Measuring the Effective Electro-Optic Coefficient of Low-Temperature-Prepared Lead Zirconate Titanate Thin Films

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussion

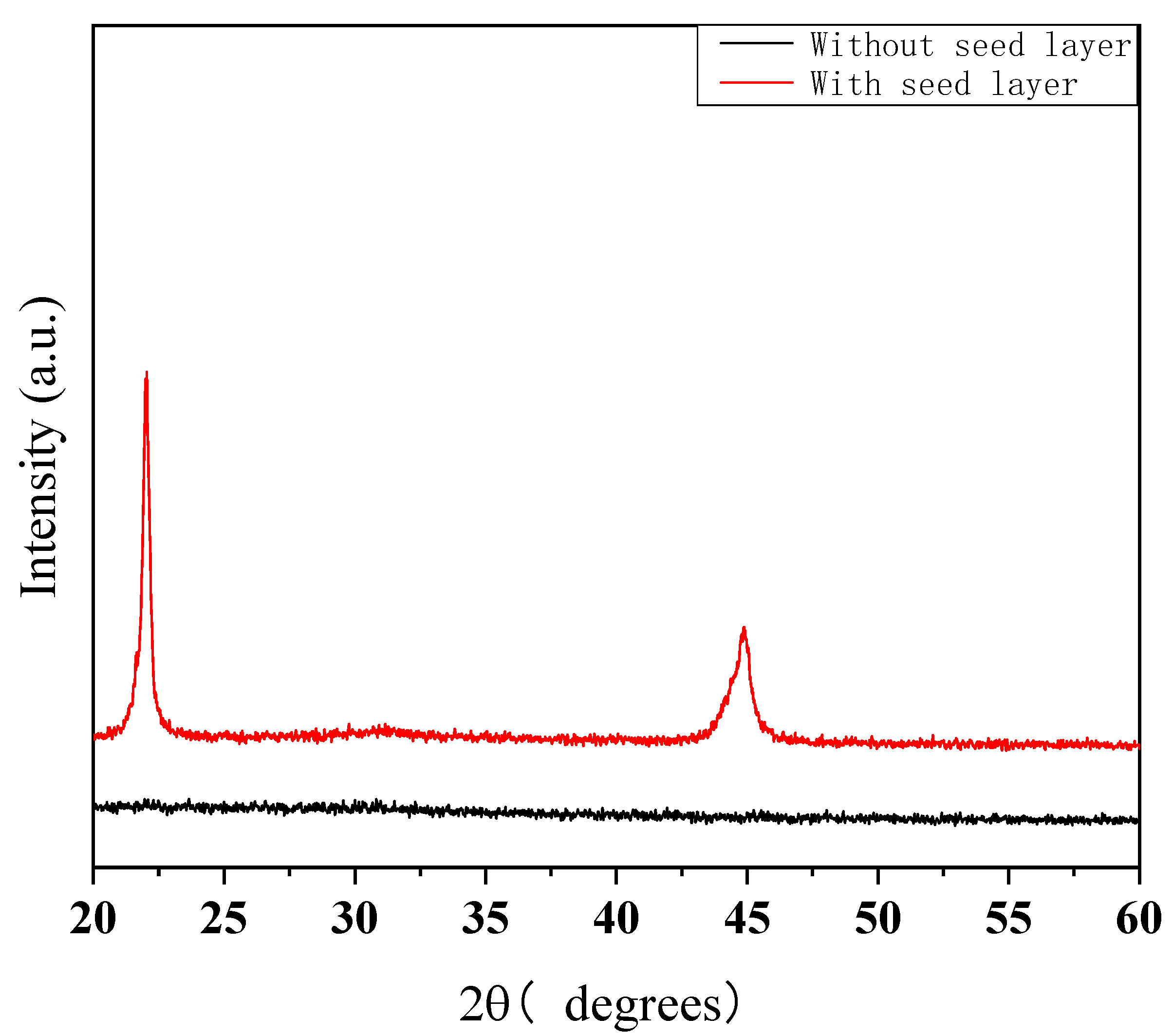

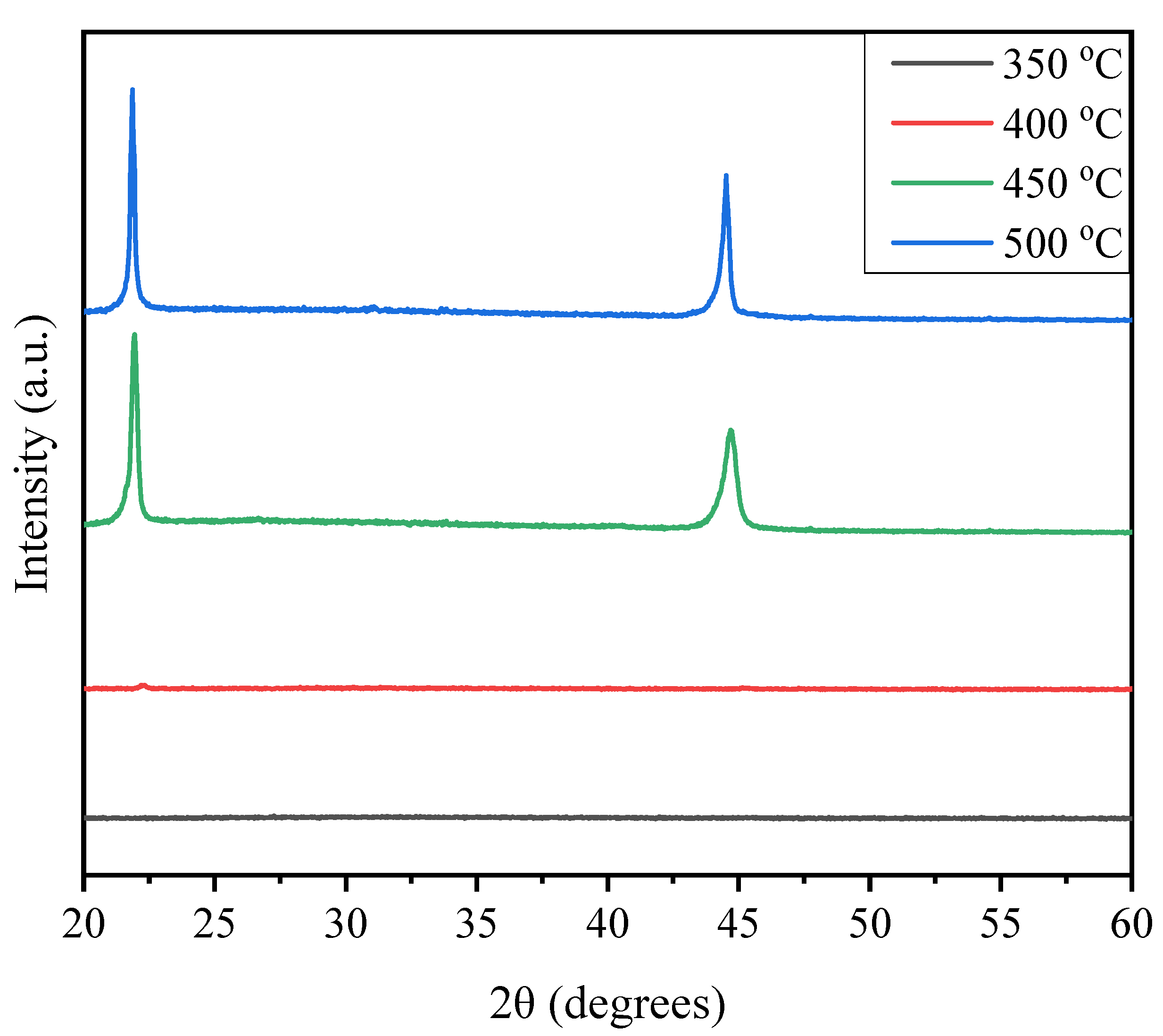

3.1. PZT Film Characterization

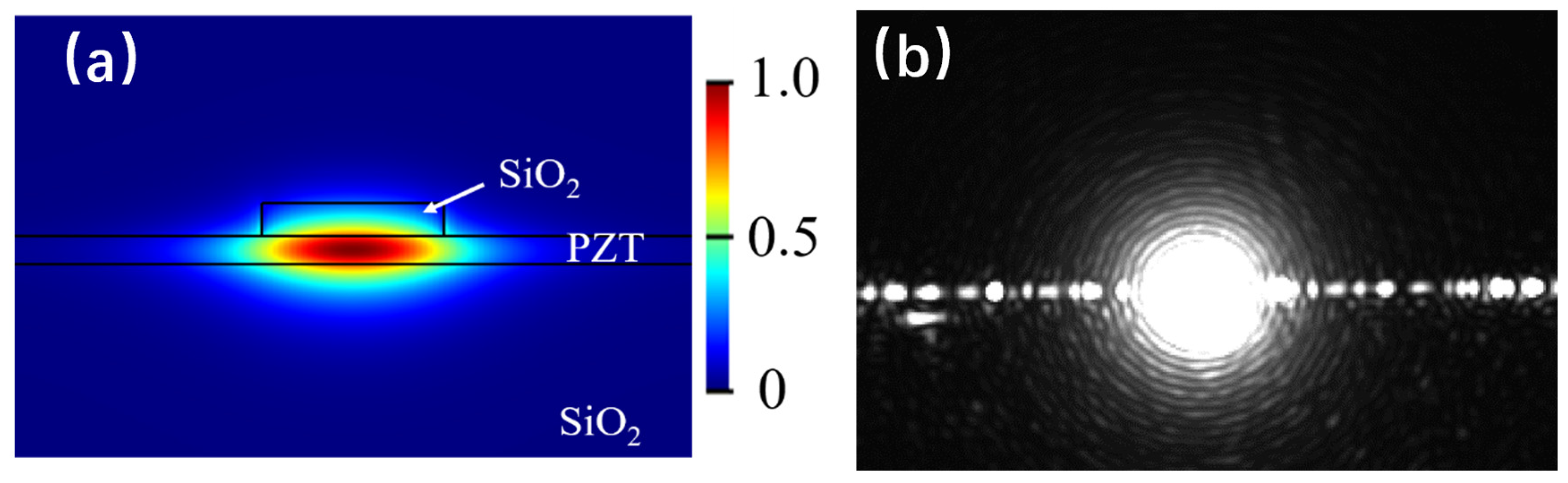

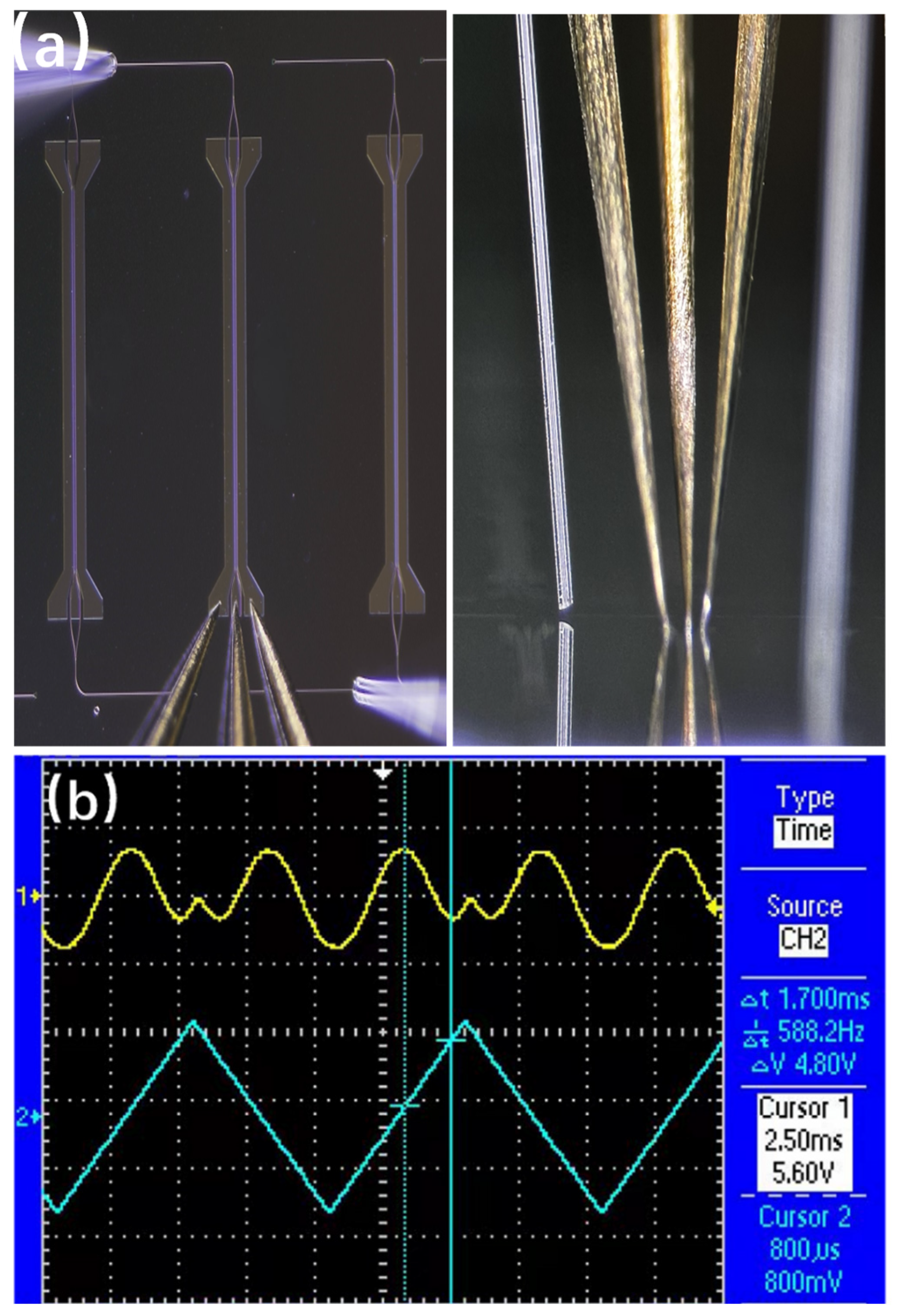

3.2. Fabrication of PZT Waveguide Modulators

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thomaschewski, M.; Bozhevolnyi, S.I. Pockels modulation in integrated nanophotonics. Appl. Phys. Rev. 2022, 9, 021311. [Google Scholar] [CrossRef]

- Kieninger, C.; Kutuvantavida, Y.; Elder, D.L.; Wolf, S.; Zwickel, H.; Blaicher, M.; Kemal, J.N.; Lauermann, M.; Randel, S.; Freude, W.; et al. Ultra-high electro-optic activity demonstrated in a silicon-organic hybrid modulator. Optica 2018, 5, 739–748. [Google Scholar] [CrossRef]

