Effect of Tempering Temperature on Microstructure and Mechanical Properties of Cr-Ni-Mo-V Rotor Steel

Highlights

- The influence of tempering temperature on the microstructure and mechanical properties of Cr–Ni–Mo–V rotor steel was studied;

- With the increase in tempering temperature, the steel strength of Cr-Ni-Mo-V rotor decreases first, then increases and then decreases again;

- The strength of Cr–Ni–Mo–V rotor steel is mainly affected by the balance between solution strengthening, precipitation strengthening, and dislocation strengthening in the matrix.

Abstract

1. Introduction

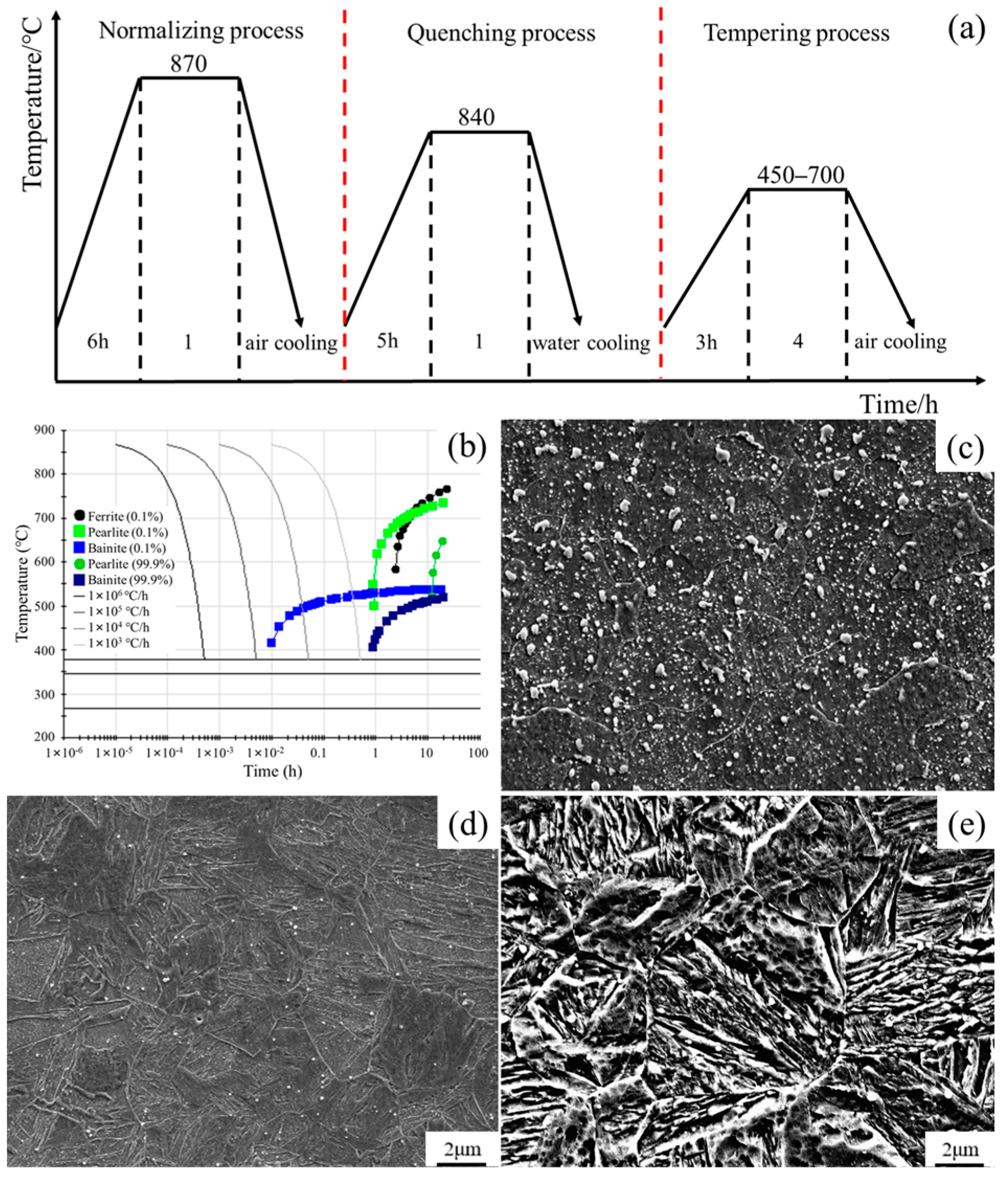

2. Materials and Methods

3. Results and Discussion

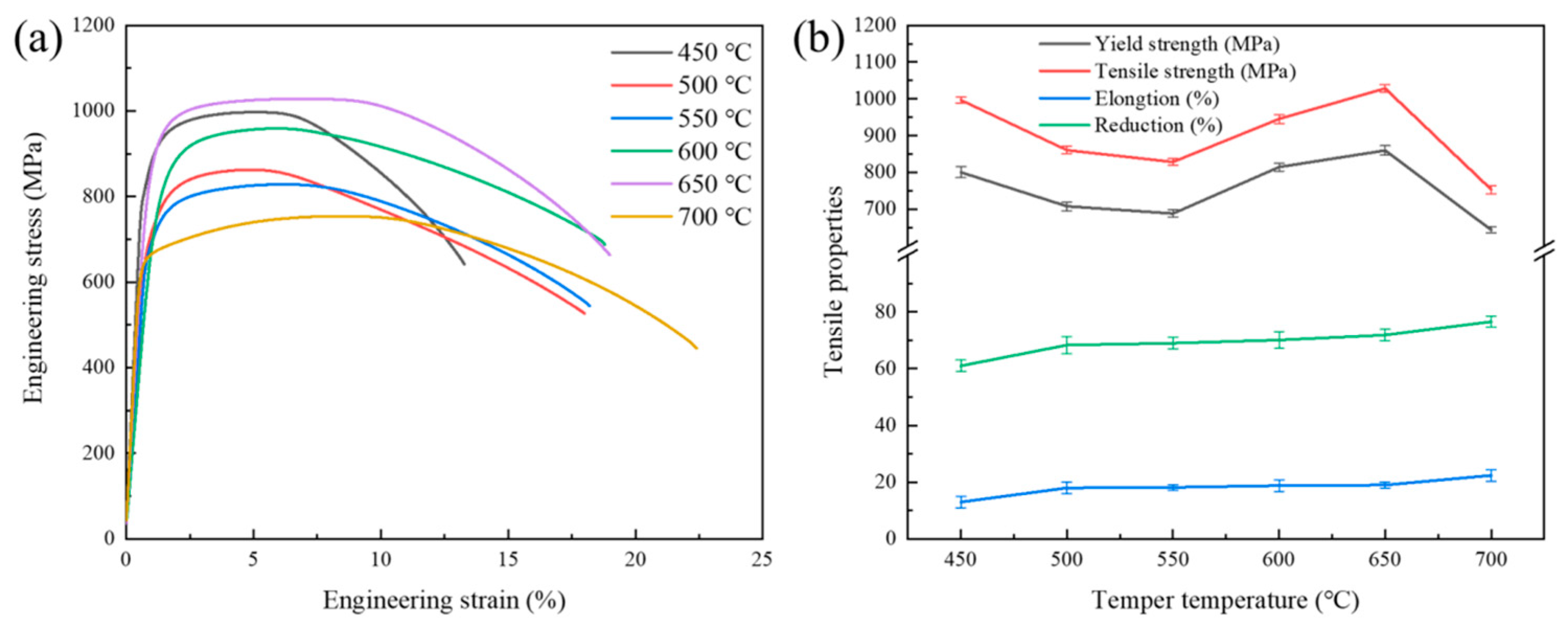

