Properties and Behavior of Sandy Soils by a New Interpretation of MICP

Abstract

1. Introduction

2. Materials and Methods

2.1. Sandy Soils Used in MICP

- Vietnam sand, crushed sand with high-electrostatic charges;

- Coarse sand with a low uniformity coefficient;

- Fine sand a with high liquefaction potential;

- Medium sand;

- Fine sand b with high liquefaction potential;

- Fine sand c (densified fine sand b);

- River sand with a high uniformity coefficient.

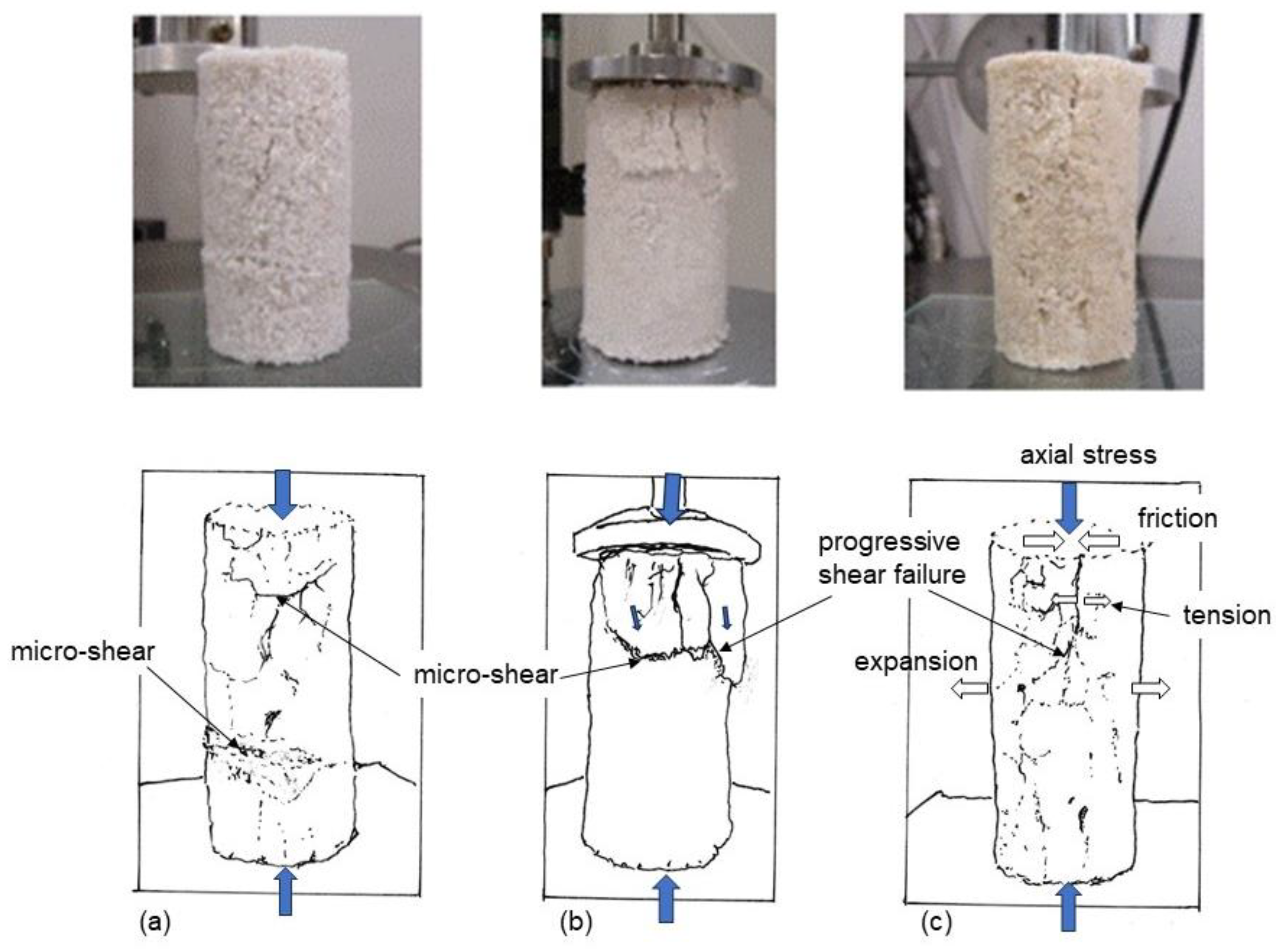