- Hamze, A.K.; Reynaud, M.; Geler-Kremer, J.; Demkov, A.A. Design rules for strong electro-optic materials. NPJ Comput. Mater. 2020, 6, 130. [Google Scholar] [CrossRef]

- Vazimali, M.G.; Fathpour, S. Applications of thin-film lithium niobate in nonlinear integrated photonics. Adv. Photon. 2022, 4, 034001. [Google Scholar] [CrossRef]

- Qi, Y.; Li, Y. Integrated lithium niobate photonics. Nanophotonics 2020, 9, 1287–1320. [Google Scholar] [CrossRef]

- Alexander, K.; George, J.P.; Verbist, J.; Neyts, K.; Kuyken, B.; Thourhout, D.V.; Beeckman, J. Nanophotonic Pockels modulators on a silicon nitride platform. Nat. Commun. 2018, 9, 3444. [Google Scholar] [CrossRef]

- Izyumskaya, N.; Alivov, Y.I.; Cho, S.J.; Morkoç, H.; Lee, H.; Kang, Y.S. Processing, Structure, Properties, and Applications of PZT Thin Films. Crit. Rev. Solid State Mater. Sci. 2007, 32, 111–202. [Google Scholar] [CrossRef]

- Picavet, E.; Geest, K.D.; Lievens, E.; Rijckaert, H.; Vandekerckhove, T.; Solano, E.; Deduytsche, D.; Van Bossele, L.; Van Thourhout, D.; De Buysser, K.; et al. Solution-Processed Pb(Zr, Ti)O3 Thin Films with Strong Remnant Pockels Coefficient. ACS Appl. Mater. Interfaces 2024, 16, 41134–41144. [Google Scholar] [CrossRef]

- George, J.P.; Smet, P.F.; Botterman, J.; Bliznuk, V.; Woestenborghs, W.; Thourhout, D.V.; Neyts, K.; Beeckman, J. Lanthanide-Assisted Deposition of Strongly Electro-optic PZT Thin Films on Silicon: Toward Integrated Active Nanophotonic Devices. ACS Appl. Mater. Interfaces 2015, 7, 13350. [Google Scholar] [CrossRef]

- Zhu, M.; Zhang, H.; Dua, Z.; Liu, C. Structural insight into the optical and electro-optic properties of lead zirconate titanate for high-performance photonic devices. Ceram. Int. 2019, 45, 22324–22330. [Google Scholar] [CrossRef]

- Bassiri-Gharb, N.; Bastani, Y.; Bernal, A. Chemical solution growth of ferroelectric oxide thin films and nanostructures. Chem. Soc. Rev. 2014, 43, 2125–2140. [Google Scholar] [CrossRef] [PubMed]

- Dey, S.K.; Budd, K.D.; Payne, D.A. Thin-film ferroelectrics of PZT of sol-gel processing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 1988, 35, 80–81. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.M.; Du, Z.H.; Ma, J. Influence of crystal phase and transparent substrates on electro-optic properties of lead zirconate titanate films. J. Appl. Phys. 2010, 108, 113119. [Google Scholar] [CrossRef]