3.1. Mechanical Properties After Quenching and Tempering

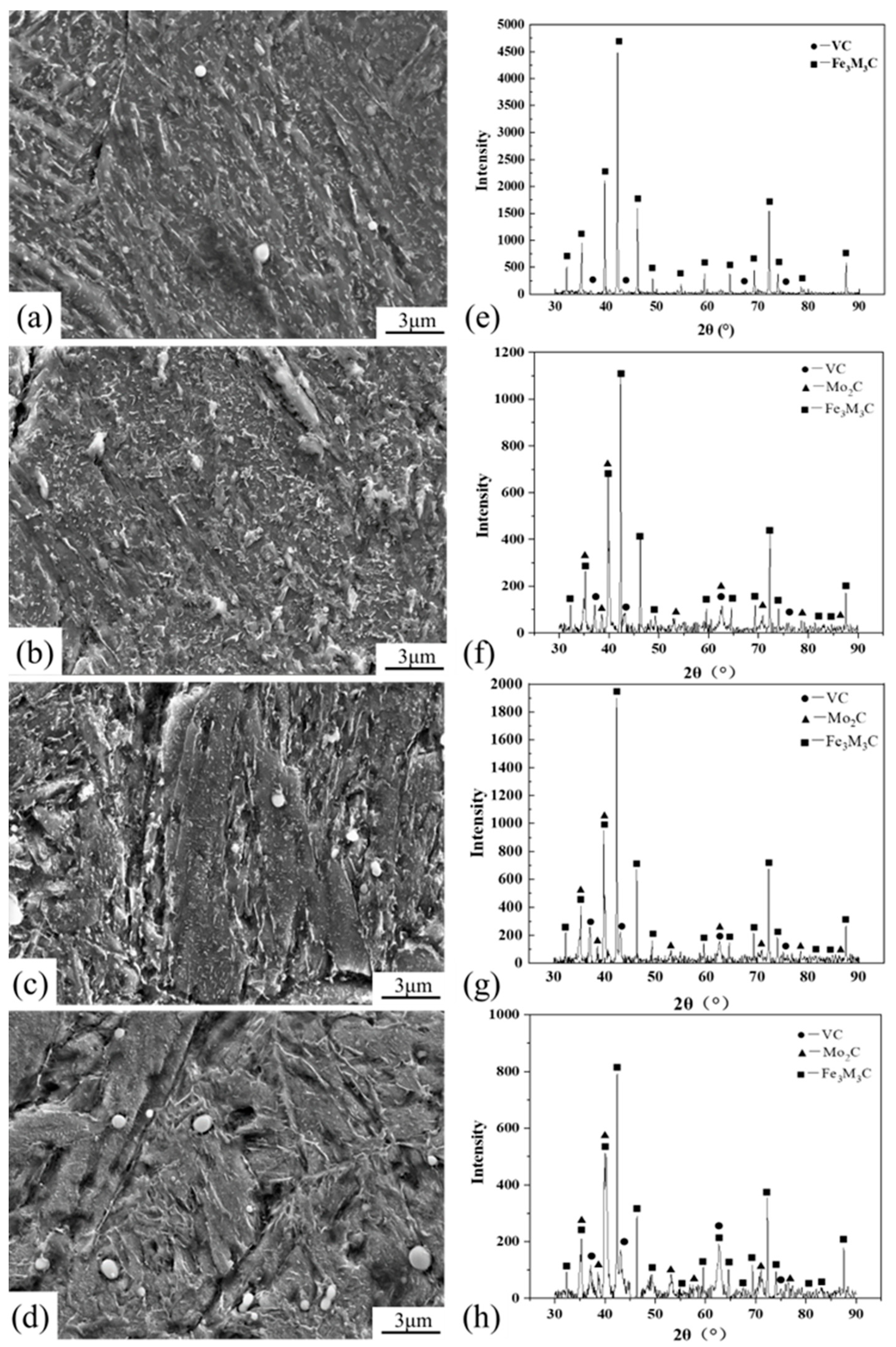

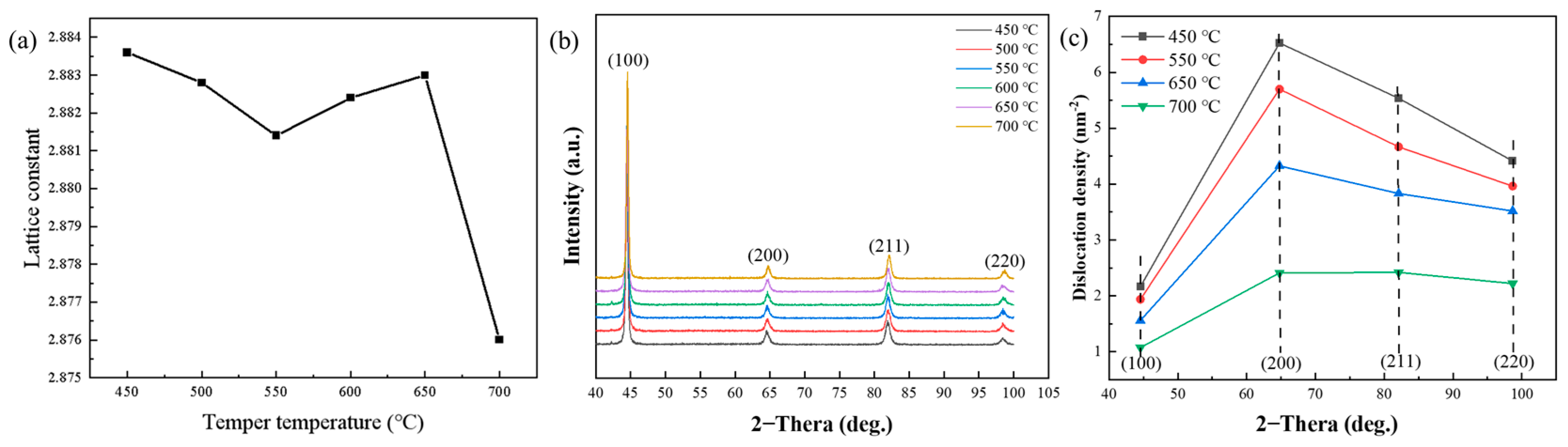

3.2. Microstructure Evolution During Tempering

3.3. Fracture Morphology

4. Conclusions

- (1)

- The microstructure of the Cr-Ni-Mo-V rotor steel in this work is mainly tempered martensite. With an increasing in tempering temperature, the tensile strength and yield strength first decrease, then increase and then decrease again, while elongation and section shrinkage gradually increase, with 650 °C having the best comprehensive mechanical properties.

- (2)

- The strength of Cr-Ni-Mo-V rotor steel is mainly influenced by dislocation strengthening in the matrix, the solid solution