2.2. Problems in UCS Measurement for Loose Sandy Soils

2.3. Experiments

2.3.1. Preparation of Specimens of Seven Types of Sandy Soils

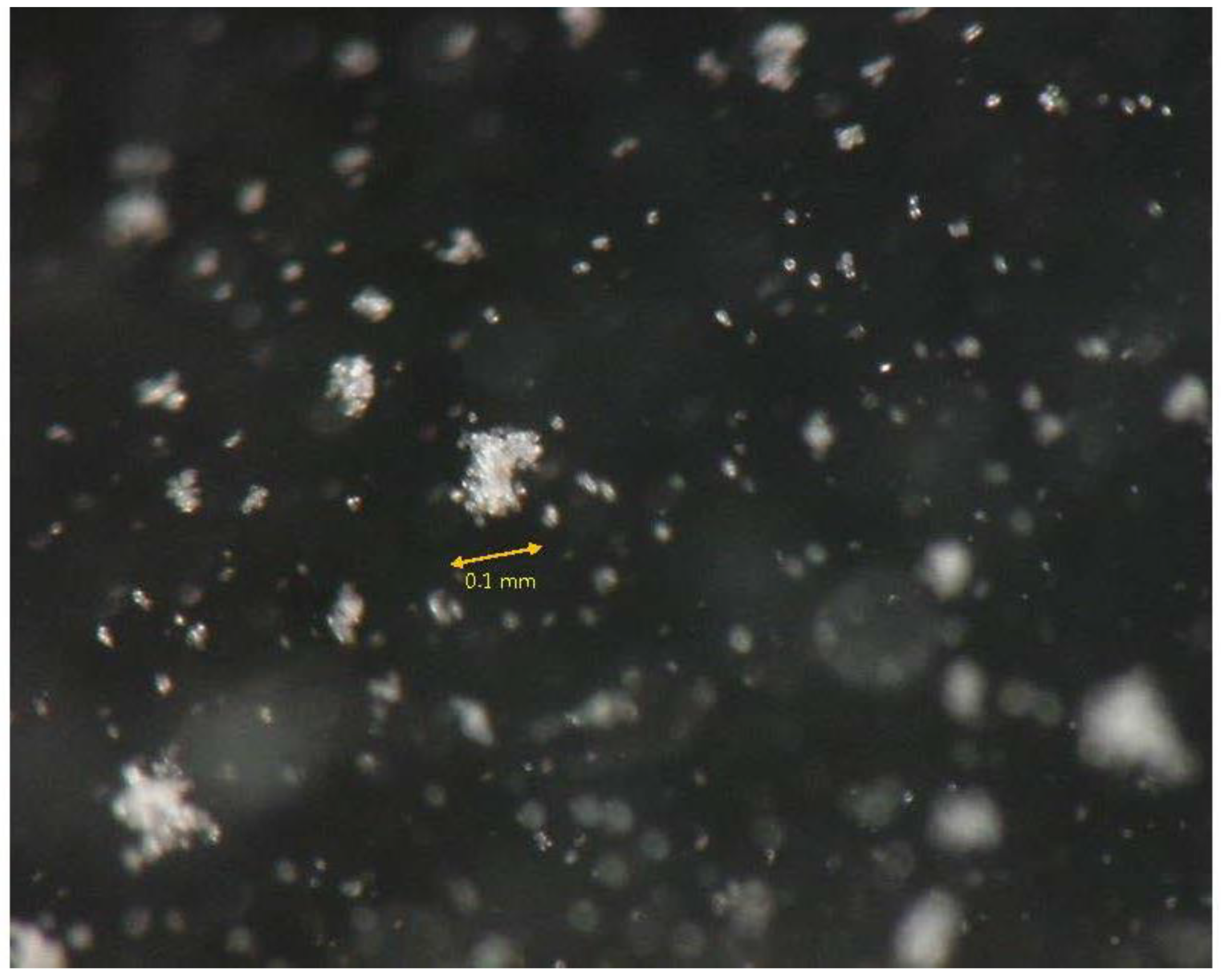

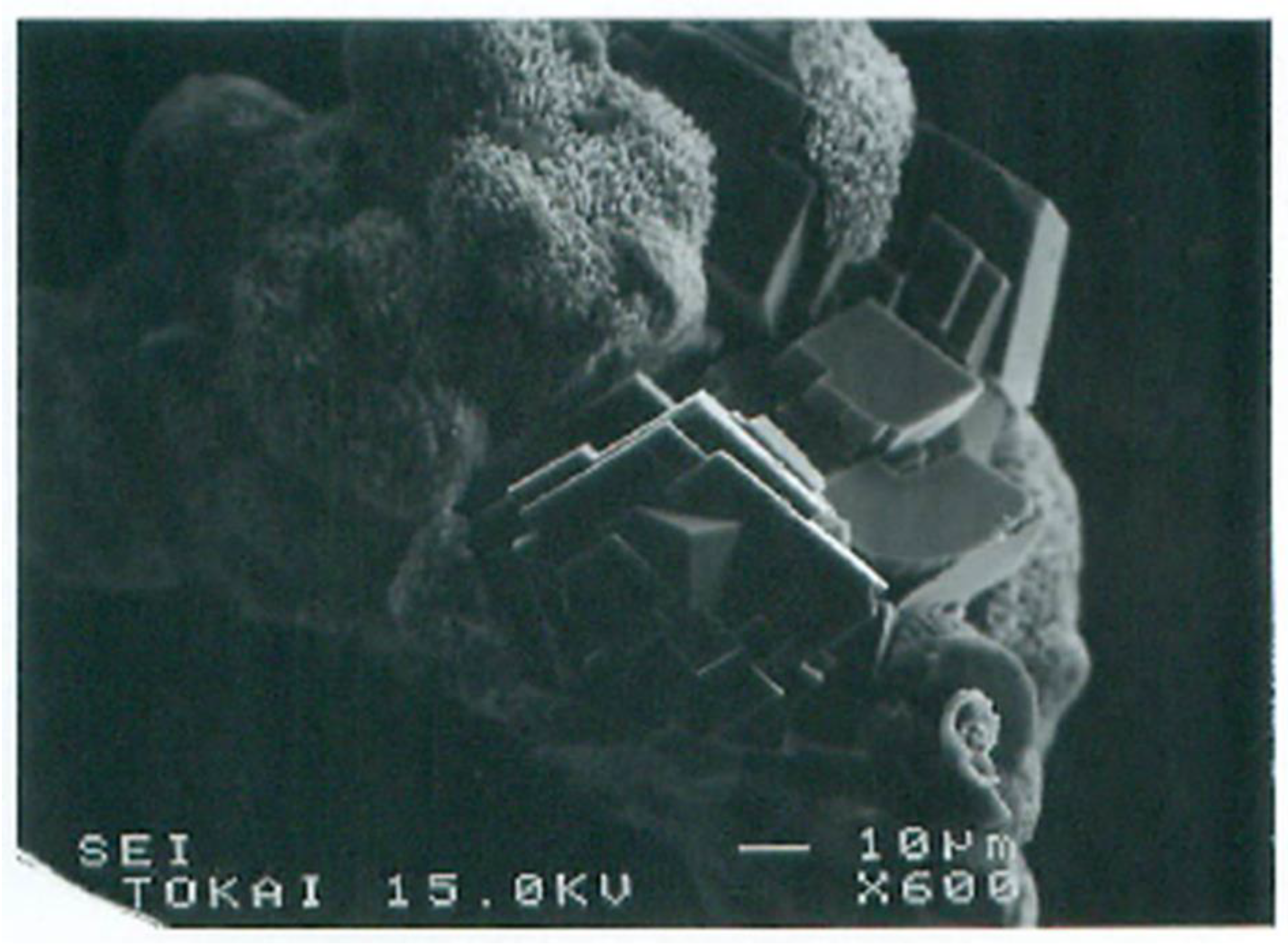

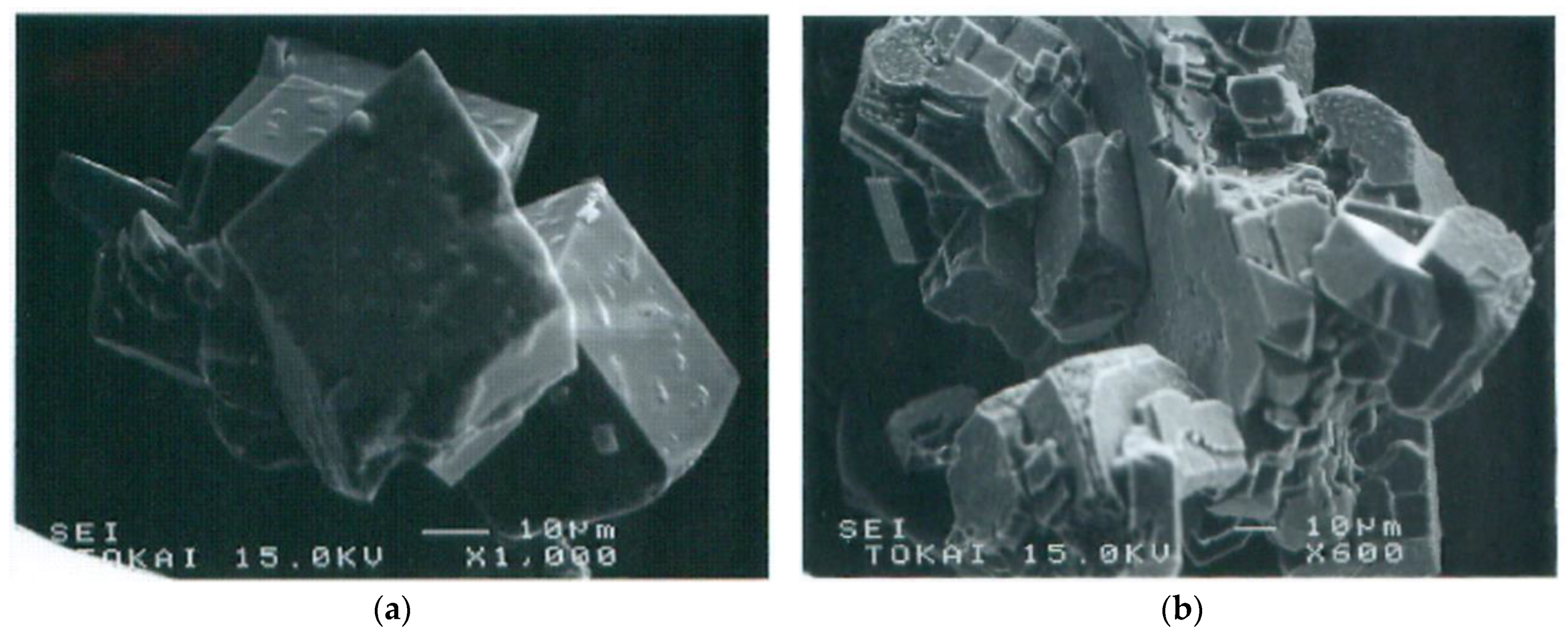

2.3.2. Carbonate Content Determination

3. Test Results

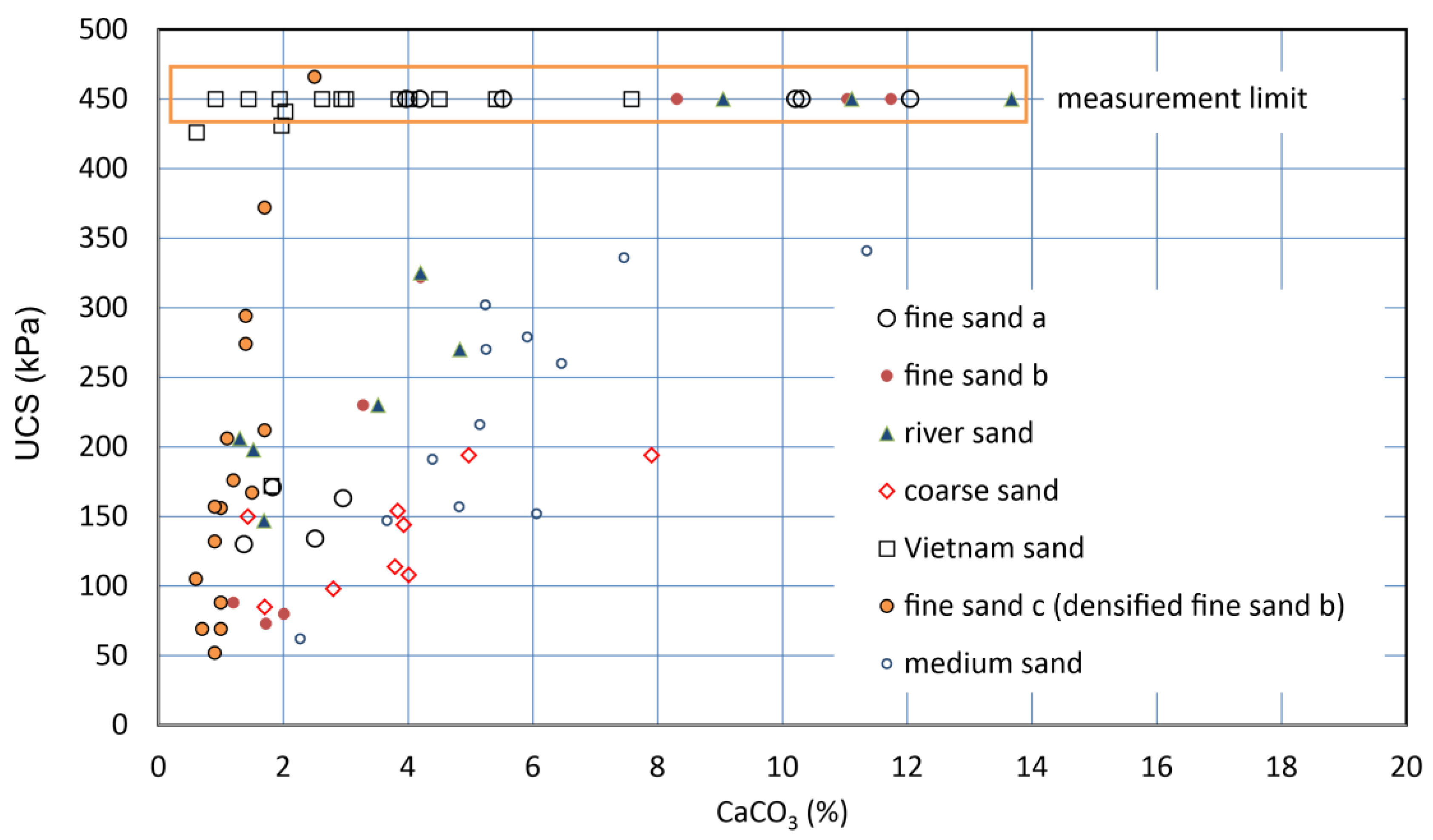

3.1. Carbonate Content and UCS

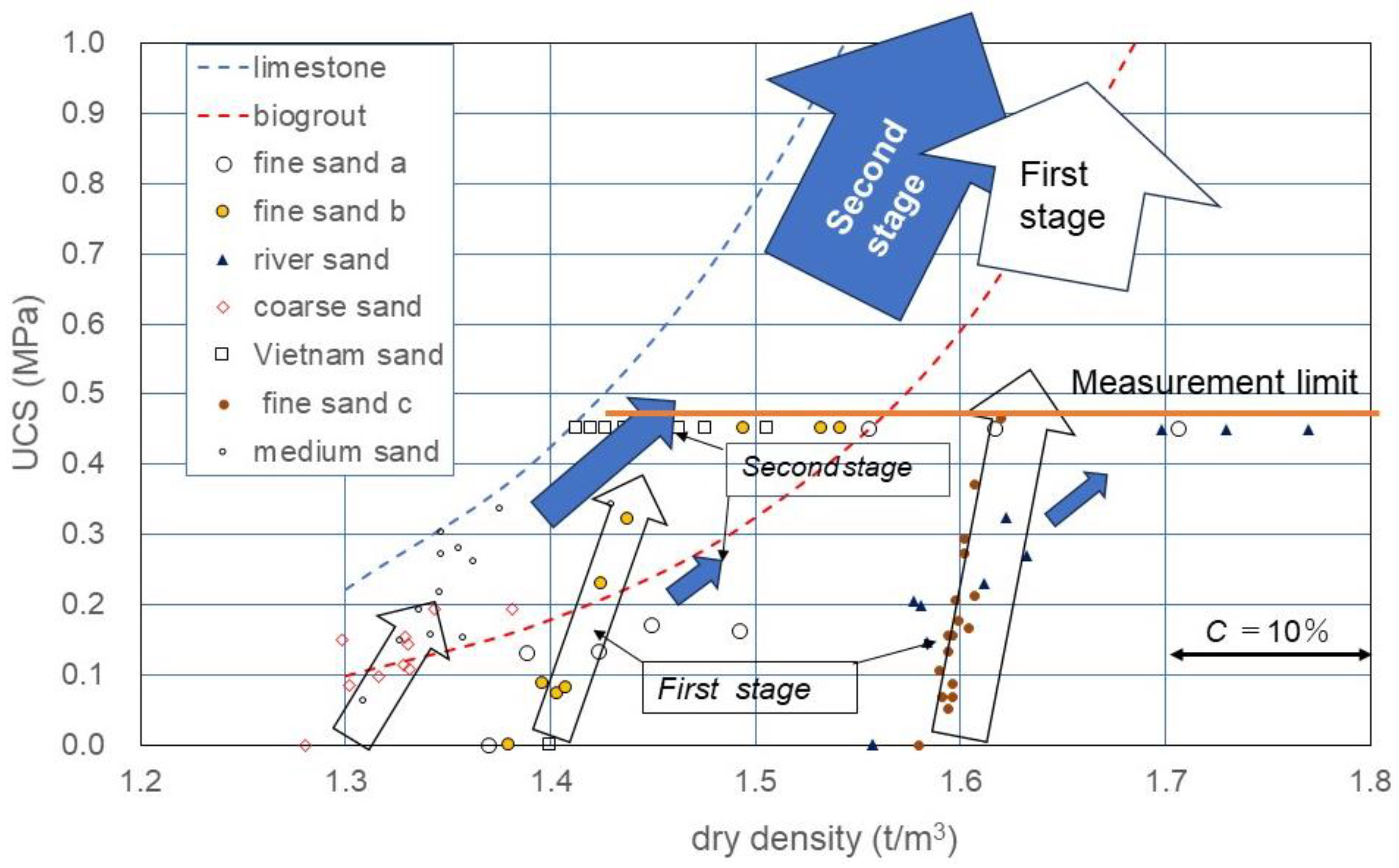

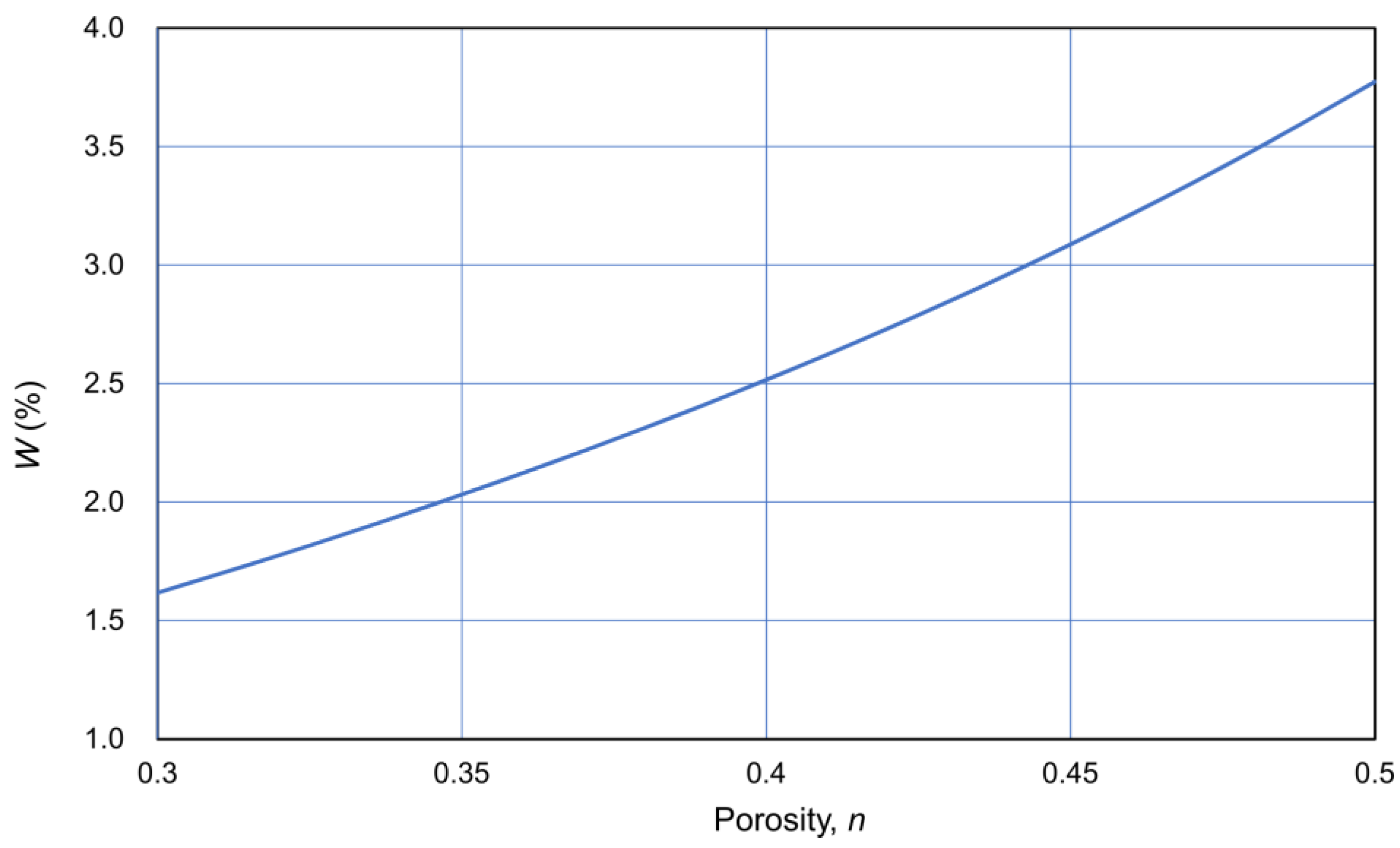