- Kondo, S.; Yamada, T.; Yoshino, M.; Teranishi, T.; Kishimoto, A.; Nagasaki, T. Revealing intrinsic electro-optic effect in single domain Pb(Zr, Ti)O3 thin films. Appl. Phys. Lett. 2021, 119, 102902. [Google Scholar] [CrossRef]

- Ban, D.; Liu, G.; Yu, H.; Sun, X.; Deng, N.; Qiu, F. High electro-optic coefficient lead zirconate titanate films toward low-power and compact modulators. Opt. Mater. Express. 2021, 11, 1733–1741. [Google Scholar] [CrossRef]

- Feutmba, G.F.; Silva, L.D.; Singh, N.; Breyne, L.; Geest, K.D.; Puthenparampil George, J.; Bauwelinck, J.; Van Thourhout, D.; Yin, X.; Beeckman, J. High frequency characterization of PZT thin-films deposited by chemical solution deposition on SOI for integrated high speed electro-optic modulators. Opt. Mater. Express. 2023, 13, 2120–2134. [Google Scholar] [CrossRef]

- Song, L.; Glinsek, S.; Defay, E. Toward low-temperature processing of lead zirconate titanate thin films: Advances, strategies, and applications. Appl. Phys. Rev. 2021, 8, 041315. [Google Scholar] [CrossRef]

- Bretos, I.; Jiménez, R.; Ricote, J.; Calzada, M.L. Low-temperature crystallization of solution-derived14 metal oxide thin films assisted by chemical processes. Chem. Soc. Rev. 2018, 47, 291–308. [Google Scholar] [CrossRef]

- Bretos, I.; Jimenez, R.; Ricote, J.; Calzada, M.L. Low-Temperature Solution Approaches for the Potential Integration of Ferroelectric Oxide Films in Flexible Electronics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2020, 67, 1967–1979. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Wei, S.; Meng, Y.; Wang, N.; Zhang, Q.; Liu, L.; Peng, B. Oxygen plasma-assisted ultra-low temperature sol-gel-preparation of the PZT thin films. Ceram. Int. 2023, 49, 10864–10870. [Google Scholar] [CrossRef]

- Tue, P.T.; Shimoda, T.; Takamura, Y. A facile solution-combustion-synthetic approach enabling low-temperature PZT thin-films. APL Mater. 2020, 8, 021112. [Google Scholar] [CrossRef]

- Ansari, I.; George, J.P.; Feutmba, G.F.; de Veire, T.V.; Pandey, A.; Beeckman, J.; Thourhout, D.V. Light Modulation in Silicon Photonics by PZT Actuated Acoustic Waves. ACS Photonics 2022, 9, 1944–1953. [Google Scholar] [CrossRef] [PubMed]

- Ban, D.; Liu, G.; Yu, H.; Wu, Y.; Qiu, F. Low Driving Voltage and Low Optical Loss Electro-Optic Modulators Based on Lead Zirconate Titanate Thin Film on Silicon Substrate. J. Light. Technol. 2022, 40, 2939–2943. [Google Scholar] [CrossRef]

- Yu, H.; Guo, N.; Deng, C.; Han, H.; Li, W.; Lebudi, C.; Wang, S.; Li, Y.; Chen, Y.; Peng, S.; et al. Tuning the Electro-Optic Properties of BaTiO3 Epitaxial Thin Films via Buffer Layer-Controlled Polarization Rotation Paths. Adv. Funct. Mater. 2024, 34, 2315579. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Yu, H.; Yang, C.; Wang, J.; Han, Y.; Qiu, F. Measuring the Effective Electro-Optic Coefficient of Low-Temperature-Prepared Lead Zirconate Titanate Thin Films. Materials 2025, 18, 837. https://doi.org/10.3390/ma18040837

Li B, Yu H, Yang C, Wang J, Han Y, Qiu F. Measuring the Effective Electro-Optic Coefficient of Low-Temperature-Prepared Lead Zirconate Titanate Thin Films. Materials. 2025; 18(4):837. https://doi.org/10.3390/ma18040837

Chicago/Turabian StyleLi, Bin, Hongyan Yu, Chen Yang, Jungan Wang, Yu Han, and Feng Qiu. 2025. "Measuring the Effective Electro-Optic Coefficient of Low-Temperature-Prepared Lead Zirconate Titanate Thin Films" Materials 18, no. 4: 837. https://doi.org/10.3390/ma18040837

APA StyleLi, B., Yu, H., Yang, C., Wang, J., Han, Y., & Qiu, F. (2025). Measuring the Effective Electro-Optic Coefficient of Low-Temperature-Prepared Lead Zirconate Titanate Thin Films. Materials, 18(4), 837. https://doi.org/10.3390/ma18040837