strengthening of the carbon and alloying elements and the precipitation strengthening of carbides. The tensile strength and plasticity are the best after tempering at 650 °C, which is mainly due to the comprehensive effect of Fe3Mo3C dissolution leading to the solid solution strengthening of the matrix and the precipitation strengthening of VC and Mo2C.

- (3)

- When the tempering temperature increases from 450 °C to 700 °C, the tensile fracture properties of Cr-Ni-Mo-V rotor steel gradually change from cleavage fracture to pitting fracture, which is mainly affected by the dissolution, precipitation and growth of Fe3Mo3C, VC and Mo2C in the structure.

- (4)

- In order to give theoretical support for further optimization of Cr-Ni-Mo-V rotor steel characteristics and heat treatment processes, future research should investigate the mechanism of carbide transition from Fe3Mo3C to Mo2C and VC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, J.; Zhao, J.; Yang, Z.; Jin, Y.; Zhang, C. Microstructure Prediction of Multi-Directional Forging for 30Cr2Ni4MoV Steel by the Secondary Development of Deform Software and BP Neural Network. Int. J. Adv. Manuf. Technol. 2022, 119, 2971–2984. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, C.; Yang, L.; Hou, S.; Cheng, R.; Zhang, H.; Ni, H. Improving Cleanliness of 30Cr2Ni4MoV Low-Pressure Rotor Steel by CaO–SiO2–MgO–Al2O3 Slag Refining. J. Iron Steel Res. Int. 2022, 29, 1434–1445. [Google Scholar] [CrossRef]

