Thermal Performance of Wood Frame Construction with Phase Change Material in the Brazilian Subtropical Climate

Abstract

1. Introduction

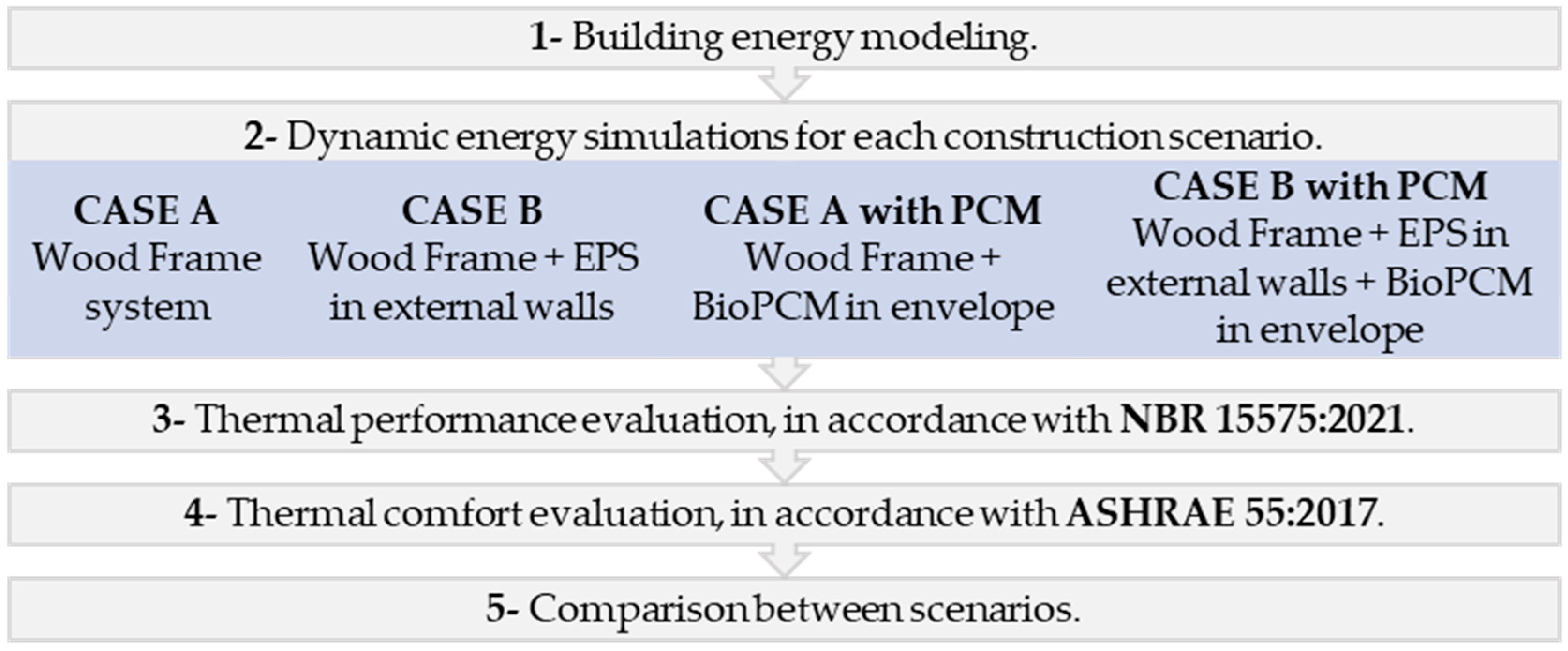

2. Materials and Methods

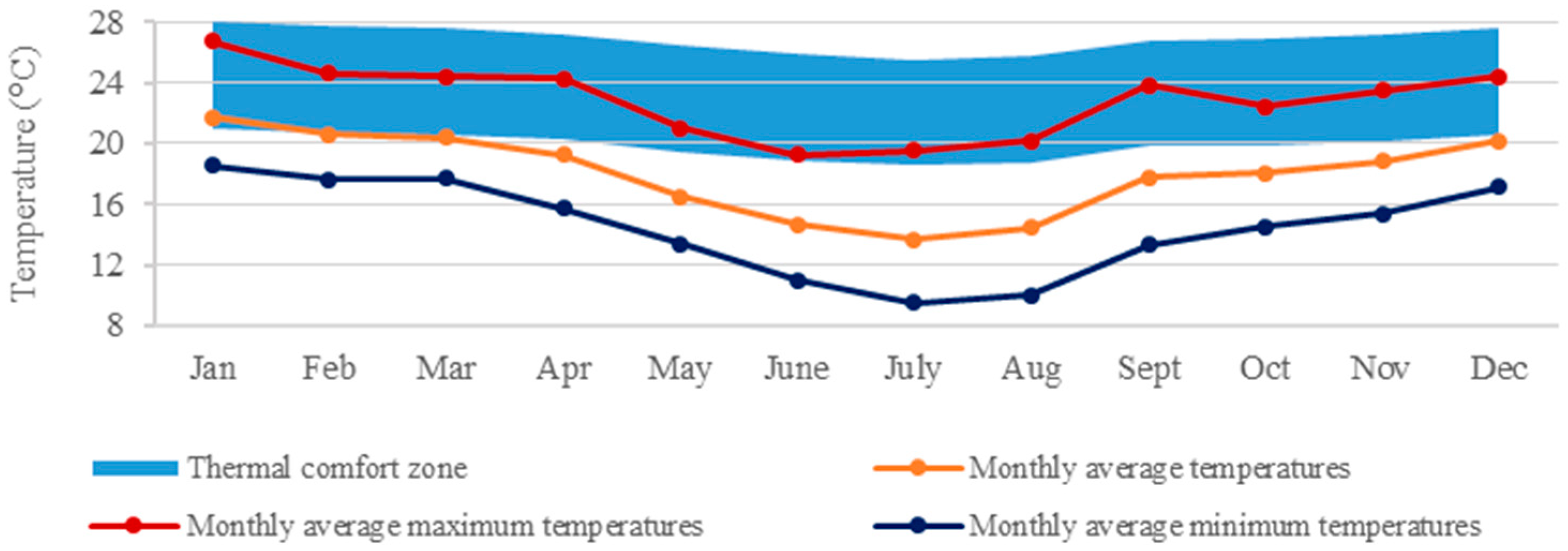

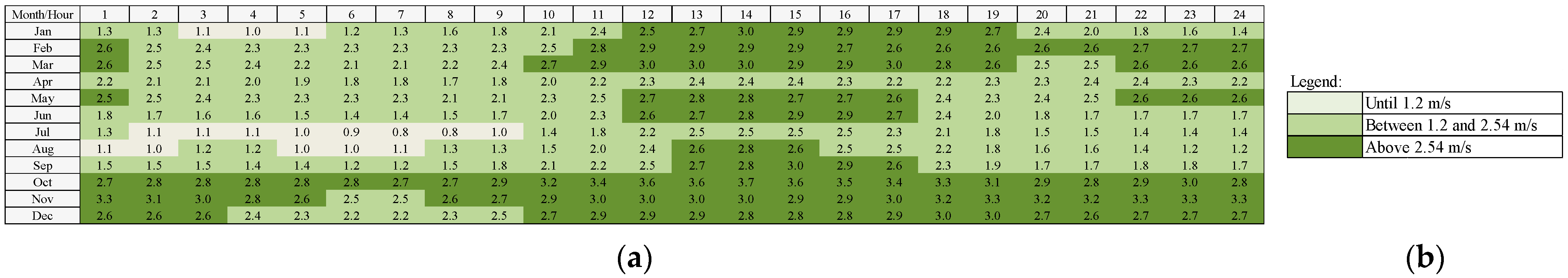

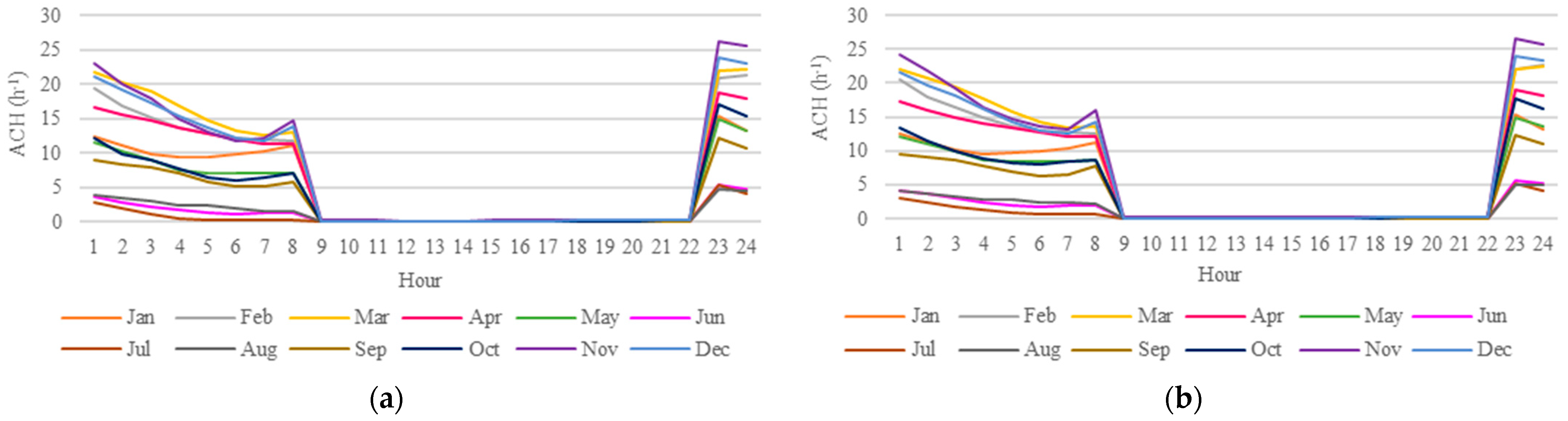

2.1. Weather Conditions

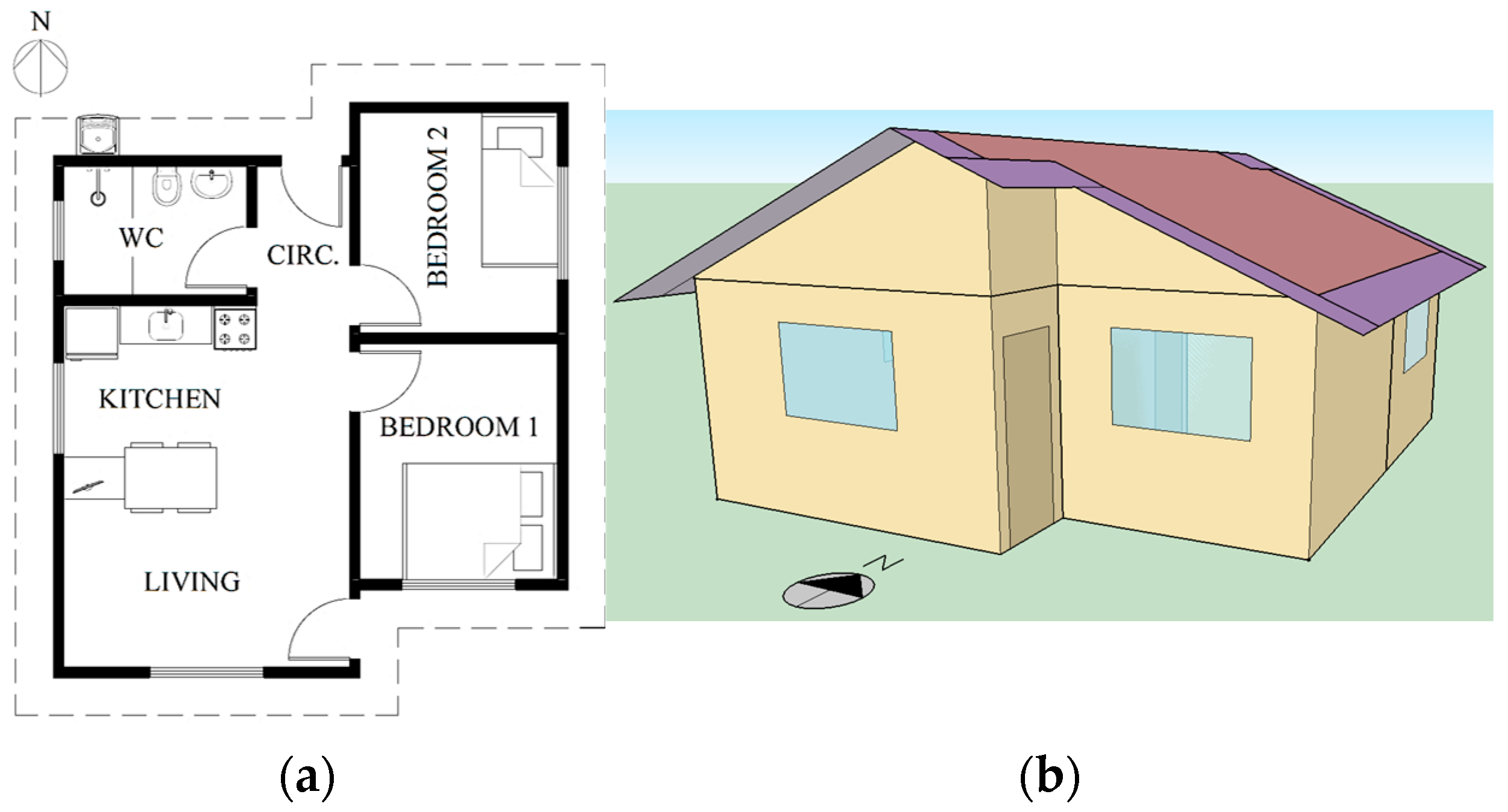

2.2. Case Study Building

2.3. Envelope Characterization

2.4. PCM Description

2.5. Building Thermal Behavior

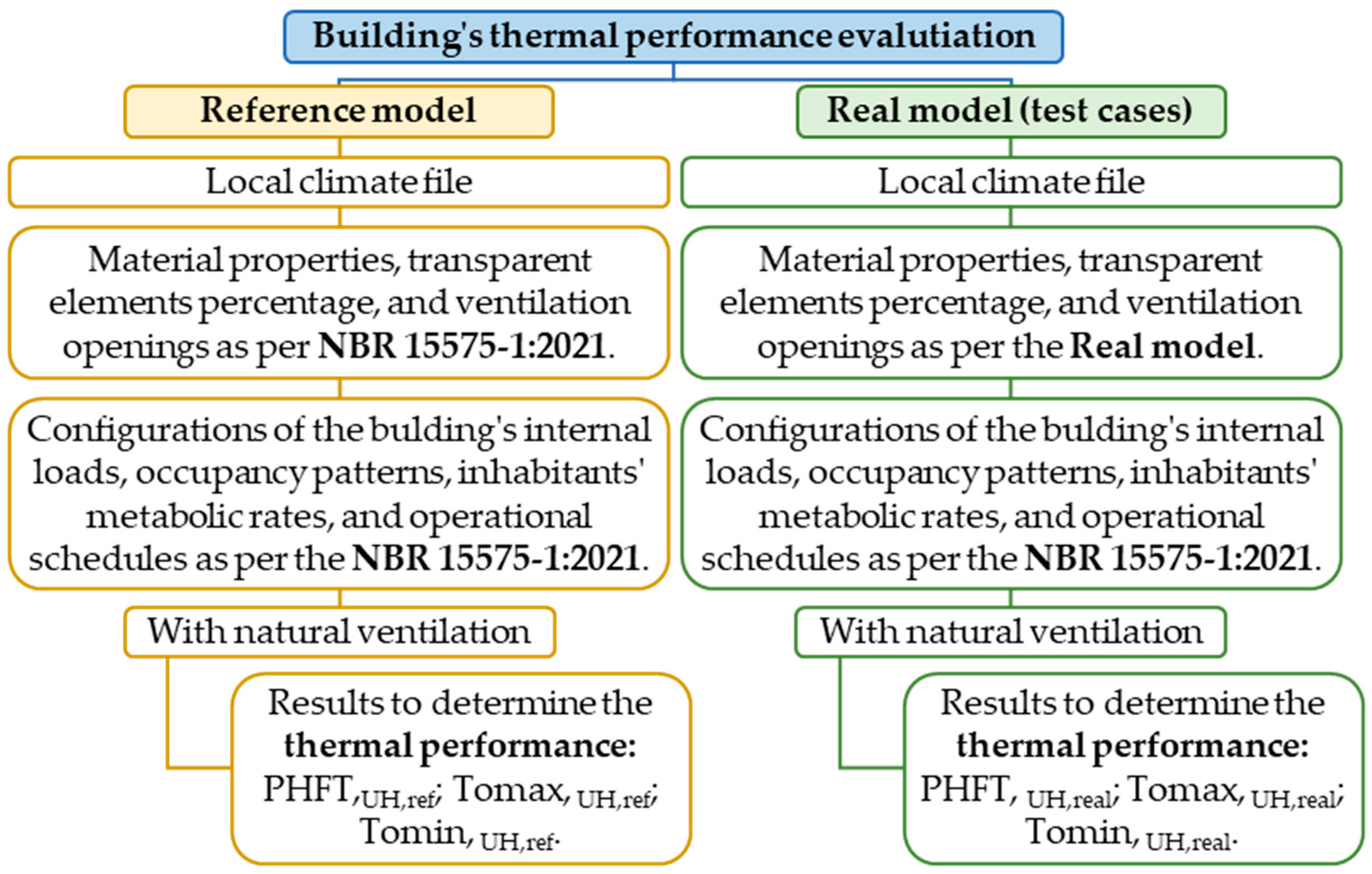

2.5.1. Thermal Performance Evaluation

2.5.2. Thermal Comfort Evaluation

2.5.3. Dynamic Energy Simulation

3. Results

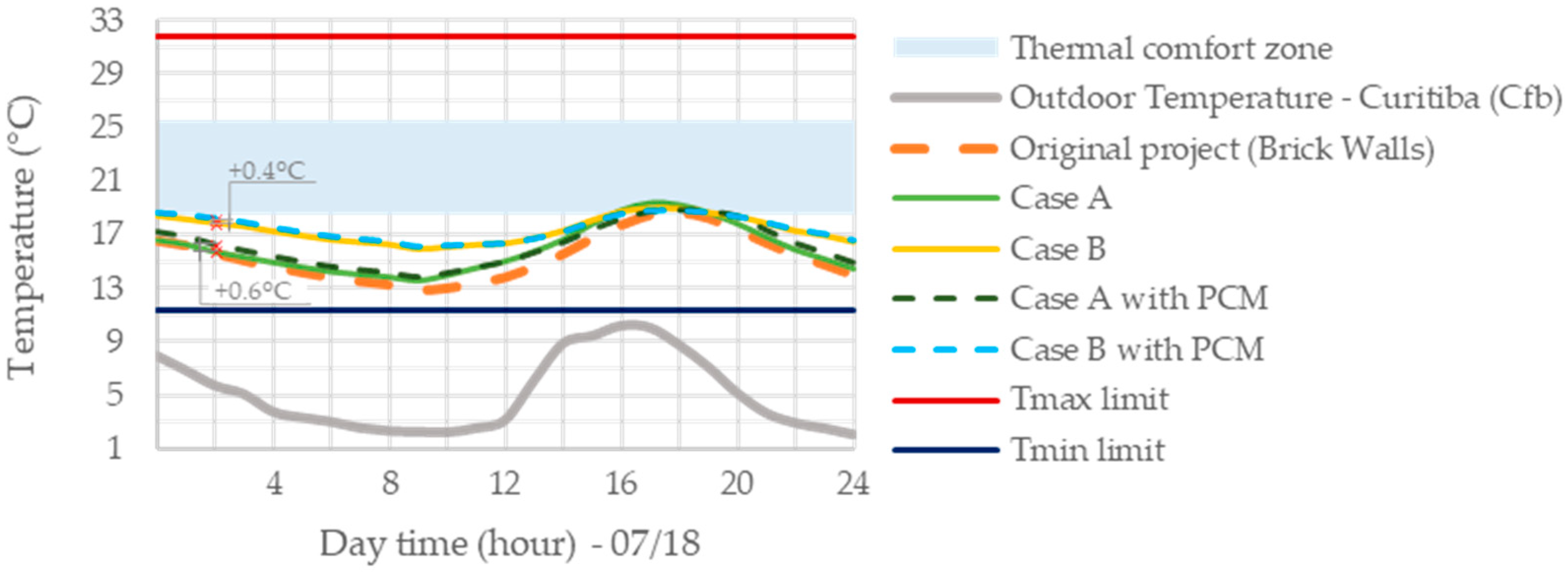

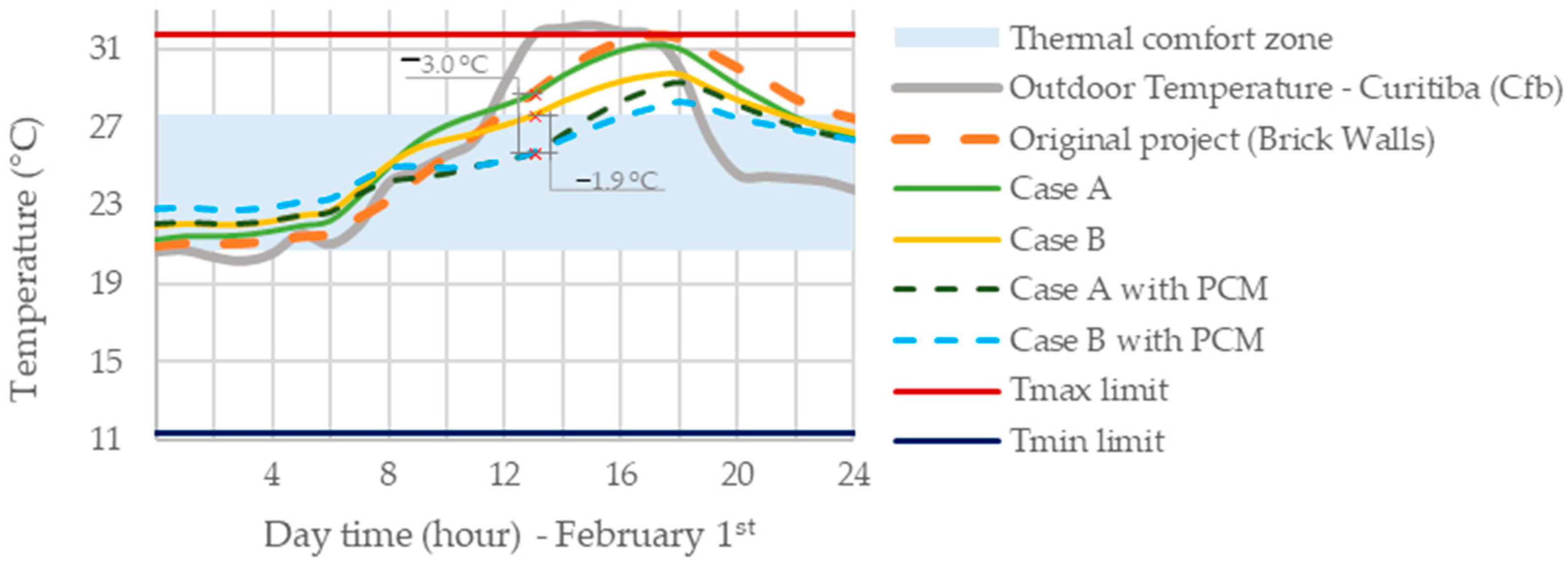

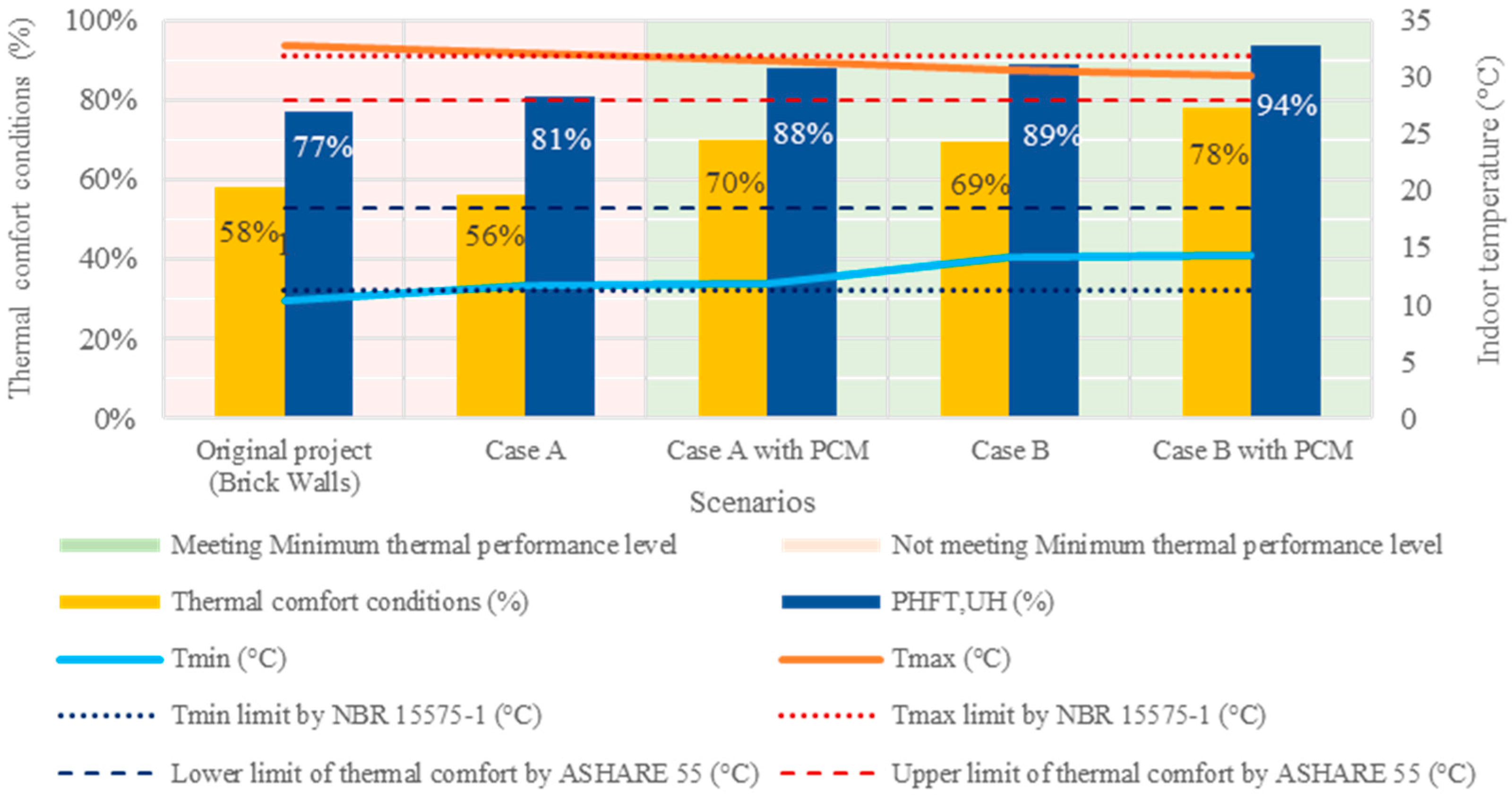

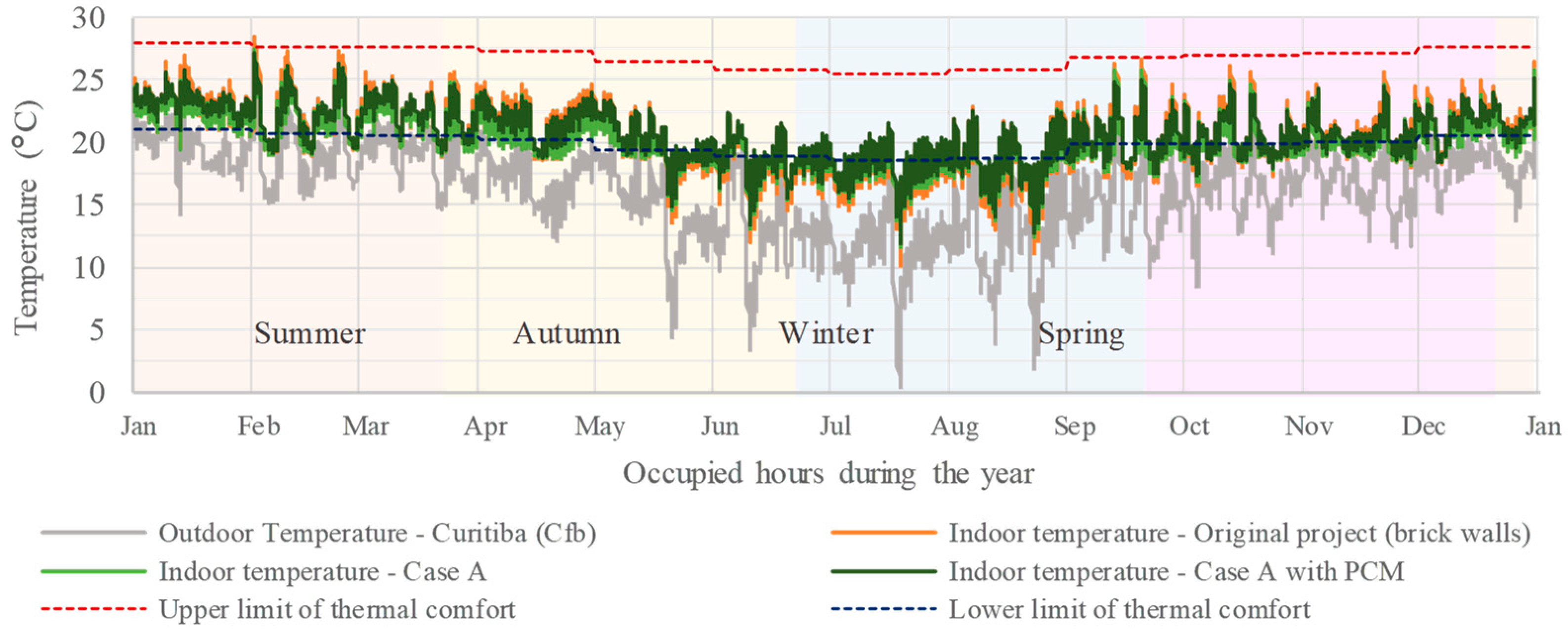

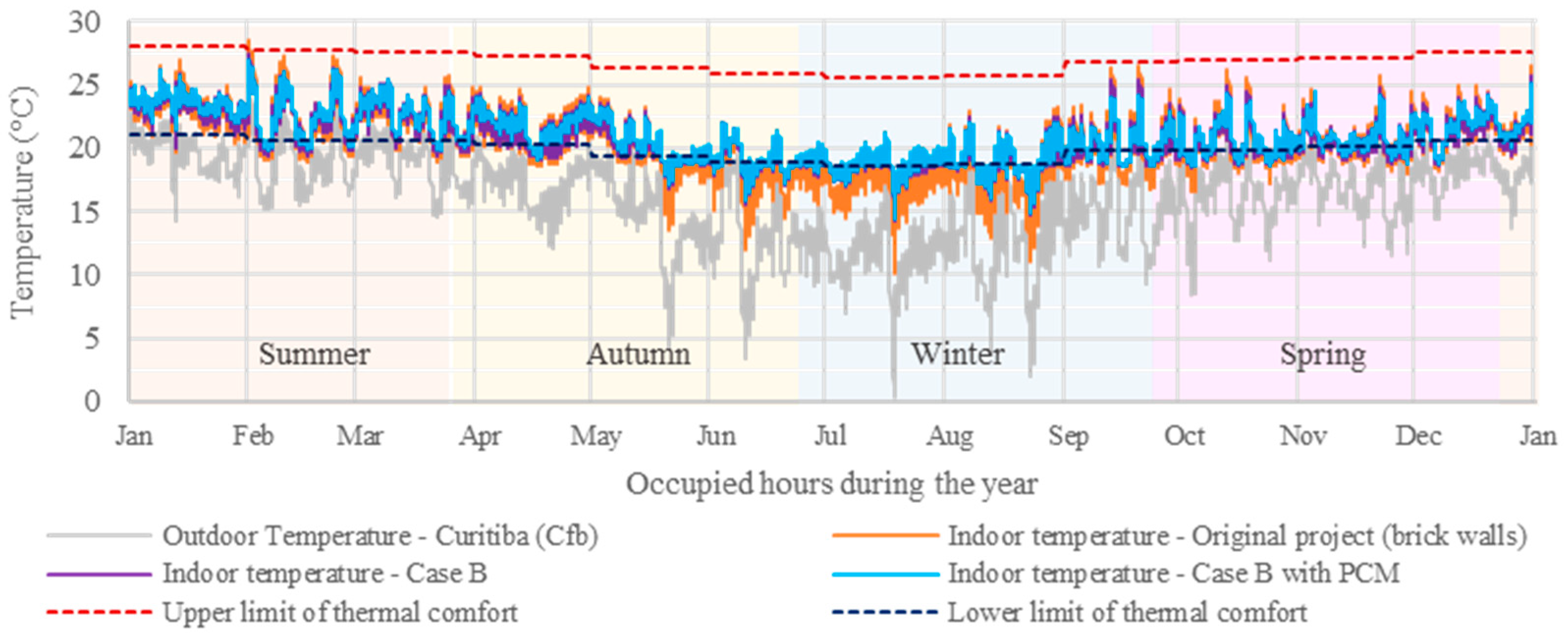

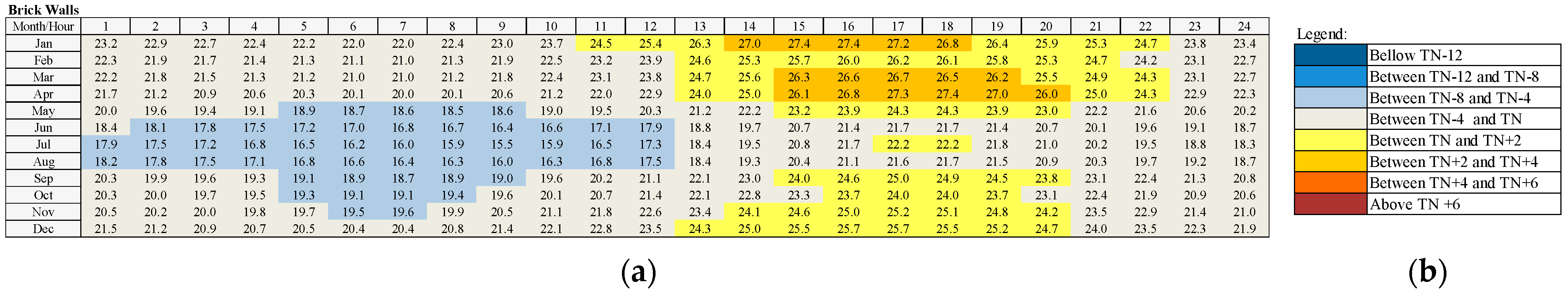

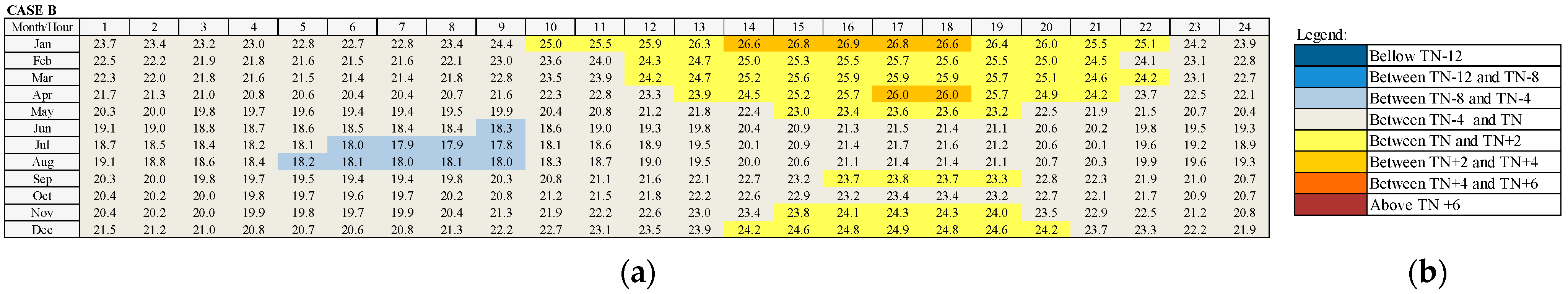