3.2. UCS as a Function of Carbonate Content and Dry Density

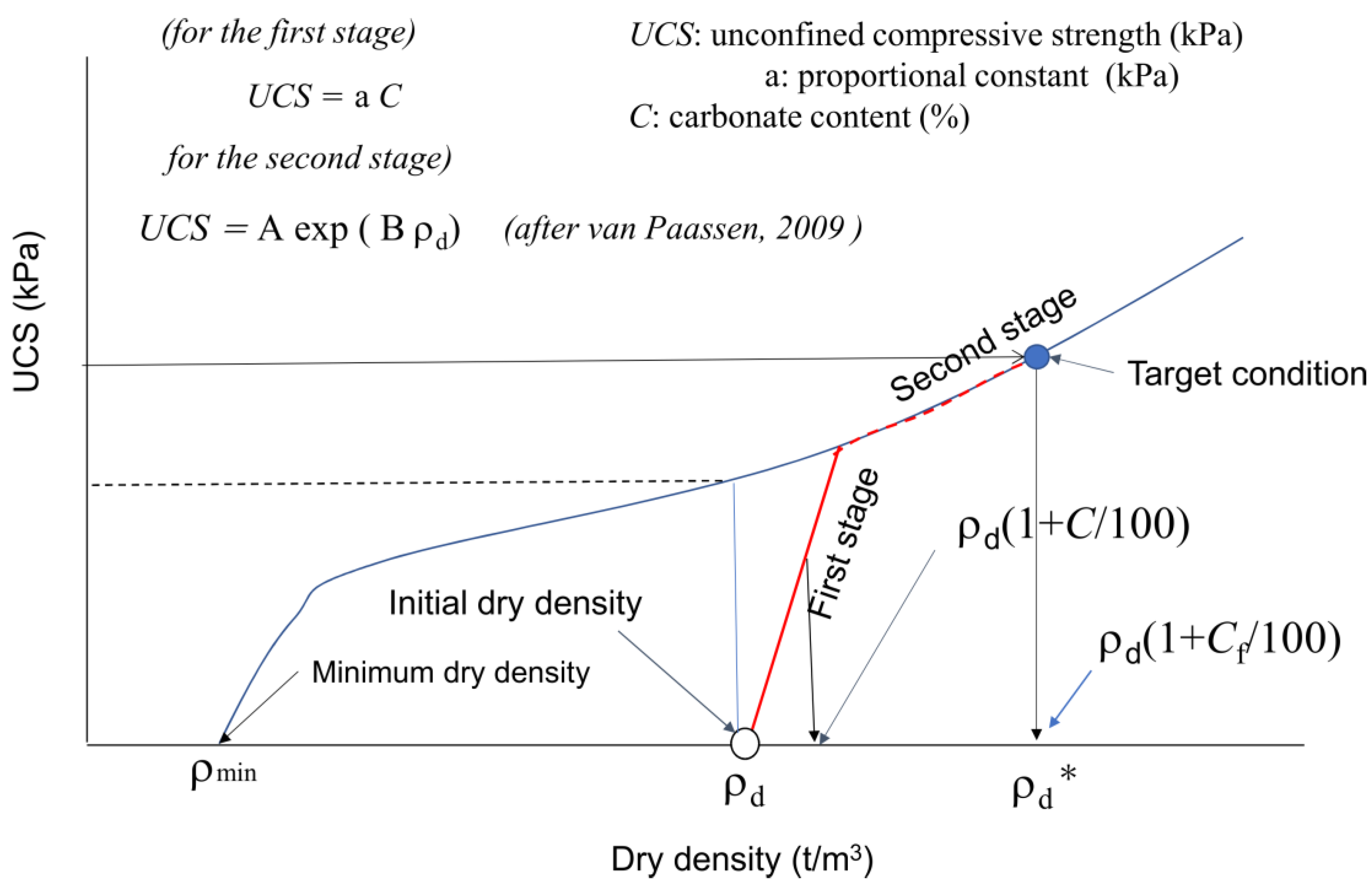

3.3. Definition of the First and Second Stages in the Carbonation Process

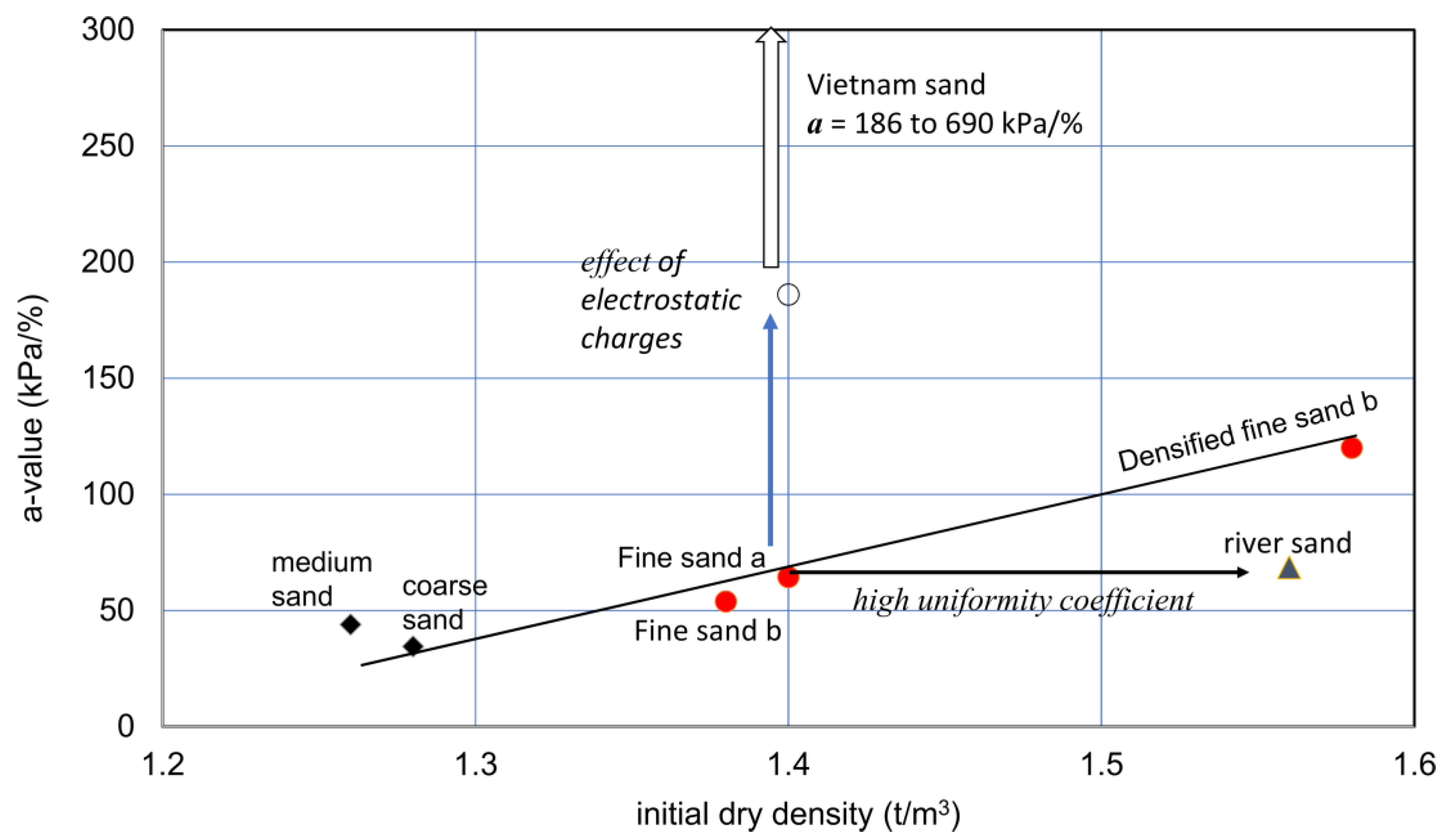

3.4. Initial Dry Density and a-Value

4. Discussion

4.1. The First and Second Stages in the MICP Process

4.2. Conversion Between C and the CPR

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, M.; Gowthaman, S.; Nakashima, K.; Komatsu, S.; Kawasaki, S. Experimental Study on Sand Stabilization Using Bio Cementation with Wastepaper Fiber Integration. Materials 2021, 14, 5164. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Tang, C.; Pan, X.; Liu, B.; Xie, Y.; Cheng, Q.; Shi, B. Application of microbial induced carbonate precipitation for loess surface erosion control. Eng. Geol. 2021, 294, 106387. [Google Scholar] [CrossRef]

- DeJong, J.T.; Gomez, M.G.; San Pablo, A.C.; Graddy, C.M.; Nelson, D.C.; Lee, M.; Ziotopoulou, K.; El Kortbawi, M.; Montoya, B.; Kwon, T.H. State of the Art: MICP soil improvement and its application to liquefaction hazard mitigation. In Proceedings of the 20th International Conference on Soil Mechanics and Geotechnical Engineering, Sydney, Australia, 1–5 May 2002; pp. 405–508, ISBN 978-0-9946261-6-5. [Google Scholar]

- Li, Y.; Guo, Z.; Wang, L.; Yang, H.; Li, Y.; Zhu, J. An Innovative Eco-friendly Method f or Scour Protection around Monopile Foundation. Appl. Ocean Res. 2022, 123, 103177. [Google Scholar] [CrossRef]