- Liu, J.; Li, M.; Zhang, P.; Zhu, Y.; Li, S. Experiment Research on the Transformation Plasticity by Tensile/Compressive Stress and Transformation Kinetics during the Martensitic Transformation of 30Cr2Ni4MoV Steel. Mater. Res. Express 2020, 6, 1265g8. [Google Scholar] [CrossRef]

- Sun, G.; Wang, Q.; Li, Z. Microstructural Evolution of High-Nickel Steel during Quenching, Lamellarizing, and Tempering Heat Treatment. J. Mater. Res. Technol. 2024, 33, 8618–8630. [Google Scholar] [CrossRef]

- Hu, D.; Dai, X.; Xie, B.; Li, W.; Yu, H.; Chen, H. Fatigue Life of Flywheel Energy Storage Rotors Composed of 30Cr2Ni4MoV Steel. Energies 2024, 17, 3730. [Google Scholar] [CrossRef]

- Lu, F.; Liu, P.; Ji, H.; Ding, Y.; Xu, X.; Gao, Y. Dramatically Enhanced Impact Toughness in Welded 10%cr Rotor Steel by High Temperature Post-Weld Heat Treatment. Mater. Charact. 2014, 92, 149–158. [Google Scholar] [CrossRef]

- Wei, A.; Feng, Y.; Wu, L.; Li, Y.; Xie, Z. Corrosion Wear Behavior of 30CrNi2MoVA Steel in Simulated Seawater. Mater. Lett. 2023, 349, 134750. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, J.; Fu, J.; Lian, Y.; Zhang, Z.; Zhang, C.; Huang, J. Low-Cycle Fatigue Behavior of the Novel Steel and 30SiMn2MoV Steel at 700 °C. Materials 2020, 13, 5753. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, X.; Wei, J.; Luo, R. Characterization of Carbide Precipitation during Tempering for Quenched Dievar Steel. Materials 2022, 15, 6448. [Google Scholar] [CrossRef]

- Lin, H.; Yang, M.; Song, B. Study on Hot Compressive Deformation Behavior and Microstructure Evolution of G13Cr4Mo4Ni4V Steel. Mater. Today Commun. 2024, 38, 108429. [Google Scholar] [CrossRef]

- DelRio, F.W.; Martin, M.L.; Santoyo, R.L.; Lucon, E. Effect of Tempering on the Ductile-to-Brittle Transitional Behavior of Ni-Cr-Mo Low-Alloy Steel. Exp. Mech. 2020, 60, 1167–1172. [Google Scholar] [CrossRef]

- Han, C.; Liu, Q.; Cai, Z.; Sun, Q.; Huo, X.; Fan, M.; He, Y.; Li, K.; Pan, J. Effect of Tempering Heat Treatment on the Microstructure and Impact Toughness of a Ni–Cr–Mo–V Steel Weld Metal. Mater. Sci. Eng. A 2022, 850, 143521. [Google Scholar] [CrossRef]

- Barrera-Villatoro, E.F.; Vázquez-Gómez, O.; Vergara-Hernández, H.J.; Gallegos-Pérez, A.I.; López-Martínez, E.; Díaz-Villaseñor, P.G.; Garnica-González, P. Non-Isothermal Tempering Kinetics in a Cr–Mo–V Medium-Carbon Low-Alloy Steel: A Modeling Proposal. J. Therm. Anal. Calorim. 2023, 148, 13791–13802. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, D.; Pang, Q.; Li, W.; Du, L. Effect of Quenching-Super Intercritical Quenching-Tempering Process on the Evolution of Microstructure and the Yield Ratio of Ni–Cr–Mo Steel. J. Mater. Res. Technol. 2024, 32, 915–925. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, X.; Qi, J.; Zhu, W.; Feng, Y.; Chen, L.; Wang, G. Effect of Tempering on the Microstructure and Properties of a New Multi-Functional 460 MPa Grade Construction Structural Steel. J. Mater. Res. Technol. 2022, 18, 1092–1104. [Google Scholar] [CrossRef]