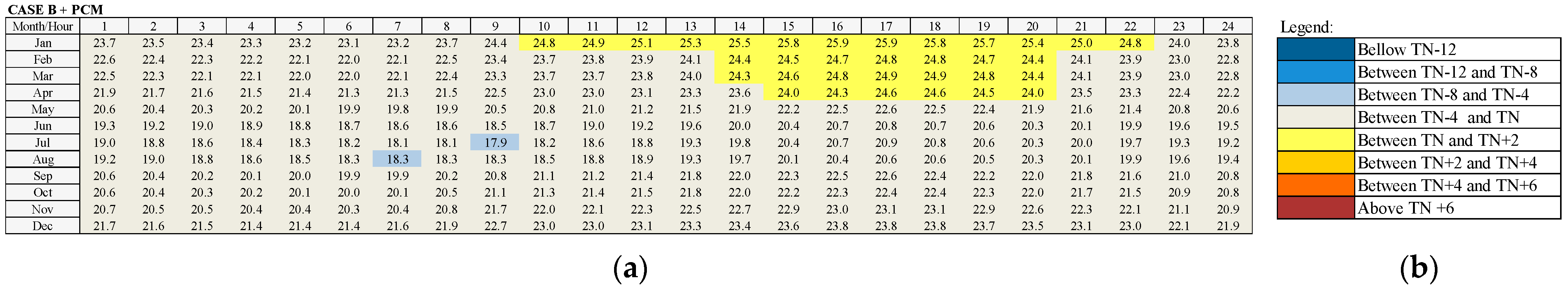

3.1. Impact of PCM on Indoor Temperatures

3.2. Thermal Behavior Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mastrucci, A.; van Ruijven, B.; Byers, E.; Poblete-Cazenave, M.; Pachauri, S. Global scenarios of residential heating and cooling energy demand and CO2 emissions. Clim. Change 2021, 168, 14. [Google Scholar] [CrossRef]

- Invidiata, A.; Ghisi, E. Impact of climate change on heating and cooling energy demand in houses in Brazil. Energy Build. 2016, 130, 20–32. [Google Scholar] [CrossRef]

- Bell, N.O.; Bilbao, J.I.; Kay, M.; Sproul, A.B. Future climate scenarios and their impact on heating, ventilation and air-conditioning system design and performance for commercial buildings for 2050. Renew. Sustain. Energy Rev. 2022, 162, 112363. [Google Scholar] [CrossRef]

- Cabeza, L.F. Advances in thermal energy storage systems: Methods and applications. In Advances in Thermal Energy Storage Systems: Methods and Applications, 2nd