- Lin, H.; Suleiman, M.; Jabbour, H.M.; Brown, D. Bio-grouting to enhance axial pull-out response of pervious concrete ground improvement piles. Can. Geotechnol. 2018, 55, 119–130. [Google Scholar] [CrossRef]

- Liu, B.; Xie, Y.; Tang, C.; Pan, X.; Jiang, N.; Singh, D.; Cheng, Y.; Shi, B. Bio-mediated method for improving surface erosion resistance of clayey soils. Eng. Geol. 2021, 293, 106295. [Google Scholar] [CrossRef]

- Meng, H.; Gao, Y.; He, J.; Qi, Y.; Hang, L. Microbially induced carbonate precipitation for wind erosion control of desert soil: Field-scale tests. Geoderma 2021, 383, 114723. [Google Scholar] [CrossRef]

- Ramos, O.; Kwon, T.-H. Development of bio-grout injection strategy and design guide using reactive transport model for field-scale soil improvement based on microbially induced calcium carbonate precipitation (MICP). Geomech. Energy Environ. 2023, 36, 100509. [Google Scholar] [CrossRef]

- Riveros, G.A.; Sadrekarimi, A. Liquefaction resistance of Fraser River sand improved by a microbially-induced cementation. Soil Dyn. Earthq. Eng. 2020, 131, 106034. [Google Scholar] [CrossRef]

- Salifu, E.; MacLachlan, E.; Lyer, K.R.; Knapp, C.W.; Tarantino, A. Application of microbially induced calcite precipitation in erosion mitigation and stabilisation of sandy soil foreshore slopes: A preliminary investigation. Eng. Geol. 2016, 201, 96–105. [Google Scholar] [CrossRef]

- van Paassen, L. Biogrout, Ground Improvement by Microbially Induced Carbonate Precipitation. Ph.D. Thesis, Delft University Technology, Delft, The Netherlands, 2009; 195p. [Google Scholar]

- Achal, V.; Pan, X.; Zhang, D. Bioremediation of strontium (Sr) contaminated aquifer quartz sand based on carbonate precipitation induced by Sr resistant Halomonas sp. Chemosphere 2012, 89, 764–768. [Google Scholar] [CrossRef] [PubMed]

- Dong, Y.; Gao, Z.; Di, J.; Wang, D.; Yang, Z.; Wang, Y.; Guo, X.; Li, K. Experimental study on solidification and remediation of lead–zinc tailings based on microbially induced calcium carbonate precipitation (MICP). Constr. Build. Mater. 2023, 369, 130611. [Google Scholar] [CrossRef]

- Fujita, Y.; Redden, G.D.; Ingram, J.C.; Cortez, F.; Ferris, G.; Smith, R.W. Strontium incorporation into calcite generated by bacterial ureolysis. Geochim. Cosmochim. Acta 2004, 68, 3261–3270. [Google Scholar] [CrossRef]

- Gerber, U.; Zirnsteinb, I.; Krawczyk-Bärscha, E.H.; Lünsdorf, H.; Arnolda, T.; Merround, M.L. Combined use of flow cytometry and microscopy to study the interactions between the gram-negative betaproteobacterium Acidovorax facilis and uranium (VI). J. Hazard. Mater. 2016, 317, 127–134. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Song, H.-W.; Mishra, S.; Zhang, W.; Zhang, Y.-L.; Zhang, Q.-R.; Yu, Z.-G. Application of microbial-induced carbonate precipitation (MICP) techniques to remove heavy metal in the natural environment: A critical review. Chemosphere 2023, 318, 137894. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Zhou, M.; Li, B.; Dong, Y. Mechanisms, application advances and future perspectives of microbial-induced heavy metal precipitation: A review. Int. Biodeter. Biodegr. 2023, 178, 105544. [Google Scholar] [CrossRef]

- Mark, J.; Jones, M.J.; Butchins, L.J.; Charnock, J.K.; Pattrick, R.A.D.; Small, J.S.; Vaughan, D.J.; Wincott, P.L.; Livens, F.R. Reactions of radium and barium with the surfaces of carbonate minerals. Appl. Geochem. 2011, 26, 1231–1238. [Google Scholar] [CrossRef]

- Mitchell, A.C.; Ferris, G.F. The coprecipitation of Sr into calcite precipitates induced by bacterial ureolysis in artificial groundwater: Temperature and kinetic dependence. Geochim. Cosmochim. Acta 2005, 69, 4199–4210. [Google Scholar] [CrossRef]

- Zhao, J.; Csetenyi, L.; Gadd, G.M. Fungal-induced CaCO3 and SrCO3 precipitation: A potential strategy for bioprotection of concrete. Sci. Total Environ. 2022, 816, 151501. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Li, Y.; Jiang, X.; Zhao, D.; Liu, X.; Zhou, J.; He, Z.; Zheng, C.; Pan, X. Study on soil physical structure after the bioremediation of Pb pollution using microbial-induced carbonate precipitation methodology. J. Hazard. Mater. 2021, 411, 125103. [Google Scholar] [CrossRef] [PubMed]

- Han, L.; Li, J.; Xue, Q.; Chen, Z.; Zhou, Y.; Poon, C.S. Bacterial-induced mineralization (BIM) for soil solidification and heavy metal stabilization: A critical review. Sci. Total Environ. 2020, 746, 140967. [Google Scholar] [CrossRef]

- Zeng, Y.; Chen, Z.; Lyu, Q.; Wang, X.; Du, Y.; Huan, C.; Liu, Y.; Yan, Z. Mechanism of microbiologically induced calcite precipitation for cadmium mineralization. Sci. Total Environ. 2022, 852, 158465. [Google Scholar] [CrossRef] [PubMed]

- Bao, S.; Di, J.; Dong, Y.; Gao, Z.; Gu, Q.; Zhao, Y.; Zhai, H. Experimental study on the effect of cementation curing time on MICP bio-cemented tailings. Constr. Build. Mater. 2024, 411, 134263. [Google Scholar] [CrossRef]

- He, Z.; Xu, Y.; Wang, W.; Yang, X.; Jin, Z.; Zhang, D.; Pan, X. Synergistic mechanism and application of microbially induced carbonate precipitation (MICP) and inorganic additives for passivation of heavy metals in copper-nickel tailings. Chemosphere 2023, 311, 136981. [Google Scholar] [CrossRef]

- Zhou, G.; Xu, Y.; Wang, Y.; Zheng, L.; Zhang, Y.; Li, L.; Sun, B.; Li, S.; Zhu, Y. Study on MICP dust suppression technology in open pit coal mine: Preparation and mechanism of microbial dust suppression material. J. Environ. Manag. 2023, 343, 118181. [Google Scholar] [CrossRef]

- Zúniga-Barra, H.; Toledo-Alarcon, J.; Torres-Aravena, A.; Jorquera, L.; Rivas, M.; Gutiérrez, L.; Jeison, D. Improving the sustainable management of mining tailings through microbially induced calcite precipitation: A review. Miner. Eng. 2022, 189, 107855. [Google Scholar] [CrossRef]

- Fukue, M.; Lechowicz, Z.; Fujimori, Y.; Emori, K.; Mulligan, C.N. Incorporation of optical density into the blending design for a biocement solution. Materials 2022, 15, 1951. [Google Scholar] [CrossRef]

- Fukue, M.; Lechowicz, Z.; Fujimori, Y.; Emori, K.; Mulligan, C.N. Inhibited and Retarded Behavior by Ca2+ and Ca2+/OD Loading Rate on Ureolytic Bacteria in MICP process. Materials 2023, 16, 3357. [Google Scholar] [CrossRef] [PubMed]