- Yang, X.; Yu, W.; Tang, D.; Li, Y.; Lv, D.; Shi, J.; Du, Q.; Mei, D.; Fan, J. Effect of Direct Quenched and Tempering Temperature on the Mechanical Properties and Microstructure of High Strength Steel. Mater. Res. Express 2020, 7, 126509. [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Wang, Q.; Liang, Z.; Gao, S.; Sun, L.; Gao, X.; Yang, Z.; Li, Y.; Zhang, F. Effect of Rapid Tempering at High Temperature on Microstructure, Mechanical Properties and Stability of Retained Austenite of Medium Carbon Ultrafine Bainitic Steel. J. Mater. Res. Technol. 2024, 28, 3144–3154. [Google Scholar] [CrossRef]

- Liu, Y.; Han, S.; Yang, C.; Geng, R.; Yuan, X.; Li, Y.; Wang, C. Evolution of Microstructures and Mechanical Properties with Tempering Temperature in a Novel Synergistic Precipitation Strengthening Ultra-High Strength Steel. Materials 2024, 17, 5314. [Google Scholar] [CrossRef]

- He, X.; Hu, C.; Wang, Z.; Zhao, H.; Wei, X.; Dong, H. Carbide Transformation Behaviors of a Cr–Mo–V Secondary Hardening Steel during over-Ageing. Mater. Res. Express 2020, 7, 36511. [Google Scholar] [CrossRef]

- Ravikanth, K.V.; Verma, A.; Singh, J.B.; Vishwanadh, B.; Rai, S.K.; Karri, M. Effect of Prior Microstructure on Carbide Precipitation in a Cr-Mo-V Pressure Vessel Steel at 650 °C. J. Nucl. Mater. 2024, 602, 155359. [Google Scholar] [CrossRef]

- Claesson, E.; Magnusson, H.; Hedström, P. Scanning Precession Electron Diffraction Study of Carbide Precipitation Sequence in Low Alloy Martensitic Cr-Mo-V Tool Steel. Mater. Charact. 2023, 202, 113032. [Google Scholar] [CrossRef]

- Zheng, C.; Fu, B.; Tang, Y.; Kong, L.; Wang, Y.; Li, N. Microstructure and Mechanical Properties of 9Cr18Mo Martensitic Stainless Steel Fabricated by Strengthening-Toughening Treatment. Mater. Sci. Eng. A 2023, 869, 144783. [Google Scholar] [CrossRef]

- Ren, Q.; Kou, Z.; Wu, J.; Hou, T.; Xu, P. Effect of Tempering Temperature on Microstructure and Mechanical Properties of 35CrMo Steel. Metals 2023, 13, 771. [Google Scholar] [CrossRef]

- Liu, L.; Yang, J.; Li, X.; Sun, M.; Ren, Y.; Li, M.; Yang, H.; Wang, H. A Heat-Resistant Steel with Excellent High-Temperature Strength-Ductility Based on a Combination of Solid-Solution Strengthening and Precipitation Hardening. Mater. Sci. Eng. A 2024, 915, 147218. [Google Scholar] [CrossRef]

- Mao, W.; Ning, A.; Guo, H. Nanoscale Precipitates and Comprehensive Strengthening Mechanism in AISI H13 Steel. Int. J. Miner. Metall. Mater. 2016, 23, 1056–1064. [Google Scholar] [CrossRef]

- Wang, C.; Luo, K.; Wang, J.; Lu, J. Carbide-Facilitated Nanocrystallization of Martensitic Laths and Carbide Deformation in AISI 420 Stainless Steel during Laser Shock Peening. Int. J. Plast. 2022, 150, 103191. [Google Scholar] [CrossRef]

- Gao, B.; Wang, L.; Liu, Y.; Liu, J.; Xiao, L.; Sui, Y.; Sun, W.; Chen, X.; Zhou, H. Achieving Ultrahigh Strength by Tuning the Hierarchical Structure of Low-Carbon Martensitic Steel. Mater. Sci. Eng. A 2023, 881, 145370. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, Y.; Chen, J.; Ye, H.; Zhao, C.; Huang, J. Microstructure Stabilities of Newly Developed Hot-working Die Steel and H13 Steel at Elevated Temperature. Steel Res. Int. 2023, 94, 2200811. [Google Scholar] [CrossRef]