ed.; Cabeza, L.F., Ed.; Woodhead Publishing: Sawston, UK, 2021; pp. 37–54. [Google Scholar]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M.M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 2004, 45, 263–275. [Google Scholar] [CrossRef]

- Kuznik, F.; David, D.; Johannes, K.; Roux, J.J. A review on phase change materials integrated in building walls. Renew. Sustain. Energy Rev. 2011, 15, 379–391. [Google Scholar] [CrossRef]

- Pielichowska, K.; Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Zeynali Famileh, I.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- De Gracia, A.; Cabeza, L.F. Phase change materials and thermal energy storage for buildings. Energy Build. 2015, 103, 414–419. [Google Scholar] [CrossRef]

- Soares, N.; Gaspar, A.R.; Santos, P.; Costa, J.J. Multi-dimensional optimization of the incorporation of PCM-drywalls in lightweight steel-framed residential buildings in different climates. Energy Build. 2014, 70, 411–421. [Google Scholar] [CrossRef]

- Alam, M.; Jamil, H.; Sanjayan, J.; Wilson, J. Energy saving potential of phase change materials in major Australian cities. Energy Build. 2014, 78, 192–201. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Fernández, C.; Cabeza, L.F. Simulation-based optimization of PCM melting temperature to improve the energy performance in buildings. Appl. Energy 2017, 202, 420–434. [Google Scholar] [CrossRef]

- Khedher, N.B.; Nasrallah, S.B. Three-dimensional simulation of the thermal performance of porous building brick impregnated with phase change material. Int. J. Heat Technol. 2014, 32, 163–169. [Google Scholar]

- Brito, A.C.; Akutsu, M.; Salles, E.M.; Castro, G.M. Características térmicas de materiais de mudança de fase adequados para edificações brasileiras. Ambient Constr. 2017, 17, 125–145. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Phase change materials for building applications: A state-of-the-art review. Energy Build. 2010, 42, 1361–1368. [Google Scholar] [CrossRef]