- Kogure, T.; Aoki, H.; Maekado, A.; Matsukura, Y. Effect of Specimen Size and Rock Properties on the Uniaxial Compressive Strength of Ryukyu Limestone. J. Jpn. Soc. Eng. Geol. 2005, 46, 2–8, (Text in Japanese with English Summary). [Google Scholar] [CrossRef]

- Fukue, M.; Nakamura, T.; Kato, Y.; Naoe, K. Correlation among carbonate content, accumulation rate and topography of seabed. Soils Found. 1996, 36, 51–60. [Google Scholar] [CrossRef][Green Version]

- Fukue, M.; Nakamura, T.; Kato, Y. Cementation of soils due to calcium carbonate. Soils Found. 1999, 39, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Sanders, D. Syndepositional dissolution of calcium carbonate in neritic carbonate environments: Geological recognition, processes, potential significance. J. Afr. Earth Sci. 2003, 36, 99–134. [Google Scholar] [CrossRef]

- Worden, R.H.; Burley, S.D. Sandstone diagenesis: The evolution of sand to stone. In Sandstone Diagenesis: Recent and Ancient; Burley, S.D., Worden, R.H., Eds.; International Association of Sedimentologists: Ghent, Belgium, 2003; ISBN 978-1-405-10897-3. [Google Scholar]

- Budak, T.O.; Gurbuz, A.; Eksioglu, B. Practical transitions among undrained shear strengths of remolded samples from pocket penetrometer tests and other laboratory tests. Catena 2022, 213, 106148. [Google Scholar] [CrossRef]

- Mousavi, F.; Abdi, E.; Ghalandarayeshi, S.; Page-Dumroese, D.S. Modeling unconfined compressive strength of fine-grained soils: Application of pocket penetrometer for predicting soil strength. Catena 2021, 196, 104890. [Google Scholar] [CrossRef]

- O’Kelly, B.C. Discussion of “Practical transitions among undrained shear strengths of remolded samples from pocket penetrometer tests and other laboratory tests” by Budak T.O., Gurbuz A. and Eksioglu B. [Catena 213 (2022) 106148]. Catena 2023, 228, 107129. [Google Scholar] [CrossRef]

- Fukue, M.; Ono, S.; Sato, Y. Cementation of sands due to Microbiologically induced Carbonate. Soils Found. 2011, 51, 83–93. [Google Scholar] [CrossRef]

- Burdalski, R.; Ribeiro, B.G.O.; Gomez, M.G.; Gorman-Lewis, D. Mineralogy, morphology, and reaction kinetics of ureolytic bio-cementation in the presence of seawater ions and varying soil materials. Sci. Rep. 2022, 12, 17100. [Google Scholar] [CrossRef] [PubMed]

- Garrels, R.M.; Christ, C.H. Solution, Minerals, and Equilibria; Croneis, C., Ed.; Happer’s Geoscience Series; Happer & Row: New York, NY, USA, 1965. [Google Scholar]

- Morais, M.M.; de Camargo, I.L.; Colombo, P.; Fortulan, C.A. Additive manufacturing of calcium carbonate parts through vat-photopolymerization and sintering in carbon dioxide atmosphere. Open Ceram. 2023, 14, 100348. [Google Scholar] [CrossRef]

- Willibalda, C.; Dual, J.; Schneebeli, M.; Löwe, H. Size controls on the crossover from normal to self-inhibited sintering of ice spheres. Acta Mater. 2021, 213, 116926. [Google Scholar] [CrossRef]

- Fukue, M.; Mulligan, C.N. Equations of state in soil compression based on statistical mechanics. Soils Found. 2009, 49, 99–114. [Google Scholar] [CrossRef][Green Version]

- Cruz, R.C.D.; Segadães, A.M.; Oberacker, R.; Hoffmann, M.J. Double layer electrical conductivity as a stability criterion for concentrated colloidal suspensions. Colloids Surf. A Physicochem. Eng. Asp. 2017, 520, 9–16. [Google Scholar] [CrossRef]

- Poortinga, A.T.; Bos, R.; Norde, W.; Busscher, H.J. Electric double layer interactions in bacterial adhesion to surfaces. Surf. Sci. Rep. 2002, 47, 1–32. [Google Scholar] [CrossRef]

- Baciocchia, R.; Bonib, M.R.B.; Lavecchia, R. Modeling of chlorophenols competitive adsorption on soils by means of the ideal adsorbed solution theory. J. Hazard. Mater. 2005, 118, 239–246. [Google Scholar] [CrossRef]

- Zhao, Y.-Y.; Zhang, M.; Hu, X.-M.; Feng, Y.; Xue, D.; Wang, Q.-S.; Geng, Z.; Liu, Y.; Zhang, J.; Jia, X.-H. Study on adsorption and dust suppression mechanism of urease-producing bacteria on coal-soil mixed dust. J. Environ. Chem. Eng. 2023, 11, 111407. [Google Scholar] [CrossRef]

