025).

- Vozár, L.; Hohenauer, W. Flash method of measuring the thermal diffusivity. A review. HTHP High Temp.-High Press. 2003, 35/36, 253–264. [Google Scholar] [CrossRef]

- Agazhanov, A.S.; Stankus, S.V.; Samoshkin, D.A. Coefficient of thermal diffusivity of ChS-139 steel in wide temperature range. Thermophys. Aeromech. 2013, 20, 651–653. [Google Scholar] [CrossRef]

- Yamane, T.; Katayama, S.; Todoki, M. Experimental investigation of nonuniform heating and heat loss from a specimen for the measurement of thermal diffusivity by the laser pulse heating method. Int. J. Thermophys. 1997, 18, 269–290. [Google Scholar] [CrossRef]

- Baba, T.; Ono, A. Improvement of the laser flash method to reduce uncertainty in thermal diffusivity measurements. Meas. Sci. Technol. 2001, 12, 2046–2057. [Google Scholar] [CrossRef]

- Akoshima, M.; Baba, T. Thermal Diffusivity Measurements of Candidate Reference Materials by the Laser Flash Method. Int. J. Thermophys. 2005, 26, 151–163. [Google Scholar] [CrossRef]

- Lim, K.-H.; Kim, S.-K.; Chung, M.-K. Improvement of the thermal diffusivity measurement of thin samples by the flash method. Thermochim. Acta 2009, 494, 71–79. [Google Scholar] [CrossRef]

- Parker, W.J.; Jenkins, R.J.; Butler, C.P.; Abbott, G.L. Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity. J. Appl. Phys. 1961, 32, 1679–1684. [Google Scholar] [CrossRef]

- Cape, J.A.; Lehman, G.W. Temperature and Finite Pulse-Time Effects in the Flash Method for Measuring Thermal Diffusivity. J. Appl. Phys. 1963, 34, 1909–1913. [Google Scholar] [CrossRef]

- Netzsch. Proteus Software Manual [Online]. Available online: https://analyzing-testing.netzsch.com/en/products/software/proteus (accessed on 22 February 2024).

- Koniorczyk, P.; Zieliński, M.; Sienkiewicz, J.; Zmywaczyk, J.; Dębski, A. Experimental Studies of Thermophysical Properties and Microstructure of X37CrMoV5-1 Hot-Work Tool Steel and Maraging 350 Steel. Materials 2023, 16, 1206. [Google Scholar] [CrossRef] [PubMed]

- Koniorczyk, P.; Zielinski, M. Some problems related to thermophysical properties of selected barrel steels. J. Phys. Conf. Ser. 2023, 2628, 012014. [Google Scholar] [CrossRef]

- Koniorczyk, P.; Sienkiewicz, J.; Zmywaczyk, J.; Dębski, A.; Zieliński, M.; Preiskorn, M. Effect of Microstructure on Thermophysical Properties of Heat-Treated Duplex Steel. Materials 2021, 14, 6043. [Google Scholar] [CrossRef] [PubMed]

- Zieliński, M.; Koniorczyk, P. Thermal diffusivity and thermal expansion investigations of WLV steel. J. Phys. Conf. Ser. 2023, 2628, 012035. [Google Scholar] [CrossRef]

- Dębski, A.; Surma, Z.; Koperski, W. Material and Technological Optimization Research in Terms of Increasing the Durability of Small Arms; Research Report; Military University of Technology: Warsaw, Poland, 2009. (In Polish) [Google Scholar]

- Blicharski, M. Materials Engineering: Steel, 2nd ed.; 1st Reprint; Publishing House WNT: Warsaw, Poland, 2017; ISBN 9788301189556. (In Polish) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).