- Suresh, C.; Hotta, T.K.; Saha, S.K. Phase change material incorporation techniques in building envelopes for enhancing the building thermal Comfort-A review. Energy Build. 2022, 268, 112225. [Google Scholar] [CrossRef]

- Peippo, K.; Kauranen, P.; Lund, P.D. A multicomponent PCM wall optimized for passive solar heating. Energy Build. 1991, 17, 259–270. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Alam, M.; Sanjayan, J.; Wilson, J. Parametric analysis for performance enhancement of phase change materials in naturally ventilated buildings. Energy Build. 2016, 124, 35–45. [Google Scholar] [CrossRef]

- Marin, P.; Saffari, M.; De Gracia, A.; Zhu, X.; Farid, M.M.; Cabeza, L.F.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–283. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Passive cooling of buildings with phase change materials using whole-building energy simulation tools: A review. Renew. Sustain. Energy Rev. 2017, 80, 1239–1255. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal performance of buildings integrated with phase change materials to reduce heat stress risks during extreme heatwave events. Appl. Energy 2017, 194, 410–421. [Google Scholar] [CrossRef]

- Abilkhassenova, Z.; Memon, S.A.; Ahmad, A.; Saurbayeva, A.; Kim, J. Utilizing the Fanger thermal comfort model to evaluate the thermal, energy, economic, and environmental performance of PCM-integrated buildings in various climate zones worldwide. Energy Build. 2023, 297, 113479. [Google Scholar] [CrossRef]

- Ahmad, A.; Memon, S.A. A novel method to evaluate phase change materials’ impact on buildings’ energy, economic, and environmental performance via controlled natural ventilation. Appl. Energy 2024, 353, 122033. [Google Scholar] [CrossRef]

- Staszczuk, A.; Kuczyński, T. The impact of wall and roof material on the summer thermal performance of building in a temperate climate. Energy 2021, 228, 120482. [Google Scholar] [CrossRef]