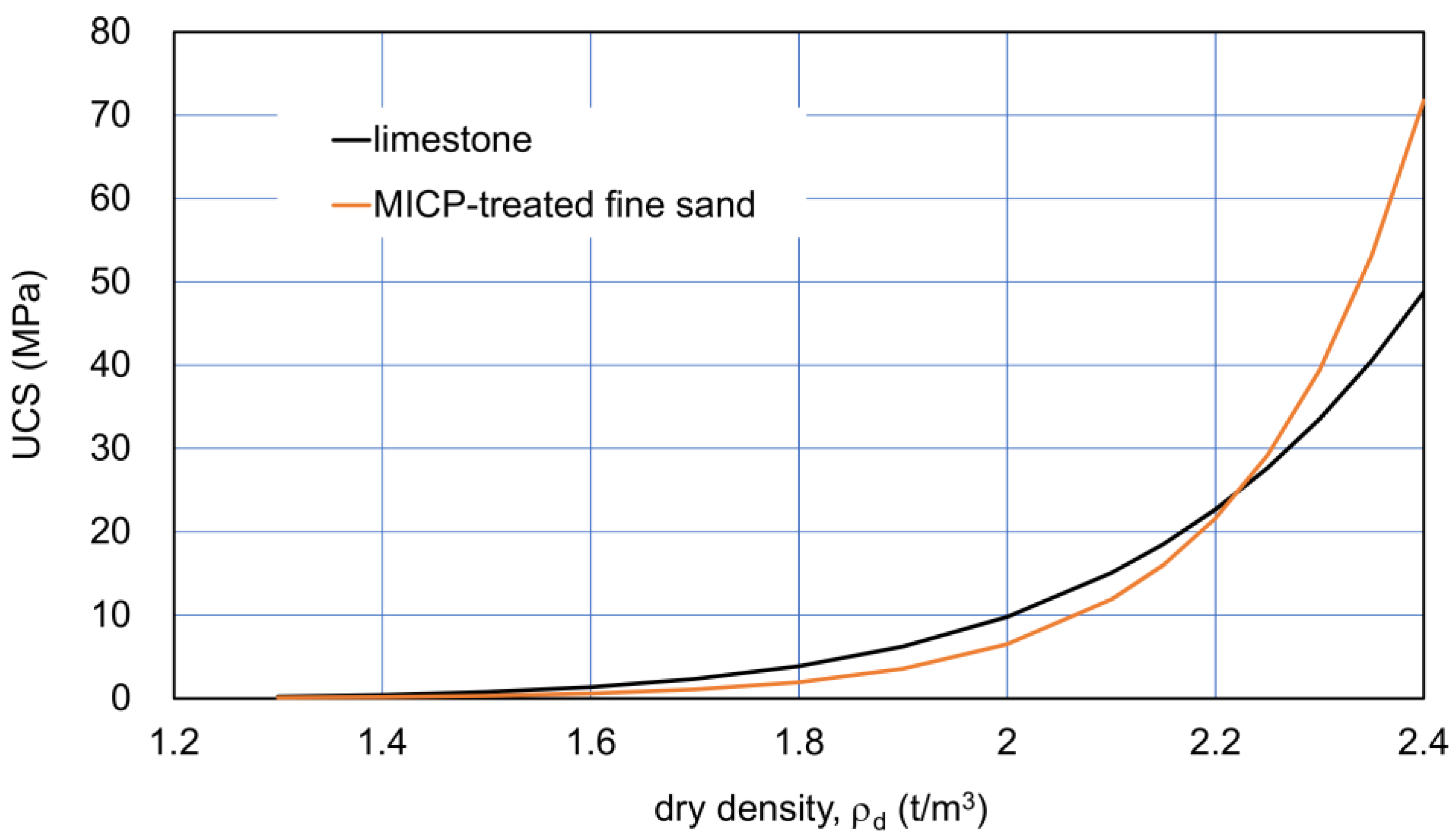

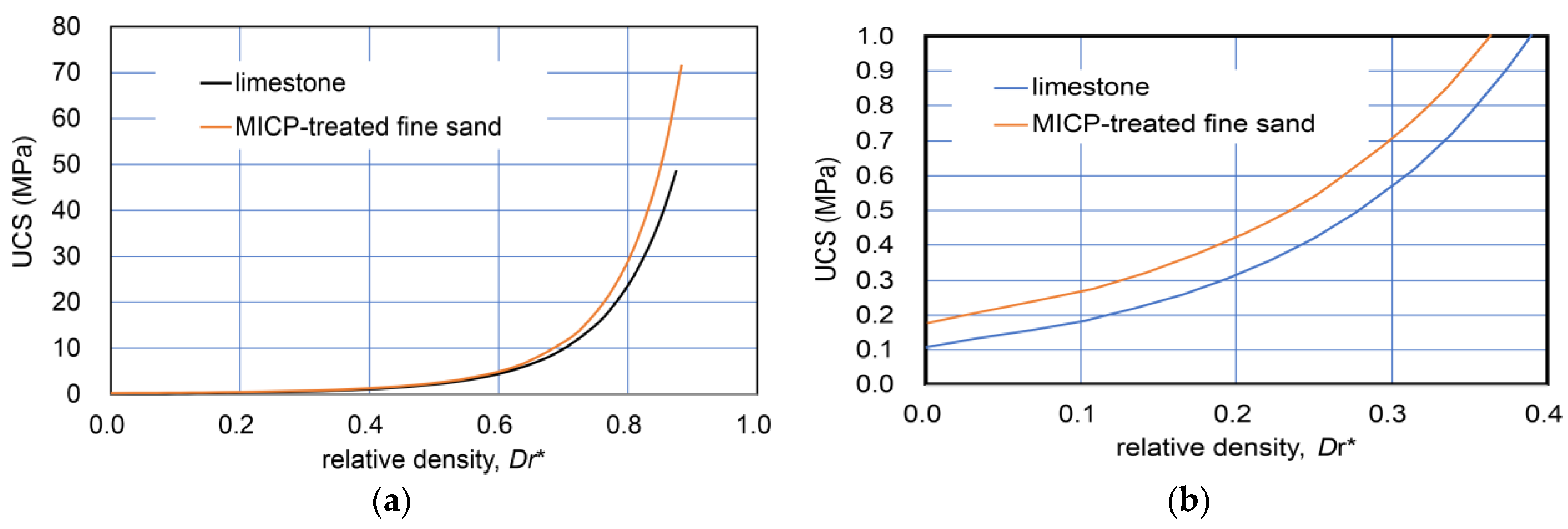

| Specimen | Assumed | ||||

|---|---|---|---|---|---|

| Shape | min. ρd (t/m3) | ρs (t/m3) | emax | emin | |

| Limestone | Square Column | 1.2 | 2.8 | 1.333 | 0 |

| Biogrout and fine sand | Cylinder | 1.4 | 2.65 | 0.893 | 0 |

| Type of Sand | Particle Density ρs (t/m3) | Dmax (mm) | D60 (mm) | D30 (mm) | D10 (mm) | Uniformity Uc | ρmax (t/m3) | ρmin (t/m3) | Initial C (%) | Initial ρd (t/m3) | a (kPa/%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Vietnam sand | 2.662 | 2 | 0.61 | 0.48 | 0.34 | 1.79 | 1.695 | 1.416 | 0.22 | 1.4 | 186–690 |

| Coarse sand | 2.65 | 2 | 1.35 | 1.05 | 0.87 | 1.55 | 1.568 | 1.336 | 0.2 | 1.28 | 34.5 |

| Fine sand a | 2.693 | 2 | 0.303 | 0.205 | 0.135 | 2.24 | 1.719 | 1.41 | 0.3 | 1.4 | 64.4 |

| Medium sand | 2.664 | 4.75 | 0.33 | 0.28 | 0.2 | 1.65 | 1.619 | 1.308 | 0.47 | 1.26 | 44 |

| Fine sand b | 2.679 | 4.75 | 0.295 | 0.195 | 0.13 | 2.27 | 1.683 | 1.377 | 0.2 | 1.38 | 53.9 |

| Fine sand c | 2.679 | 4.75 | 0.295 | 0.195 | 0.13 | 2.27 | 1.683 | 1.377 | 0.2 | 1.58 | 120 |

| River sand | 2.65 | 4.75 | 0.5 | 0.301 | 0.155 | 3.23 | 1.752 | 1.404 | 0.38 | 1.56 | 68.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fukue, M.; Lechowicz, Z.; Mulligan, C.N.; Takeuchi, S.; Fujimori, Y.; Emori, K. Properties and Behavior of Sandy Soils by a New Interpretation of MICP. Materials 2025, 18, 809. https://doi.org/10.3390/ma18040809

Fukue M, Lechowicz Z, Mulligan CN, Takeuchi S, Fujimori Y, Emori K. Properties and Behavior of Sandy Soils by a New Interpretation of MICP. Materials. 2025; 18(4):809. https://doi.org/10.3390/ma18040809

Chicago/Turabian StyleFukue, Masaharu, Zbigniew Lechowicz, Catherine N. Mulligan, Seiichi Takeuchi, Yuichi Fujimori, and Kentaro Emori. 2025. "Properties and Behavior of Sandy Soils by a New Interpretation of MICP" Materials 18, no. 4: 809. https://doi.org/10.3390/ma18040809

APA StyleFukue, M., Lechowicz, Z., Mulligan, C. N., Takeuchi, S., Fujimori, Y., & Emori, K. (2025). Properties and Behavior of Sandy Soils by a New Interpretation of MICP. Materials, 18(4), 809. https://doi.org/10.3390/ma18040809