- Lin, H.; Yang, M.; Song, B. Study of Microstructure Uniformity and Impact Toughness Enhancement Mechanism of G13Cr4Mo4Ni4V Bearing Steel. J. Mater. Res. Technol. 2024, 31, 4059–4072. [Google Scholar] [CrossRef]

- Wang, Y.; Song, K.; Zhang, Y.; Wang, G. Microstructure Evolution and Fracture Mechanism of H13 Steel during High Temperature Tensile Deformation. Mater. Sci. Eng. A 2019, 746, 127–133. [Google Scholar] [CrossRef]

- Wang, H.; Feng, H.; Li, H.; Zhang, S.; Zhu, H.; Jiang, Z. Effect of Isothermal Tempering Time and Temperature on Microstructure and Hardness of 3Cr5Mo2SiVN Hot-Work Die Steel. Mater. Charact. 2024, 212, 114010. [Google Scholar] [CrossRef]

- Meshkabadi, R.; Pouyafar, V.; Soltanikia, R. Investigation on Microstructure, Hardness and Fracture Energy of AISI H13 Hot Work Tool Steel by Cyclic Heat Treatment. J. Mater. Eng. Perform. 2024, 33, 6620–6629. [Google Scholar] [CrossRef]

- Lee, C.-H.; Seol, W.-K.; Kim, B.H.; Kim, S.-D.; Jang, J.H.; Lee, T.-H.; Moon, S.-W.; Kim, S.-Y. Investigation on New Type of Fracture in Cr-Mo-V Steel Slab. Eng. Fail. Anal. 2019, 98, 240–248. [Google Scholar] [CrossRef]

| Element | C | Cr | Mo | W | Ni | V |

|---|---|---|---|---|---|---|

| Standard | 0.25–0.28 | 2.5–2.8 | 1.6–1.9 | 0.2–0.6 | 0.5–0.8 | 0.2–0.5 |

| Experimental | 0.27 | 2.68 | 1.75 | 0.40 | 0.68 | 0.42 |

| Temperature (°C) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Reduction (%) |

|---|---|---|---|---|

| 450 | 800.75 | 997.091 | 13 | 61 |

| 500 | 708.469 | 861.016 | 18 | 68.34 |

| 550 | 688.665 | 828.902 | 18.2 | 69 |

| 600 | 814.953 | 945.651 | 18.8 | 70.11 |

| 650 | 860.271 | 1028.608 | 19 | 71.88 |

| 700 | 644.205 | 754.004 | 22.4 | 76.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Zhang, X.; Liang, X.; Song, G.; Wang, B.; Guo, L.; Zhang, P.; Zhang, S. Effect of Tempering Temperature on Microstructure and Mechanical Properties of Cr-Ni-Mo-V Rotor Steel. Materials 2025, 18, 555. https://doi.org/10.3390/ma18030555

Zhao C, Zhang X, Liang X, Song G, Wang B, Guo L, Zhang P, Zhang S. Effect of Tempering Temperature on Microstructure and Mechanical Properties of Cr-Ni-Mo-V Rotor Steel. Materials. 2025; 18(3):555. https://doi.org/10.3390/ma18030555

Chicago/Turabian StyleZhao, Chao, Xinyi Zhang, Xiaojie Liang, Guowang Song, Bin Wang, Liqiang Guo, Pengjun Zhang, and Shuguang Zhang. 2025. "Effect of Tempering Temperature on Microstructure and Mechanical Properties of Cr-Ni-Mo-V Rotor Steel" Materials 18, no. 3: 555. https://doi.org/10.3390/ma18030555

APA StyleZhao, C., Zhang, X., Liang, X., Song, G., Wang, B., Guo, L., Zhang, P., & Zhang, S. (2025). Effect of Tempering Temperature on Microstructure and Mechanical Properties of Cr-Ni-Mo-V Rotor Steel. Materials, 18(3), 555. https://doi.org/10.3390/ma18030555