- Auzeby, M.; Wei, S.; Underwood, C.; Tindall, J.; Chen, C.; Ling, H.; Buswell, R. Effectiveness of Using Phase Change Materials on Reducing Summer Overheating Issues in UK Residential Buildings with Identification of Influential Factors. Energies 2016, 9, 605. [Google Scholar] [CrossRef]

- Leitzke, R.K.; da Cunha, E.G.; Ferrugem, A.P.; da Silva, T.L. The use of multi-objective evolutionary algorithms to assess phase change materials in a residence with light framings in bioclimatic zones 1, 2 and 3. Energy Build. 2023, 284, 112847. [Google Scholar] [CrossRef]

- Pons, V.; Stanescu, G. Materiais com mudança de fase: Análise de desempenho energético para o Brasil. PARC Pesqui. Em Arquitetura E Construção 2017, 8, 127–140. [Google Scholar] [CrossRef]

- Bracht, M.K.; Geraldi, M.; de Souza, L.P.; Bavaresco, M.; Melo, A.P.; Lamberts, R. Simulação do desempenho termo-energético de coberturas com PCM em 3 cidades brasileiras. In Proceedings of the XVII Encontro Nacional de Conforto no Ambiente Construído, São Paulo, Brazil, 30–31 October 2023; pp. 1–10. [Google Scholar]

- Liu, L.; Hammami, N.; Trovalet, L.; Bigot, D.; Habas, J.P.; Malet-Damour, B. Description of phase change materials (PCMs) used in buildings under various climates: A review. J. Energy Storage 2022, 56, 105760. [Google Scholar] [CrossRef]

- de Oliveira, R.B.; Gonzales, T.S.; Carvalho, M.T.M. Uso de PCM para edificações em região de clima quente: Uma revisão sistemática. PARC Pesqui. Em Arquitetura E Construção 2021, 12, e021001. [Google Scholar] [CrossRef]

- Molina, J.C.; Calil, C., Jr. Sistema construtivo em “wood frame” para casas de madeira. Semin. Ciências Exatas E Tecnológicas 2010, 31, 143–156. [Google Scholar] [CrossRef]

- Němeček, M.; Kalousek, M. Influence of thermal storage mass on summer thermal stability in a passive wooden house in the Czech Republic. Energy Build. 2015, 107, 68–75. [Google Scholar] [CrossRef]

- Afonso, R.; Miller, D.C. Forest plantations and local economic development: Evidence from Minas Gerais, Brazil. For Policy Econ. 2021, 133, 102618. [Google Scholar] [CrossRef]

- FAOSTAT. Top 10 Commodities Production in Brazil 2022. Commodities by Country. Available online: https://www.fao.org/faostat/en/#rankings/commodities_by_country (accessed on 10 February 2024).

- Eller, C.; Rida, M.; Boudier, K.; Otoni, C.; Celani, G.; Labaki, L.; Hoffmann, S. Climate-based analysis for the potential use of coconut oil as phase change material in buildings. Sustainability 2021, 13, 10731. [Google Scholar] [CrossRef]

- Vieira, J.C.; Oliveira, R.D. Uso de PCMs para melhoria do desempenho térmico de edificações residenciais no clima temperado úmido: Uma revisão sistemática. In Proceedings of the XVI Encontro Nacional de Conforto no Ambiente Construído/XII Encontro Latino-Americano de Conforto no Ambiente Construído, Palmas, Brazil, 20–23 April 2021; pp. 1173–1182. [Google Scholar]

- Oliveira, M.M.; Lucarelli, C.C.; Carlo, J.C. Uso de materiais de mudança de fase em sistemas construtivos: Revisão integrativa de literatura. Ambient Construído 2022, 22, 67–111. [Google Scholar] [CrossRef]

- INMET. Normais Climatológicas do Brasil. Available online: https://portal.inmet.gov.br/normais (accessed on 26 February 2023).

- ELETROBRAS. Pesquisa de posse e hábitos de uso de equipamentos elétricos na classe residencial. Available online: https://eletrobras.com/pt/AreasdeAtuacao/BRASIL.pdf (accessed on 9 November 2022).

- Triana, M.A.; Lamberts, R.; Sassi, P. Characterisation of representative building typologies for social housing projects in Brazil and its energy performance. Energy Policy 2015, 87, 524–541. [Google Scholar] [CrossRef]

- NBR 15220-3; Associação Brasileira de Normas Técnicas. ABNT: Rio de Janeiro, Brazil, 2005.

- Nunes, G.H.; Giglio, T.G.F. Influência das mudanças climáticas no desempenho térmico de uma habitação com diferentes sistemas construtivos: Análise do clima de São Paulo. Rev. Principia Divulg Científica E Tecnológica Do IFPB 2020, 1, 46–61. [Google Scholar] [CrossRef]

- NBR 15220-2; Associação Brasileira de Normas Técnicas. ABNT: Rio de Janeiro, Brazil, 2022.

- NBR 15575-1; Associação Brasileira de Normas Técnicas. ABNT: Rio de Janeiro, Brazil, 2024.

- Vieira, J.C. Uso de Materiais de Mudança de Fase Como Alternativa Para a Melhoria do Desempenho Térmico de Habitações no Clima Subtropical Brasileiro. Master’s Thesis, Centro Federal de Educação Tecnológica de Minas Gerais, Belo Horizonte, Brazil, 2022. [Google Scholar]

- Wijesuriya, S.; Tabares-Velasco, P.C. Experimental apparatus and methodology to test and quantify thermal performance of micro and macro-encapsulated phase change materials in building envelope applications. J. Energy Storage 2020, 32, 101770. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 55-2017: Therm Environ Cond Hum occupancy; American Society of Heating Refrigerating and Air-Conditioning Engineers. ASHRAE: Atlanta, GA, USA, 2017.

- Climate.OneBuilding. WMO Region 3—South America. BRA—Brazil. Available online: https://climate.onebuilding.org/WMO_Region_3_South_America/default.html (accessed on 19 March 2024).

- Department of Energy. Engineering Reference, EnergyPlusTM Version 8.9.0 Documentation; U.S. DOE: Washington, DC, USA, 2018.

- Tabares-Velasco, P.C.; Christensen, C.; Bianchi, M. Verification and validation of EnergyPlus phase change material model for opaque wall assemblies. Build Environ. 2012, 54, 186–196. [Google Scholar] [CrossRef]

- Al-Saadi, S.N.; Zhai, Z. Modeling phase change materials embedded in building enclosure: A review. Renew. Sustain. Energy Rev. 2013, 21, 659–673. [Google Scholar] [CrossRef]

- Sage-Lauck, J.S.; Sailor, D.J. Evaluation of phase change materials for improving thermal comfort in a super-insulated residential building. Energy Build. 2014, 79, 32–40. [Google Scholar] [CrossRef]

- Mateus, N.M.; Pinto, A.; Da Graça, G.C. Validation of EnergyPlus thermal simulation of a double skin naturally and mechanically ventilated test cell. Energy Build. 2014, 75, 511–522. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; De Masi, R.F.; De’Rossi, F.; Vanoli, G.P. Energy retrofit of an educational building in the ancient center of Benevento. Feasibility study of energy savings and respect of the historical value. Energy Build. 2015, 95, 172–183. [Google Scholar] [CrossRef]

- Lee, K.O.; Medina, M.A.; Sun, X. Development and verification of an EnergyPlus-based algorithm to predict heat transfer through building walls integrated with phase change materials. J. Build. Phys. 2016, 40, 77–95. [Google Scholar] [CrossRef]

- Nghana, B.; Tariku, F. Phase change material’s (PCM) impacts on the energy performance and thermal comfort of buildings in a mild climate. Build. Environ. 2016, 99, 221–238. [Google Scholar] [CrossRef]

- Mohseni, E.; Tang, W.; Wang, S. Development of thermal energy storage lightweight structural cementitious composites by means of macro-encapsulated PCM. Constr. Build. Mater. 2019, 225, 182–195. [Google Scholar] [CrossRef]

- Brandalise, M.P.; Almeida, F.S.; Ordenes, M. Materiais de mudança de fase implantados em vedações como sistema passivo para habitações. In Proceedings of the XVIII Encontro Nacional de Tecnologia do Ambiente Construído, Porto Alegre, Brazil, 4–6 November 2020; pp. 1–8. [Google Scholar]

- Matera, N.; Bevilacqua, P.; Arcuri, N.; Oliveti, G.; Mazzeo, D.; Romagnoni, P. Optimal design of pcm in internal walls for nZEB Buildings. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018. [Google Scholar] [CrossRef]

- Sang, G.; Zeng, H.; Guo, Z.; Cui, H.; Zhang, Y.; Cui, X.; Zhang, L.; Han, W. Studies of eutectic hydrated salt/polymer hydrogel composite as form-stable phase change material for building thermal energy storage. J. Build. Eng. 2022, 59, 105010. [Google Scholar] [CrossRef]

| City | Elevation | Average Annual Outdoor Temperature | Average Annual Relative Humidity | Annual Precipitation | Average Wind Intensity |

|---|---|---|---|---|---|

| Curitiba-PR | 925 m | 18.0 °C | 81% | 1575.8 mm | 2.2 m/s |

| Description | Dimensions |

|---|---|

| Floor-to-ceiling height | 2.50 m |

| Living room | 17.81 m2 |

| Bedroom 1 (B1) | 8.06 m2 |

| Bedroom 2 (B2) | 7.54 m2 |

| WC | 4.08 m2 |

| Corridor | 2.23 m2 |

| Net area | 39.73 m2 |

| Description | External Walls | Roof | |

|---|---|---|---|

| Case A | Case B | Cases A and B | |

| Construction Element |  |  |  |

| Thermal Transmittance (W/m2 K) | U = 1.93 | U = 0.89 | U = 0.37 |

| Thermal Capacity (kJ/m2 K) | CT = 67.4 | CT = 54.7 | CT = 25.0 |

| Solar Absorptance | α = 0.58 | α = 0.58 | α = 0.65 |

| Element | Equivalent Thickness (cm) | Thermal Conductivity (W/m K) | Specific Heat (kJ/kg K) | Density (kg/m3) | |

|---|---|---|---|---|---|

| 1 | Acrylic finish | 0.30 | 1.15 | 1.00 | 2000 |

| 2 | Base coat | 0.50 | 1.15 | 1.00 | 1840 |

| 3 | Cement board | 0.80 | 0.35 | 1.00 | 1700 |

| 4 | Pine wood | 0.15 | 0.15 | 1.34 | 494 |

| 5 | OSB | 0.95 | 0.17 | 2.30 | 681 |

| 6 | Gypsum board (wall) | 1.25 | 0.35 | 0.84 | 750 |

| 7 | EPS | 2.50 | 0.04 | 1.42 | 25 |

| 8 | Roof tile | 0.60 | 0.65 | 0.84 | 1700 |

| 9 | Glass wool | 10.00 | 0.045 | 0.70 | 10.35 |

| 10 | Gypsum board (roof) | 2.50 | 0.35 | 0.84 | 750 |

| BioPCM | |

|---|---|

| Product name | M-51 BioPCMTM |

| Peak nominal melting temperature (°C) | 23 |

| Latent heat capacity (kJ/kg) | ~230 |

| Specific heat capacity (J/kg K) | 1970 |

| Thermal conductivity (W/m K) | Liquid: ~0.15 Solid: ~0.25 |

| Density (kg/m3) | 860 |

| Average thickness of the pouch (m) | 0.0064 |

| Latent heat–area (kJ/m2) | ~580 |

| Enclosure/pouch material | Plastic foil/white plastic sheeting |

| Pouch material thickness between the pouches (mm) | 0.508 |

| Zone | Occupation Period | Activity | Het Gains from People [W] | Fraction Radiant |

|---|---|---|---|---|

| Bedrooms | 00 h 00 a.m.–07 h 59 a.m. 10 h 00 p.m.–11 h 59 p.m. | Sleeping or resting | 81 | 0.30 |

| Living | 0 2h 00 p.m.–09 h 59 p.m. | Sitting or watching TV | 108 | 0.30 |

| Zone | Usage period | Installed Power Density [W/m2] | Fraction Visible | Fraction Radiant |

|---|---|---|---|---|

| Bedrooms | 06 h 00 a.m.–07 h 59 a.m. 10 h 00 p.m.–11 h 59 p.m. | 5.00 | 0.23 | 0.30 |

| Living | 04 h 00 p.m.–09 h 59 p.m. | 5.00 | 0.23 | 0.30 |

| Zone | Usage Period | Electric Equipment Design Level [W] | Fraction Radiant |

|---|---|---|---|

| Living | 02 h 00 p.m.–09 h 59 p.m. | 120 | 0.30 |

| Maximum Impact | Case | |||

|---|---|---|---|---|

| A | A with PCM | B | B with PCM | |

| Tmin increase (°C) | 1.4 | 1.6 | 3.9 | 4.1 |

| Tmax reduction (°C) | 0.7 | 1.4 | 2.1 | 2.6 |

| Daily thermal amplitude decrease (°C) | 1.2 | 4.5 | 3.9 | 6.4 |

| Comparison Between Cases | Thermal Comfort Condition Impact (%) | |

|---|---|---|

| B–A | EPS effect | +13.0% |

| (B with PCM)–(A with PCM) | +8.0% | |

| (A with PCM)–A | BioPCM effect | +13.8% |

| (B with PCM)–B | +8.8% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vieira, J.; Oliveira, R.; Abreu, A.; Różycki, M.; Niemiec, T.; Sitarz, M. Thermal Performance of Wood Frame Construction with Phase Change Material in the Brazilian Subtropical Climate. Materials 2025, 18, 681. https://doi.org/10.3390/ma18030681

Vieira J, Oliveira R, Abreu A, Różycki M, Niemiec T, Sitarz M. Thermal Performance of Wood Frame Construction with Phase Change Material in the Brazilian Subtropical Climate. Materials. 2025; 18(3):681. https://doi.org/10.3390/ma18030681

Chicago/Turabian StyleVieira, Julia, Raquel Oliveira, Ana Abreu, Marcin Różycki, Tomasz Niemiec, and Mateusz Sitarz. 2025. "Thermal Performance of Wood Frame Construction with Phase Change Material in the Brazilian Subtropical Climate" Materials 18, no. 3: 681. https://doi.org/10.3390/ma18030681

APA StyleVieira, J., Oliveira, R., Abreu, A., Różycki, M., Niemiec, T., & Sitarz, M. (2025). Thermal Performance of Wood Frame Construction with Phase Change Material in the Brazilian Subtropical Climate. Materials, 18(3), 681. https://doi.org/10.3390/ma18030681